System and method for fused salt or heat transfer oil steam generation adopting in-pipe evaporation and avoiding external force for driving

A heat-conducting oil, no external force technology, applied in the field of molten salt or heat-conducting oil steam generation system, can solve the problems that affect the safe operation of the system, difficult to discharge clean, large temperature difference, etc., to reduce the risk of molten salt freezing and save high temperature material, effect of reducing shell thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

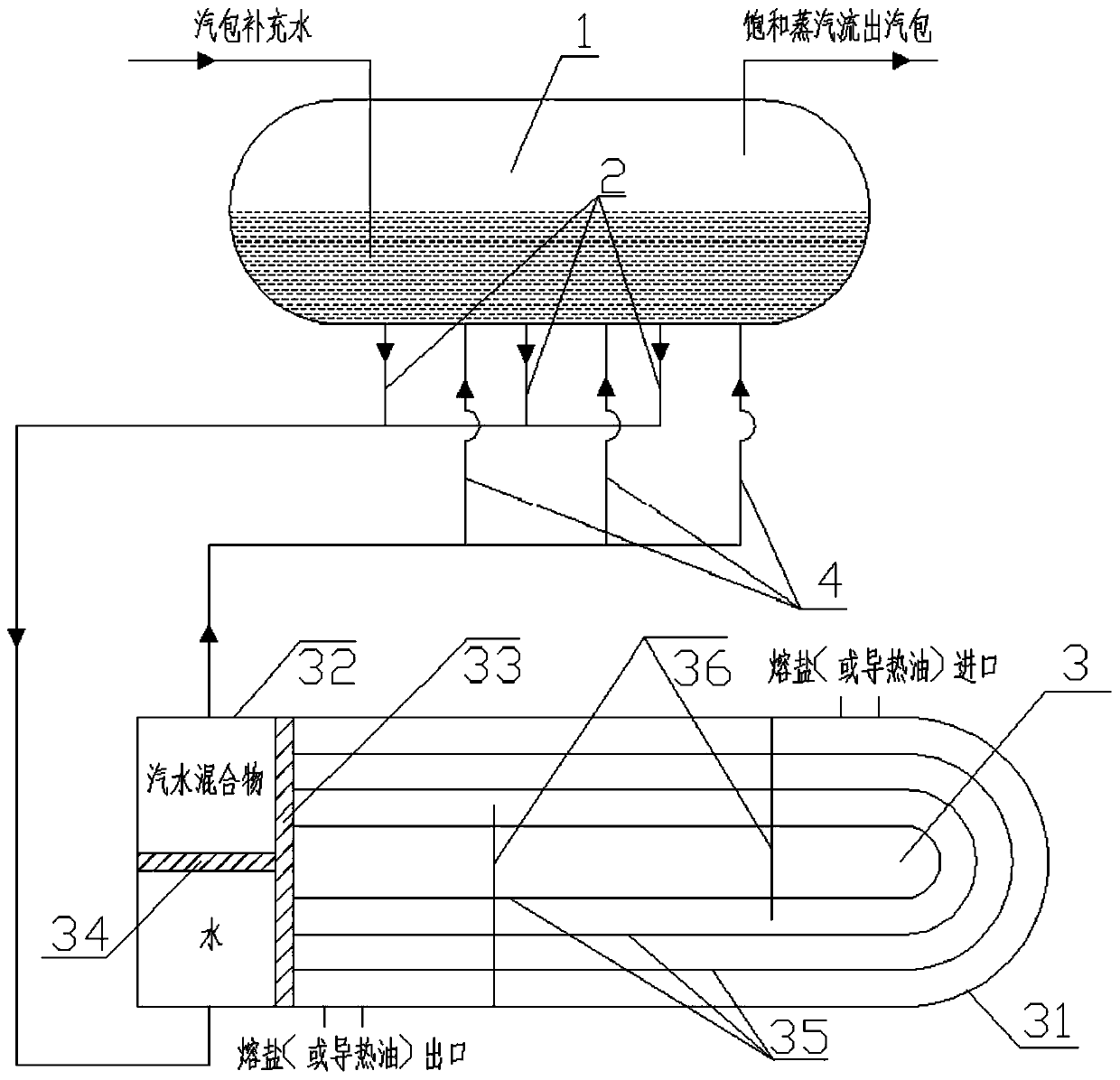

[0024] Such as figure 1 As shown, the present invention is a molten salt or heat conduction oil vapor generation system that evaporates without external force in the tube, including a steam drum 1 , a downcomer 2 , an evaporator 3 , and an upcomer 4 . The evaporator 3 further includes a shell 31 , a head 32 , a tube sheet 33 , a partition plate 34 , a tube bundle 35 , a baffle plate 36 and the like. The steam drum 1 is located above the evaporator 3 , and the steam drum 1 and the evaporator 3 are connected through the downpipe 2 and the uppipe 4 to form a system.

[0025] The outer side of the shell 31, the tube sheet 33 and the tube bundle 35 of the evaporator 3 is the shell side space; the inner side of the head 32, the tube sheet 33 and the tube bundle 35 is the tube side space; There are two parts, the water chamber and the steam-water mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com