Nanometer micropore thermal insulation plate and manufacturing method thereof

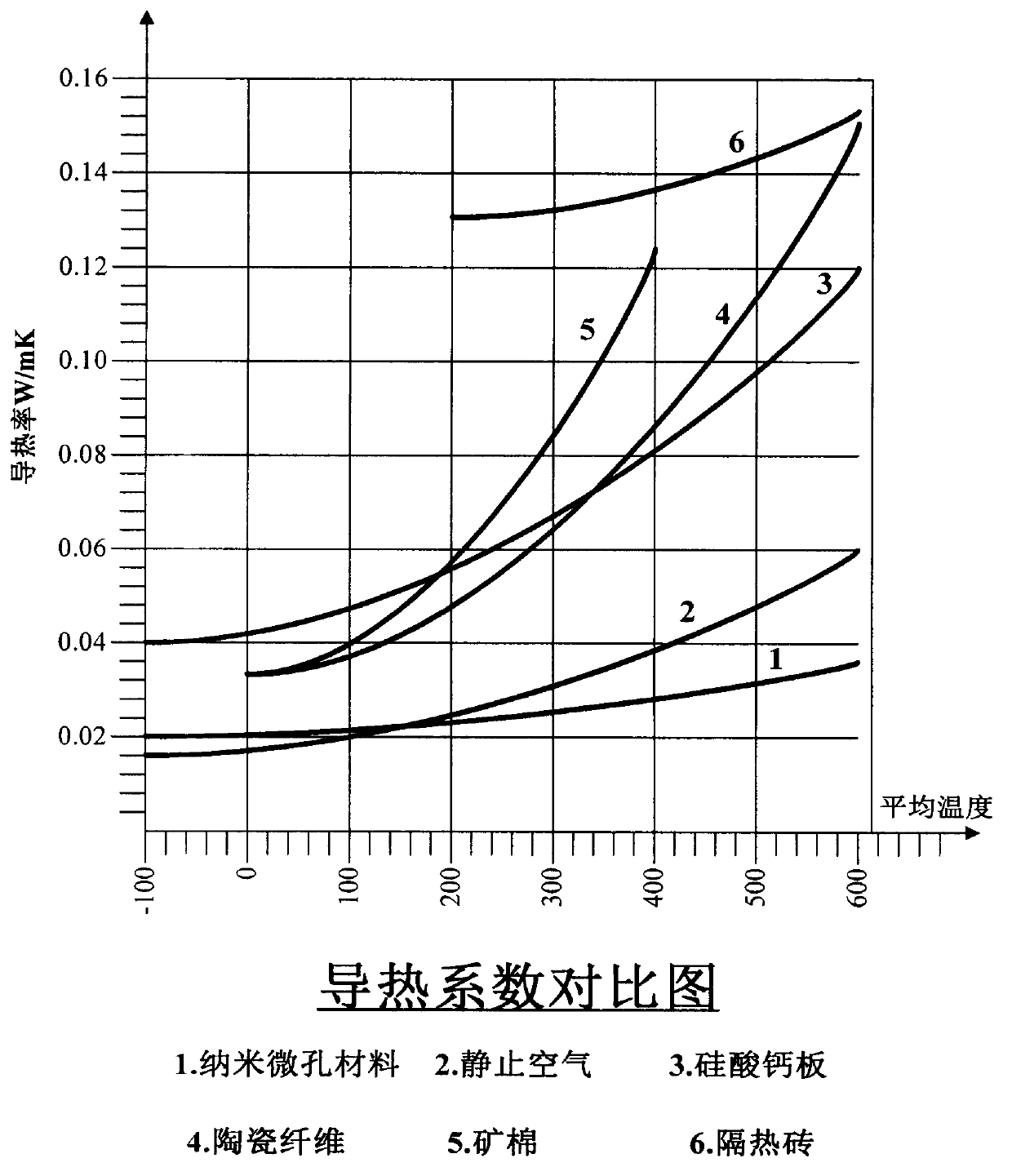

A technology of nano-micropores and manufacturing methods, which is applied in the field of high-temperature-resistant nano-micro-porous heat insulation boards and its manufacturing, can solve the problems of low temperature resistance, limit the use temperature range of nano-micro-porous heat insulation boards, and low thermal conductivity, and achieve Retain low, increase the use temperature range, retain the effect of thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

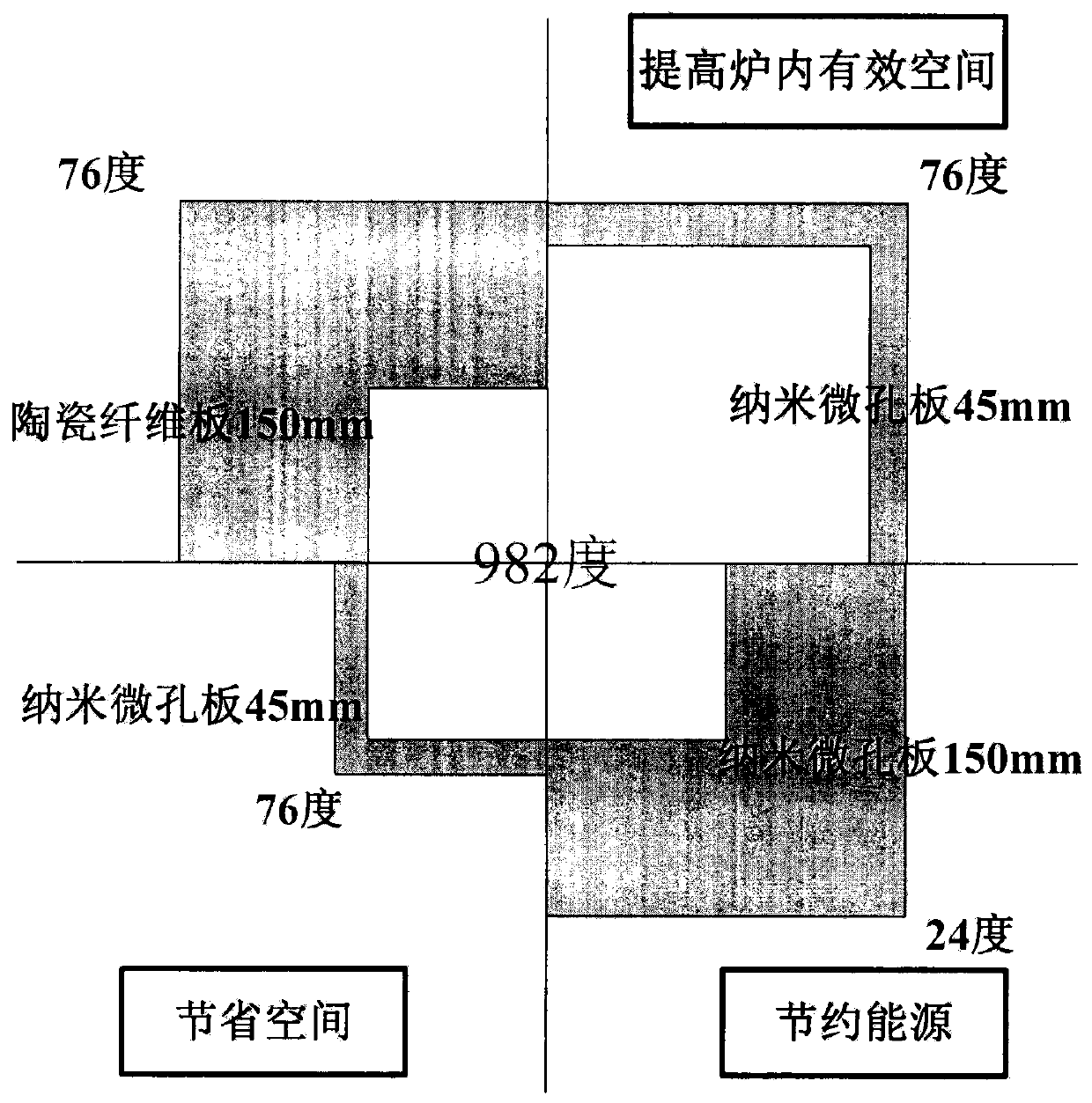

[0020] The following will combine figure 1 , figure 2 The present invention is further described.

[0021] A nano-microporous heat insulation board, which includes silicon dioxide with a particle size range of 5-20nm, silicon carbide with a particle size range of 2-12um, zirconium silicate with a particle size range of 2-15um and a diameter range of 5- 15um high-silica glass fiber, the length of high-silica glass fiber is 5-15mm, and the silicon carbide material can be replaced by other metal oxides such as titanium dioxide and aluminum oxide.

[0022] A method for manufacturing a nano-microporous heat insulation board, comprising the steps of:

[0023] Weigh silicon dioxide, silicon carbide, zirconium silicate, and high-silica glass fiber raw materials by weight;

[0024] Fully mix the prepared raw materials in a high-speed mixer;

[0025] The mixed material is dry-pressed in a special mold of a hydraulic press.

[0026] Wherein the weight ratio range of silicon dioxide...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com