A high-performance magnesium alloy

A magnesium alloy, high-performance technology, applied in metal material coating process, solid-state diffusion coating, coating, etc., can solve the problem of magnesium alloy room temperature formability and corrosion resistance, which is limited by the poor high temperature creep performance. Wide application, complex surface treatment process and other problems, to achieve good high temperature creep resistance, small grain size and good corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

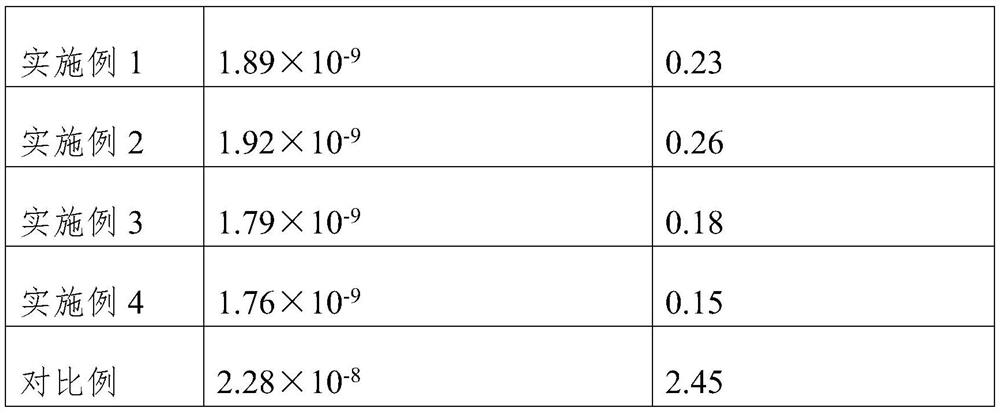

Embodiment 1

[0029] This embodiment provides a high-performance magnesium alloy. According to weight percentage, the composition of the alloy is: Bi 0.36%, Ca 0.83%, Si 8.23%, Sn 1.95%, Zn 0.3%, Na 0.09%, K 0.12%, Ni 0.44%, Cu 0.18%, Ti 1.4%, B 0.36%, and the balance is magnesium.

[0030] The preparation method of the high-performance magnesium alloy is:

[0031] 1) Melting: Under the condition of protective gas, after the industrial pure magnesium is completely melted, a refining agent with a mass of 200ppm of pure magnesium is added, and Bi, Ca, Sn, B. Cu and Ti elements are completely dissolved. After the heat preservation reaction for 10 minutes, Si and Na elements are added in the form of silicon dioxide and sodium chloride until they are completely dissolved. The heat preservation reaction is 10 minutes, and then added in the form of Bi-Zn-K-Ni master alloy. Bi, Zn, K, and Ni are all dissolved, and the heat preservation reaction is carried out for 10 minutes to obtain a melt; the t...

Embodiment 2

[0043] This embodiment provides a high-performance magnesium alloy. According to weight percentage, the composition of the alloy is: Bi 0.28%, Ca 0.51%, Si 5.05%, Sn 1.62%, Zn 0.1%, Na 0.05%, K 0.07%, Ni 0.26%, Cu 0.06%, Ti 1.2%, B 0.24%, and the balance is magnesium.

[0044] The preparation method of the high-performance magnesium alloy is:

[0045] 1) Melting: Under the condition of protective gas, after the industrial pure magnesium is completely melted, a refining agent with a mass of 150ppm of pure magnesium is added, and Bi, Ca, Sn, B. Cu and Ti elements are completely dissolved. After the heat preservation reaction for 8 minutes, Si and Na elements are added in the form of silicon dioxide and sodium chloride until they are completely dissolved. The heat preservation reaction is 8 minutes, and then added in the form of Bi-Zn-K-Ni master alloy. Bi, Zn, K, and Ni are all dissolved, and the heat preservation reaction is carried out for 8 minutes to obtain a melt; the temp...

Embodiment 3

[0057] This embodiment provides a high-performance magnesium alloy. According to weight percentage, the composition of the alloy is: Bi 0.32%, Ca 0.75%, Si 7.01%, Sn 1.77%, Zn 0.23%, Na 0.07%, K 0.1%, Ni 0.3%, Cu 0.12%, Ti 1.3%, B 0.28%, and the balance is magnesium.

[0058] The preparation method of the high-performance magnesium alloy is:

[0059] 1) Melting: Under the condition of protective gas, after the industrial pure magnesium is completely melted, a refining agent with a mass of 180ppm of pure magnesium is added, and Bi, Ca, Sn, B. Cu and Ti elements are completely dissolved. After the heat preservation reaction for 9 minutes, Si and Na elements are added in the form of silicon dioxide and sodium chloride until they are completely dissolved. The heat preservation reaction is 9 minutes, and then added in the form of Bi-Zn-K-Ni master alloy. Bi, Zn, K, and Ni are all dissolved, and the heat preservation reaction is carried out for 9 minutes to obtain a melt; the tempe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com