Patents

Literature

62results about How to "Less prone to stress" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

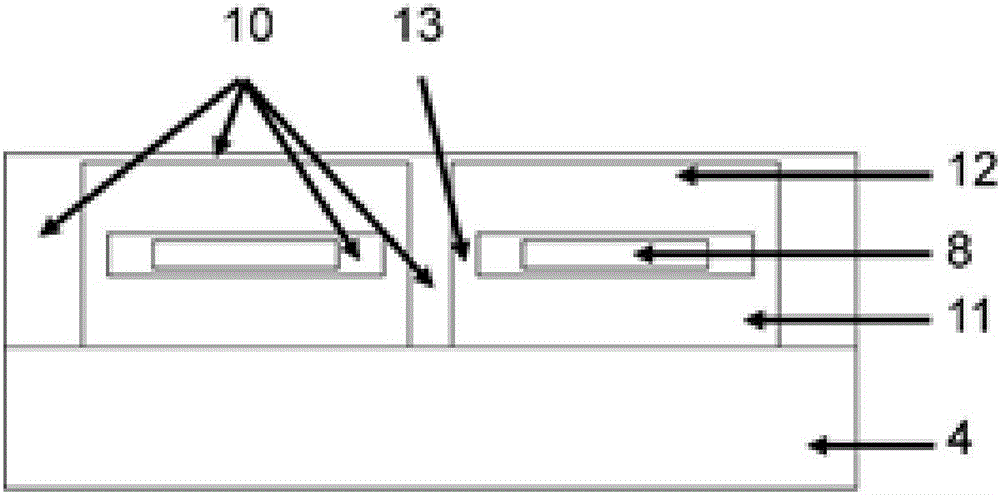

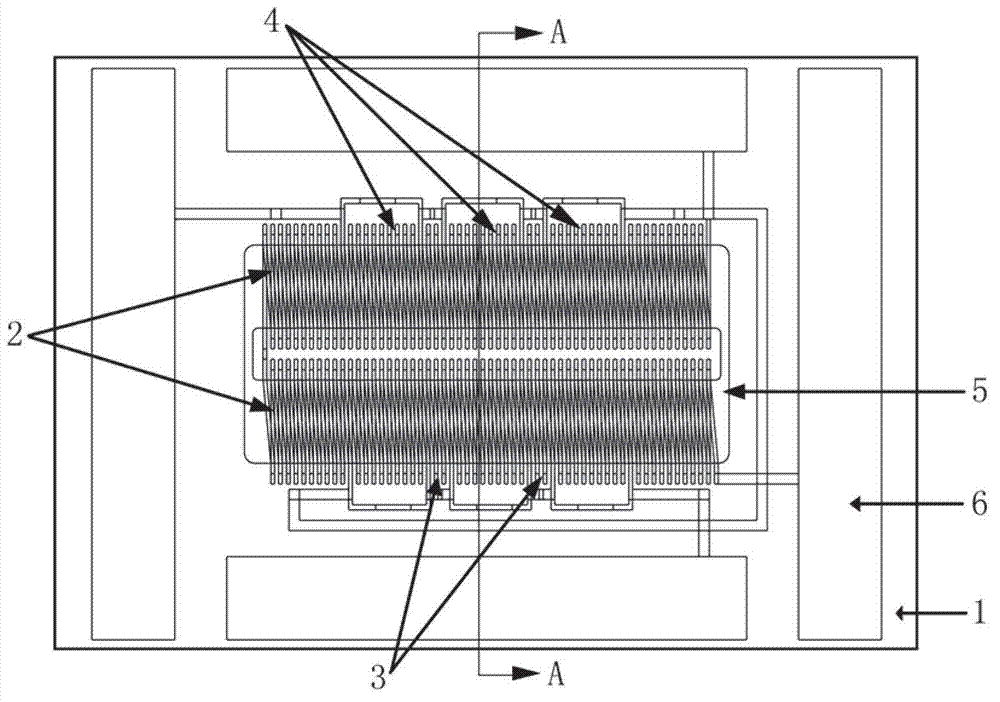

Miniaturized fluxgate sensor of micro-electro-mechanism system

InactiveCN101481083AHigh sensitivityWide linear measurement rangeTelevision system detailsSemi-permeable membranesAlloyEngineering

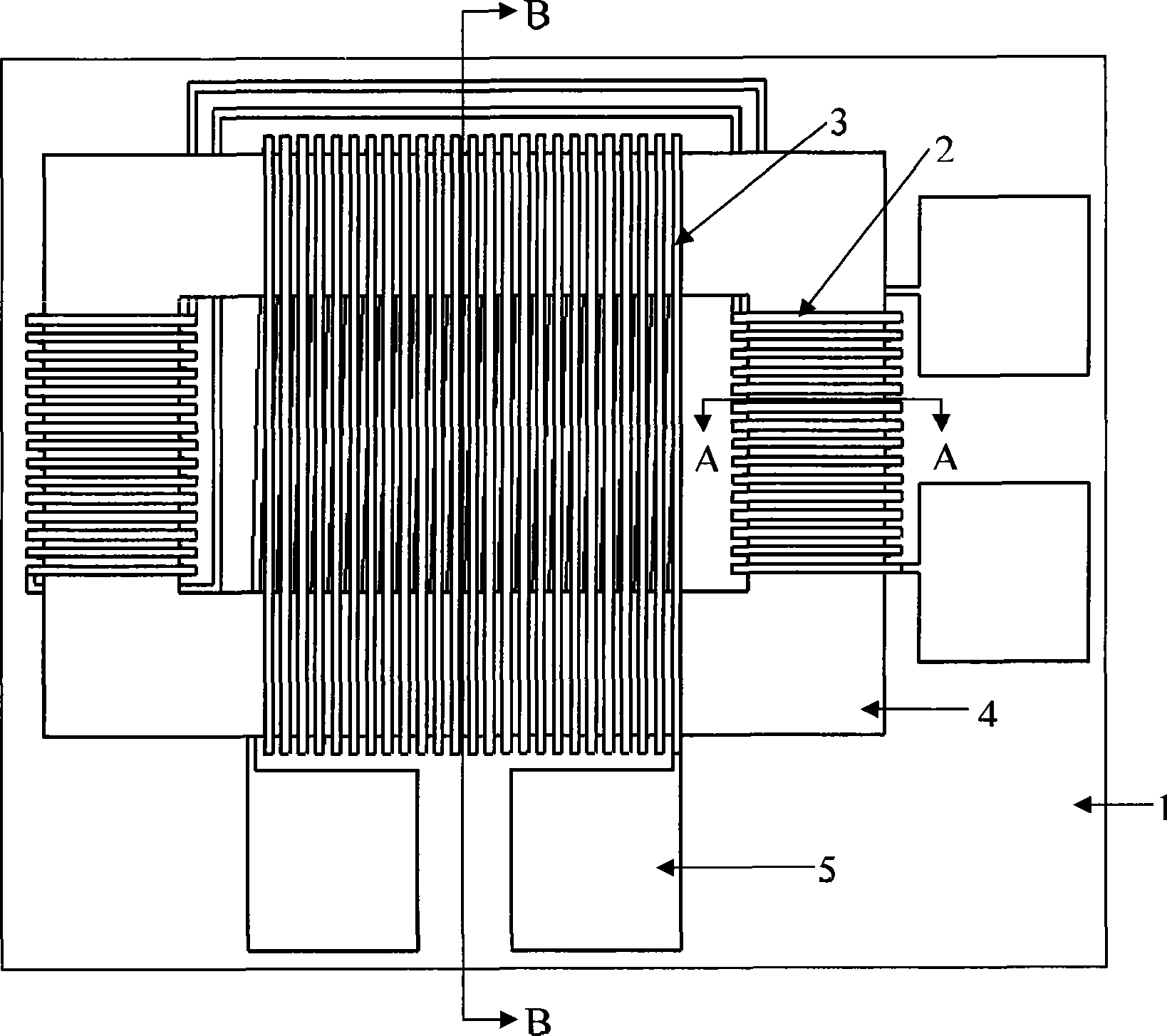

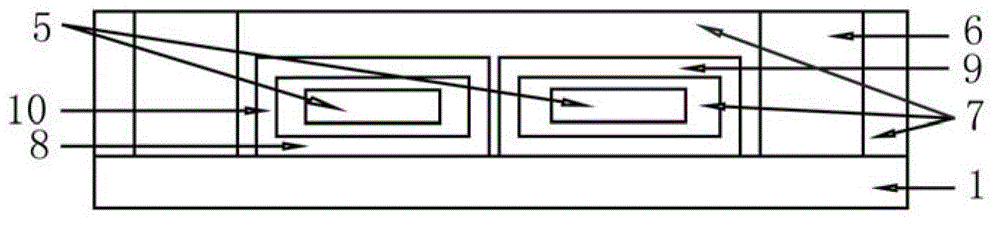

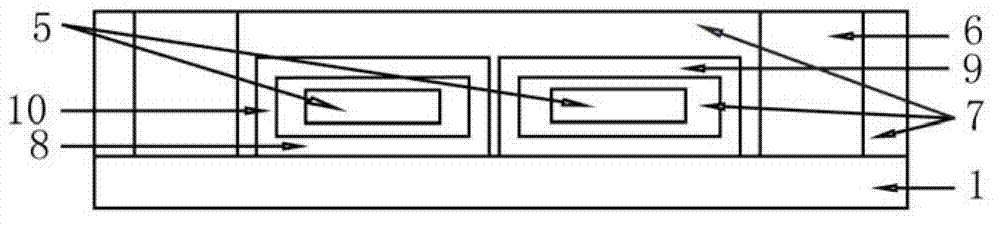

The invention provides a minimized fluxgate sensor of a micro electromechanical system in the micro electromechanical technical field. The minimized fluxgate sensor comprises an underlay, drive coils, receiving coils, a magnetic core, pins and polyimide insulating material, wherein the closed rectangular magnetic core is symmetrically wound with two groups of connected three-dimensional solenoid drive coils and is wound with a group of three-dimensional solenoid receiving coils perpendicular to the drive coils, the drive coils and the receiving coils are insulated and separated from the magnetic core by the polyimide insulating material, the drive coils and the receiving coils are positioned on the underlay, and the two ends are connected with the pins. The magnetic core material is plated NiFe alloy. The invention solves the problems of the traditional fluxgate sensor of difficult installation and debugging, poor stability and poor repetitiveness, ensures that the production technique is compatible with the large-scale integrated circuit technique, can be manufactured by integrating the interface circuit, and is widely applied in a plurality of new fields.

Owner:SHANGHAI JIAO TONG UNIV

Method for manufacturing miniaturized fluxgate sensor

InactiveCN101481080AEase of mass productionGood repeatabilityTelevision system detailsSemi-permeable membranesResistElectrical conductor

The invention provides a method for producing a minimized fluxgate sensor in the micro electromechanical technical field, which comprises the following steps: producing a double-sized alignment symbol; sputtering a bottom layer; flinging positive photoresists, exposing and developing; plating a drive coil and a bottom layer coil of a receiving coil, connecting a conductor with a pin of the coil; removing photosensitive resist and a bottom layer; flinging polyimide, solidifying and polishing; sputtering the bottom layer; flinging positive photoresists, exposing and developing; plating a magnetic core, connecting the conductor with a pin; removing positive photoresists and the bottom layer; flinging polyimide, solidifying and polishing; sputtering the bottom layer; flinging the positive photoresists, exposing and developing; plating the drive coil and a top layer coil of the receiving coil and a pin; removing the photosensitive resist and the bottom layer; and magnetic annealing. The invention solves the problems of the traditional fluxgate sensor of poor stability, poor repetitiveness and poor mass production, ensures that the production technique is compatible with the large-scale integrated circuit technique, can be manufactured by integrating the interface circuit, and is widely applied in a plurality of new fields.

Owner:SHANGHAI JIAO TONG UNIV

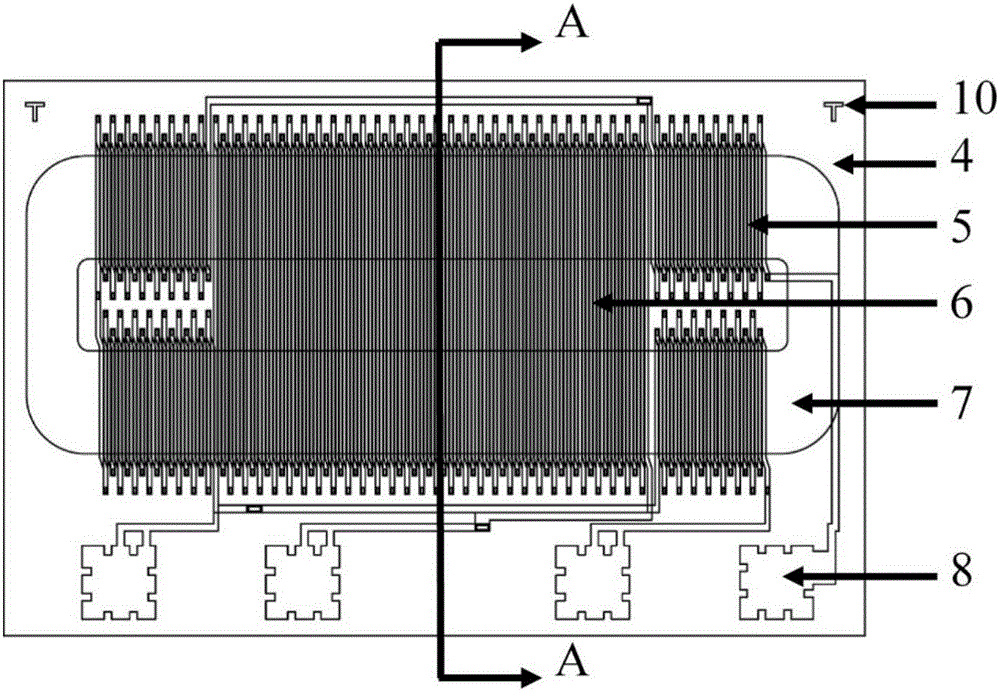

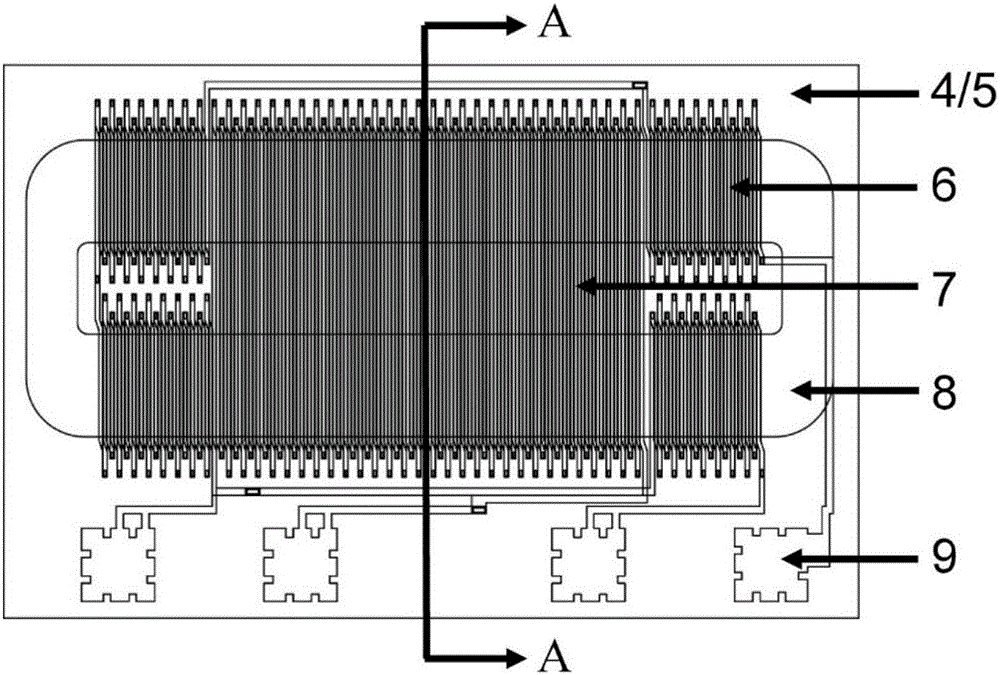

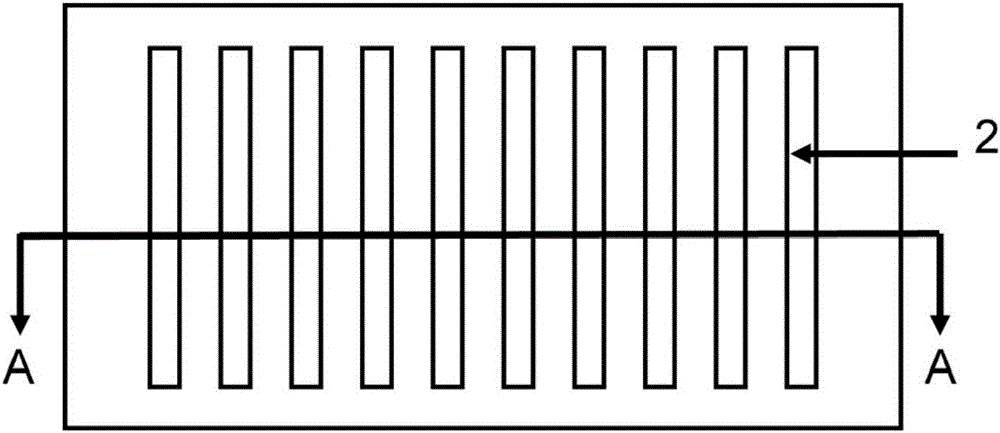

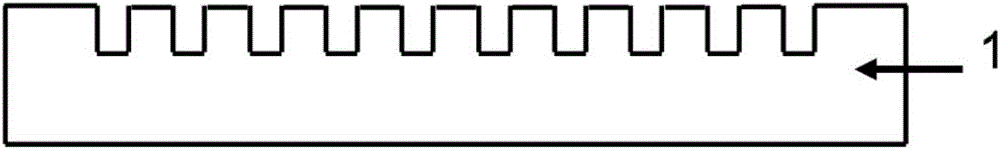

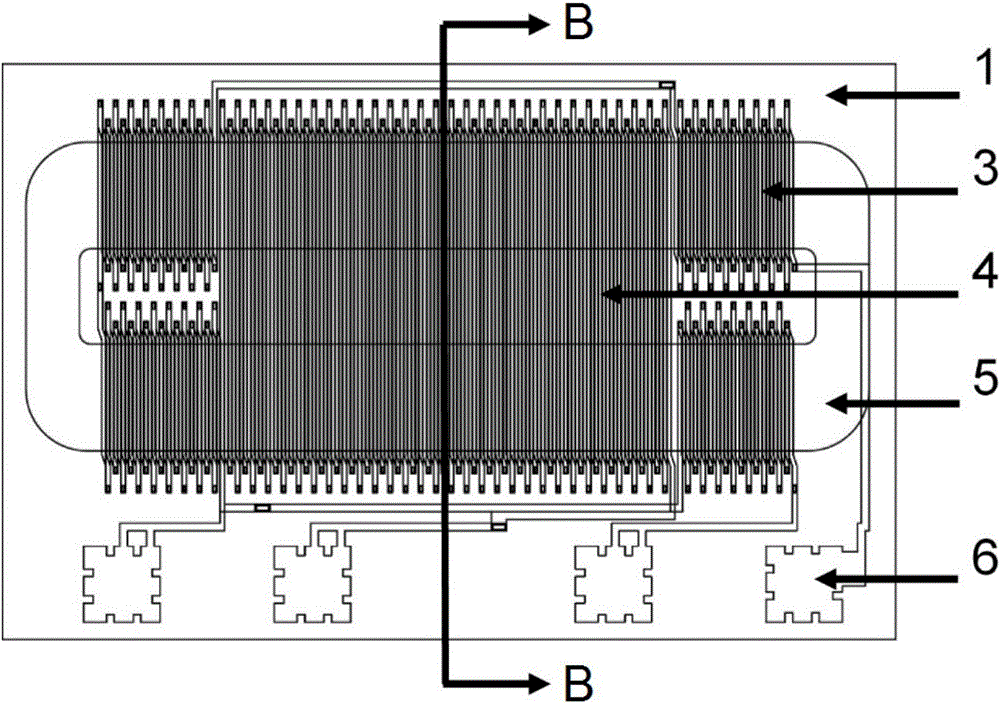

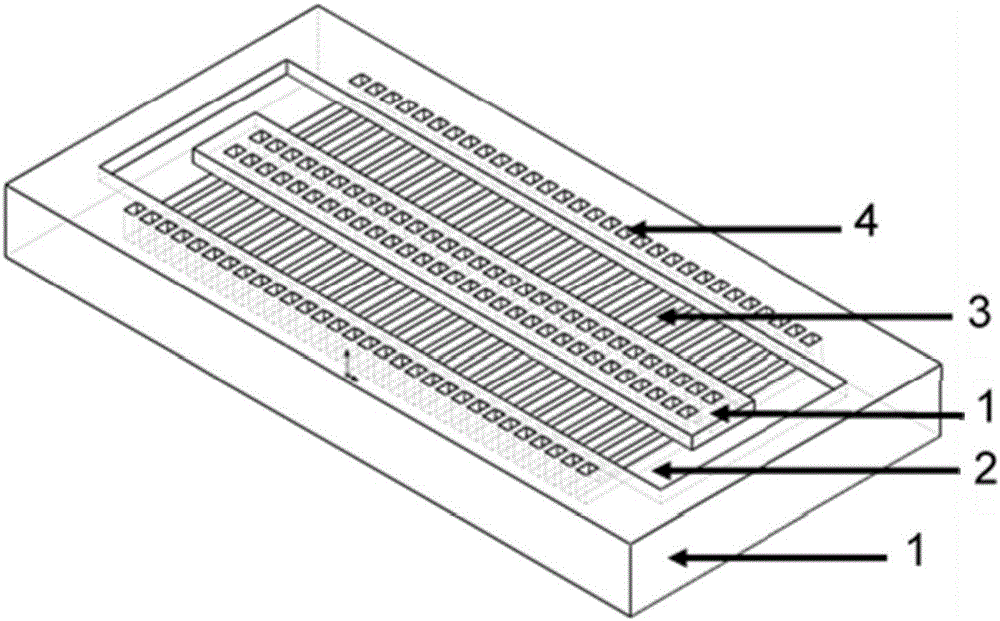

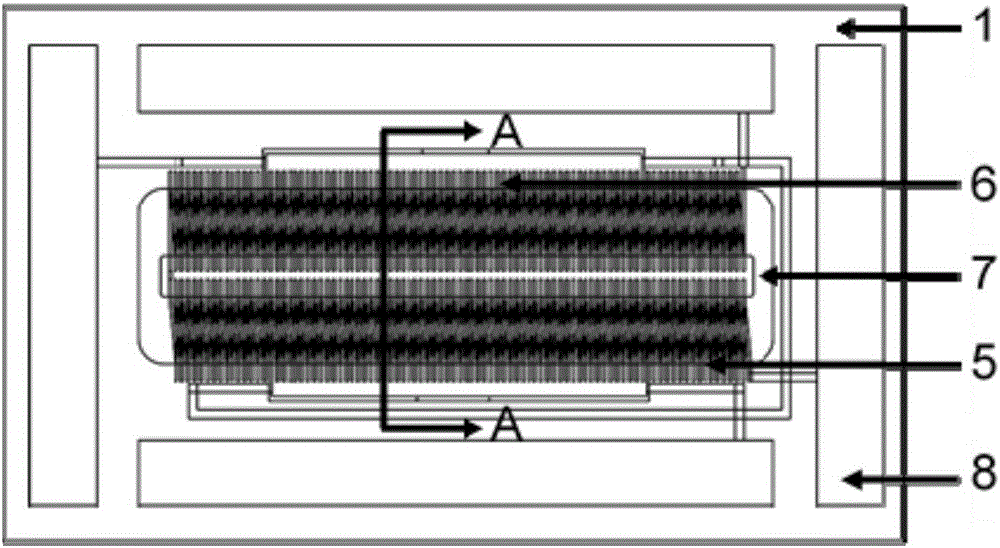

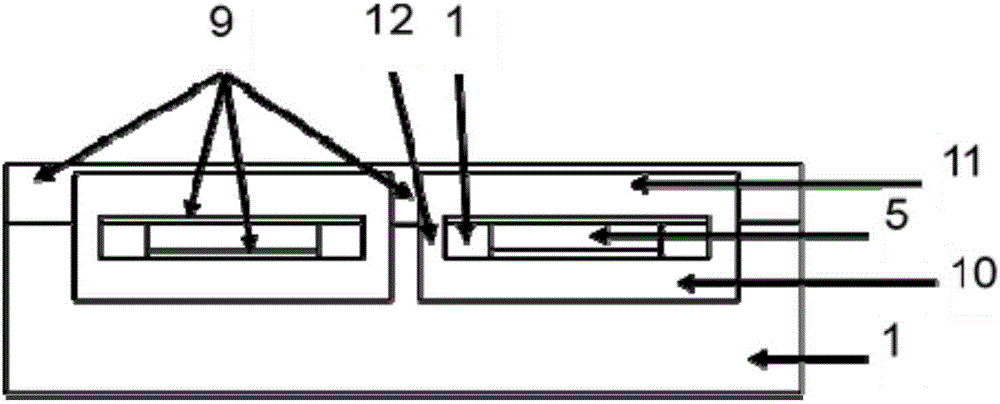

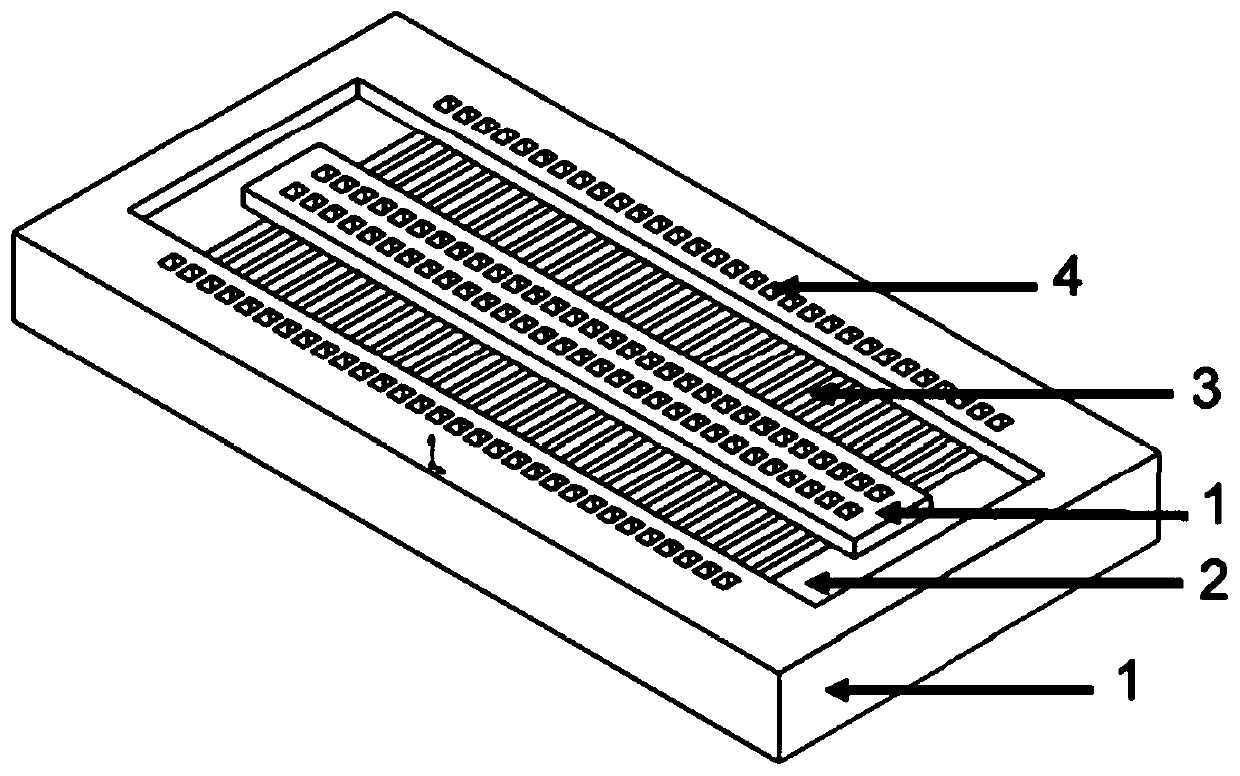

Low-noise micro plane fluxgate sensor based on main and auxiliary coil double incentive

InactiveCN102981131AReduce noiseReduce energy consumptionMagnetic field measurement using flux-gate principleLow noiseRepeatability

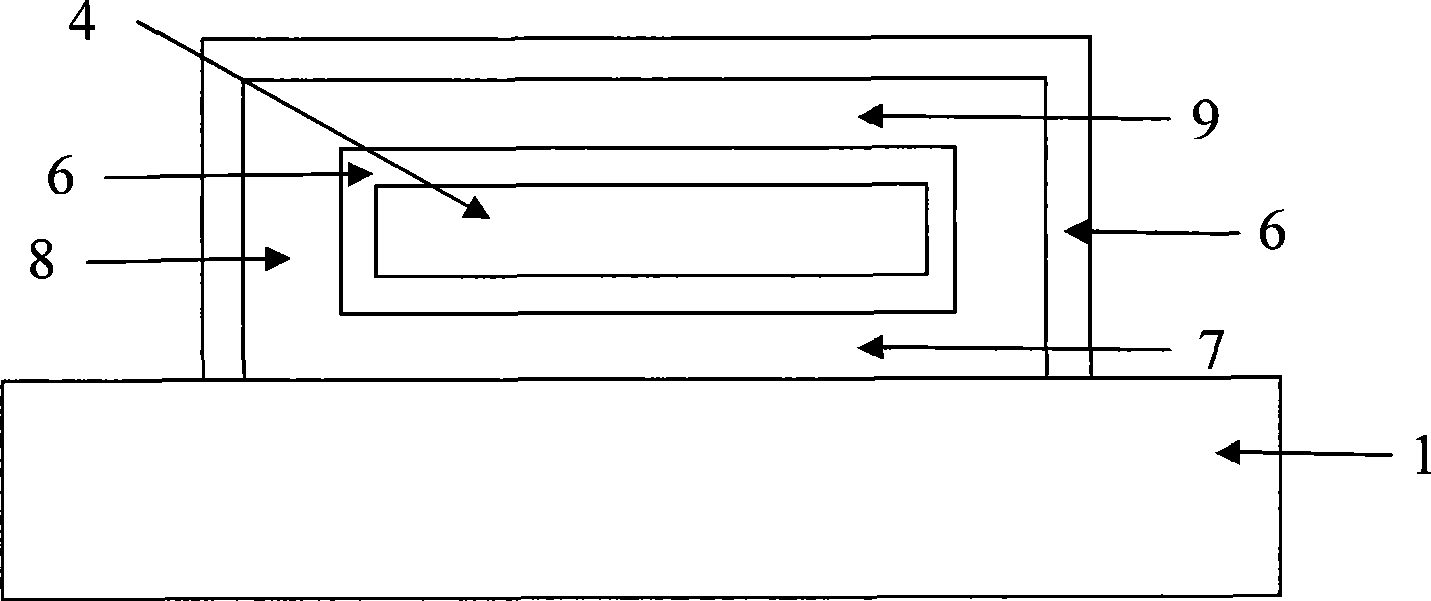

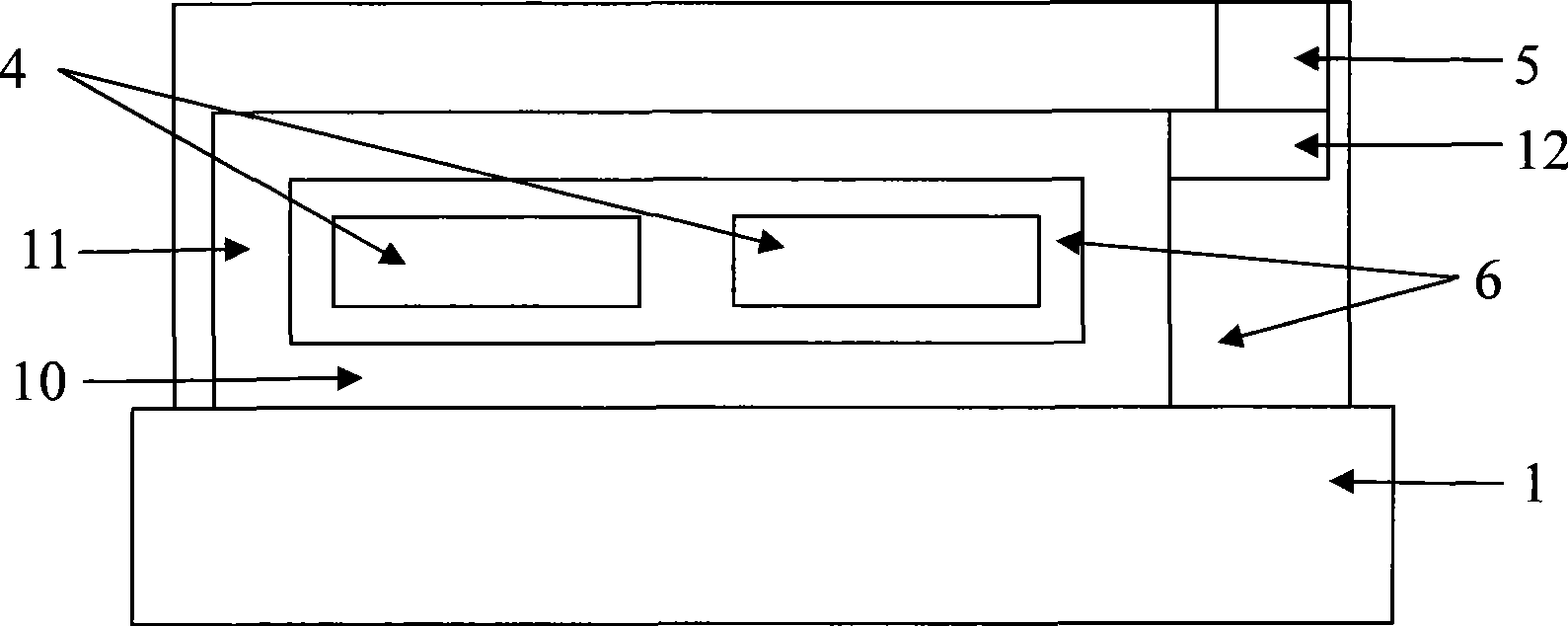

The invention discloses a low-noise micro plane fluxgate sensor based on main and auxiliary coil double incentive. The low-noise micro plane fluxgate sensor based on the main and auxiliary coil double incentive comprises a substrate, main incentive coils, auxiliary incentive coils, detecting coils, a magnetic core, electrodes and a polyimide film. Two ends of each of two long shafts of the magnetic core are symmetrically provided with two groups of the main incentive coils in a wound mode, wherein the two long shafts are arranged in parallel. The middle portions of the long shafts are symmetrically provided with three groups of the detecting coils and two groups of the auxiliary incentive coils in a wound mode. In the same long shaft, one group of the auxiliary incentive coils are arranged between each two groups of the detecting coils. The main incentive coils, the auxiliary incentive coils and the detecting coils are all arranged on the surface of the substrate. Two ends of each main incentive coil are connected with the electrodes. The low-noise micro plane fluxgate sensor based on the main and auxiliary coil double incentive solves the problems that a traditional fluxgate sensor is poor in manufacturing stability and repeatability, utilizes the main and auxiliary coil double incentive to improves the incentive efficiency of the micro fluxgate sensor, effectively lowers output signal noise and energy consumption, is capable of being manufactured together with an interface circuit in an integrated mode, and can be widely used in many novel fields.

Owner:SHANGHAI JIAO TONG UNIV

Deformation joint treatment method and deformation joint waterproof structure

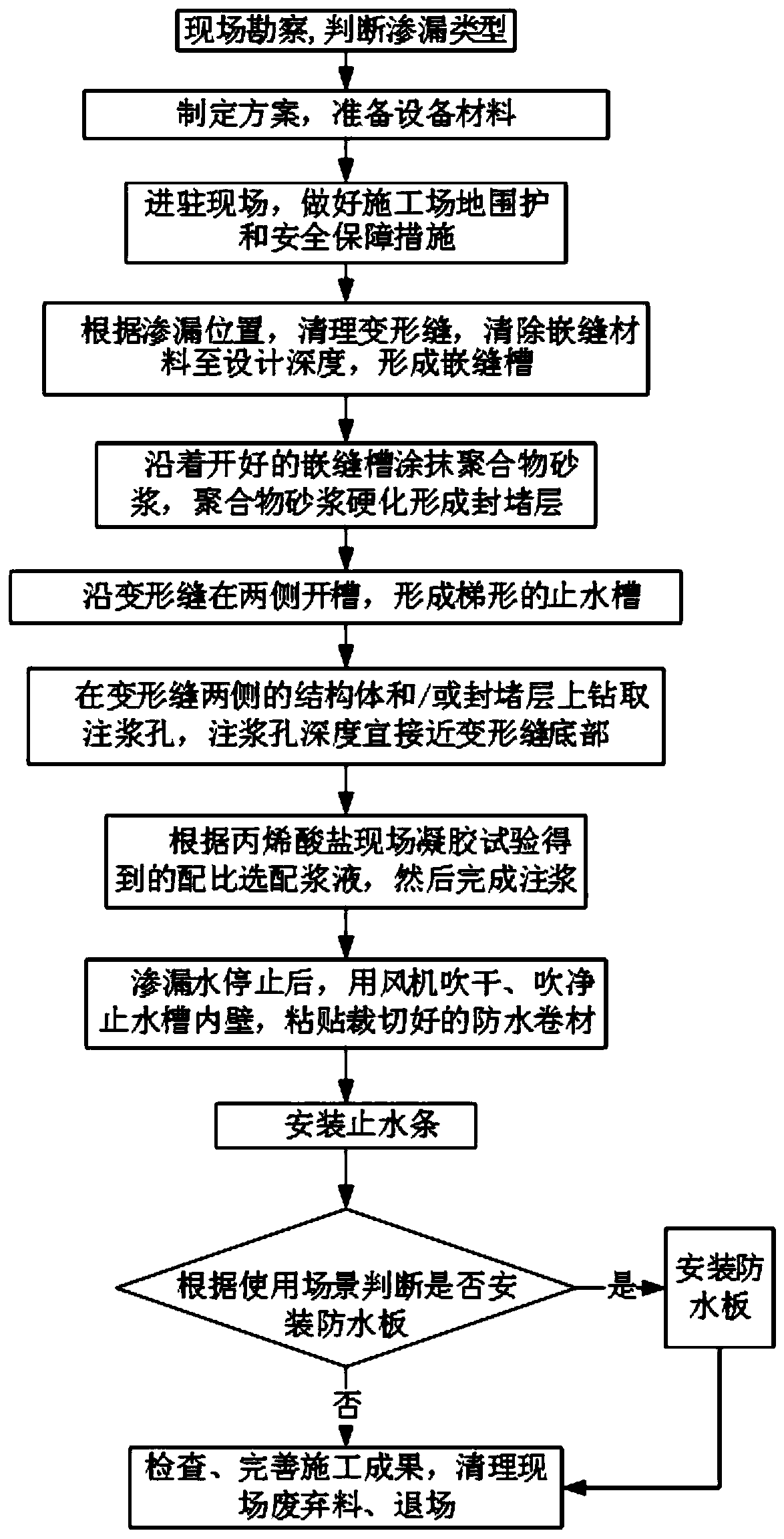

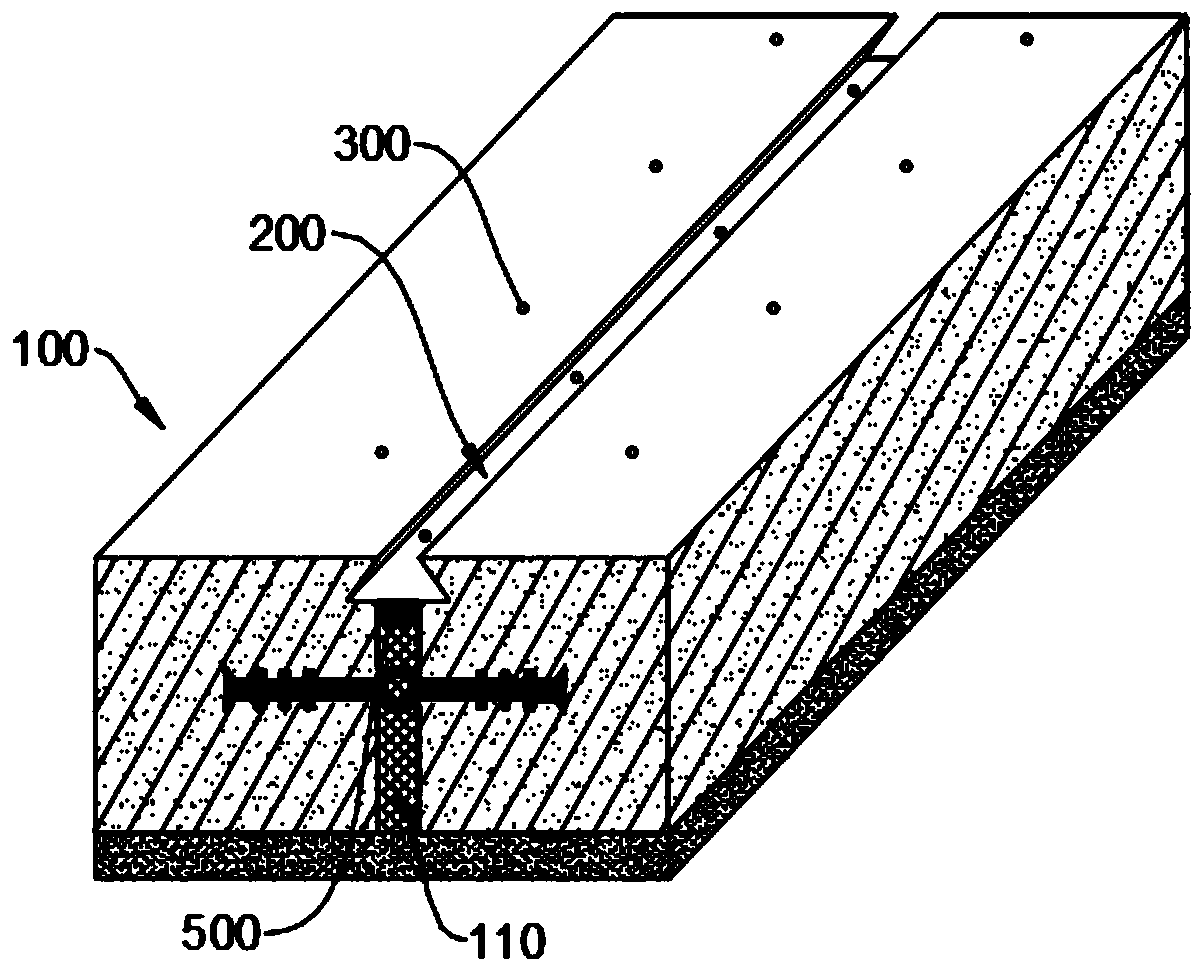

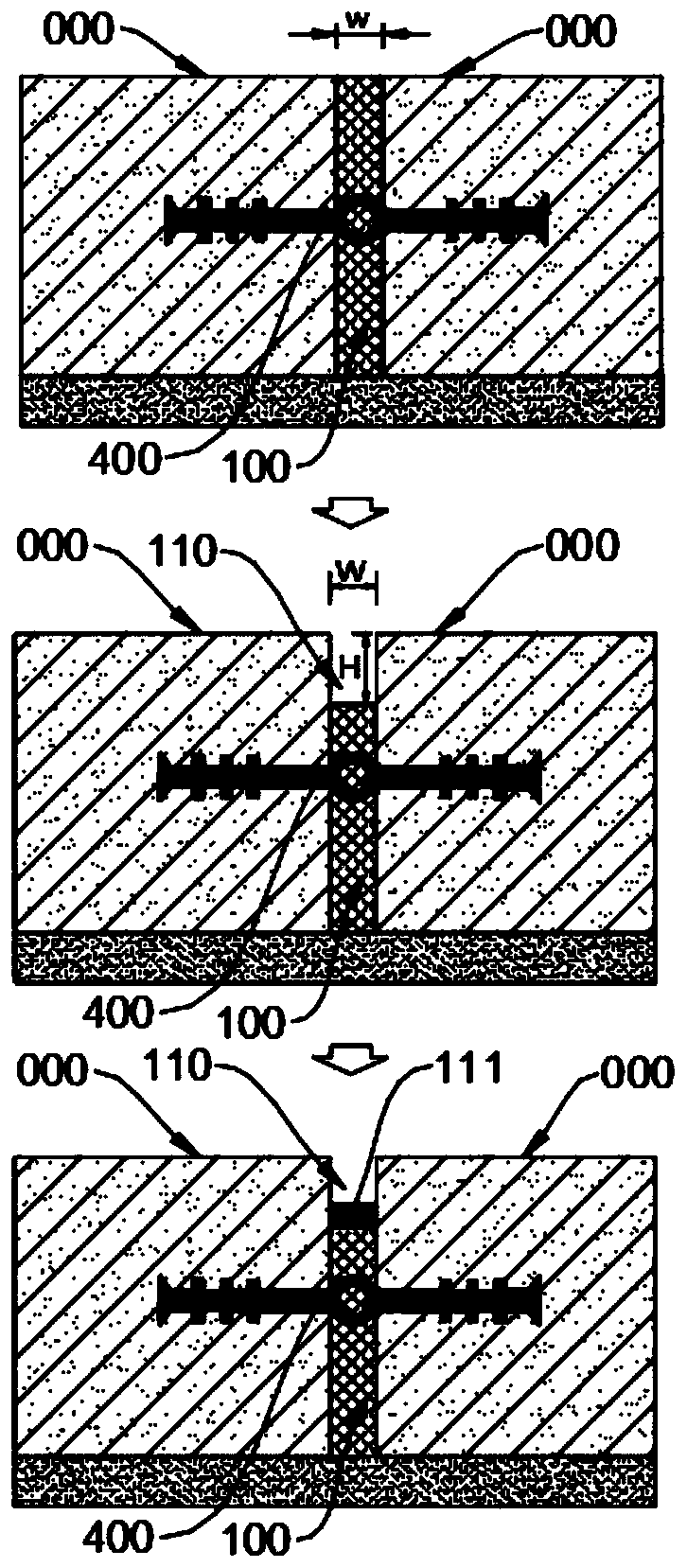

InactiveCN110629800AEasy to manageBroaden applicationArtificial islandsProtective foundationWater leakageWater seepage

The invention relates to the field of water leakage treatment of building joints, in particular to a deformation joint treatment method and a deformation joint waterproof structure. The deformation joint treatment method comprises the steps that 1, on-site survey is conducted; 2, the type of deformation joint leakage is determined based on the result of the on-site survey; and 3, a construction plan is made based on the type of the deformation joint leakage. According to the deformation joint treatment method, the on-site survey is firstly conducted, information of the deformation joint is collected, the width and length of the deformation joint, the location and cause of water seepage, the number of water seepage points, the amount of water seepage, and the damage condition of a water stop are obtained; the type of the deformation joint leakage is determined based on the location and cause of water seepage, the number of water seepage, the amount of water seepage, and the damage condition of the water stop; according to the determined type of the deformation joint leakage, a targeted construction plan is made to better treat the leakage. According to the deformation joint treatment method, a flexible waterproof structure is formed, in the process of water blocking, a water blocking material can passively adapt to the deformation of the structure, and the problem of water leakage caused by the material damage due to the deformation of the structure is alleviated.

Owner:SUBWAY OPERATION TECH R & D CENT BEIJING SUBWAY OPERATION CO LTD +1

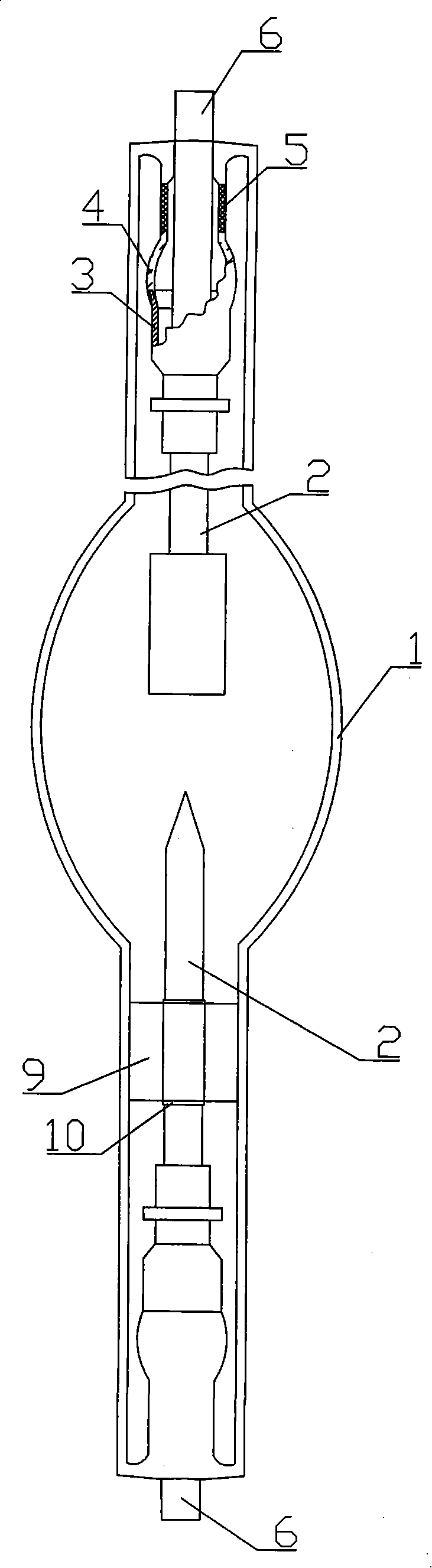

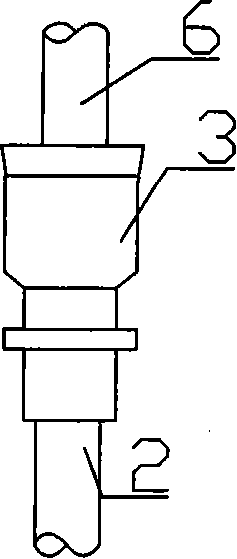

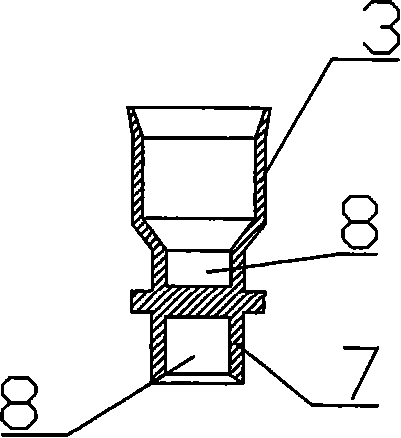

Transition sealing-in type xenon lamp

ActiveCN101246800AStable structureReduce production efficiencyGas discharge lamp detailsEngineeringKovar

The invention relates to the field of high-powder xenon lamp technology, particularly to an intermediate sealing xenon lamp, comprising a quartz glass casing and an electrode in the quartz glass casing, the electrode is provided with a Kovar ring connected with the quartz glass casing by Kovar glass and intermediate sealing connector, the Kovar ring and the Kovar glass are matchedly sealed and have same swell factor, therefore gas leakage phenomena hardly occurs. Compared with the old structure in which bubble, molybdenum foil and quartz glass casing are unmatchedly sealed, the air outlet of the xenon lamp can be arranged on a tail tube, so that the casing of the xenon lamp is kept smooth. The smooth spherical casing is uneasy to generate stress when the xenon lamp glows, thus to avoid lamp explosion.

Owner:CHANGZHOU YUYU ELECTRIC LIGHT APPLIANCE

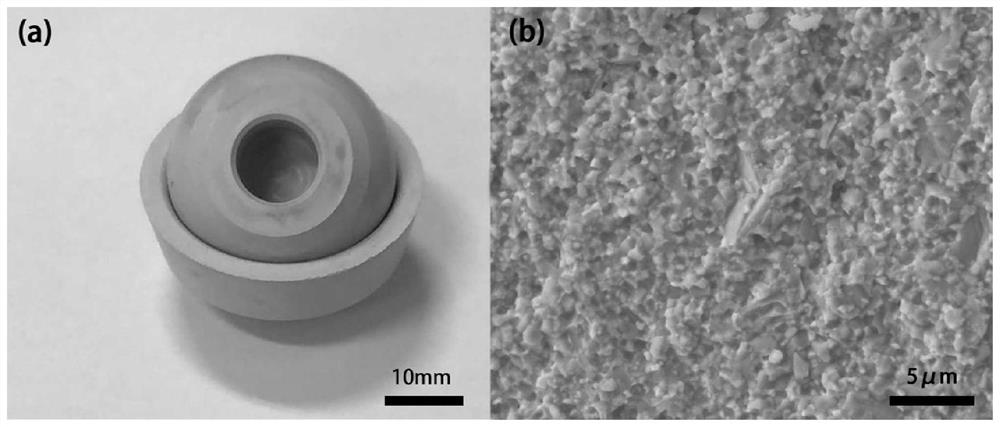

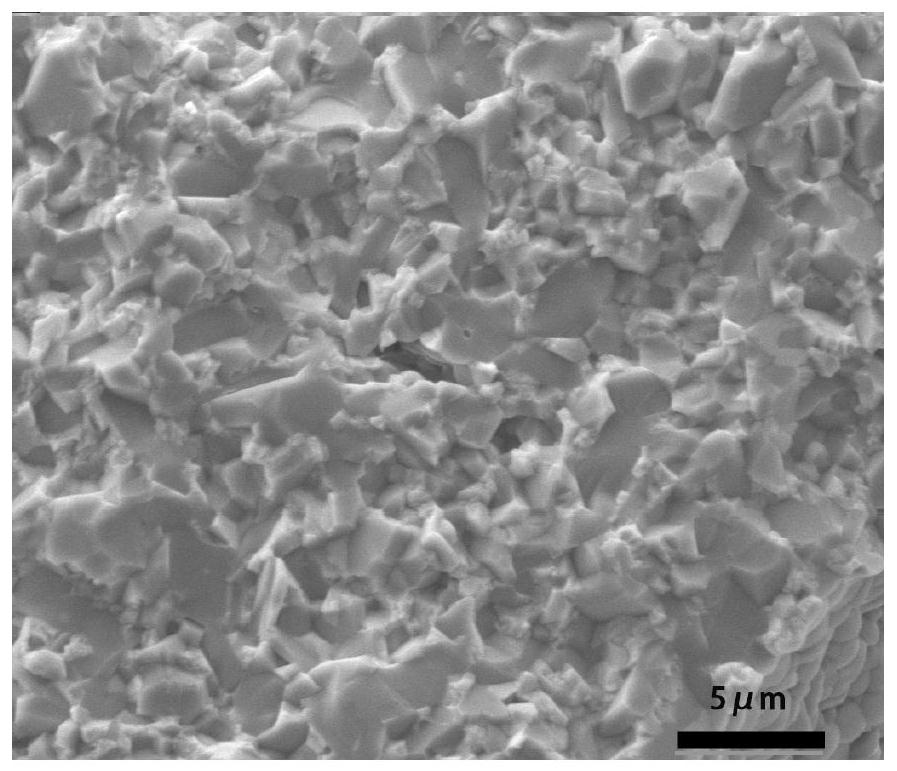

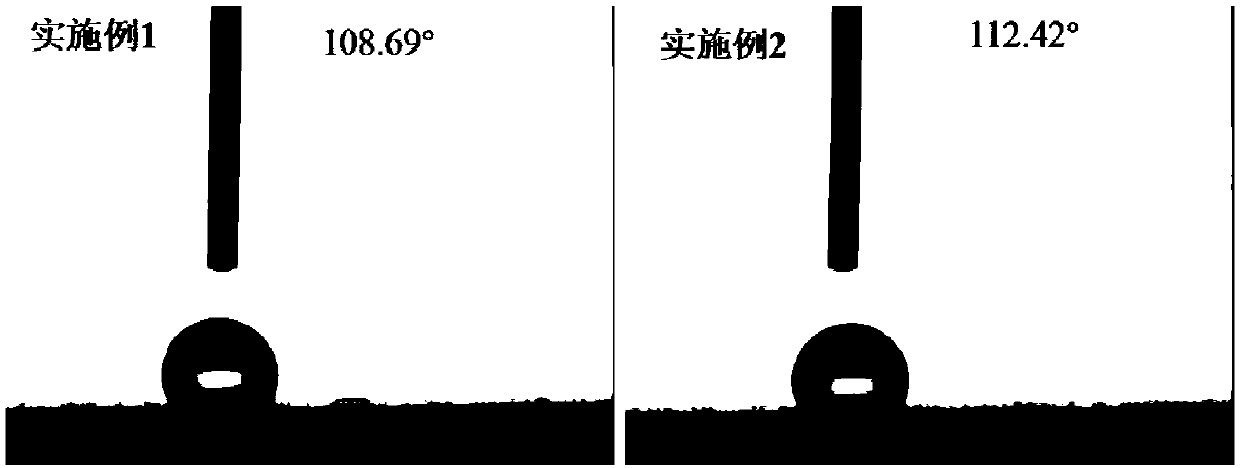

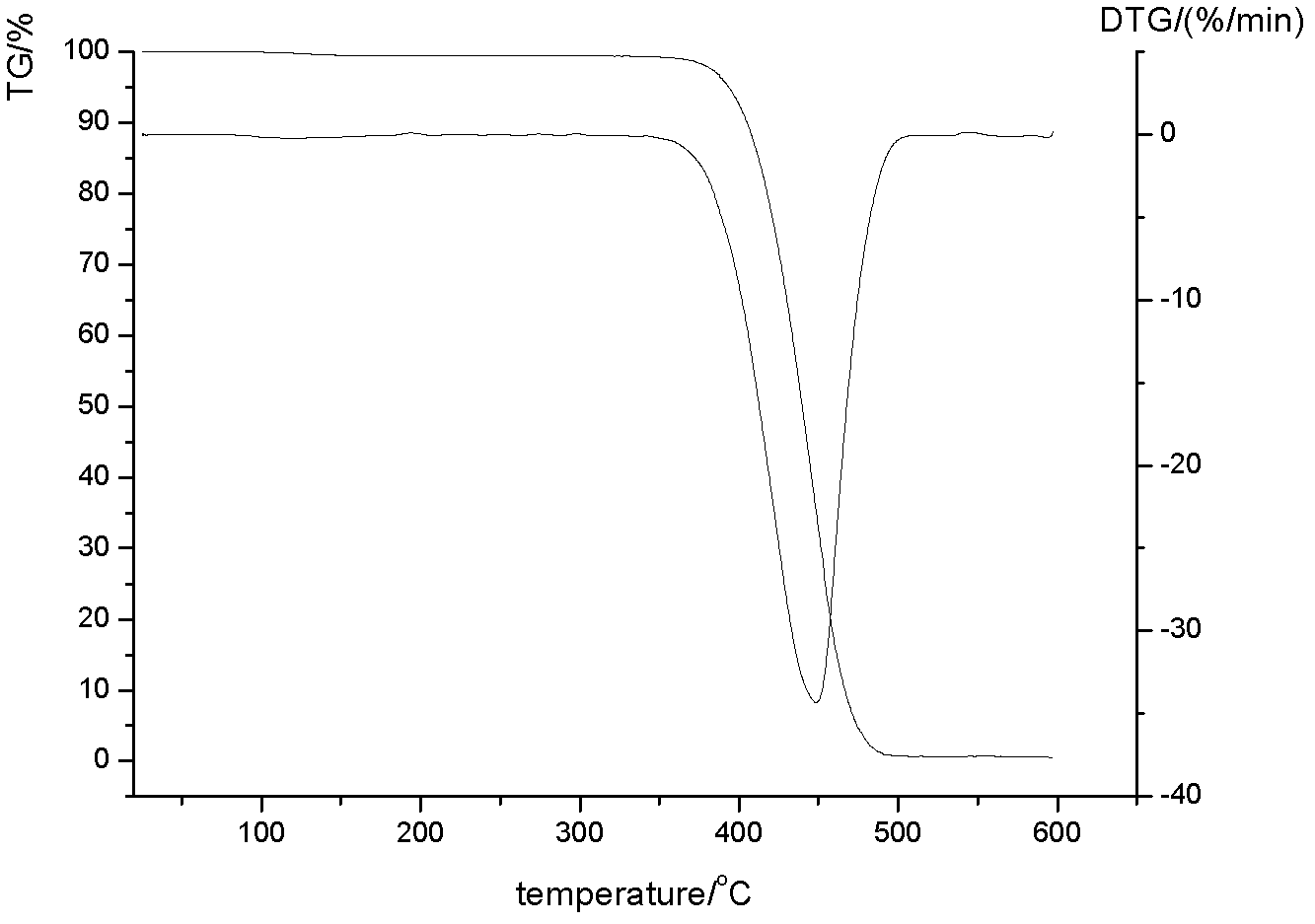

Fine-grain pink ZTA ceramic and preparation method thereof

The invention discloses a preparation method of fine-grain pink ZTA ceramic. The preparation method comprises the following steps of: mixing aluminum oxide, yttria-stabilized zirconia, carbonic acid and a chromium source to obtain mixed powder; adding the mixed powder into an alkaline solution containing an anionic dispersant; obtaining a mixture, adding an adhesive into the mixture; ball-millingto obtain ceramic slurries, carrying out spray granulation and drying on the obtained ceramic slurry to obtain ZTA composite powder, carrying out compression molding on the ZTA composite powder to obtain a green body, placing the obtained green body in an air atmosphere, carrying out primary sintering to obtain a primary blank, and carrying out hot isostatic pressing sintering on the primary blankto obtain a ZTA ceramic material, wherein the temperature of the hot isostatic pressing sintering is 20-50 DEG C lower than the temperature of the primary sintering. The fine-grain ZTA ceramic obtained by the preparation method has high hardness, toughness, wear resistance and biocompatibility, and can be widely used as a cutting tool, structural ceramic, a human body wear-resistant implant material and the like.

Owner:XIANGYA HOSPITAL CENT SOUTH UNIV

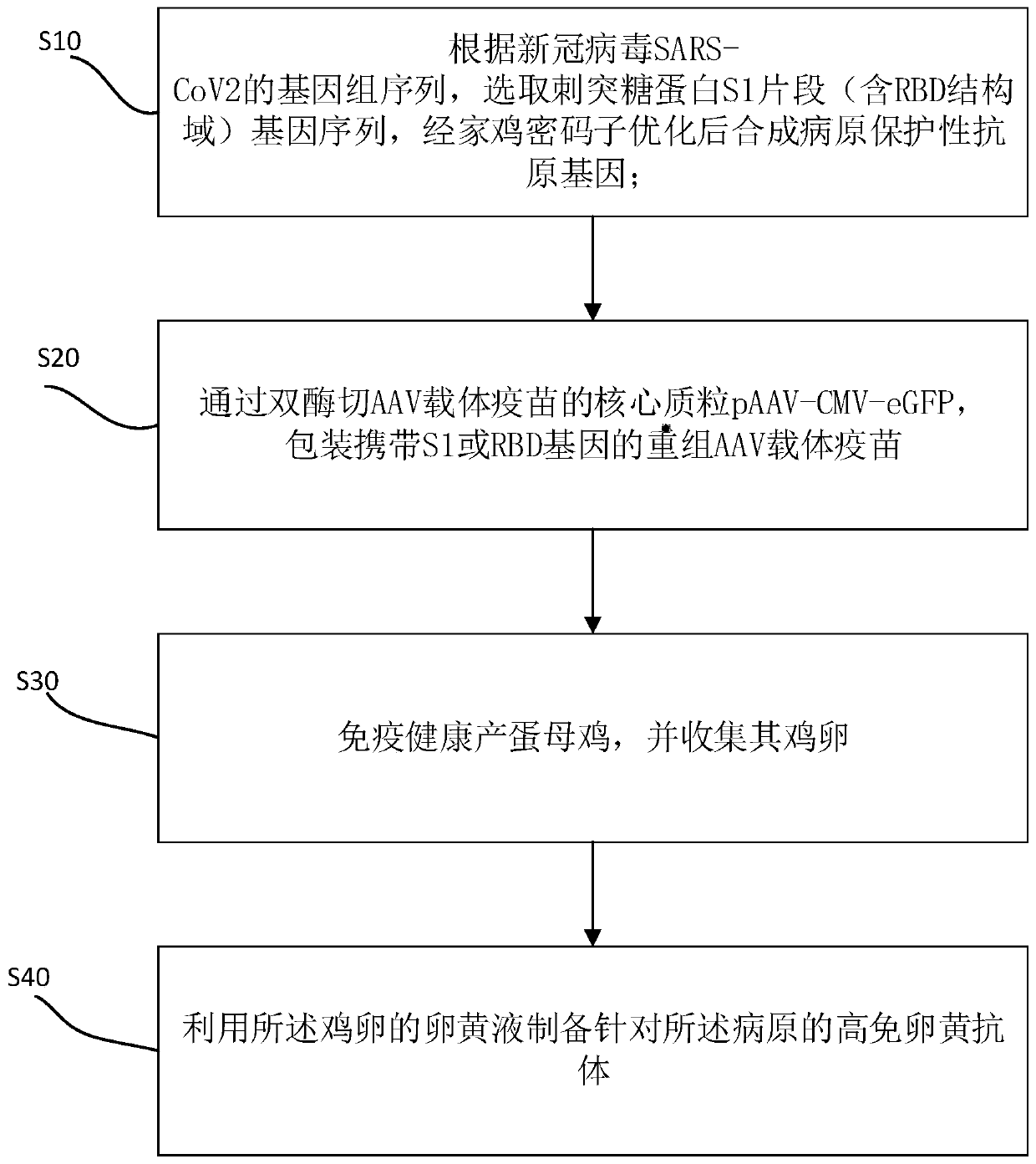

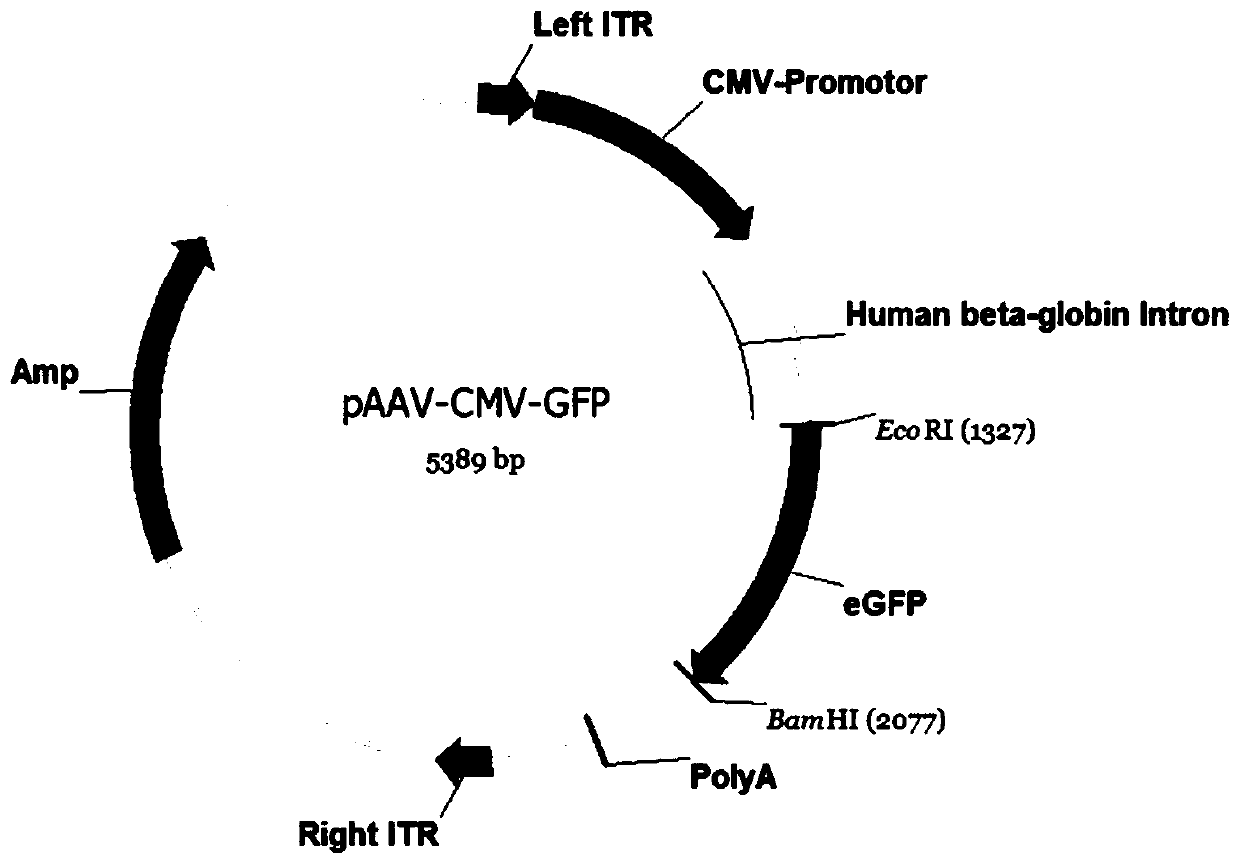

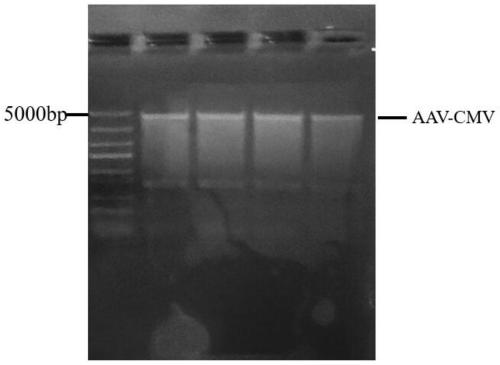

Anti-pathogen hyperimmune yolk antibody, AAV vector vaccine based preparation method and preparation

PendingCN111411118AReduce workloadMaterial and time cost reductionEgg immunoglobulinsNitro compound active ingredientsPathogenAntigenic protein

The invention discloses an anti-pathogen hyperimmune yolk antibody, an AAV vector vaccine based preparation method and a preparation. The preparation method of the hyperimmune yolk antibody comprisesthe steps of selecting a first gene sequence containing an antigen protein fragment from a genomic sequence of a pathogen, and synthesizing a pathogen protective antigen gene through codon optimization; packaging a recombinant AAV vector vaccine carrying the antigen gene; and immunizing a healthy laying hen, and preparing the yolk antibody from a hen egg of the laying hen. According to the method,recombinant adeno-associated viruses with high safety, quick and simple packaging, low cost and stable expression are used as the vector vaccine for expressing protective antigen proteins of virusesor bacteria, the hen egg can be collected by immunizing the healthy laying hen once, the antivirus or antibacterial yolk antibody as an active component in yolk is extracted, and the antibody is natural immune globulin and can kill the viruses or bacteria and prevent viral or bacterial infection.

Owner:鲲羽生物科技(江门)有限公司

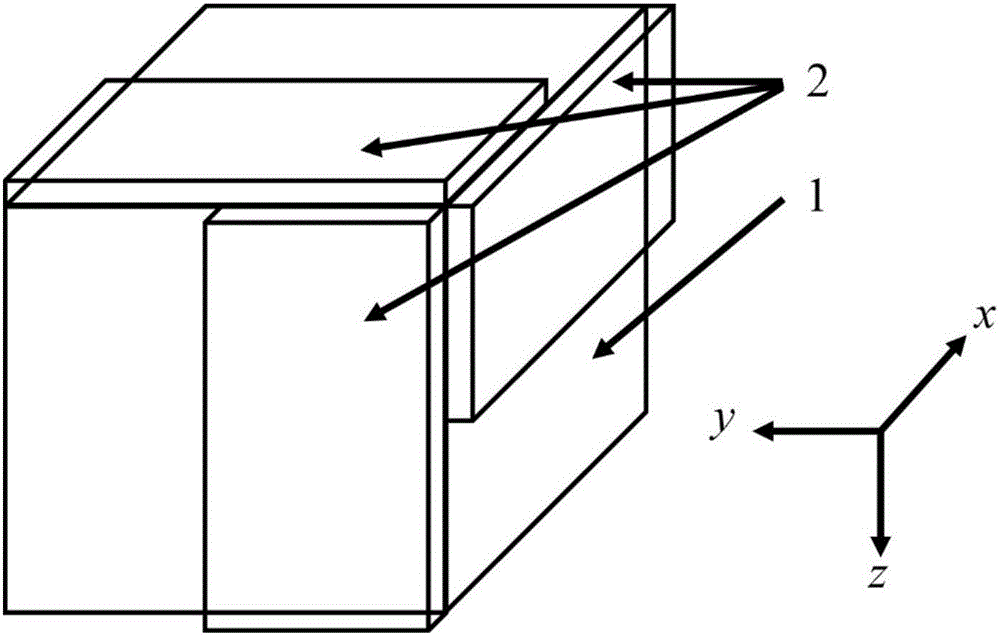

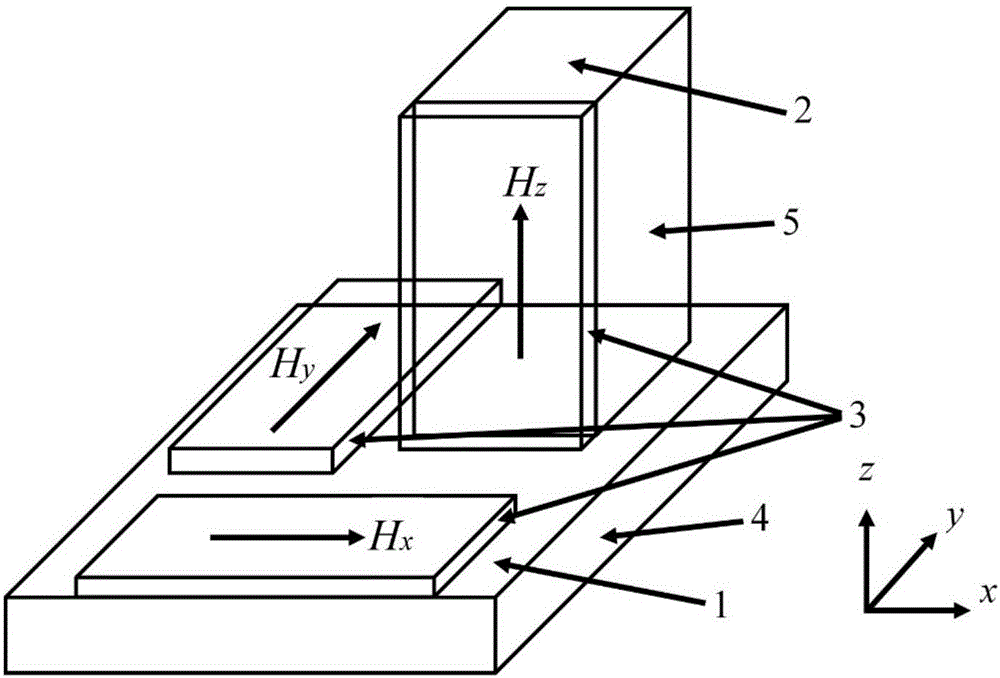

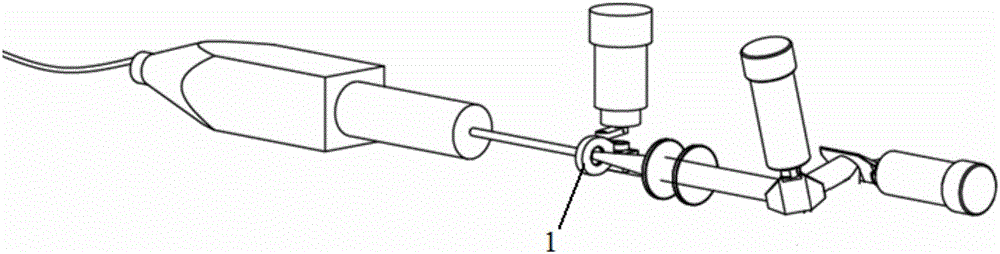

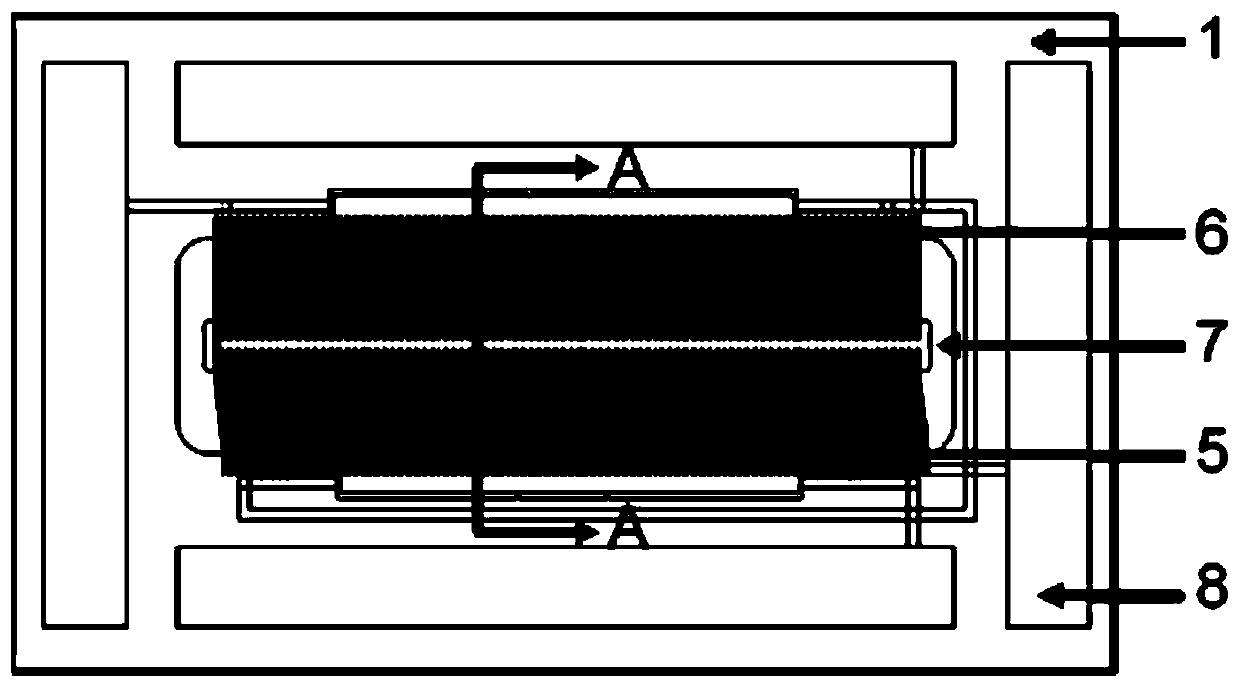

Three-shaft fluxgate sensor

The invention discloses a micro electro mechanical system three-shaft fluxgate sensor based on silicon cube-glass bonding, and relates to the field of micro electro mechanical systems. The three-shaft fluxgate sensor comprises a 1 cubic centimeter silicon cube base and three micro electro mechanical system single-shaft fluxgate sensor chips. Each micro electro mechanical system single-shaft fluxgate sensor chip comprises a glass substrate, an exciting coil, a detecting coil, a magnetic core, an electrode and a polyimide film. The three micro electro mechanical system single-shaft fluxgate sensor chips are precisely located and fixed to three planes with orthorhombic peaks of the silicon cube base respectively in the three orthorhombic directions through silicon-glass bonding. The problem that an existing three-shaft fluxgate sensor is large in size, large in weight and large in power consumption is solved, and bonding of the micro electro mechanical system single-shaft fluxgate sensor chips and the silicon cube base is adopted for the micro electro mechanical system three-shaft fluxgate sensor adopting silicon cube-glass bonding, so that the size of the high-precision three-shaft fluxgate sensor is effectively reduced.

Owner:SHANGHAI JIAO TONG UNIV

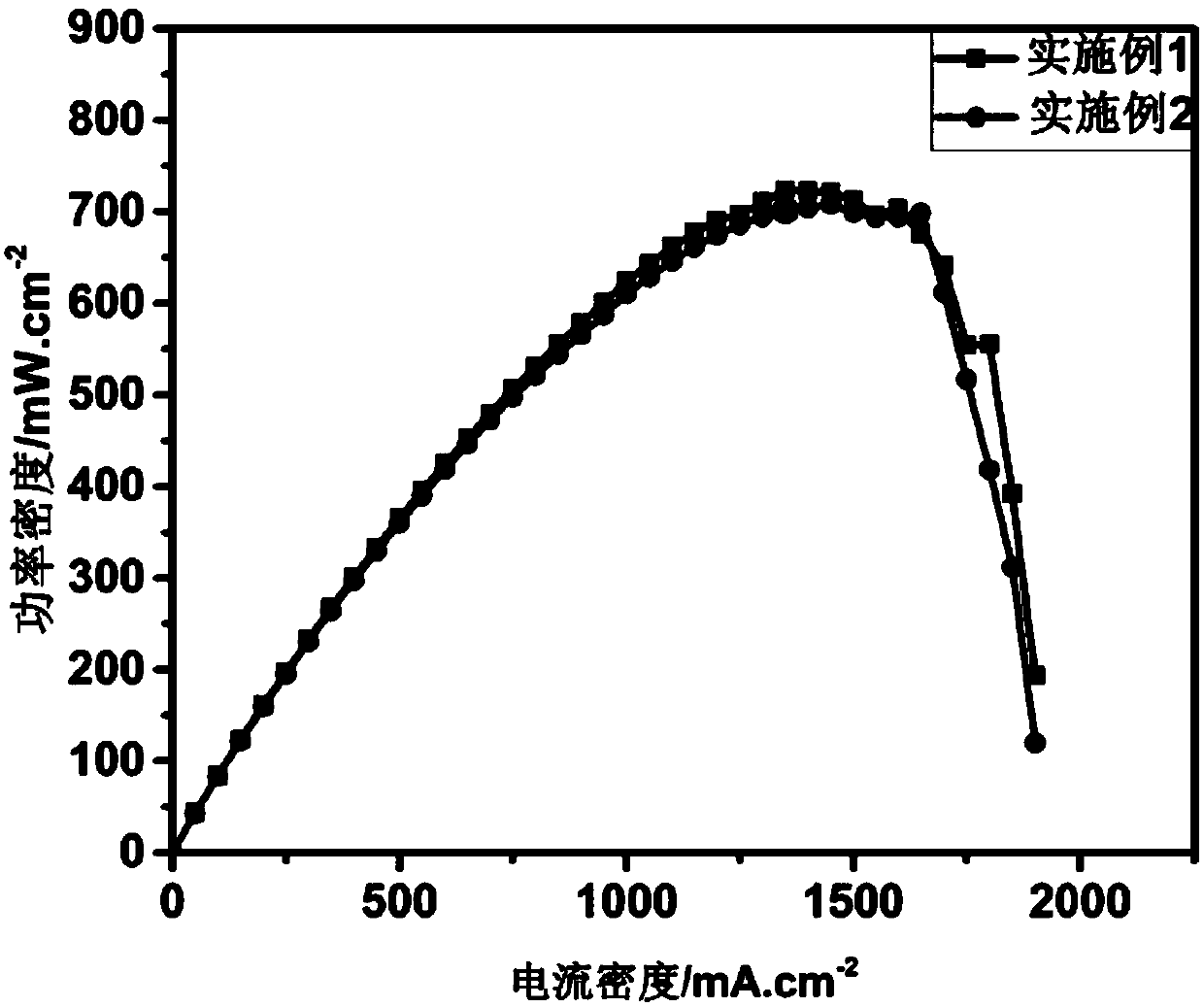

Composite bipolar plate for fuel cell and preparation method and application thereof

ActiveCN109599573AIncrease stressImproved ability to creep at high temperaturesDomestic articlesFuel cellsFiberPolystyrene

The invention relates to the field of the fuel cell, and discloses a preparation method of a carbon / polymer composite bipolar plate. The bipolar plate is composed of polystyrene resin, hydrogenated ethylene-butylene-styrene triblock copolymer, conductive filler and fiber reinforced material. The composite bipolar plate is low in air permeability, good in machining, and excellent in conductivity and corrosion resistance. The composite plate provided by the invention can be applied to a proton exchange membrane fuel cell, alkaline anion-exchange membrane fuel cell and methanol fuel cell.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

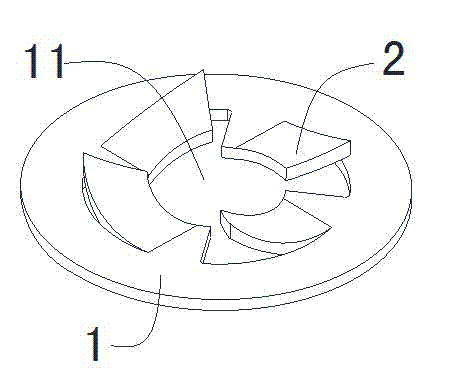

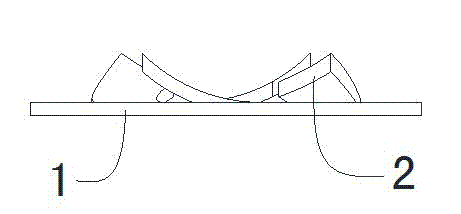

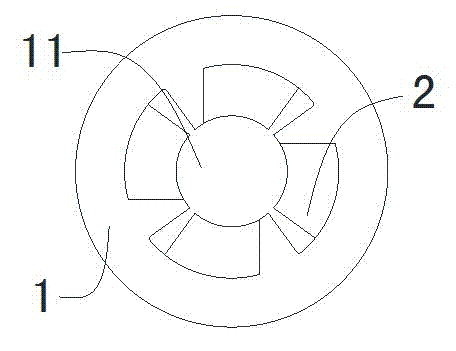

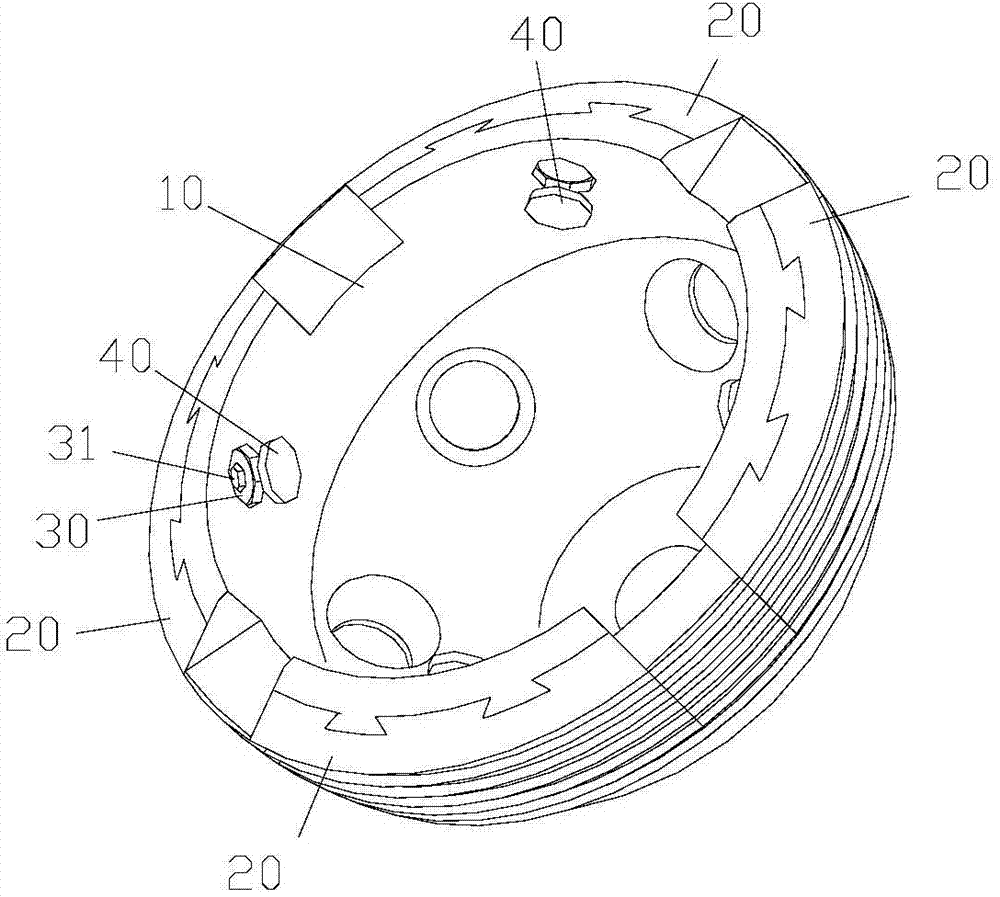

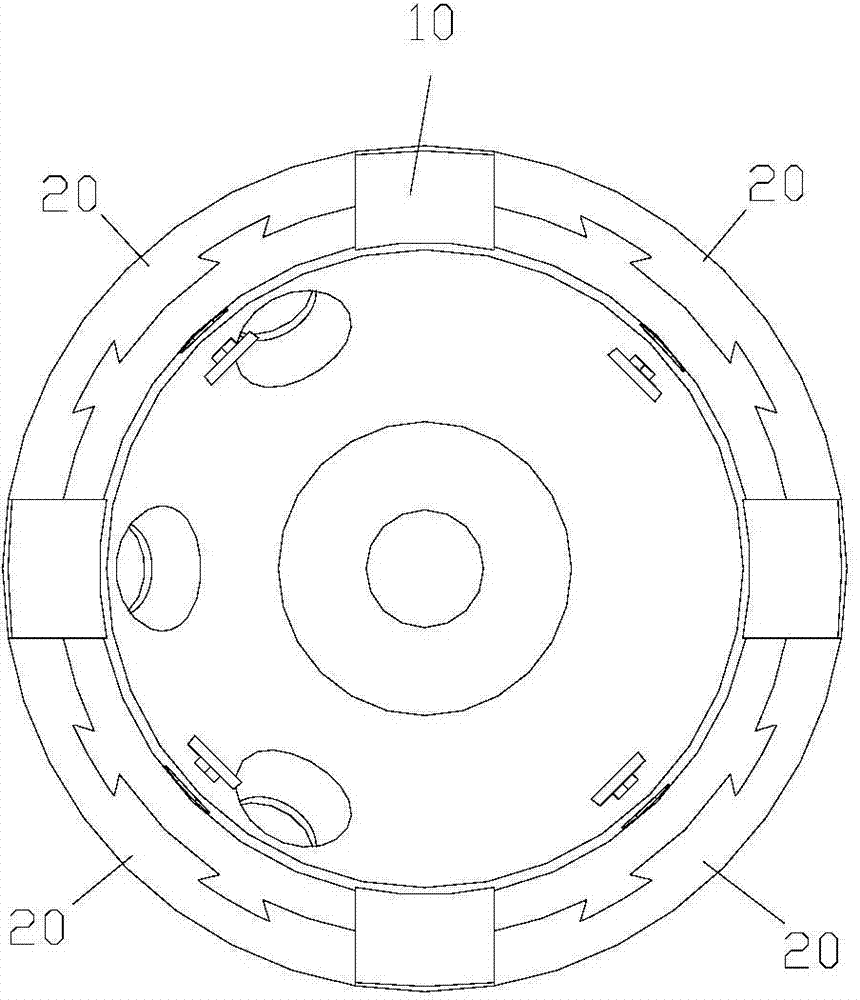

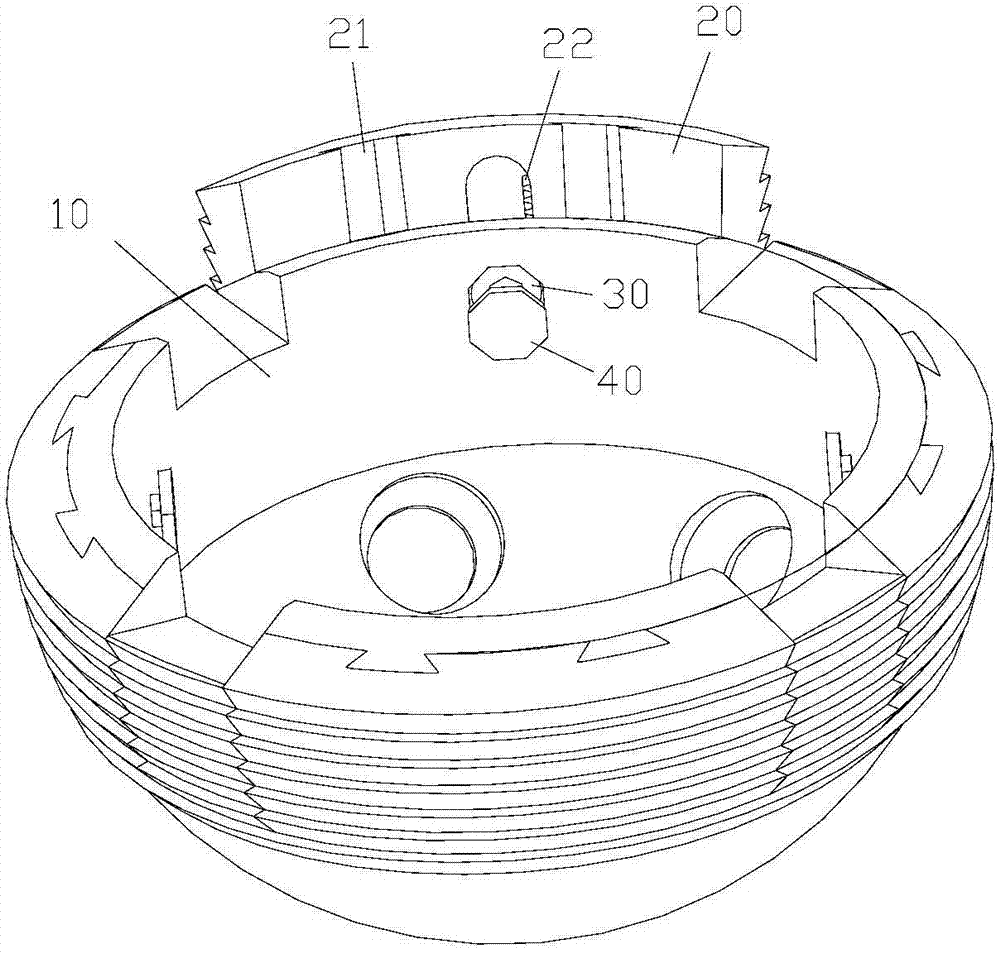

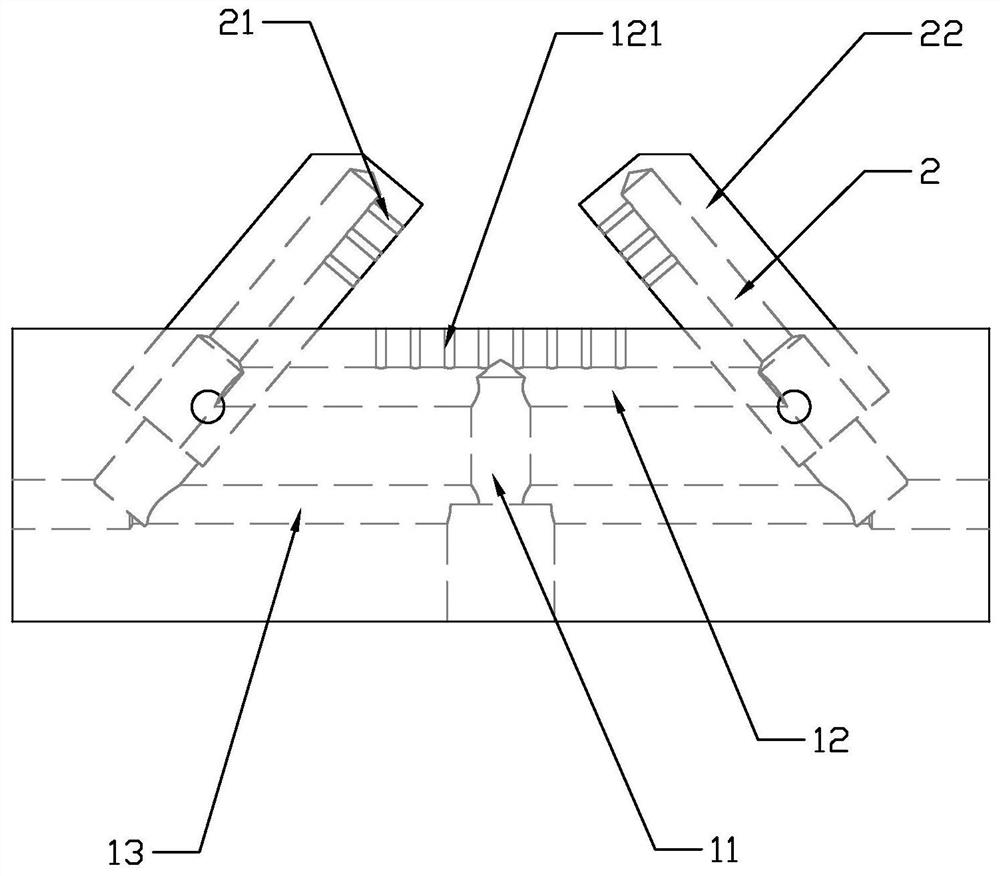

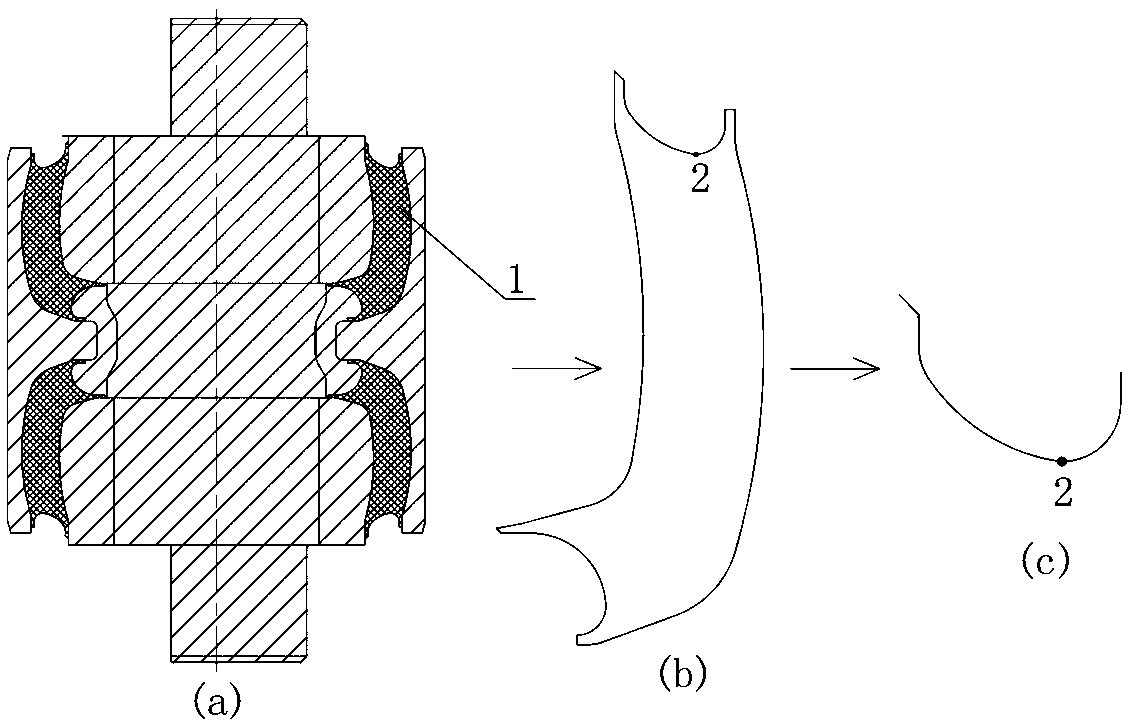

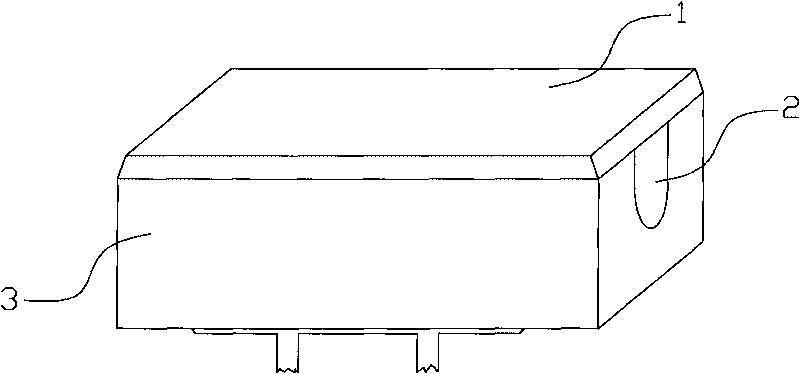

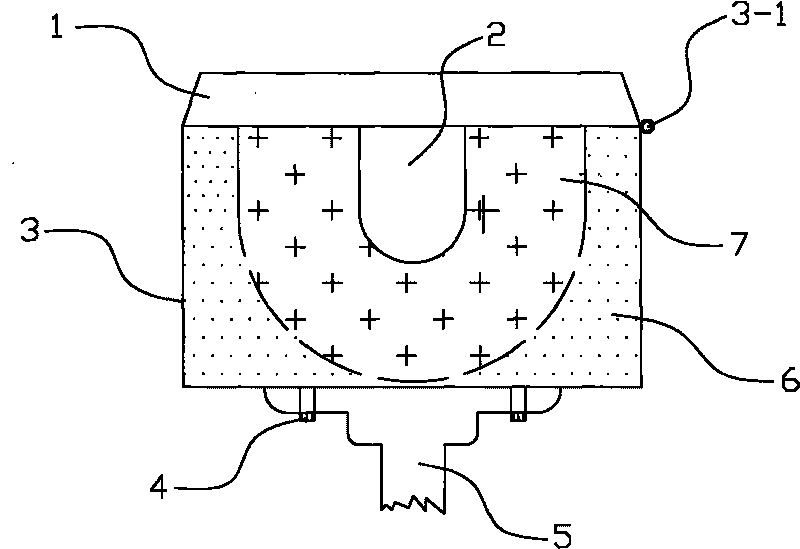

Elastic washer with elastic buffer points

The invention discloses an elastic washer with elastic buffer points. The elastic washer comprises an annular tabular washer body (1), wherein a mounting through hole (11) is formed in the middle of the washer body (1); the washer body (1) is provided with a plurality of elastic sheets (2) which cock towards the same side of the washer body (1); and the elastic sheets (2) are arranged symmetrically to the center of the washer body (1). The elastic sheets form a structure with elastic buffer points, so that the elastic washer with the elastic buffer points acts on a fastener very uniformly when in use, and is not liable to generate stress, age and break down, and the connection structure is very reliable, so that the elastic washer has the advantages of uniform stress, firmness and reliability, simple structure and low cost.

Owner:胡和萍

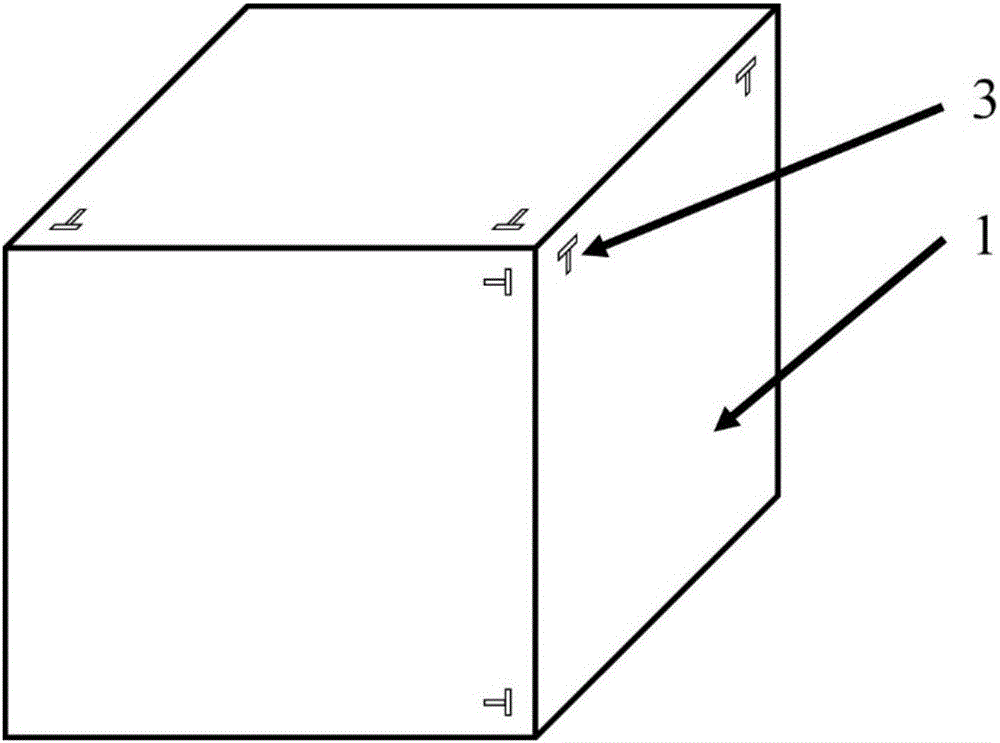

Triaxial fluxgate sensor

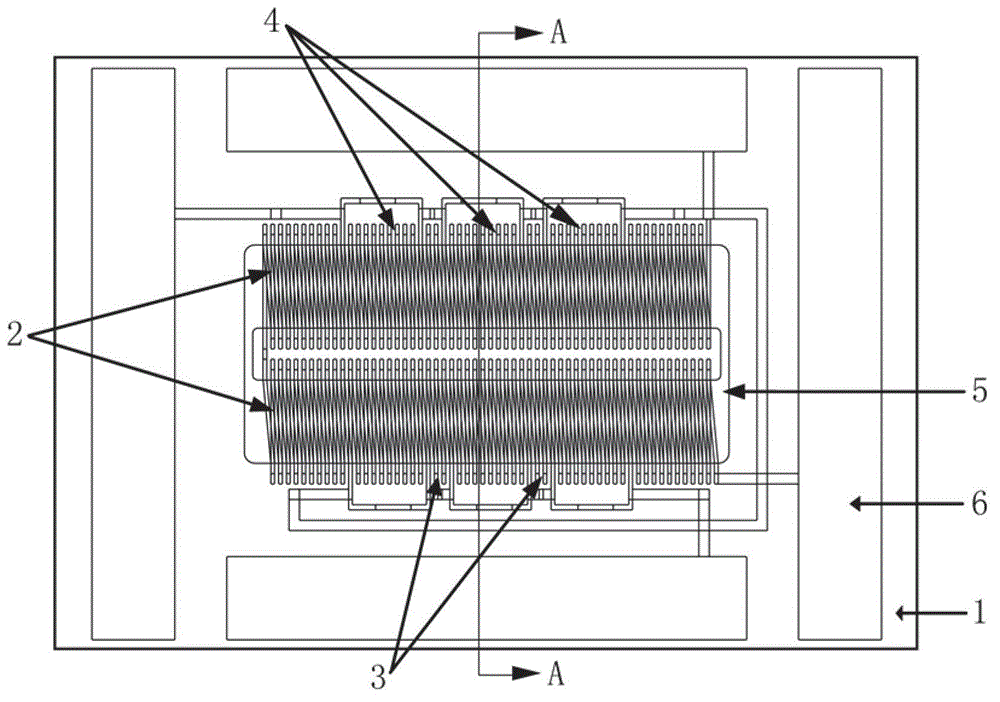

InactiveCN106405453ASmall sizeReduce weightMagnetic field measurement using flux-gate principleLarge sizeDual axis

The invention discloses a triaxial fluxgate sensor, which comprises an x-y biaxial planar fluxgate sensor and a z-axis uniaxial planar fluxgate sensor, wherein an x-y biaxial chip comprises two independent uniaxial planar fluxgate sensor units which are in orthogonal distribution and arranged on a same silicon substrate, and the z-axis uniaxial planar fluxgate sensor comprises a substrate only which is made of large-thickness glass. By utilizing a silicon-glass bonding technology, the side surface of a short axial end of a z-axis uniaxial chip is bonded and fixed on the surface of the silicon substrate of the x-y biaxial chip, so that a magnetic sensitive axis of the z-axis uniaxial chip is perpendicularly orthogonal to x and y axial magnetic sensitive axes of the x-y biaxial chip, thereby realizing x, y and z orthogonality three-component detection of a magnetic field. The triaxial fluxgate sensor solves the problem of large size, heavy weight and high power consumption of an existing triaxial fluxgate sensor, and fully utilizes the advantages of small size, low power consumption, high consistency and small bonding alignment orthogonal error of a uniaxial fluxgate sensor chip of the micro-electro-mechanical system.

Owner:SHANGHAI JIAO TONG UNIV

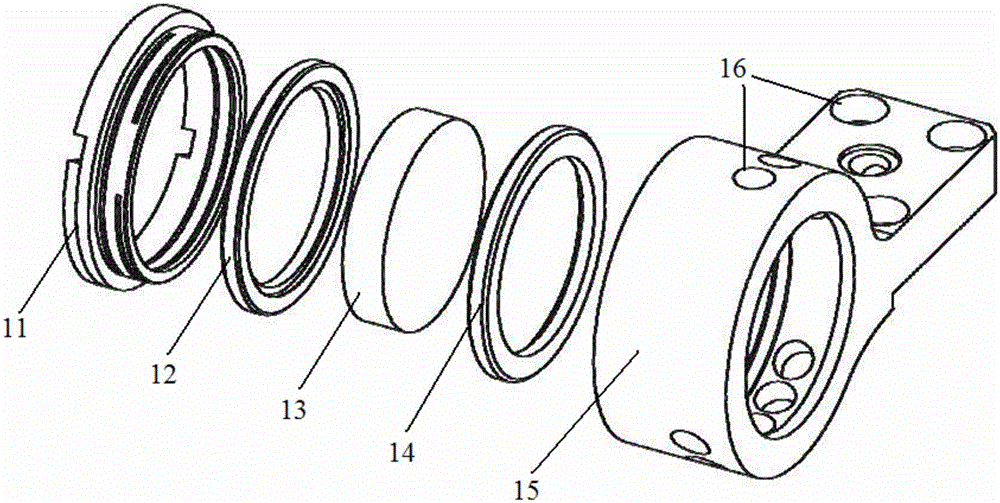

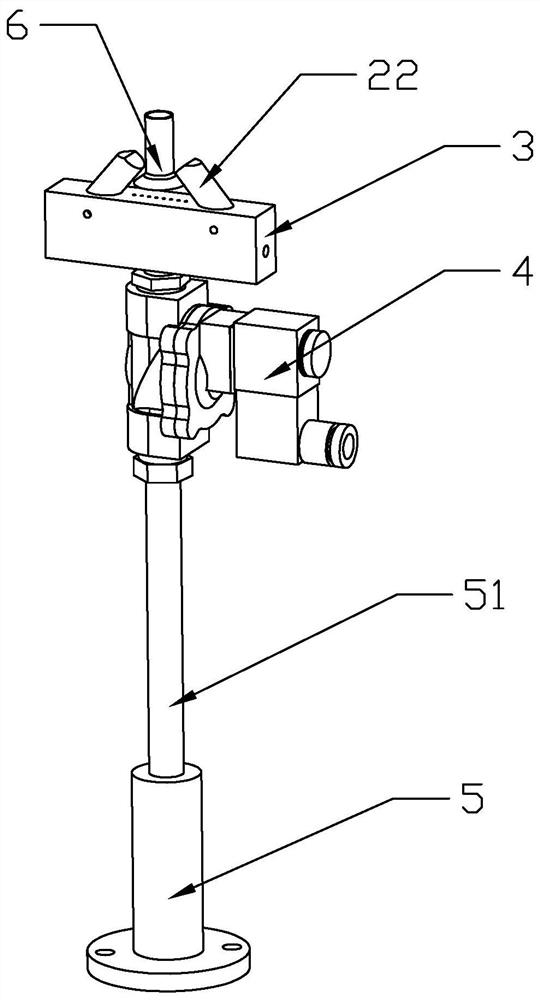

Dynamic axis mirror bracket

ActiveCN106353869AHigh movement precisionImprove stabilityMountingsLaser beam welding apparatusGalvanometerMirror mount

The invention discloses a dynamic axis mirror bracket. The dynamic axis mirror bracket comprises a lens cone main body, a pressing ring, a lens and a gasket, wherein the lens and the gasket are disposed in the lens cone main body and are fixed by virtue of the pressing ring, the lens cone main body is made of an aluminum-based composite material, the aluminum-based composite material is formed by compounding metal aluminum and a reinforcing body, wherein the weight percentage of the aluminum element is 40 to 95 percent, the density is 1.8 to 3.5 g / cm<3>, the elasticity modulus is 80 to 150 GPa, and the heat conductivity is 100 to 200 W / m.k. By compounding aluminum and the material with high strength and good rigidity, the high elasticity modulus, high heat conduction coefficient and low heat expansion coefficient are realized, the bending stress deformation and hot strain are unlikely to occur, and the machining property is good; and the weight can be further reduced on the basis of the original mirror bracket structure, the wall thickness of components can be reduced, a porous structure is machined, a ribbed plate structure is added, the weight of the mirror bracket is reduced, the surface area of the structure is increased, so that the heat dissipation performance is improved, the comprehensive performance is excellent, and a Z galvanometer mirror bracket is high in motion precision and stability.

Owner:苏州菲镭泰克激光技术有限公司

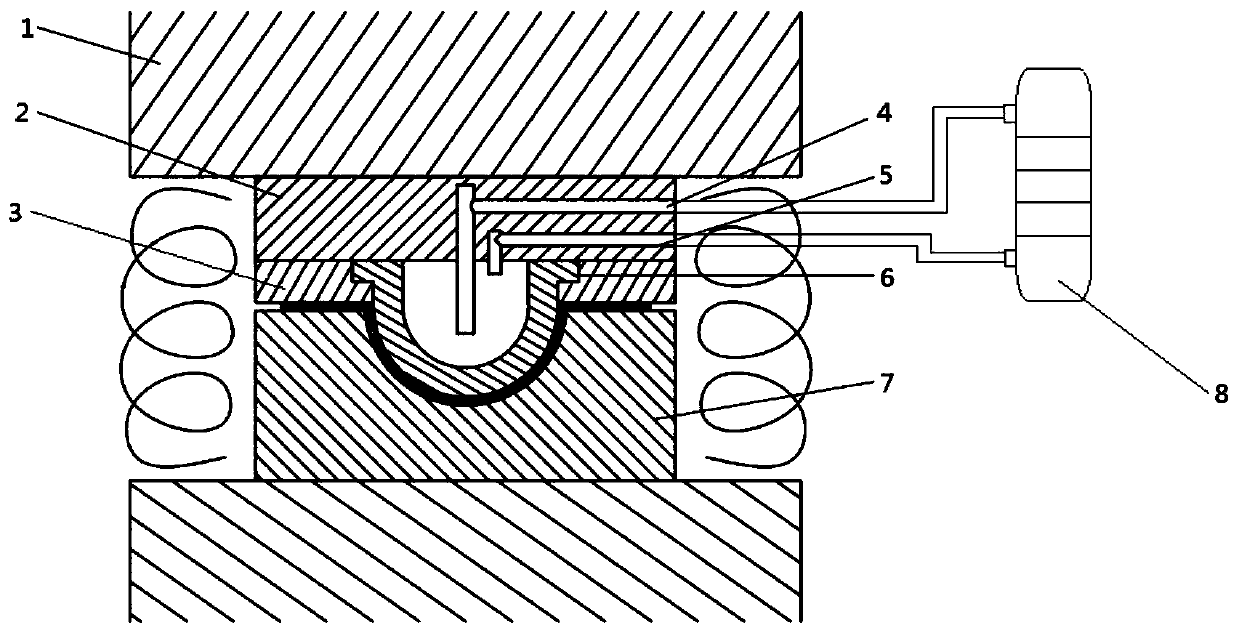

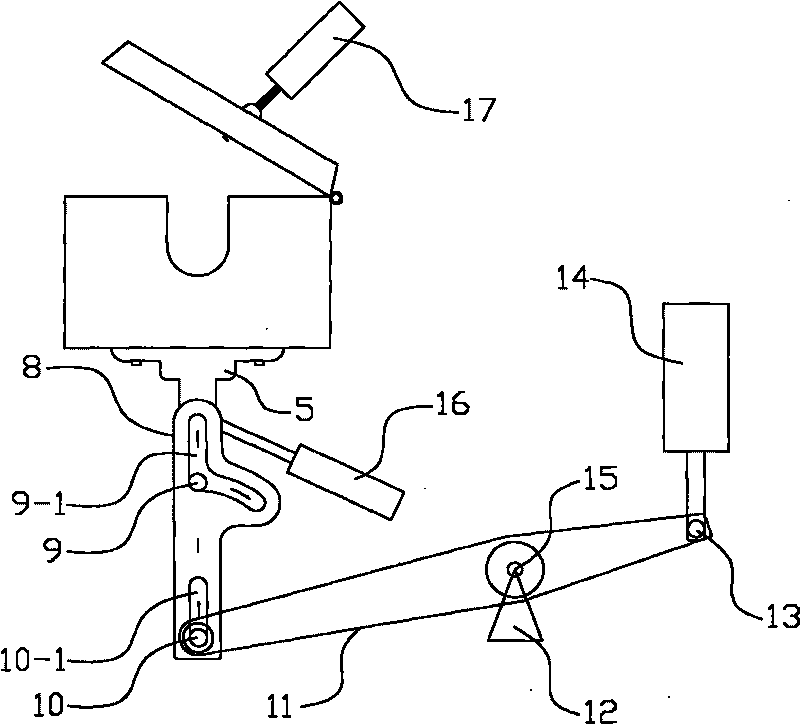

Equal-temperature hot drawing forming device and method for controlling wall thickness uniformity of component

The invention discloses an equal-temperature hot drawing forming device and method for controlling wall thickness uniformity of a component, and relates to the field of equal-temperature hot drawing forming devices and methods by controlling the wall thickness uniformity of the component, which solves the technical problem that in an existing hot drawing technology method, bottom part reduction issevere, and thus blank deformation is nonuniform. The equal-temperature hot drawing forming device includes a hot forming press machine, a die and a gas cooler, wherein the die includes a template, afixing plate, an air inlet pipe, an air outlet pipe, a male die and a female die. The method includes the steps that 1, the die is mounted on the hot forming press machine; 2, heating is conducted, sheet materials are put into, heat insulation is conducted, cooling gas is introduced, drawing forming is conducted, and pressure maintaining is conducted; and 3, the die is opened and is cooled to a room temperature, and inspection and acceptance are conducted. According to the equal-temperature hot drawing forming device and method, circulating helium is introduced into a male die hollow structural cavity through an air passage of an upper male die to lower the temperature of the upper die, the degree of deformation of the contact part of the sheet materials and the upper male die is reduced,the thicknesses of the arc positions of the bottom parts of the sheet materials are increased, and uniform deformation of a formed part is achieved. The equal-temperature hot drawing forming device and method are used for preparing sheet material parts.

Owner:HARBIN INST OF TECH

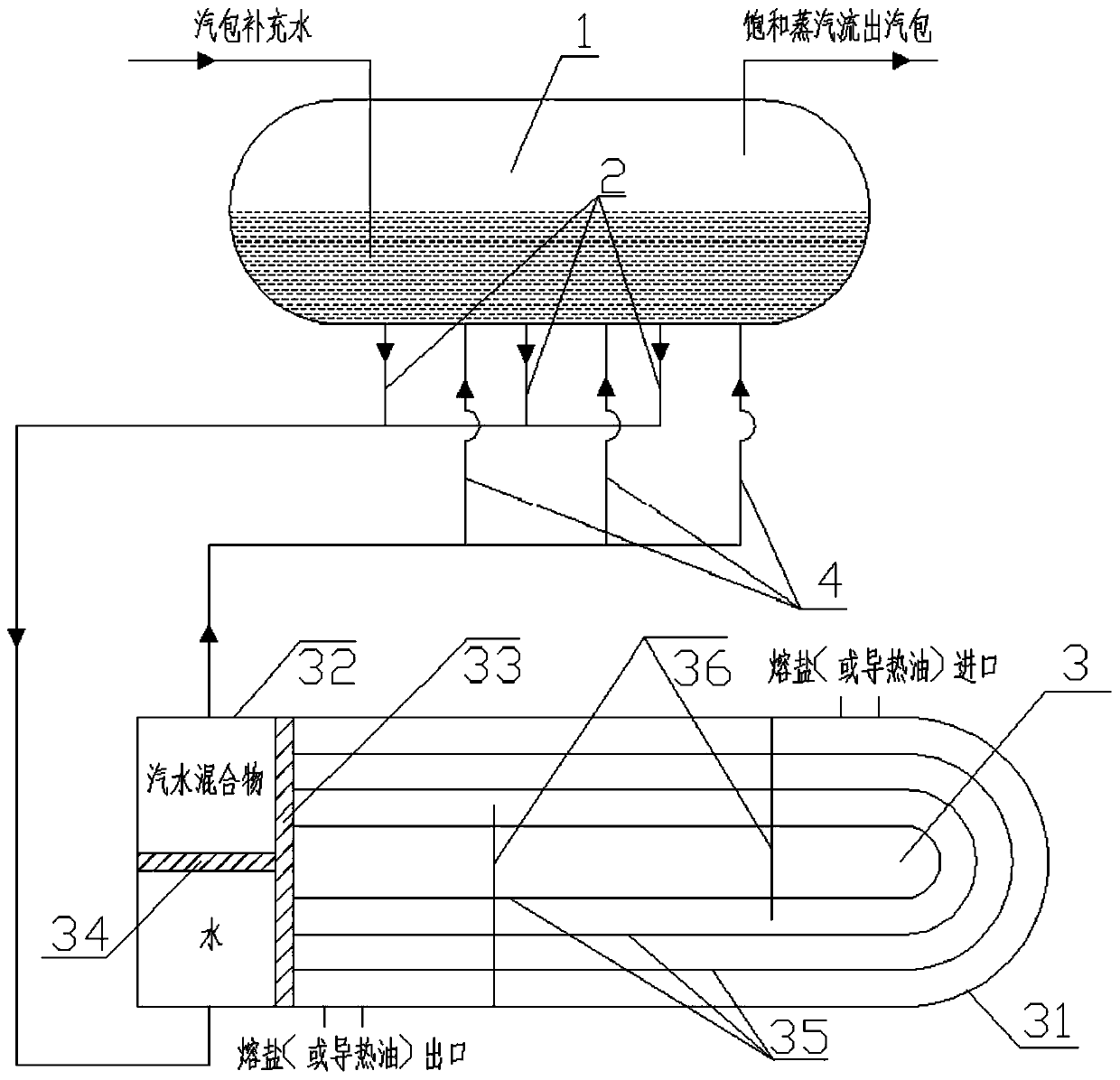

System and method for fused salt or heat transfer oil steam generation adopting in-pipe evaporation and avoiding external force for driving

PendingCN110160027ASave investment costSave running costSteam generation using hot heat carriersMolten saltEvaporation

The invention relates to a system and method for fused salt or heat transfer oil steam generation adopting in-pipe evaporation and avoiding external force for driving. The steam generation system comprises a steam drum, a downcomer, an evaporator and a riser; the evaporator comprises a shell, a sealing head, a tube plate, a partition plate, a U-shaped tube bundle and a baffle plate; the steam drumis arranged above the evaporator, and the steam drum and the evaporator are connected into a whole through the downcomer and the riser; the inner side of the evaporator shell, the tube plate and theouter side of the U-shape tube bundle form a shell side space; the sealing head, the tube plate and the inner side of the U-shaped tube bundle form a tube side space; fused salt or heat transfer oil medium runs in the shell side space, and water / steam and water mixture medium runs in the tube side space; the space in the sealing head is divided into a water chamber and a steam-water mixing chamberby a partition plate, the water chamber is on the lower part and the steam-water mixing chamber is on the upper part; and the plurality of baffle plates are designed outside the U-shaped tube bundleto form a channel with a certain shape to guide fused salt or heat transfer oil to flow through the channel.

Owner:HANGZHOU BOILER GRP CO LTD

Acetabular cup and artificial hip joint

ActiveCN104840278ANot easy to collapseReduce stressJoint implantsAcetabular cupsAnatomical structuresArtificial hip joints

The invention provides an acetabular cup and an artificial hip joint. The acetabular cup comprises a hemispherical body and an extension component or a plurality of extension components. The body comprises an acetabular cup opening, and femoral heads can penetrate the acetabular cup opening; the extension components are connected onto the body in an extensible manner and can be extended towards the outer side of the acetabular cup opening. According to the technical scheme, the acetabular cup and the artificial hip joint have the advantages that extension and retraction of the extension components can be adjusted according to the acetabular fossea of the anatomical structures of different patients, the original peripheral portion of the body is in contact with the cancellous bones of the patients, and accordingly excellent bone ingrowth effects can be realized; the extension components which are extended out of the edge of the outer wall of the acetabular cup opening are in contact with the cortical bones at the outer edges of the acetabular fossea of the patients, accordingly, force can be effectively transferred to the cortical bones of the patients, stress generated between the acetabular cup and the cancellous bones can be reduced, the cancellous bones are difficult to collapse, the acetabular cup can be firmly fixed into the acetabular fossea and is excellent in stability, the problems of collapse of the cancellous bones and fixing failures of existing acetabular cups due to excessively high stress can be solved, and the service life of the artificial hip joint can be prolonged.

Owner:BEIJING AKEC MEDICAL

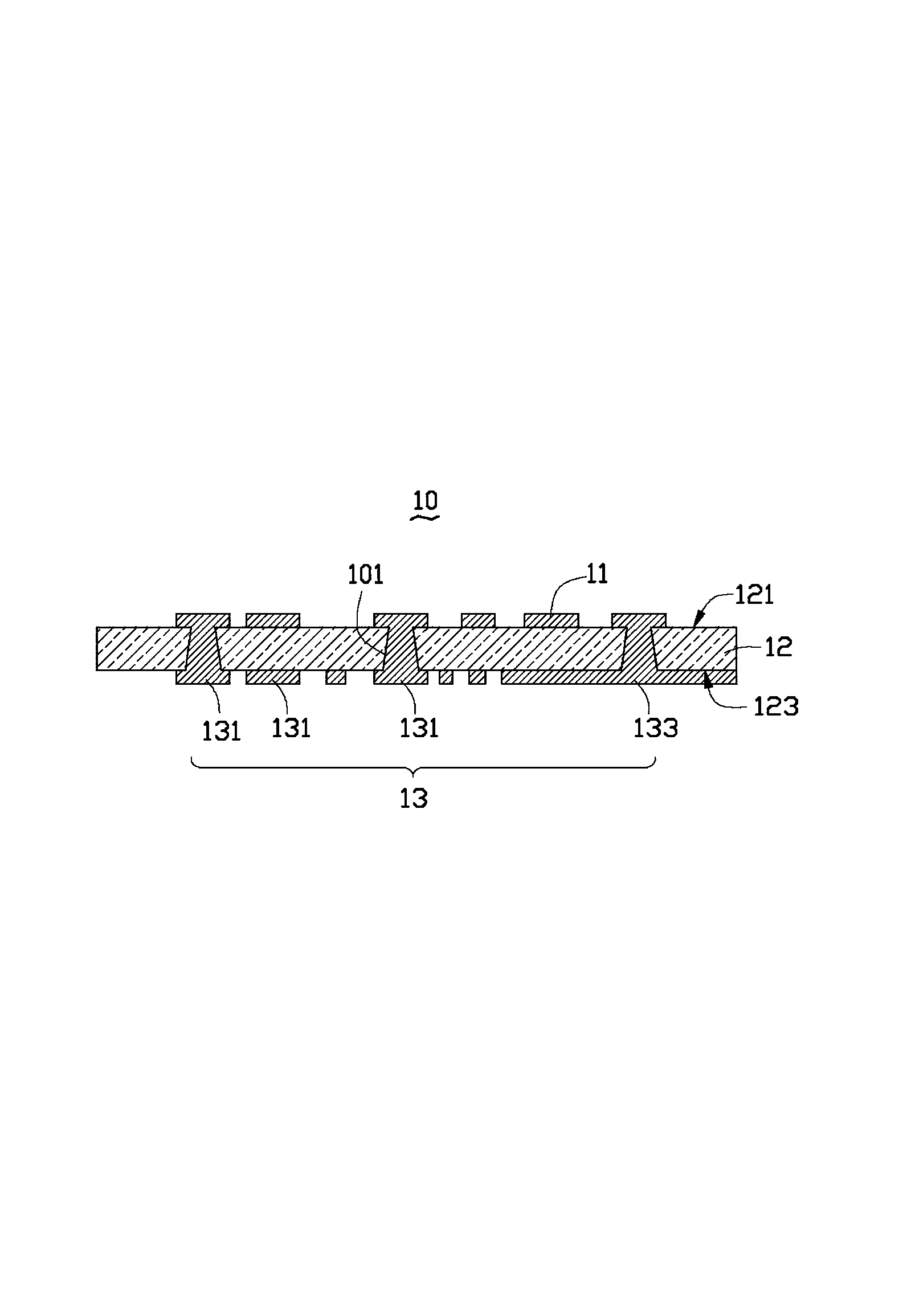

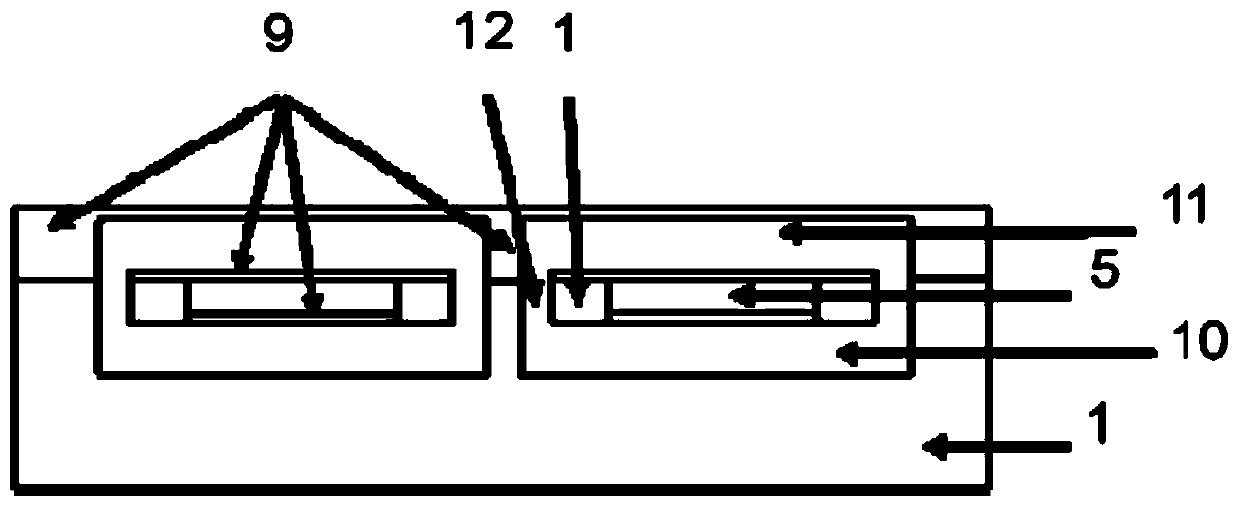

Fluxgate sensor chip

ActiveCN106569153AImprove manufacturing yieldSolve the problems of poor process compatibility and serious process pollutionMagnetic measurementsCMOSSilicon oxide

The invention discloses a fluxgate sensor chip, and relates to the field of MEMS integration micro manufacturing. The fluxgate sensor chip comprises a high-sensitivity silicon substrate, an excitation coil, a detection coil, a magnetic core, electrodes and silicon oxide films, wherein both the excitation coil and the detection coil are micro electro-mechanical three-dimensional solenoid coils, bottom coils of the excitation coil and the detection coil are located in a silicon microgroove array at the surface of the high-sensitivity silicon substrate, the upper surfaces of the bottom coils are flush with the surface of the silicon substrate, and the bottom coils are insulated from the silicon substrate and the magnetic core through the silicon dioxide films; and the bottom coils, the magnetic core and top coils are insulated from each other through the silicon dioxide films. The fluxgate sensor chip adopts the silicon dioxide films to perform insulation coating, so that the mechanical strength of the integrated fluxgate sensor chip is improved. In addition, the fluxgate sensor chip is completely compatible with a microelectronic process, and compatible and synchronous integrated manufacturing of the integrated fluxgate sensor chip and a CMOS interface circuit can be realized.

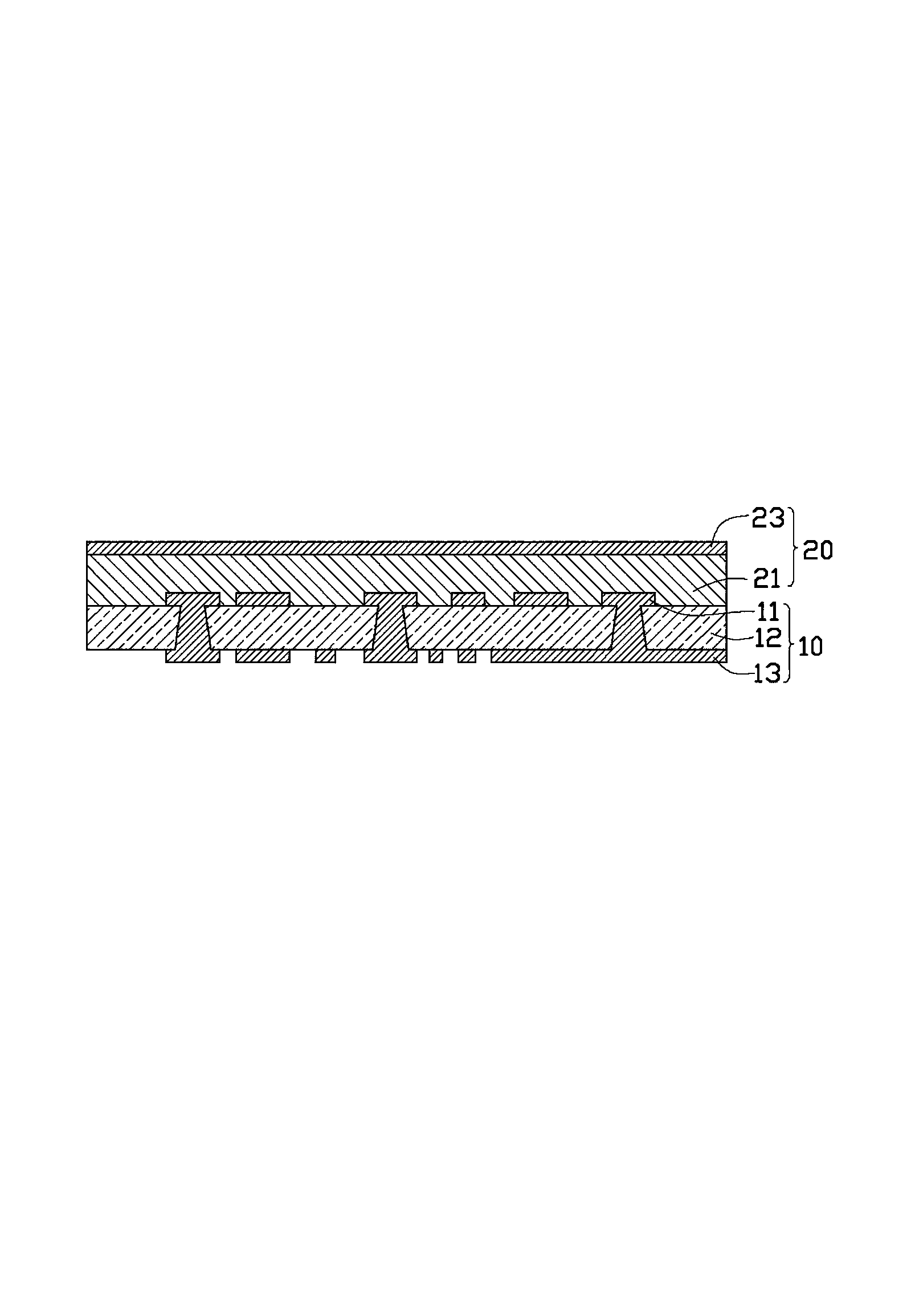

Micro fluxgate sensor

ActiveCN106772143AExtended operating temperature rangeImprove manufacturing yieldMagnetic measurementsChemical vapor depositionExcitation coil

The invention discloses a silicon carbide based integrated micro fluxgate sensor, which comprises a silicon carbide substrate, an excitation coil, a detection coil, a magnetic core, electrodes and silicon carbide films, and is characterized in that the rectangular magnetic core is located in a rectangular groove at the surface of the silicon carbide substrate, and the upper surface of the magnetic core is flush with the surface of the silicon carbide substrate; both the excitation coil and the detection coil are a micro electromechanical three-dimensional solenoid coil, bottom coils of the excitation coil and the detection coil are located in a microgroove array at the bottom of the rectangular groove, electrified wires of the bottom coils are insulated by the silicon carbide substrate at clearances of the microgroove array, and the bottom coils are insulated from the magnetic core through chemical vapor deposition silicon carbide films; top coils of the excitation coil and the detection coil are insulated from the magnetic core through the chemical vapor deposition silicon carbide films, and clearances of electrified wires of the top coils are filled and insulated by the chemical vapor deposition silicon carbide films; the surface of the sensor is covered by the chemical vapor deposition silicon carbide films and is isolated and protected from the air, and the electrodes are exposed via through holes.

Owner:SHANGHAI JIAO TONG UNIV

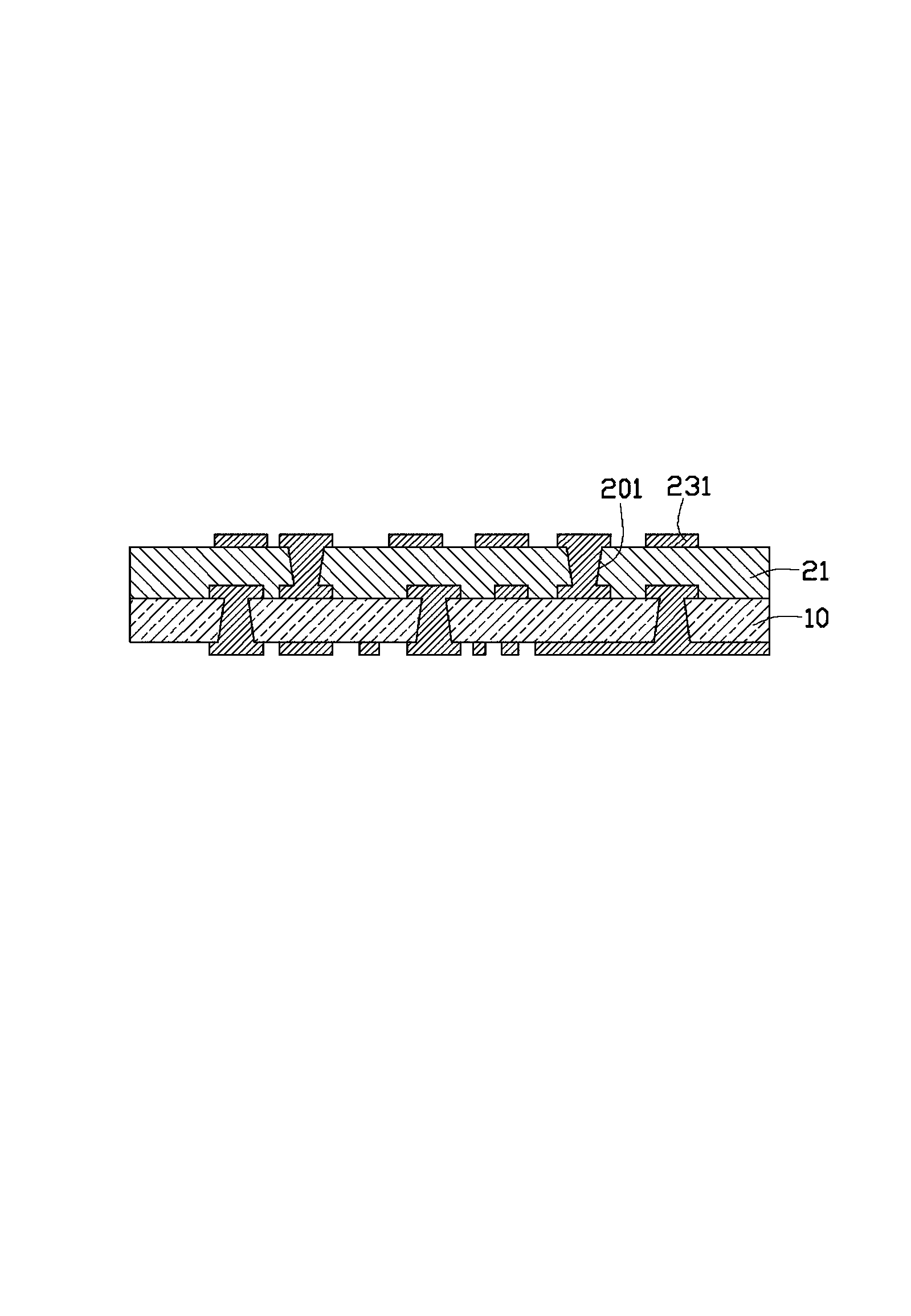

Multi-layer circuit board and manufacturing method thereof

ActiveCN103458629AExtended service lifeThe preparation method is simple and easyPrinted circuit detailsMultilayer circuit manufactureEngineeringConductive materials

The invention provides a manufacturing method of a multi-layer circuit board. The method includes providing a glass circuit substrate plate comprising a first conductive circuit pattern, a glass substrate, and a second conductive circuit pattern which is provided with a plurality of first bonding pads; pressing a first pressed substrate plate, comprising a first substrate layer and a first conductive material layer, on the glass circuit substrate plate, and allowing the first substrate layer to locate between the first conductive circuit pattern and a first conductive material layer; manufacturing the first conductive material layer into a third conductive circuit pattern, and electrically connecting the third conductive circuit pattern and the first conductive circuit pattern; forming a first bonding-proof layer, provided with a plurality of first openings corresponding to first bonding pad, on the surface of the glass circuit substrate plate to expose a plurality of the first bonding pads so as to form a multi-layer circuit board. The first conductive circuit pattern and the second conductive circuit pattern are connected electrically. The invention further provides a multi-layer circuit board manufactured by the method.

Owner:QI DING TECHNOLOGY QINHUANGDAO CO LTD +1

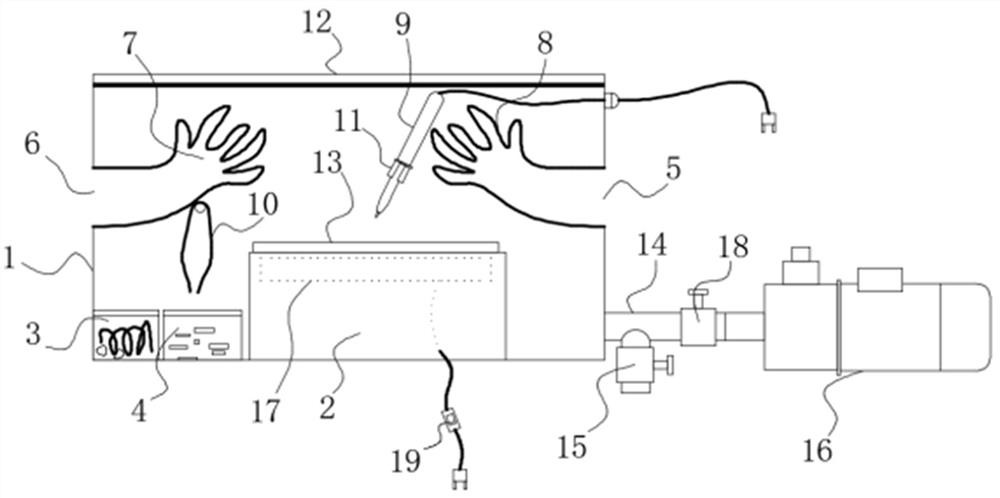

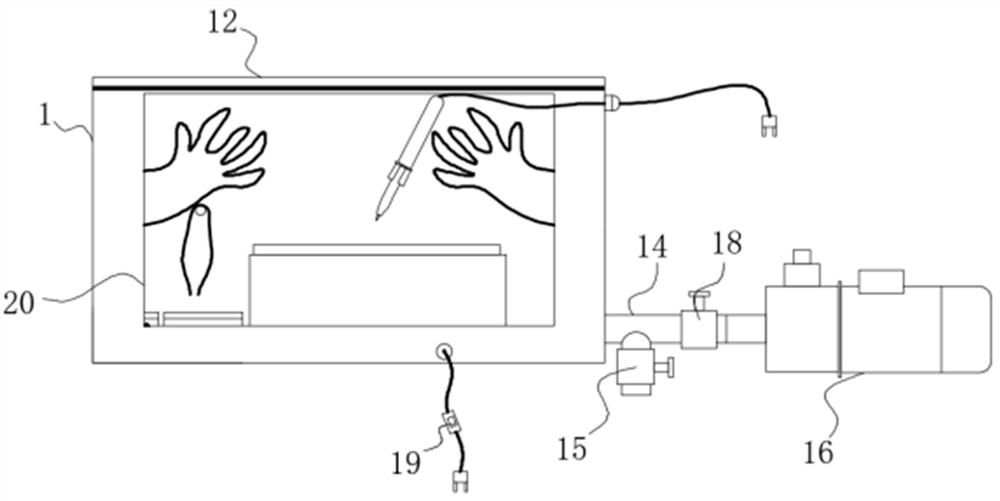

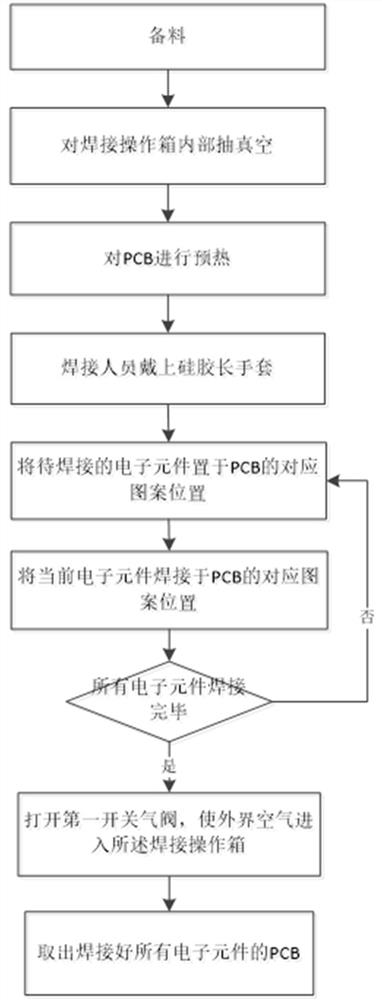

Welding device and method for electronic component

PendingCN113732427AStable structureFully and correctly connectedPrinted circuit assemblingMetal working apparatusProcess engineeringWeld seam

The invention discloses a welding device and method for an electronic component, and relates to the technical field of electronic component welding. The adopted welding method adopts the designed unique electronic component welding device, the welding time is shortened, the reliable structure of a welding spot part can be ensured, and the electronic component and the corresponding pattern of the PCB can be fully and correctly connected. In the welding process of the electronic component, a vacuum environment is created, oxygen does not exist in a welding seam, the stress tendency is not prone to occurring, and welding flux is not prone to generating cracks. In the preheating process, the whole PCB is preheated at a time, due to the fact that the PCB is in the vacuum environment, the PCB can keep the preheating temperature for a long time, and the preheating time is greatly shortened.

Owner:广东愈焜健康科技有限公司

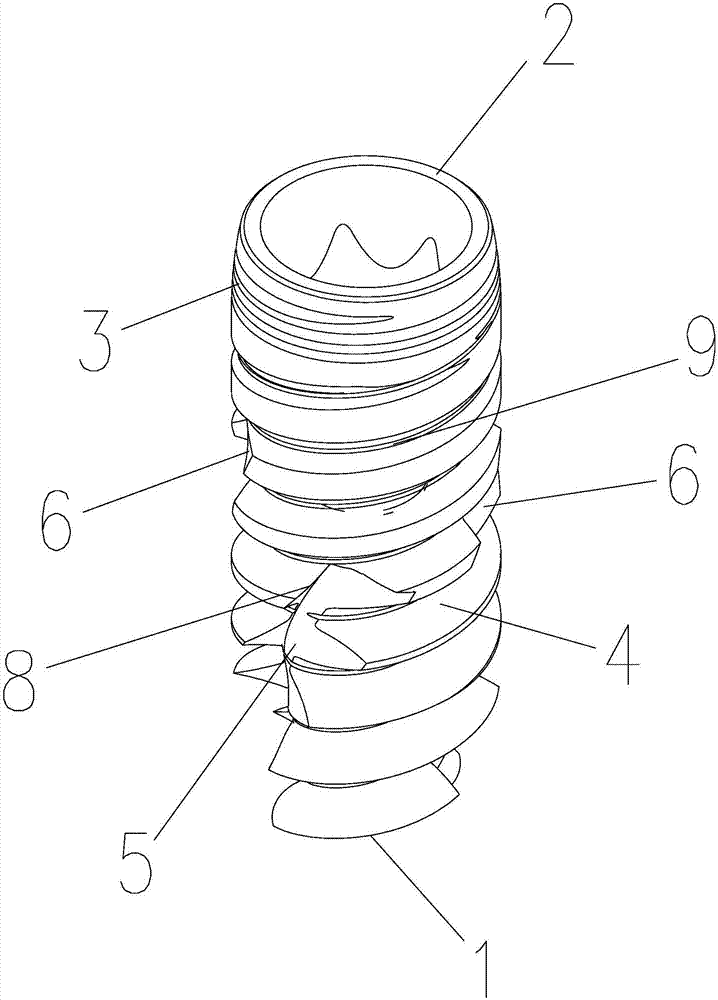

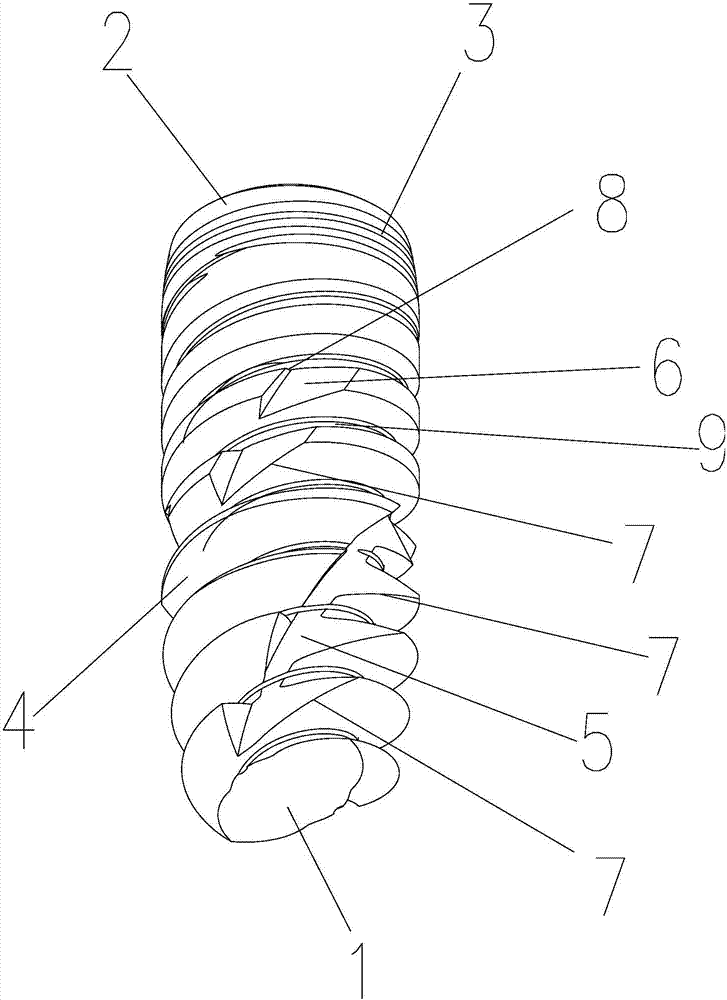

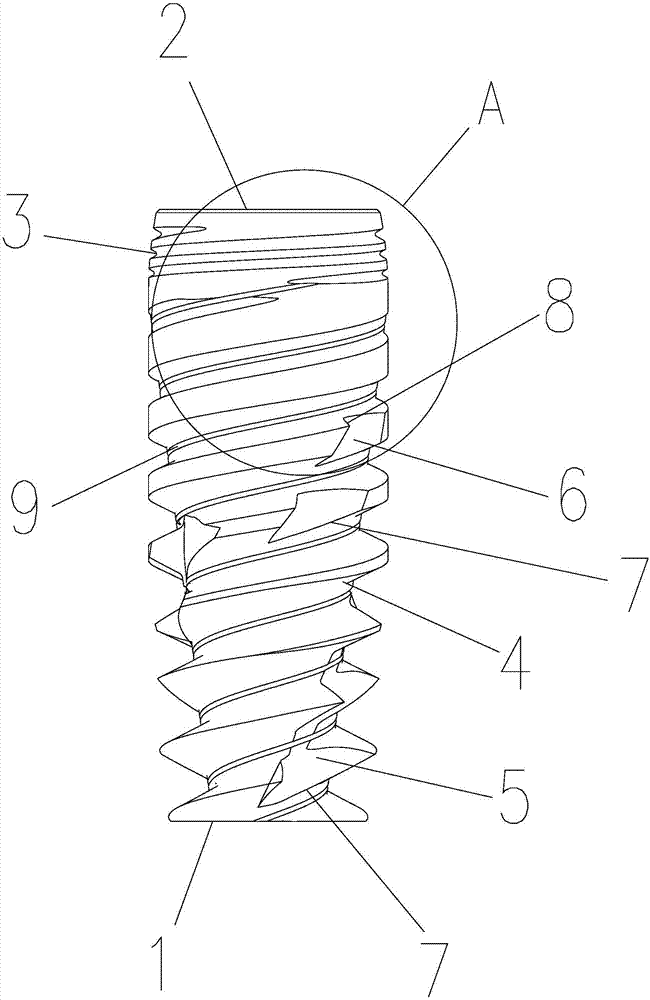

Self-tapping dental implant

PendingCN107874852AEasy transitionEasy to processDental implantsStress concentrationOsseointegration

The invention belongs to the technical field of dental implants and in particular relates to a self-tapping dental implant. The self-tapping dental implant comprises a body, wherein a screw-in end anda crown end used for connecting with the dental implant are respectively arranged at two ends of the body; and a double-headed screw thread starting from the body and ending at an mouth edge of the crown end is arranged on an outer side face of the crown end. The self-tapping dental implant disclosed by the invention has the beneficial effects that friction force formed by screwing the double-headed screw thread and a ridge crest is weak, and the dental implant is conveniently self-tapped; destruction of bones on the ridge crest is the minimal in the implanting process, the stress is low, thedistribution is uniform, and local stress concentration is avoided; an area attachment area is enlarged, the bone bonding strength of the implant is easily improved, and the later stress level is low; under external load and constraint conditions, stress and strain stressed by cortical bones are decreased, local stress concentration is difficult to cause, and the teeth are very strong; and when being screwed into the ridge crest, the self-tapping dental implant is low in resistance, excellent in self-tapping property, capable of containing alveolar bones at a high quantity and high in stability.

Owner:JIANGSU TRAUSIM MEDICAL INSTR

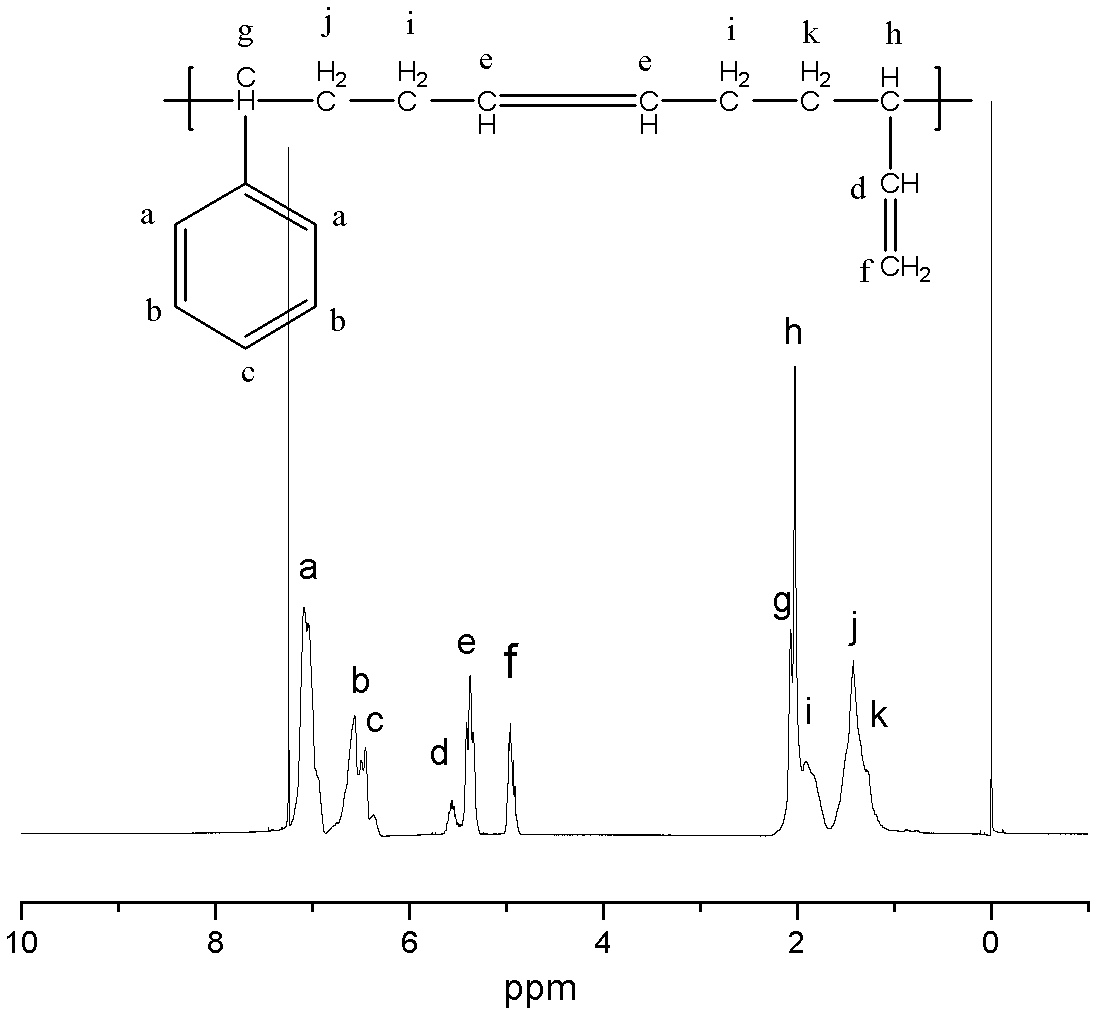

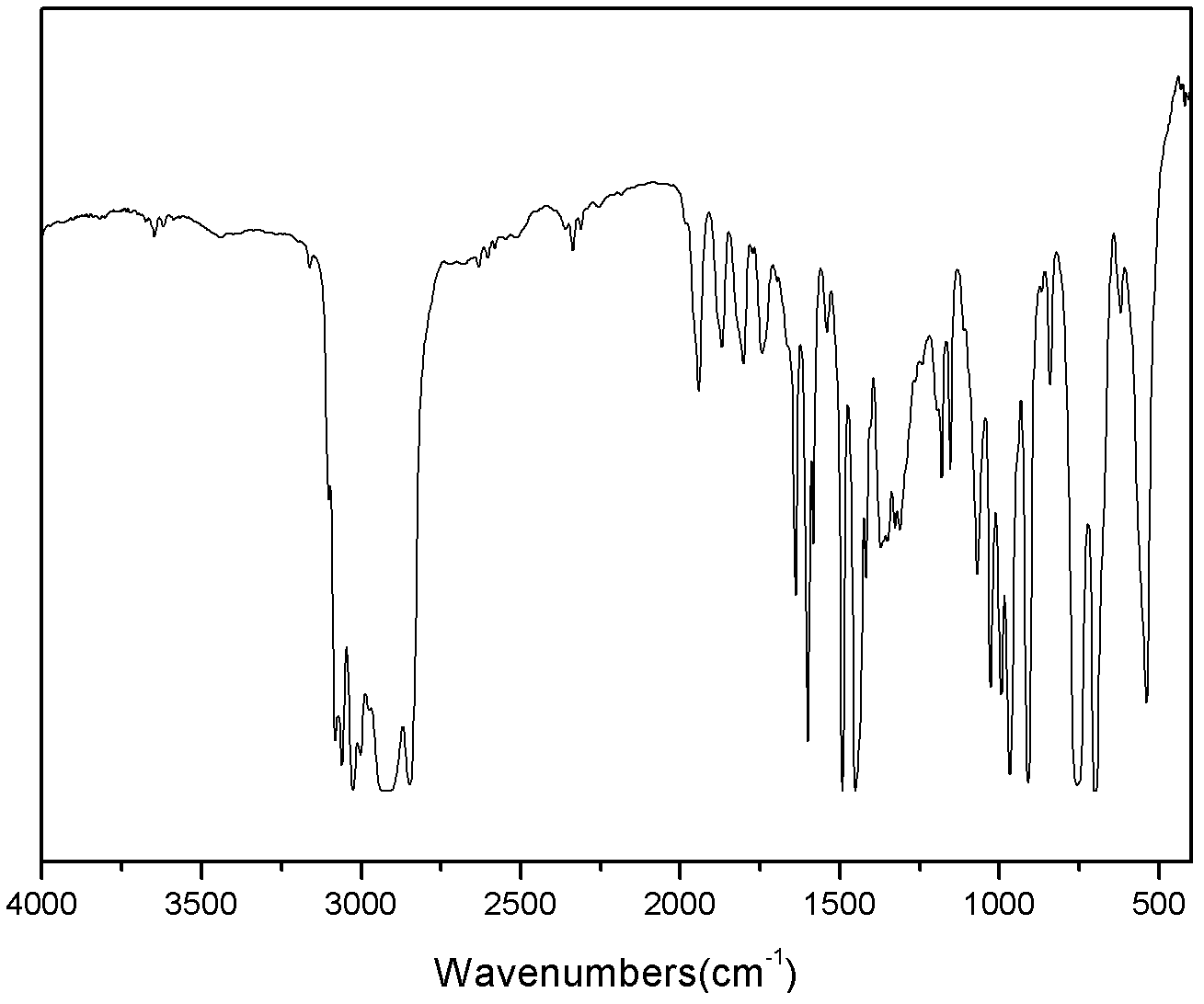

Synthesis method of transparent block copolymer

The invention discloses a synthesis method of transparent block copolymer, which comprises the following steps of: mixing diluent and polar compounds of 60 to 90 percent of the total weight of diluent, initiator of 40-70 percent and monovinylarene aryl hydrocarbon of 20-30 percent of total monomer under conditions with no water or oxygen but with high-purity argon, and vigorously stirring for 40-80min at 50-80 DEG C; adding monovinylarene aryl hydrocarbon of 13-22 percent of total monomer, and stirring 40-80min; adding conjugated diene of 4-7 percent of total monomer, and stirring for 40-80min; adding initiator of 30-60 percent and monovinylarene of 18-25 percent of total monomer, and stirring for 40-80min; adding conjugated diene of 18-20 percent of total monomer into a polymerization reactor, and making mixture react for 40-80min; adding monovinylarene aryl hydrocarbon into the polymerization reactor, making mixture reactor for 40-80 min, and adding CO2; and adding methanol or ethanol to prepare polymerization products, and naturally drying the polymerization products. The invention has the advantages of no coupling, simple steps and high transmittance.

Owner:宁波长鸿高分子科技股份有限公司

Filament wick column horn cooling device

InactiveCN111825320AAccurate control parametersImprove product qualityGlass tempering apparatusThermodynamicsEngineering

The invention discloses a filament wick column horn cooling device, which comprises a middle air pipe and a side air pipe. The middle air pipe is provided with a middle air outlet aligned with the inner side of a wick column horn, the side air pipe is provided with a side air outlet aligned with the outer side of the wick column horn, and the middle air pipe and the side air pipe are communicatedwith an air supply system. The invention has the following beneficial effects that: (1) high-pressure air supply is simultaneously carried out on the inner and outer sides of the wick column horn mouth, tempered crystals are rapidly cooled, the hardness and strength of the horn mouth are ensured, the product is not easy to break and the rejection rate is low; (2) a plurality of air outlets are formed to uniformly supply air to the horn mouth, so that stress is not easily generated, and the horn mouth has good toughness; (3) an electromagnetic valve accurately controls air outlet related parameters, and stable quality is guaranteed; and (4) the structure is simple, the cooling efficiency is high and the cost is low.

Owner:ZHEJIANG KAIYAO LIGHTING

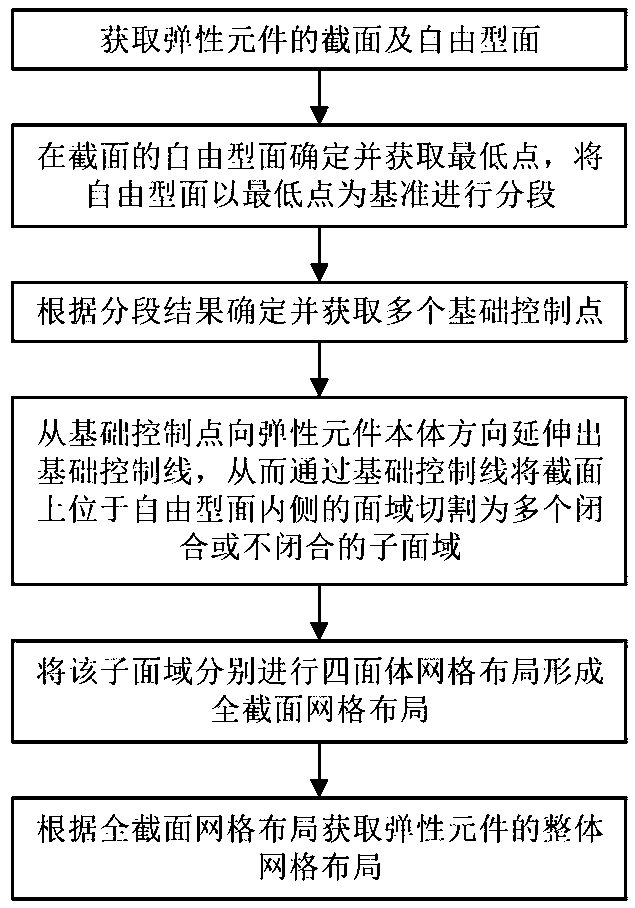

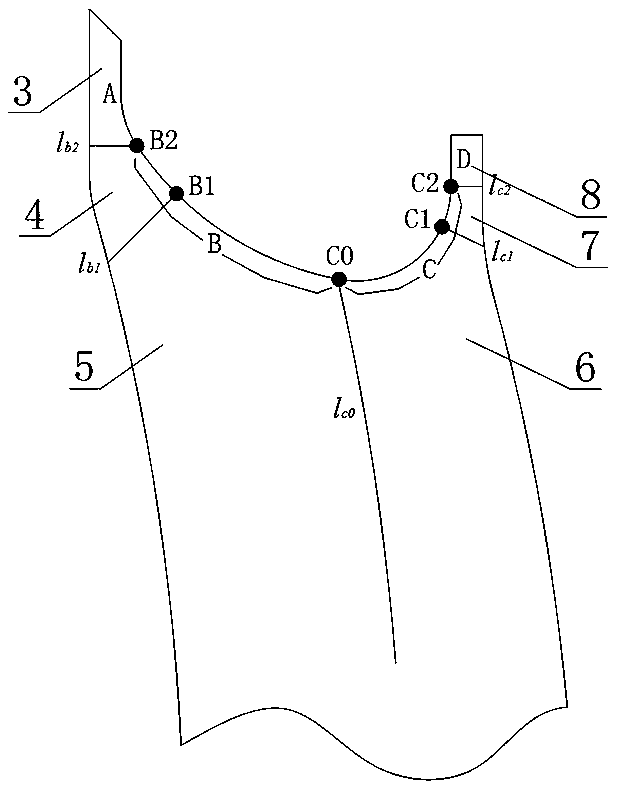

Free-form surface grid layout and finite element analysis method and system for elastic element and medium

ActiveCN111159954AGreat deformabilityQuick layoutGeometric CADDesign optimisation/simulationElement analysisLayout

The invention discloses a free-form surface grid layout and finite element analysis method and system for an elastic element and a medium. The method comprises the steps of obtaining a section and a free-form surface of the elastic element; determining the lowest point on the free profile and performing segmenting by taking the lowest point as a reference; determining and obtaining a plurality ofbasic control points according to the segmentation result; enabling a basic control line to extend from the basic control point to the direction of the elastic element body, and cutting a surface domain, located on the inner side of the free profile, on the cross section into a plurality of closed or unclosed sub-surface domains through the basic control line; respectively carrying out tetrahedralmesh layout on the sub-surface domains to form a full-section mesh layout; and obtaining the overall grid layout of the elastic element according to the full-section grid layout. According to the method, grid layout can be rapidly and effectively carried out on the total cross section of the positioning node with the detail structure, the formed grid has better super-large deformation capacity and good grid distortion resistance, and analysis and calculation can be rapidly, effectively, accurately and smoothly completed.

Owner:ZHUZHOU TIMES NEW MATERIALS TECH

Low-noise micro plane fluxgate sensor based on main and auxiliary coil double incentive

InactiveCN102981131BReduce noiseReduce energy consumptionMagnetic field measurement using flux-gate principleLow noiseAcoustics

The invention discloses a low-noise micro plane fluxgate sensor based on main and auxiliary coil double incentive. The low-noise micro plane fluxgate sensor based on the main and auxiliary coil double incentive comprises a substrate, main incentive coils, auxiliary incentive coils, detecting coils, a magnetic core, electrodes and a polyimide film. Two ends of each of two long shafts of the magnetic core are symmetrically provided with two groups of the main incentive coils in a wound mode, wherein the two long shafts are arranged in parallel. The middle portions of the long shafts are symmetrically provided with three groups of the detecting coils and two groups of the auxiliary incentive coils in a wound mode. In the same long shaft, one group of the auxiliary incentive coils are arranged between each two groups of the detecting coils. The main incentive coils, the auxiliary incentive coils and the detecting coils are all arranged on the surface of the substrate. Two ends of each main incentive coil are connected with the electrodes. The low-noise micro plane fluxgate sensor based on the main and auxiliary coil double incentive solves the problems that a traditional fluxgate sensor is poor in manufacturing stability and repeatability, utilizes the main and auxiliary coil double incentive to improves the incentive efficiency of the micro fluxgate sensor, effectively lowers output signal noise and energy consumption, is capable of being manufactured together with an interface circuit in an integrated mode, and can be widely used in many novel fields.

Owner:SHANGHAI JIAOTONG UNIV

A Miniature Fluxgate Sensor

ActiveCN106772143BExtended operating temperature rangeImprove manufacturing yieldMagnetic measurementsChemical vapor depositionExcitation coil

The invention discloses a silicon carbide based integrated micro fluxgate sensor, which comprises a silicon carbide substrate, an excitation coil, a detection coil, a magnetic core, electrodes and silicon carbide films, and is characterized in that the rectangular magnetic core is located in a rectangular groove at the surface of the silicon carbide substrate, and the upper surface of the magnetic core is flush with the surface of the silicon carbide substrate; both the excitation coil and the detection coil are a micro electromechanical three-dimensional solenoid coil, bottom coils of the excitation coil and the detection coil are located in a microgroove array at the bottom of the rectangular groove, electrified wires of the bottom coils are insulated by the silicon carbide substrate at clearances of the microgroove array, and the bottom coils are insulated from the magnetic core through chemical vapor deposition silicon carbide films; top coils of the excitation coil and the detection coil are insulated from the magnetic core through the chemical vapor deposition silicon carbide films, and clearances of electrified wires of the top coils are filled and insulated by the chemical vapor deposition silicon carbide films; the surface of the sensor is covered by the chemical vapor deposition silicon carbide films and is isolated and protected from the air, and the electrodes are exposed via through holes.

Owner:SHANGHAI JIAOTONG UNIV

Manufacturing method of micro fluxgate sensor with amorphous magnetic core

InactiveCN101885467AEase of mass productionGood repeatabilityDecorative surface effectsMagnetic field measurement using flux-gate principleCooking & bakingElectrical conductor

The invention discloses a manufacturing method of a micro fluxgate sensor with an amorphous magnetic core, belonging to the technical field of micro electronmechanical systems. The manufacturing method comprises the following steps of: sputtering a Cr / Cu bottom layer on one surface of a substrate; spinning a positive photoresist and baking to obtain bottom coils of an excitation coil and an induction coil and photoresist graph of a positioning mark; electroplating the bottom coils and the positioning mark; spinning the positive photoresist to obtain a bonding conductor and the photoresist graph of the positioning mark; electroplating the bonding conductor and the positioning mark; removing the photoresist and etching the Cr / Cu bottom layer; spinning polyimide; spinning the polyimide, adhering prefabricated amorphous magnetically soft alloy magnetic cores one by one and baking; spinning the polyimide, baking and curing; polishing the polyimide until the bonding conductor is exposed; sputtering the Cr / Cu bottom layer; spinning the positive photoresist and baking to obtain the top coils of the excitation coil and the induction coil and the photoresist graph of an electrode; electroplating the bottom coils and the electrode; and removing the photoresist and etching the Cr / Cu bottom layer to obtain the sensor which has high sensitivity and wide linear measurement range.

Owner:SHANGHAI JIAO TONG UNIV

Bent-tube heating furnace

InactiveCN101734843AUniform temperature distributionFast heat conductionVessels or leading-in conductors manufactureGlass reforming apparatusTemperature controlTube furnace

The invention provides a bent-tube heating furnace for heating and softening when a straight tube is processed into a spiral tube by bending in energy-saving lamp manufacture. The conventional heating furnace has a heating wire structure, temperature distribution of a heating bath of the heating furnace is not uniform; the inside of the heated and softened straight tube easily generates stress, which has the defects of tube explosion and chronic gas leak; and the heating wire has difficult temperature control and high power consumption, and is easily burnt out if the heating wire is used continuously to affect production. The invention provides the bent-tube heating furnace with heating convenience, accurate temperature control, good production continuity and high yield aiming at the defects, which comprises a furnace body with a bilayer structure and a heating cavity, wherein the furnace body is coupled with a furnace cover; the bilayer structure is a graphite layer with a U-shaped section and an insulating layer coated outside the graphite layer; and the heating cavity is a heating groove which is formed by the U-shaped concave part of the graphite layer and is provided with twoopenings at two ends. By heating and softening the straight tube by the bent-tube furnace, the treated straight tube cannot easily generate stress in the tube so as to eliminate the hidden danger of tube explosion and chronic gas leak.

Owner:浙江江山三友电子有限公司

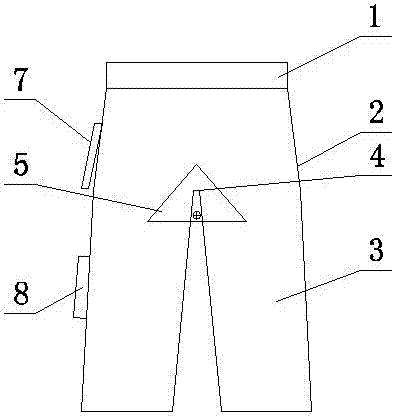

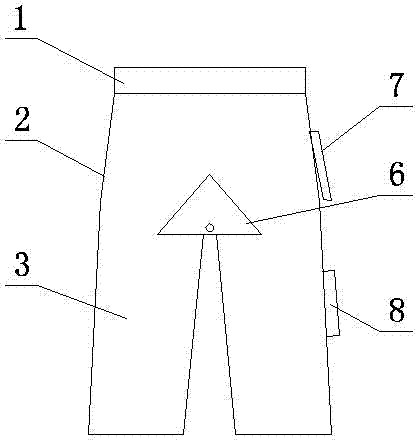

Novel pants for patients

InactiveCN107307484AReduce the chance of infectionModerate heightProtective garmentUpper urinary tract infectionMedicine

The invention discloses novel pants for patients. The novel pants comprise a waist portion, a body portion and leg portions sequentially from top to bottom, and the crotch of the waist portion is split and provided with a front cover and a rear cover respectively. A urinary catheter and a urine bag can directly penetrate through the popliteal fossa of a patient lying in bed from the split crotch to be fixed to the bedside, and the front cover and the rear cover directly cover the perineum to make it convenient for perineum cleaning and can be directly open for operation or observation. The novel pants have advantages that by modification of normal pants for the patients, the urinary catheter and the urine bag can directly and conveniently penetrate through the popliteal fossa from the split crotch to be fixed, and appropriate height, comfort and less proneness to reflection, compression, inadequate drainage and adverse current are realized; repeatedly putting on and taking off the pants for cleaning is avoided; probability of urinary tract infection is greatly decreased, and structural simplicity and practicality are achieved.

Owner:芜湖通全科技有限公司

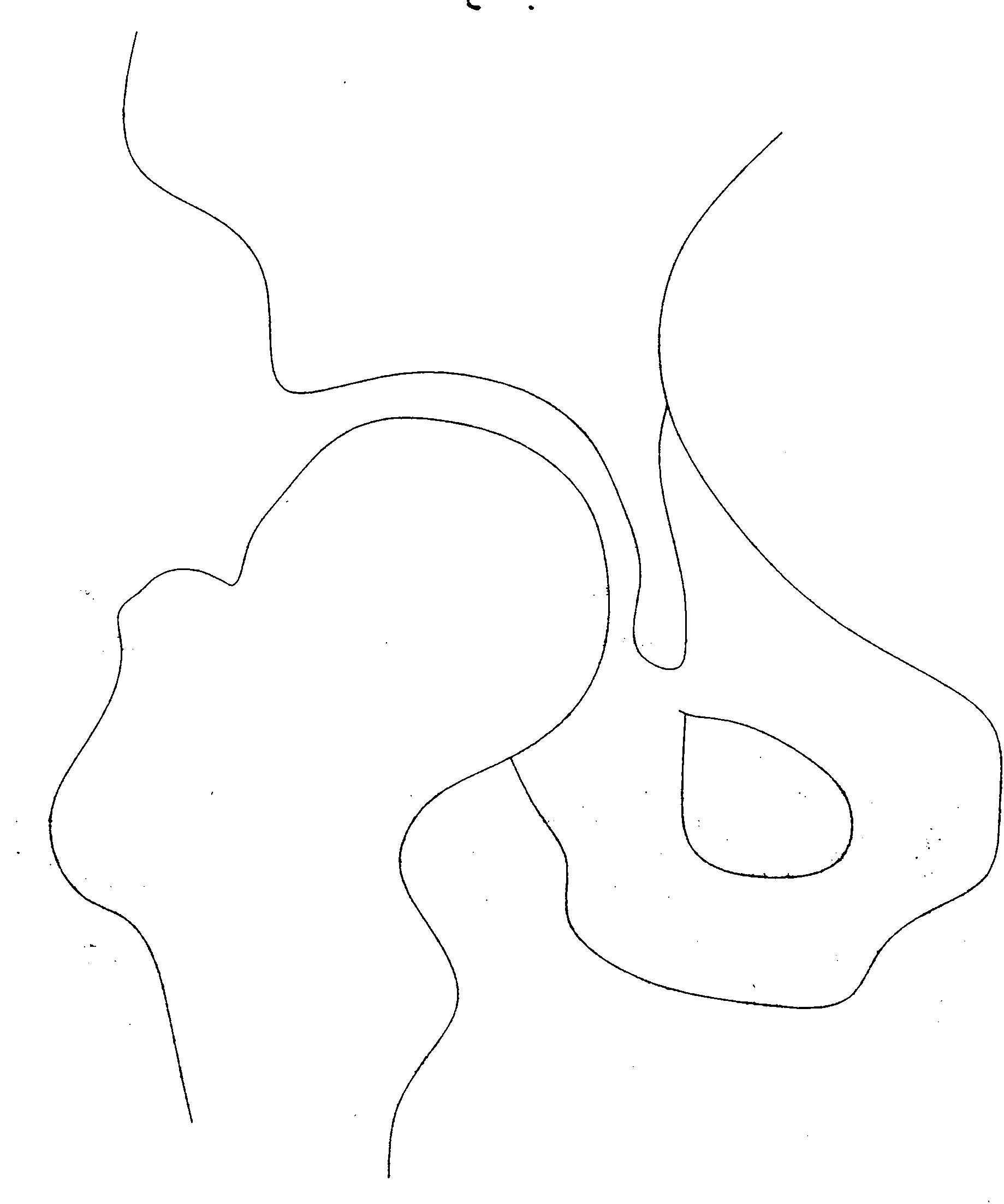

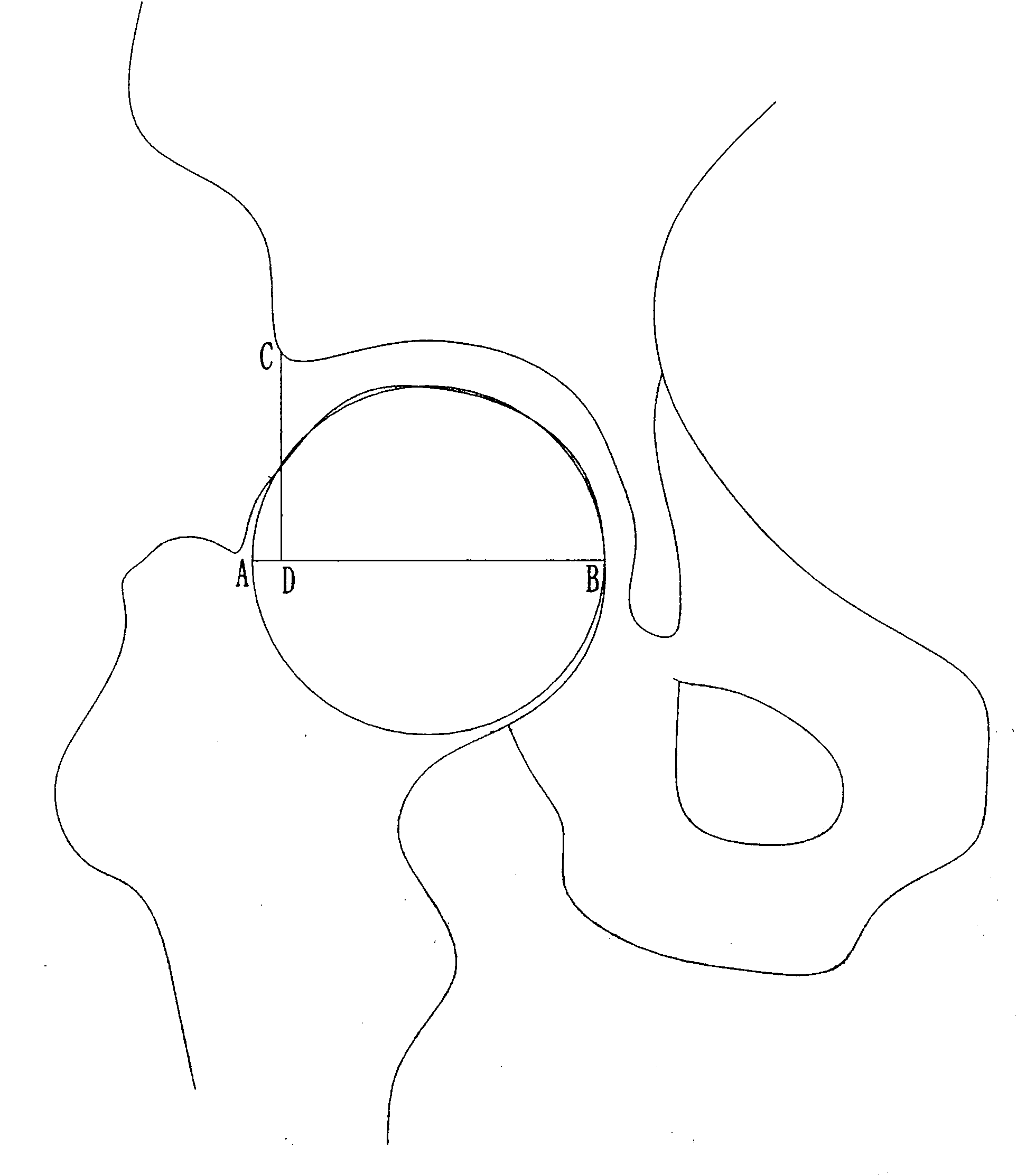

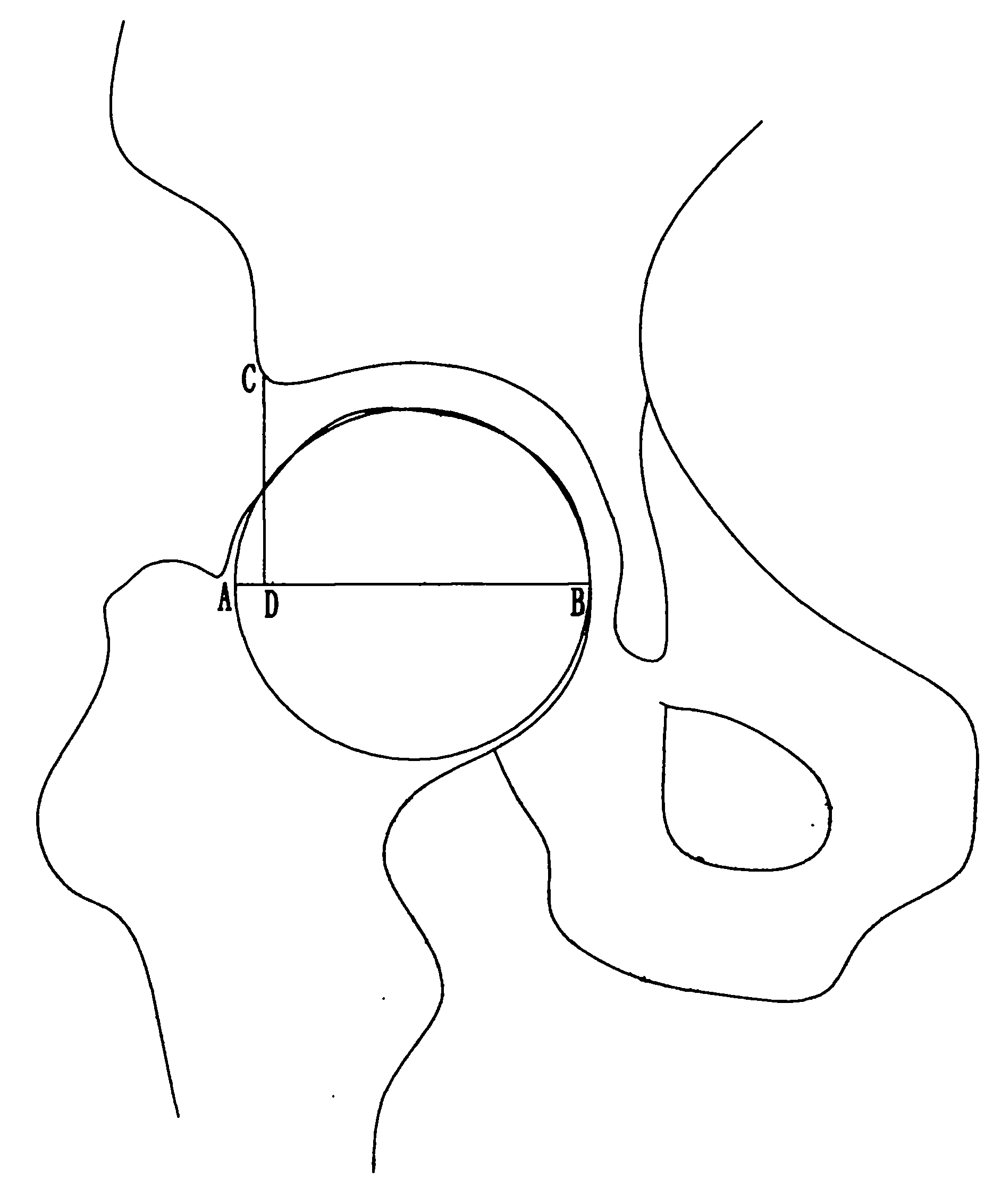

Method for measuring central bearing diameter of hip joint

InactiveCN102204829AEasy to analyzeEasy to measureComputerised tomographsTomographyArticular surfacesRight femoral head

The invention discloses a method for measuring a hip joint by utilizing a multi-slice spiral computer tomography (CT) three-dimensional reconstruction technology. The method for measuring the central bearing diameter of the hip joint comprises the following steps of: 1, placing an object to be measured; 2, performing CT scanning and three-dimensional reconstruction; and 3, acquiring a definition line of the central bearing diameter, adjusting a three-dimensional image of the hip joint to a lateral image, clipping and removing a front side image of the whole hip joint along the central axis position of femoral neck; adjusting the three-dimensional image of the hip joint to a frontal image, fitting femoral head articular surfaces, drawing a circle, making horizontal diameter through a corresponding center, wherein the intersection points of the horizontal diameter and the circle are a point A and a point B, the point B is an inner side intersection point, and the point A is an outer side intersection point; and making a vertical line of the point A and point B through an external acetabulum edge C, wherein the vertical point is a point D, and a line segment BD is the central bearingdiameter of the hip joint. By the method for measuring the central bearing diameter of the hip joint, the technical defect of measuring middle bearing parameters in the prior art is overcome, and simple measuring for shape parameters of bearing stability of the hip joint is realized.

Owner:THE FIRST AFFILIATED HOSPITAL OF THIRD MILITARY MEDICAL UNIVERSITY OF PLA

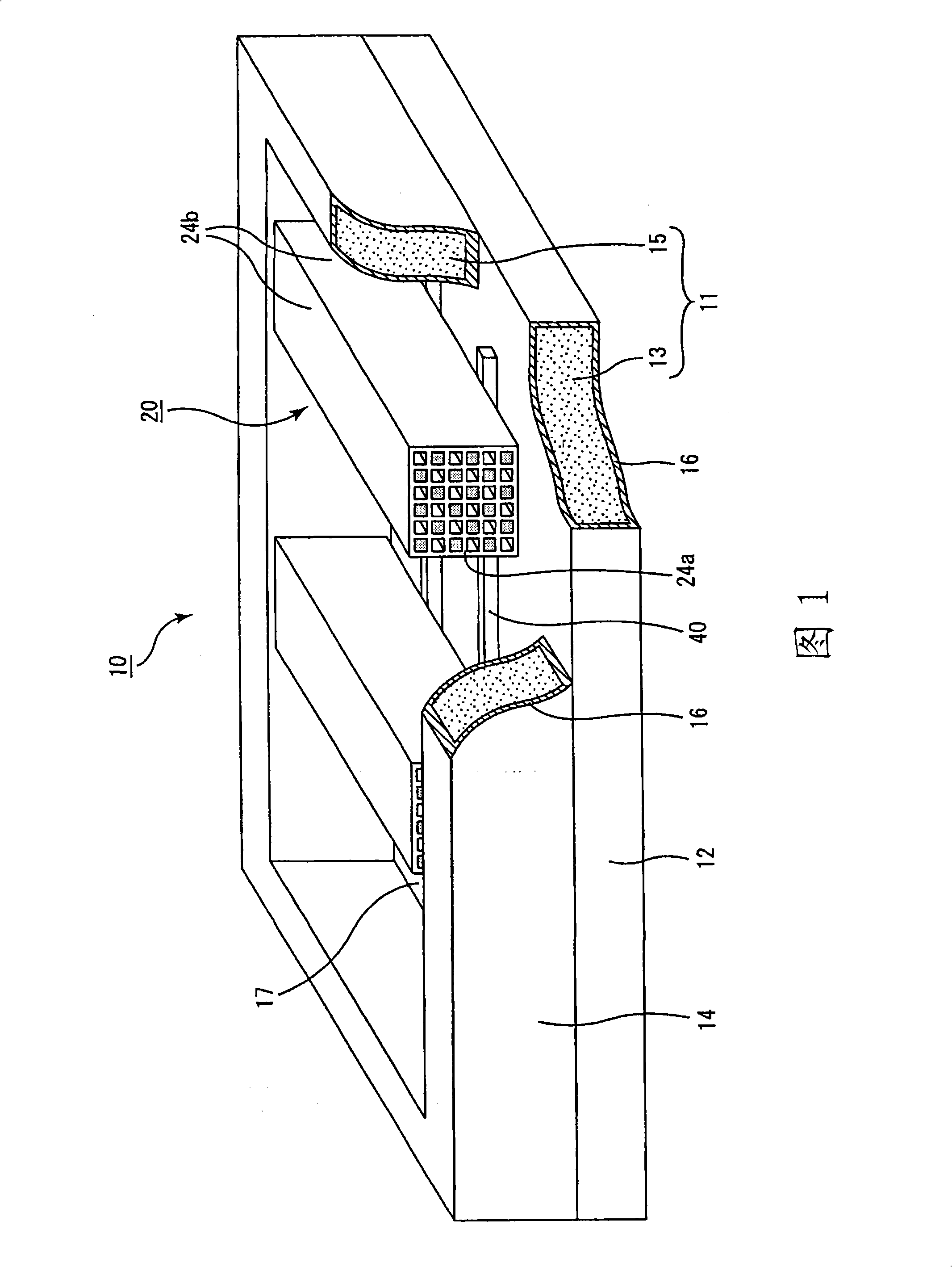

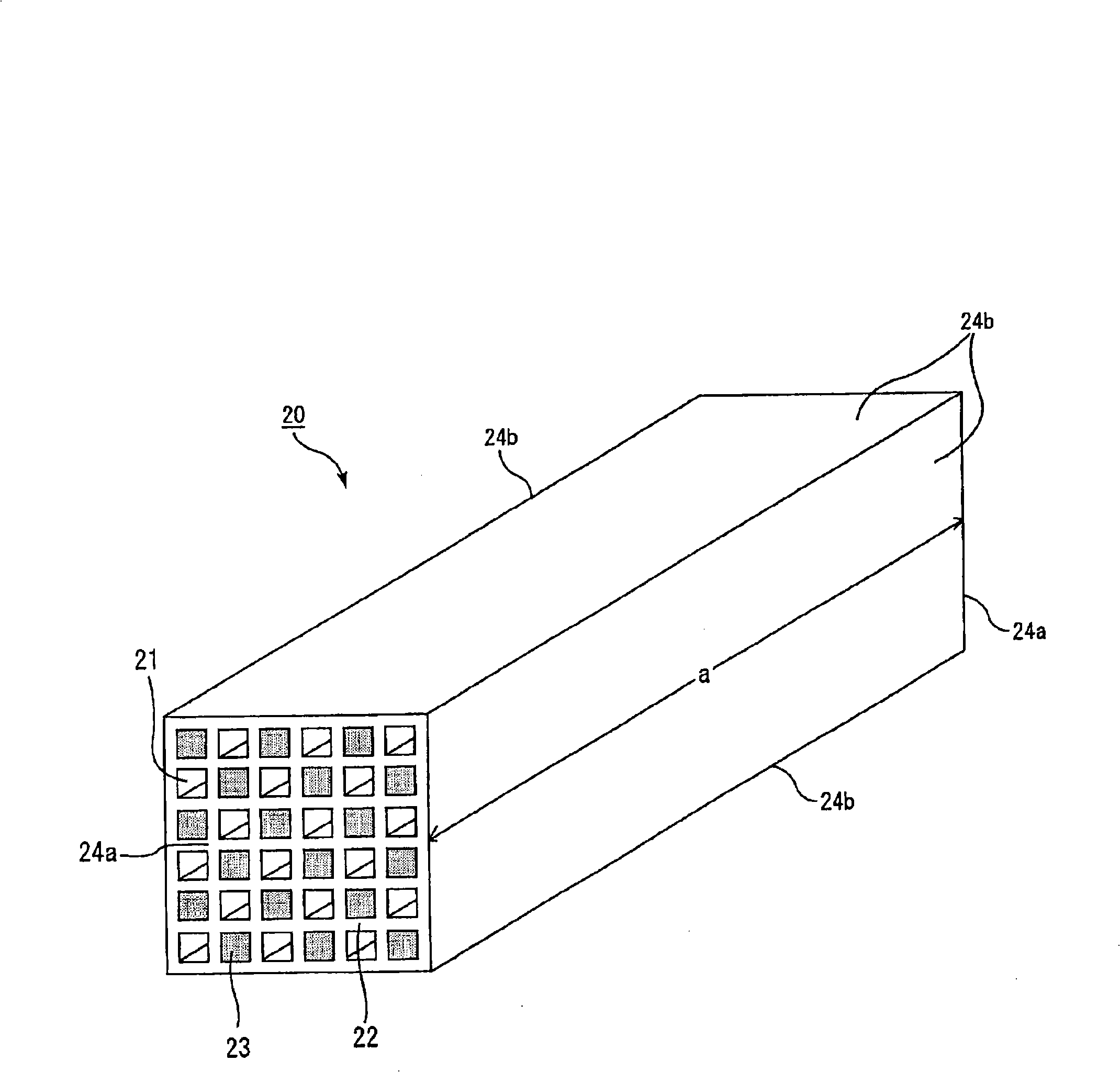

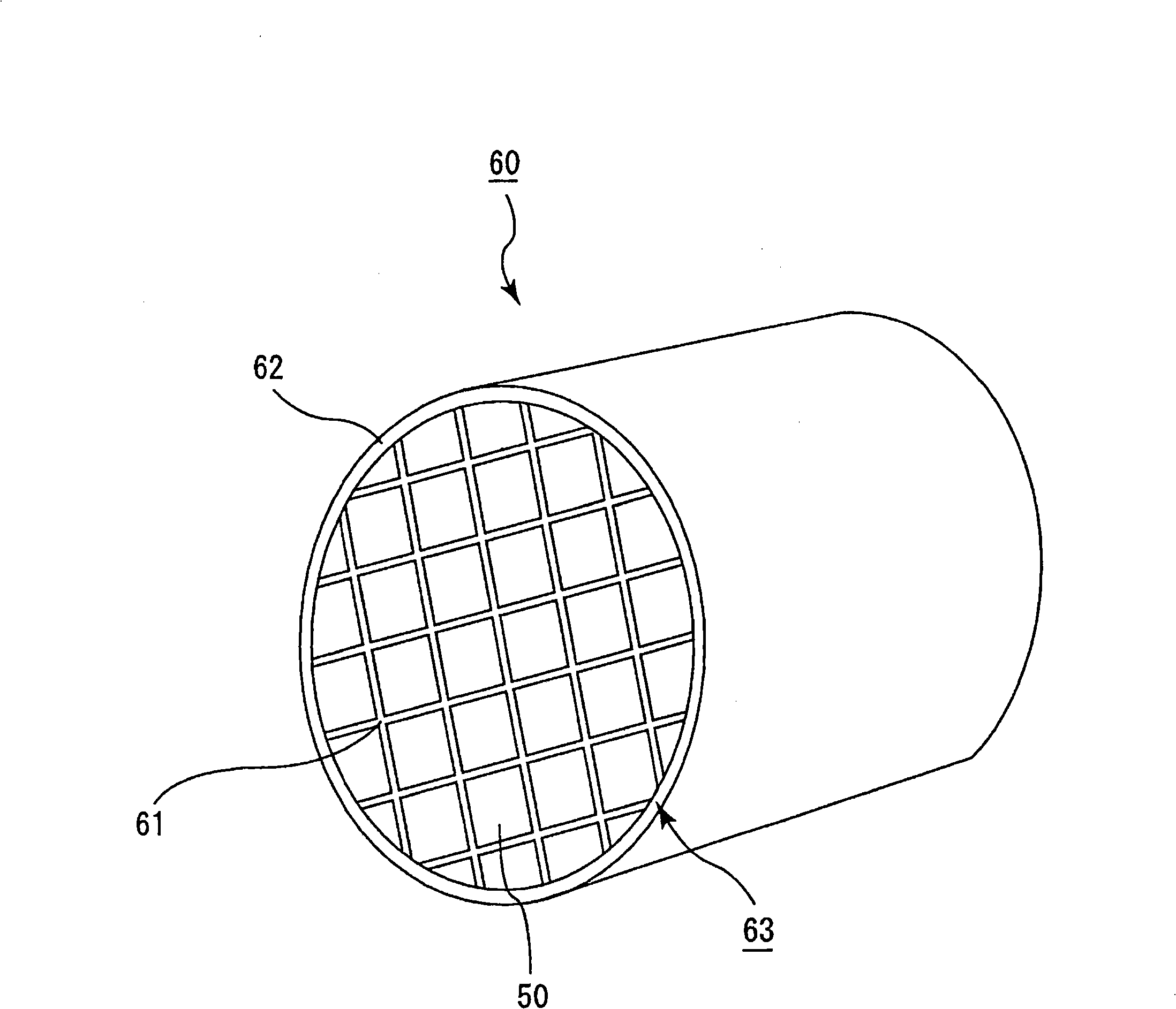

Firing jig and method for manufacturing honeycomb structured body

InactiveCN101318826AAvoid lostGuaranteed qualityCharge supportsThin material handlingHoneycomb structureMaterials science

Provided is a manufacturing method for a jig for firing and a honeycomb structural body. The jig for firing that even when repeatedly used in the firing of honeycomb molding while satisfactorily advancing the reaction of sintered body generation, is capable of preventing any coat layer detachment and is employable over a prolonged period of time to thereby attain reduction of running cost. The jig for firing is a jig for honeycomb molding firing including a housing for mounting thereon a columnar honeycomb molding composed mainly of silicon carbide with its side face laid down and including a coat layer provided on at least a face for honeycomb molding mounting of the housing, characterized in that the coat layer is composed mainly of silicon carbide, and that the arithmetic mean height of the coat layer determined in accordance with JIS B 0601(2001) is 10 mum or less.

Owner:IBIDEN CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com