Free-form surface grid layout and finite element analysis method and system for elastic element and medium

A technology of elastic components and layout methods, applied in geometric CAD, design optimization/simulation, etc., can solve problems such as inability to perform multiple rounds of optimization analysis, difficult to perform one round of analysis, and inability to converge analysis, and achieves difficult stress-strain mutation and non-uniformity. Uniform, good resistance to grid distortion, and consistent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

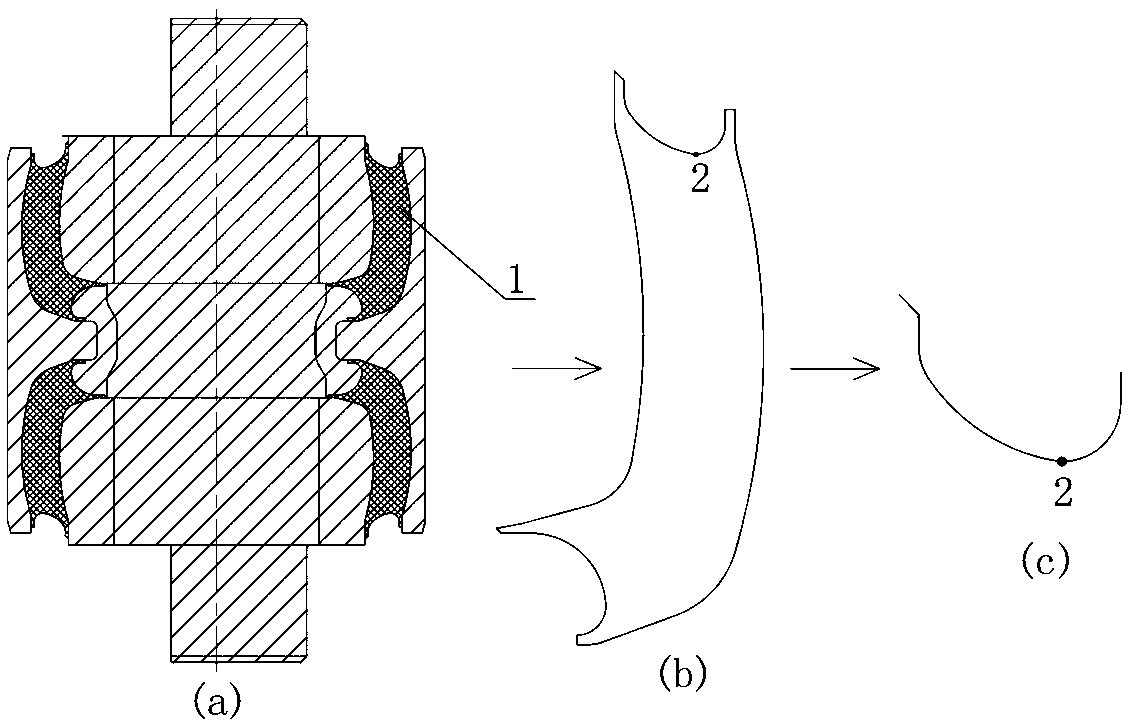

[0038] The following will be figure 1 Taking the positioning node for high-speed EMUs shown in (a) as an example, the free-form surface grid layout for elastic elements and the finite element analysis method, system and medium of the present invention are further described in detail.

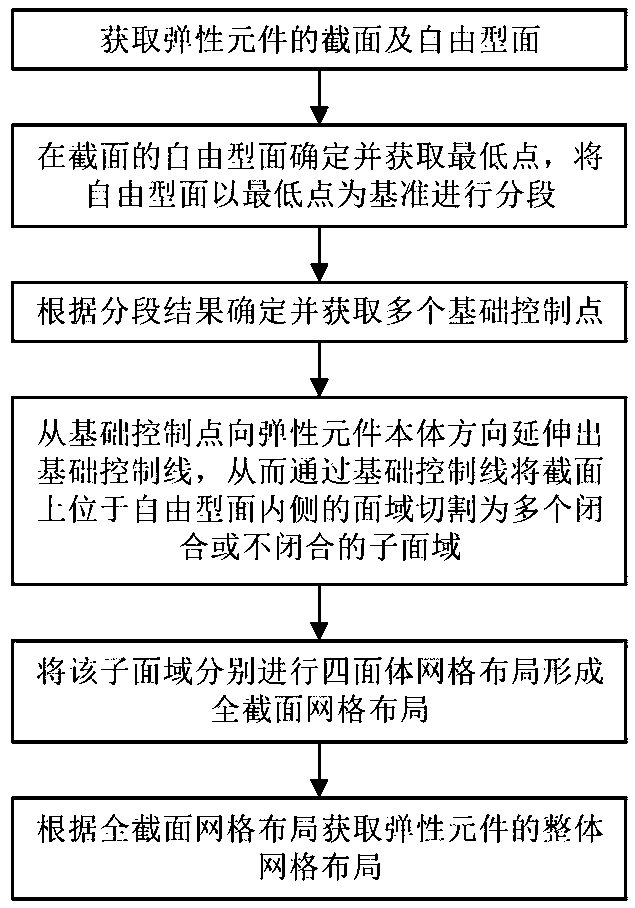

[0039] Such as figure 2 As shown, this embodiment is used for the free-form surface grid layout method of elastic elements, and the implementation steps include:

[0040] 1) Obtain the section and free surface of the elastic element, figure 1 (a) The cross-section of the elastic element 1 is as follows figure 1 As shown in (b), the freeform surface is as figure 1 as shown in (c);

[0041]2) Determine and obtain the lowest point on the free-form surface of the section, and segment the free-form surface based on the lowest point; the free-form surface of the section of the elastic element 1 is as follows figure 1 (c), where the lowest point is point 2;

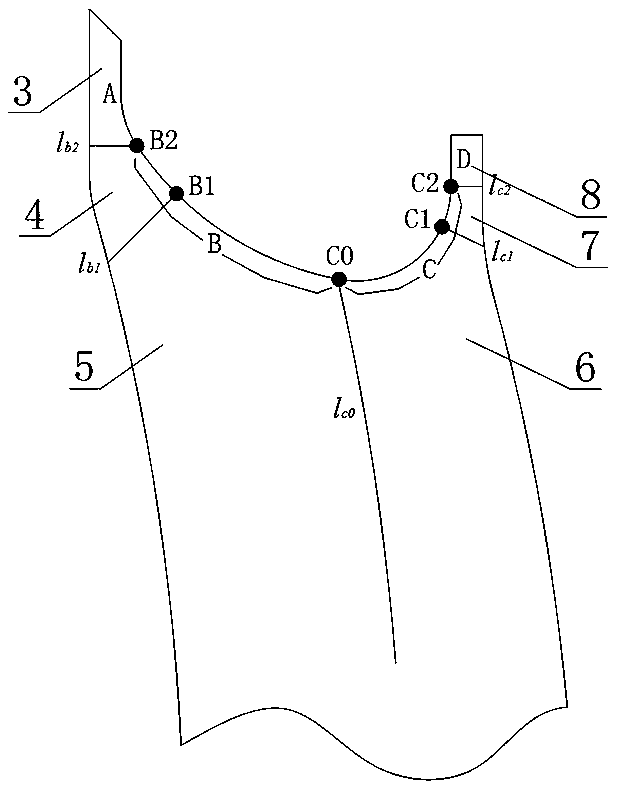

[0042] 3) Determine and obtain multi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com