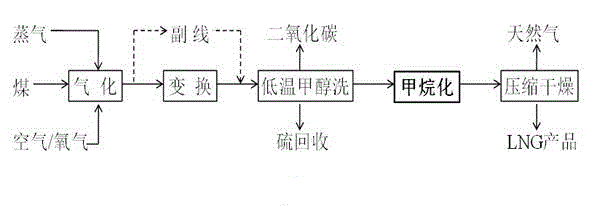

Process for preparing substitute natural gas through sulphur-tolerant methanation of coal synthesis gas

A sulfur-resistant methanation technology that replaces natural gas. It is applied in the petroleum industry, gas fuel, and fuel. It can solve problems such as lower conversion rate, increased equipment investment and energy consumption, and impact on natural gas quality. It can reduce equipment size and energy consumption. consumption, save investment and operating costs, and increase the temperature of sulfur-resistant transformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

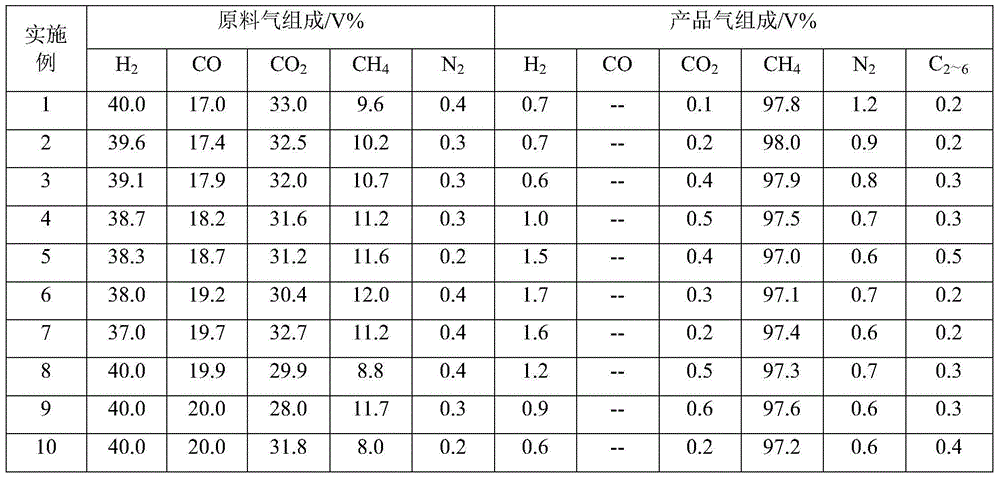

Embodiment 1

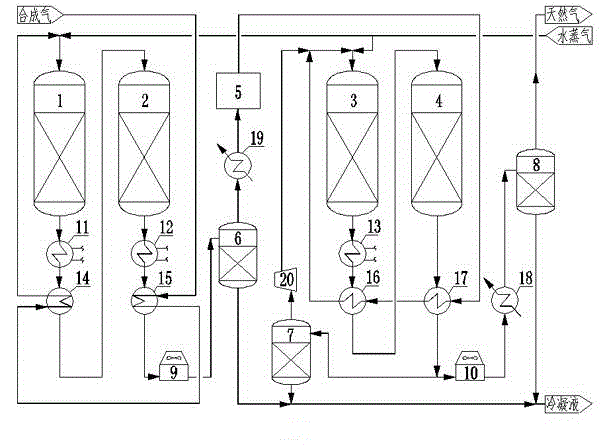

[0035] In this example, the catalysts used in sulfur-tolerant methanation reactor I and sulfur-tolerant methanation reactor II are the same, and the mass composition of the oxide is MoO 3 25wt%-Co 2 o 3 +ZrO 2 15wt% / CeO 2 -Al 2 o 3 60 wt% catalyst, active component MoO 3 and additive Co 2 o 3 +ZrO 2 Loaded on the carrier CeO by impregnation 2 -Al 2 o 3 For the specific preparation method and process, see Example 5 of CN102463118A; the nickel-based catalyst in methanation reactor I and methanation reactor II adopts Topsoe's MCR-2X catalyst. Adopt above-mentioned catalyzer, its concrete technological process and condition are as follows:

[0036] (1) After dust removal and oil removal, the volume composition is H 2 40.0%, CO17.0%, CO 2 33.0%, CH 4 9.6% and N 2 The 0.4% synthetic gas first exchanges heat with the outlet gas of the sulfur-tolerant methanation reactor II through the inlet and outlet heat exchanger II, and then exchanges heat with the outlet gas of t...

Embodiment 2

[0041] In this example, the catalysts used in sulfur-tolerant methanation reactor I and sulfur-tolerant methanation reactor II are the same, and the mass composition of the oxide is MoO 3 30wt%-Co 2 o 3 +Fe 2 o 3 +NiO20wt% / CeO 2 -Al 2 o 3 50 wt% catalyst, active component MoO 3 and additive Co 2 o 3 +Fe 2 o 3 +NiO is loaded on the carrier CeO by impregnation 2 -Al 2 o 3 For the specific preparation method and process, see Example 5 of CN102463118A; the nickel-based catalyst in methanation reactor I and methanation reactor II adopts Topsoe's MCR-2X catalyst. Adopt above-mentioned catalyzer, its concrete technological process and condition are as follows:

[0042] (1) After dust removal and oil removal, the volume composition is H 2 39.6%, CO17.4%, CO 2 32.5%, CH 4 10.2% and N 2 The 0.3% synthetic gas first exchanges heat with the outlet gas of the sulfur-tolerant methanation reactor II through the inlet and outlet heat exchanger II, and then exchanges heat wit...

Embodiment 3

[0047] In this embodiment, the catalyst used in the sulfur-tolerant methanation reactor I and the sulfur-tolerant methanation reactor II is the same, and its mass composition is MoO 3 35wt%-Co 2 o 3 +KO 2 2wt% / ZrO 2 63 wt% catalyst, active component MoO 3 and additive Co 2 o 3 +KO 2 Loaded on the carrier ZrO by impregnation 2 For the specific preparation method and process, see Example 14 of CN103495421A; the nickel-based catalyst in methanation reactor I and methanation reactor II adopts Davy's CEG-LH catalyst. Adopt above-mentioned catalyzer, its concrete technological process and condition are as follows:

[0048] (1) After dust removal and oil removal, the volume composition is H 2 39.1%, CO17.9%, CO 2 32.0%, CH 4 10.7% and N 2 The 0.3% synthetic gas first exchanges heat with the outlet gas of the sulfur-tolerant methanation reactor II through the inlet and outlet heat exchanger II, and then exchanges heat with the outlet gas of the sulfur-tolerant methanation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com