Miniaturized fluxgate sensor of micro-electro-mechanism system

A technology of fluxgate sensor and micro-electromechanical system, applied in the field of magnetic sensor, can solve the problems of poor mechanical properties of photoresist, large influence of external impact, poor thermal stability, etc., and achieve high sensitivity, good binding force and stability Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The embodiments of the present invention will be described in detail below with reference to the drawings: this embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation modes and specific operation procedures are given, but the protection scope of the present invention is not limited to the following Mentioned examples.

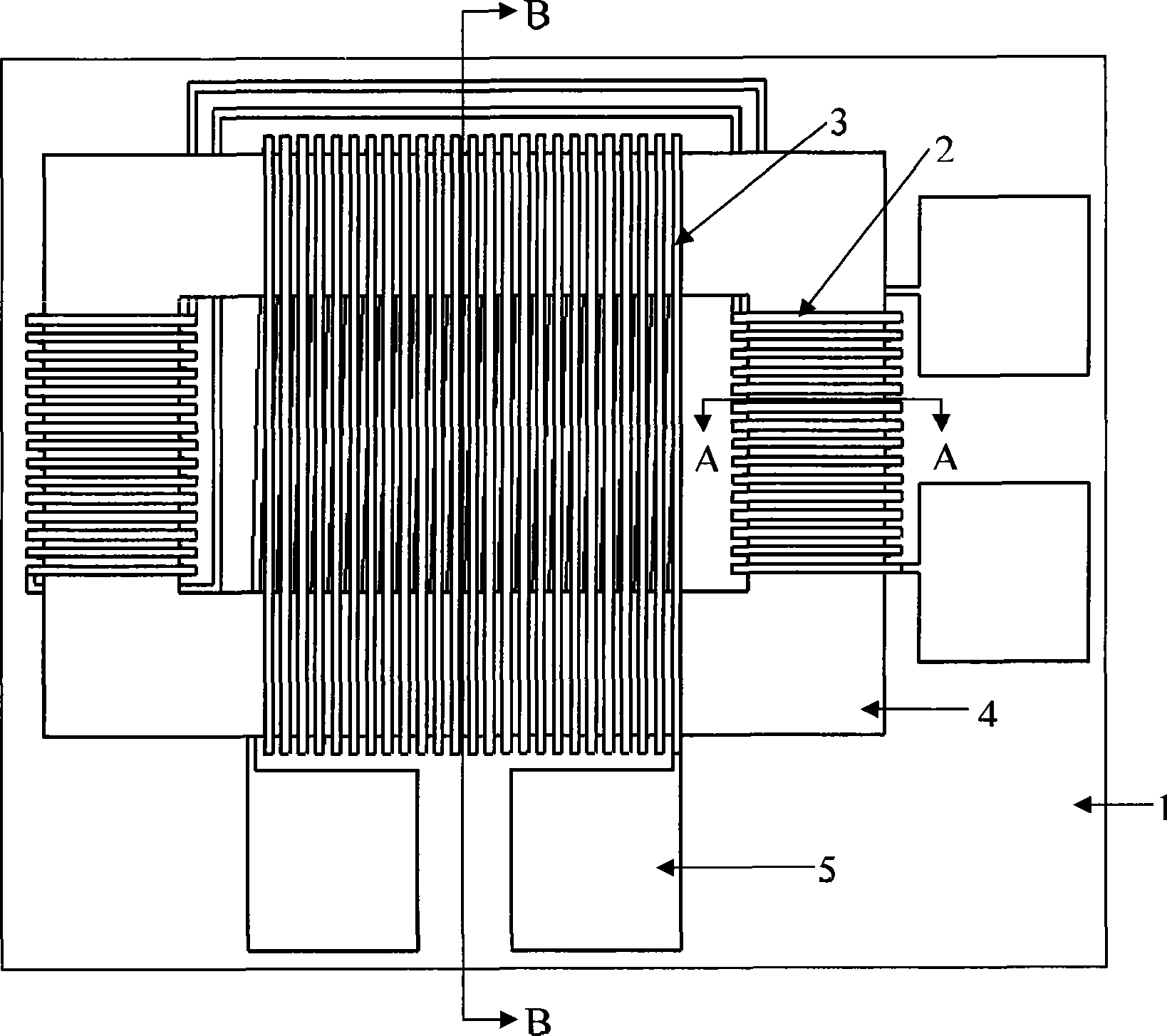

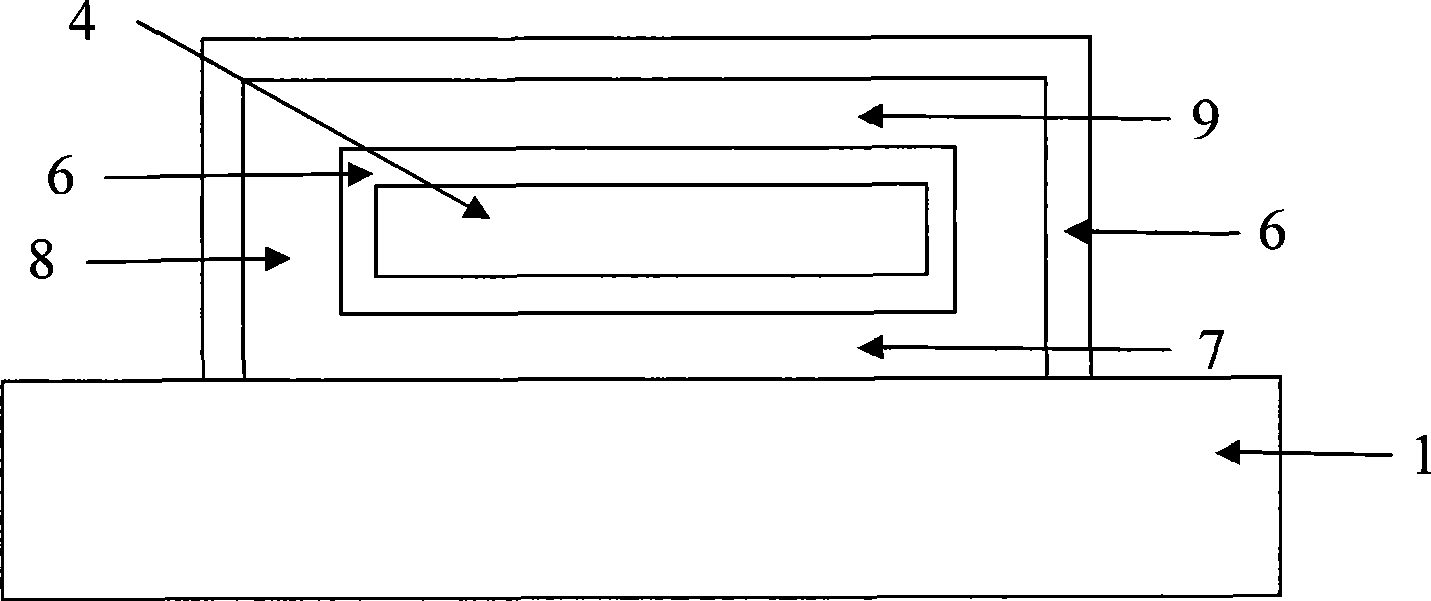

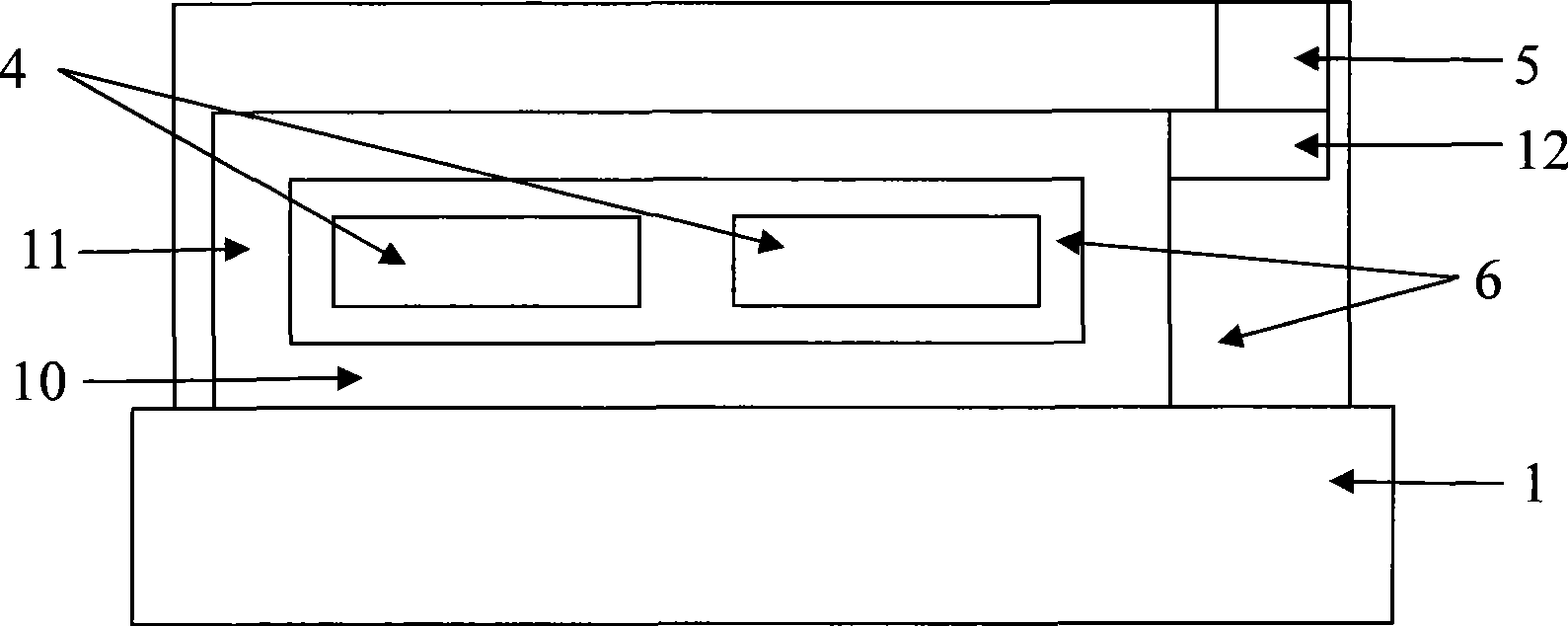

[0022] Such as Figure 1-3 As shown, this embodiment includes a substrate 1, an excitation coil 2, a receiving coil 3, a magnetic core 4, a pin 5, and a polyimide insulating material 6. The closed rectangular magnetic core 4 is symmetrically wound with two sets of connected three-dimensional The solenoid excitation coil 2 is wound with a group of three-dimensional solenoid receiving coils 3 perpendicular to the excitation coil 2; the excitation coil 2 is located on the substrate 1, and is formed by connecting the bottom coil 7 and the top coil 9 through the connecting conductor 8. The excitatio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com