Patents

Literature

36results about How to "Easy to deform" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Stretchable or bendable composite circuit system and fabrication method thereof

InactiveCN107249254AReduce the deformation fieldGood compatibilityConductive pattern formationCircuit susbtrate materialsRoom temperatureEngineering

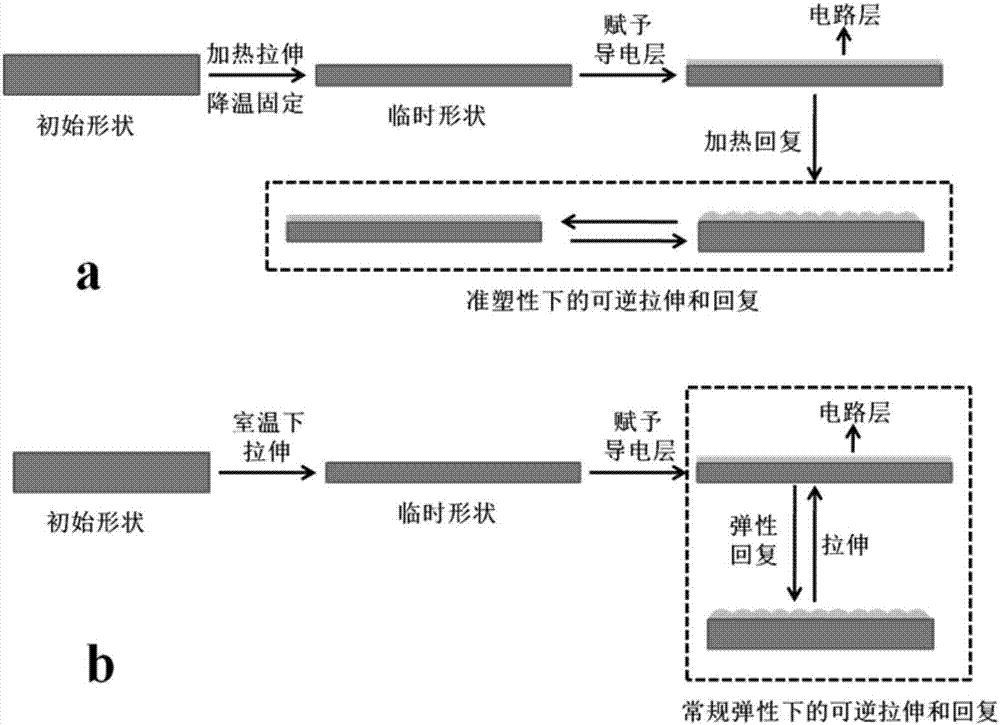

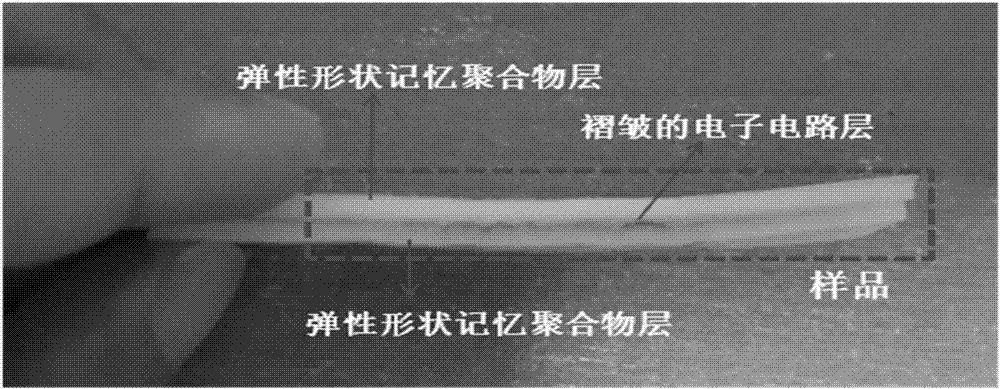

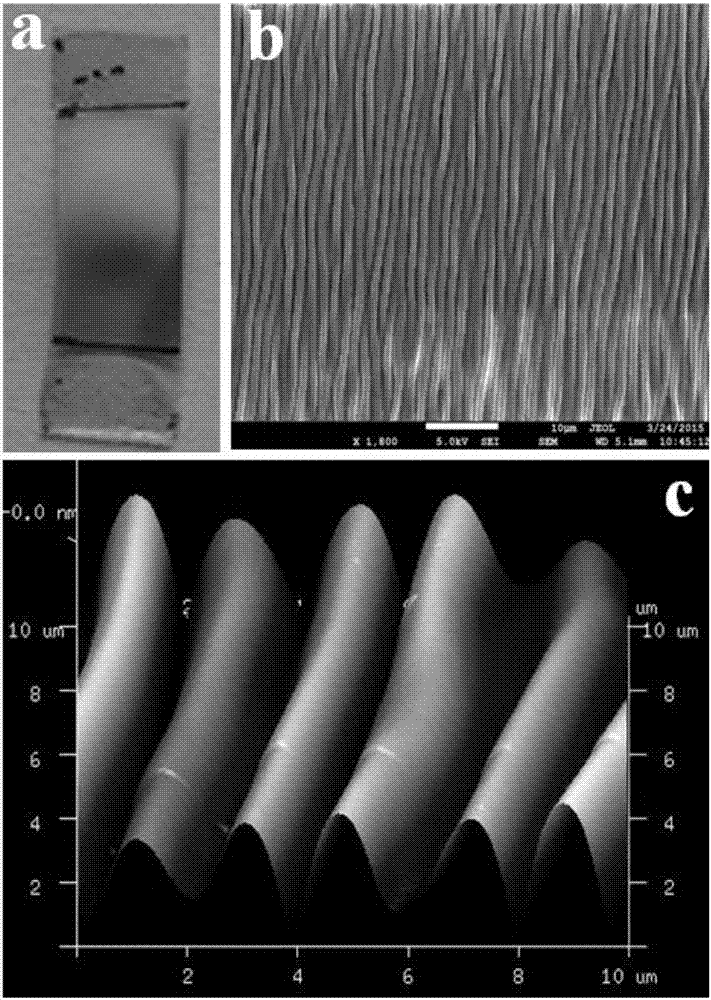

The invention discloses a stretchable or bendable composite circuit system and a fabrication method thereof. The method comprises the following steps of S1, fabricating an elastic shape memory polymer; S2, pre-stretching the elastic shape memory polymer fabricated in the step S1 by 10-150% under 60-120 DEG C, cooling to a room temperature and fixing a temporary shape of the elastic shape memory polymer; S3, fabricating a circuit system in the pre-stretched elastic shape memory polymer or a surface of the pre-stretched elastic shape memory polymer by a spraying or pasting or circuit printing process; and S4, heating and trigging the elastic shape memory polymer processed in the step S3 to restore, and causing the circuit system to form drape and obtain the stretchable or bendable composite circuit system. The invention also discloses the stretchable or bendable composite circuit system. The elastic shape memory polymer is employed to be combined with the relatively rigid circuit system so as to achieve a bendable / stretchable effect of a circuit.

Owner:GUANGDONG UNIV OF TECH

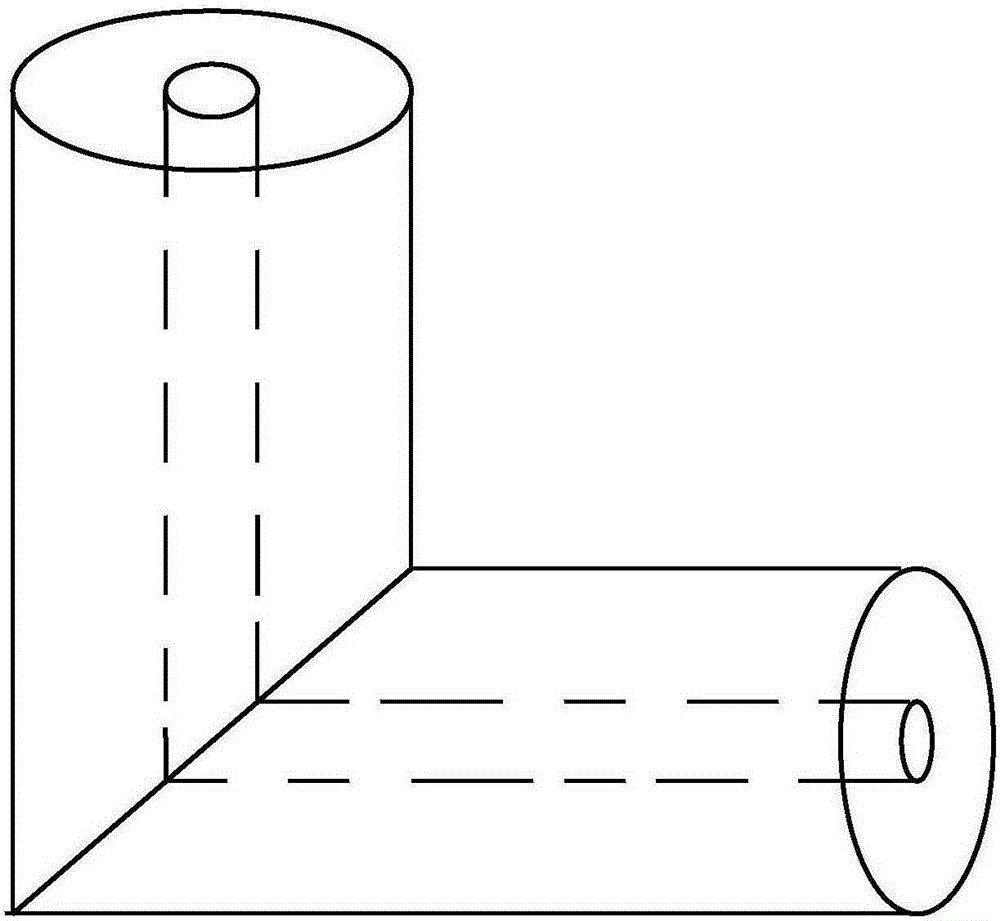

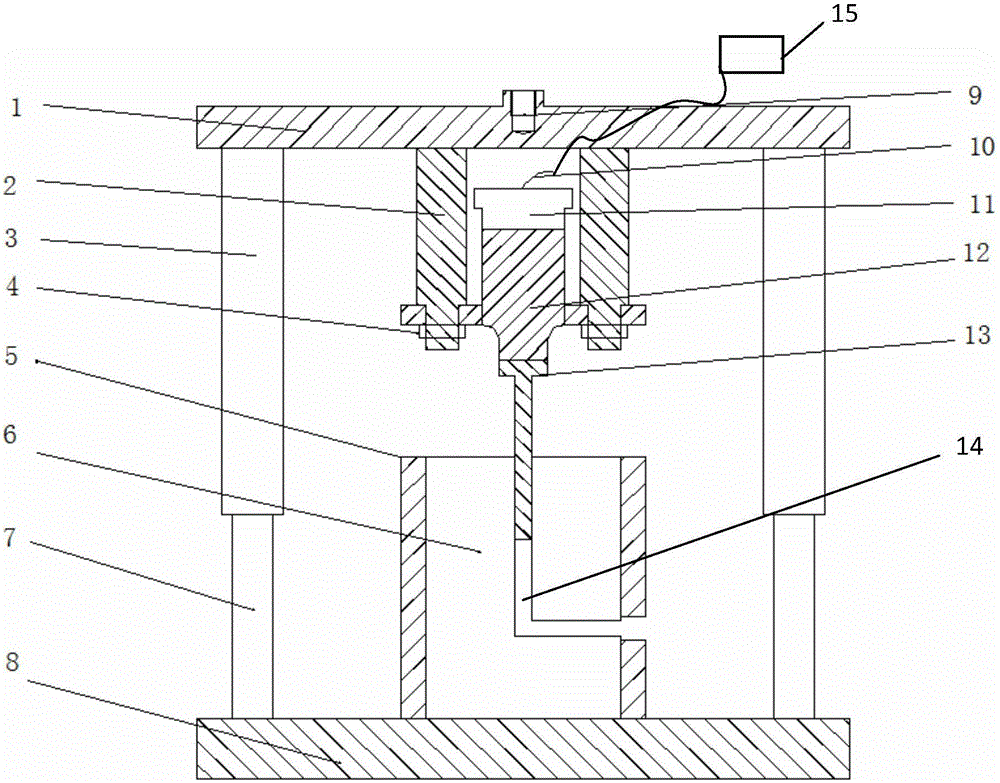

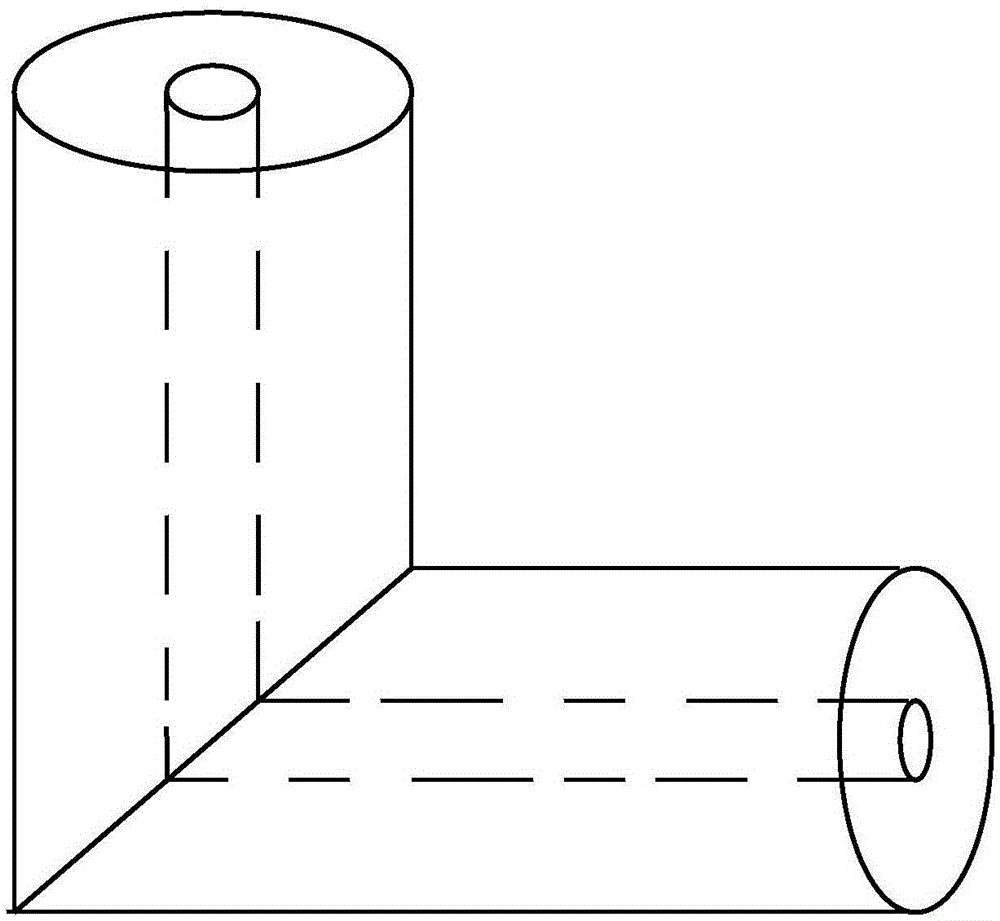

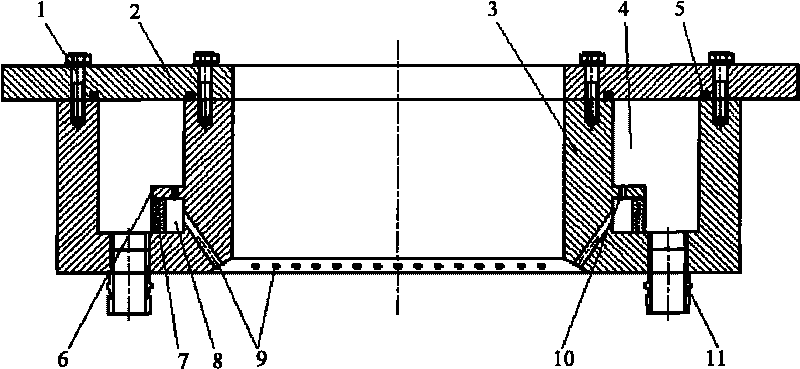

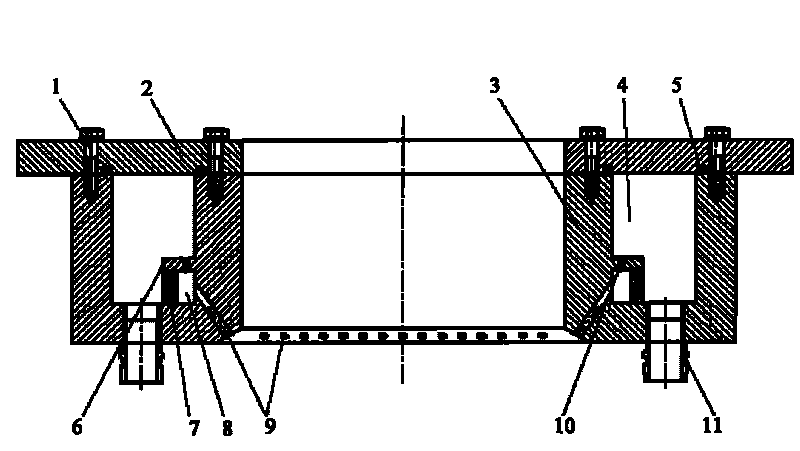

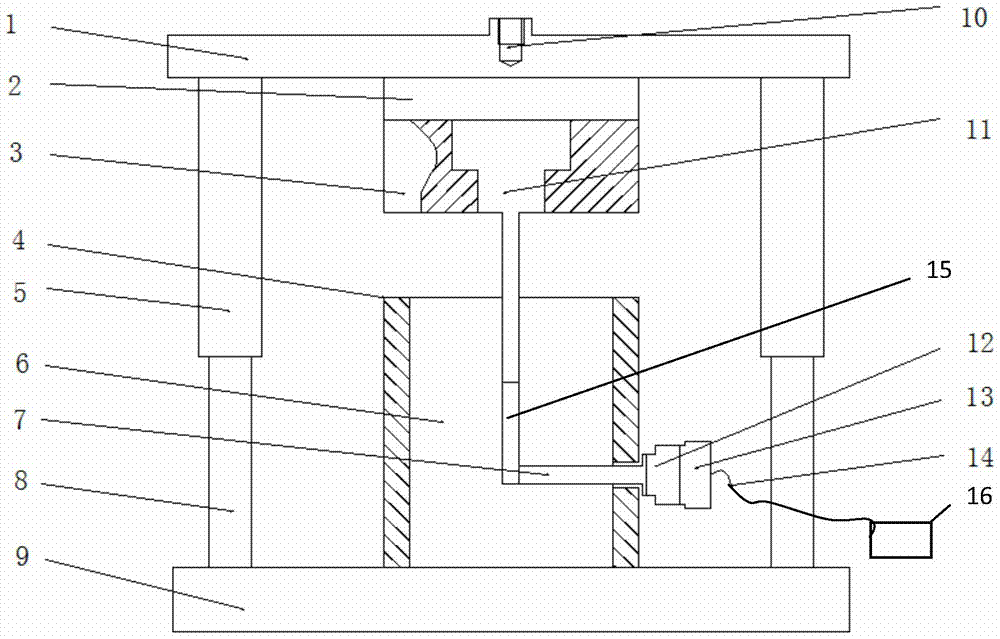

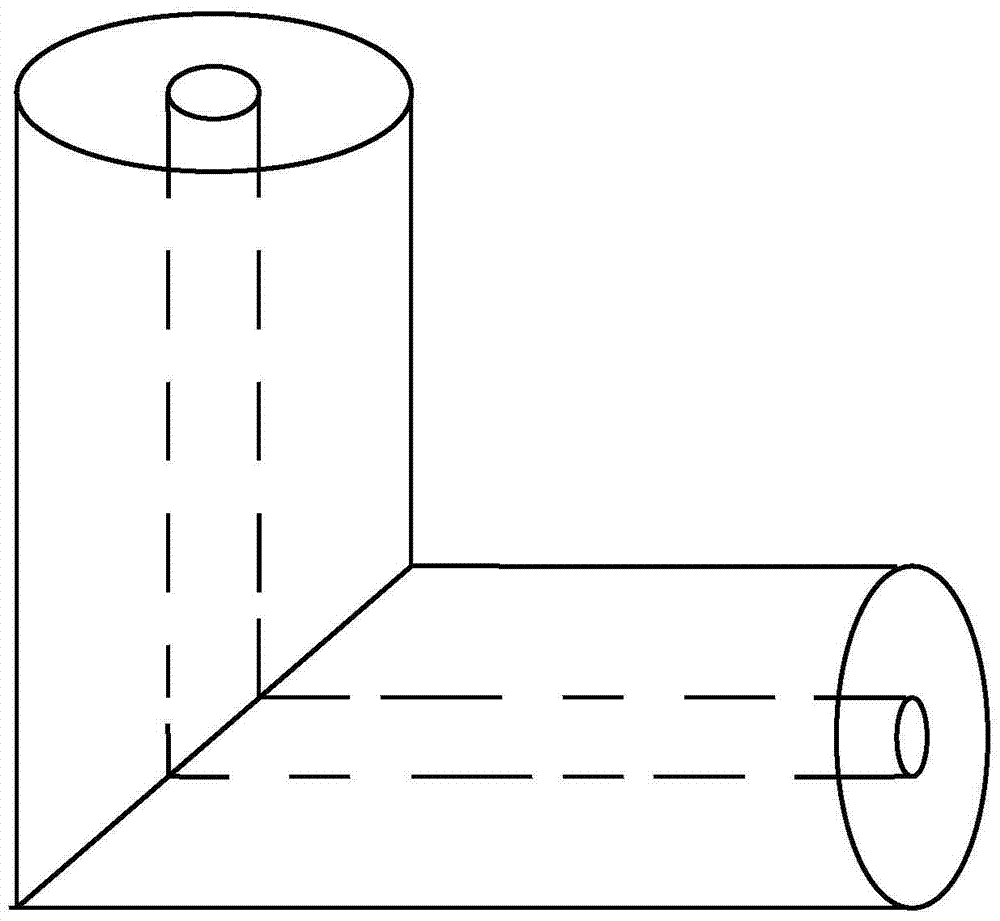

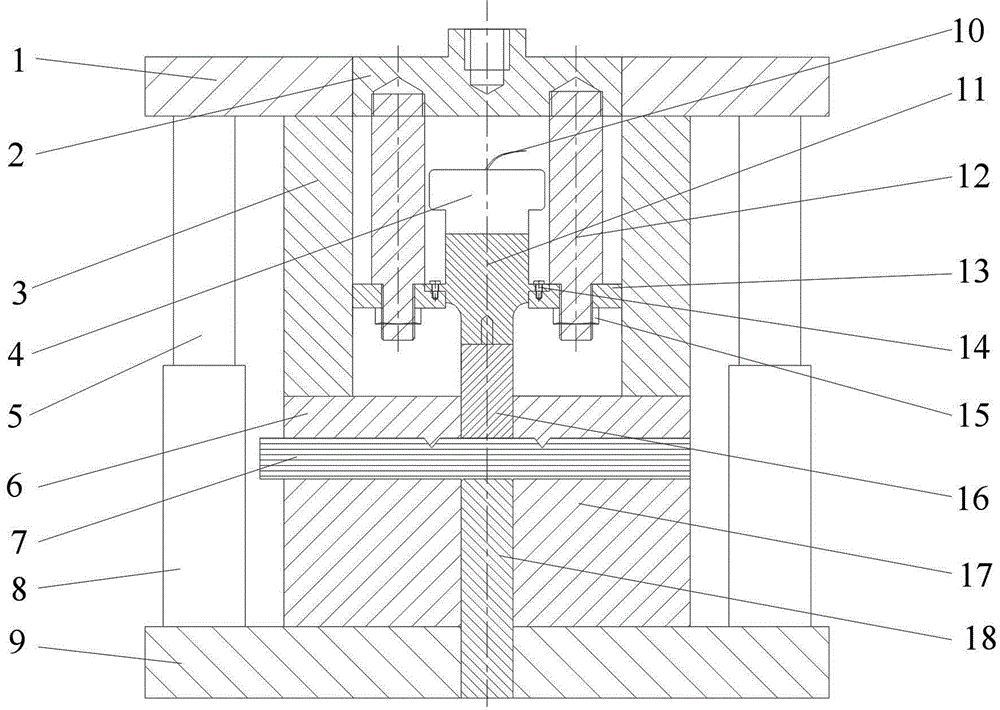

Equal channel angular extrusion device of ultrasonic vibration female die

InactiveCN105170681AIncrease the dislocation densityReduce internal frictionExtrusion diesMechanical vibrations separationEngineeringUltrasound

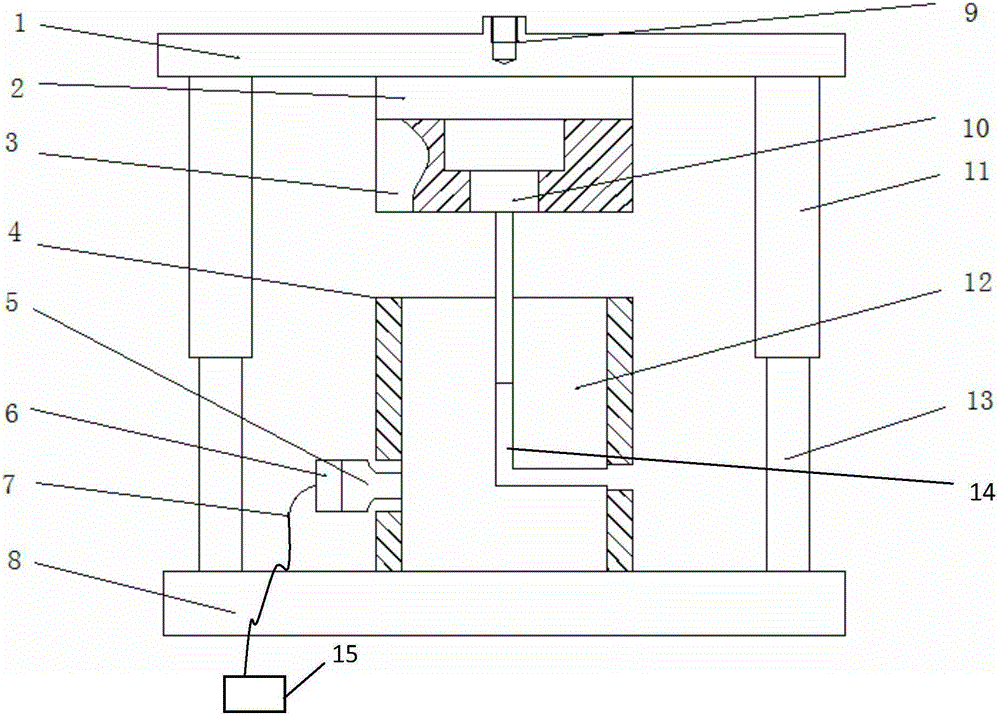

The invention provides an equal channel angular extrusion device of an ultrasonic vibration female die. The equal channel angular extrusion device is composed of an upper template and a lower template. A threaded hole in the upper end of the upper template is connected with a hydraulic plunger on a hydraulic machine. The upper end of a cushion block is connected with the upper template. The lower end of the cushion block is connected with a male die. The male die is fixed in a blocking ring. The upper end of the blocking ring is fixedly connected with the cushion block. The upper end of a guide sleeve is fixedly connected with the upper template. The lower end of the guide sleeve is connected with the upper end of a guide column. The lower end of the guide column is fixedly connected with the lower template. The lower end of the female die is fixed to the lower template. The side face of the female die is fixed through a split stress ring. An ultrasonic vibration device is fixedly connected to the side face of the female die. High-strength ultrasonic waves are input into the female die, high-frequency periodic vibration displacement is generated on the surface of the female die, grain uniformizing and refining of an extrusion piece are improved, and the problems that an equal channel angular extrusion die is nonuniform in grain refining, and cracks exist on the extrusion piece are solved effectively.

Owner:GUANGXI UNIV

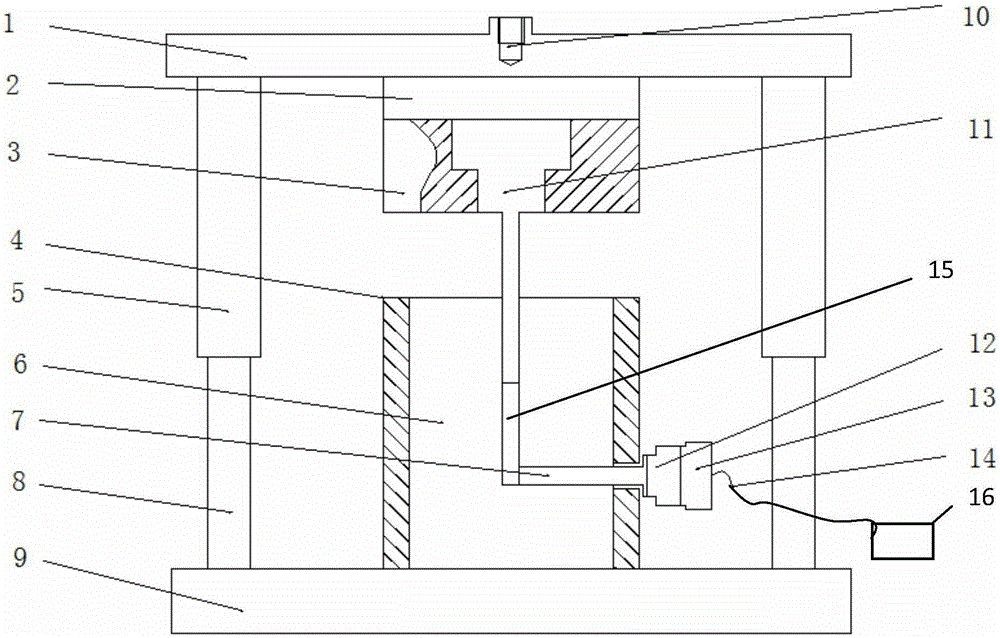

Equal channel angular pressing device of ultrasonic vibration male die

InactiveCN105080992AIncrease the dislocation densityReduce internal frictionExtrusion diesHydraulic ramHigh intensity

Provided is an equal channel angular pressing device of an ultrasonic vibration male die. The upper ends of pressure columns of the device are fixed to an upper die plate. A threaded hole in the upper end of the upper die plate is connected with a hydraulic plunger on a hydraulic machine. The upper ends of guide sleeves are fixedly connected with the upper die plate. The lower ends of the guide sleeves are connected with guide columns. The lower ends of the guide columns are fixedly connected with a lower die plate. The side face of a female die is fixed through a stress ring. An ultrasonic vibration device is fixedly connected between the upper end of the male die and the upper die plate. According to the device, high-intensity ultrasonic waves are input into the male die, high-frequency periodic vibration displacement is generated on the surface of the male die, uniformity of extruded elements is improved, crystal particles are refined, and the problems that according to an equal channel angular pressing die, the crystal particles are not uniform in refining and the extruded elements have cracks are solved.

Owner:GUANGXI UNIV

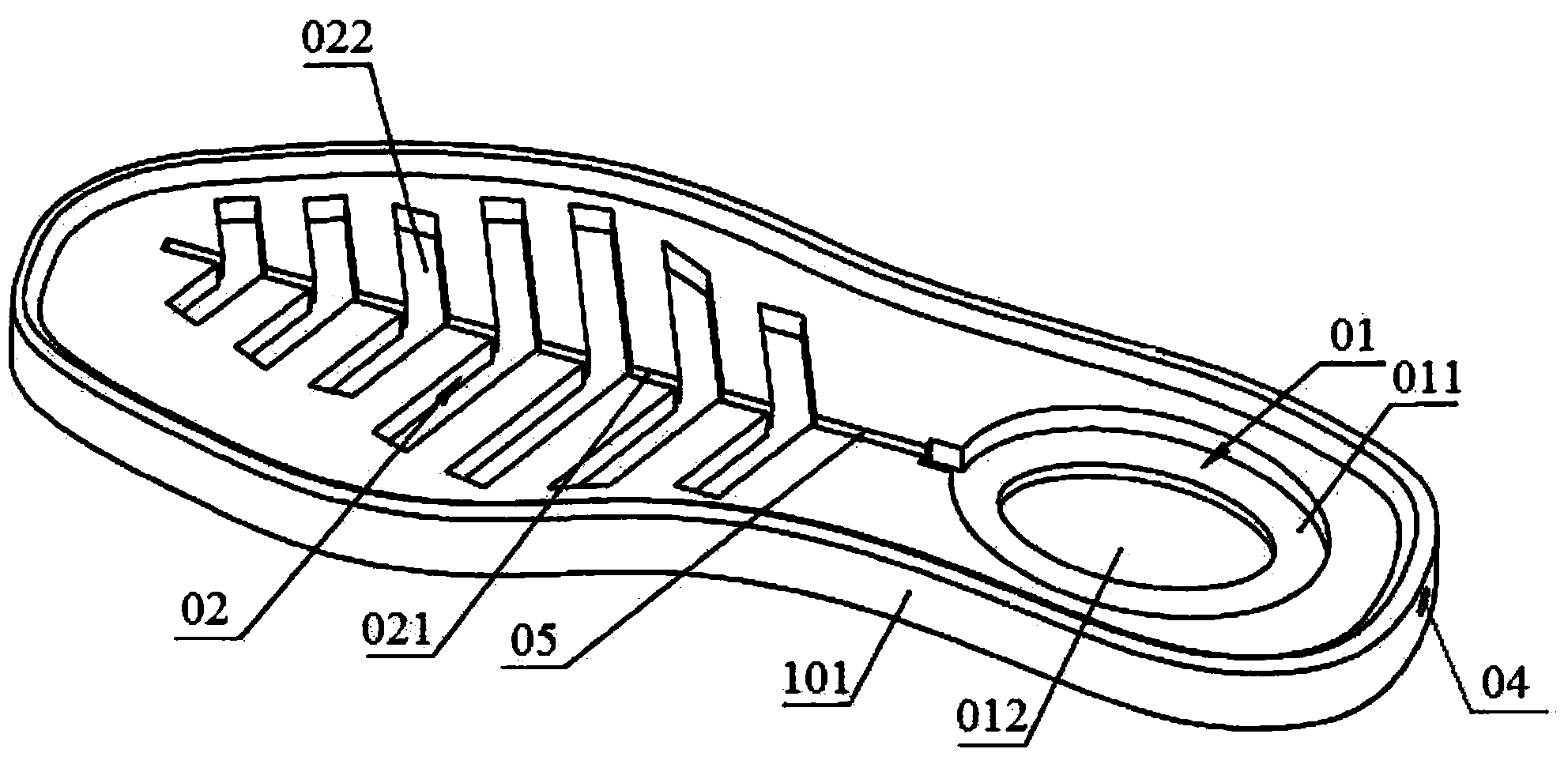

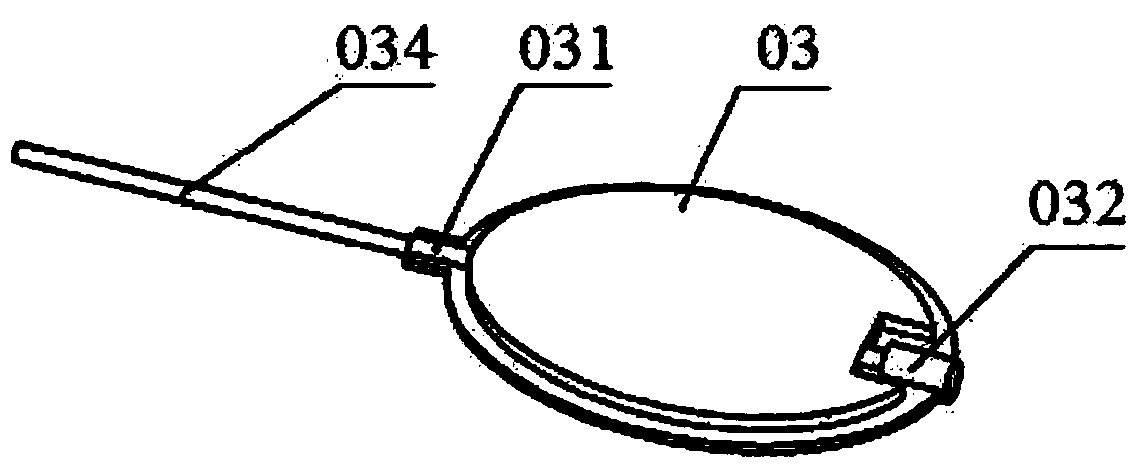

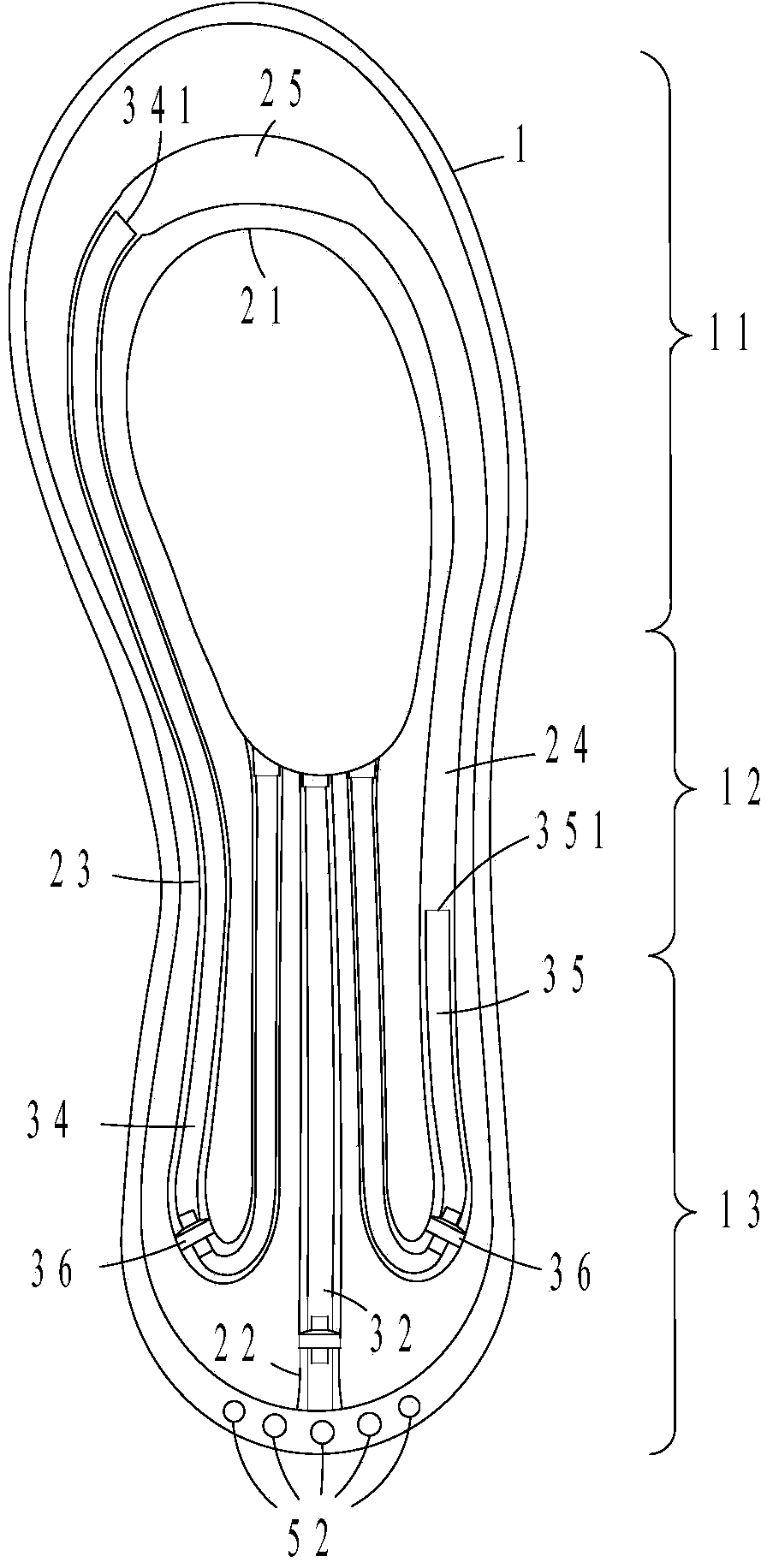

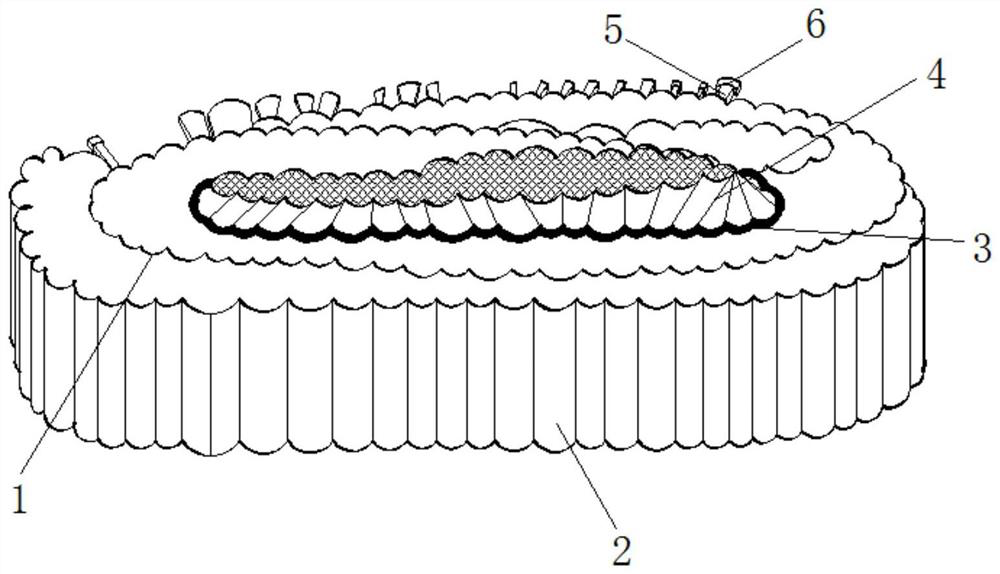

Ventilation shoes

The invention relates to a pair of breathable shoes. Each breathable shoe comprises a shoe sole body, an air bag component and a groove. Each air bag component comprises an inlet pipe and at least one outlet pipe; an inlet check valve and an outlet check valve are respectively arranged in the inlet pipe and each outlet pipe; each shoe sole body is connected with a waist plate; an inlet passage communicated with the outside is arranged in each waist plate; each inlet passage is communicated with the corresponding inlet pipe; each shoe sole body comprises a half sole part, an arch part and a heelpiece part; each half sole part is provided with a release slot and an air bag; the outlet pipes on each air bag are communicated with the corresponding release slot; each inlet check valve and each outlet check valve are located at the corresponding heelpiece part. Air inlets of each breathable shoe are located on the corresponding waist plate far away from the ground, and therefore, the phenomenon that water or dust enters the inlet passages to cause the air bag components to be blocked can be effectively prevented, and the reliability is high. Each inlet check valve and each outlet check valve are arranged on the corresponding heelpiece part, so that the safety and the comfort are better; each air bag is arranged at the corresponding half sole part, and is capable of sucking and releasing more air to play a role of rapidly cleaning air in the shoes, so that the ventilation Efficiency of the interiors of the shoes is improved.

Owner:周立新 +1

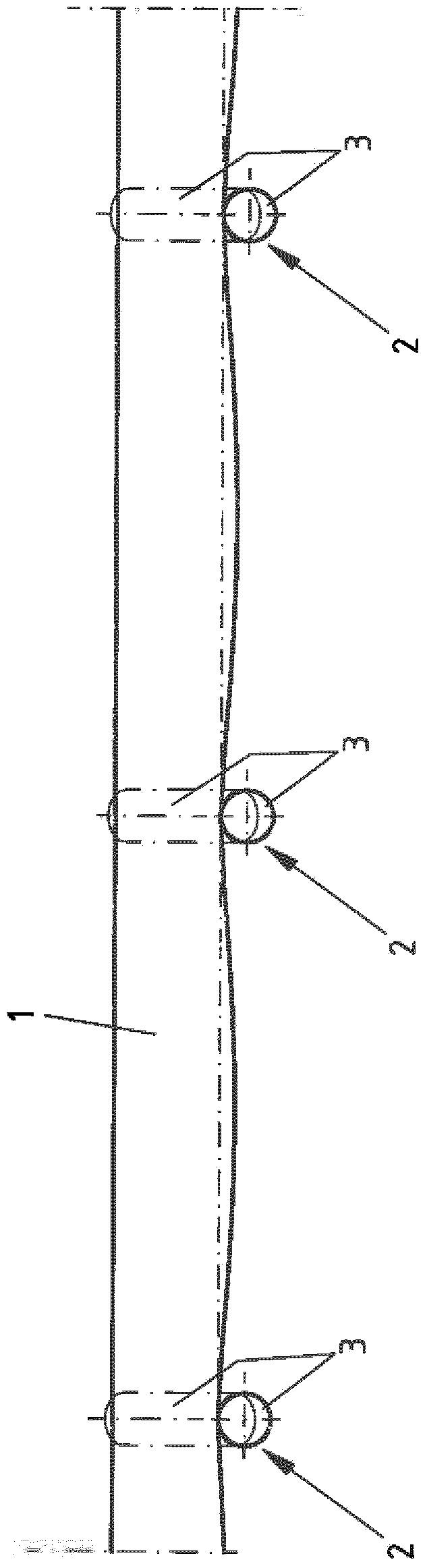

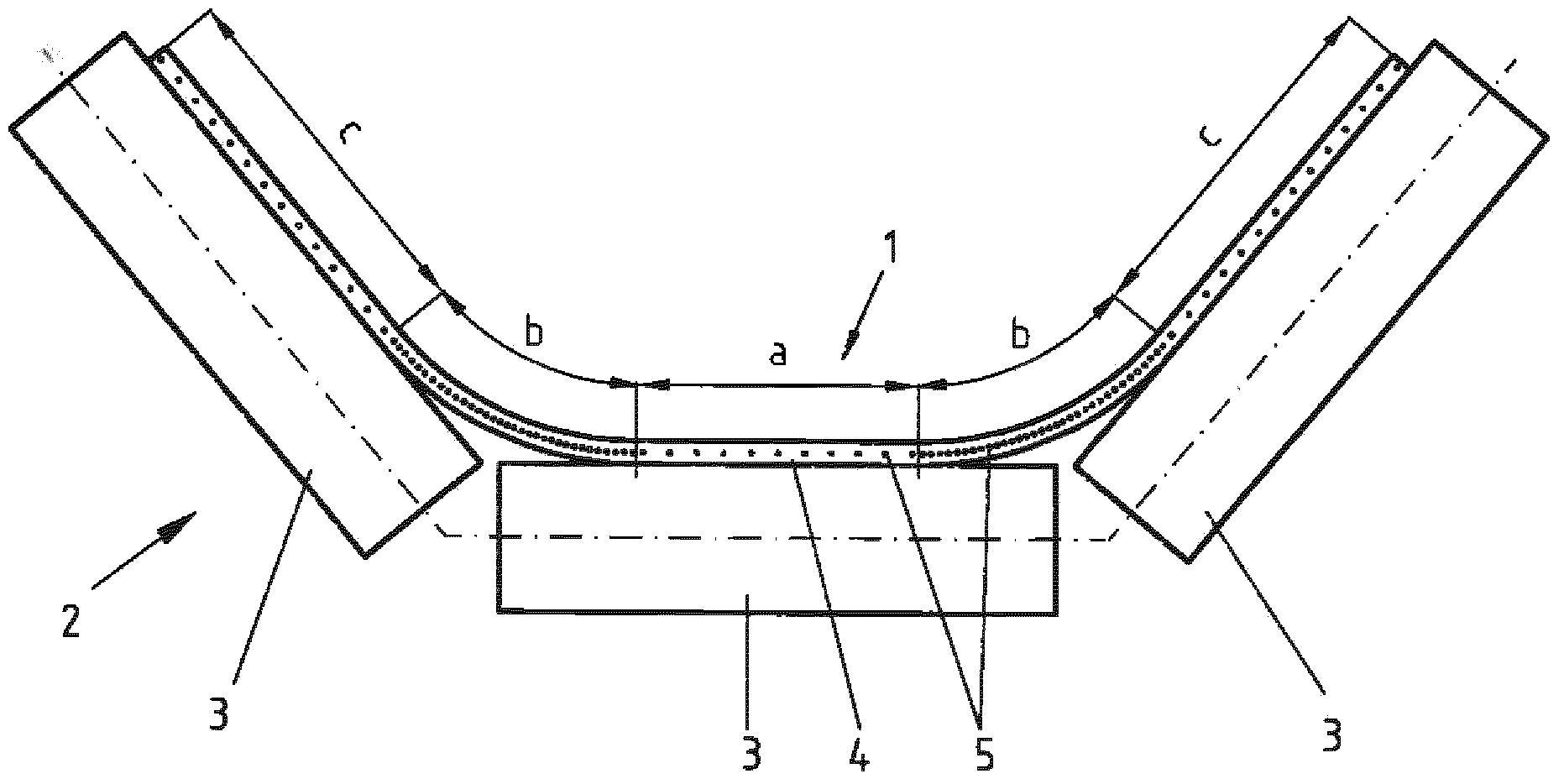

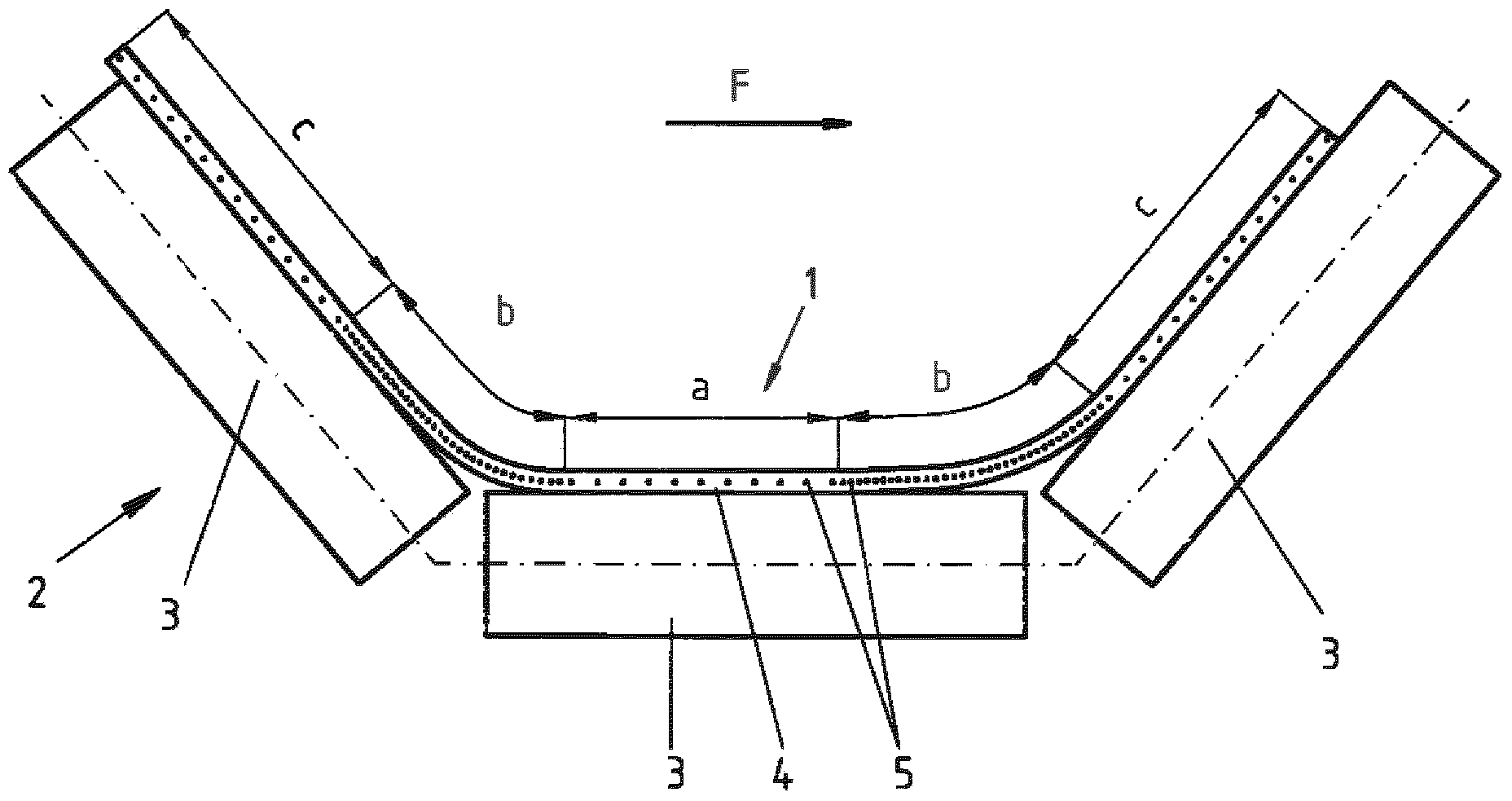

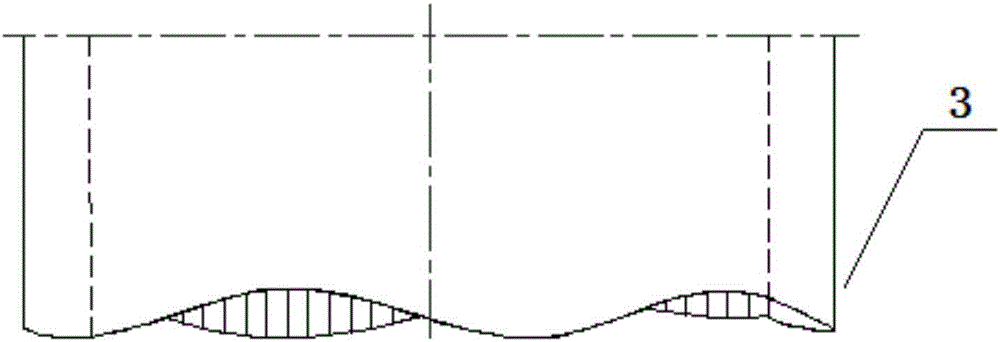

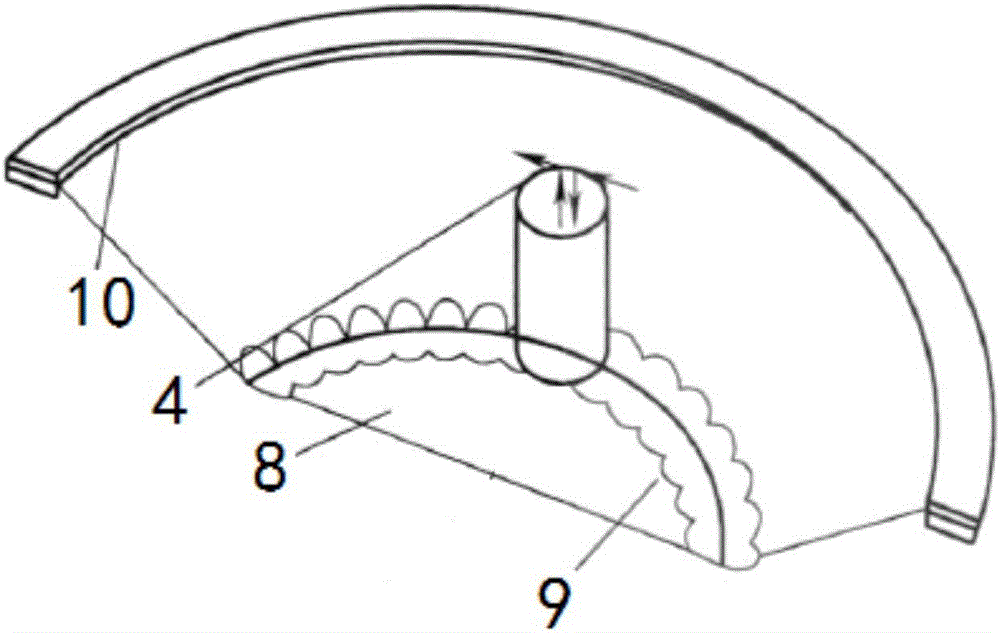

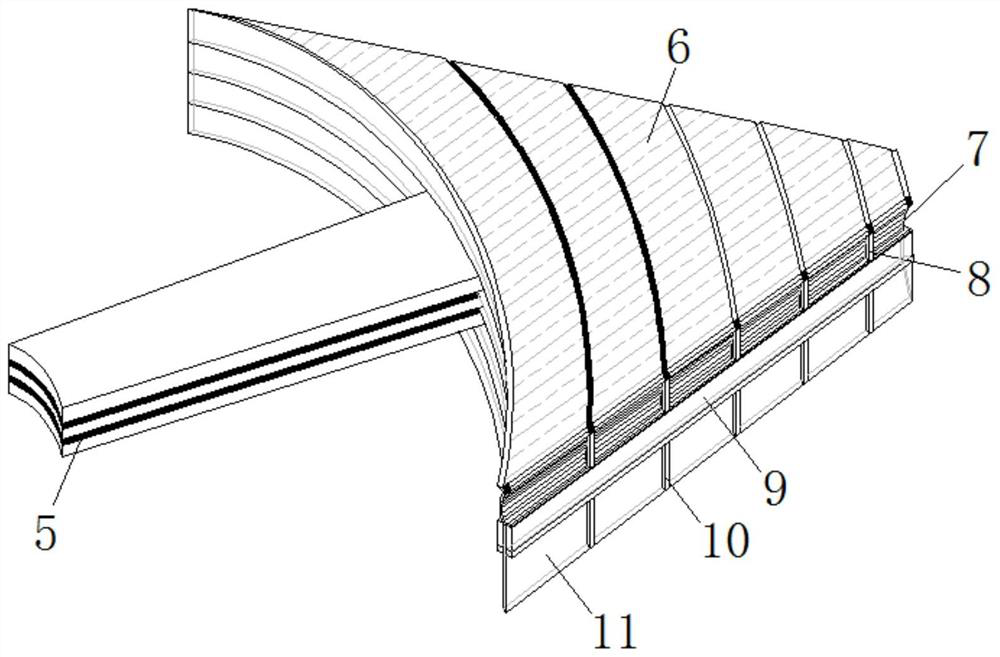

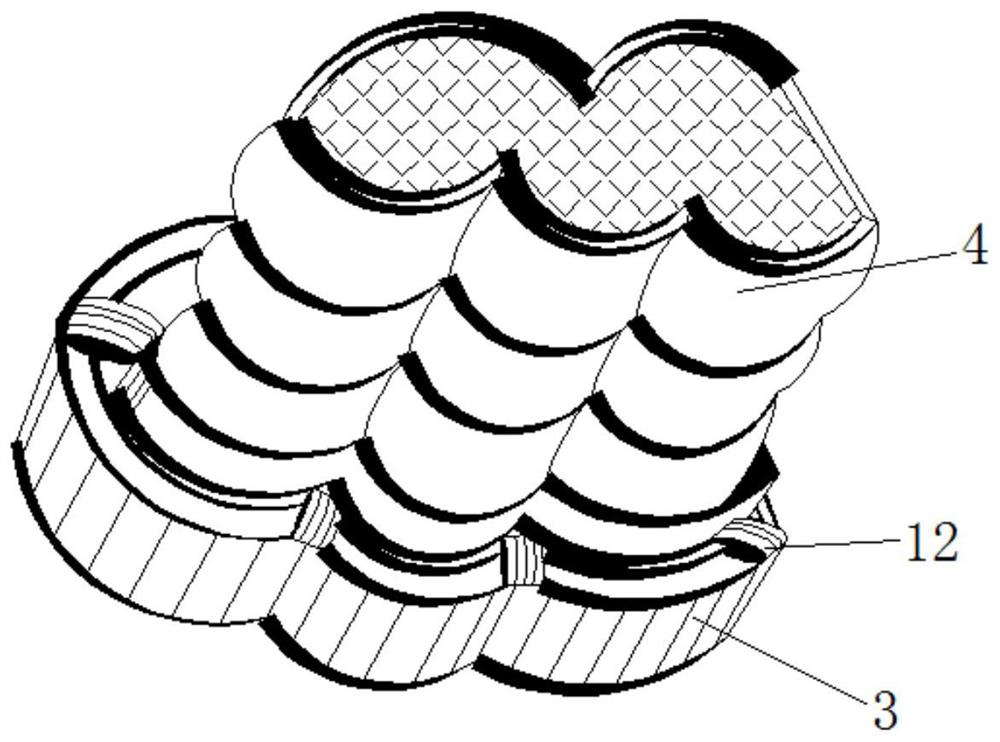

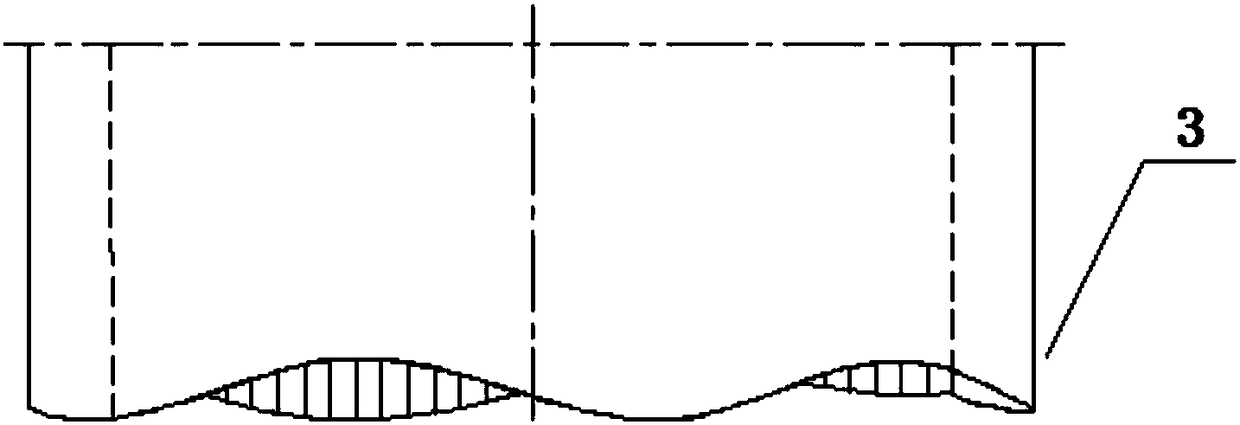

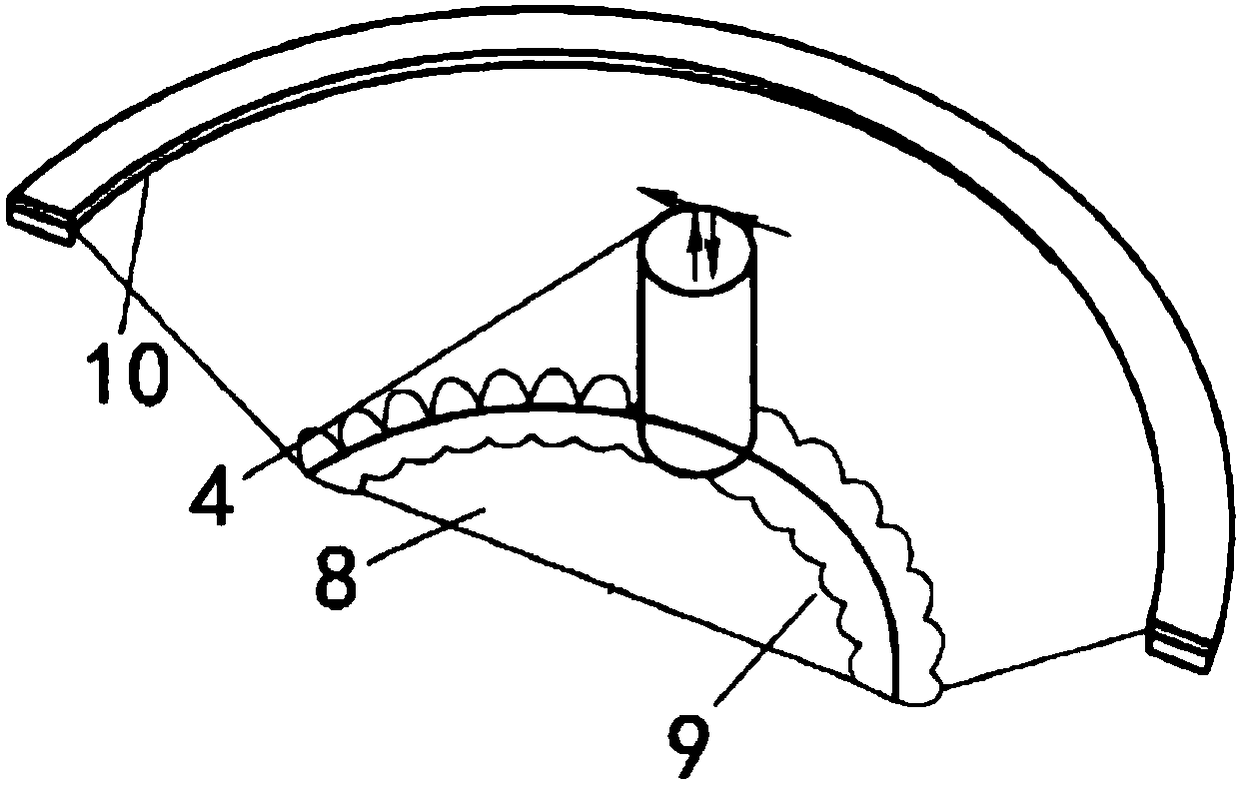

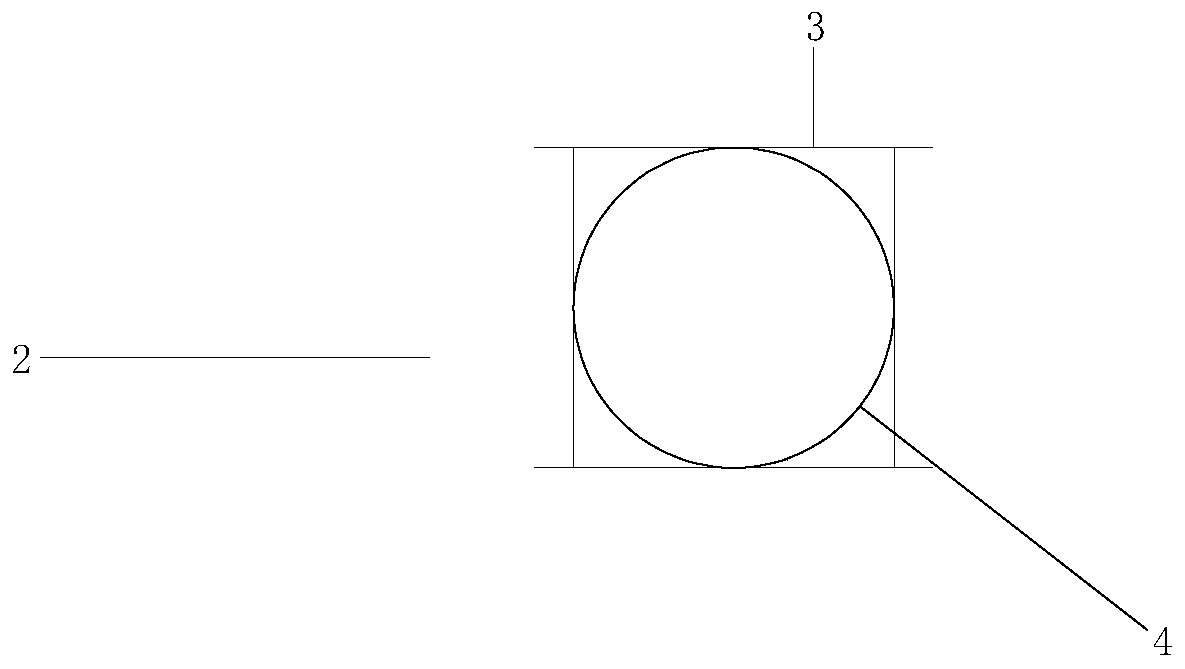

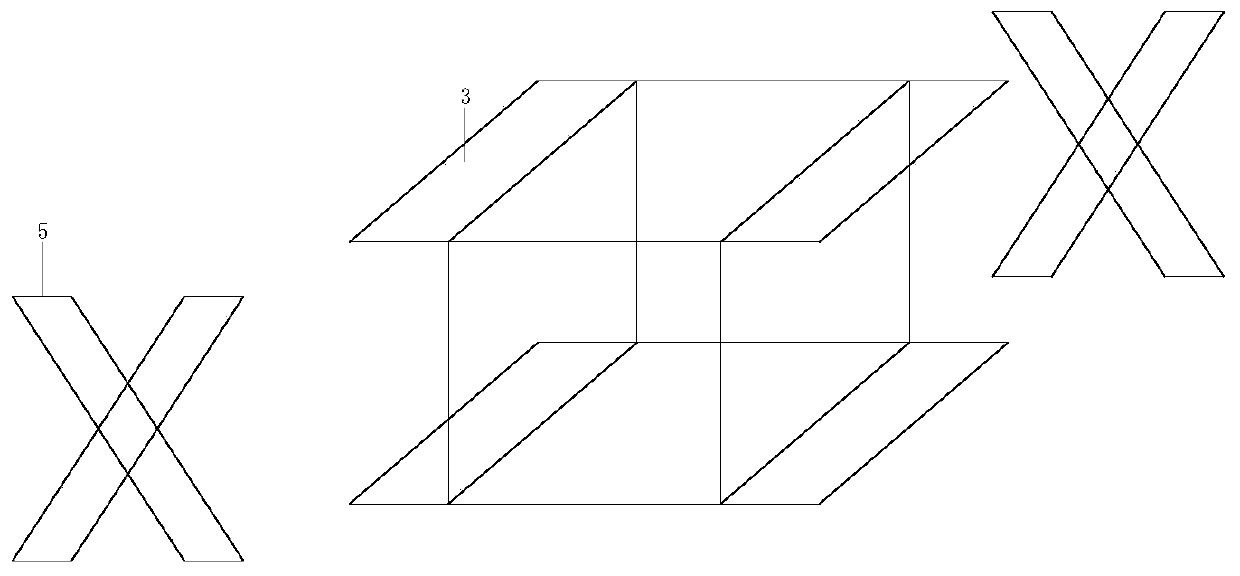

Conveyor belt system and conveyor belt

The invention relates to a conveyor belt system comprising a conveyor belt (1) extending in the longitudinal direction and a plurality of support roller stations (2) arranged at a distance from each other in the longitudinal direction and on which the conveyor belt (1) is supported by support rollers (3), said conveyor belt (1) being formed from a flexible base material (4) and a plurality of unconnected traction means (5) which determine the tensile strength of the conveyor belt (1) and which extend in the longitudinal direction. According to the invention, in the cross-section of the conveyor belt (1) and with respect to a desired position on a central belt section (a) supported on a support roller (3) of the support roller station (2), the tensile strength relative to the belt width is less than on the laterally adjoining belt sections (b) which are not supported in the desired position by a support roller (3). The invention also relates to the conveyor belt (1) itself.

Owner:THYSSENKRUPP RESOURSE TECH GMBH

Equal-diameter angle extrusion device under combined effect of ultrasound waves and back pressure

An equal-diameter angle extrusion device under the combined effect of ultrasound waves and back pressure comprises an upper mold plate and a lower mold plate. A threaded hole in the upper end of the upper mold plate is connected with a hydraulic plunger on a hydraulic machine. The upper end of a cushion block is connected with the upper mold plate, and the lower end of the cushion block is connected with a male mold. The male mold is fixed in a check ring, and the upper end of the check ring is fixedly connected with the cushion block. The upper end of a guide sleeve is fixedly connected with the upper mold plate. The lower end of the guide sleeve is connected with a guide column, and the lower end of the guide column is fixedly connected with the lower mold plate. The lower end of a female mold is fixed to the lower mold plate. The lateral face of the female mold is fixed with a split stress ring. The front section of an ejector rod penetrates through an ejector rod through hole in the female mold. An ultrasound wave vibration device is fixed to the ejector rod. The high-intensity ultrasound waves are input into the ejector rod, high-frequency periodic vibration and displacement are generated on the surface of the ejector rod, and after back pressure is applied, the homogenization of an extruded part is improved, grains are refined, and the problems that grains are refined unevenly and the extruded part has cracks in an equal-diameter angle extrusion mold are effectively solved.

Owner:GUANGXI UNIV

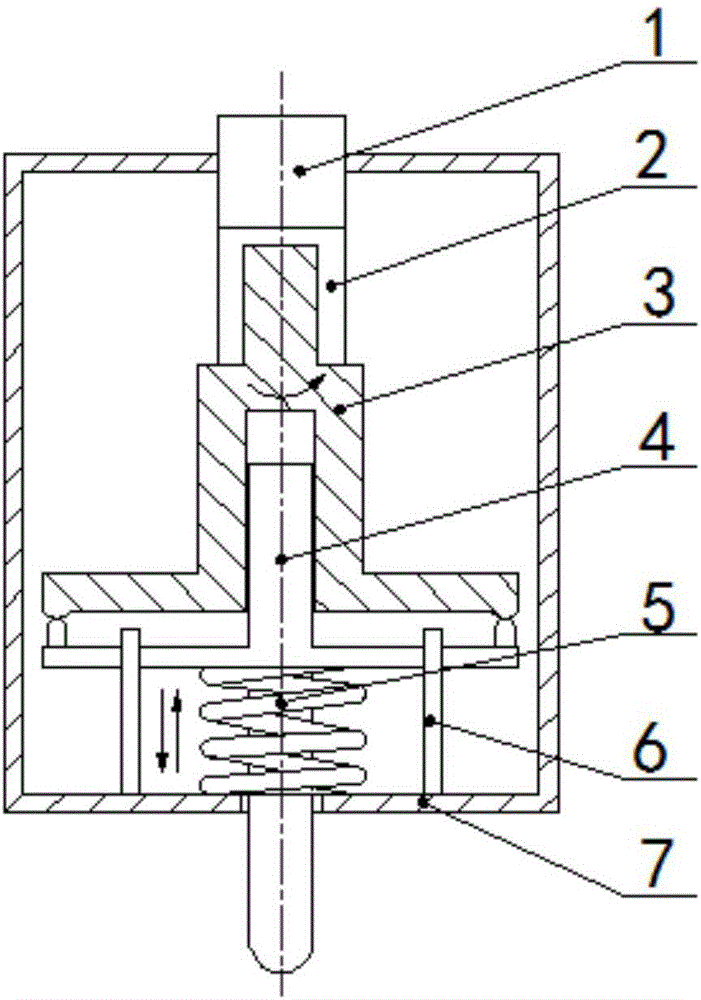

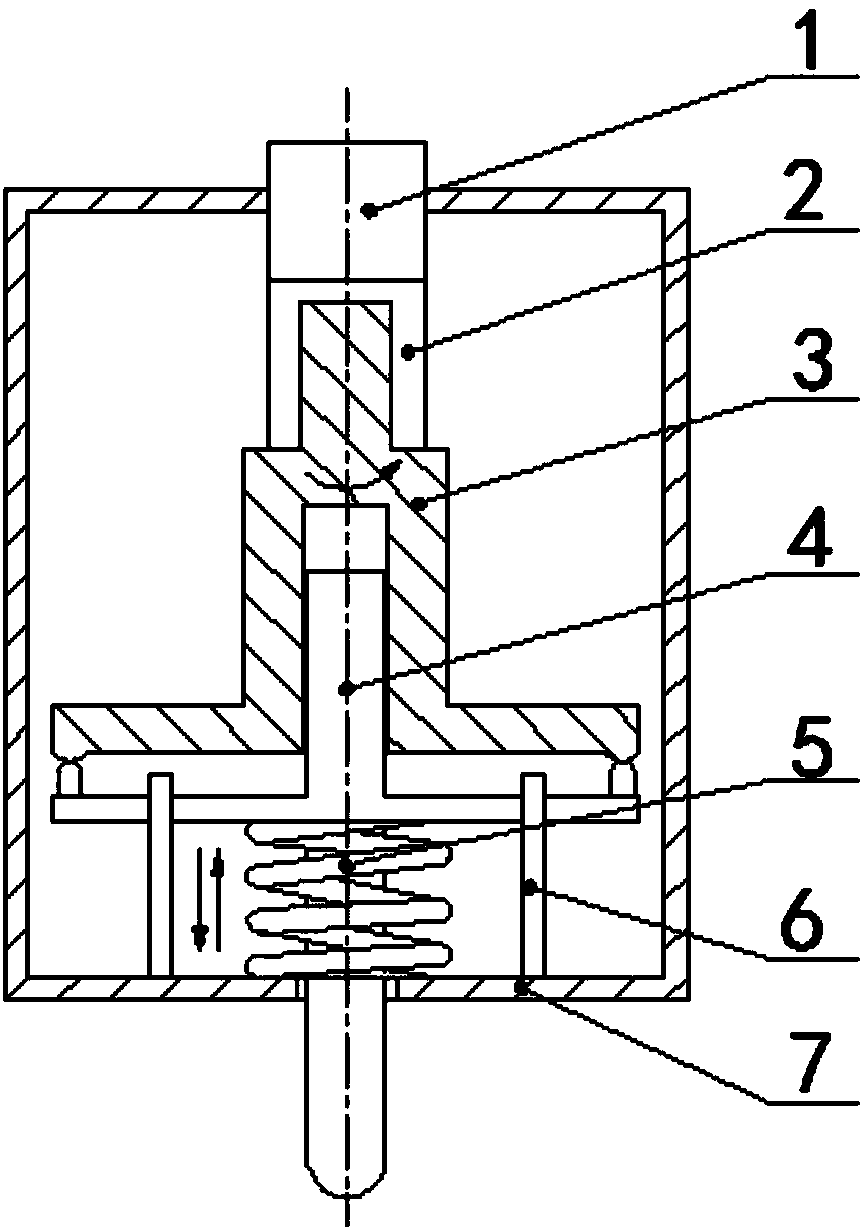

Single-point incremental forming tool head axial vibration device

The invention discloses a single-point incremental forming tool head axial vibration device. The device comprises a supporting frame and a tool head with a push rod. A spring and two guide posts are connected to the inner bottom of the supporting frame. The spring is located in the center. The two guide posts are located on the left side and the right side of the spring correspondingly. The tool head with the push rod is composed of a tool head body arranged horizontally and the protruding push rod perpendicularly and fixedly connected to the tool head body. The upper end of the spring and the upper ends of the two guide posts are all connected with the tool head body. The upper portion of the protruding push rod is connected with a sleeve. A gap is reserved between the tool head body and the bottom surface of the sleeve. The upper portion of the sleeve is clamped to one end of a tool holder of a machine tool. The other end of the tool holder of the machine tool is connected with a rocker arm of the machine tool. According to the single-point incremental forming tool head axial vibration device, the tool head with the push rod is driven through rotation of a machine tool spindle to generate axial vibration, so that original continuous extrusion friction motion is converted into high-frequency point pressure motion, deformation processing is facilitated, and forming force required in the forming process is reduced.

Owner:XIAN UNIV OF TECH

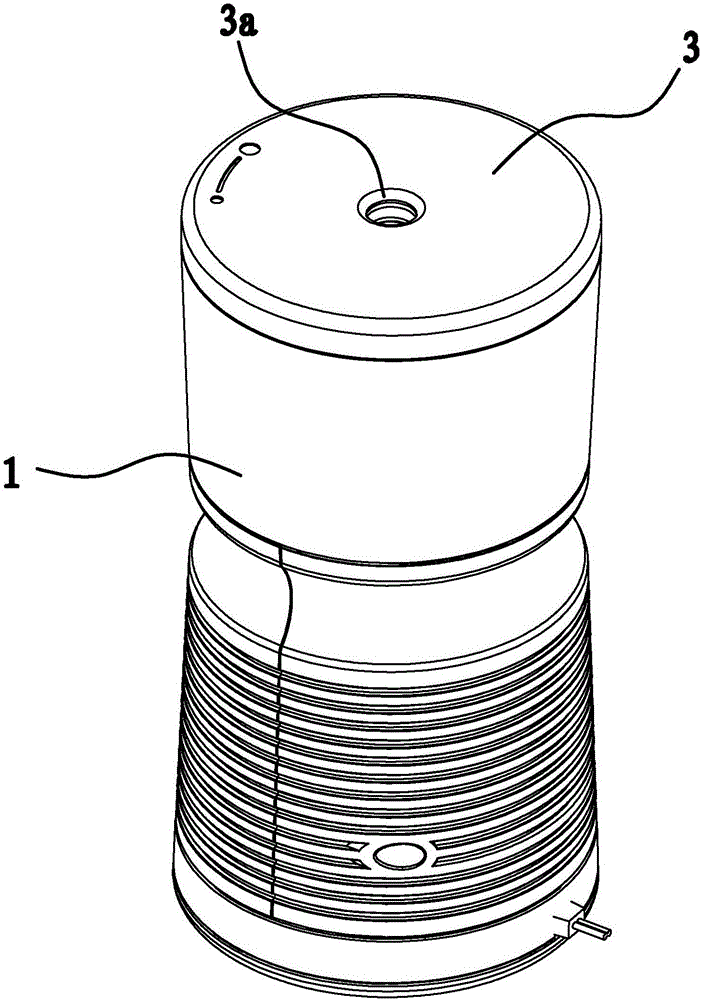

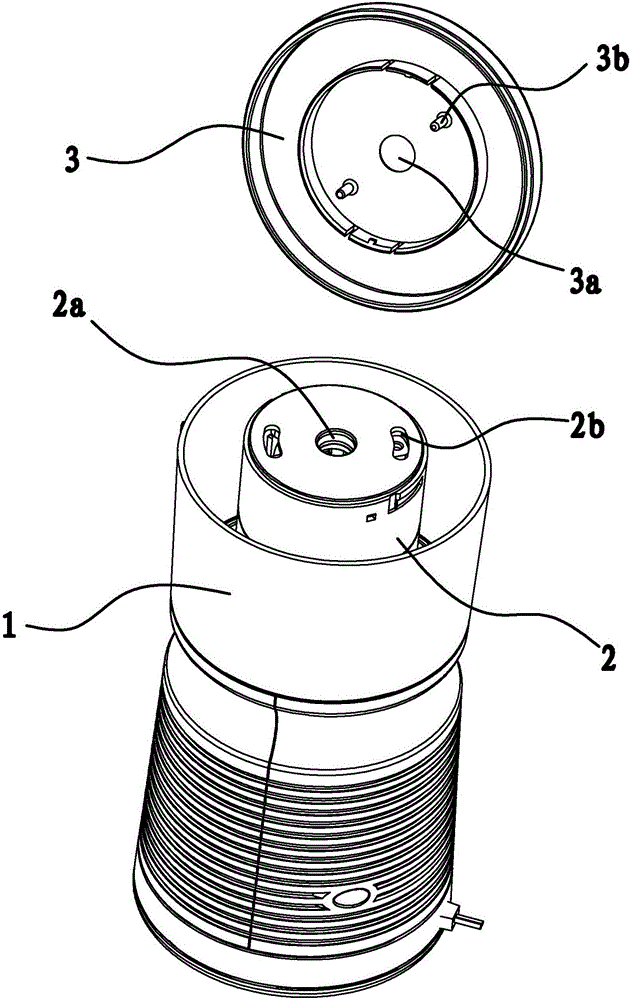

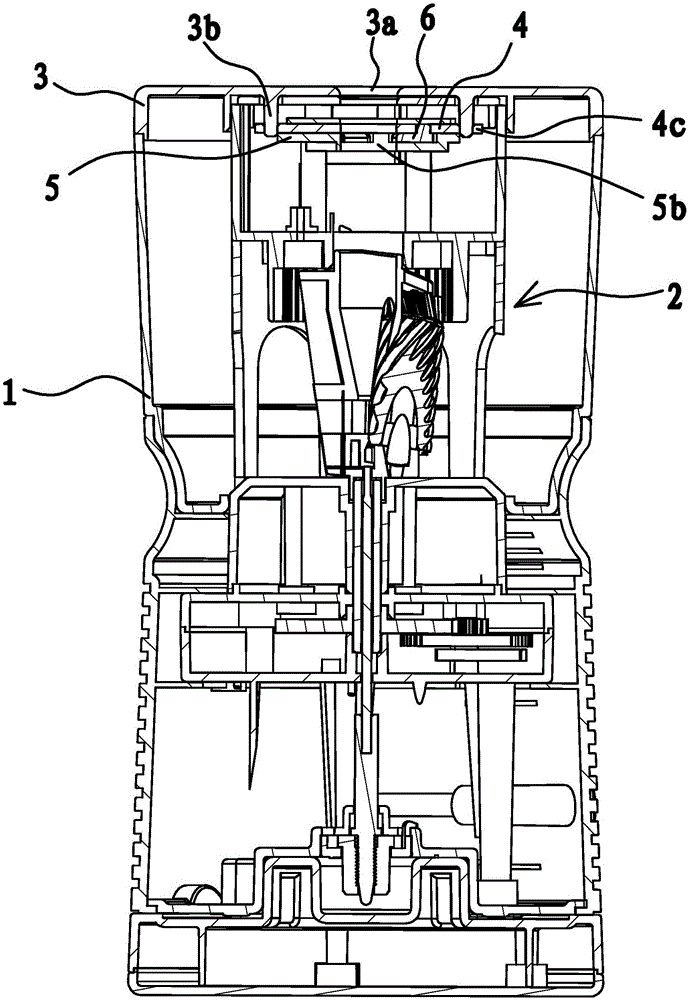

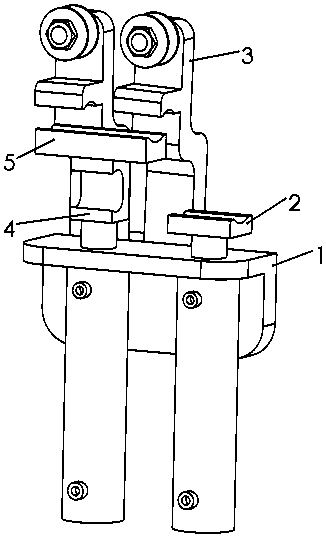

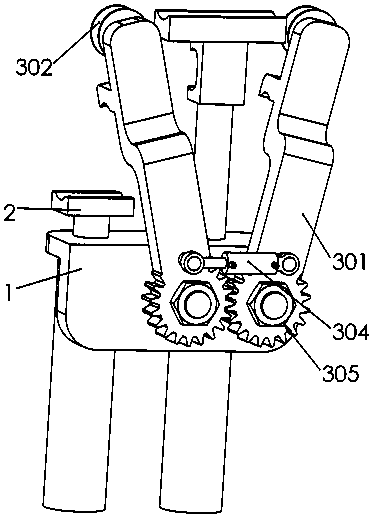

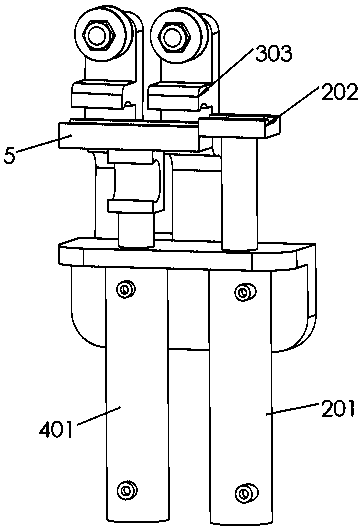

Pencil clamping mechanism of pencil sharpener

Owner:SUNWOOD HLDG GROUP

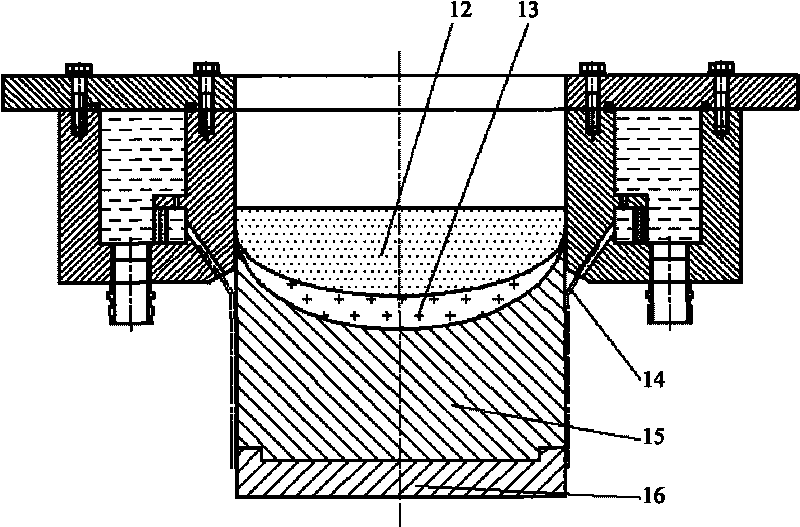

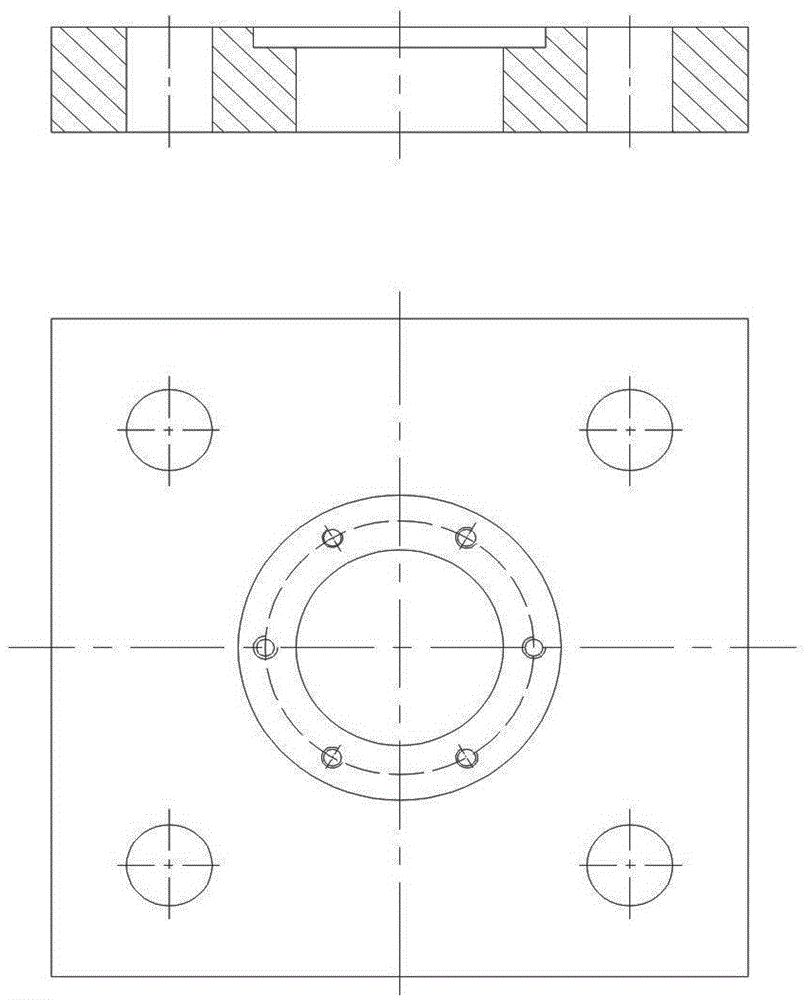

Integrated diversion board crystallizer for casting aluminium alloy

The invention relates to an integrated diversion board crystallizer for casting aluminium alloy, an upper cover plate is connected on a crystallizer body, an inner cavity of which is internally provided with an integrated diversion board; the integrated diversion board is vertically connected with the inner wall of the inner cavity of the crystallizer body; a rubber strip is used for sealing the integrated diversion board and the bottom surface of the inner cavity of the crystallizer body; the inner cavity of the crystallizer body is divided into an outer water cavity and an inner water cavity; the integrated diversion board is evenly distributed with diversion holes used for leading the outer water cavity to be communicated with the inner water cavity; and the inner wall of the crystallizer body is provided with a water spray hole which is communicated with the inner water cavity. The integrated diversion board crystallizer leads the diversion board and the crystallizer body to be in an integrated design, has the function of evenly distributing cold water, solves the problem that the diversion board is easily deformed and difficult to assemble, and is beneficial to improving the cast ingot quality and increasing the finished product ratio of cast ingots.

Owner:苏州有色金属研究院有限公司

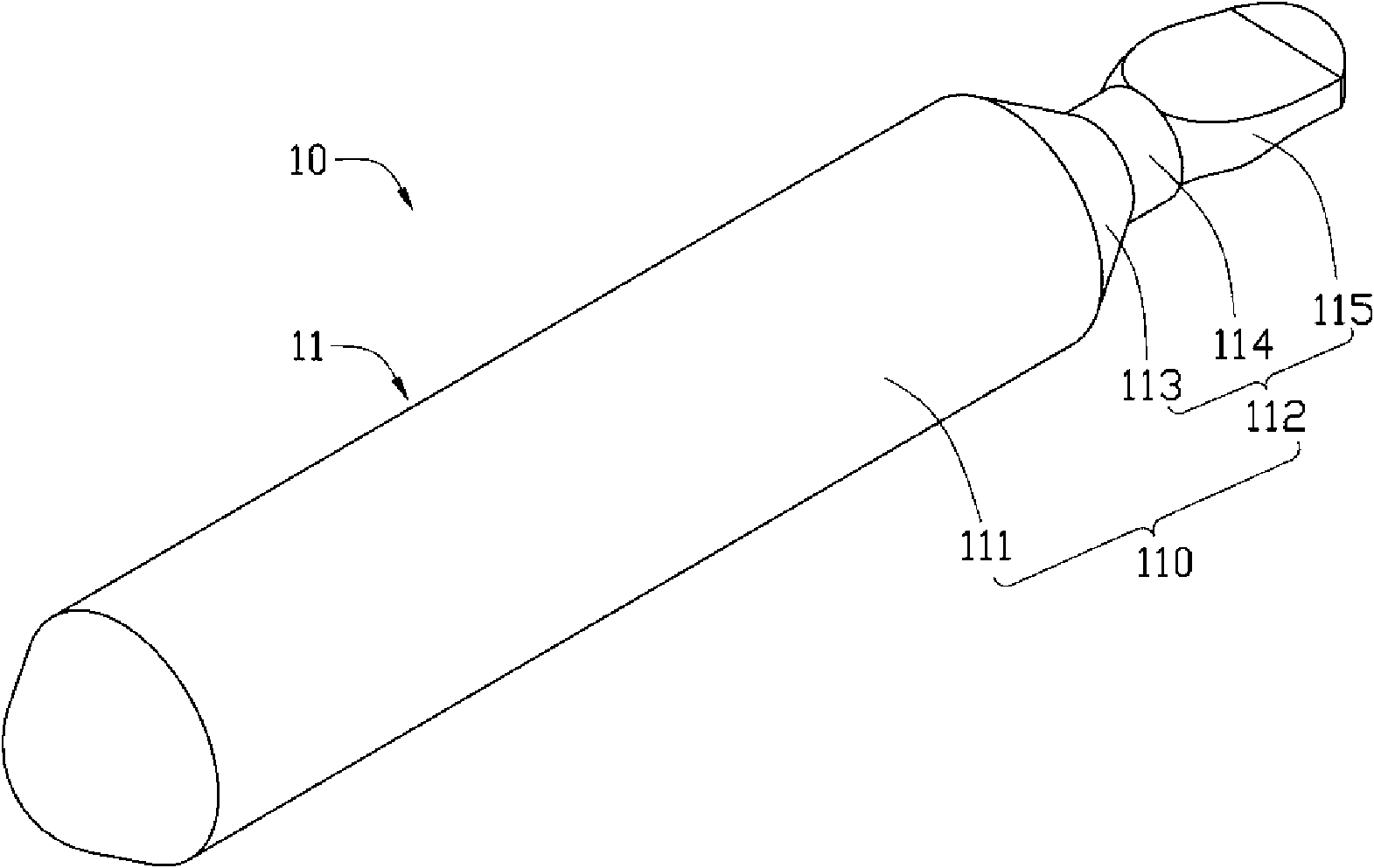

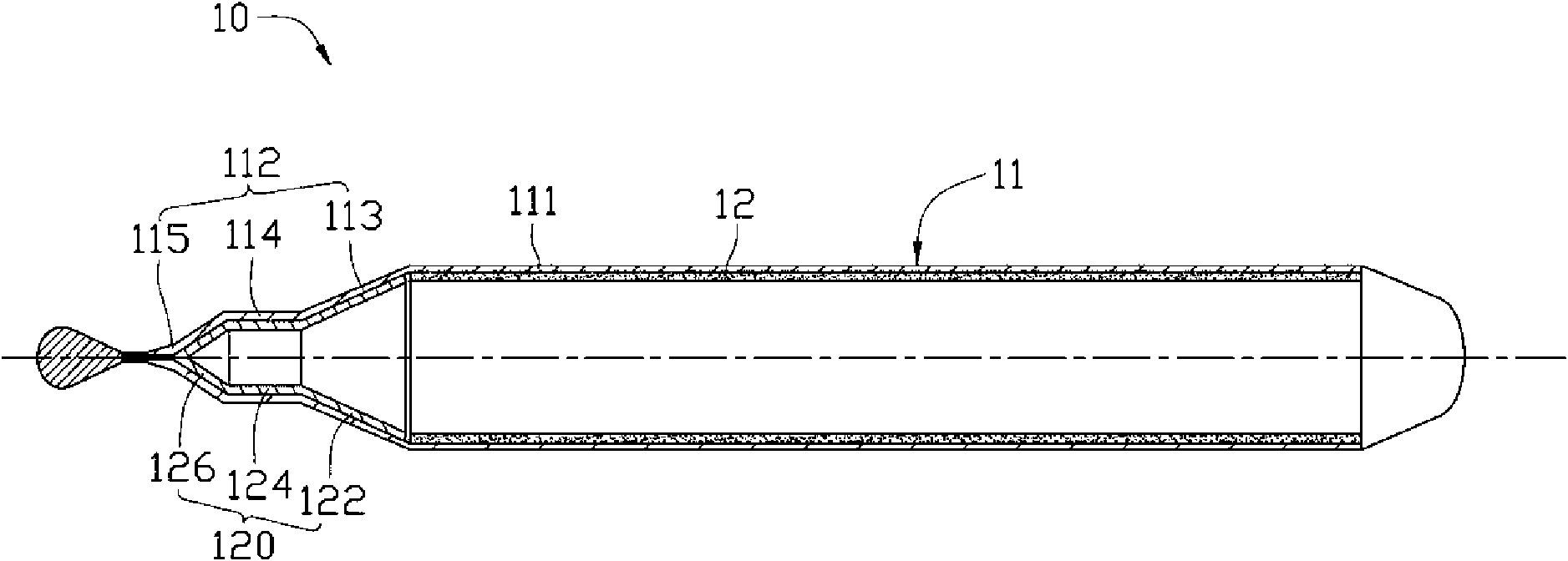

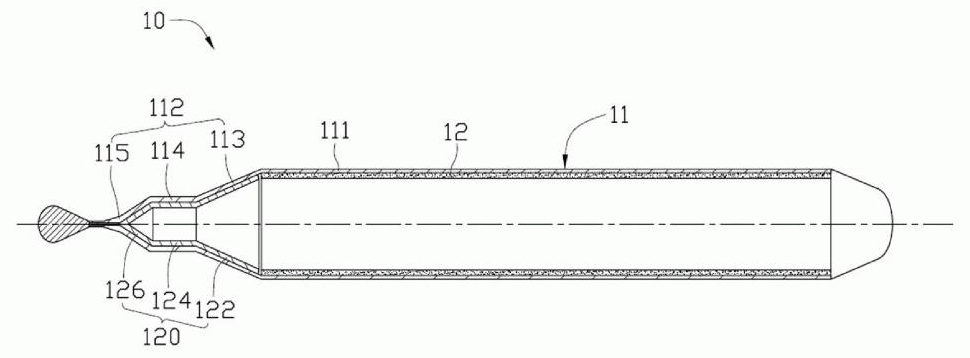

Heat pipe

InactiveCN101907412AReduce weightAffect thermal conductivitySemiconductor/solid-state device detailsSolid-state devicesRheniumNiobium

A heat pipe comprises a sealed shell, wherein the shell comprises a pipe body. One end of the pipe body is provided with a sealing part. The pipe body is made of titanium. A supporter is contained in the sealing part. The supporter is made of copper, aluminum, stainless steel, low-carbon steel, iron, nickel, tungsten, tantalum, molybdenum, rhenium or niobium. The whole weight of the heat pipe is light and the fissure caused by over large deformation when processing the sealing part is prevented, so as to protect the thermal conductivity of the heat pipe.

Owner:FURUI PRECISE COMPONENT (KUNSHAN) CO LTD +1

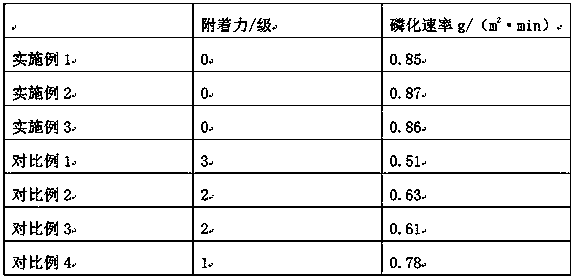

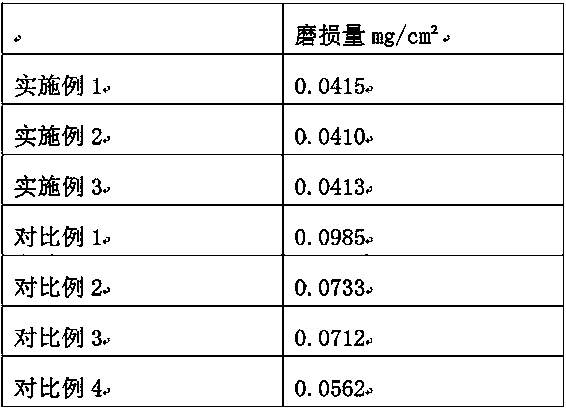

Steel rim vehicle wheel surface phosphating treatment method

InactiveCN108914110AImprove compactnessImprove uniformityAnti-corrosive paintsMetallic material coating processesHigh phosphateWear resistance

The invention discloses a steel rim vehicle wheel surface phosphating treatment method and relates to the technical field of steel treatment. The method comprises: (1) grinding, (2) cleaning, (3) plasma treatment and (4) phosphating treatment. The method can well protect the steel rim vehicle wheel surface, improve the film forming stability, greatly improve the compactness and uniformity of the phosphated film, realize high phosphated film adhesion, improve the corrosion resistance and wear resistance of the surface of the steel rim vehicle wheel surface, realize high phosphated film purity,facilitate precipitate removal, shorten the conventional high-temperature surface phosphating treatment time, realize fast phosphating treatment at the normal temperature, prevent heating, solve the problem that the conventional high-temperature phosphating treatment method easily causes phosphated film impurities and precipitates difficult to remove, and improve the phosphating efficiency.

Owner:ANHUI JIANGHUAI WHEEL CO LTD

Vehicle side wall lower sill plate edge beam end molding method

The invention discloses a vehicle side wall lower sill plate edge beam end molding method. Before three surfaces of a vehicle side wall lower sill plate edge beam end are processed through a punching process, a stress damage pit is processed in a sheet metal part as a raw material beforehand to damage original stress of the sheet metal part; the stress damage pit is positioned in the middle position of a middle surface to be processed; and then, the three surfaces are molded through punching. The stress damage pit is an arc pit of which the middle part is deep and the depth is gradually decreased from middle part to periphery. The method can eliminate the defects of difficult processing and poor molding quality caused by material stress in the molding process of the vehicle side wall lower sill plate edge beam end, and improves the processing quality and efficiency.

Owner:CHONGQING DAFA TIANDI MACHINERY MFG IND CO LTD

An Equal Angle Squeeze Device under the Combined Action of Ultrasonic and Back Pressure

An equal-diameter angle extrusion device under the combined effect of ultrasound waves and back pressure comprises an upper mold plate and a lower mold plate. A threaded hole in the upper end of the upper mold plate is connected with a hydraulic plunger on a hydraulic machine. The upper end of a cushion block is connected with the upper mold plate, and the lower end of the cushion block is connected with a male mold. The male mold is fixed in a check ring, and the upper end of the check ring is fixedly connected with the cushion block. The upper end of a guide sleeve is fixedly connected with the upper mold plate. The lower end of the guide sleeve is connected with a guide column, and the lower end of the guide column is fixedly connected with the lower mold plate. The lower end of a female mold is fixed to the lower mold plate. The lateral face of the female mold is fixed with a split stress ring. The front section of an ejector rod penetrates through an ejector rod through hole in the female mold. An ultrasound wave vibration device is fixed to the ejector rod. The high-intensity ultrasound waves are input into the ejector rod, high-frequency periodic vibration and displacement are generated on the surface of the ejector rod, and after back pressure is applied, the homogenization of an extruded part is improved, grains are refined, and the problems that grains are refined unevenly and the extruded part has cracks in an equal-diameter angle extrusion mold are effectively solved.

Owner:GUANGXI UNIV

Method for preparing copper/phosphorus double-metal capillary tube

The invention belongs to the technical field of preparation of metal composite capillary tubes and relates to a method for preparing a copper / phosphorus double-metal capillary tube. The method comprises the following steps: performing rotary swaging to realize close combination of a copper tube and a phosphorus tube, performing high-temperature diffusion annealing treatment to obtain a copper / phosphorus composite tube with the interface achieving a metallurgical bonding state, performing drawing or / and non-mandrel drawing by adopting a floating core head and performing intermediate annealing cooperatively to obtain the high-performance copper / phosphorus double-metal capillary tube. According to the method, by combining drawing and non-mandrel drawing of the floating core head, cooperating with the necessary intermediate annealing, the obtained composite capillary tube is high in size precision and good in surface quality. Through sequential diffusion annealing and drawing processing, deformation force needed by forming is small, the service life of tools and molds is long, driving force needed by equipment is small, and production cost is low.

Owner:枣庄铭世新型材料有限公司

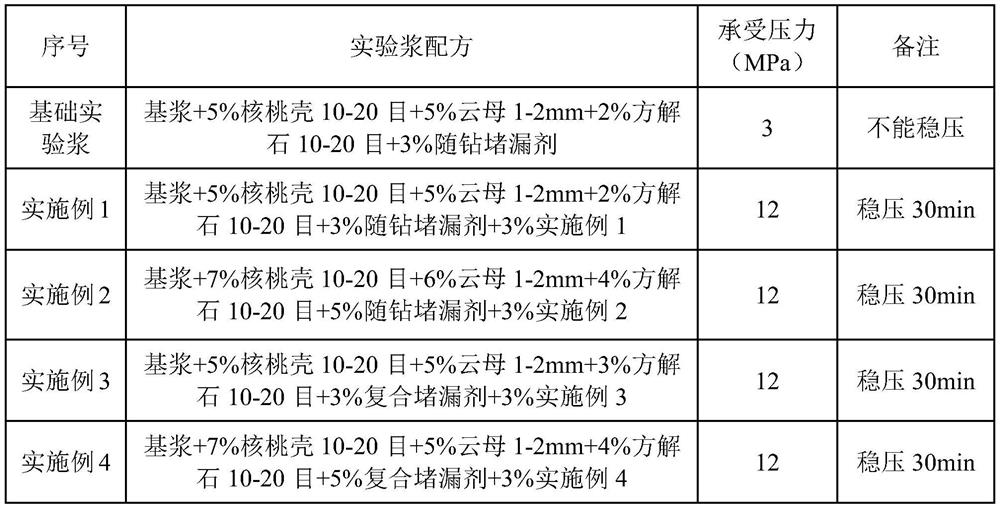

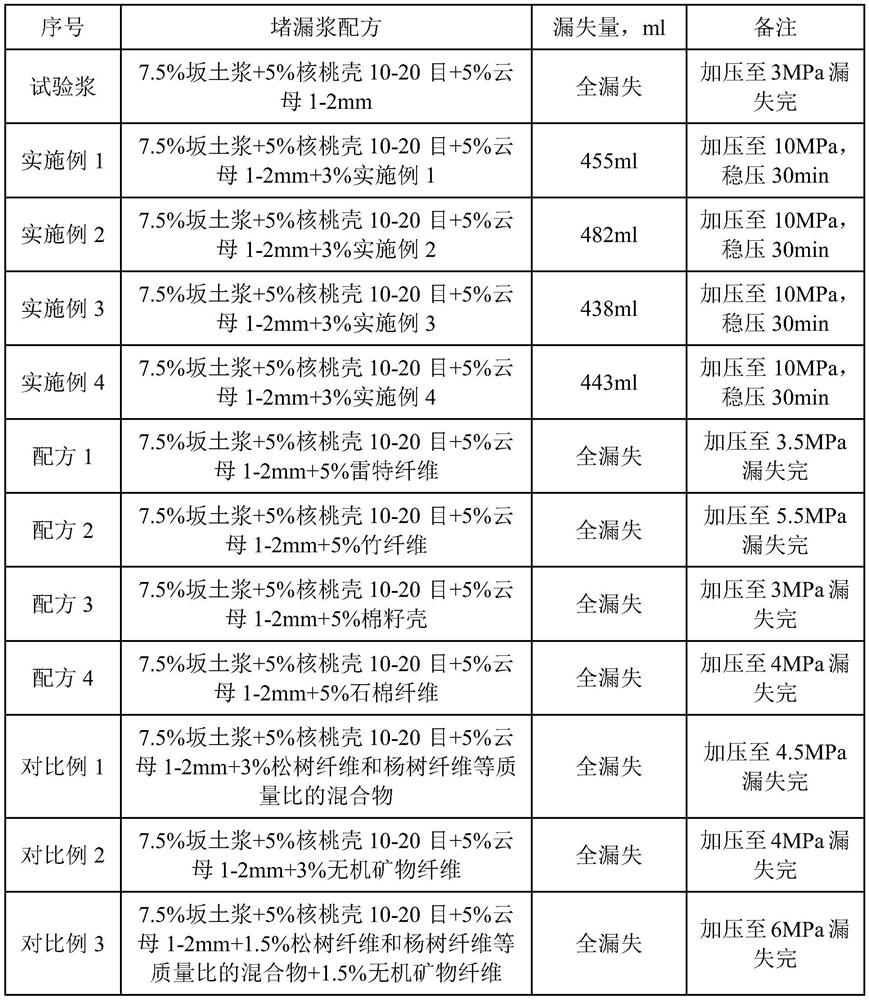

Bridge plugging synergist for drilling fluid

PendingCN112480885AImprove plugging success rateStrong bridging abilityDrilling compositionCarbon fibersPhysical chemistry

The invention discloses a bridge plugging synergist for drilling fluid. The bridge plugging synergist comprises the following components in percentage by mass: 20-40% of wood fibers, 35-40% of inorganic mineral fibers, 20-30% of inorganic rigid particles and 5-10% of an inorganic reinforcing agent. The inorganic rigid particles are resin sand with the particle size of 200 meshes or a compound of the resin sand and ceramic powder; the inorganic mineral fiber is a combination of brucite fibers, aluminum silicate fibers and carbon fibers, wherein the brucite fibers are 1-3 mm in length and 0.5-16[mu] m in diameter, the aluminum silicate fibers are 2-4 mm in length and 0.7-20 [mu] m in diameter, and the carbon fibers are 1-4 mm in length and 0.5-18 [mu] m in diameter; wherein the mass ratio of the brucite fibers to the aluminum silicate fibers to the carbon fibers is 5: 4: 1. According to the bridge plugging synergist disclosed by the invention, through the cooperative use of the microfibers and the microparticles, microcracks can be effectively plugged, and the compactness of a bridge plug is improved, so that the pressure bearing capacity is enhanced.

Owner:ASTAR PETROTECH

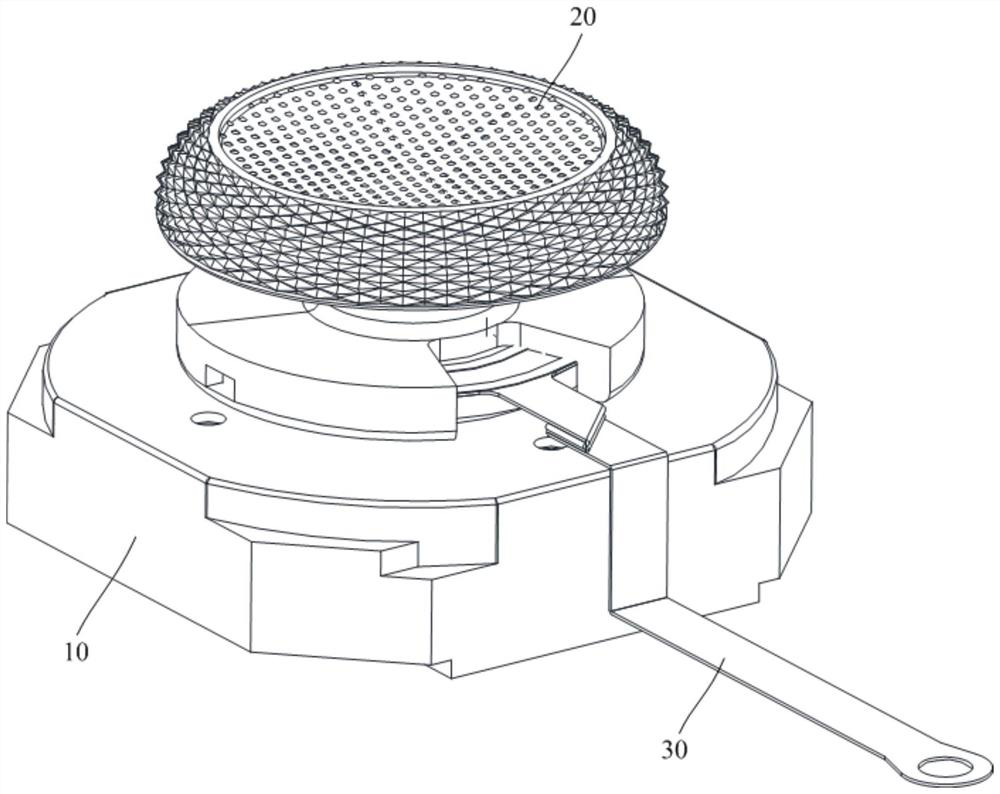

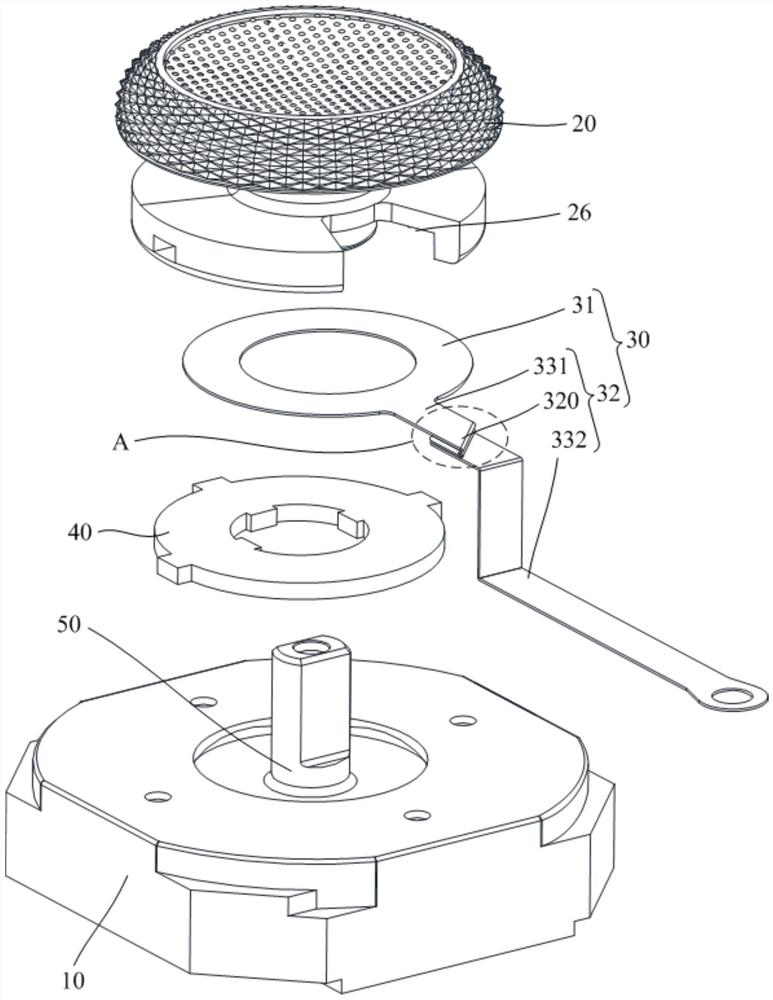

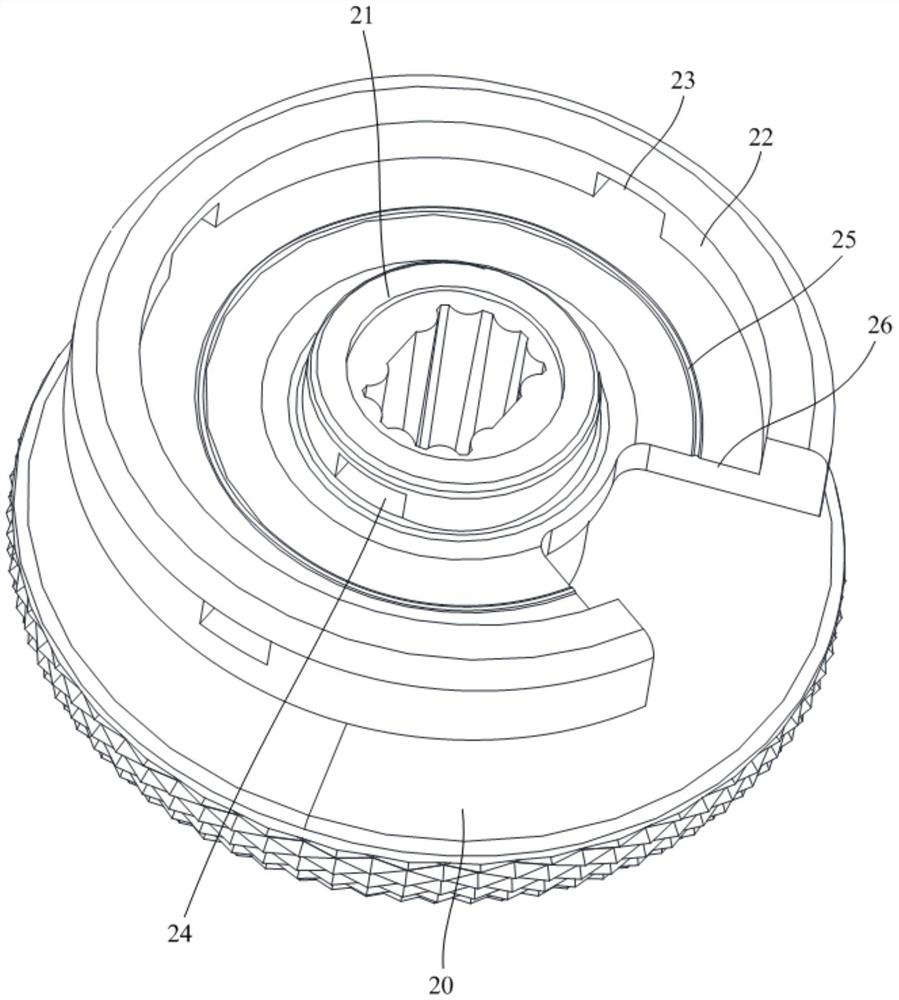

Handle rocker assembly, VR handle and VR equipment

The invention discloses a handle rocker assembly, a VR handle and VR equipment, the handle rocker assembly comprises a base, a rotating mechanism, a conductive rocker cap and a conductive mesh, the rotating mechanism is arranged on the base, the conductive rocker cap is installed on the rotating mechanism, and the conductive mesh is electrically connected with the conductive rocker cap. According to the technical scheme, the obstruction of the conductive screen cloth to the rocker can be reduced.

Owner:GEER TECH CO LTD

Phosphating treatment method for fastener surface of pump body

InactiveCN108149234ACrystallizationAvoid coarse and loose crystalsMetallic material coating processesRare-earth elementPhosphate

The invention relates to the technical field of performance research of a pump, and discloses a phosphating treatment method for fastener surface of a pump body. Due to the particularity of the outerelectronic structure of rare earth elements, each rare earth element is provided with a large ionic radius, is easy to polarize and deform, and is easily adsorbed on the surface of the substrate metal, so that more active points are provided, more crystalline nuclei are formed, and the phosphorylation process is accelerated. The formation speed of the phosphating film reaches 0.7 to 0.8g / (m2.min),and the phosphating crystals are refined and dense to increase the corrosion resistance of the film. The phosphating additive increases the percentage of reactive molecules in the phosphating solution and the thermal motion of the reacting molecules, and avoids the problem of excessive coarsening of the phosphating film and poor binding force due to excessive temperature, and the obtained phosphate film is 2.5-2.8g / m2, uniform and dense.

Owner:安徽江南泵阀集团有限公司

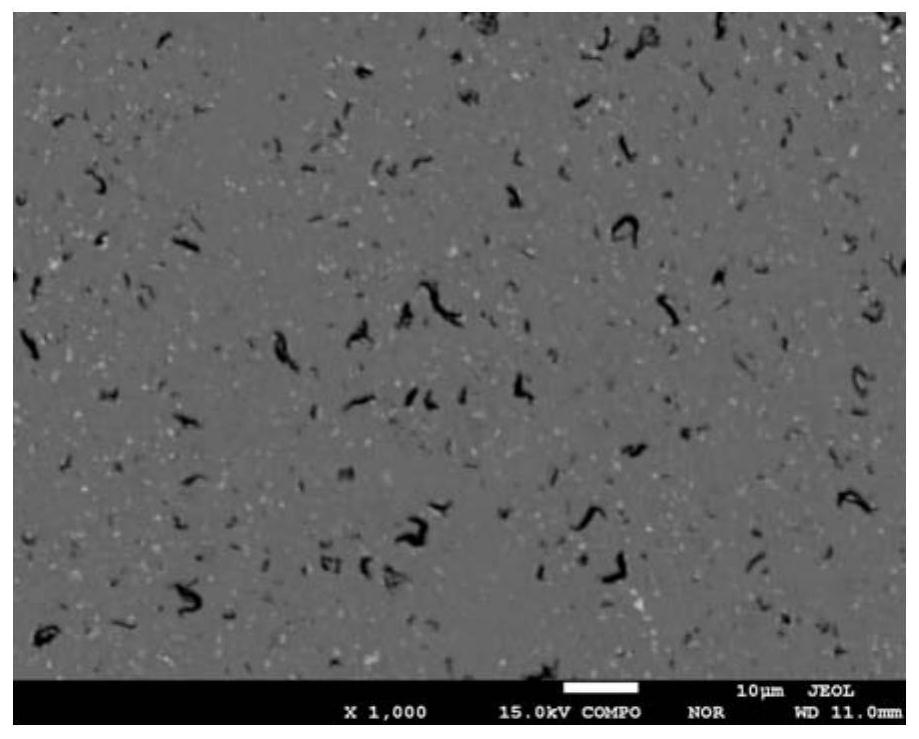

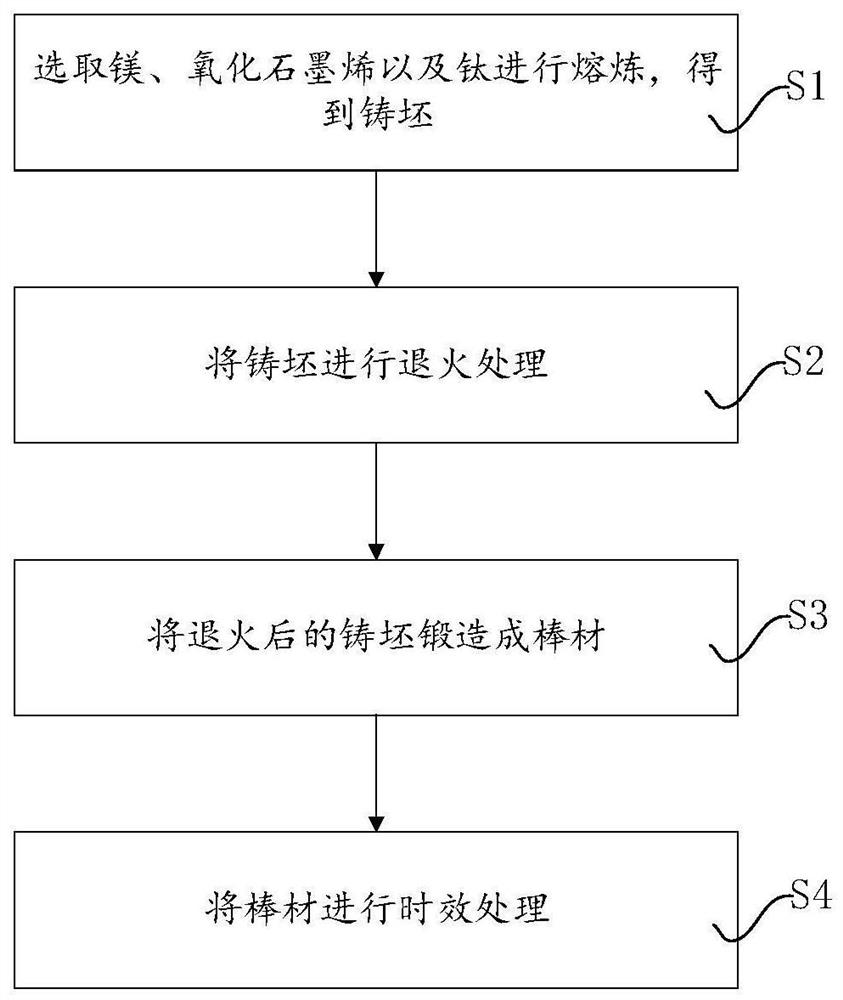

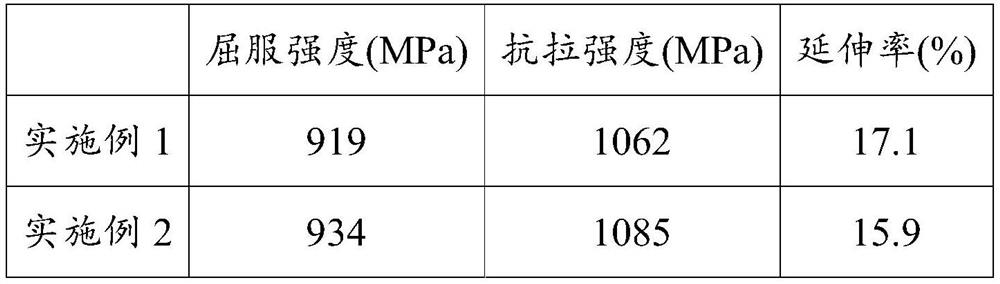

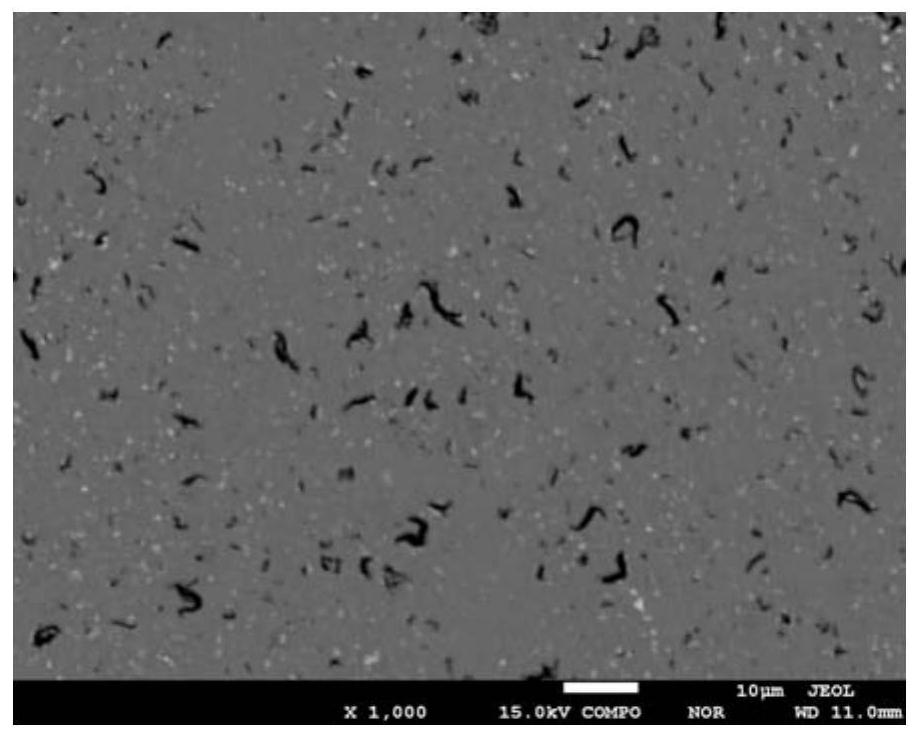

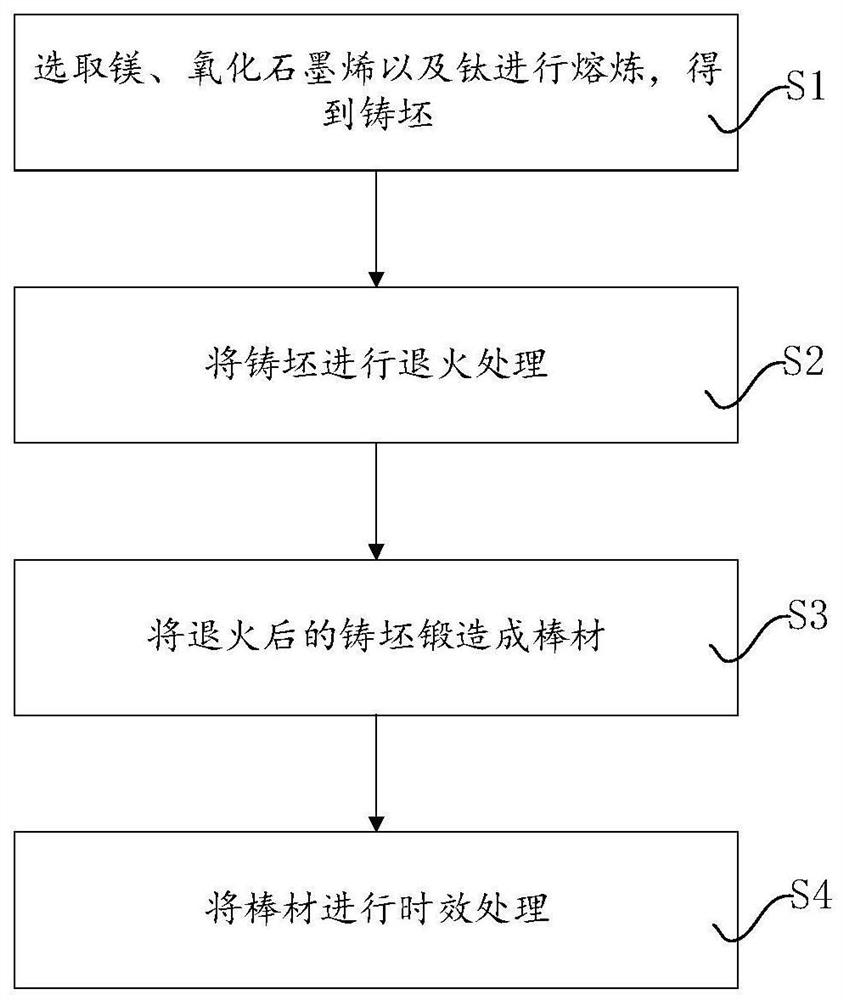

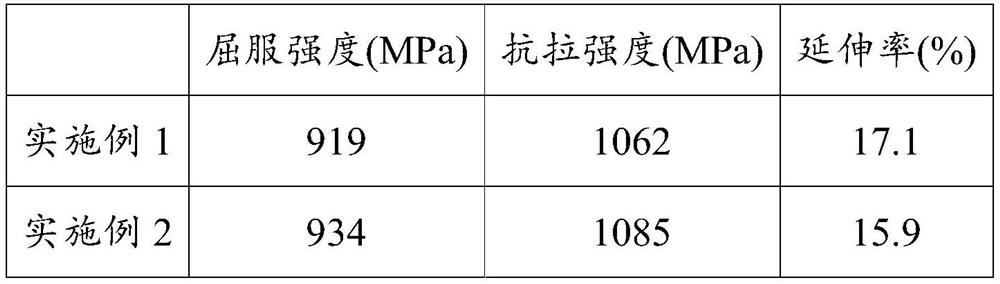

A kind of graphene oxide reinforced titanium alloy and preparation method thereof

The invention belongs to the field of titanium alloys, and discloses a graphene oxide-reinforced titanium alloy and a preparation method thereof. The graphene oxide-reinforced titanium alloy includes magnesium: 0.10% to 0.30% and graphene oxide: 0.45% by weight percentage. %~0.50%; the rest is titanium and unavoidable impurities. The preparation method includes: selecting magnesium, graphene oxide and titanium for smelting to obtain cast slabs, annealing the cast slabs at a temperature of 910-960°C, and forging the annealed cast slabs into rods at a forging temperature of 800-960°C, the bar is subjected to aging treatment, the aging treatment temperature is 700-800°C, and the holding time is 1-2h. The solid-solution strengthening effect of Mg element and its neutral stabilizing effect on α-phase and β-phase are fully utilized. The process is simple and the processing performance is good. The prepared graphene oxide-reinforced titanium alloy has high strength and does not reduce , Even improve the ductility of the alloy, so that the titanium alloy material has excellent strength and plasticity at the same time, and can process larger-sized finished products.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

An Ultrasonic Assisted Fine Blanking Process and Its Die

InactiveCN103611774BReduce flow stressImprove fine blanking performanceShaping toolsEjection devicesFlow stressUltrasonic assisted

The invention relates to an ultrasonic-assisted fine blanking process and device. According to the process, ultrasonic wave is input to a male die during the process of fine blanking to allow the male die to resonate, the bottom of the male die vibrates under high frequency, and accordingly the features of the traditional fine blanking formation are changed and the quality of blanks is improved. Compared to the traditional fine blanking, the ultrasonic-assisted fine blanking process has the advantages that forming property of fine blanking material is improved, flow stress of the material is reduced, and the quality of fine-blanked parts is improved; forming load is reduced, and the service life of the fine blanking die is prolonged. The invention further designs an ultrasonic-assisted fine blanking die device. The ultrasonic-assisted fine blanking process and device is significant to widening the range of fine blanking materials, improving the quality of fine blanks and prolonging the service life of the fine blanking die.

Owner:WUHAN UNIV OF TECH

A kind of preparation method of copper/phosphorus bimetallic capillary

The invention belongs to the technical field of metal composite capillary material preparation, and relates to a method for preparing a copper / phosphorus bimetallic capillary. The method is to use rotary forging to realize the tight combination of copper tube and phosphorus tube, and obtain a copper / phosphorus composite tube whose interface reaches a metallurgical bonding state through high-temperature diffusion annealing treatment; then use floating core drawing or / and empty drawing processing, Combined with intermediate annealing, a high-performance copper / phosphorus bimetallic capillary is obtained. The invention adopts the method of combining the drawing of the floating core head and the empty drawing, together with the necessary intermediate annealing, the obtained composite capillary has high dimensional accuracy and good surface quality. After diffusion annealing and drawing processing, the deformation force required for forming is small, the life of tools and molds is long, the driving force required for equipment is small, and the production cost is low.

Owner:枣庄铭世新型材料有限公司

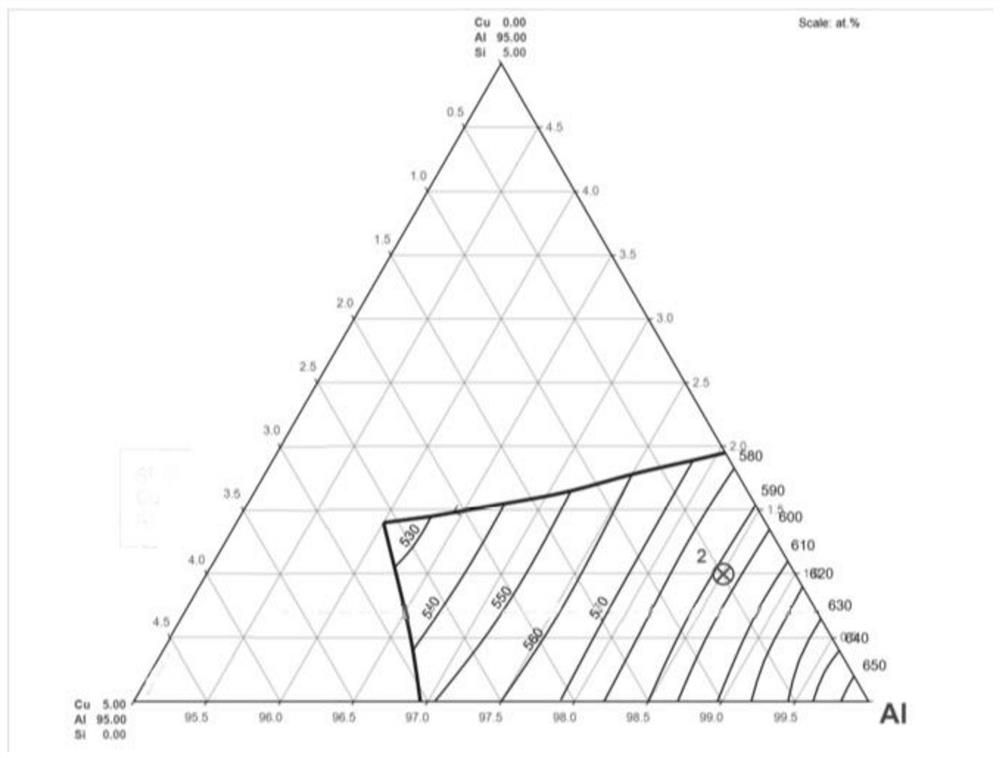

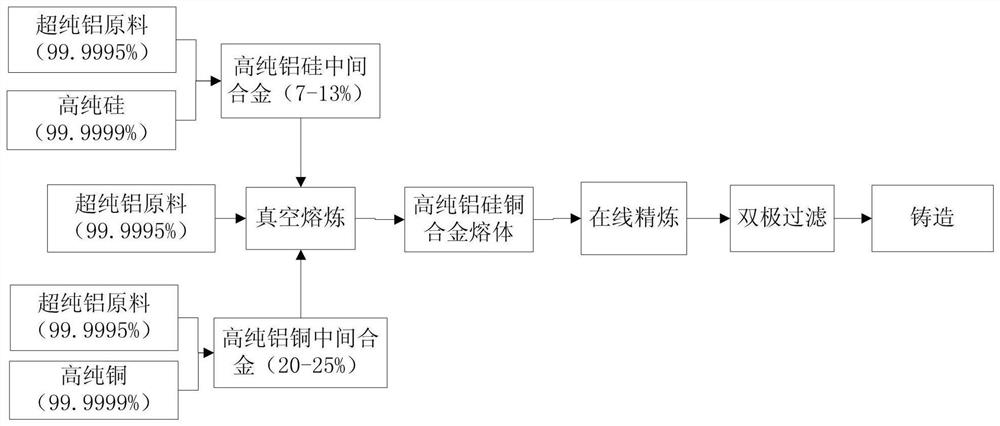

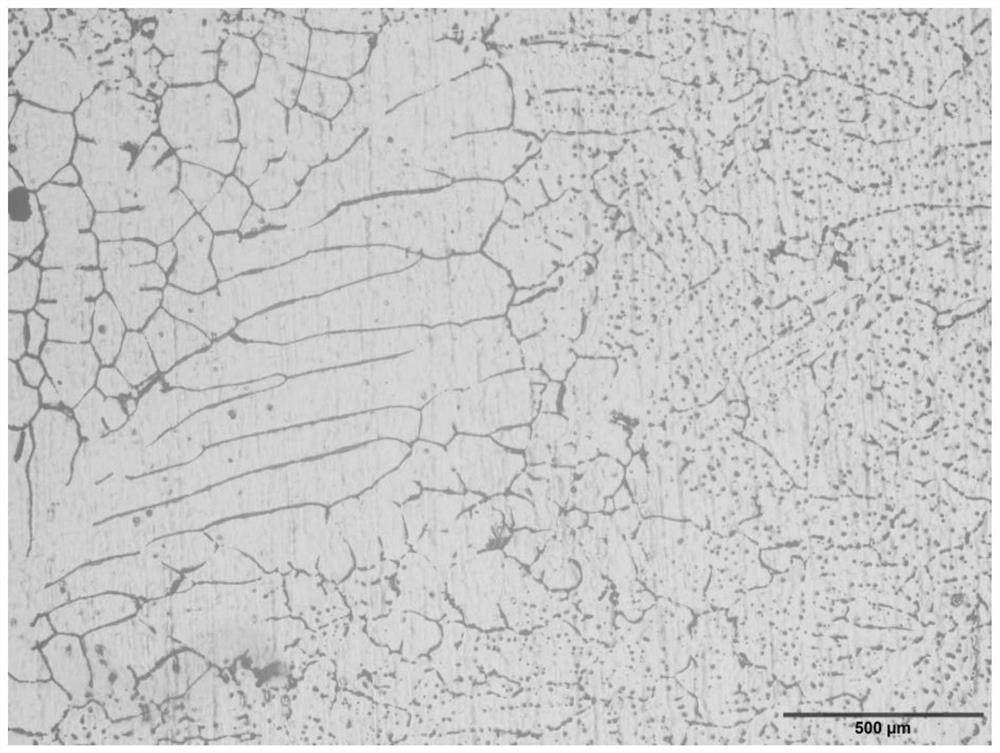

A preparation method of fine-grained high-purity aluminum-silicon-copper alloy target blank for sputtering

ActiveCN111719059BReduce purityControl UniformityVacuum evaporation coatingSputtering coatingSputteringSilicon

The invention relates to a method for preparing a fine-grained high-purity aluminum-silicon-copper alloy target blank for sputtering. A method for preparing a fine-grained high-purity aluminum-silicon-copper alloy target blank for sputtering, comprising: S10 preparing a master alloy: the master alloy is an aluminum-copper master alloy and an aluminum-silicon master alloy; S20: making the master alloy The alloy and high-purity aluminum with a purity of 99.9995% are melted in a vacuum melting furnace, and after complete melting, an alloy liquid is obtained; the silicon content in the alloy liquid is 0.9-1.1wt%, and the copper content is 0.45-0.55wt%; S30: The alloy liquid is refined on-line with high-purity argon; S40: the alloy liquid that has been refined on-line is subjected to bipolar filtration; S50: the alloy liquid that has been filtered by two stages is cast into a φ120-164mm bar blank, and the obtained The above-mentioned fine-grained high-purity aluminum-silicon-copper alloy target blank for sputtering. According to the preparation method of a fine-grained high-purity aluminum-silicon-copper alloy target blank for sputtering according to the present invention, the content of trace impurity elements in the prepared high-purity AL‑1wt%Si‑0.5wt%Cu target blank for sputtering Very low, sputtering film formation performance is good, and the composition is uniform.

Owner:XINJIANG JOINWORLD CO LTD

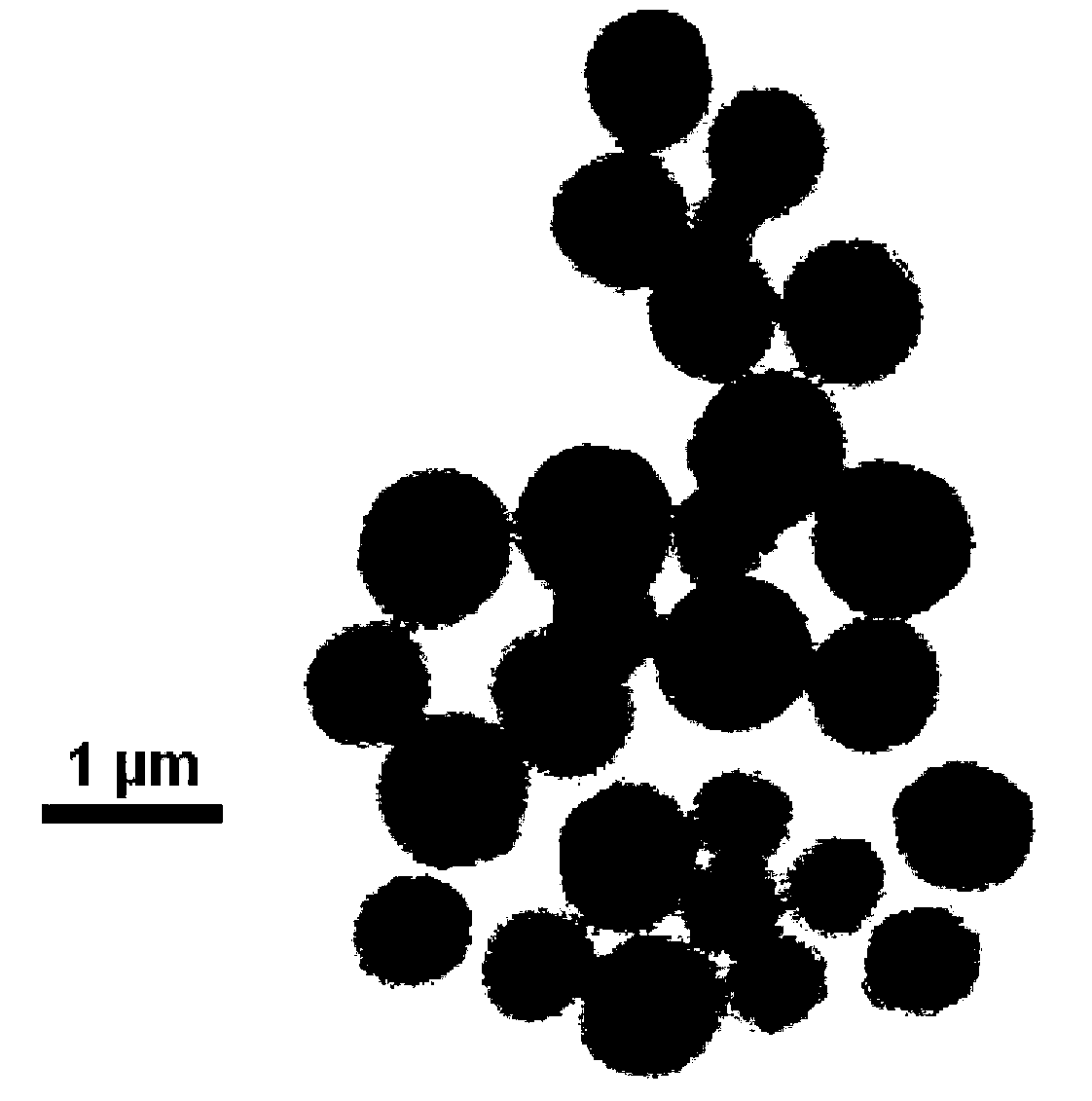

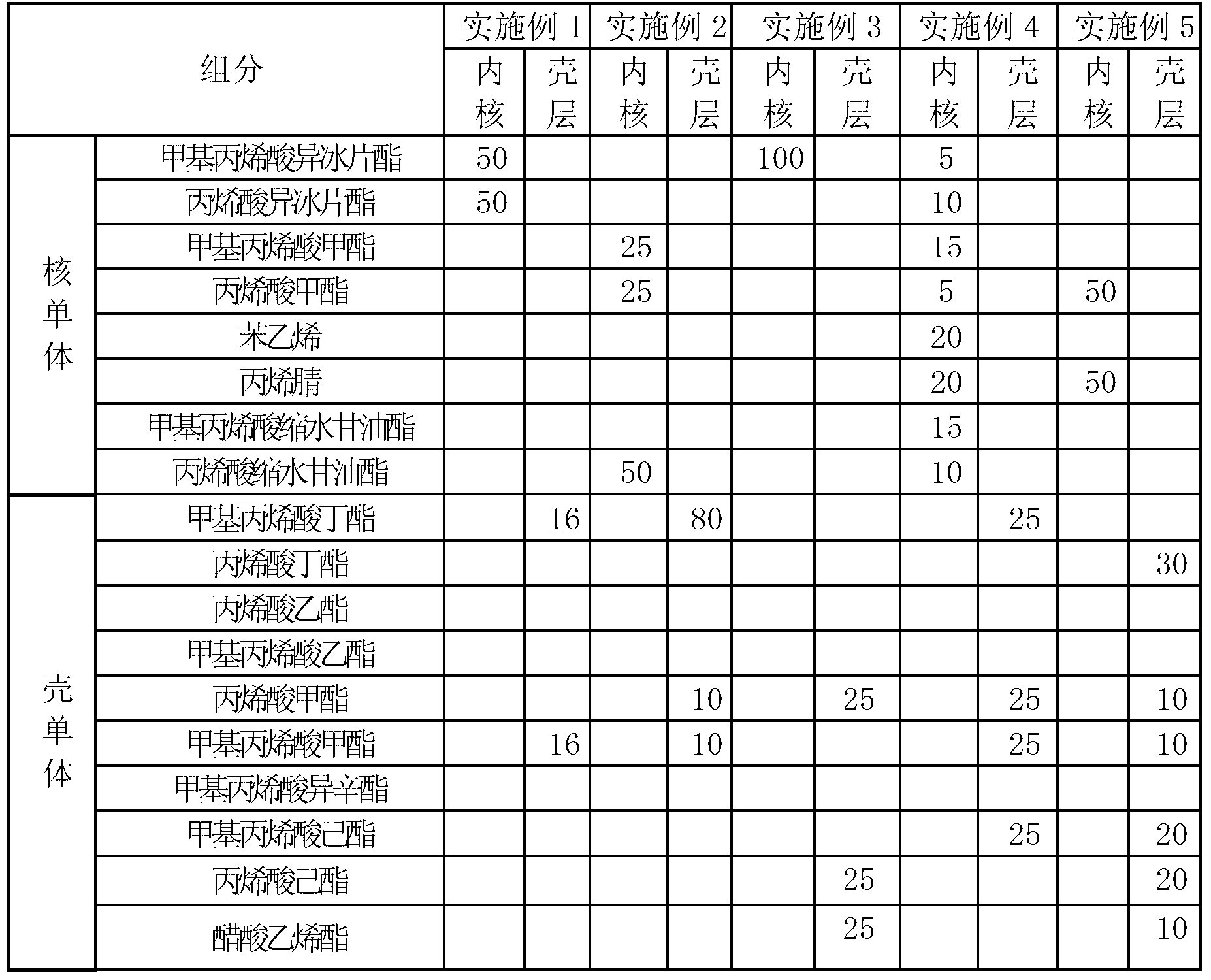

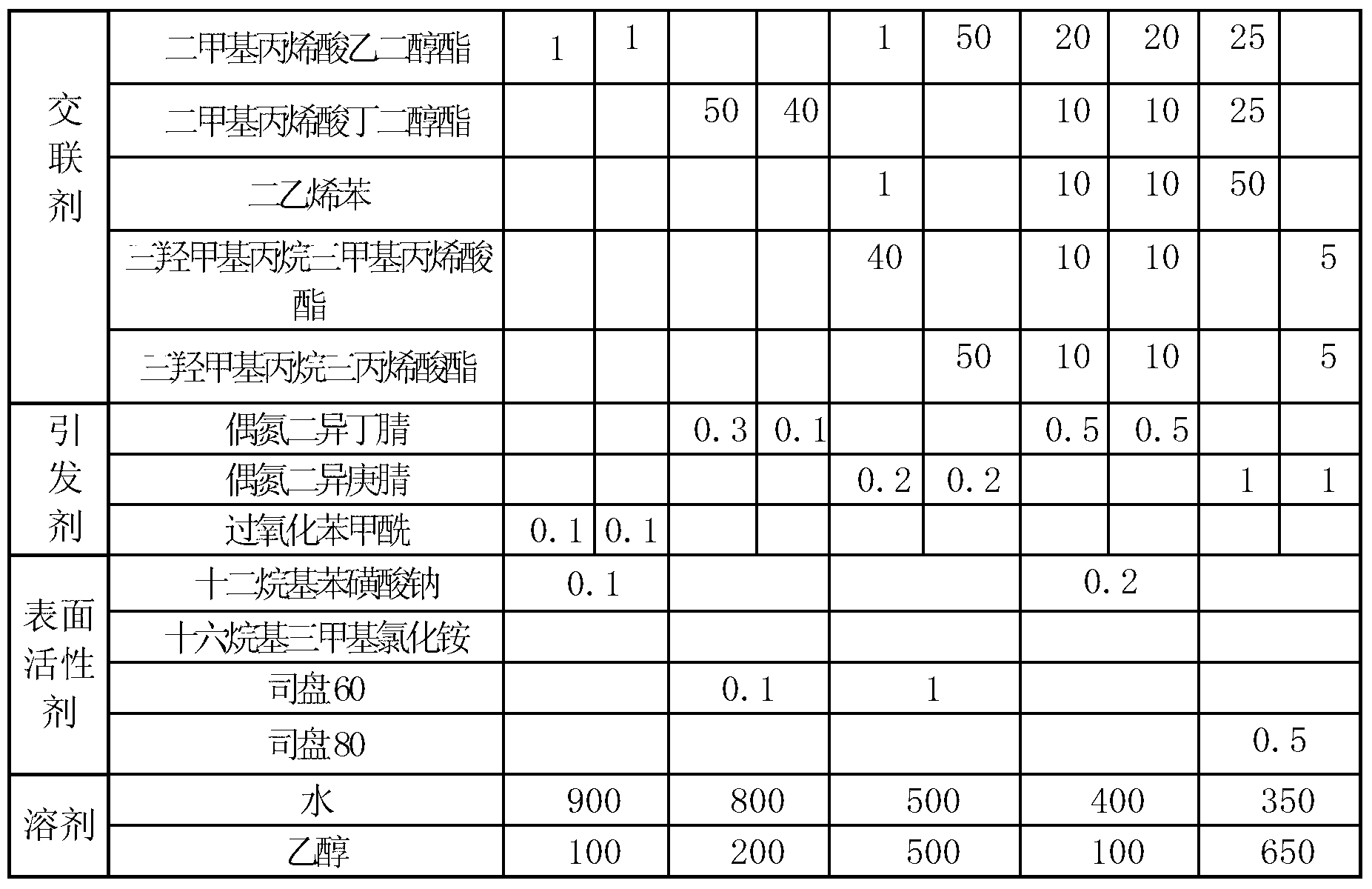

Polymeric microsphere with core-shell structure polymer for polyester reflective film and preparation method of polymeric microsphere

The invention relates to a polymeric microsphere with a core-shell structure polymer for a polyester reflective film. The polymeric microsphere with the core-shell structure polymer comprises an inner core and a hard-core and soft-shell structure which is formed by a shell layer coated at the periphery of the inner core, wherein the ratio of the inner core to the shell of the polymeric microsphere is 1 to (0.08-1) according to the ratio of mass fraction; the glass transition temperature Tg of the inner core of the polymeric microsphere is greater than 130 DEG C; the glass transition temperature Tg of the shell layer is smaller than 75 DEG C; and the particle size of the polymeric microsphere is 0.40-5.0 microns. The polymeric microsphere obtained by a reasonable formula system disclosed by the invention forms the hard-core and soft-shell structure; the particle size of the polymeric microsphere can be accurately controlled and is even; the polymeric microsphere can be easily dispersed in a polyester substrate; the film-forming property in a two-way stretching process is good; the equipment load is reduced; the rupture phenomenon is reduced; the manufacturing cost is reduced; and the production efficiency can be improved; and large-scale industrial production is also facilitated.

Owner:JIANGSU YUXING FILM TECH

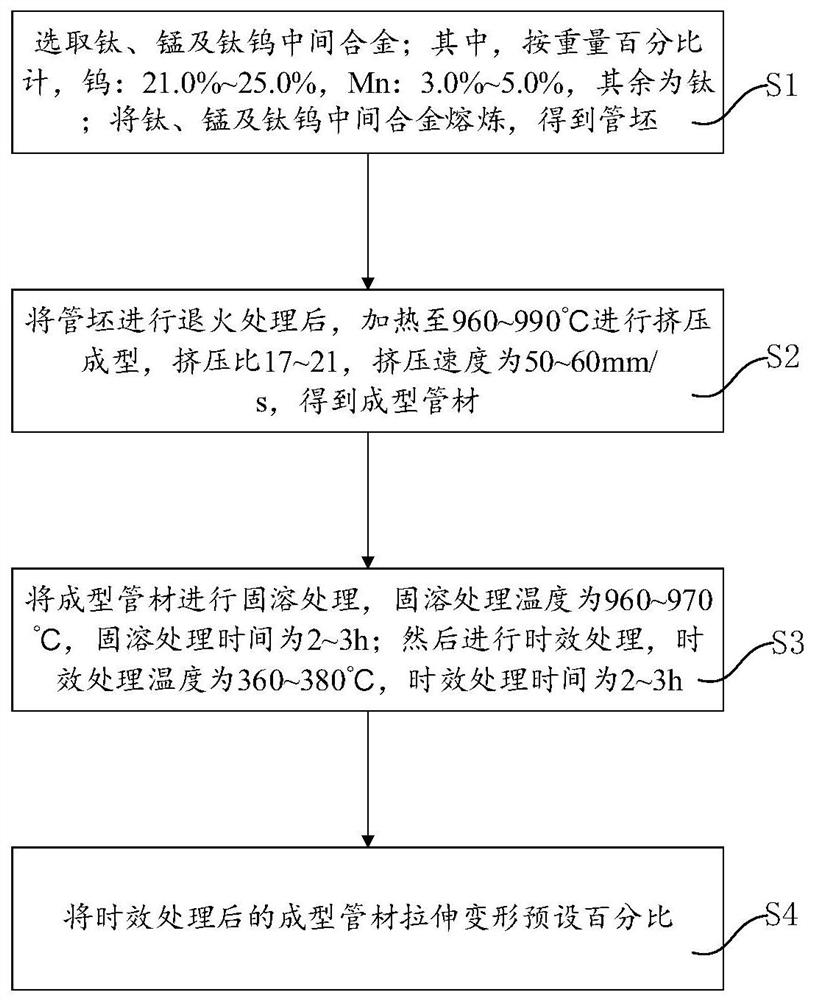

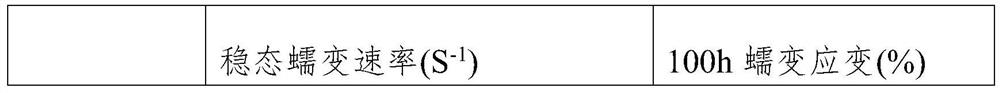

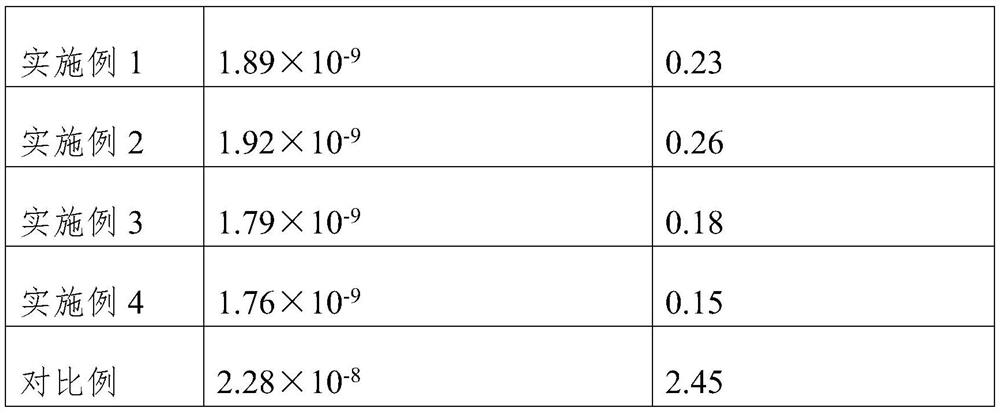

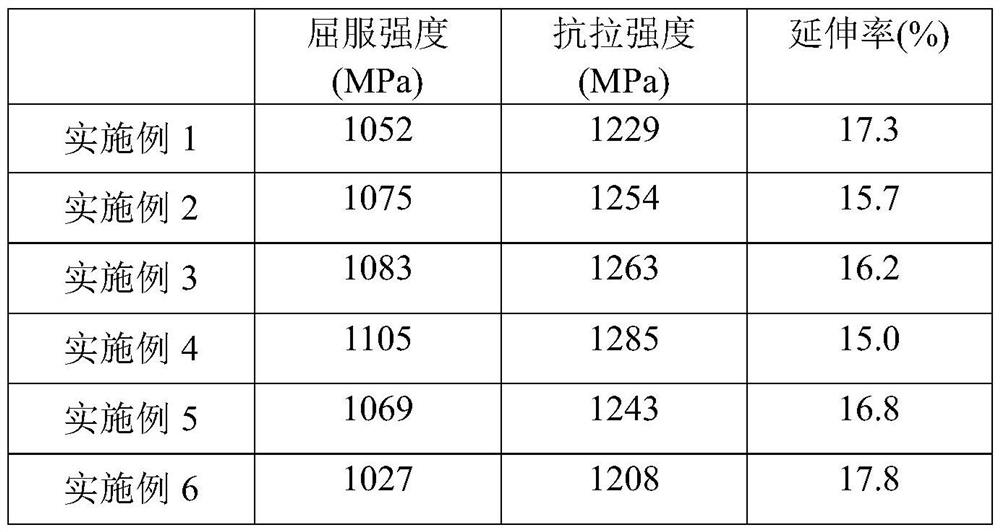

A kind of 135ksi grade titanium alloy, titanium alloy drill pipe and preparation method thereof

ActiveCN112159913BThe chemical composition is relatively simpleLow costDrilling rodsFurnace typesSolution treatmentManganese

The invention belongs to the technical field of oil pipe preparation, and discloses a 135ksi-grade titanium alloy, a 135ksi-grade titanium alloy drill pipe and a preparation method thereof, which include, by weight percentage: tungsten: 21.0% to 25.0%, Mn: 3.0% to 5.0% %, the rest is titanium and unavoidable impurities. The preparation method includes: selecting titanium, manganese and titanium-tungsten master alloy; melting titanium, manganese and titanium-tungsten master alloy to obtain a tube blank; Extrusion molding is carried out at 960-990°C, the extrusion ratio is 17-21, and the extrusion speed is 50-60mm / s to obtain a formed pipe; the formed pipe is subjected to solution treatment, and the solution treatment temperature is 960-970°C. The treatment time is 2-3 hours; then aging treatment is carried out, the aging treatment temperature is 360-380°C, and the aging treatment time is 2-3 hours; the tensile deformation of the formed pipe after the aging treatment is preset by a percentage. The cost is 9%-11% lower than that of the existing 135ksi grade titanium alloy with the same level of performance index, the comprehensive performance of the product is improved, and the flexible thermal processing production process can be adopted to improve the production efficiency and yield.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

A high-performance magnesium alloy

ActiveCN109355539BAccelerated corrosionImprove high temperature creep resistanceSolid state diffusion coatingAnti-corrosive paintsMg alloysMechanical property

Owner:贵州航天风华精密设备有限公司

A kind of graphene reinforced titanium alloy for 1200mpa grade titanium alloy drill pipe and its pipe material manufacturing method

ActiveCN109487120BImprove ductilityImprove plastic deformation abilityExtrusion control devicesTitaniumGraphene

The invention discloses a titanium alloy for a graphene reinforced 1200 MPa-grade titanium alloy drill rod and a pipe manufacturing method thereof. The titanium alloy comprises the following components in percentage by weight: 3.0-5.0% of Fe, 3.0-5.0% of Al, 0.02-0.05% of graphene, and the balance of titanium; pure iron, pure aluminum, titanium and graphene are smelted by adopting a vacuum suspension casting method to obtain a pipe blank; the pipe blank is heated for uniform annealing; the heated pipe blank is extruded by an extruder; and then, the pre-stretching deformation is performed. Thecomprehensive cost of the alloy is reduced by 25-30% compared with a traditional titanium alloy with the same performance indexes. The solid solution reinforcing effect of Fe and Al elements and the stabilizing effect on an alpha phase and a beta phase are fully used; a one-step direct deformation heat treatment (hot extrusion) process is adopted to improve the comprehensive performances of products; and a flexible extrusion production process can be adopted to improve the productivity and the yield.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Constant-temperature aging device for deep processing of beeves

The invention relates to the technical field of beef aging and discloses a constant-temperature aging device for deep processing of beeves. The constant-temperature aging device comprises a mobile layer, wherein a mobile shell is arranged on the external sidewall of the mobile layer, a fitting ring is arranged on the internal sidewall of the mobile layer, a center block penetrates through an axisof the mobile layer, a turn button is movably connected between the sidewall of the center block and the sidewall of the fitting ring, a mobile block is movably connected with the external sidewall ofthe mobile layer, and one end, far away from the mobile layer, of the mobile block is movably connected with a slider. When a joint between the mobile layer and the fitting ring is in an unparallel state, the sidewall of the fitting ring is located at the upper side of the inner side of the mobile layer, the center block will located at a high point, a connecting rod is driven to move through rotation between the sidewall of the center block and the sidewall of the turn button, the sidewall of the connecting rod is hooked upwards, the space of a bottom sidewall of a meat product can be overhead, veins of the sidewall of the meat product can be drawn partially, and steamed caking is avoided.

Owner:彭先福

A single-point incremental forming tool head axial vibration device

The invention discloses a single-point incremental forming tool head axial vibration device. The device comprises a supporting frame and a tool head with a push rod. A spring and two guide posts are connected to the inner bottom of the supporting frame. The spring is located in the center. The two guide posts are located on the left side and the right side of the spring correspondingly. The tool head with the push rod is composed of a tool head body arranged horizontally and the protruding push rod perpendicularly and fixedly connected to the tool head body. The upper end of the spring and the upper ends of the two guide posts are all connected with the tool head body. The upper portion of the protruding push rod is connected with a sleeve. A gap is reserved between the tool head body and the bottom surface of the sleeve. The upper portion of the sleeve is clamped to one end of a tool holder of a machine tool. The other end of the tool holder of the machine tool is connected with a rocker arm of the machine tool. According to the single-point incremental forming tool head axial vibration device, the tool head with the push rod is driven through rotation of a machine tool spindle to generate axial vibration, so that original continuous extrusion friction motion is converted into high-frequency point pressure motion, deformation processing is facilitated, and forming force required in the forming process is reduced.

Owner:XIAN UNIV OF TECH

Handheld type steel bar shearing and bending machine

ActiveCN111151683AReduce typesEasy to operatePortable handheld shearing machinesClassical mechanicsHand held

A steel bar shearing and bending machine comprises a base part, a shearing knife part, a swing arm part, a bending groove part and a shearing clamping groove, a steel bar to be sheared is fixed in a shearing fixing groove of the swing arm part through the shearing clamping groove, the steel bar is cut off through the shearing knife part, and the steel bar to be bent and placed on a bending rod isbent through a bending groove, so that the functions of shearing and bending are integrated, meanwhile, the opening angles of two swing arms can be adjusted according to actual conditions, the steel bar to be bent can be bent upwards or downwards according to requirements, the use is convenient, and the working efficiency is improved.

Owner:暴伟杰

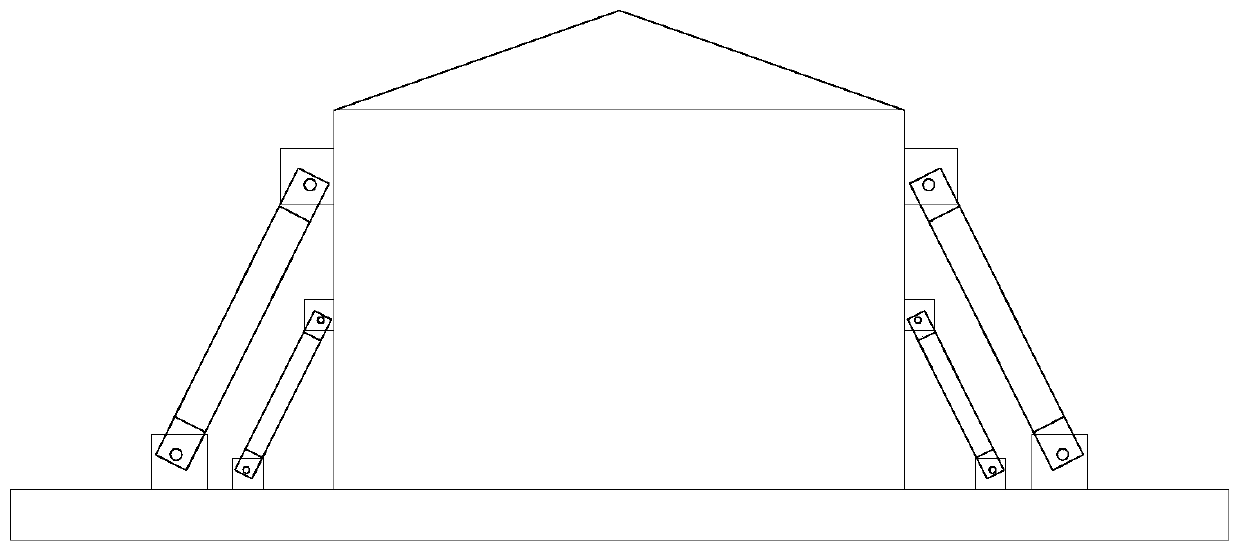

Wind-resistant box-type substation and construction method thereof

ActiveCN109763680AEasy to deformFree to adjust the lengthProtective buildings/sheltersBuilding material handlingExternal connectionRear quarter

The invention discloses a wind-resistant box-type substation and a construction method thereof. The key points of the design are as follows: a slant energy-consuming support is formed by assembling aplurality of slant energy-consuming support unit bodies; each slant energy-consuming support unit body comprises an outer frame and an inner cylindrical structure; the cross section of the outer frameand the cross section of the cylindrical structure maintain external connection relation in roundness; the cylindrical structure is made of soft steel; the frame comprises a top plate, a bottom plate, two vertical side plates and two X-shaped connecting plates; bolt holes are formed in the edge parts of the top plate and the bottom plate; the X-shaped connecting plates are arranged on the two corresponding faces, corresponding to the two end faces of the cylindrical structure, of the frame; and the slant energy-consuming support unit bodies are connected together through the top plate, the bottom plate and the bolt holes to form a rod-shaped slant energy-consuming support. According to the wind-resistant box-type substation and the construction method thereof, the wind-resistant effect can be improved.

Owner:临沂顺恒电气设备有限公司

Graphene oxide enhanced titanium alloy and preparation method thereof

The invention belongs to the field of titanium alloys and discloses a graphene oxide enhanced titanium alloy and a preparation method thereof. The graphene oxide enhanced titanium alloy comprises thefollowing components in percent by weight: 0.10-0.30% of magnesium, 0.45-0.50% of graphene oxide and the balance titanium and inevitable impurities. The preparation method comprises the following steps of selecting magnesium, graphene oxide and titanium to smelt to obtain a casting blank; annealing the casting blank at 910-960 DEG C; forging the annealed casting blank into a bar at 800-960 DEG C;and carrying out aging treatment on the bar at 700-800 DEG C and insulting the bar for 1-2 hours. By making full use of solution strengthening action of Mg and neutral stability action of Mg on alphaphase and beta phase, the preparation method is simple in process and good in processing performance. The ductility of the prepared graphene oxide enhanced titanium alloy is not reduced or even is improved while the prepared graphene oxide enhanced titanium alloy is high in strength, so that a titanium alloy material has excellent strength and plasticity and can be processed into products with larger dimensions.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com