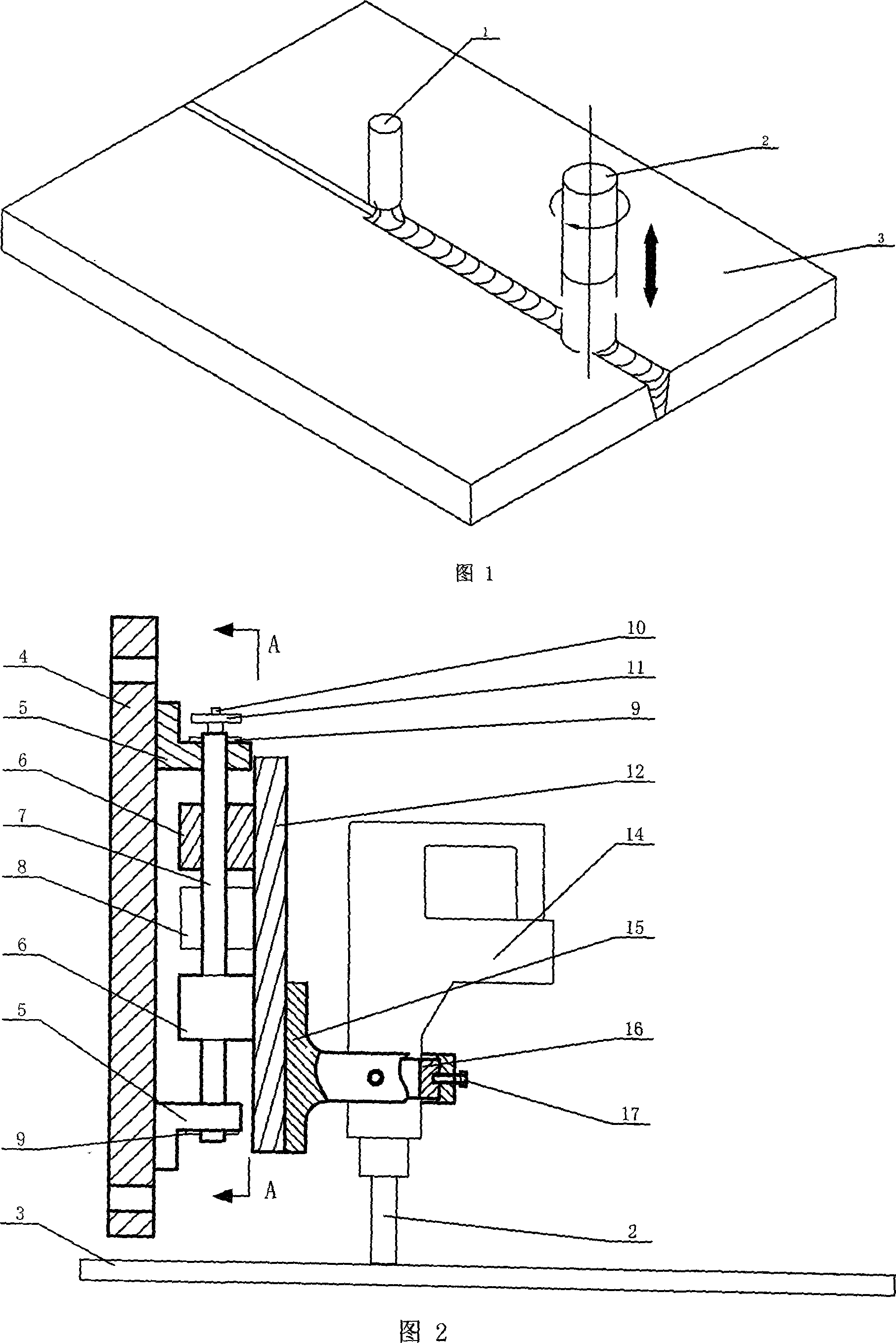

Device for controlling welding stress deformation along with soldering impact, revolving and extrusion pressing

A technology that follows welding impact and welding stress. It is applied in the direction of auxiliary equipment, welding equipment, auxiliary welding equipment, etc. It can solve the problems of poor working environment, high noise, and the distance between wheel and gun that cannot meet the theoretical ideal value, etc., and achieve low cost and low noise. The effect of small and small residual deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 2

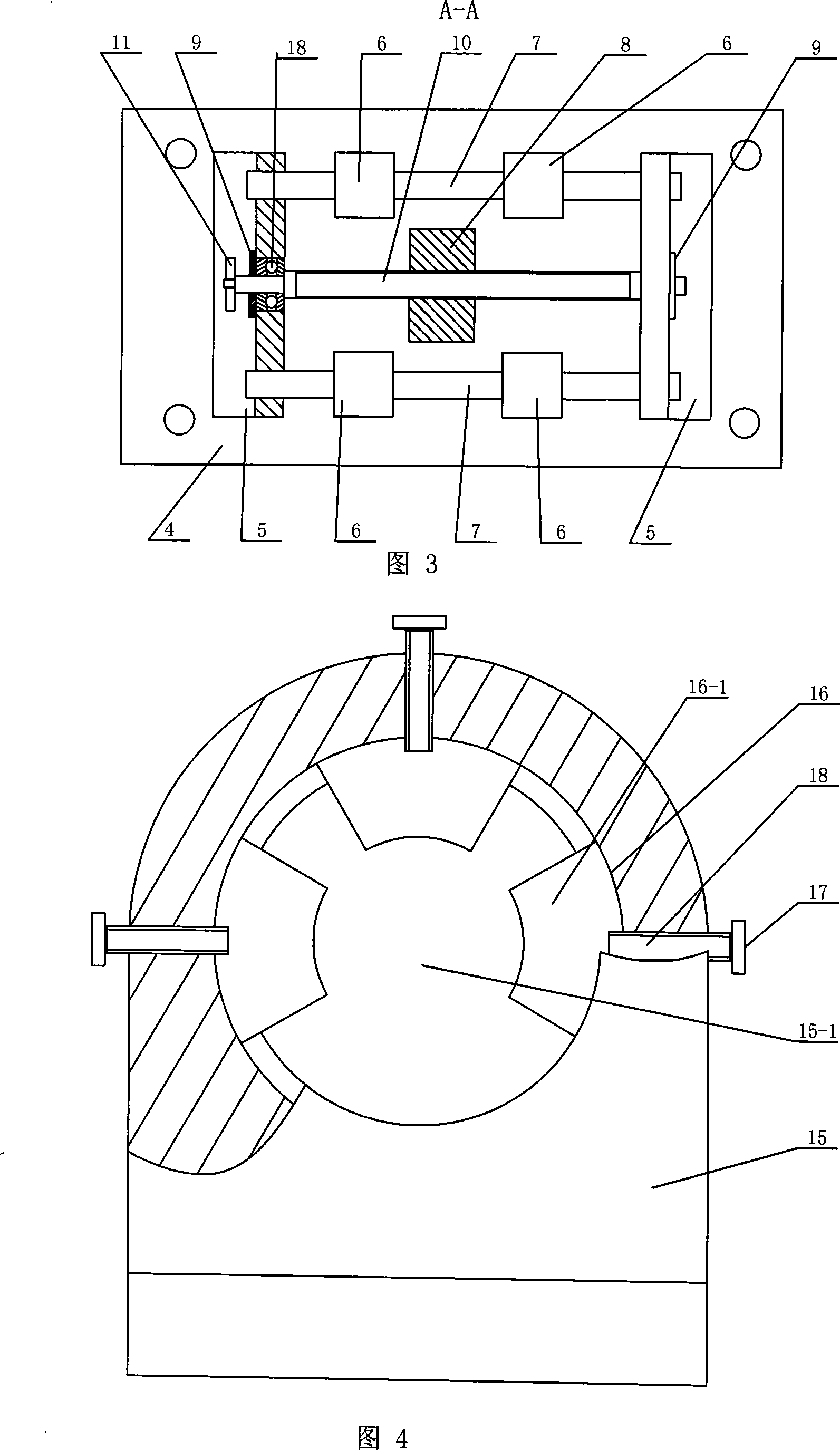

[0007] Specific Embodiment 2: This embodiment is described in conjunction with FIG. 4 . In this embodiment, the clamping block 16 is composed of three clamping block monomers 16-1, and the three clamping block monomers 16-1 are fixed on the channel of the second support 15. In the hole 15-1 and evenly distributed along the circumference of the hole wall, the outer end surface of the block unit 16-1 is tangent to the inner hole wall of the through hole 15-1, and the inner end surface of the block unit 16-1 is in contact with the electric hammer 14 Tangent to the outer wall. Such setting is for positioning the electric hammer 14 . Other compositions and connections are the same as those in the first embodiment.

[0008] Specific embodiment three: This embodiment is described in conjunction with FIG. 4. In this embodiment, the adjustment member 17 is a set screw 18, and the three clamping block monomers 16-1 are fixed to the second support 15 through three set screws 18, respect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com