High-efficiency high-precision white vehicle body static stiffness measurement system and test method

A measurement system and technology of body-in-white, which is applied in the field of high-efficiency and high-precision body-in-white static stiffness measurement system, can solve the problems of signal interference, inability to calculate the stiffness value accurately, and difficult to achieve, achieve accurate alignment and level adjustment, and shorten the test preparation. time, the effect of improving measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

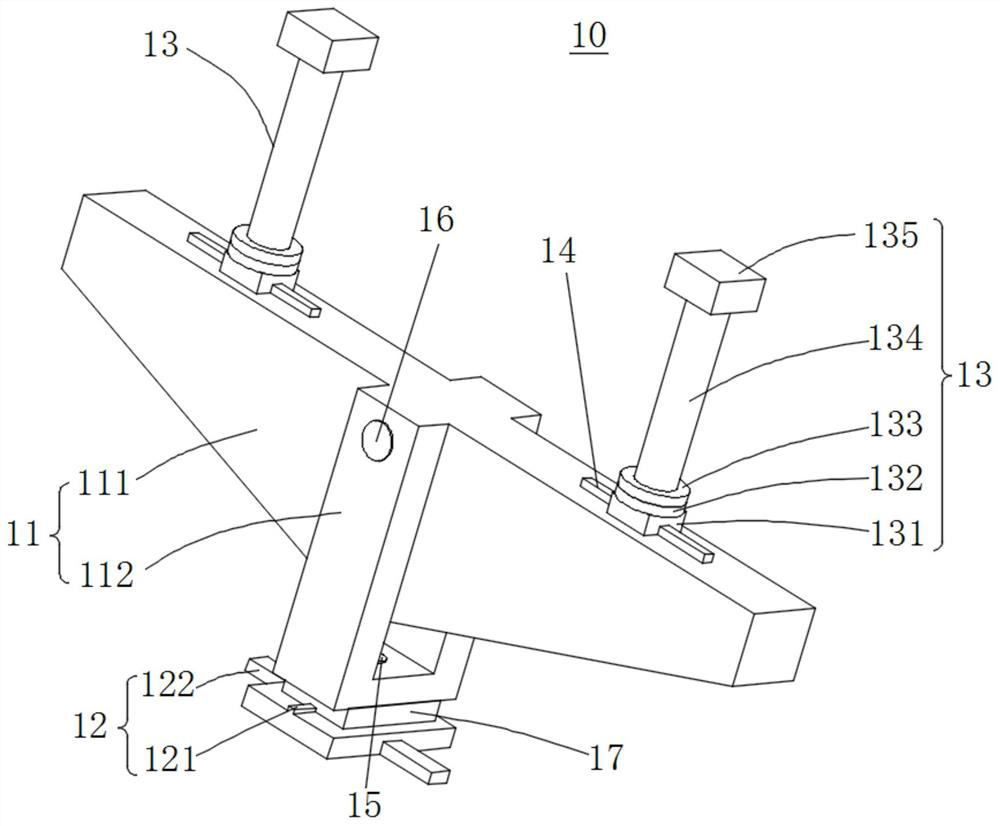

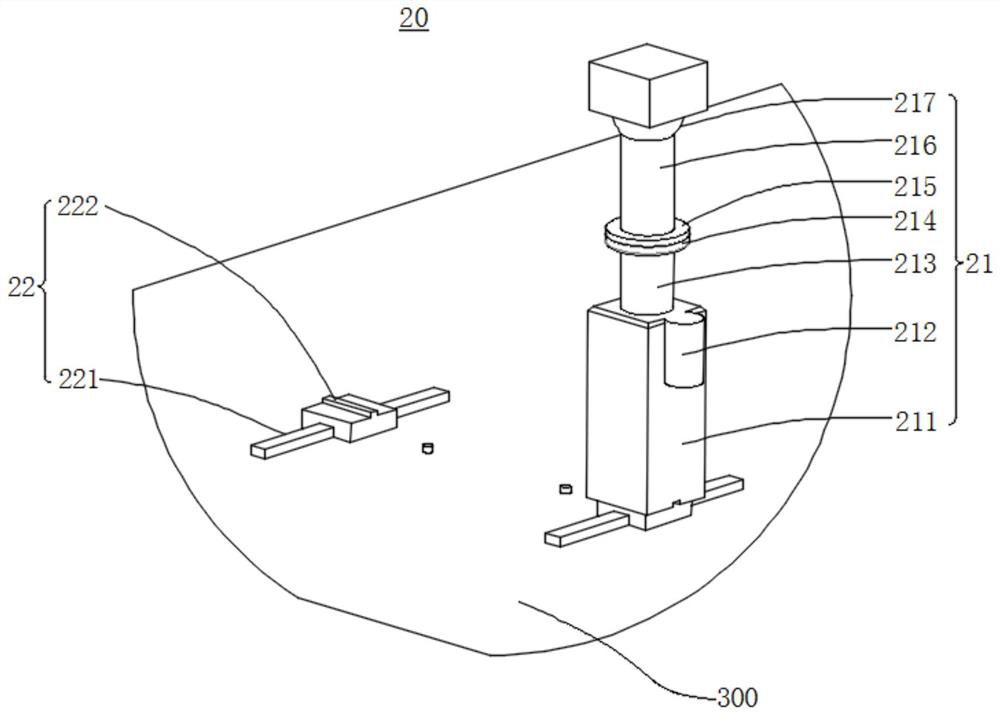

[0056] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described in detail with reference to the accompanying drawings. In the scheme described below, the longitudinal axis of the body-in-white 200 to be tested is the X direction, the left and right sides of the body-in-white are the Y direction, and the direction perpendicular to the iron floor of the test bench is the Z direction.

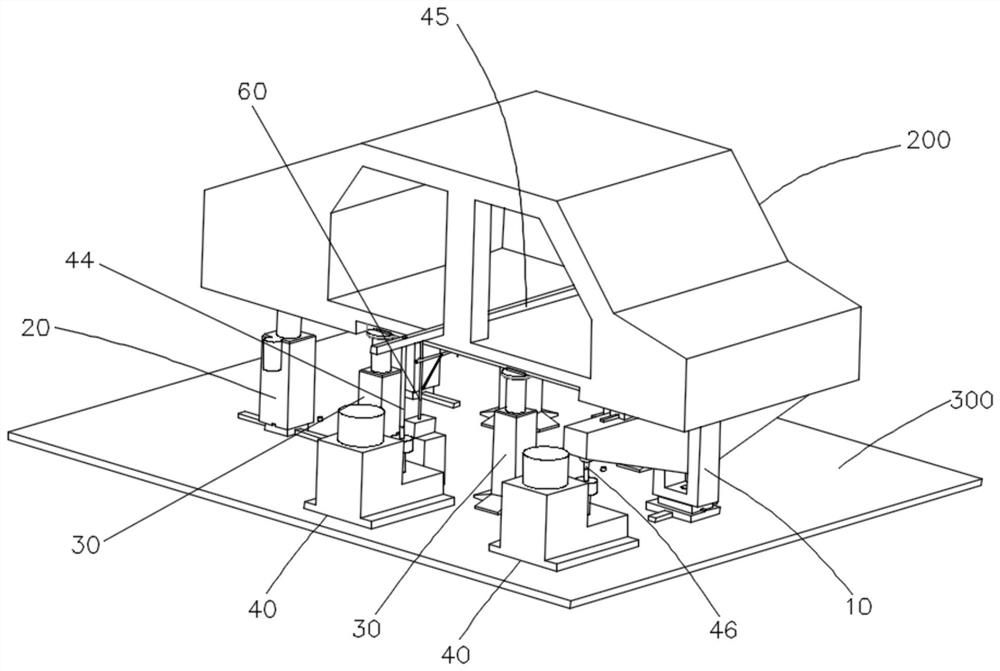

[0057] Such as figure 1 As shown, a high-efficiency and high-precision body-in-white static stiffness measurement system provided by an embodiment of the present invention includes a restraint support system, a servo loading system, a vehicle body attitude level detection device 50, a displacement measurement device 60, and a data acquisition and processing system. Wherein, the constraint support system includes a front suspension constraint support device 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com