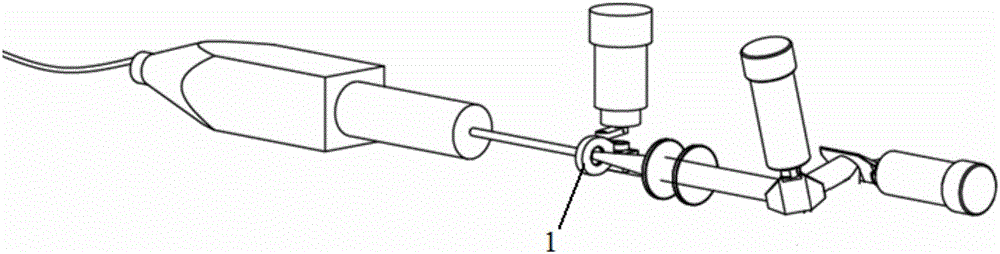

Dynamic axis mirror bracket

A dynamic shaft and mirror frame technology, applied in instruments, laser welding equipment, optics, etc., can solve the problems that low-power motors cannot achieve high-speed motion, rigidity is difficult to be significantly improved, and it is difficult to meet the needs of high-speed motion, so as to achieve good machining performance, excellent overall performance, and the effect of low thermal expansion coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

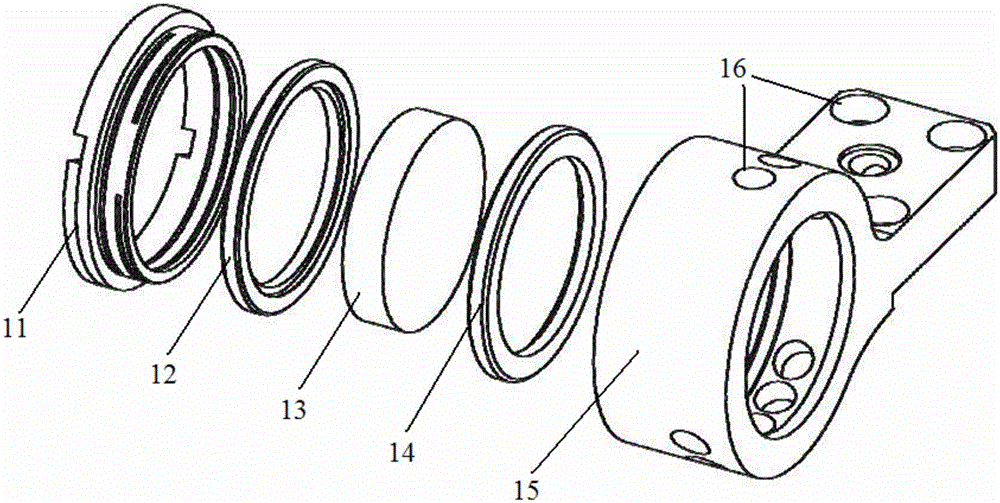

[0028] A1-AlN composite frame

[0029] The material composition ratio is A1-10wt.% AlN, adding A1N ceramic particles into the liquid aluminum, stirring and mixing and casting to prepare a particle-reinforced aluminum matrix composite material. The density of the aluminum matrix composite material is about 2.75g / cm 3 , no pores, cracks and other defects, the density reaches more than 98%, the elastic modulus reaches 95GPa, the thermal conductivity is about 160W / m.K, and the processing performance is good.

[0030] Compared with the aluminum alloy material, the wall thickness of the processed lens barrel is reduced to 12mm, and the lens barrel is punched and grooved at the same time. With the addition of aluminum alloy pressure rings, gaskets, etc., the overall weight of the frame is 0.49kg, and the overall weight reduction can reach 18%. The high-speed movement of the galvanometer can reach a linear speed of 9000mm / s, maintaining the stable operation of the dynamic focusing sys...

Embodiment 2

[0032] A1-15wt.% SiC composite mirror frame

[0033] The material composition ratio is A1-15wt.% SiC, aluminum alloy powder and SiC fiber material are used, and vacuum hot pressing is used to prepare a fiber-reinforced aluminum matrix composite material. The density of the aluminum matrix composite material is about 2.77g / cm 3 , no pores, cracks and other defects, the density reaches more than 95%, the elastic modulus reaches 120GPa, the thermal conductivity is about 230W / m·K, and the machinability is good.

[0034] Compared with the aluminum alloy material, the wall thickness of the processed lens barrel is reduced to 10mm, and the lens barrel is punched and grooved at the same time. With the addition of aluminum alloy pressure rings, spacers, etc., the overall weight of the frame is 0.4kg, and the overall weight reduction can reach 33%. The linear speed of the high-speed movement of the galvanometer can reach 15000mm / s, which keeps the dynamic focus system working stably.

Embodiment 3

[0036] A1-28wt.% Si composite mirror frame

[0037] The material composition ratio is A1-30wt.%Si, the aluminum powder and silicon powder are melted into a liquid state, and the particle-reinforced aluminum-based composite material is prepared by spray deposition. The density of the aluminum-based composite material is about 2.64g / cm 3 , no pores, cracks and other defects, the density reaches more than 98%, the elastic modulus reaches 90GPa, the thermal conductivity is about 110W / m.K, and the machinability is good.

[0038] Compared with the aluminum alloy material, the wall thickness of the processed lens barrel is reduced to 12mm, and the lens barrel is punched and grooved at the same time. With the addition of A1-30wt.% Si composite pressure rings, gaskets, etc., the overall weight of the frame is 0.42kg, and the overall weight reduction can reach 30%. The linear speed of the high-speed movement of the galvanometer can reach 10000mm / s, and the dynamic focusing system can be...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com