Micro fluxgate sensor

A fluxgate sensor, a miniature technology, used in instruments, measuring magnetic variables, measuring devices, etc., can solve the problems of difficulty in reducing the size of the fluxgate sensor, the printed circuit board cannot withstand high temperature environments, and the sensor is damaged. Avoid chemical mechanical polishing process, improve magnetic field coupling, reduce noise and energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The idea, specific structure and technical effects of the present invention will be further described below in conjunction with the accompanying drawings, so as to fully understand the purpose, features and effects of the present invention.

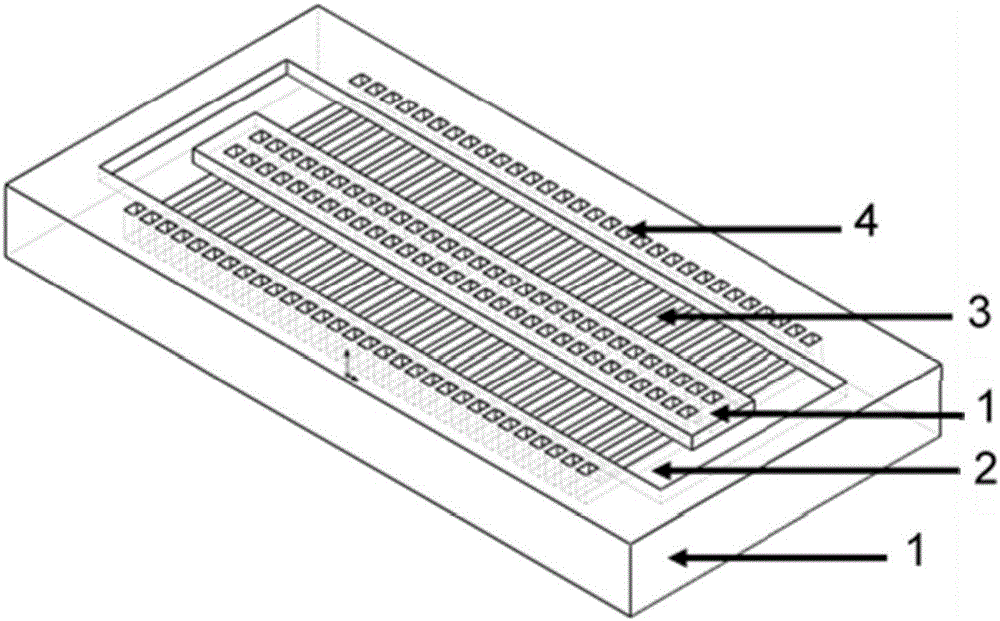

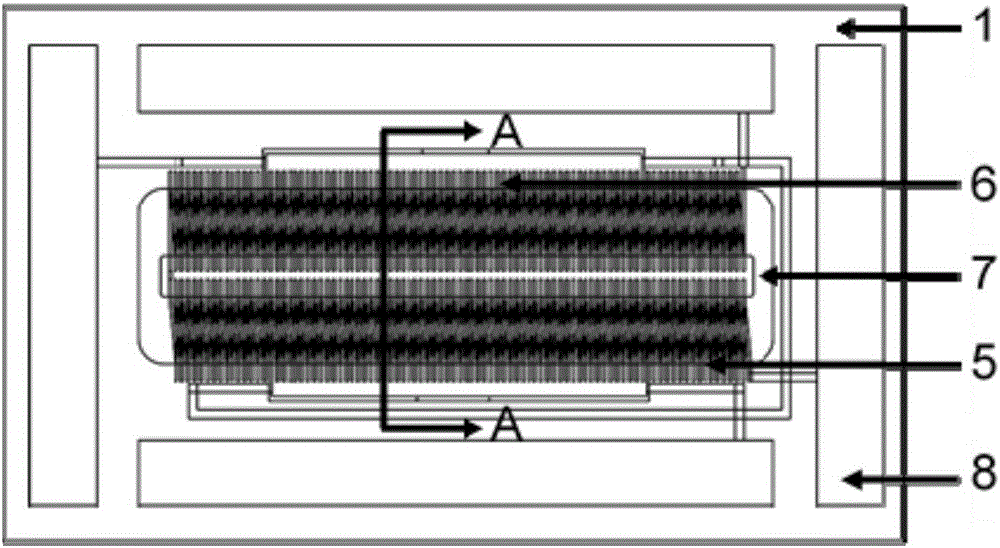

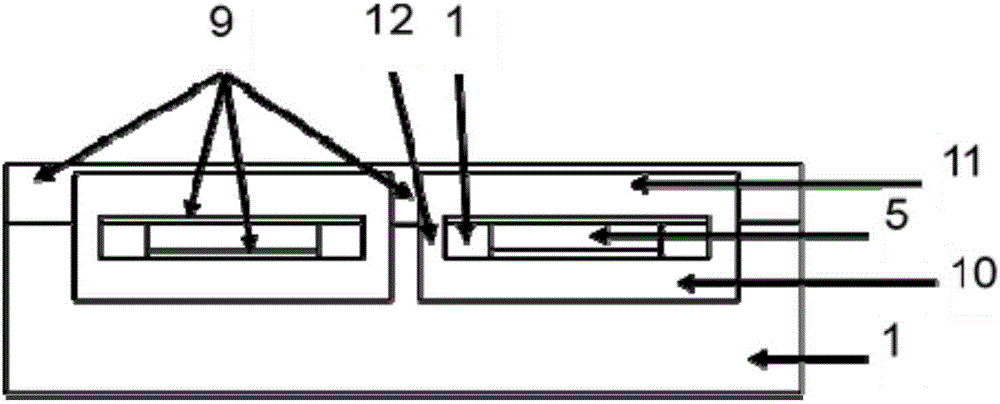

[0029] Such as Figure 1-3 As shown, the silicon carbide-based integrated miniaturized fluxgate sensor of the present invention includes: a silicon carbide substrate 1, an excitation coil 5, a detection coil 6, a magnetic core 7, an electrode 8 and a silicon carbide film 9; In the 20 μm deep rectangular groove 2 on the surface of the silicon substrate, the thickness of the magnetic core is 20 μm; the bottom of the rectangular groove is distributed with a microgroove array 3, and the two ends of the microgroove array 3 extend into the silicon carbide substrate 1 at 300 μm. The surface of the silicon carbide substrate 1 at 200 μm on both sides of the slot 2 is etched with array through holes 4 to expose both ends of the micro-groove ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Curie point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| Sensitivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com