Expansion vitrification micro-bead thermal insulation pipe case and production method thereof

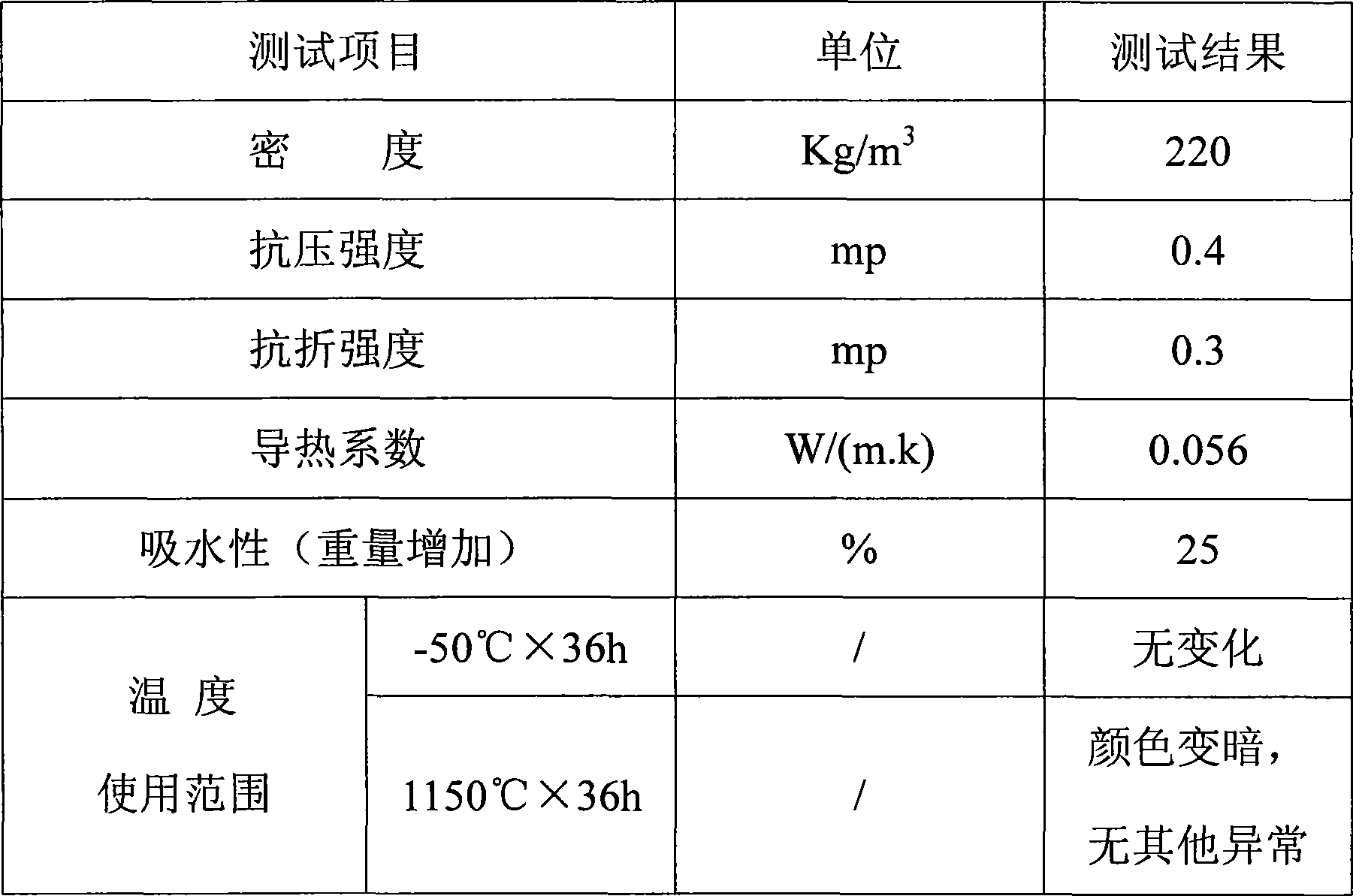

A technology of expanded vitrified microbeads and thermal insulation tube shells, which is applied in the directions of thermal insulation, pipeline protection through thermal insulation, pipeline protection, etc., can solve the problems of large thermal conductivity of thermal insulation tube shells, small operating temperature range and low tensile strength, etc. Achieve the effect of obvious thermal insulation effect, large operating temperature range and small thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Expanded vitrified microbeads 15%, brucite 12%, attapulgite 10%

[0028] Silicon calcium powder 10% binder 0.1% emulsion 0.2% water 48%

[0029] Antioxidant 0.02% Aluminum silicate cotton 4.48% Infrared reflective coating 0.2%

Embodiment 2

[0031] Expanded vitrified microbeads 12% brucite 15% convex clay 12%

[0032] Calcium silicon powder 11% binder 0.1% emulsion 0.2% water 45%

[0033] Antioxidant 0.02% Aluminum silicate cotton 4.48% Infrared reflective coating 0.2%

Embodiment 3

[0035] Expanded vitrified microbeads 10%, brucite 13%, attapulgite 11%

[0036] Calcium silicon powder 13% binder 0.1% emulsion 0.3% water 48%

[0037] Antioxidant 0.02% Aluminum silicate wool 4.28% Infrared reflective coating 0.3%

[0038] The production method of product of the present invention comprises the following steps:

[0039] a. Color sorting of turpentine ore, after processing the ore with the same color and luster, it will expand and vitrify, and then screen the vitrified microbeads with the same color and luster to prepare the insulation shell.

[0040] b. Put brucite, attapulgite, silicon-calcium powder, aluminum silicate cotton and water into a high-pressure metering pump according to the above ratio and mix evenly, referred to as material A.

[0041] c. Inject antioxidants, binders and emulsions into material A, and stir evenly at a temperature of 150 degrees—cool down.

[0042] d. Then add the expanded vitrified microbeads, continue to heat and stir evenly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com