Titanium alloy narrow-gap laser welding wire feeding and gas protection integrated mechanism

A technology of laser welding and gas protection, which is applied in the direction of laser welding equipment, welding equipment, welding/welding/cutting items, etc., can solve problems that cannot be directly applied, achieve good gas protection effect, compact overall structure, and reduce turbulence Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

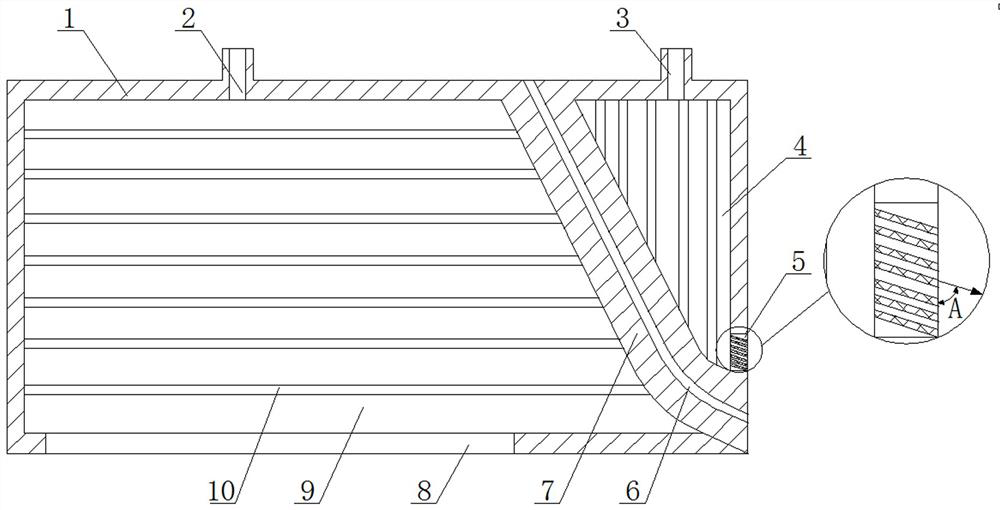

[0032] The core of the present invention is to provide a titanium alloy narrow-gap laser welding wire feeding and gas protection integrated mechanism, which solves the difficulties of titanium alloy narrow-gap laser welding wire feeding to accurately reach the bottom of the narrow-gap groove, welding plasma interference and titanium alloy Alloy welding process and the difficulty of effective protection of high-temperature welds after welding. The whole mechanism is set on the head of the laser welding torch to achieve a good positional fit with the laser tube bundle.

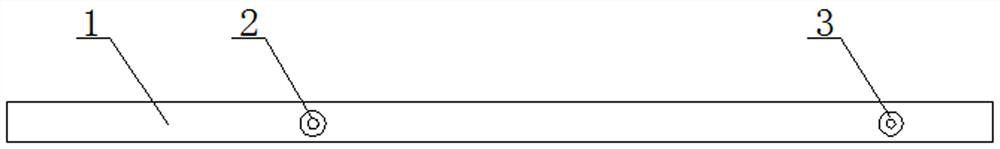

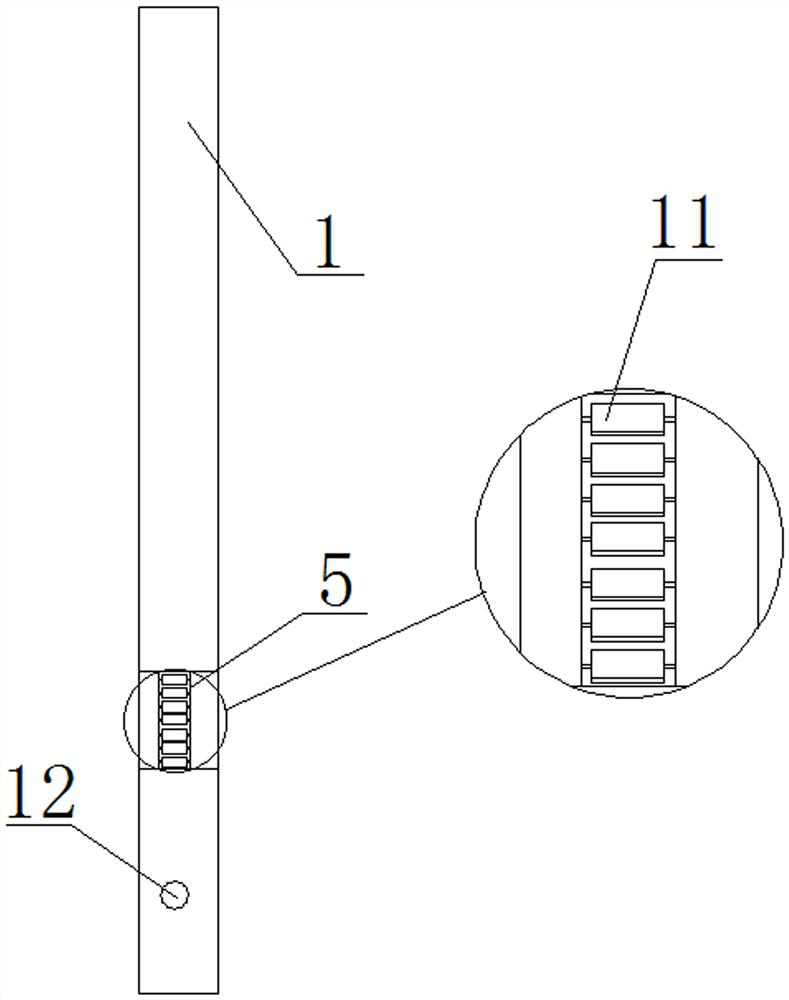

[0033] Specifically, a titanium alloy narrow gap laser welding wire feeding and gas protection integrated mechanism, please refer to Figure 1~Figure 3 , the mechanism mainly includes a shell 1 that can extend into the gap to be welded in structure, and the shell 1 is a hollow cuboid; The wire feeding channel 7 at the lower part of the right side wall, the wire feeding channel 7 can send the welding wire at an ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com