Pulping method with zero discharge of sewage water

A zero-emission, pulping technology, applied in the field of papermaking and pulping, can solve the problems of high operating costs and large investment in alkali recovery technology, and achieve the effects of saving investment, high yield of finished pulp, and high washing and bleaching efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

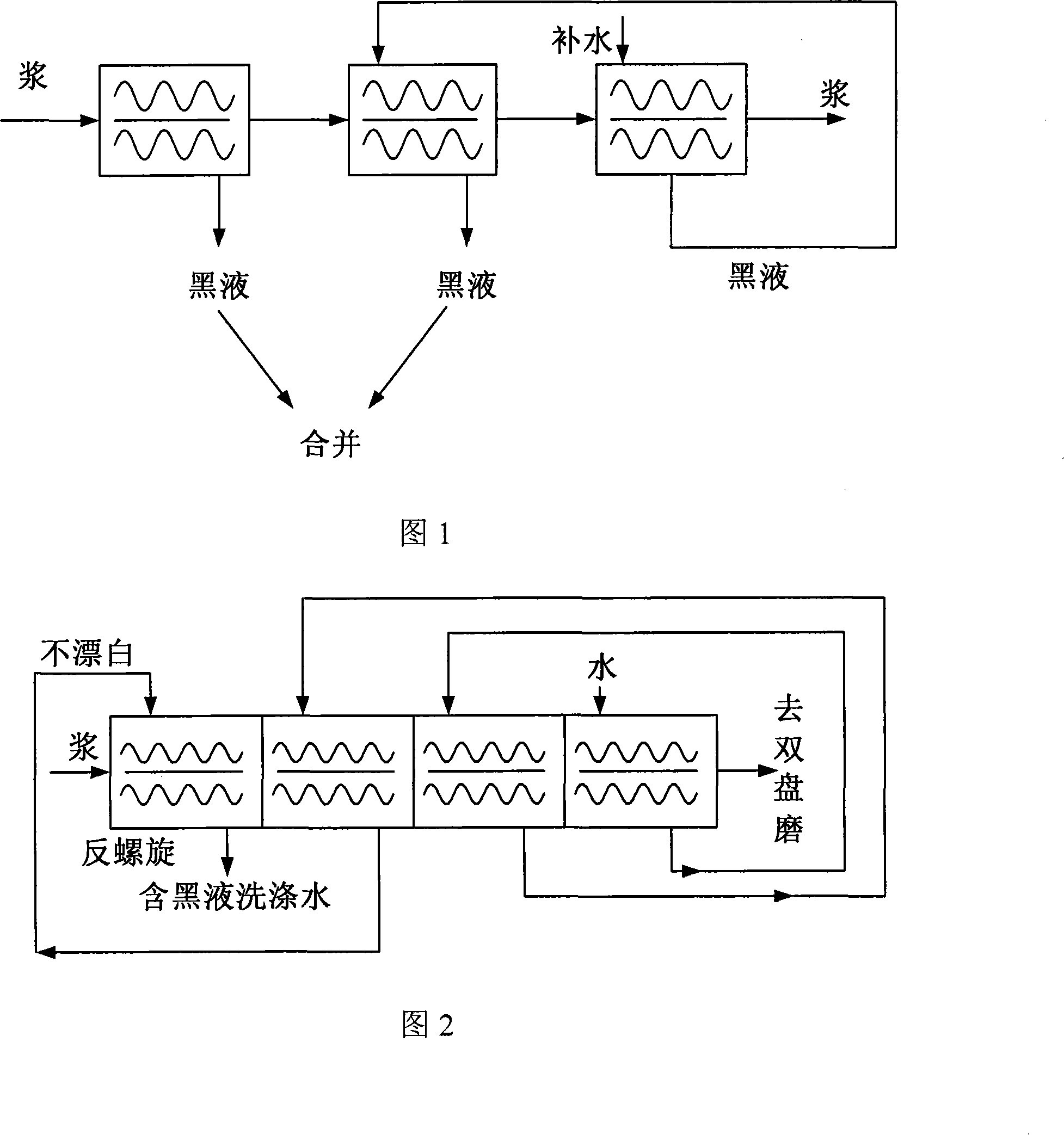

[0037] The flow process is shown in Figure 1. In 2000kg of crushed and dust-removed reeds, add 700L of sodium hydroxide solution with a temperature of 80°C and a concentration of 10%. Add the catalyst under stirring. After stirring evenly, add it to the cooking pot for cooking. The cooking pressure is 0.4-0.8Mpa, the cooking time is 2 hours, the slurry concentration is controlled at 20-45%, and the mass dosage of the catalyst is 3.1%, wherein anthraquinone is 0.1%, and methanol is 3%. After cooking, the pulp first passes through three twin-screw extruders for three-stage serial countercurrent high-concentration extrusion, and the supplementary water is added by the last twin-screw extruder, and the amount of water added is 4-5m 3 / ton of pulp, the black liquor obtained by extruding the slurry from the last twin-screw extruder is returned to the second twin-screw extruder, and the black liquor obtained by the extrusion of the first and second twin-screw extruders is combined (...

Embodiment 2

[0039] See Figure 1 for the flow process. Add 700L of sodium hydroxide solution with a temperature of 80°C and a concentration of 12% to 2000kg of broken and dust-removed cotton stalks. Add the catalyst under stirring. After stirring evenly, add it to the cooking pot for cooking. . The cooking pressure is 0.4-0.8Mpa, the cooking time is 3 hours, the slurry concentration is controlled at 20-45%, the catalyst mass consumption is 3.15%, wherein the oxygen chlorine is 0.15%, and the methanol is 3%. After cooking, the pulp first passes through three twin-screw extruders for three-stage serial countercurrent high-concentration extrusion, and the supplementary water is added by the last twin-screw extruder, and the amount of water added is 4-5m 3 / ton of pulp, the black liquor obtained by extruding the slurry from the last twin-screw extruder is returned to the second twin-screw extruder, and the black liquor obtained by the extrusion of the first and second twin-screw extruders is ...

Embodiment 3

[0041] The process is shown in Figure 1. In 2000kg of crushed and dedusted poplar chips, add 700L of a cooking agent solution with a temperature of 80°C and a concentration of 15%, add the catalyst under stirring, stir evenly, and then add it to the cooking pot for cooking. The cooking pressure is 0.4-0.8Mpa, the cooking time is 2 hours, the slurry concentration is controlled at 20-45%, and the mass dosage of catalyst is 4.15%, of which chlorine oxygen is 0.15%, methanol is 3%, and urea is 1%. The cooking agent is a mixture of sodium sulfite and sodium hydroxide at a ratio of 4:1. After cooking, the slurry is firstly extruded through three twin-screw extruders in series in three stages of countercurrent high-concentration extrusion, and the supplemented water is extruded by the last twin-screw extruder. Added by machine, the amount of water added is 4-5m 3 / ton of pulp, the black liquor obtained by extruding the slurry from the last twin-screw extruder is returned to the seco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com