Patents

Literature

32results about How to "Good quality joints" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing bimetal composite plate by stirring friction braze welding

InactiveCN101530947APrevent thinningAvoid direct contactNon-electric welding apparatusSurface layerShielding gas

The invention discloses a method for preparing a bimetal composite plate by stirring friction braze welding. The method comprises that: a plate with small hardness is used as a covering layer metal plate; a plate with high hardness is used as a base layer metal plate; the covering layer metal plate and the base layer metal plate are horizontally fixed on a working platform surface in a lap joint mode; solders which can generate eutectic reaction with one of the upper / base layer metal plates are preset between the upper / base layer metal plates; a non-needle type cylinder friction device is arranged over the covering layer metal plate; the non-needle type cylindrical friction device is made to rotate and be pressed to be closely contacted with the surface layer of the covering layer metal plate, but not penetrate the covering layer metal plate, and the non-needle type cylindrical friction device rotates in the original position or moves forward along the surface of the covering layer metal plate while rotating; by utilizing frictional heat to melt the solders, the upper / base layer metal plates are both quickly melted in the solders, thereby achieving excellent interface combination; and the excessive solders are squeezed out, and a thin and dense soldering seam is formed, so that the bimetal composite plate is prepared. Compared with the braze welding in a furnace, the method has the advantages of high efficiency, energy conservation, pressure lead-in, unnecessary soldering flux and gas protection and short holding time at a high temperature.

Owner:XI AN JIAOTONG UNIV

Composite zinc-aluminum flux cored wire containing beryllium and magnesium and rubidium salt and preparation method of flux cored wire

ActiveCN102935559AImprove cleanlinessImprove intergranular corrosion resistanceWelding/cutting media/materialsSoldering mediaRare-earth elementAluminum fluoride

The invention discloses a composite zinc-aluminum flux cored wire containing beryllium and magnesium and rubidium salt. The composite zinc-aluminum flux cored wire comprises a wire body consisting of an outer metal skin and core brazing flux powder, wherein the outer metal skin is prepared by the following raw materials by weight percent: 80.5 to 98.5% of zinc, 0.01 to 6.5% of silver, 0.01 to 3% of copper, 0.001 to 2% of nickel, 0.001 to 0.5% of beryllium, 0.001 to 1.2% of magnesium, 0.001 to 0.5% of rare earth element and the balance of aluminum; and the brazing flux powder is prepared by the following raw materials by weight percent: 15 to 35% of aluminum fluoride, 30 to 75% of cesium fluoride, 2.5 to 10% of rubidium fluoride, and the balance of potassium fluoride. The invention also provides a preparation method of the composite zinc-aluminum flux cored wire. The preparation method has the advantages that trace Be and Mg are introduced based on the conventional Zn-Al-Ag-Cu alloy system in the brazing filed, so that the cleanness of the wire can be improved, the quality and the reliability of a brazing joint are ensured, and the intercrystalline corrosion resistance of the wire can be greatly improved, and as a result, the phenomenon of 'embrittlement' can be delayed or inhibited.

Owner:ZHENGZHOU RES INST OF MECHANICAL ENG CO LTD

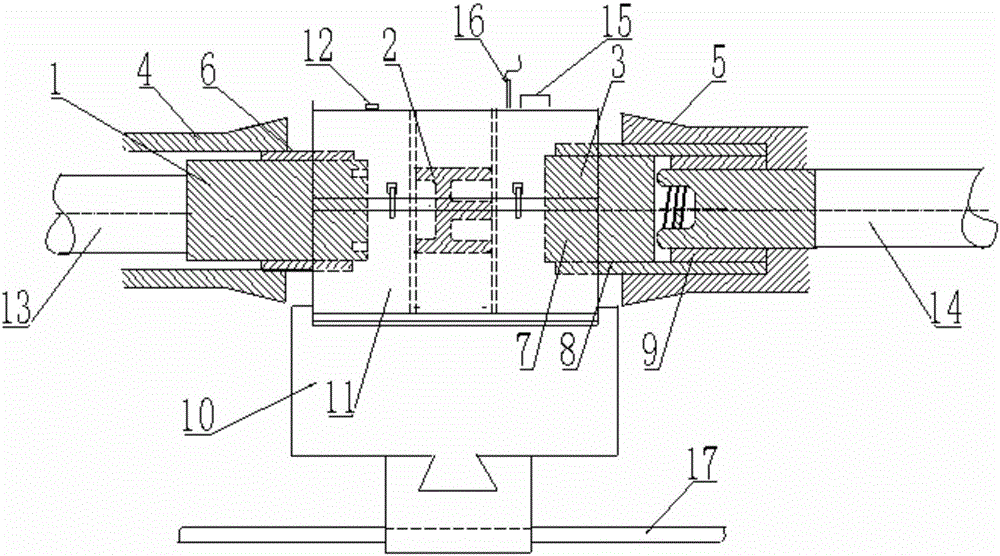

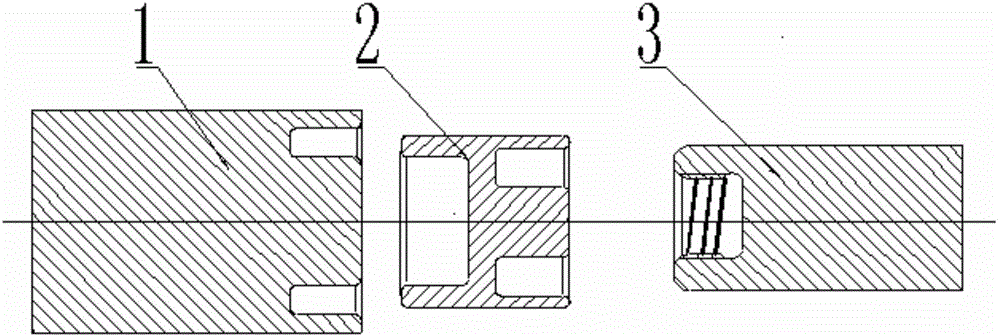

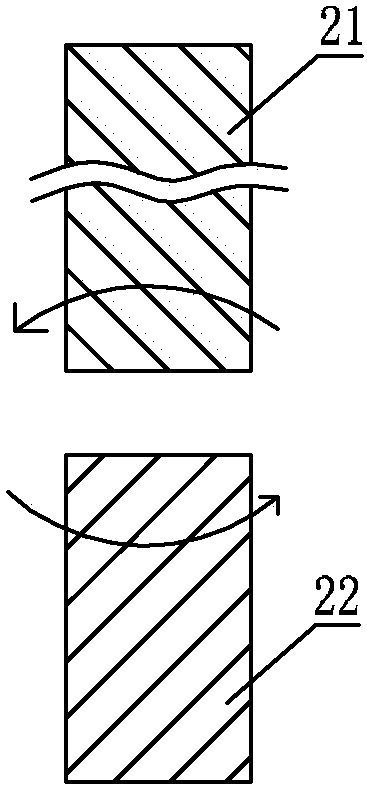

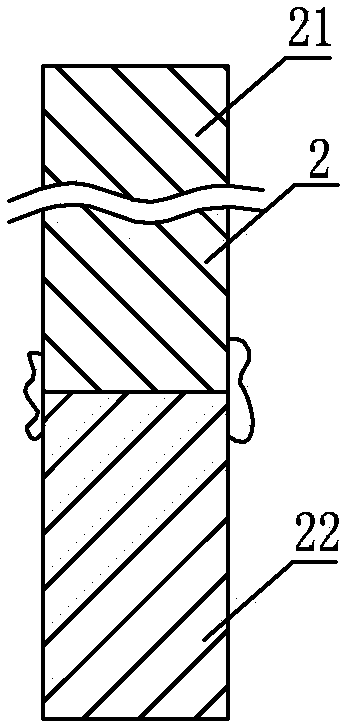

Dissimilar material composite welding method

ActiveCN106735969AImprove welding qualityGood quality jointsWelding/soldering/cutting articlesWelding apparatusFriction weldingTransition layer

The invention discloses a dissimilar material composite welding method. The dissimilar material composite welding method comprises the following steps: firstly, a welding device is obtained; secondly, a to-be-welded part a and a to-be-welded part c which are each made of dissimilar materials and wholly in a columnar shape are obtained, and the dissimilar material composite welding method is characterized in that the welding device in the first step further comprises a heater; thirdly, a middle transition layer and a top pressure bar are obtained; fourthly, the middle transition layer and the to-be-welded part a are in diffusion welding; fifthly, friction pre-welding clamping is carried out; sixthly, friction pre-welding preheating is carried out; seventhly, inertia friction welding connection of a material with the middle transition layer is carried out; and eighthly, after-welding treatment is carried out. The dissimilar material composite welding method has the beneficial effects of being higher in welding efficiency and better in welding quality.

Owner:CHONGQING UNIV OF TECH

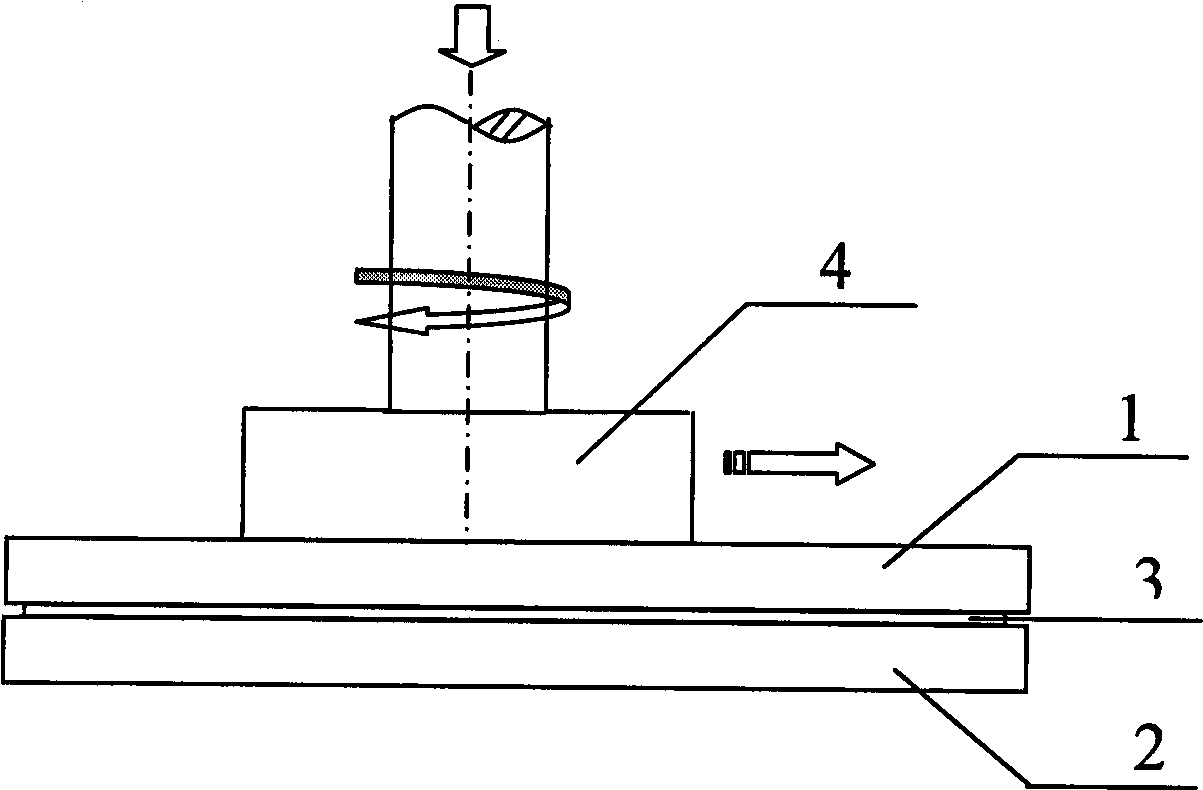

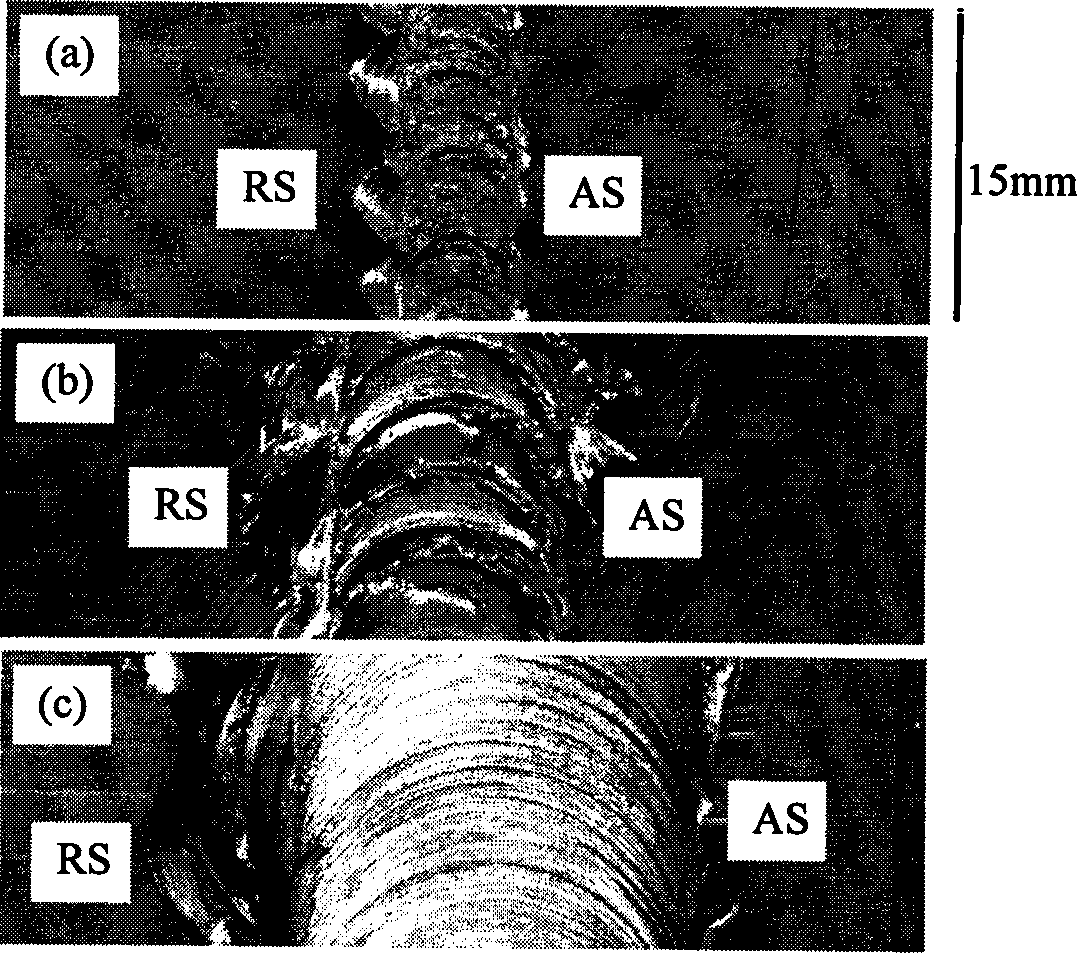

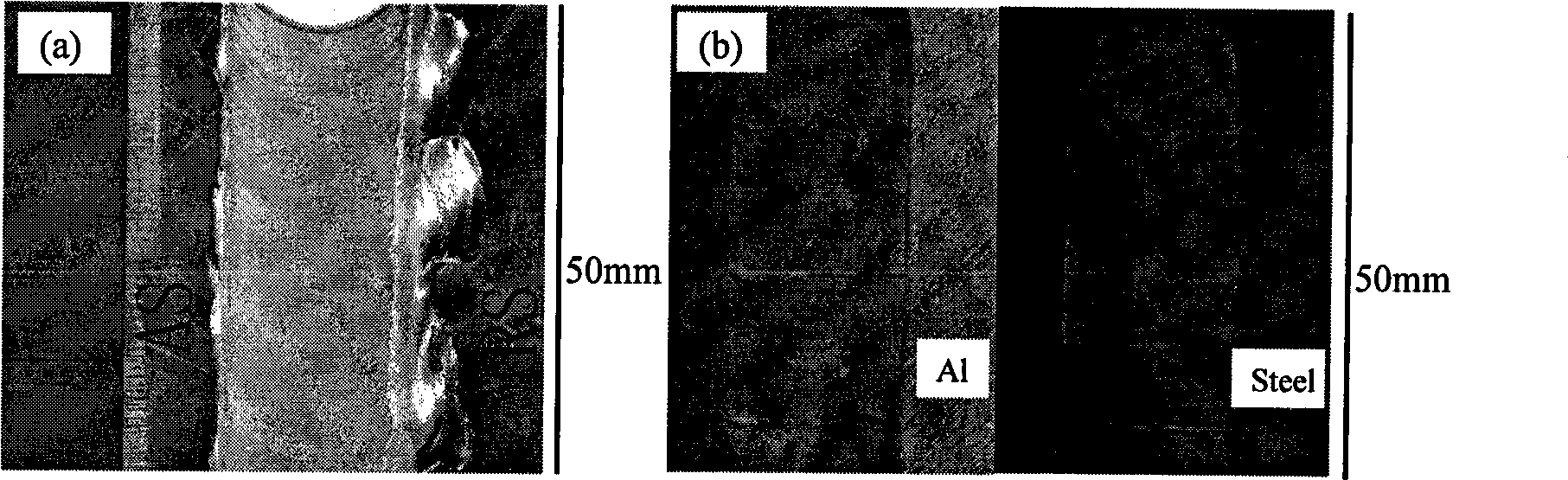

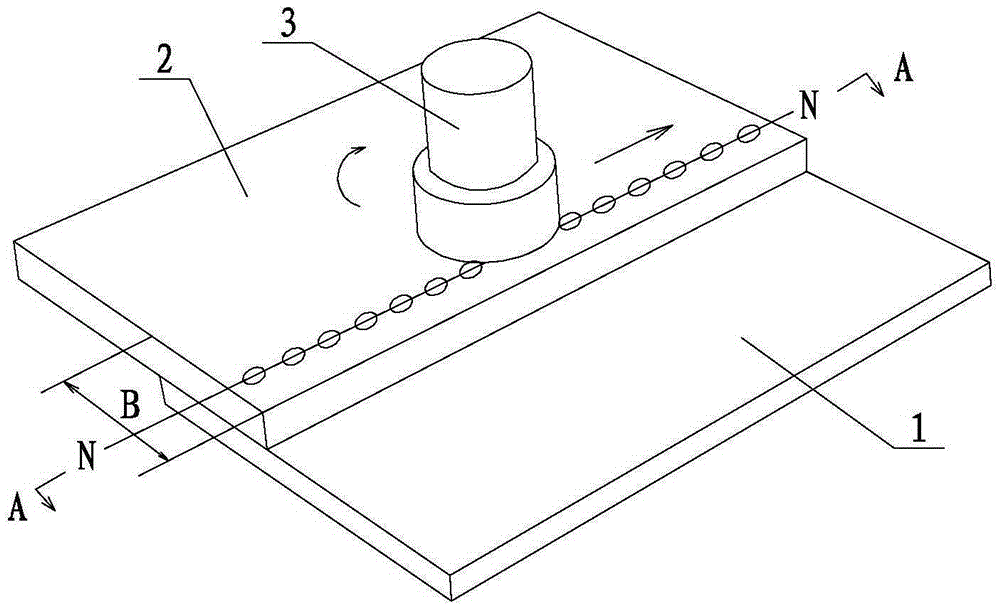

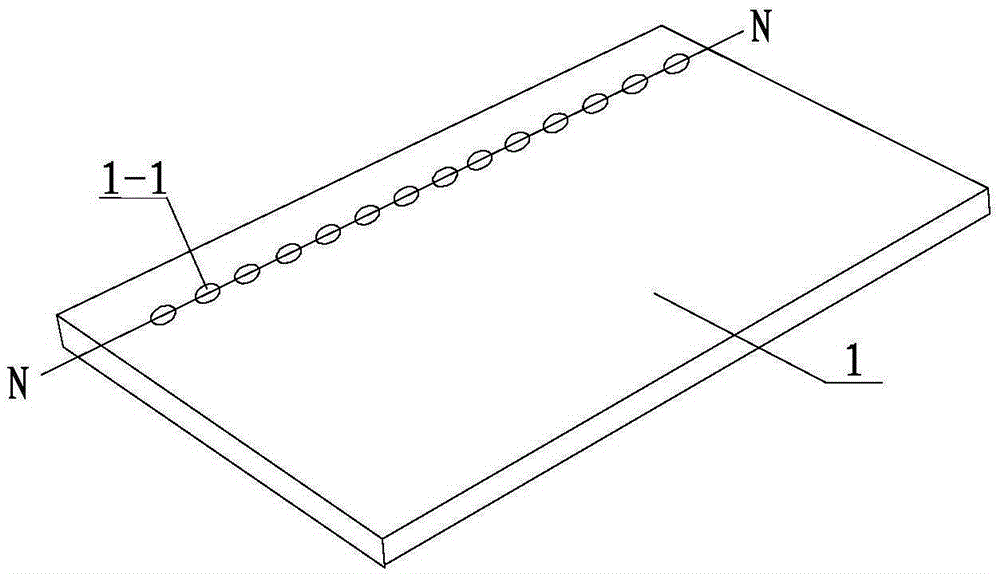

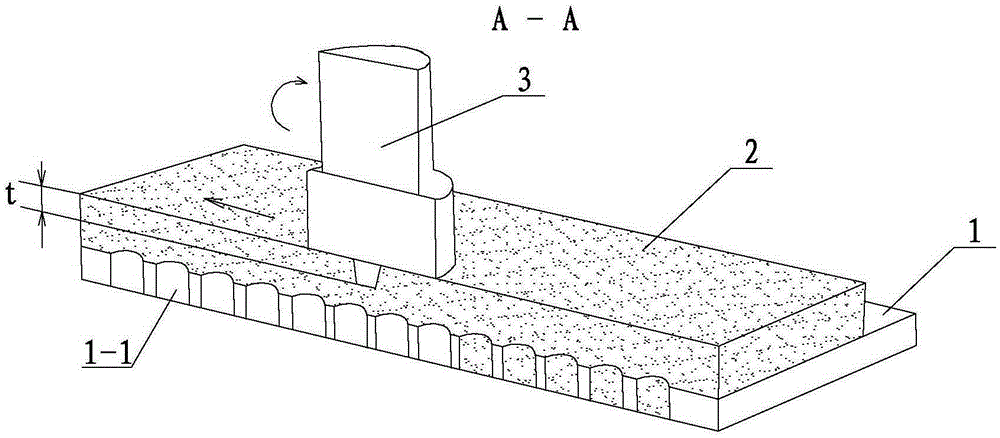

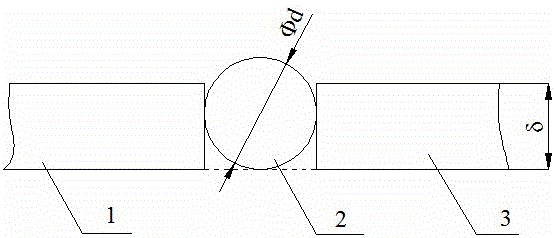

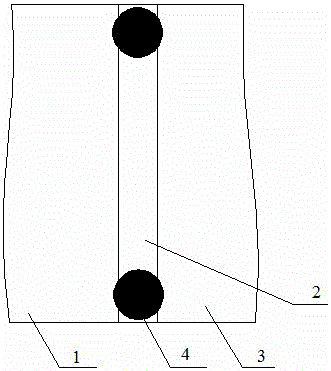

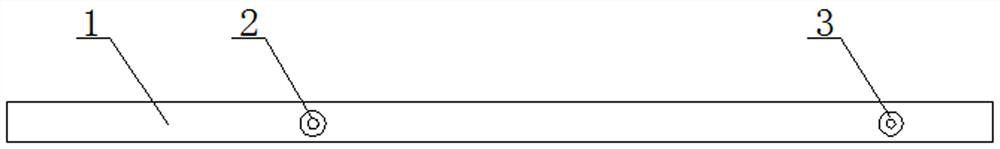

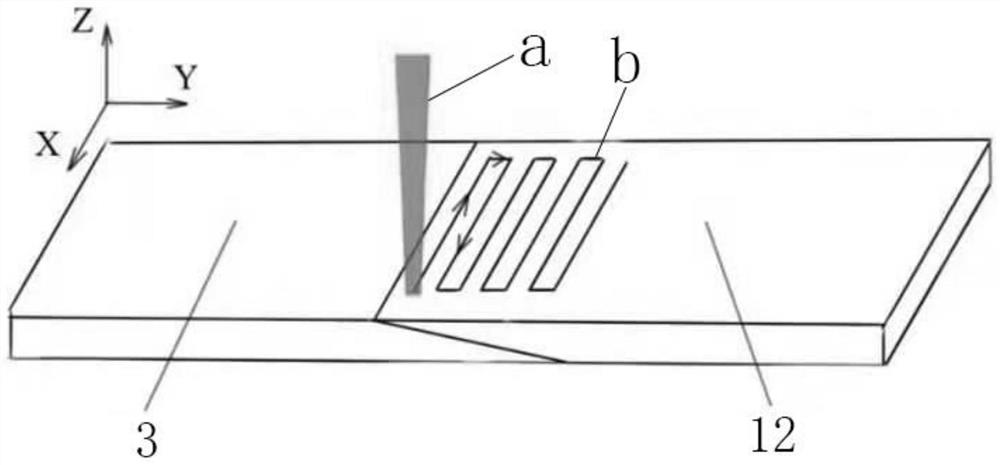

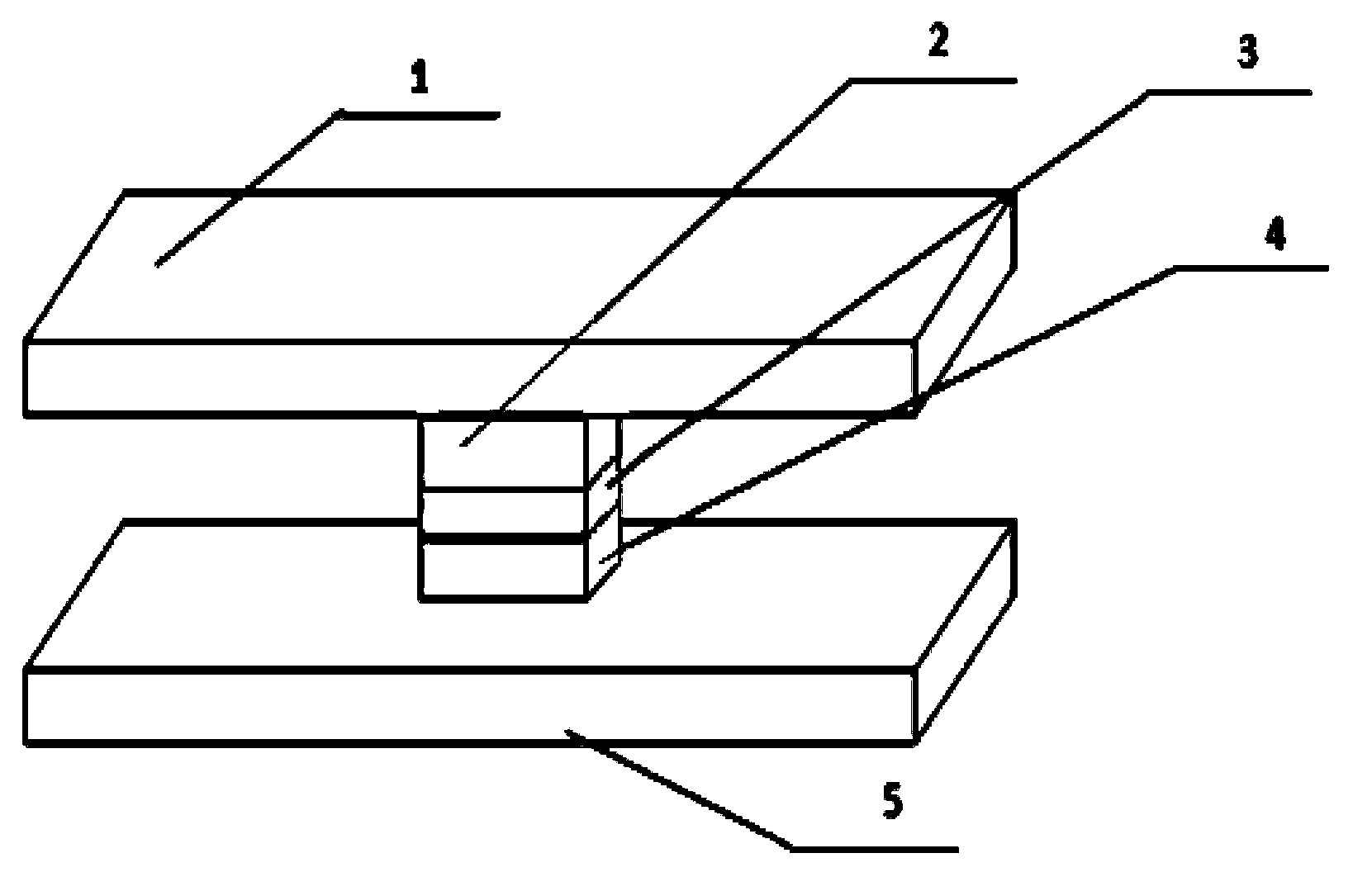

Aluminum/steel dissimilar material friction-stir lap joint method assisted by rivet type mechanical connection

InactiveCN105290608AReduce wearWeakening Effects of Weakening Carrying CapacityWelding/soldering/cutting articlesNon-electric welding apparatusLap jointDrill hole

Provided is an aluminum / steel dissimilar material friction-stir lap joint method assisted by rivet type mechanical connection. The lap join method aims at solving the problems that aluminum / steel dissimilar metals are prone to reaction to generate brittle intermetallic compounds in the existing connection process of brazing or fusion welding, and the bearing area of connectors is small and the bearing capacity of the aluminum / steel dissimilar connectors is weakened in the friction-stir-welding lap joint process. The method comprises the steps that (1) a row of pre-drilled holes are drilled in the lap joint width direction B of a steel plate along the longitudinal central line; (2) contact surfaces and the peripheral areas of the steel plate and an aluminum plate are cleaned up, and oxides on the surface of the steel plate and the surface of the aluminum plate are removed; (3) the surface of the steel plate and the surface of the aluminum plate are wiped with organic solvents or cleaning agents; and (4) the aluminum plate and the steel plate are fixed through a clamp, in the friction stir welding process, a stirring head and the aluminum plate rub, softened aluminum flows downwards, and then the pre-drilled holes in the steel plate are filled, so that a rivet type connecting structure is formed, and an aluminum / steel friction-stir lap joint connector which is strengthened through mechanical connection is obtained. The method is used for friction-stir lap joint of dissimilar materials.

Owner:HARBIN INST OF TECH

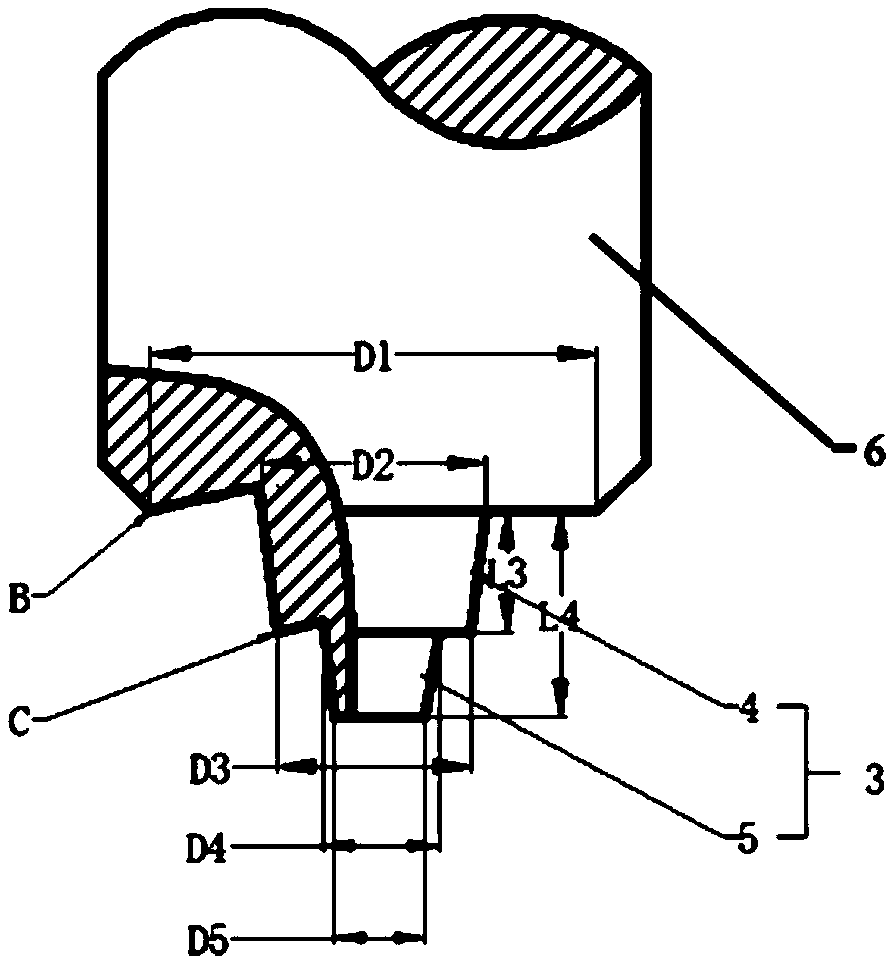

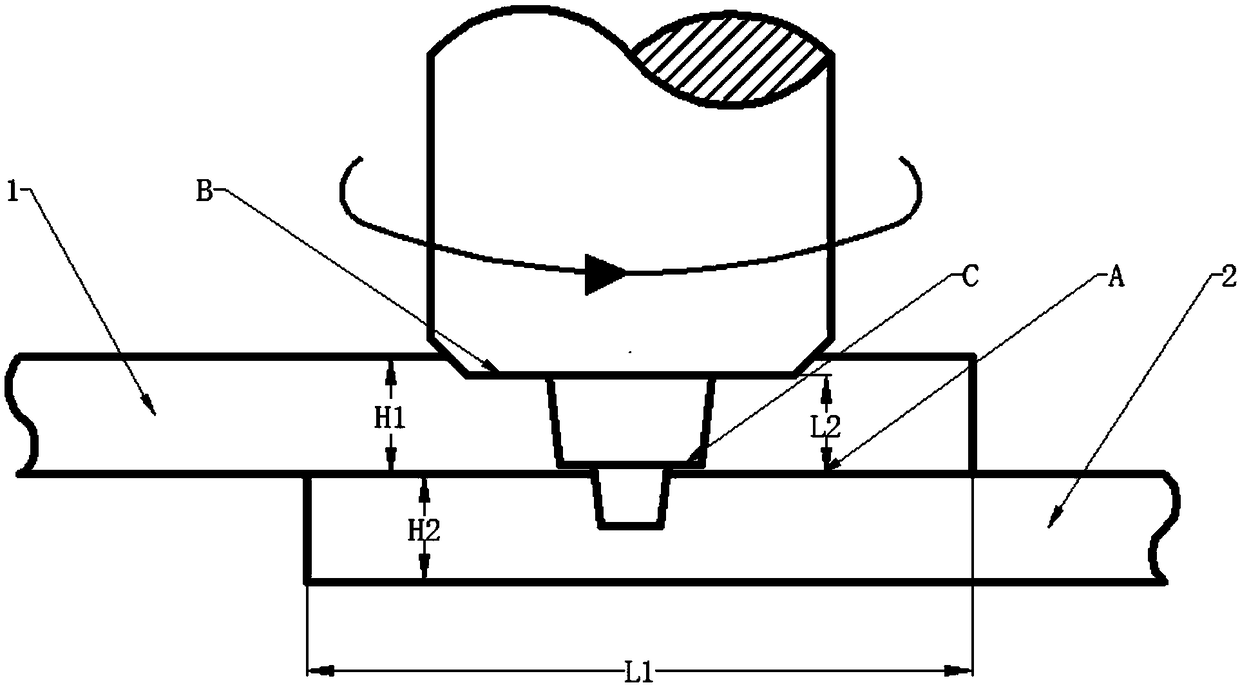

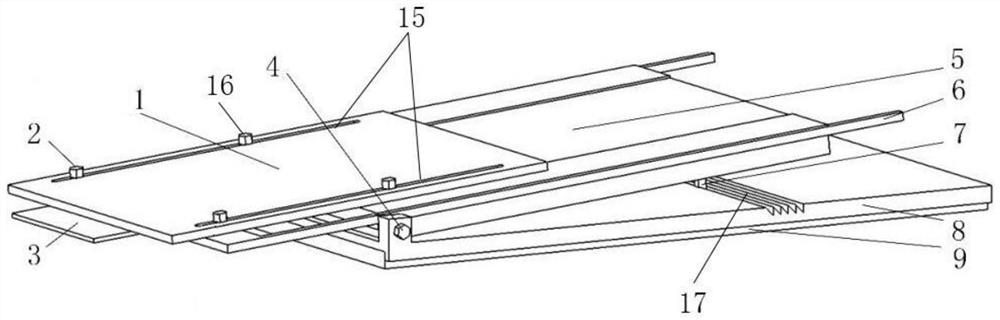

Welding device and method for improving hook-shaped defects of friction stir welding overlap joint

ActiveCN108838510AIncrease the effective bearing thicknessAvoid detrimental effects on performanceNon-electric welding apparatusBiomedical engineeringFriction stir welding

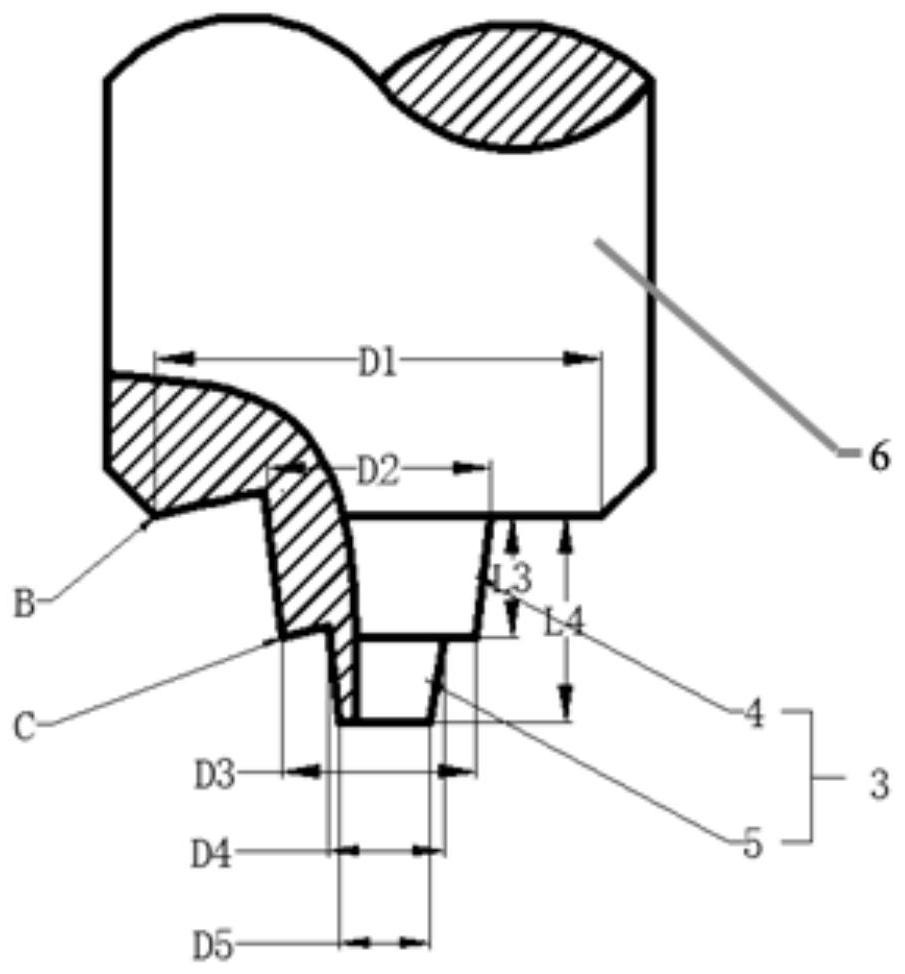

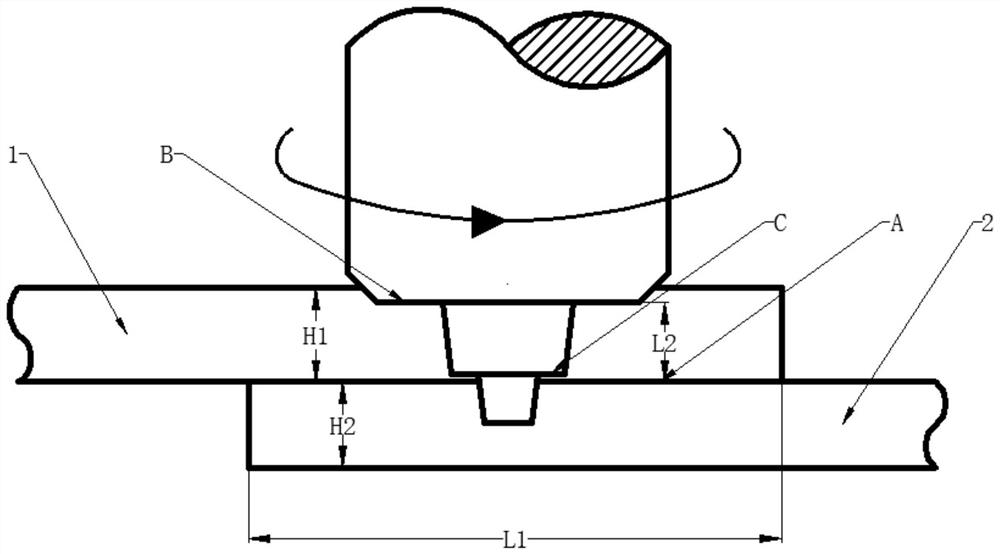

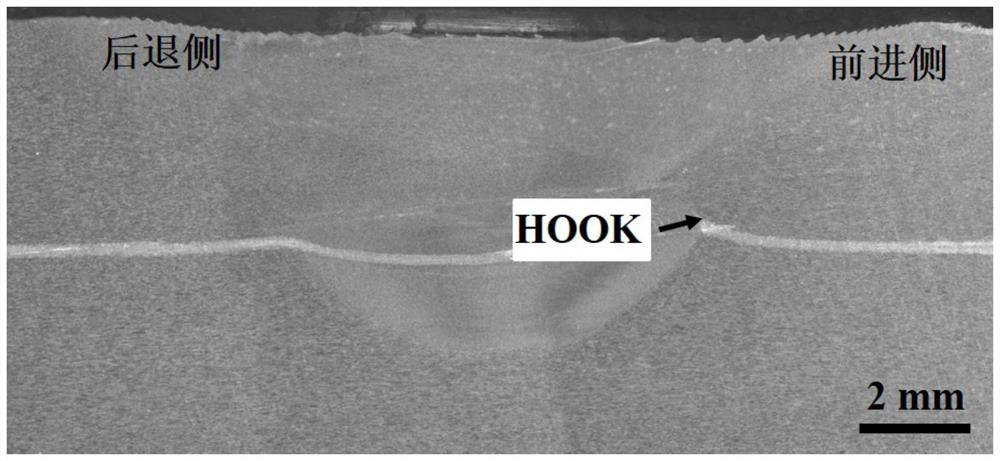

The invention provides a welding device and method for improving hook-shaped defects of a friction stir welding overlap joint. The device comprises a stirring head and a motor connected with the stirring head. The stirring head is composed of a shaft shoulder and bottom two-stage stirring needles coaxially and integrally arranged with the shaft shoulder. The first-stage stirring needle and the second-stage stirring needle of the two-stage stirring needles are of a conical or cylindrical structure, the first-stage stirring needle is located above the second-stage stirring needle, and the diameter of the lower bottom surface of the first-stage stirring needle is larger than the diameter of the upper bottom surface of the second-stage stirring needle. The method comprises the steps of measuring geometric parameters of workpieces to be welded and the stirring head, fixing the workpieces to be welded, determining the position of welding, determining the depth of pressing and friction stir welding. By adopting the welding device and method for improving the hook-shaped defects of the friction stir welding overlap joint, an overlap joint with a "HOOK" shape and a horizontal or even slightly downward bending feature can be obtained, and the effective load bearing thickness of the joint can be significantly increased. In addition, the welding device and method for improving the hook-shaped defects of the friction stir welding overlap joint are simple in operation, easy to implement, and suitable for friction stir welding of overlap joint structures of various thicknesses.

Owner:SHENYANG AEROSPACE UNIVERSITY

Martensite heat resistant steel electrode for 650 DEG C supercritical thermal power unit with back side free of argon filling, single-side welding and double-side molding

ActiveCN110508968AIncrease marginSolve the need for argon backfilling in large buildsWelding/cutting media/materialsSoldering mediaSlagMartensite

The invention discloses a martensite heat resistant steel electrode a 650 DEG C supercritical thermal power unit with a back side free of argon filling, single-side welding and double-side molding. Aslag series formula of CaO-CaF2-TiO2-Zr2O3 is adopted, and the main components of deposited metal comprise 9% of Cr, 3% of W and 3% of Co. The martensite heat resistant steel electrode has excellent single-side welding and double-side molding technological properties; during welding, an electrode coating can be molten for forming a layer of thin slag infiltrated into the back side of a workpiece and uniformly covering the surface of a weld joint at the back side so that the weld joint is protected from being oxidized; and slag is easy to clear. Under the heat treatment condition of 100 DEG Cx1h+780 DEG Cx3 h, the tensile strength of the deposited metal is not lower than 720 MPa, and the elongation and normal temperature impact property of the deposited metal are particularly excellent, and are not lower than 150 J; and the martensite heat resistant steel electrode is especially suitable for the priming requirements of the 650 DEG C supercritical thermal power unit with the back side free of argon filling, single-side welding and double-side molding.

Owner:KUSN GINTUNE WELDING

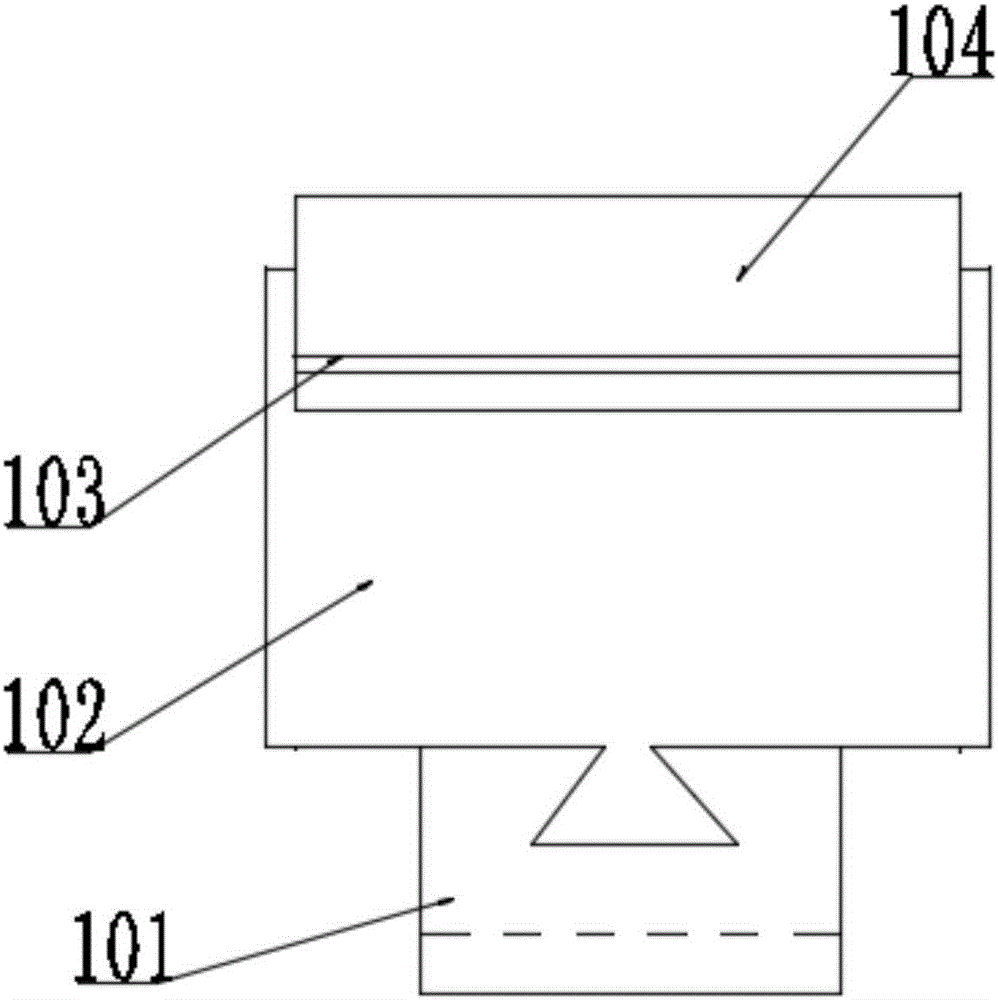

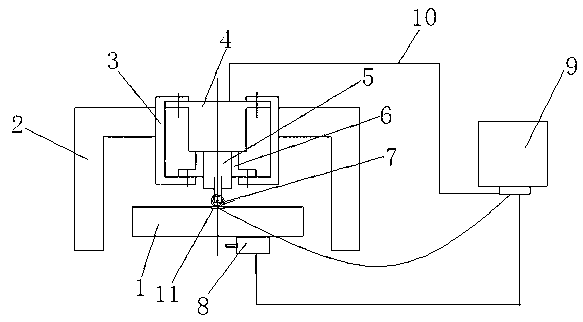

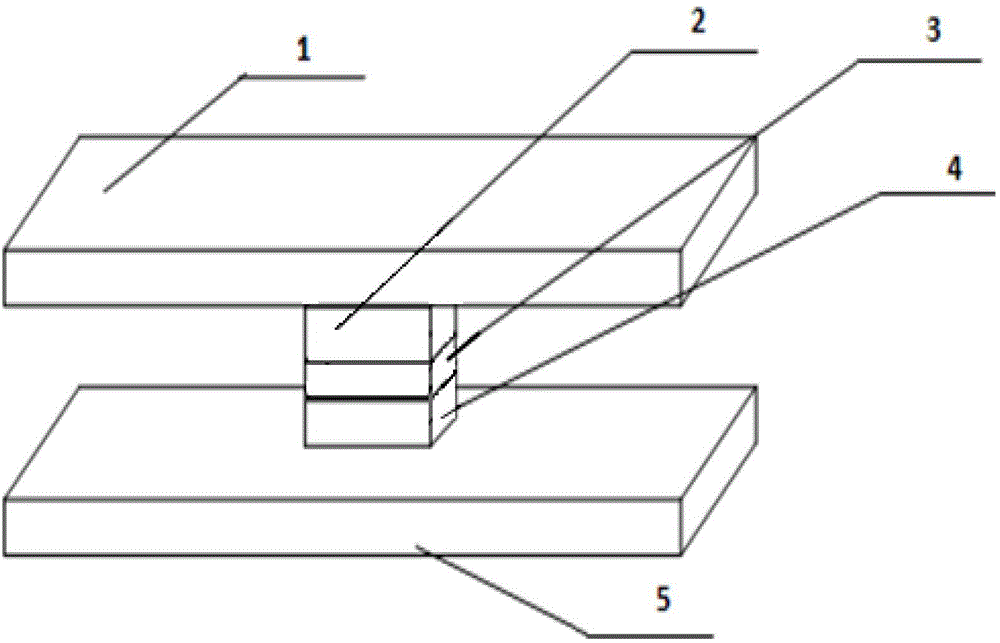

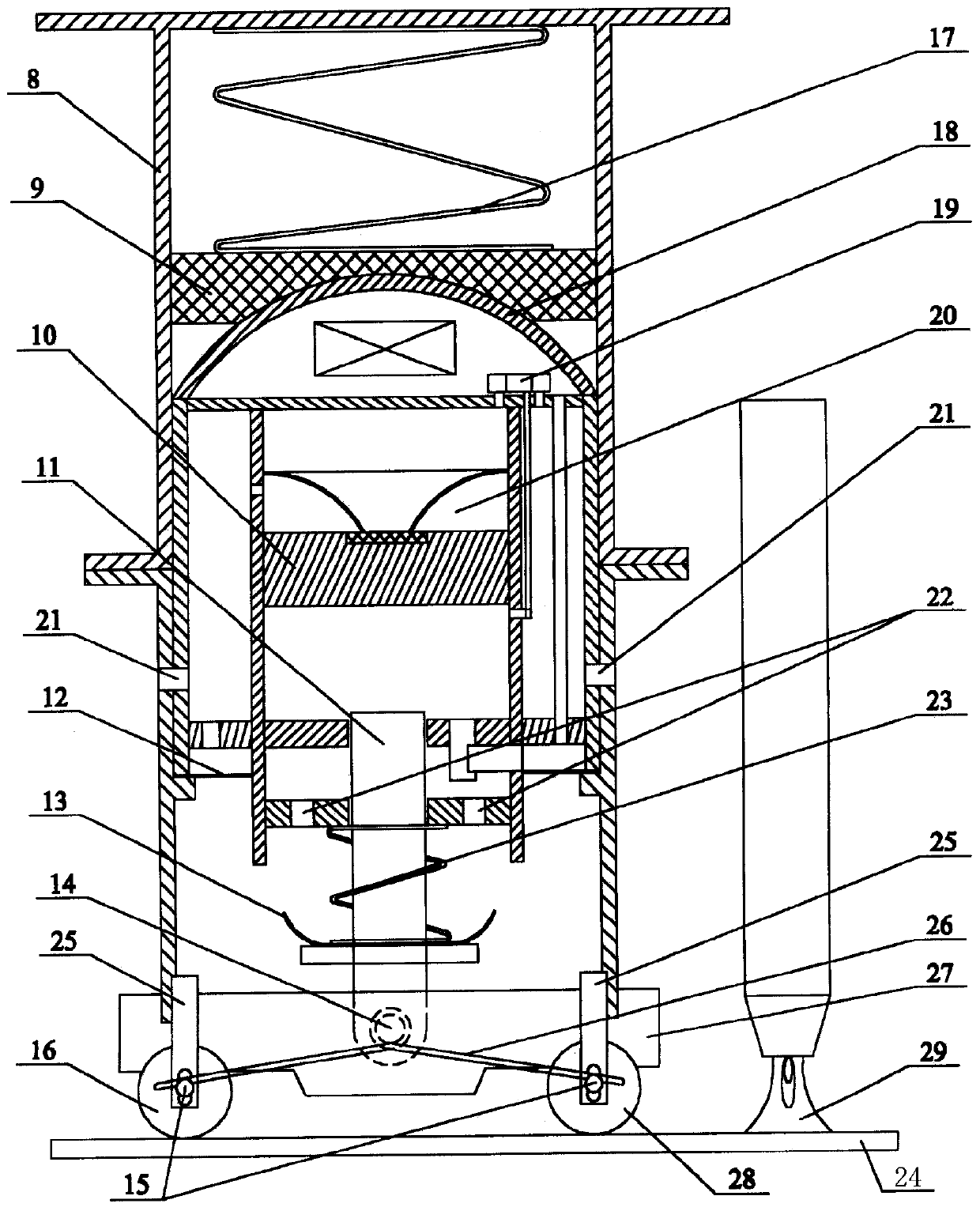

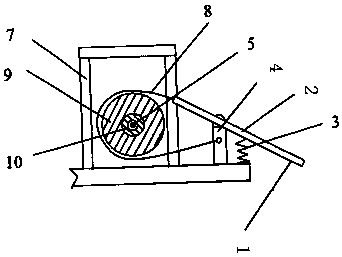

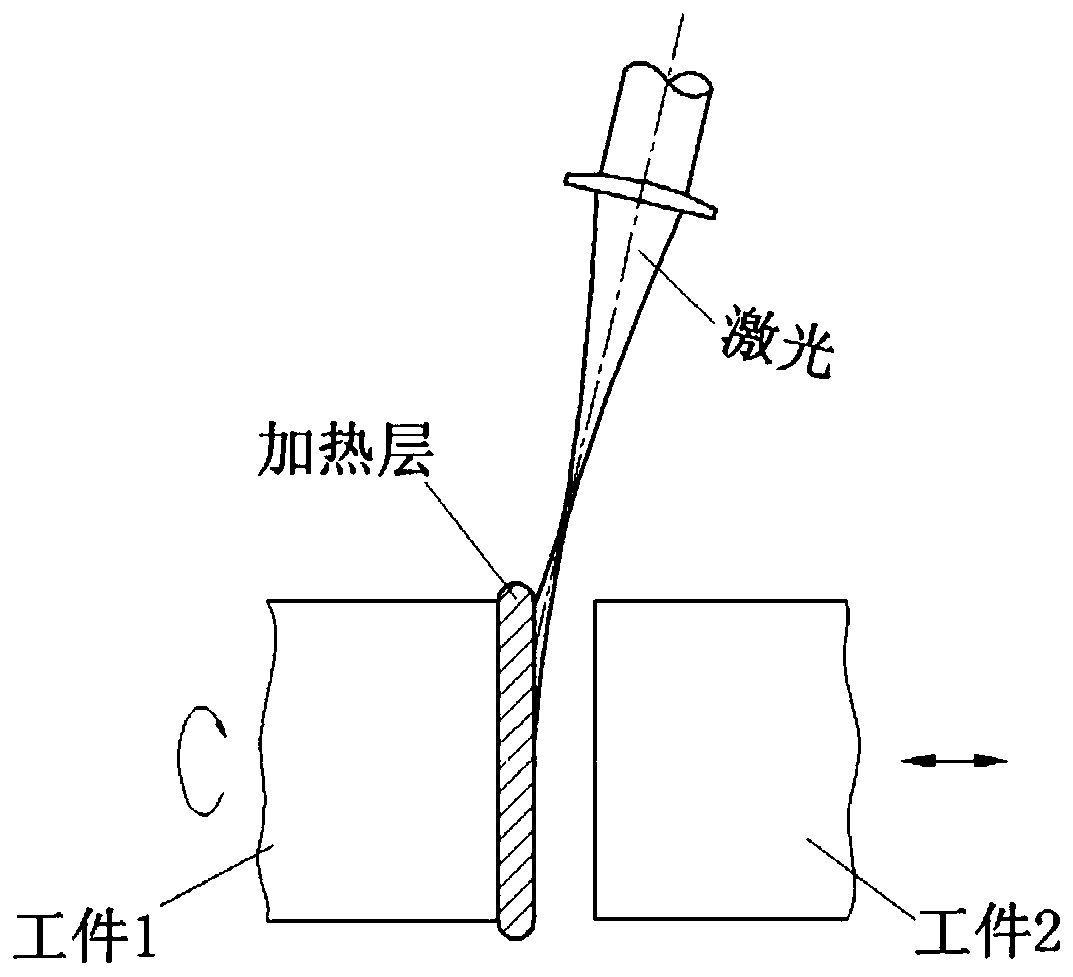

Laser auxiliary hot-pressure welding device and welding method for connecting titanium / aluminum dissimilar materials

InactiveCN103273206AEasy to weldLow costWelding/soldering/cutting articlesWelding apparatusLap jointTitanium alloy

The invention provides a laser auxiliary hot-pressure welding device and welding method for connecting titanium / aluminum dissimilar materials. The implementation process of the laser auxiliary hot-pressure welding device and welding method comprises the following steps that titanium alloy base metal and aluminum alloy base metal are arranged on a workbench after being connected in a lap joint mode according to the principle that the titanium alloy base metal is arranged above the aluminum alloy base metal; after a microprocessor is started, according to a preset pressure value and a preset stepping speed of the workbench, the microprocessor controls the rotation speed of a stepping motor, a pressure control valve controls the working pressure of an air cylinder, a pressure test of an idler wheel is conducted first, then pressure by the idler wheel at a welding point on the base metal is transmitted through a pressure sensor, and the air cylinder is controlled in time so as to amend the pressure value; laser beams are irradiated on a weld joint of the base metal connected in the lap joint mode, the idler wheel is used for acting on the dissimilar materials, and the dissimilar materials mutually diffuse under the pressure action so that the purpose of welding can be achieved. According to the laser auxiliary hot-pressure welding device and welding method for connecting the titanium / aluminum dissimilar materials, brittle intermetallic compounds generated when the titanium / aluminum dissimilar materials are connected can be reduced remarkably, welding of thin dissimilar metal plates is easy to realize, welding efficiency is high, welding cost is low, the quality of a connector is high because the content of the intermetallic compounds is small, the welding cost is quite low, and the quality of the connector is good.

Owner:NANCHANG HANGKONG UNIVERSITY

Method for controlling welding cracks of ultrathin tantalum and molybdenum dissimilar materials

InactiveCN106392359ACrack suppressionEliminate cracksWelding/soldering/cutting articlesLaser beam welding apparatusMelting tankGlass cover

The invention provides a method for controlling welding cracks of ultrathin tantalum and molybdenum dissimilar materials. The method comprises the following steps: (1) washing and cleaning impurities on metal surfaces of tantalum / molybdenum base materials and drying to remove water; (2) selecting a TC4 wire with a suitable diameter, putting the TC4 wire between the tantalum / molybdenum base materials and fixing the TC4 wire by using a tool clamp; (3) protecting by adopting Ar gas, firstly charging Ar gas for 3min and completely exhausting the air in a glass cover; (4) performing before-welding location at the two ends of a sample, and positioning the TC4 wire and the base materials by adopting relatively small laser power; (5) adjusting to use suitable laser power to weld the sample. The method disclosed by the invention is capable of inhibiting generation of cracks generated when an ultrahigh-temperature melting tank is quickly cooled to room temperature during welding of tantalum and molybdenum, and realizing good laser welding of the ultrathin tantalum and molybdenum dissimilar materials; a relatively good joint can be obtained when tantalum and molybdenum are welded under suitable parameters, and tensile failure on a tantalum base material is prevented. The welding method provided by the invention is low in cost, high in efficiency and good in joint quality.

Owner:NANCHANG HANGKONG UNIVERSITY

Method for connecting glass with copper or copper alloy

The invention relates to a method for connecting glass with copper or copper alloy, particularly a method for connecting glass with copper or copper alloy by soft soldering. The invention aims to solve the problems of complex technique, high connecting temperature and poor joint quality in the existing method for connecting glass with metal. The method comprises the following steps: 1. cleaning copper or copper alloy in acetone, cleaning with absolute ethanol and deionized water, carrying out blow-drying, and baking; 2. cleaning a sanded glass substrate in acetone, cleaning with absolute ethanol and deionized water, carrying out blow-drying, bombarding with an ion beam, coating a Cr film on the glass substrate by vaporization, and coating a Cu film by vaporization; 3. cleaning low-temperature solder in acetone, cleaning with absolute ethanol and deionized water, and carrying out blow-drying; 4. preparing a rosin zinc chloride-base soldering flux; 5. assembling a soldering workpiece by using a graphite plate; and 6. putting the soldering workpiece into a heating apparatus to carry out soldering. The invention has the advantages of lower connecting temperature, simple technique and better joint quality. The invention is applicable to soldering of glass and metal.

Owner:HARBIN INST OF TECH

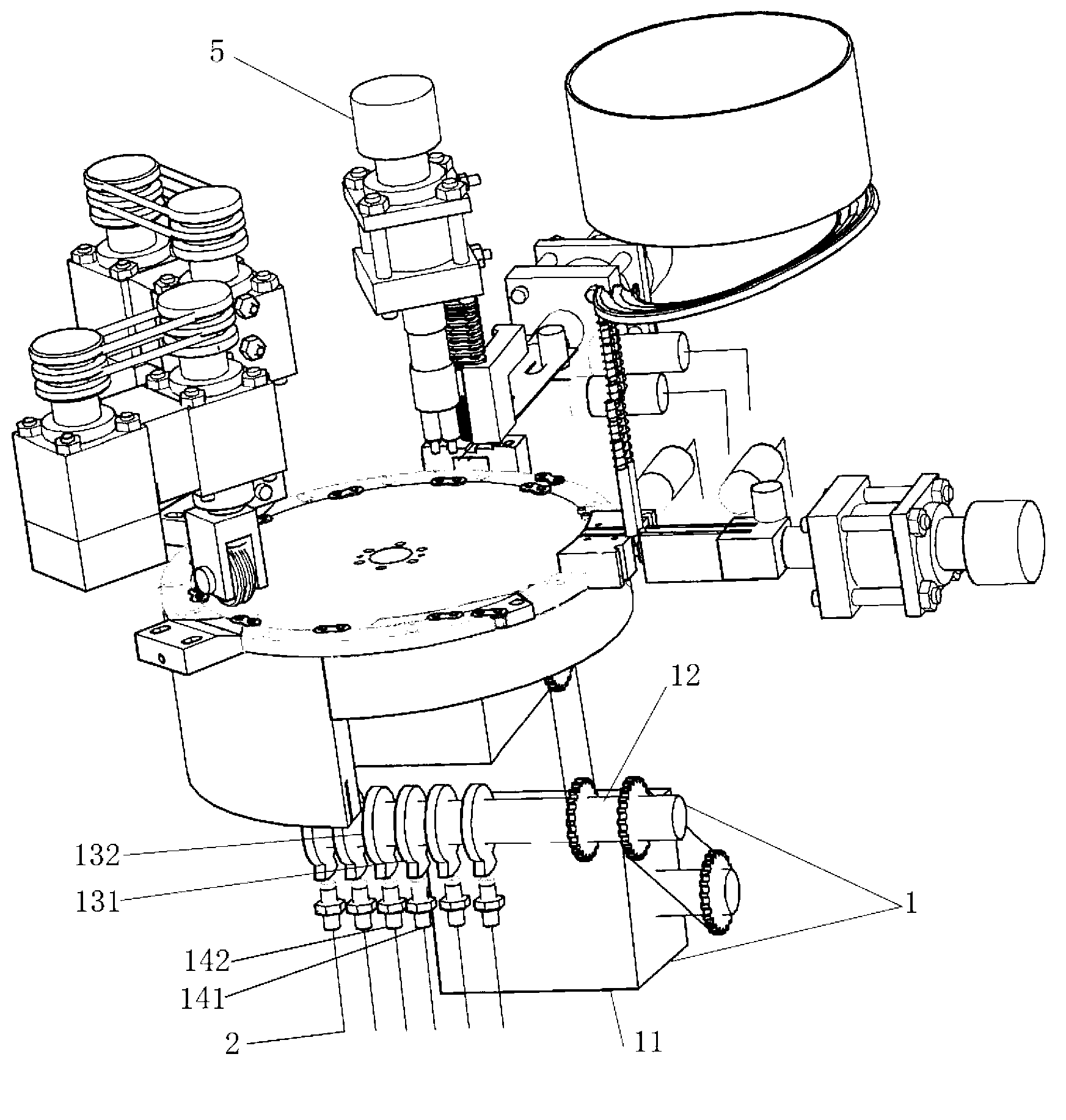

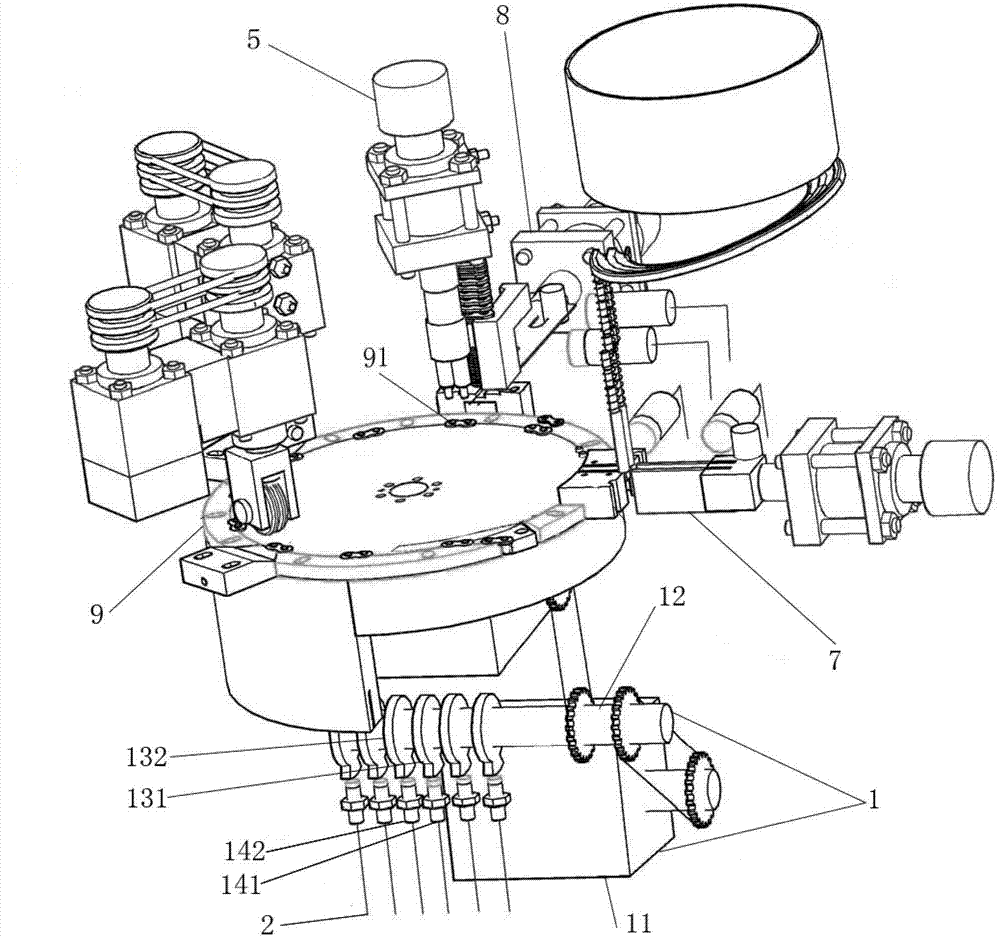

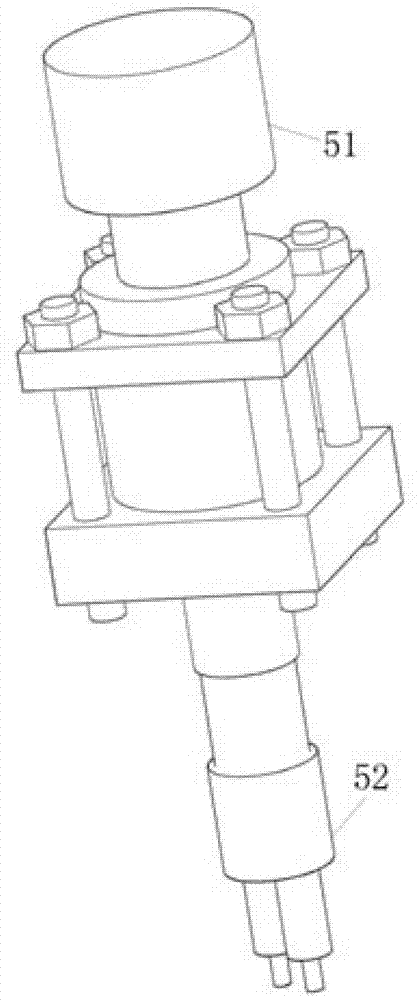

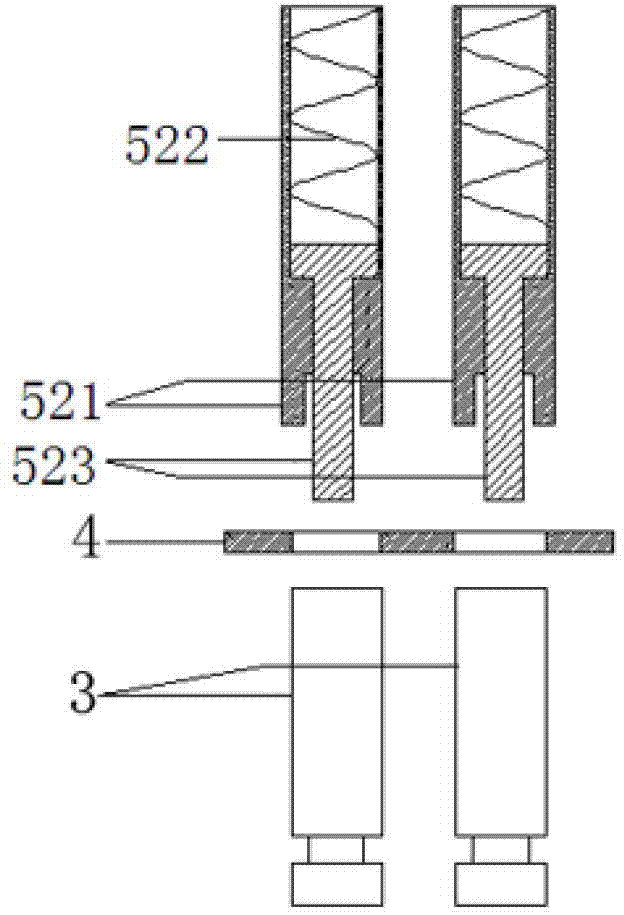

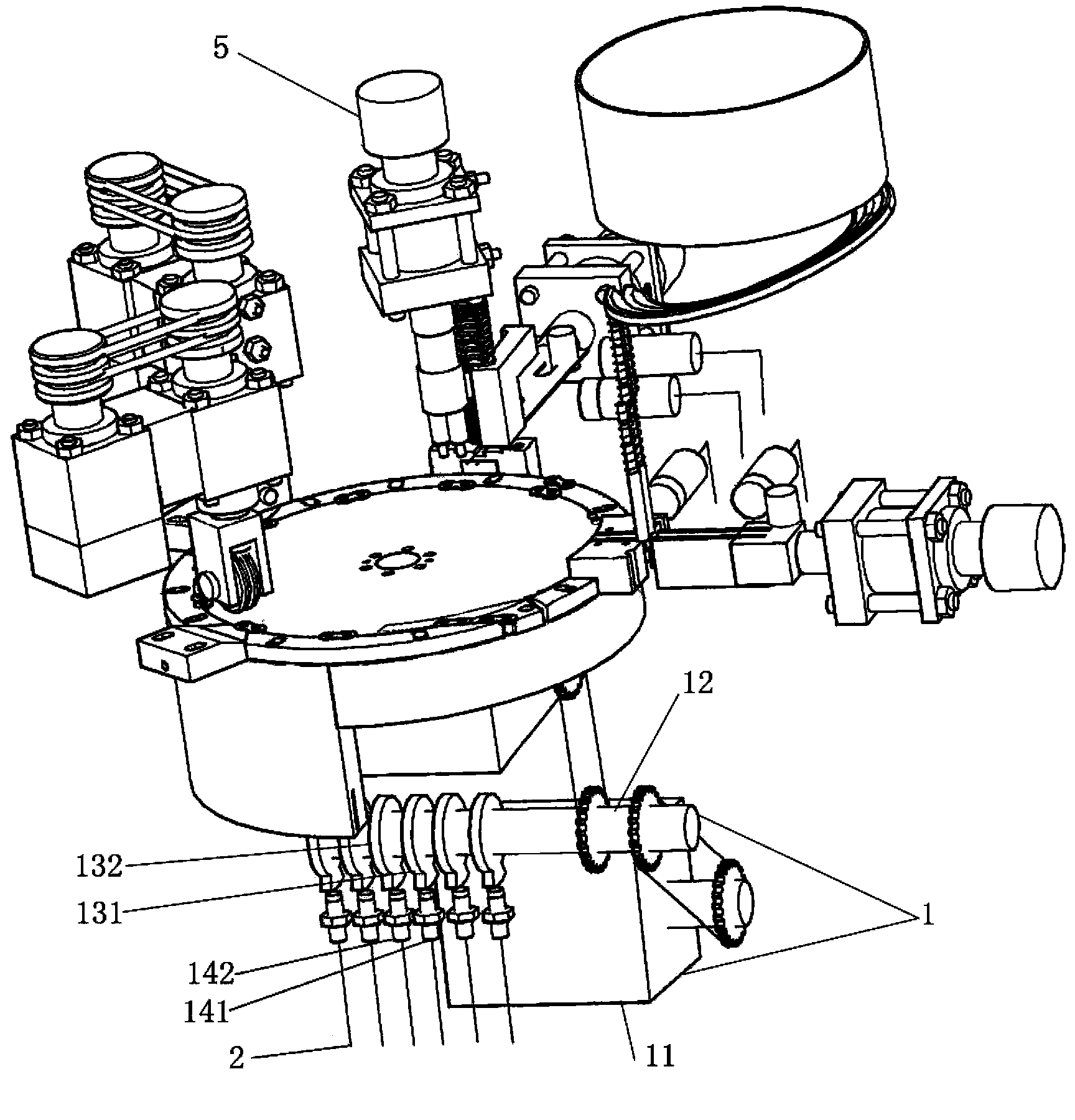

Piece assembly device used for chain assembly

The invention provides a piece assembly device used for chain assembly and relates to the field of chain production. The piece assembly device comprises a lifting device, a piece press device connected with the lower end of the lifting device, a control device, a first piece assembly cam, a sensor corresponding to the first piece assembly cam, a second piece assembly cam and a sensor corresponding to the second piece assembly cam. The lifting device is connected with the control device. The piece press device comprises a piece press mould and a pair of guide collision devices installed in the piece press mould and elastically connected with the piece press mould, and the sensors are connected with the control device. The piece assembly device has the advantages of being safe in production, high in efficiency, good in quality, high in stability and the like, thereby being a full automatic piece assembly device used for chain assembly.

Owner:SUZHOU CHUNMENG INTELLIGENT TECHNOLOGY CO LTD

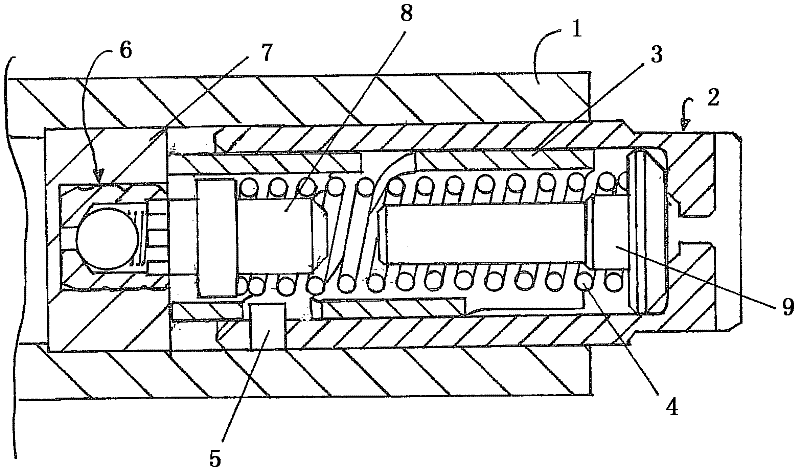

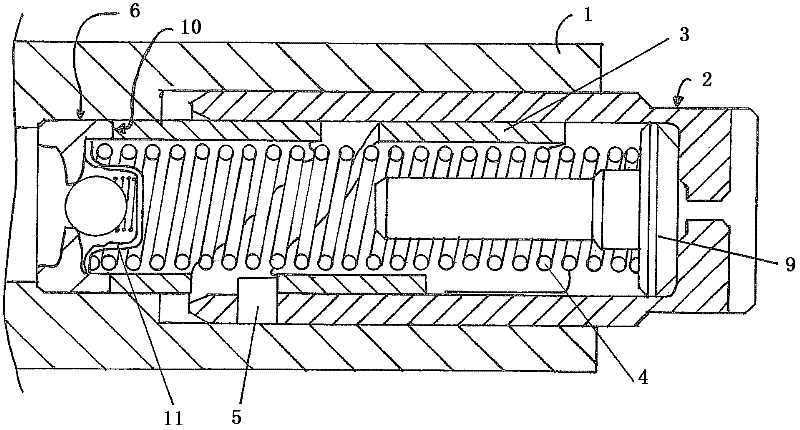

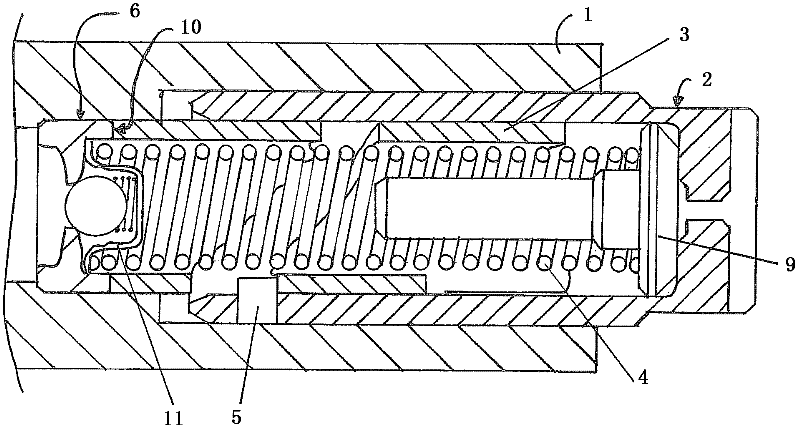

Tensioning device with a cylindrical latching system

A tensioning device for an endless traction element in an engine. The tensioning device has a housing, a plunger, which can he moved in the housing, a compression spring arranged in the plunger, a nonreturn valve arranged between the plunger and the housing, a cylinder arranged in the plunger, and an engagement element. The plunger and the cylinder are connected to one another by a latching system via engagement of the engagement element, and the cylinder is connected materially to the nonreturn valve.

Owner:SCHAEFFLER TECH AG & CO KG

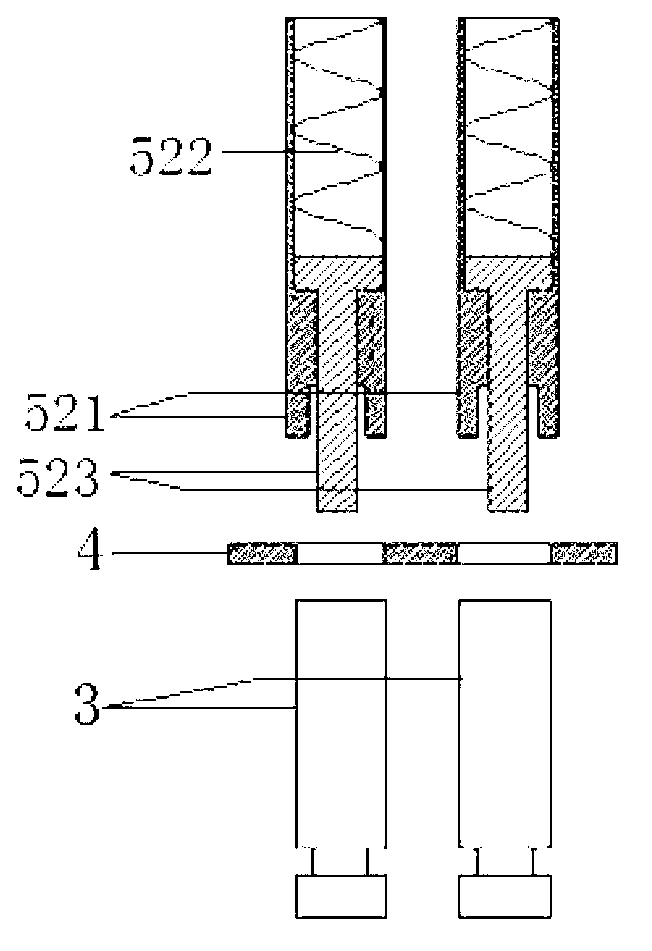

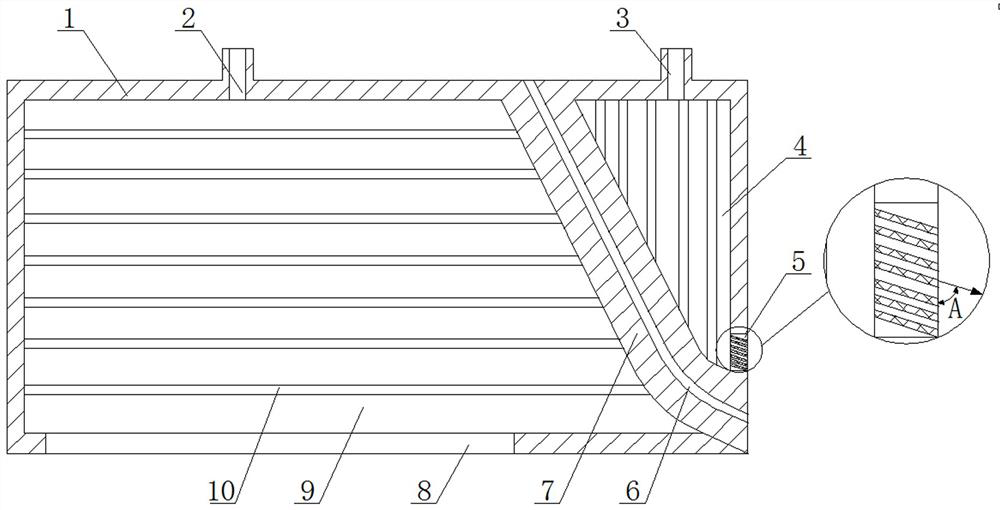

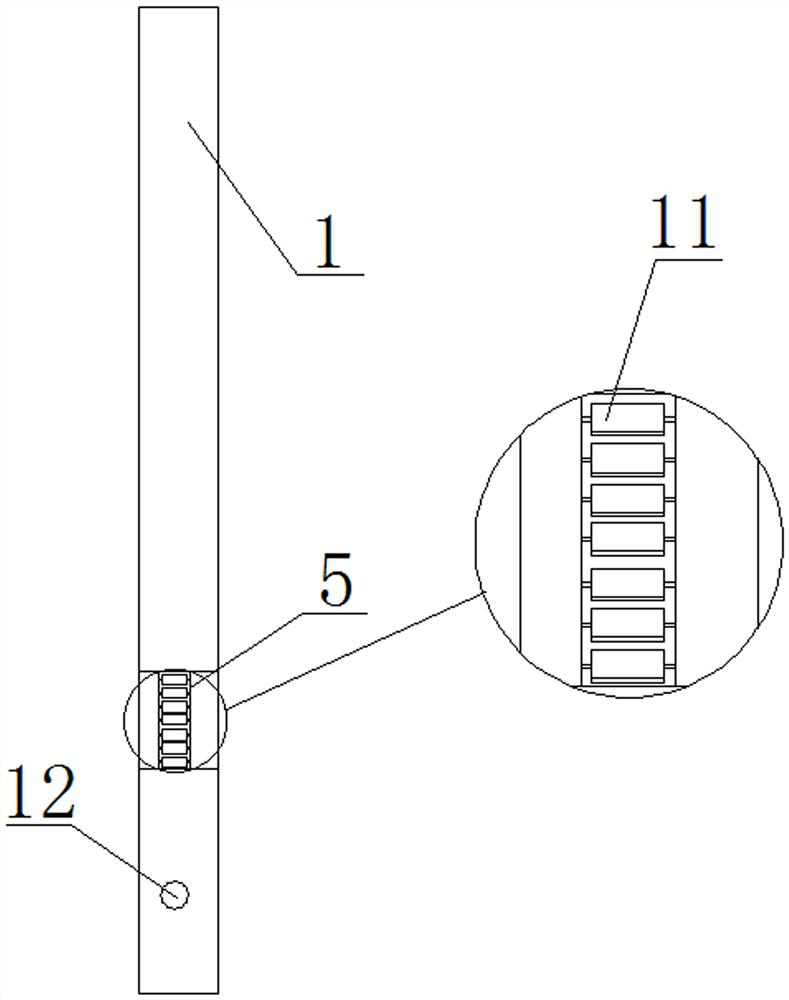

Titanium alloy narrow-gap laser welding wire feeding and gas protection integrated mechanism

ActiveCN112108765AImprove accuracyGood tow position relationshipWelding/soldering/cutting articlesLaser beam welding apparatusWeld seamGas protection

The invention discloses a titanium alloy narrow-gap laser welding wire feeding and gas protection integrated mechanism. The titanium alloy narrow-gap laser welding wire feeding and gas protection integrated mechanism comprises a shell capable of extending into a to-be-welded gap, and the shell is in a hollow cuboid shape; a wire feeding channel smoothly extending from the top wall of the shell tothe lower portion of the right side wall of the shell is obliquely arranged in the shell, and the wire feeding channel can feed a welding wire to the position to be welded at the angle of 15-60 degrees relative to the horizontal plane; and the wire feeding channel divides an inner cavity of the shell into a left cavity and a right cavity which are independent of each other, the left cavity can enable gas for protecting a weld joint introduced into the left cavity to be evenly and stably blown to the weld joint in the vertical direction, and the right cavity can enable gas for protecting a molten pool introduced into the right cavity to be evenly and stably blown to the molten pool at an angle of 0-30 degrees relative to the horizontal plane. By the adoption of the mechanism, the requirements for narrow-gap laser welding alignment wire feeding and welding protection can be met; and meanwhile, plasmas generated in the welding process are effectively blown away, welding power fluctuationcaused by energy dissipation is reduced, and therefore the stability of the welding process is improved.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

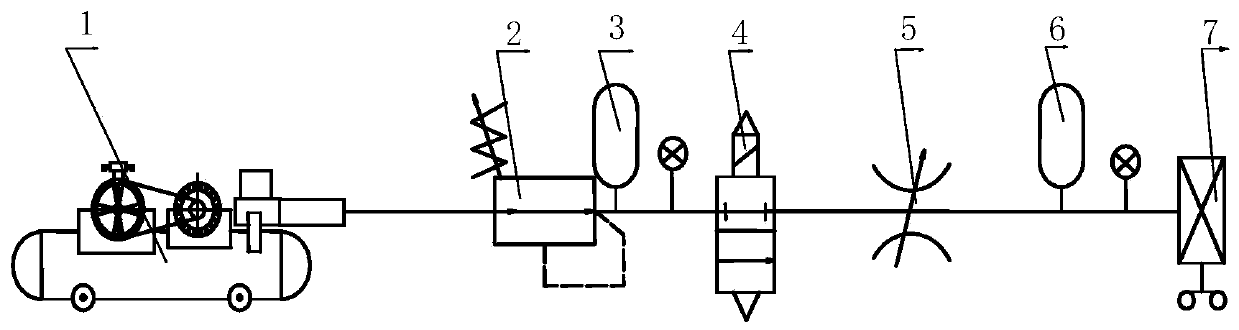

Impact rolling machine head for welding and welding with trailing device

InactiveCN110576238AWork reliablySolution to short lifeGas flame welding apparatusMechanical impactPiston

The invention relates to the field of welding, in particular to an impact rolling machine head for welding and a welding with trailing device. The welding with trailing device comprises an air pump and the impact rolling machine head for welding. An air inlet is formed in a housing of the impact rolling machine head for welding; an air cylinder is arranged in the housing; a piston divides the aircylinder into an upper space and a lower space; the upper end of an impact rod penetrates through the bottom wall of the air cylinder in a sliding manner and extends into the lower space; the lower end of the impact rod is connected with a rolling wheel structure; the rolling wheel structure comprises a rolling cam and a rolling concave wheel; the rolling concave wheel is positioned at the front end of the impact rolling machine head for welding in the moving direction; and the rolling cam is positioned at the rear end of the impact rolling machine head for welding in the moving direction. Thepiston in the air cylinder is pushed by the air pressure to move, a mechanical impact force is applied to weld metal in the high-temperature state, a melt in a high-temperature welding area is extruded to the middle by the rolling concave wheel, and when being cooled, the melt is transversely rolled by the rolling cam, so that the purpose of preventing welding hot cracks and delayed cold cracks generated in a welding seam area is achieved.

Owner:CRRC QINGDAO SIFANG CO LTD

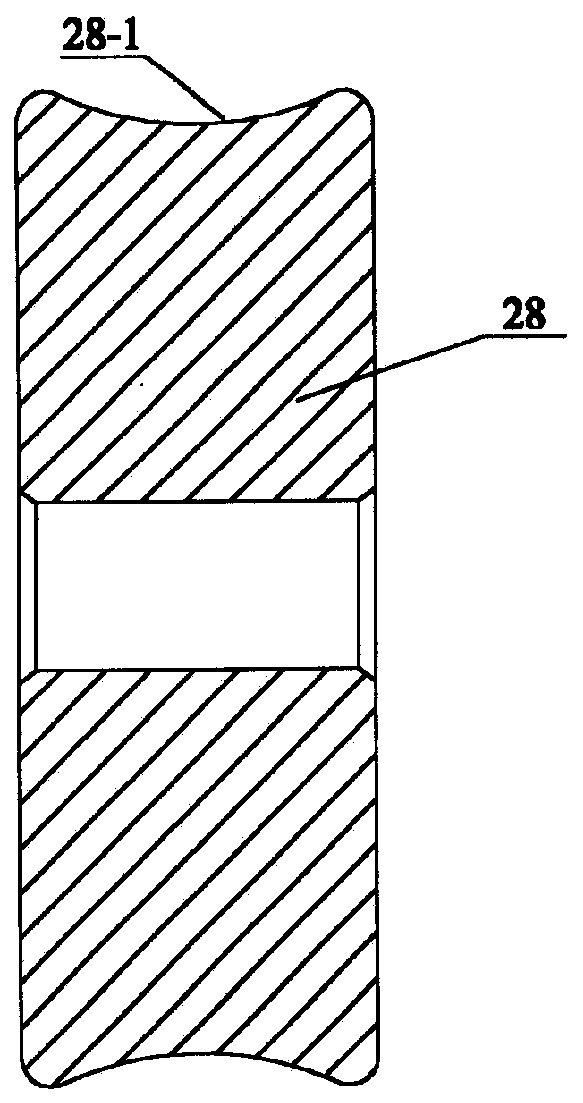

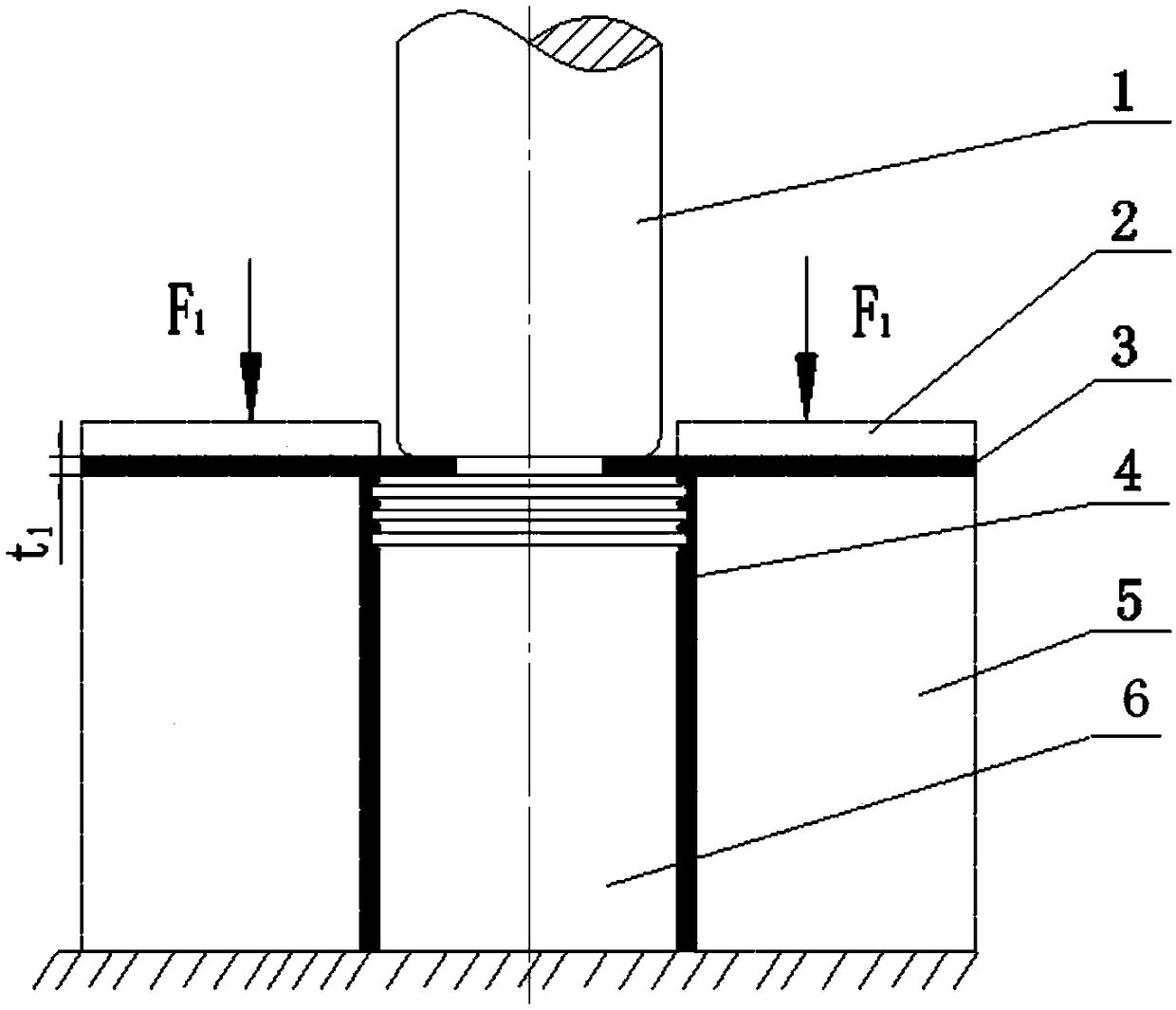

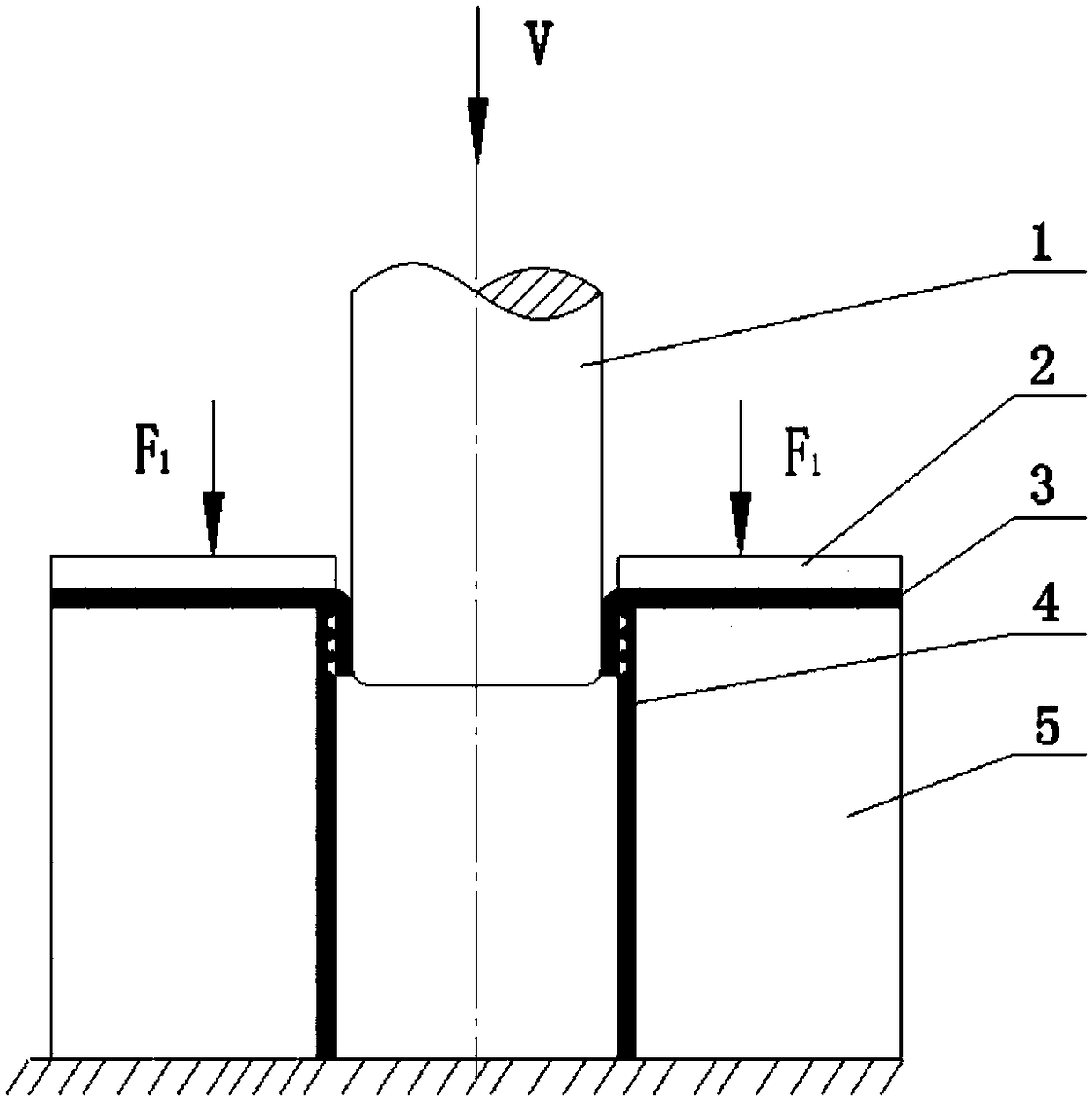

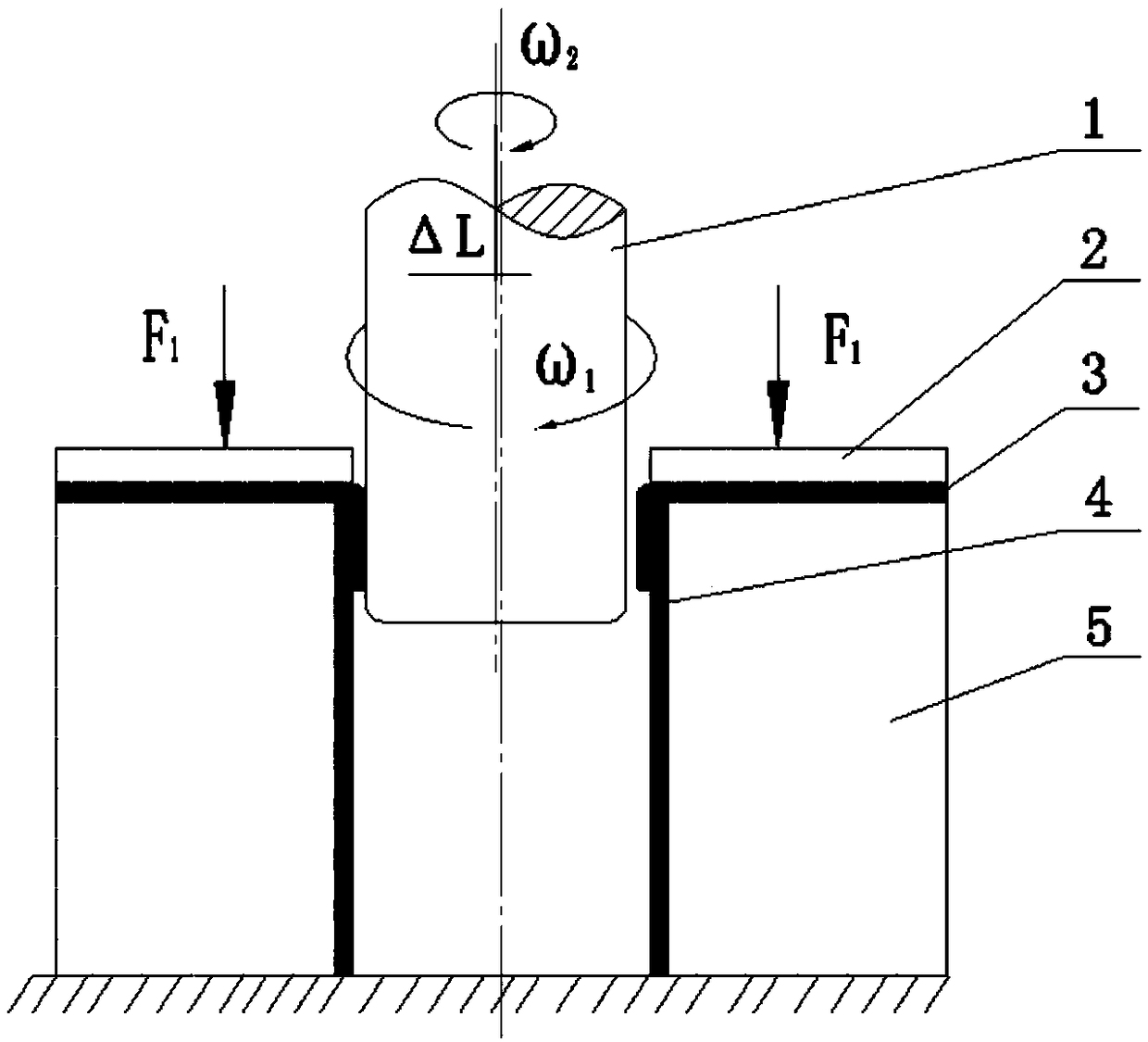

Method and device for plastically connecting metal pipes and plates with one another

ActiveCN109261816AFast plastic connectionEfficient plastic connectionShaping toolsFriction effectHigh volume manufacturing

The invention discloses a method and a device for plastically connecting metal pipes and plates with one another, and belongs to the technical field of material connection. The device comprises a maledie, an edge pressing ring and a female die. The device and the method have the advantages that the pipes and the plates which are required to be connected with one another are prefabricated, then the pipes can be placed in the female die, the plates can be clamped by the female die and the edge pressing ring, the male die can revolve at the high speeds and can rotate along the axes of the pipesat the low speeds, and the plasticity of the pipes can be enhanced by the aid of friction effects; plastic deformation portions of the plates can be promoted by rolling of the male die to flow into annular grooves of the pipes, and accordingly the pipes and the plates can be quickly and efficiently plastically connected with one another in a green manner; the device is high in production efficiency, low in cost and suitable for mass production and is environmentally friendly; plastic forming modes are adopted by the method for connecting the metal pipes and the plates with one another by the aid of the device, the annular grooves are filled with materials for the plates, connectors are good in quality, high tensile stress can be borne, and the problem of difficulty in connecting plate metal with heterogeneous pipes difficult to weld can be solved by the aid of the method and the device.

Owner:SHAANXI UNIV OF SCI & TECH

Welding method for friction stud welding

InactiveCN105108321ASimple welding methodImprove joint welding strengthNon-electric welding apparatusEngineeringFriction stir welding

The invention discloses a welding method for friction stud welding. The welding method for friction stud welding comprises the following steps: S1, pressing workpieces by using a pressing device and putting the workpieces in a welding box; S2, introducing protective gas into the welding box and pressing studs rotating at high speed on the surfaces of the workpieces; and S3, pressing the studs into the surfaces of the workpieces to be integrated and moving to the interiors of the workpieces at the same time, in whichwherein the range of the pressing depth is 0.1-1mm; the generated friction heat is used for enabling the studs to be integrated with the workpieces. The welding method for friction stud welding has the advantages that the welding method is relatively simple and practical, the joint welding strength can be effectively improved, the welding efficiency and the joint quality can be optimized, and the possible defects of faulty welding, cracks and air holes in the conventional stud welding can be avoided.

Owner:昆山斯格威电子科技有限公司

A Welding Device and Method for Improving Hook Defects in Friction Stir Welded Lap Joints

ActiveCN108838510BIncrease the effective bearing thicknessAvoid detrimental effects on performanceNon-electric welding apparatusLap jointMechanical engineering

The invention provides a welding device and method for improving hook-shaped defects of a friction stir welding overlap joint. The device comprises a stirring head and a motor connected with the stirring head. The stirring head is composed of a shaft shoulder and bottom two-stage stirring needles coaxially and integrally arranged with the shaft shoulder. The first-stage stirring needle and the second-stage stirring needle of the two-stage stirring needles are of a conical or cylindrical structure, the first-stage stirring needle is located above the second-stage stirring needle, and the diameter of the lower bottom surface of the first-stage stirring needle is larger than the diameter of the upper bottom surface of the second-stage stirring needle. The method comprises the steps of measuring geometric parameters of workpieces to be welded and the stirring head, fixing the workpieces to be welded, determining the position of welding, determining the depth of pressing and friction stir welding. By adopting the welding device and method for improving the hook-shaped defects of the friction stir welding overlap joint, an overlap joint with a "HOOK" shape and a horizontal or even slightly downward bending feature can be obtained, and the effective load bearing thickness of the joint can be significantly increased. In addition, the welding device and method for improving the hook-shaped defects of the friction stir welding overlap joint are simple in operation, easy to implement, and suitable for friction stir welding of overlap joint structures of various thicknesses.

Owner:SHENYANG AEROSPACE UNIVERSITY

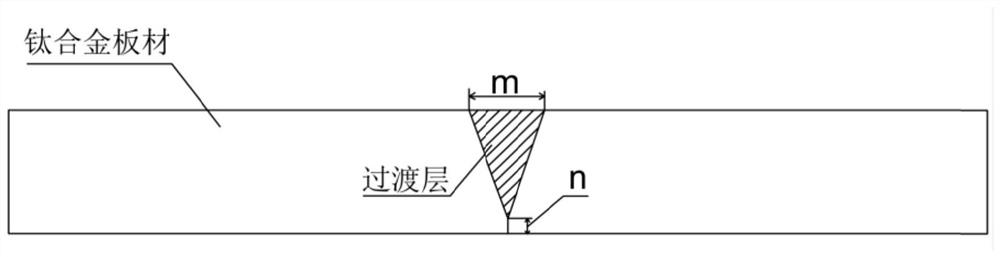

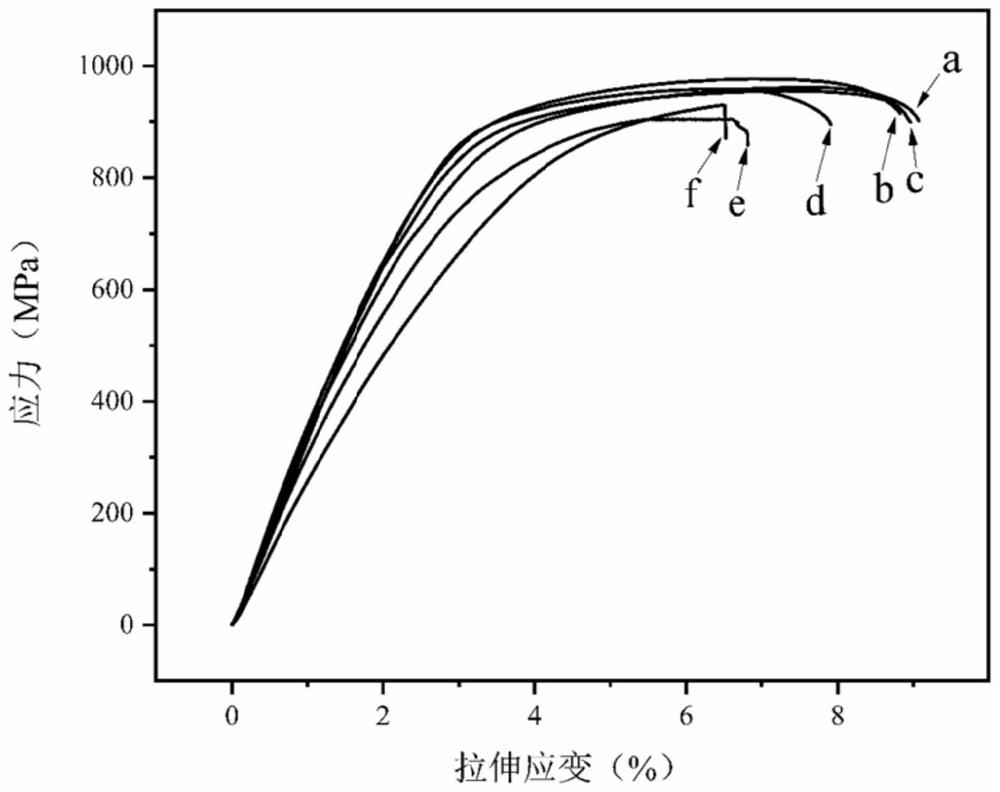

Titanium alloy plate welding method for improving welding performance

ActiveCN114211117AHigh quality weldingWelding process complex limitationsIncreasing energy efficiencyWelding/soldering/cutting articlesButt jointMetal particle

A titanium alloy plate welding method capable of improving welding performance comprises the following steps that S1, a Ti6Al4V titanium alloy plate with the thickness ranging from 2 mm to 4 mm is taken, a V-shaped welding groove is formed in the position to be welded, a butt joint is formed, the groove angle of the welding groove ranges from 18 degrees to 22 degrees, the width of an upper opening of the groove ranges from 0.8 mm to 1.2 mm, the groove gap ranges from 0 mm to 1 mm, and the truncated edge of the groove ranges from 0.1 mm to 0.5 mm; s2, metal particles are weighed according to the mass percent of 6wt% of Al, 4wt% of V, 0.1-0.7 wt% of Ce and the balance Ti, an alloy ingot is prepared through vacuum induction melting, and then the alloy ingot is machined into a transition layer matched with the welding groove; s3, the transition layer is placed in a welding groove of the Ti6Al4V titanium alloy plate butt joint, and a to-be-welded welding joint is formed; s4, pulse laser welding is conducted on the to-be-welded welding joint; according to the welding process parameters, the pulse frequency ranges from 20 Hz to 30 Hz, the pulse width ranges from 23 ms to 27 ms, the welding speed ranges from 22 mm / s to 28 mm / s, the laser base value power ranges from 2800 W to 3200 W, the laser peak power ranges from 3800 W to 4200 W, and the protective argon flow ranges from 12 L / min to 20 L / min. The welding method is low in cost, high in efficiency and good in joint quality, and the obtained welding seam is excellent in performance.

Owner:SOUTHWEST JIAOTONG UNIV

A method of loading pieces for chain assembly

ActiveCN102847864BGuaranteed longest contactImprove reliabilityMetal chainsEngineeringAssembly machine

The invention provides a piece assembly method used for chain assembly and relates to the field of chain production. The method includes the following steps that step1 a chain connector assembly machine is provided; step2 chain pieces are delivered to the position above a pin roll through a piece delivery plate; step3 a control device controls a lifting device to descend, the lifting device drives a piece press device connected with the lower end of the lifting device to descend, the piece press device comprises a piece press die and a pair of guide collision devices, the collision devices descend correspondingly to locate the chain pieces, then the control device controls the lifting device of ascend, and the piece press device ascends correspondingly; step4 the control device controls the lifting device to descend, the piece press device descends correspondingly, the piece press die presses the chain pieces downwards to enable a part of the pin roll to stretch out of chain piece holes; and step5 the control device controls the lifting device to ascend to further drive the piece press device to ascend to finish piece assembly. The piece assembly method has the advantages of being safe in production, high in efficiency, good in quality, high in stability and the like, thereby being a full automatic piece assembly device used for chain assembly.

Owner:SUZHOU CHUNMENG INTELLIGENT TECHNOLOGY CO LTD

Composite zinc-aluminum flux cored wire containing beryllium and magnesium and rubidium salt and preparation method of flux cored wire

ActiveCN102935559BImprove cleanlinessImprove intergranular corrosion resistanceWelding/cutting media/materialsSoldering mediaRare-earth elementAluminum fluoride

The invention discloses a composite zinc-aluminum flux cored wire containing beryllium and magnesium and rubidium salt. The composite zinc-aluminum flux cored wire comprises a wire body consisting of an outer metal skin and core brazing flux powder, wherein the outer metal skin is prepared by the following raw materials by weight percent: 80.5 to 98.5% of zinc, 0.01 to 6.5% of silver, 0.01 to 3% of copper, 0.001 to 2% of nickel, 0.001 to 0.5% of beryllium, 0.001 to 1.2% of magnesium, 0.001 to 0.5% of rare earth element and the balance of aluminum; and the brazing flux powder is prepared by the following raw materials by weight percent: 15 to 35% of aluminum fluoride, 30 to 75% of cesium fluoride, 2.5 to 10% of rubidium fluoride, and the balance of potassium fluoride. The invention also provides a preparation method of the composite zinc-aluminum flux cored wire. The preparation method has the advantages that trace Be and Mg are introduced based on the conventional Zn-Al-Ag-Cu alloy system in the brazing filed, so that the cleanness of the wire can be improved, the quality and the reliability of a brazing joint are ensured, and the intercrystalline corrosion resistance of the wire can be greatly improved, and as a result, the phenomenon of 'embrittlement' can be delayed or inhibited.

Owner:ZHENGZHOU RES INST OF MECHANICAL ENG CO LTD

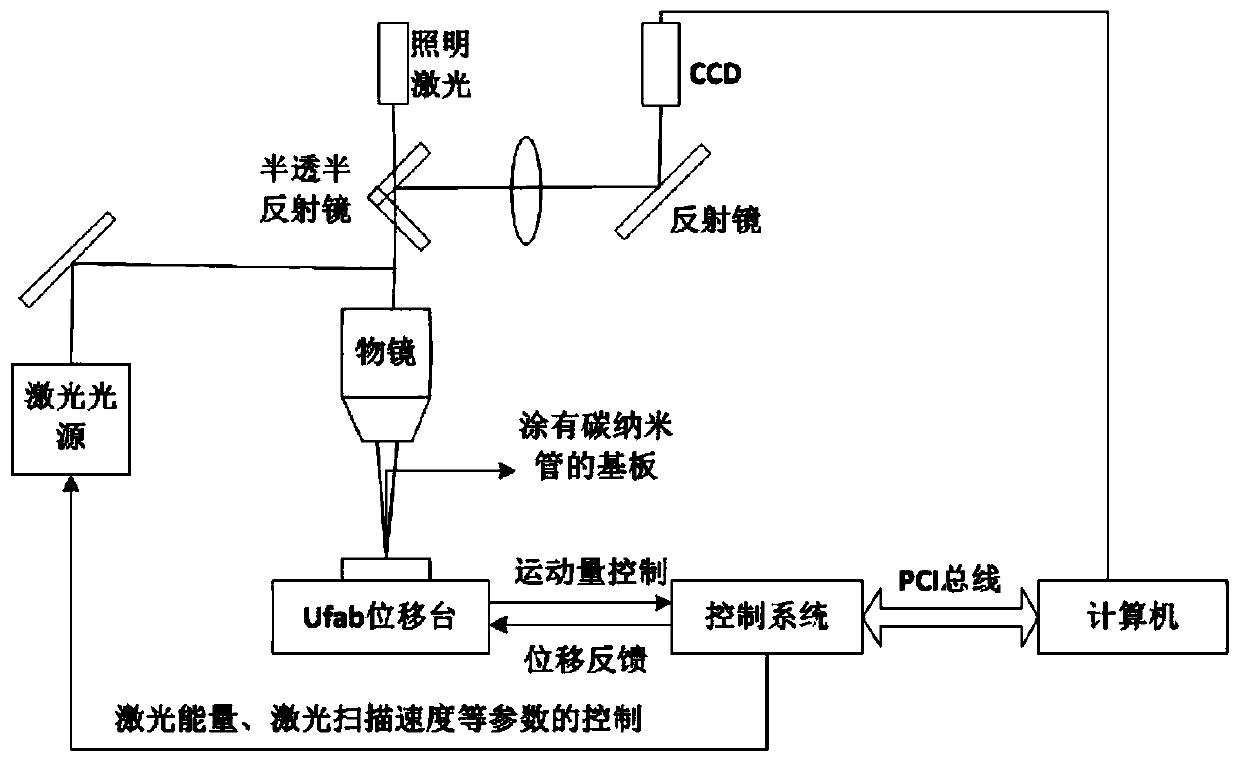

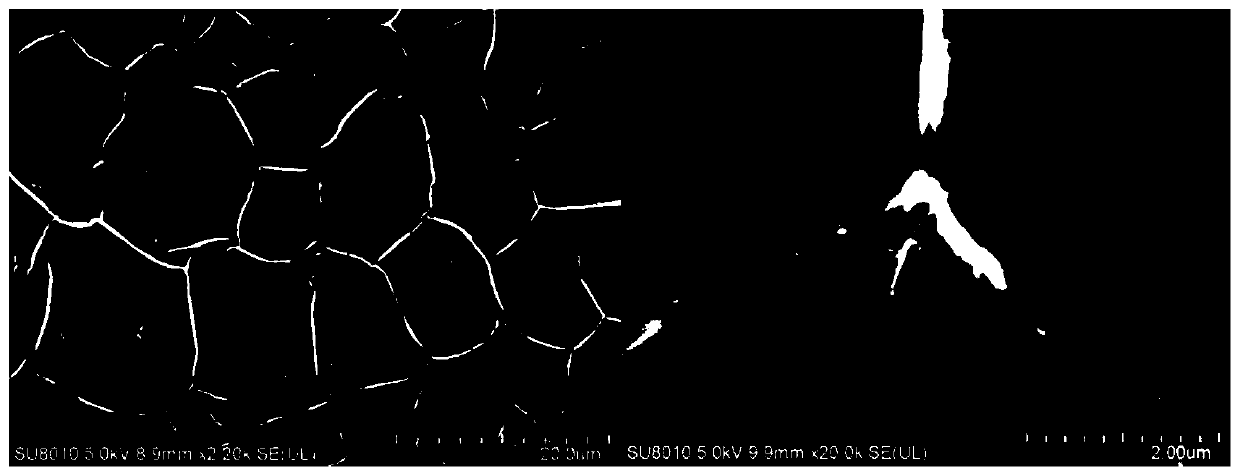

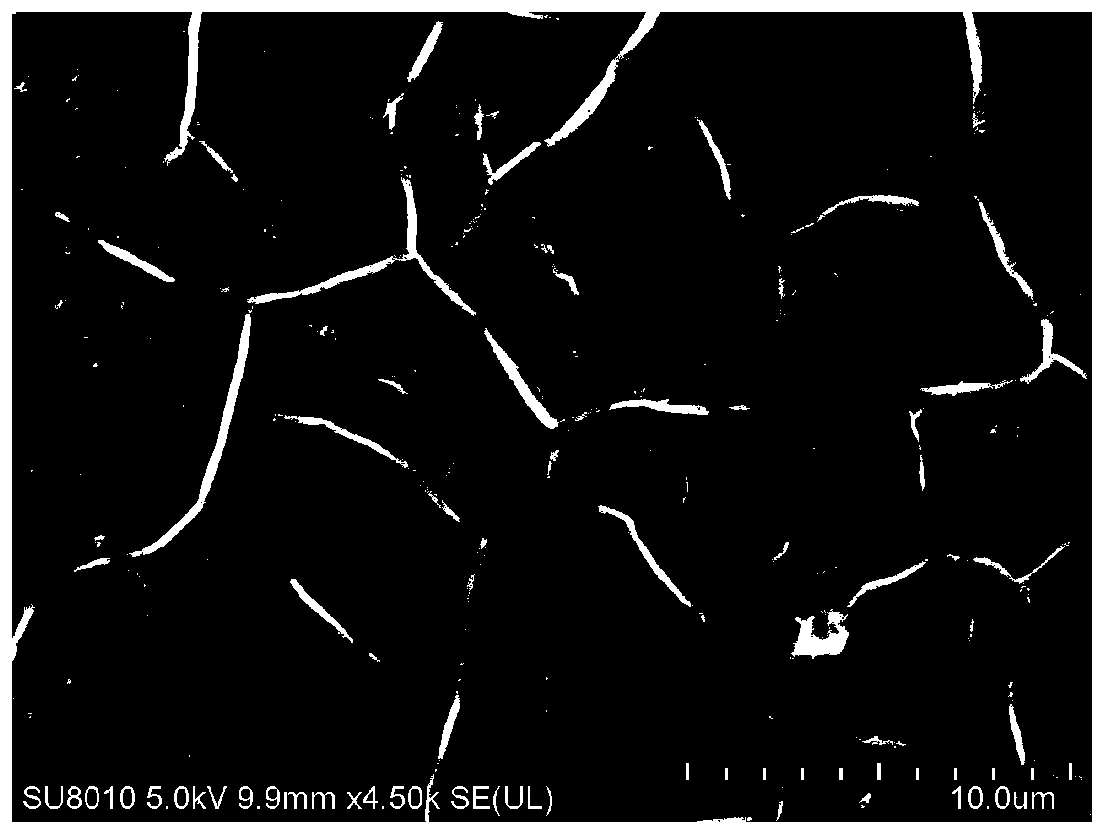

A Method for Inducing Super Graphene Network Structure Using Femtosecond Pulsed Laser

The invention provides a method for inducing a super-graphene network structure by utilizing femtosecond pulse laser. The method comprises the following steps: firstly, carrying out ultrasonic treatment on MWCNTs (Multi-walled Carbon Nanotubes) in a sodium dodecyl sulfate water solution to obtain non-covalent modified MWCNTs in a water environment; then coating the surface of a silicon dioxide substrate with the non-covalent modified MWCNTs by utilizing a spin-coating technology; then heating the substrate on a heating platform to remove surplus water molecules, so as to obtain an induced substrate; finally, carrying out laser radiation induction on the induced substrate. According to the method provided by the invention, accurate positioning is not needed, a technology is simple and the processing efficiency is high; the method can be used in a large scale and a connector of the obtained super-graphene network structure is smooth.

Owner:XI AN JIAOTONG UNIV

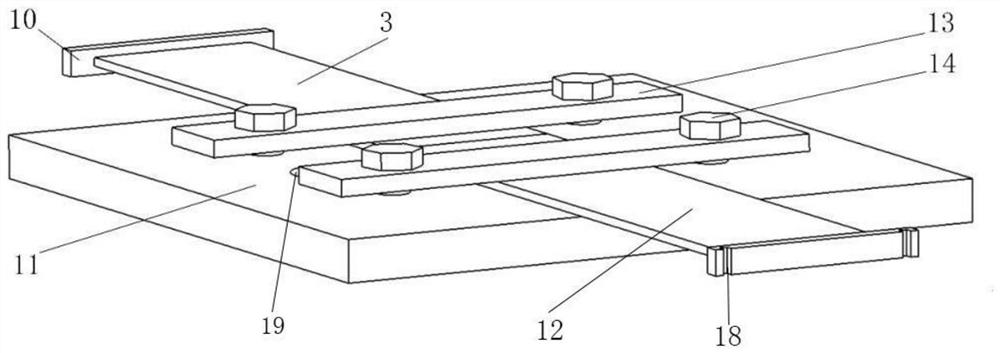

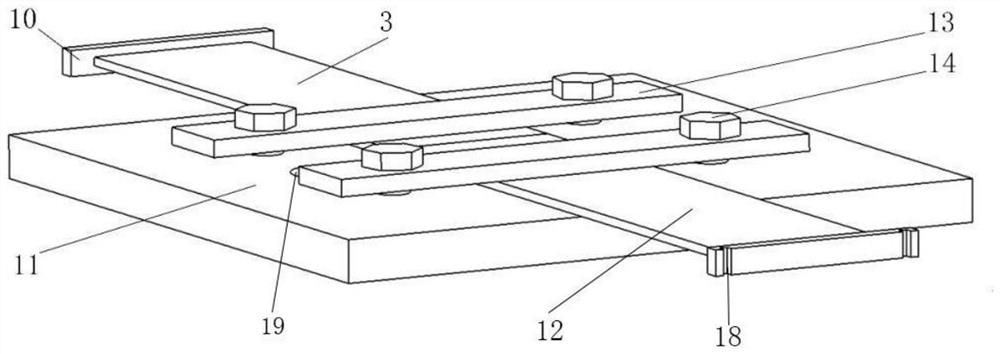

Grinding clamp

InactiveCN112548854AHigh strengthLarge horizontal resistanceGrinding work supportsLaser beam welding apparatusBraced frameMechanical engineering

The invention provides a grinding clamp which comprises a base and a sliding rail slidably connected with the base. A sample carrying table is arranged above the sliding rail, one end of the sample carrying table is hinged to the sliding rail, the other end of the sample carrying table is connected with the sliding rail in an inserted mode through a supporting rod, and a lower supporting frame isslidably connected to the sample carrying table. One end of an aluminum alloy sample and one end of a plastic sample are placed on the sample carrying table, the other end of the aluminum alloy sampleand the other end of the plastic sample are placed on the lower supporting frame and extend out of the end of the lower supporting frame, an upper pressing plate is placed on the aluminum alloy sample and the plastic sample, the width of the upper pressing plate, the lower supporting frame and the sample carrying table are greater than that of the aluminum alloy sample and the plastic sample, strip-shaped holes are formed in the two sides of the upper pressing plate in the width direction respectively, loose bolts matched with the upper end face of the sample carrying table are arranged at the ends, close to the supporting rod, of the inner parts of the strip-shaped holes, and fastening bolts matched with the end of the lower supporting frame are arranged in the end, away from the supporting rod, of the inner parts of the strip-shaped holes. The grinding clamp is used for grinding the to-be-welded surfaces of the aluminum alloy sample and the plastic sample.

Owner:JILIN UNIV

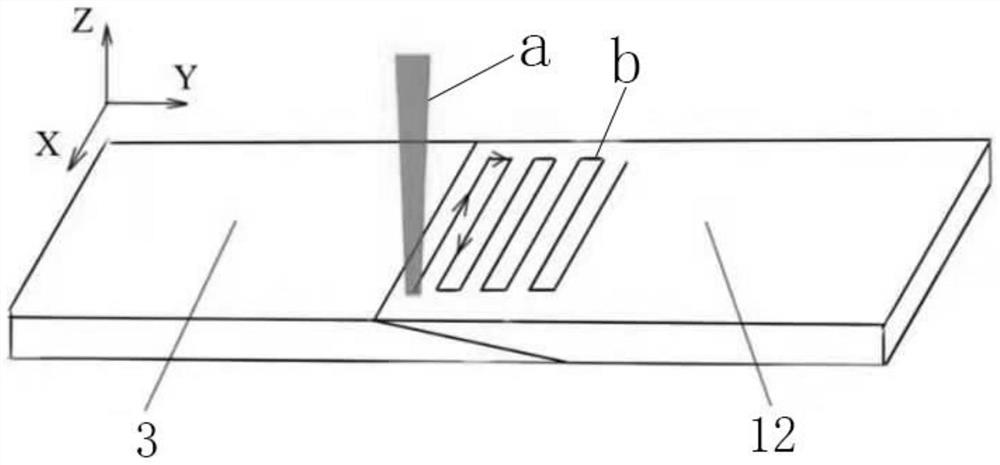

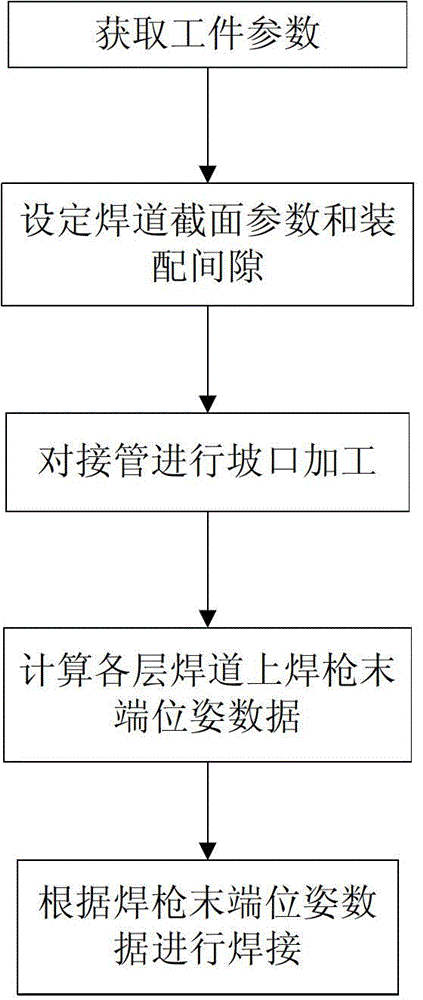

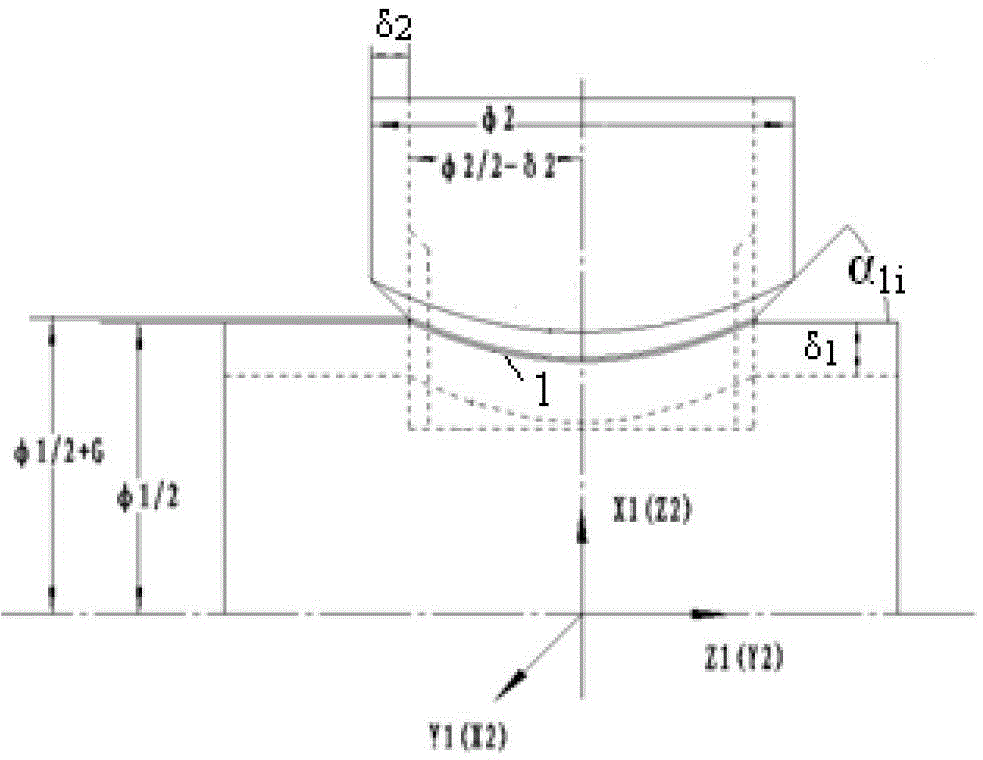

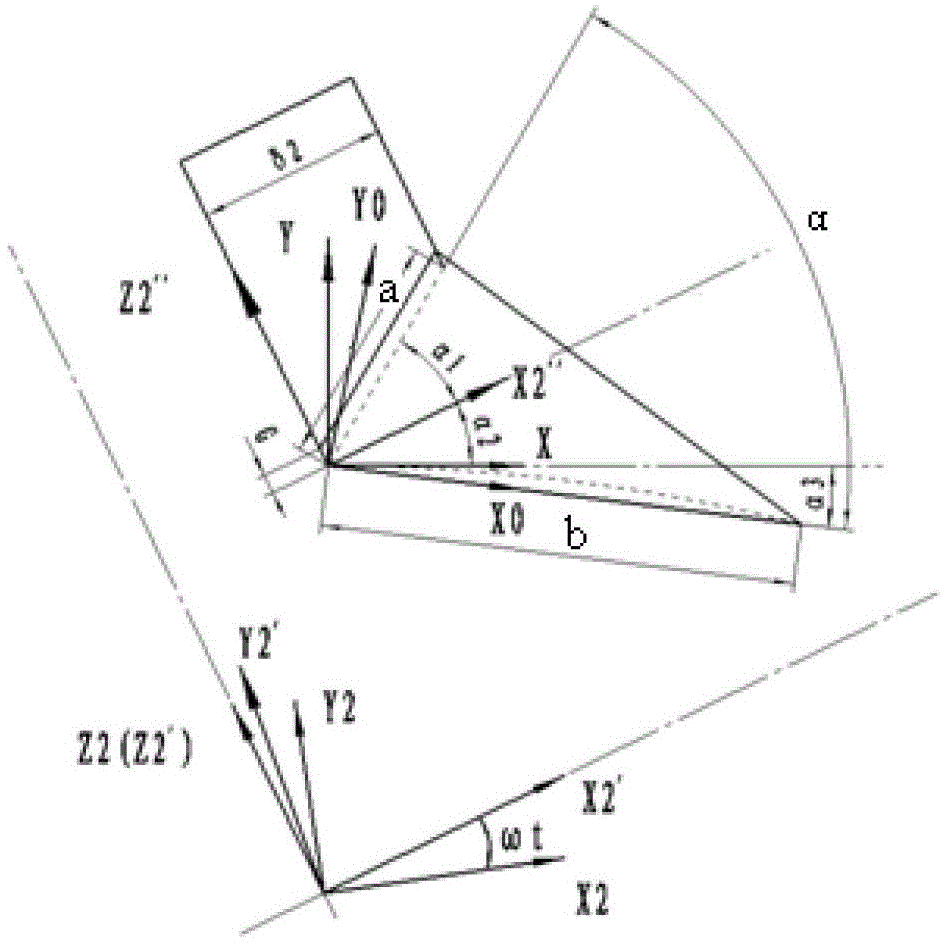

Saddle-shaped track automation welding method of collection box large tube socket

ActiveCN103111730BSolve automatic continuous weldingSuitable temperatureArc welding apparatusData controlNumerical control

The invention relates to a saddle-shaped track automation welding method of a collection box large tube socket. The saddle-shaped track automation welding method comprises a first step of acquiring tool parameters, a second step of setting weld pass section parameters and a fit-up gap G, a third step of edge preparation, wherein bevel angles of connecting tubes and female tube intersecting lines at different positions are determined according to a design principle of a uniform section bevel angle, connector portions of the connecting tubes are machined in a cutting mode, a fourth step of inputting the weld pass section parameters, the fit-up gap G, the tool parameters, the bevel angles and related technological parameters of planned adoptive welding technology into a numerical control welding system to calculate pose data of the tail end of a welding gun, and a fifth step of controlling the welding gun to continuously weld in a layer mode by the numerical control welding system according to the pose data. According to the saddle-shaped track automation welding method of the collection box large tube socket, the purpose of automatic, fast and continuous welding of the intersection line track under different pipe diameters is achieved, weld pass is arranged reasonably, connector quality is good, appearance is attractive, arrangement is ordered, and a technique is wide in application range.

Owner:WISE WELDING TECH & ENG

Oppositely-opening type connecting pipe rotary device

InactiveCN107755963AImprove productivityEasy to operateWelding/cutting auxillary devicesAuxillary welding devicesGroove widthProduction rate

The invention discloses a split-type connecting pipe rotating device, which is characterized in that it includes a base, a split-type pipe mold, and a sliding clamp for locking, and the groove width of the base matches the thickness of the belt pulley; The copper pipe blank is installed in the rotating fixture, and the split pipe mold is locked with the rotating fixture. The sliding fixture is fixed on the side wall of the base and penetrates into the groove; the welding end surface of the copper pipe blank extends It can be seen that the copper tube blank and the aluminum tube blank are on the same axis. The device of the invention has the advantages of simple equipment, high productivity, easy operation, energy saving and good joint quality.

Owner:李欢

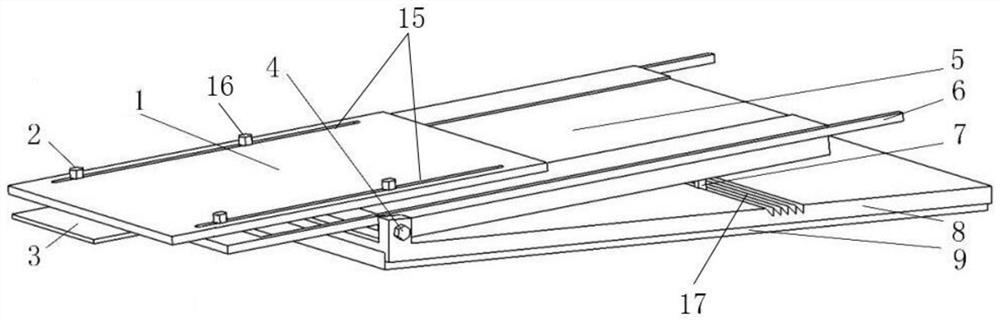

Laser welding method of aluminum alloy and plastic, grinding jig and clamping jig

ActiveCN111168240BHigh strengthLarge horizontal resistanceWelding/cutting auxillary devicesAuxillary welding devicesNanosecond laserStress concentration

The invention provides a laser welding method of aluminum alloy and plastic, a grinding jig and a clamping jig. The laser welding method comprises the following steps: (1) surface grinding treatment of the joint end faces of the aluminum alloy sample and the plastic sample; (2) Nanosecond laser pre-etching treatment on the end face of the aluminum alloy sample; (3) The joint ends of the aluminum alloy sample and the plastic sample are assembled and welded by laser. The laser welding method of the present invention uses a grinding fixture to grind the surfaces to be welded of the aluminum alloy sample and the plastic sample, so that the two can obtain inclined end faces with the same slope, and perform nanosecond laser welding on the aluminum alloy surface Pre-etching treatment, finally clamped by a clamping fixture and formed by laser multi-pass welding, can effectively improve the design freedom of the aluminum alloy sample and plastic sample joint, reduce the stress concentration caused by the lap joint form, and the welding speed Fast, the quality of the joint is good, the sample after welding does not need post-processing and has reliable strength.

Owner:汇创造(济南)技术服务有限公司

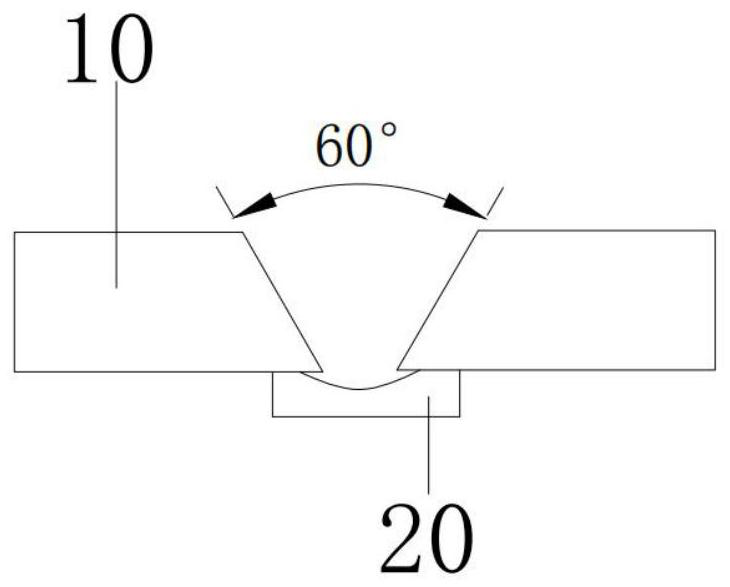

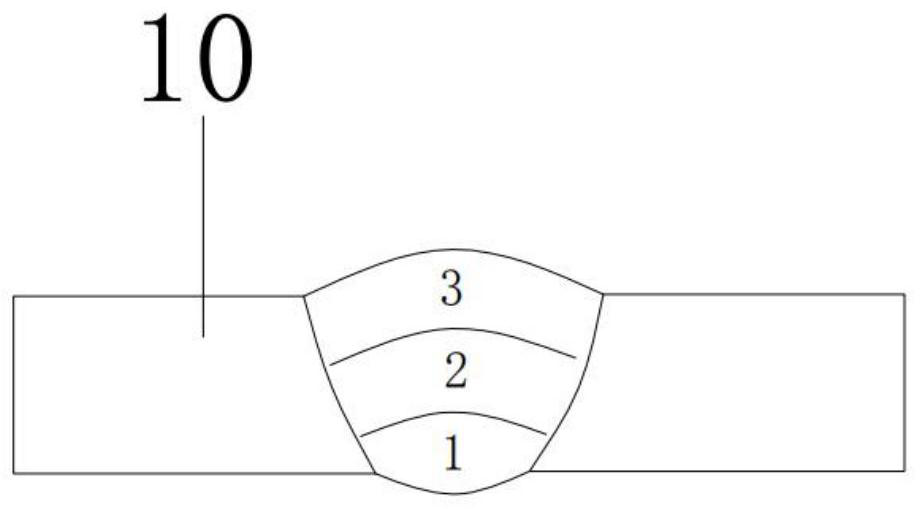

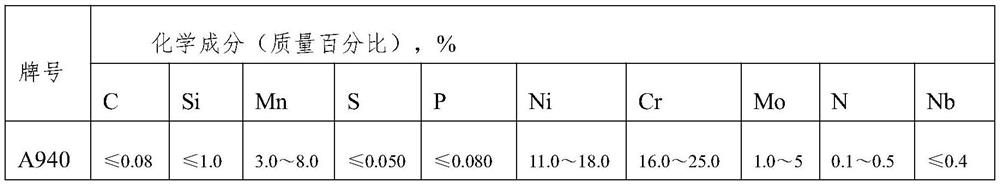

A welding method for single-sided welding and double-sided forming of a940 steel

ActiveCN111069801BQuality assuranceAvoid thermal cracksWelding/soldering/cutting articlesWelding apparatusWeld seamMechanical properties of carbon nanotubes

The invention provides a single-sided welding and double-sided forming welding method for A940 steel, which adopts a special ceramic liner and a gas shielded welding welding method to realize single-sided welding and double-sided forming of A940 steel. The single-sided welding and double-sided forming welding method of A940 steel solves the problem that the steel can not be welded with double-sided welding structure in engineering applications, and improves the welding efficiency. The test plate welded by the invention has beautiful welding seam shape, meets the requirements in size, non-destructive testing, ray according to GB / T3323 rating and meets the requirements of class I, penetration according to NB / T47013.5 rating meets the requirements of class I, all mechanical properties are excellent and meet GJB4000‑2000 requirements.

Owner:WUHAN WUCHUAN MEASUREMENT & TEST

A kind of martensitic heat-resistant steel electrode for 650 ℃ ultra-supercritical thermal power unit with single-sided welding and double-sided forming without argon filling on the back

ActiveCN110508968BArc stabilizationReduce splashWelding/cutting media/materialsSoldering mediaSlag (welding)Power unit

Owner:KUSN GINTUNE WELDING

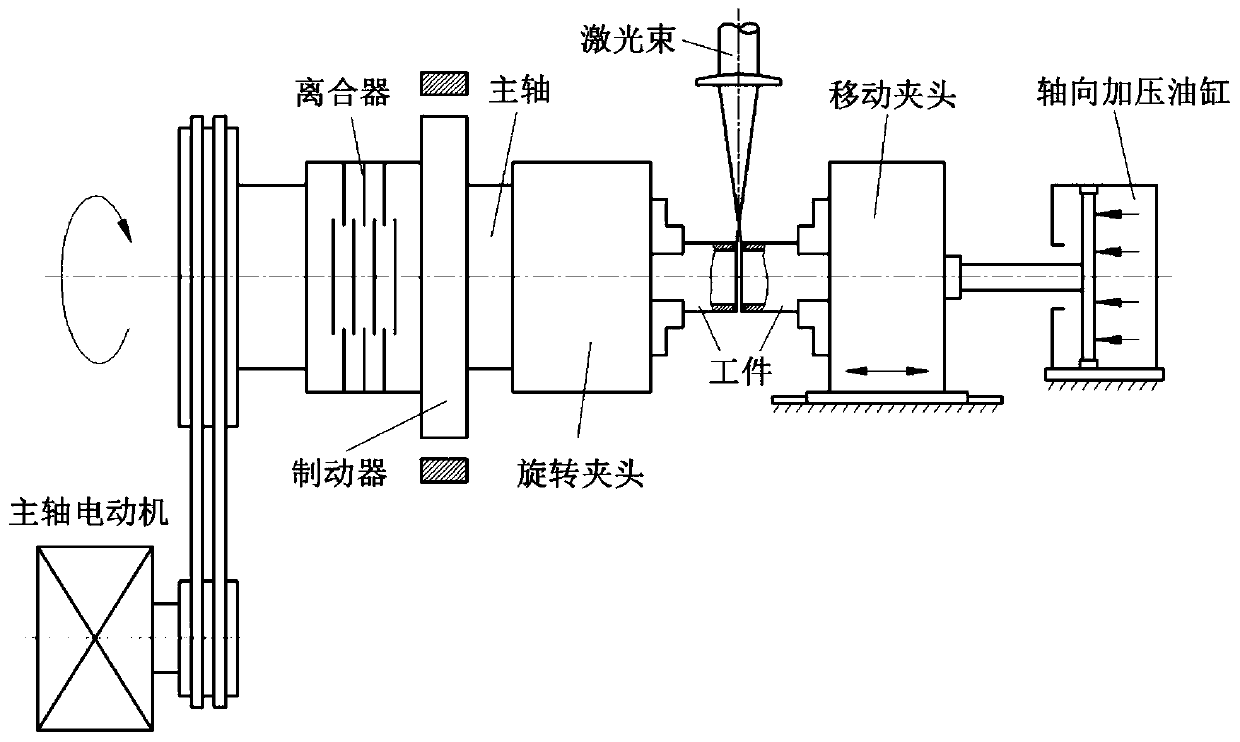

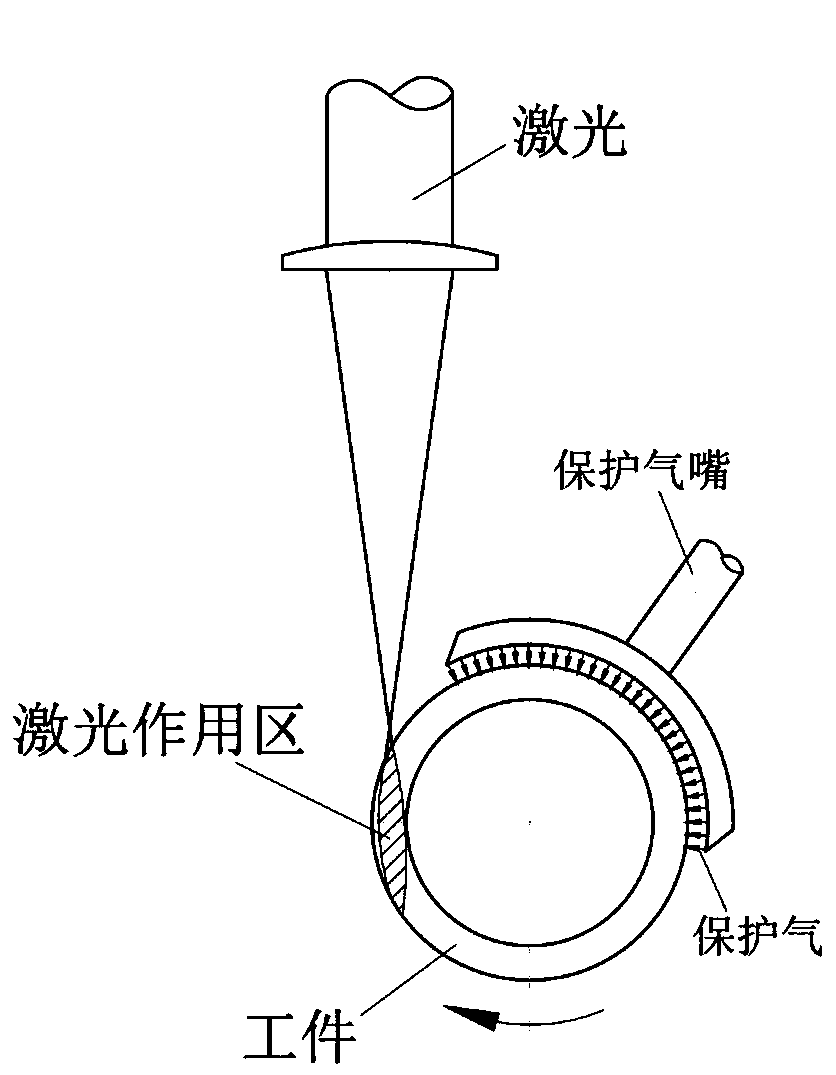

Laser heating friction welding method

ActiveCN106808095BHigh densityPrecise and controllable heating zoneLaser beam welding apparatusLiquid metalFriction stud welding

The invention relates to the field offriction welding, and provides a friction welding heating method by using laser. Particularly, before welding, end faces of work piecesare radiated by the laser, so as to make the surface layer in ahigh temperature or micro melting state, then friction and upsetting process are conducted swiftly, so as to extrude liquid metals and parts of thermoplastic metals, finally the connection is formed through diffusion and recrystallization. According to the method, the unique advantages of highdensity of laser energy, precise and controllable airspace and time domain, and the characteristics of good quality of friction welding joint and high production efficiency and the like are synthetically utilized. The method has the advantages that external input energy is used as a main energy source; the required pressure and torque of friction welding are greatly decreased; the requirementfora welding equipment is reduced; processing ranges of traditional friction welding are expanded: the heterogenetic materials with big difference in physical and chemical characteristics, workpieces with small stiffness, thin walls and minor diameters, and workpieces with low friction coefficient, with-surface layer, high temperature and strength are welded.

Owner:BEIJING UNIV OF TECH

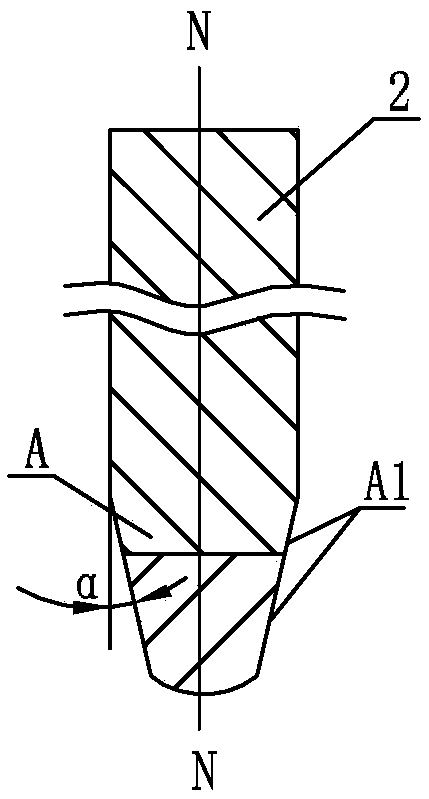

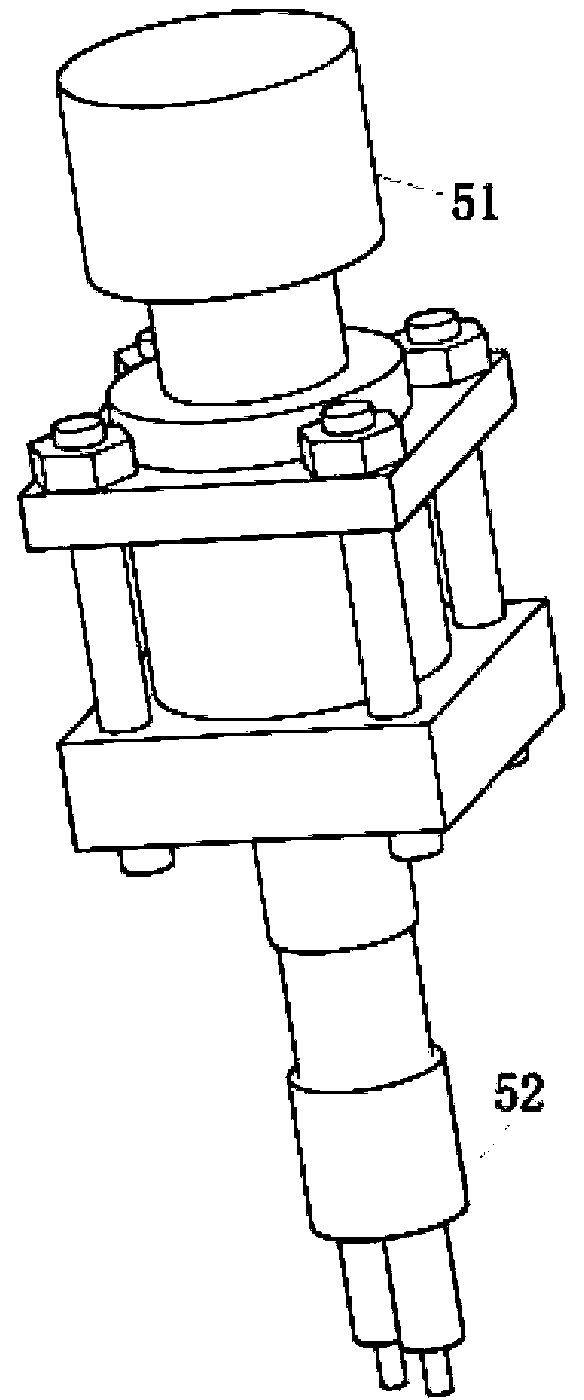

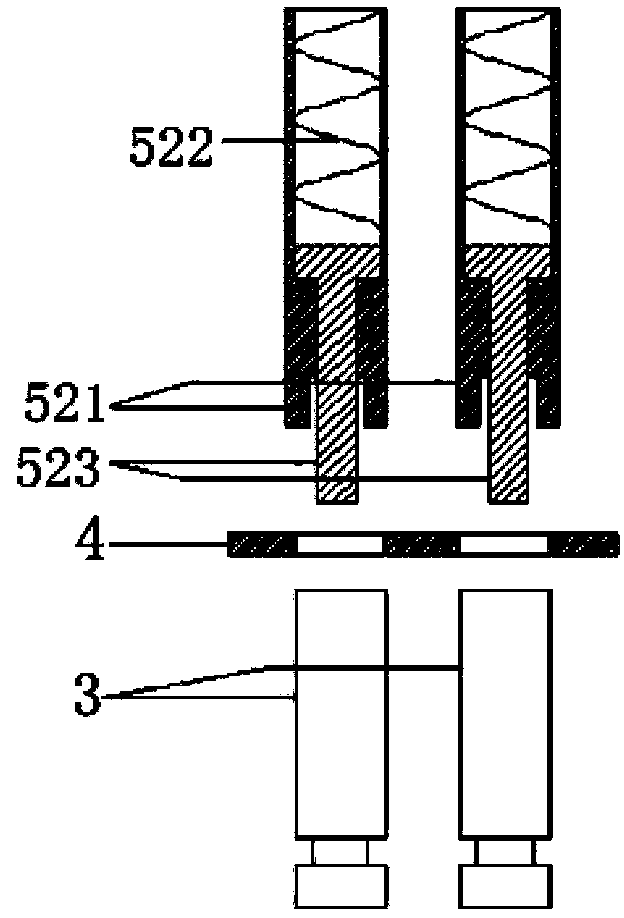

Combined trigger type friction stir plug brazing repair welding method and its welding tool

ActiveCN105855693BIncrease stiffnessSolve the strength problemNon-electric welding apparatusEngineeringFriction stir welding

The invention provides a combined triggering type friction stir plug braze welding and repair welding method and a welding tool thereof. The method comprises the following steps: 1, machining the lower end of a stirring body 2 into a stirring needle which is conical, wherein the upper part of the stirring needle is made of a metal material, and the lower part of the stirring needle is made of an aluminum zinc material; 2, determining the size of the stirring needle; 3, positioning a key hole required to be repaired; and 4, in a braze welding and repair welding process of a friction stir plug, rubbing the stirring needle with the material of the inner wall of the key hole to be subjected to repair welding, rubbing an aluminum zinc bar with the inner wall of the key hole in advance at the low temperature so as to plastify, continuing carrying out friction stir downwards by using a metal bar, and rubbing the upper part of the stirring needle of the metal bar with the inner wall of the key hole to generate heat so that the key hole which needs to be subjected to repair welding and has been filled with the aluminum zinc bar is fully filled with the aluminum zinc bar. According to the welding tool, the stirring body is arranged in a clamping hole of a clamping body, circumferential surfaces of the stirring needle at the upper end and the stirring needle at the lower end are conical surfaces, the stirring needle at the upper end and the stirring needle at the lower end form the stirring needle, and the stirring needle is exposed out of the lower end surface of a lower cylinder. The combined triggering type friction stir plug braze welding and repair welding method and the welding tool thereof are used for repair welding of the friction stir welding key hole.

Owner:安徽万宇机械设备科技有限公司

Piece assembly device used for chain assembly

ActiveCN102847865BGuaranteed longest contactPrevent crushingMetal chainsEngineeringMechanical engineering

The invention provides a piece assembly device used for chain assembly and relates to the field of chain production. The piece assembly device comprises a lifting device, a piece press device connected with the lower end of the lifting device, a control device, a first piece assembly cam, a sensor corresponding to the first piece assembly cam, a second piece assembly cam and a sensor corresponding to the second piece assembly cam. The lifting device is connected with the control device. The piece press device comprises a piece press mould and a pair of guide collision devices installed in the piece press mould and elastically connected with the piece press mould, and the sensors are connected with the control device. The piece assembly device has the advantages of being safe in production, high in efficiency, good in quality, high in stability and the like, thereby being a full automatic piece assembly device used for chain assembly.

Owner:SUZHOU CHUNMENG INTELLIGENT TECHNOLOGY CO LTD

Method for connecting glass with copper or copper alloy

The invention relates to a method for connecting glass with copper or copper alloy, particularly a method for connecting glass with copper or copper alloy by soft soldering. The invention aims to solve the problems of complex technique, high connecting temperature and poor joint quality in the existing method for connecting glass with metal. The method comprises the following steps: 1. cleaning copper or copper alloy in acetone, cleaning with absolute ethanol and deionized water, carrying out blow-drying, and baking; 2. cleaning a sanded glass substrate in acetone, cleaning with absolute ethanol and deionized water, carrying out blow-drying, bombarding with an ion beam, coating a Cr film on the glass substrate by vaporization, and coating a Cu film by vaporization; 3. cleaning low-temperature solder in acetone, cleaning with absolute ethanol and deionized water, and carrying out blow-drying; 4. preparing a rosin zinc chloride-base soldering flux; 5. assembling a soldering workpiece by using a graphite plate; and 6. putting the soldering workpiece into a heating apparatus to carry out soldering. The invention has the advantages of lower connecting temperature, simple technique and better joint quality. The invention is applicable to soldering of glass and metal.

Owner:HARBIN INST OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com