Composite bipolar plate for fuel cell and preparation method and application thereof

A bipolar plate and polymer technology, applied in fuel cells, applications, circuits, etc., can solve the problems of bipolar plate cost reduction, complex preparation process, low production efficiency, etc., and achieve crack resistance and stress deformation, and simple equipment requirements , Good product quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] a) take by weighing 0.6kg polystyrene resin (particle diameter is 400 orders, molecular weight 52W), 5.0kg flake graphite (particle diameter is 600 orders), 0.2kg SEBS triblock copolymer (melt index is 5g / min), 0.15kg of carbon fiber is ball milled, the ball milling speed is 20r / min, and the ball milling time is 18min;

[0030] b) Transfer the above mixed material to the mold, the pre-compression pressure is 40MPa, the molding temperature is 220°C, the molding pressure is 80MPa, and the molding time is 20min;

[0031] c) Cooling with circulating water, reducing the temperature of the mold in step b) to room temperature, releasing the pressure, and demoulding to obtain the bipolar plate.

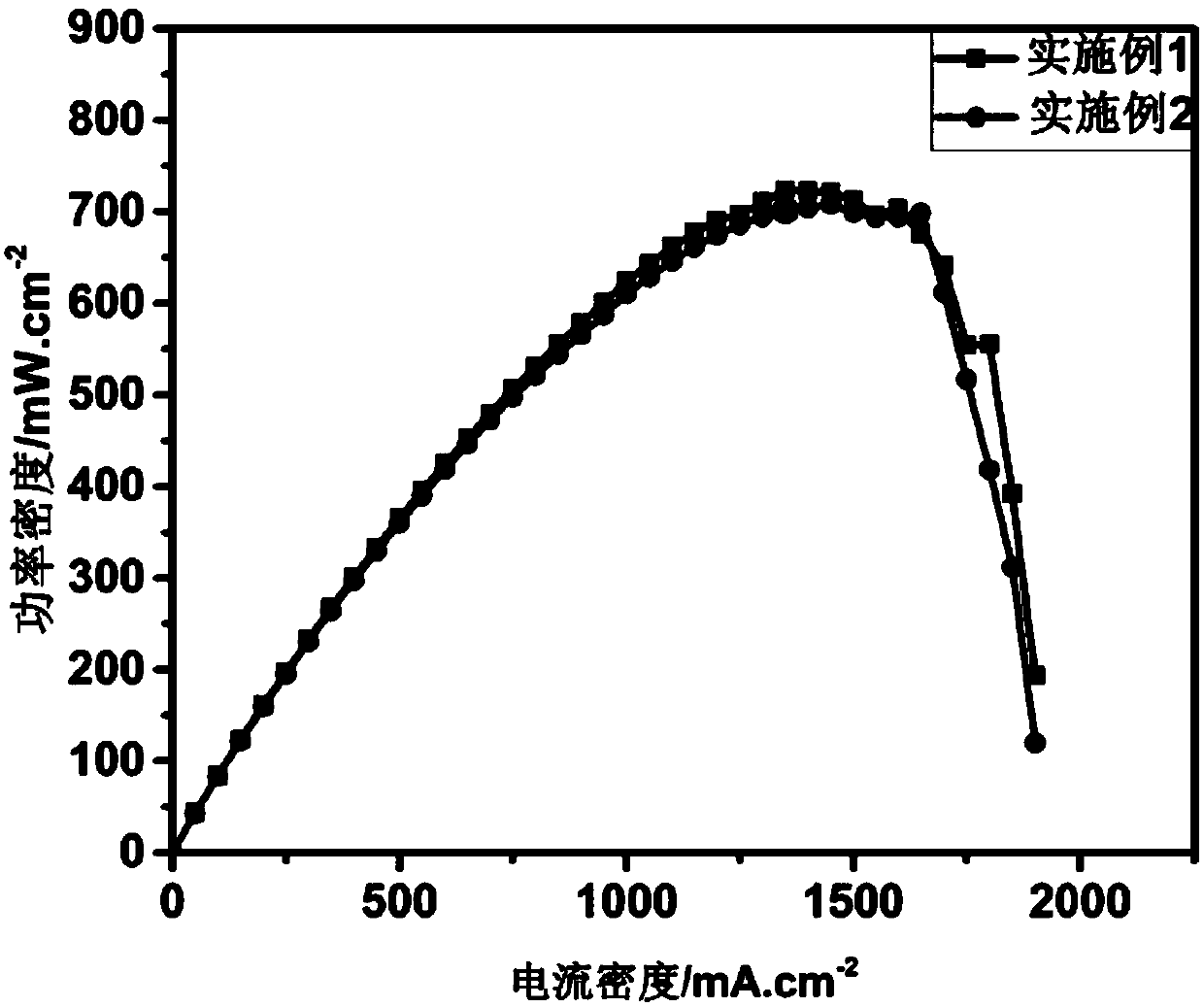

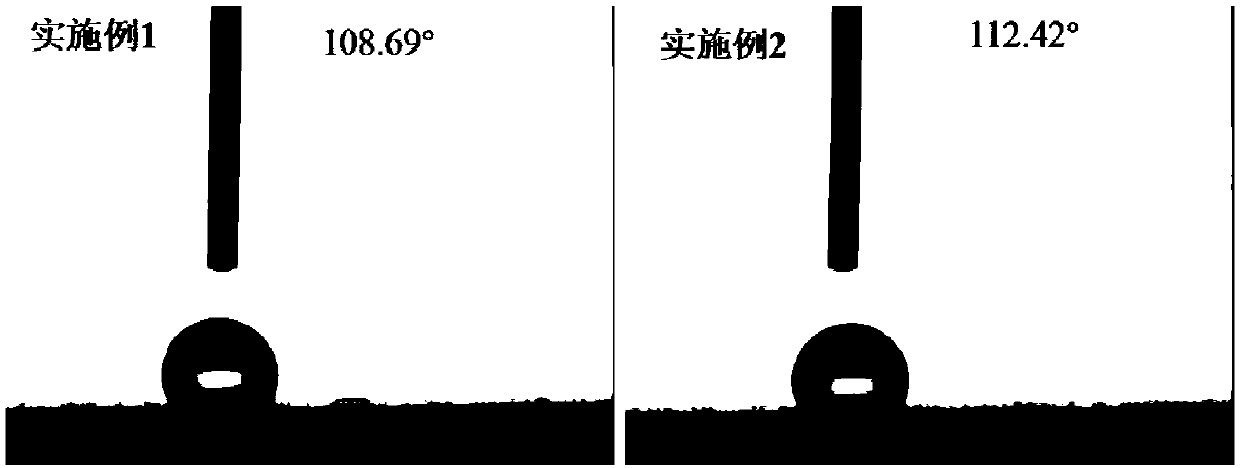

[0032] Such as figure 1 and figure 2 As shown, the measured conductivity of the obtained bipolar plate is 180S / cm, the bending strength is 51.8MPa, and the contact resistance is 6.8mΩ.cm 2 , the gas permeability is 1.24×10 -6 cm 3 / (cm 2 .s), the corrosion current is 1.13×10 -6...

Embodiment 2

[0034] a) take by weighing 0.8kg polystyrene resin (particle diameter is 600 orders, molecular weight 52W), 4.8kg flake graphite (particle diameter is 1000 orders), 0.25kg SEBS triblock copolymer (melt index is 12g / min), 0.25kg carbon fiber is ball milled, the ball milling speed is 30r / min, and the ball milling time is 27min;

[0035] b) Transfer the above mixed material to the mold, the pre-compression pressure is 50MPa, the molding temperature is 240°C, the molding pressure is 100MPa, and the molding time is 30min;

[0036] c) Using air cooling, the temperature of the mold in step b) is lowered to room temperature, the pressure is released, and the mold is demoulded to obtain the bipolar plate.

[0037] Such as figure 1 and figure 2As mentioned above, the measured conductivity of the obtained bipolar plate is 165S / cm, the bending strength is 58.6MPa, and the contact resistance is 8.3mΩ.cm 2 , the gas permeability is 0.88×10 -6 cm 3 / (cm 2 .s), the corrosion current is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com