Polymeric microsphere with core-shell structure polymer for polyester reflective film and preparation method of polymeric microsphere

A technology of core-shell structure and polymer, which is applied in the field of core-shell structure polymer microspheres and its preparation, can solve the problems of limiting the production efficiency of reflective film reflectivity, increasing the difficulty of film forming of reflective film, and reducing the reflectivity of reflective film. Achieve the effects of small tensile stress, high yield and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

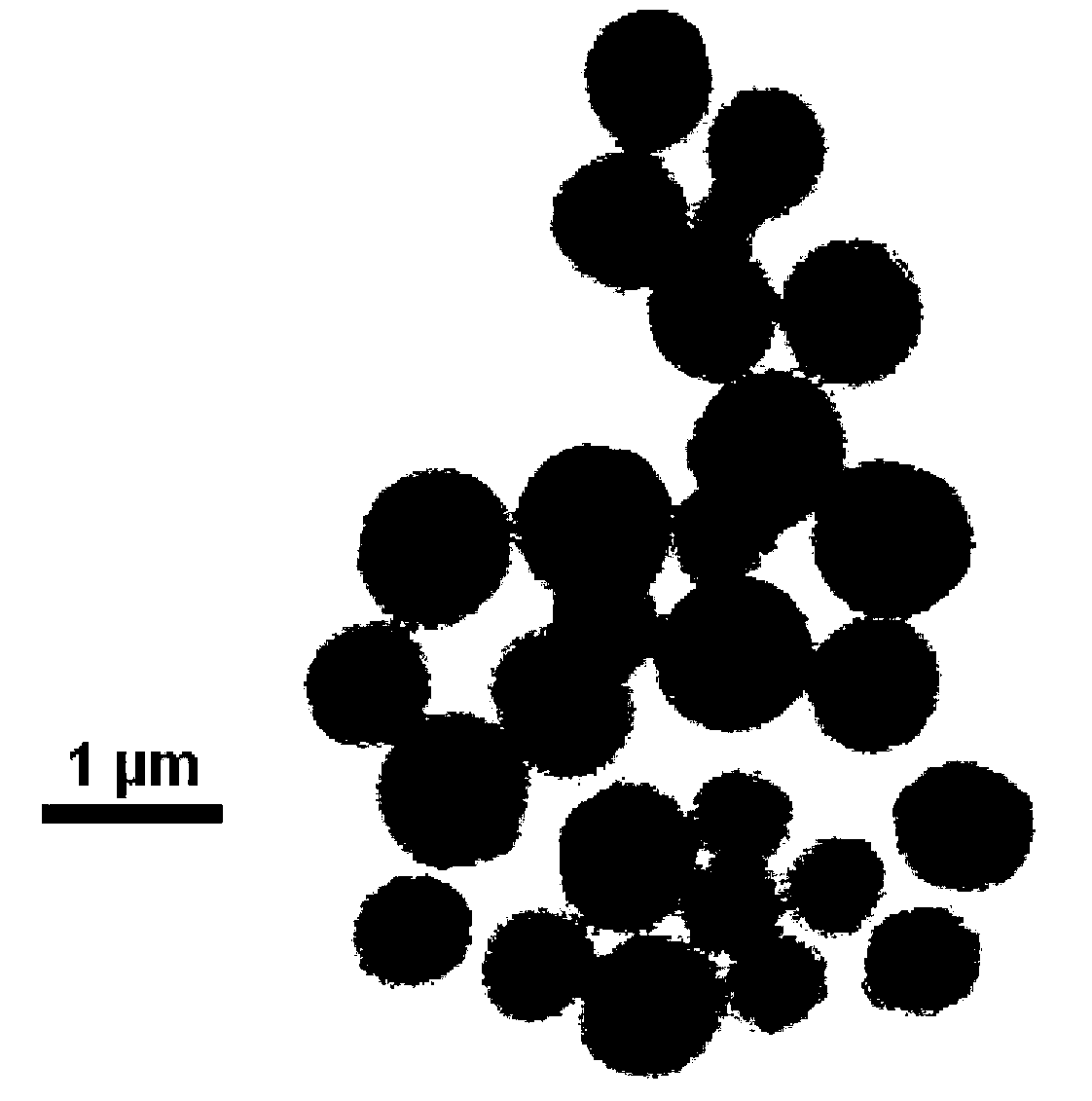

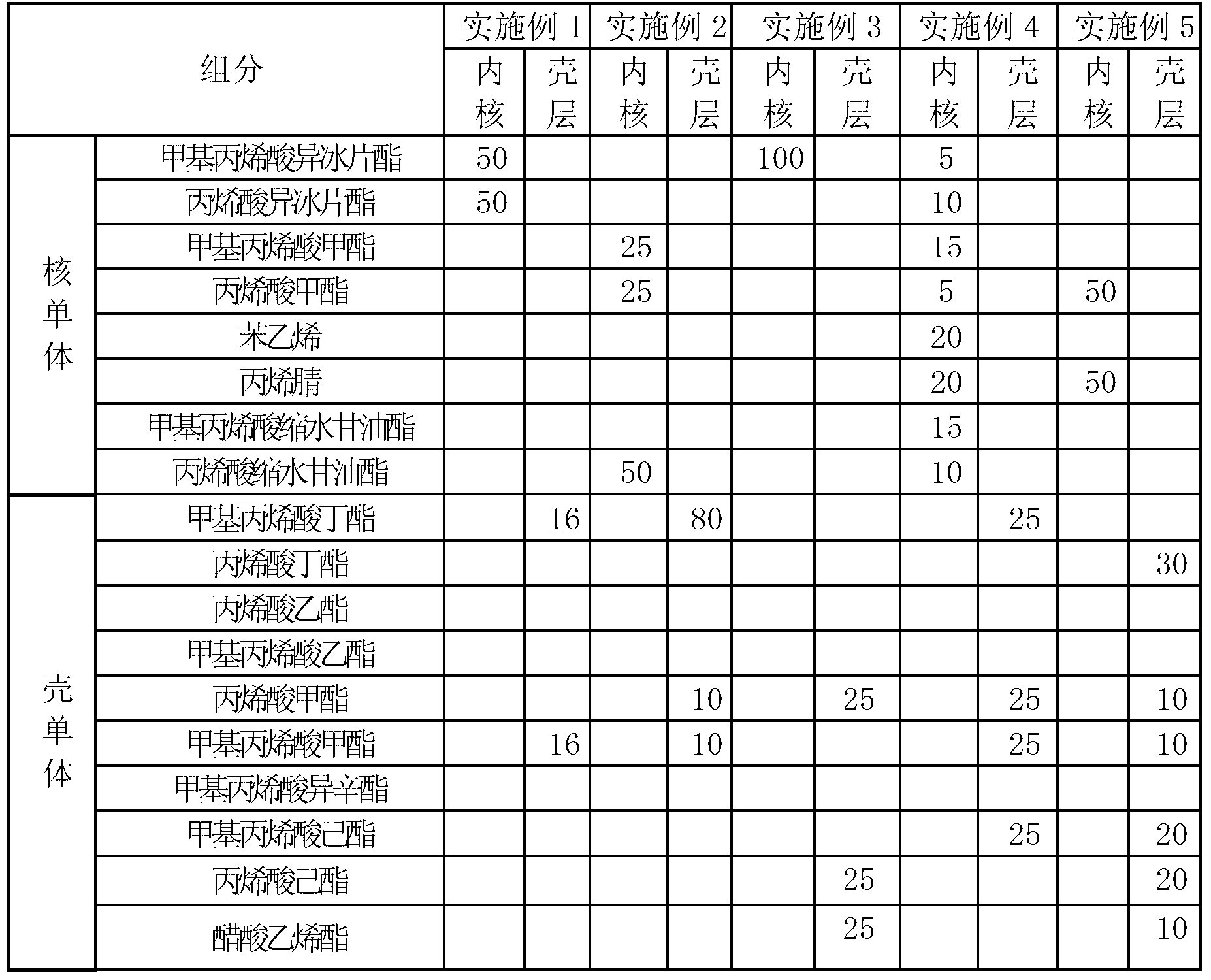

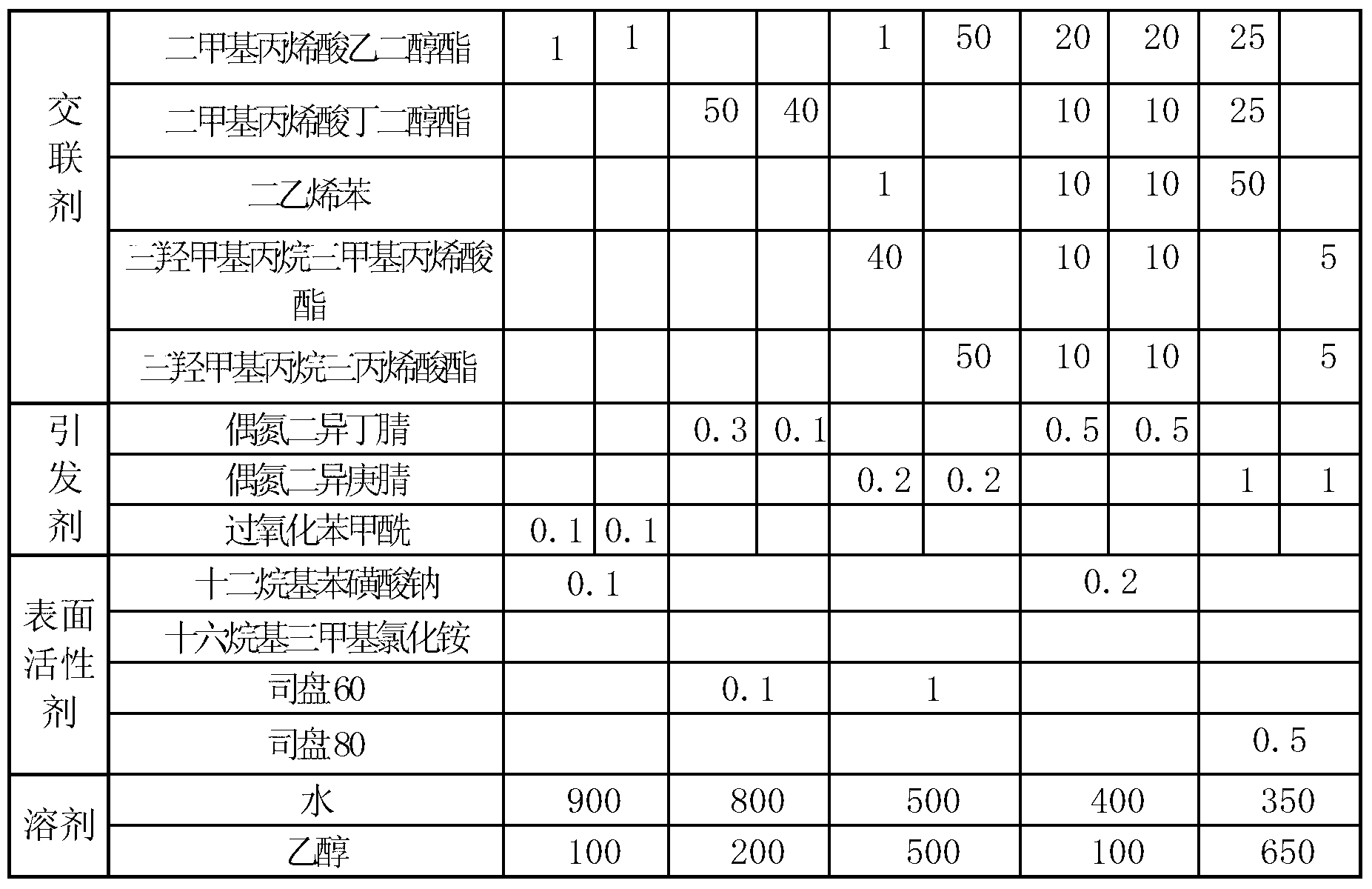

[0024] The present invention is used for the core-shell structure polymer microsphere of polyester reflective film, comprises the inner core and the hard-core soft-shell structure that the shell layer that is coated on the inner periphery constitutes, and wherein, by mass fraction, the inner core of polymer microsphere and The ratio of the outer shell is 1:0.08~1, and the glass transition temperature T of the inner core of the polymer microsphere is g Greater than 130°C, the glass transition temperature T of the shell g Less than 75°C. Its glass transition temperature T of the inner core of polymer microsphere of the present invention is preferably at 135~290 ℃, its glass transition temperature T of the shell layer of polymer microsphere g Preferably at 10-70°C, the particle size of the polymer microspheres is 0.40-5.0 μm. See figure 1 Shown is a transmission electron micrograph of the core-shell polymer microspheres obtained in Example 1. The particle size of the polymer m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com