Patents

Literature

122results about How to "Simple welding method" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Metal bar fast-diffusion welding method based on pulse current treatment

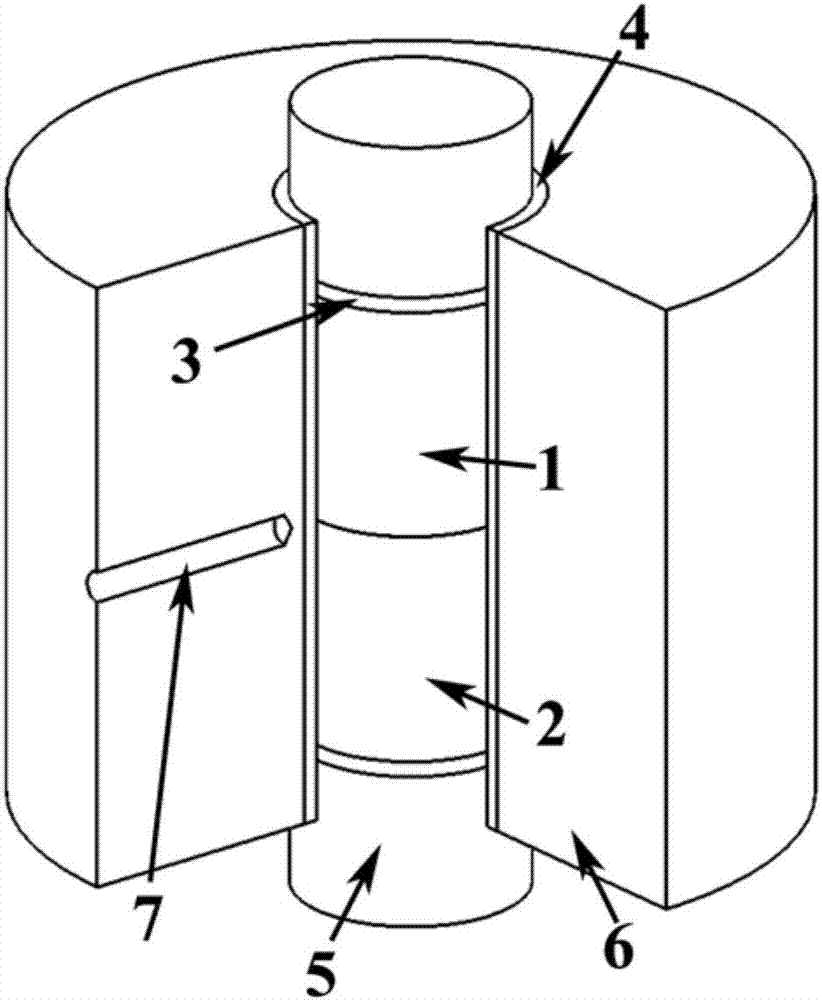

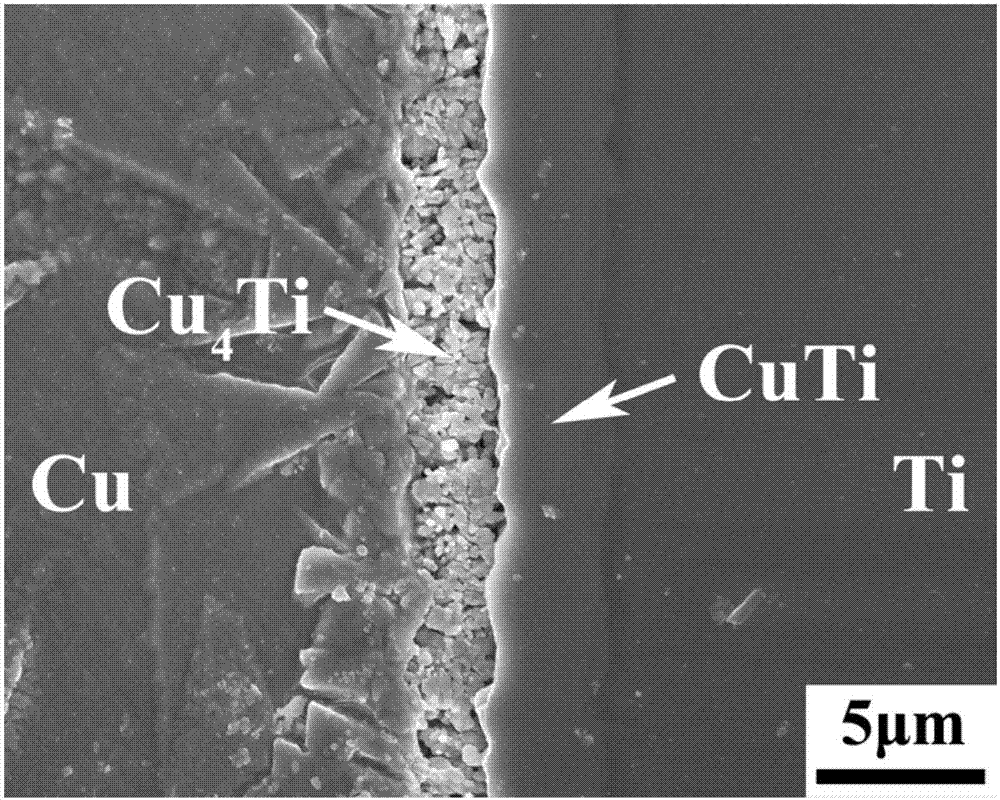

The invention belongs to a connecting method of a dissimilar metal material and discloses a metal bar fast-diffusion welding method based on pulse current treatment. The welding method comprises the steps that end faces of metal bars of two different materials make contact and are arranged in a graphite die cavity, and the other end faces of the metal bars are connected with a graphite punch pin. An equipped die is arranged in a spark plasma sintering system, then pressure is exerted on the graphite punch pin, meanwhile, pulse currents flow through the two metal materials through the graphite punch pin from top to bottom, the contact end faces of the two metal bars will react, under the effect of vacuum conditions and pulse currents, a new diffusion layer is generated, the two metal bars form good metallurgical bonding, and reliable connection is obtained. Compared with conventional vacuum diffusion welding, time needed by pulse current diffusion welding is short, thus, the production efficiency is improved, and time cost is saved.

Owner:SOUTH CHINA UNIV OF TECH

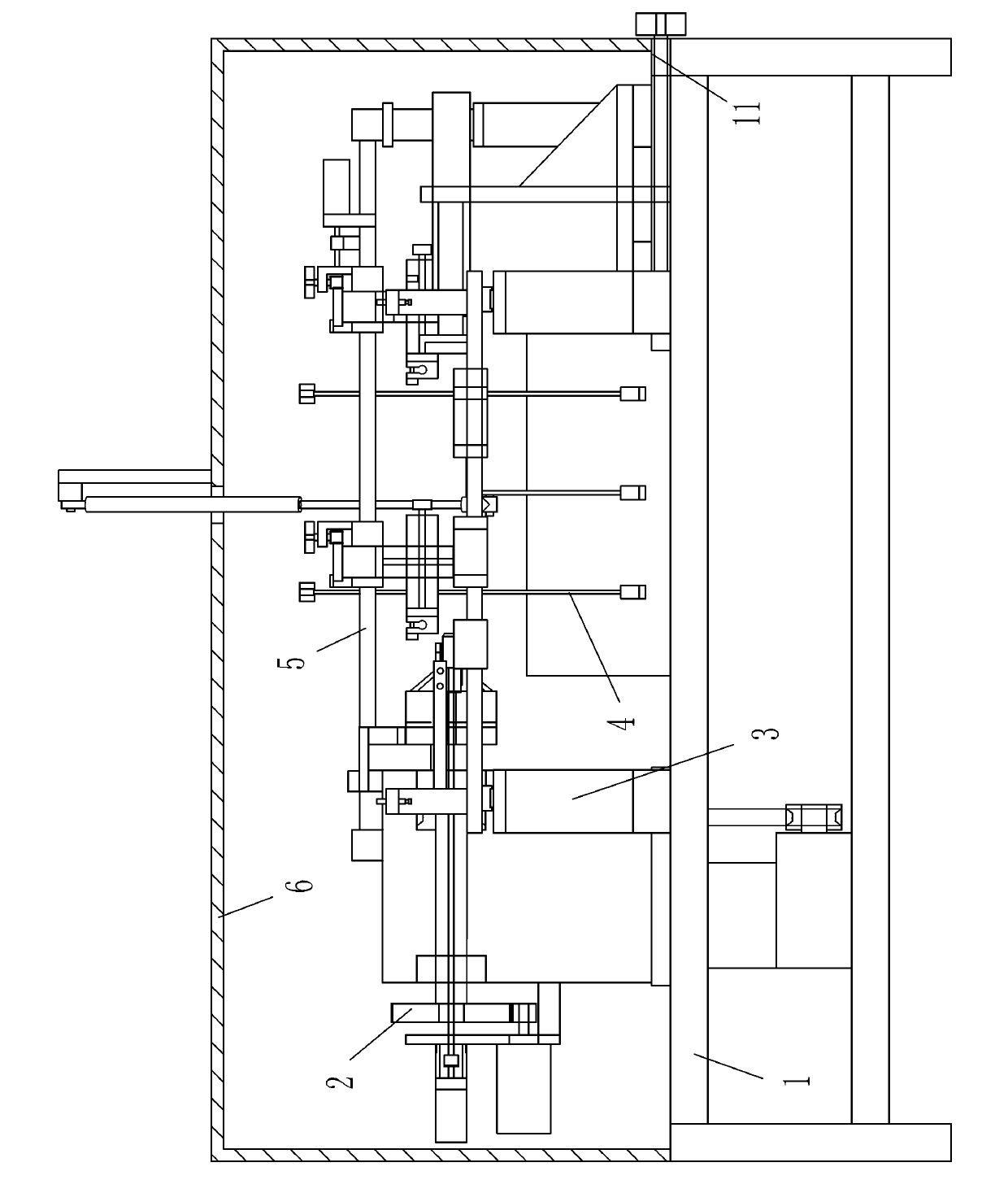

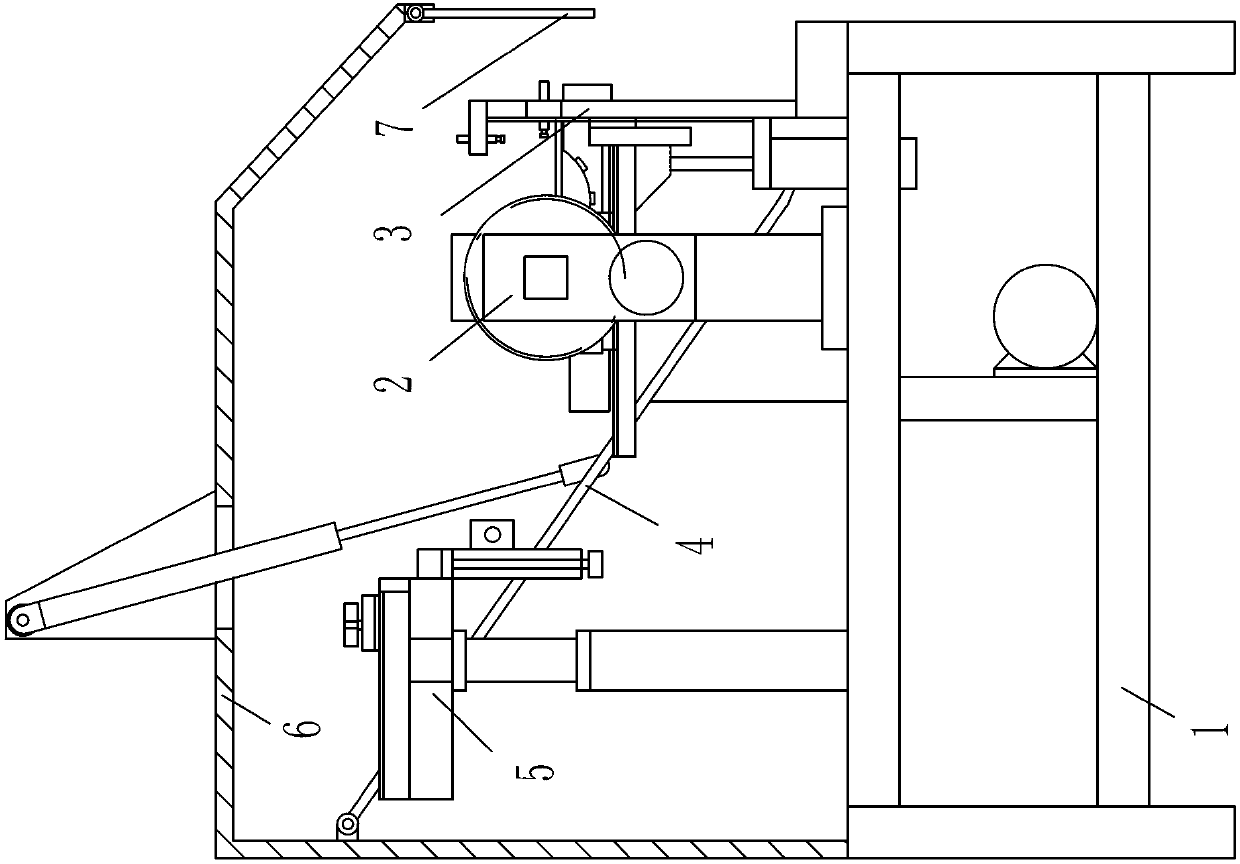

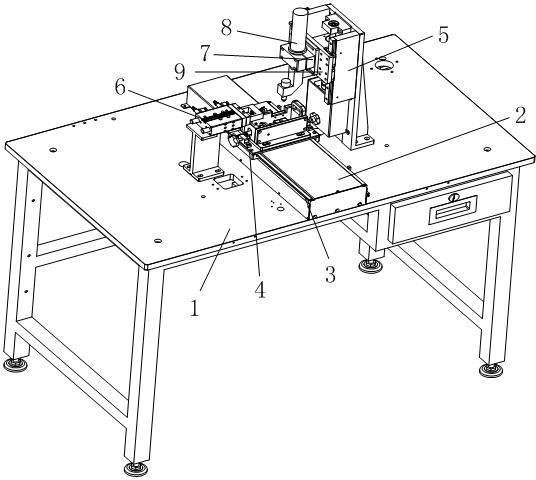

Extinguisher cylinder welding machine and welding method thereof

ActiveCN103286487AReduce labor intensityLow labor intensity and low welding efficiencyWelding/cutting auxillary devicesAuxillary welding devicesFire extinguisherWelding

The invention relates to the field of fire fighting and aims to provide an extinguisher cylinder welding machine and a welding method thereof, wherein the extinguisher cylinder welding machine is low in labor intensity and high in welding efficiency. The extinguisher cylinder welding machine comprises a base, a cylinder clamping device, a cylinder positioning device, a welding gun clamping device and a cylinder blanking device; and the cylinder clamping device comprises a valve base end mounting base, a valve base positioning bar with a protruding key arranged at the outer circumference, a bottom cover positioning mould relative to one end of the valve base positioning bar, a positioning bar sliding sleeve, a rotating device used for driving the positioning bar sliding sleeve to rotate, a positioning bar pushing device used for pushing the valve base positioning bar to move in the axial direction, a positioning mould pushing device used for pushing the bottom cover positioning mould to axially move and connected with a first guide rail in a sliding manner and a positioning regulation device, wherein the positioning bar sliding sleeve is arranged outside the valve base positioning bar in a sleeving manner, and a sliding groove is formed in the inner side wall of the positioning bar sliding sleeve in the axial direction. The extinguisher cylinder welding machine is low in the labor intensity and high in the welding efficiency. The welding method for the extinguisher cylinder welding machine is simple and practical.

Owner:余姚市超成机械制造有限公司

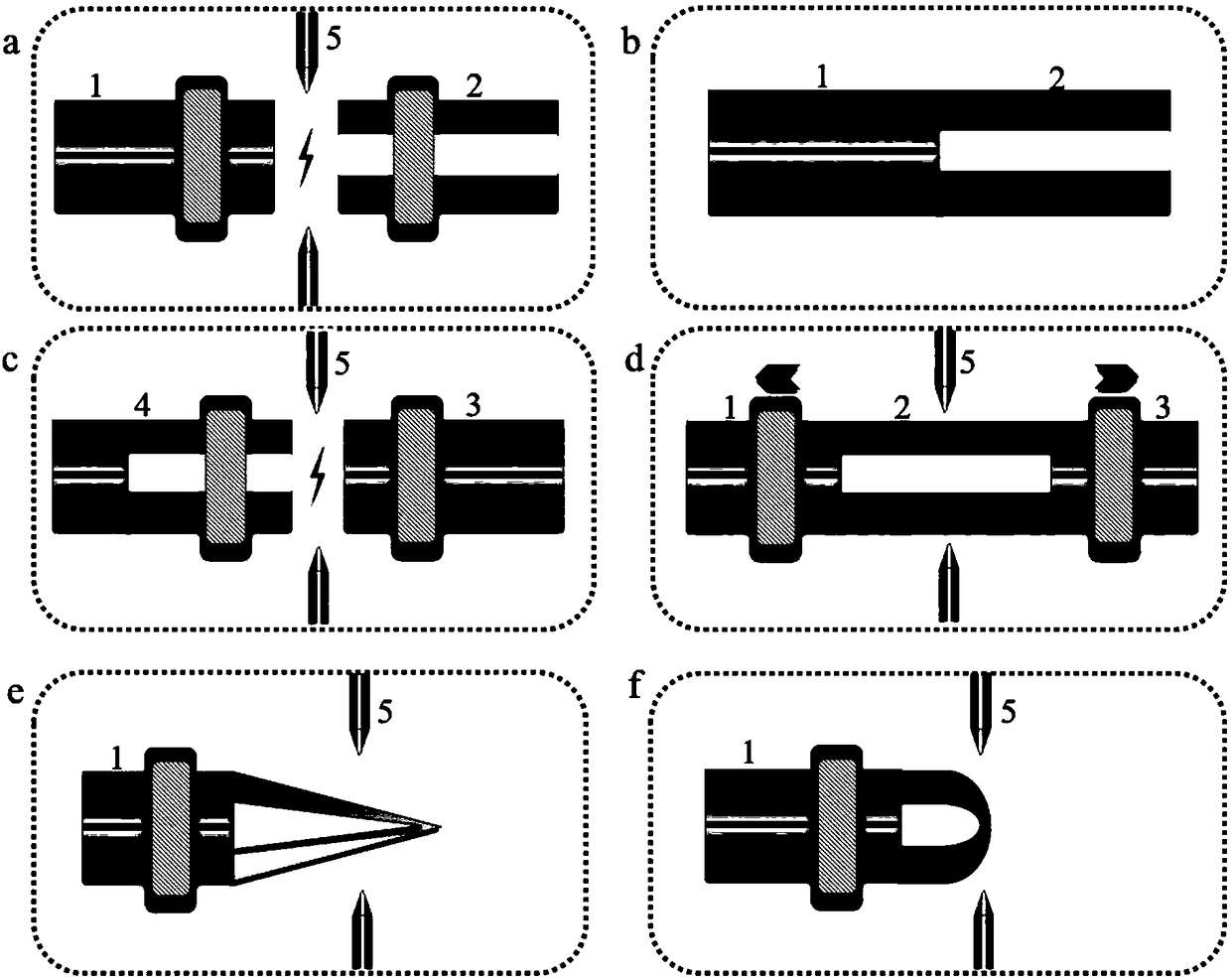

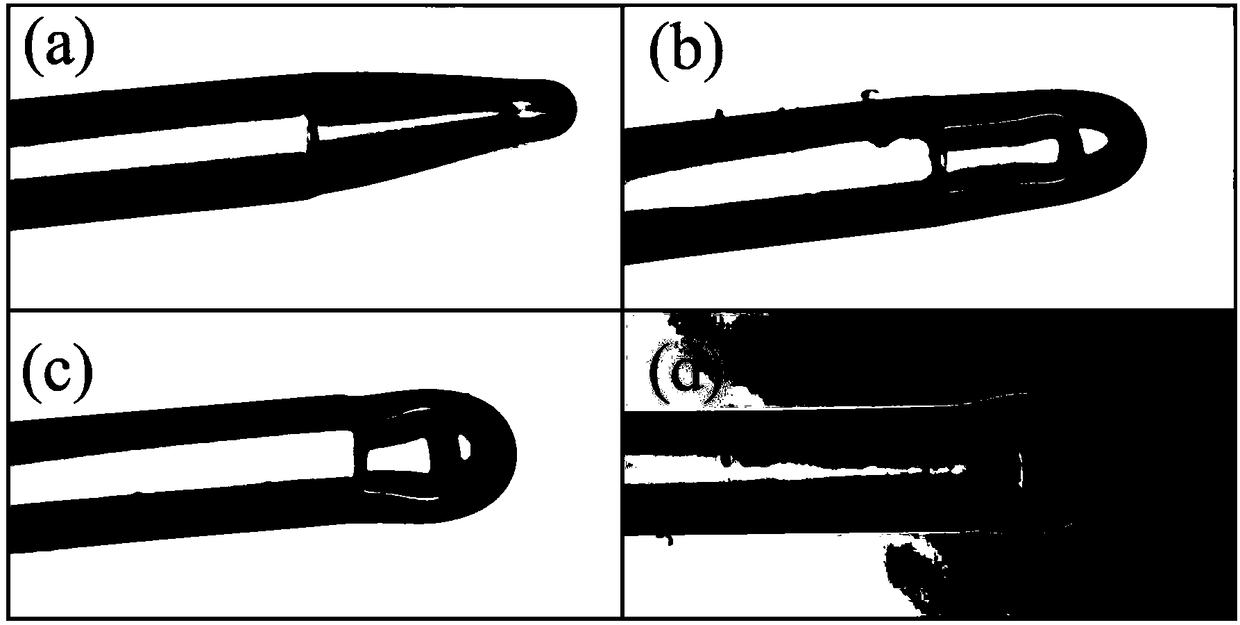

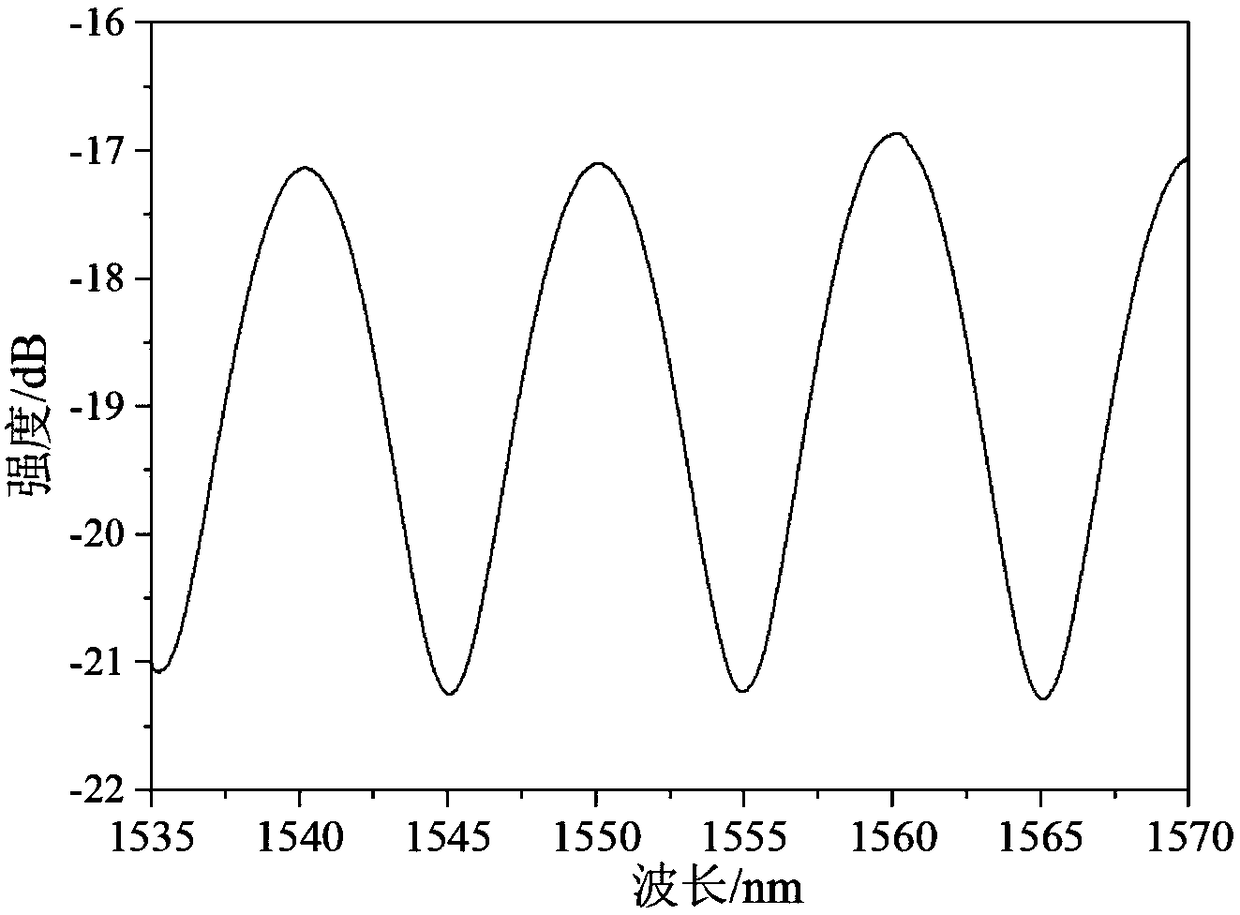

Fabrication method of miniature optical fiber Fabry-Perot interferometer with controllable cavity length

InactiveCN108332654ASolve the problems of difficult production and structural size controlHigh mechanical strengthUsing optical meansConverting sensor output opticallyInterferometric sensorEngineering

The invention belongs to the technical field of optical fiber device fabrication, and discloses a fabrication method of a miniature optical fiber Fabry-Perot interferometer (FPI) with a controllable cavity length. A method in which a single mode optical fiber splices a hollow optical fiber (HCF) and a discharging taper is adopted to fabricate a miniature air cavity FPI. The structural size can becontrolled by adjusting a series of parameters such as an HCP length and various welding parameters such as a taper length, a two-fiber overlapping amplitude, a discharge parameter and the number of discharge times. By means of the method, the size-controllable, repeatable and efficient miniature air cavity Fabry-Perot interferometer can be obtained, and plays a vital role in an interference-typesensor based on Fabry-Perot. The method can make the microcavity level and perpendicular length of the FPI cover from a small value to a large value, and efficient fabrication can be achieved. By means of the method, according to user requirements, miniature air cavity FPIs with random sizes can be fabricated. Besides, a probe of the miniature air cavity FPI can be used for detection of parameterssuch as axial stress and temperature.

Owner:NORTHEASTERN UNIV

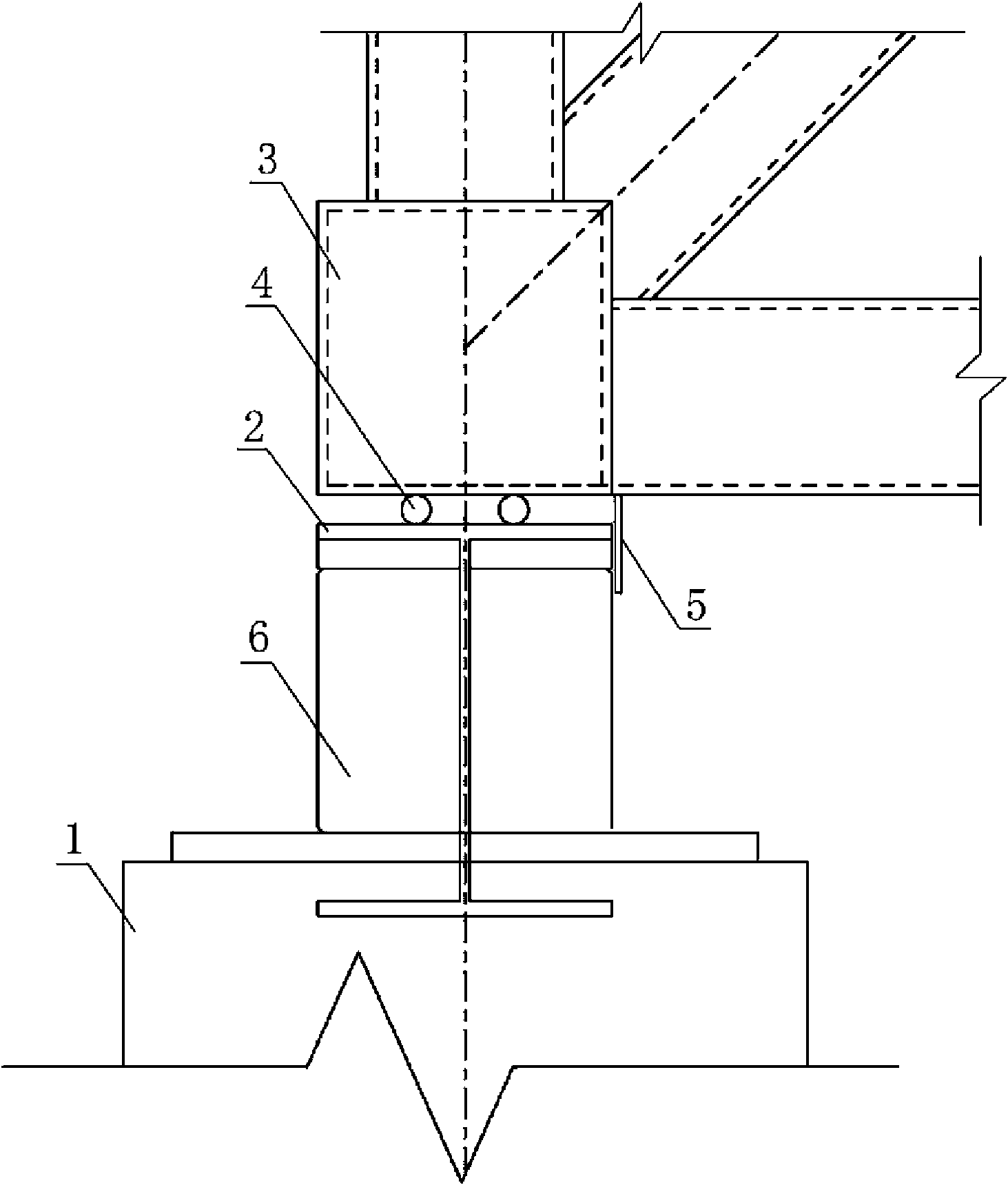

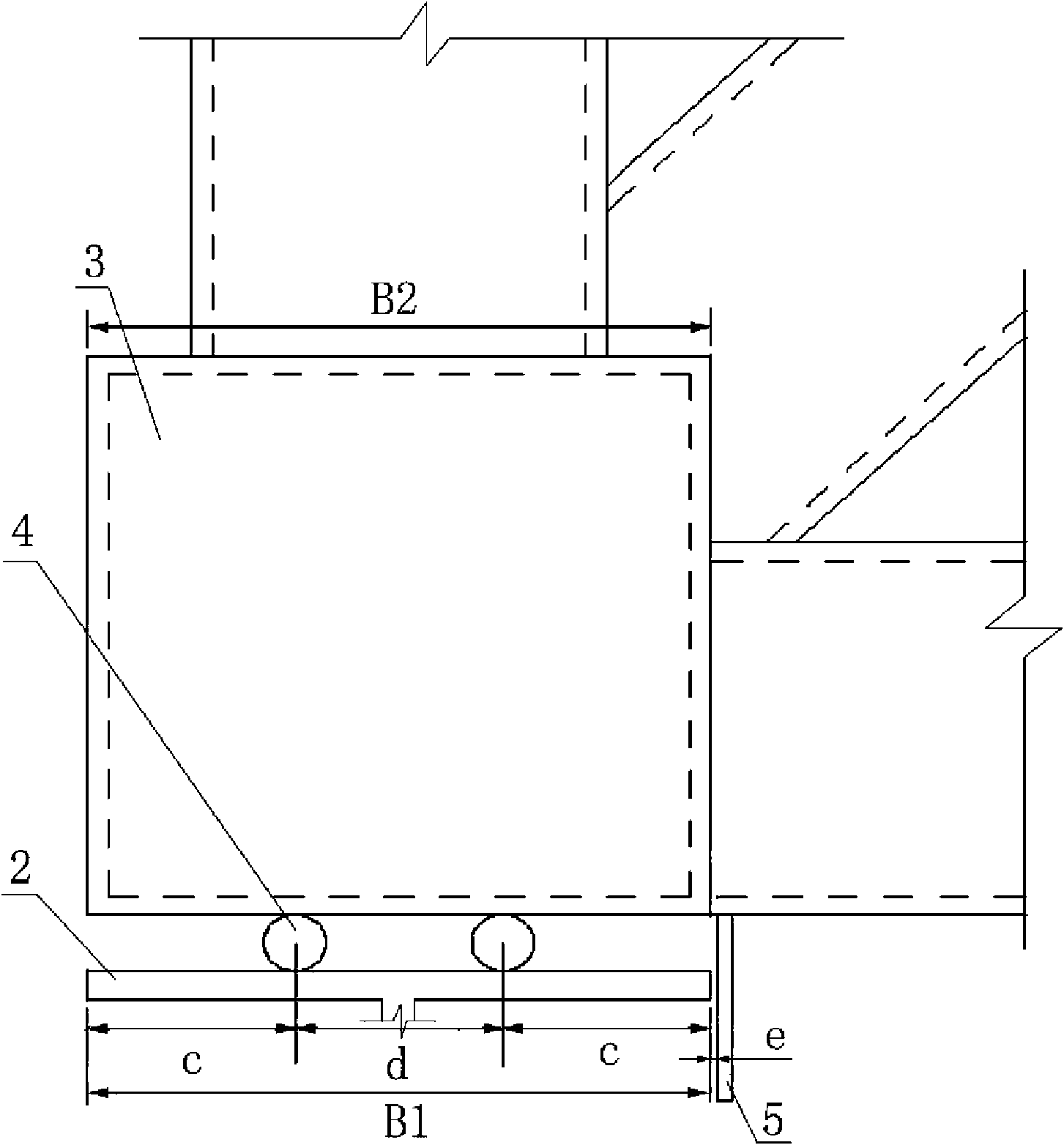

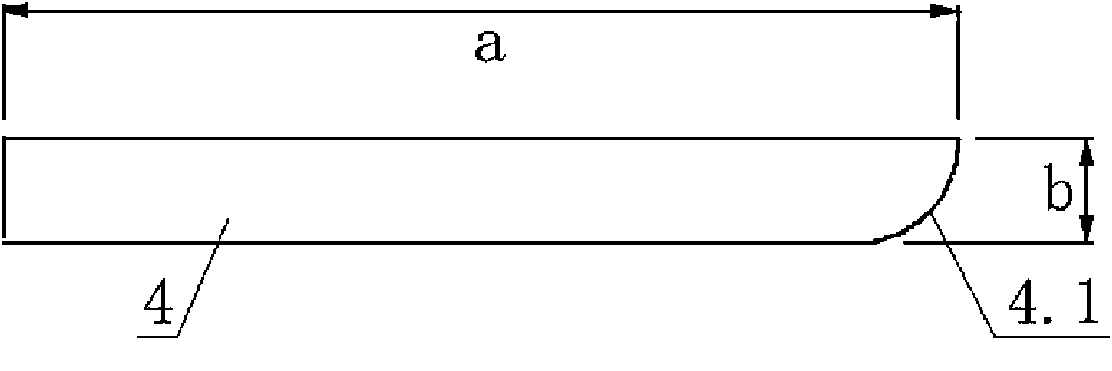

Accumulation slippage construction device in icesword manner and construction method thereof

The invention relates to an accumulation slippage construction device in an icesword manner and a construction method thereof. The accumulation slippage construction device comprises gliders at the lower part of a steel truss and a slide rail fixed above a steel truss support, wherein the gliders are icesword-type gliders distributed at the lower part of the steel truss at intervals along the direction of the slide rail; each section of icesword-type glider is two plain round bars parallel to the slide rail; the top of the plain round bar is welded together with the bottom of the steel truss; the bottom of the plain round bar is linearly contacted with the upper surface of the slide rail; and the bottoms of the steel truss closed to the slide rail are respectively connected with limit baffle plates. Using slippage contacting plain round bars with profile steel flat rails to replace slippage contacting flat gliders with train steel rails, the invention is economical, convenient, practical and effective, is applicable to places where cranes can not enter into the construction area in the presence of basement or other structures, as well as steel structures of small and intermediate spans where pushing jacks and train steel rails are difficult to purchase or the construction is not economical, and has great influence on the construction period by other construction methods.

Owner:北京城建精工钢结构工程有限公司

Welding method of H-type steel member

InactiveCN105458540ASimple welding methodSmall sizeWelding/soldering/cutting articlesWelding apparatusNumerical controlSlag

The invention discloses a welding method of an H-type steel member. The welding method comprises the following steps of part blanking, wherein as for a wing plate and a web of H-type steel, a straight strip cutting machine is adopted for carrying out vertical blanking on two faces at the same time, and a numerical control cutting machine is adopted for carrying out blanking on irregular parts; assembling, wherein the appearance cutting quality of the parts is checked, no gap or burr exists on cut faces, and a manual jig frame is adopted for assembling the H-type steel; welding, wherein two manners of n-shaped submerged-arc welding and cart type submerged-arc welding are adopted, welding is finished, and slags and splash in a welding seam area are removed; correction, wherein no concave face or damage or scratch exists on corrected surfaces; cutting-off, wherein allowance cutting is carried out on the two ends of the H-type steel, and grinding and leveling are carried out after cutting; and locking, wherein marking is carried out, manual cutting is adopted, and flat grinding is achieved. The welding method is simple, the surface of the machined H-type steel is flat, the size is accurate, and consistency is good.

Owner:ANHUI WEIHONG STEEL STRUCTURE GRP

Welding technology for steel plates

InactiveCN104588850AWelding safetyGuarantee welding qualityArc welding apparatusSheet steelEngineering

The invention discloses a welding technology for steel plates, and relates to the technical field of welding technologies. The welding technology includes the four steps of pre-welding preparing, temporary tack welding, welding and post-welding processing. By means of the welding technology for the steel plates, the welding steps are simplified, the welding mode is simple, standard specifications are selected for materials, and the steel tube welding quality can be guaranteed; a regular welding mode is provided for the steel plates which are 3 mm in thickness, and rapid and safe welding of the steel plates which are 3 mm in thickness is facilitated.

Owner:WUHU CIMC RUIJIANG AUTOMOBILE

Welding technology for steel plate

The invention discloses a welding technology for a steel plate and relates to the technical field of welding technologies. The welding technology includes four steps of preparing before welding, tack welding, welding and processing after welding. According to the welding technology for the steel plate, the welding steps are simplified, the welding mode is simple, material selection is accurate and standard, the welding quality of a steel pipe can be ensured, a standard welding mode is provided for the steel plate 1 millimeter in thickness, and the steel plate which is 1 mm in thickness can be easily, rapidly and safely welded.

Owner:WUHU CIMC RUIJIANG AUTOMOBILE

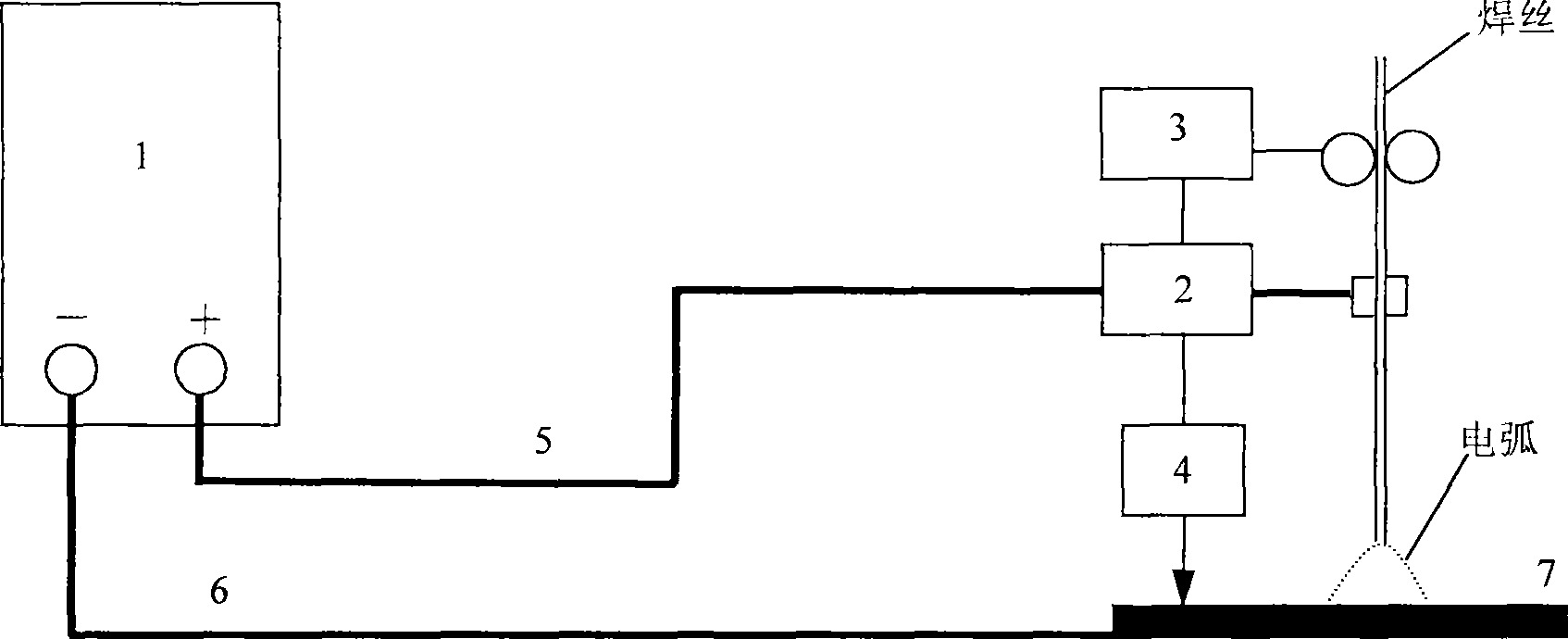

Method and system for realizing electric arc wire feeding for arc welding power source

ActiveCN101474708ASimple welding methodImprove use reliability and stabilityArc welding apparatusCarrier signalElectric arc

The invention discloses a method used for an arc welding power to realize electric arc wire feed. The method dispenses with a control cable or a carrier cable between the arc welding power and a far wire feeder, wherein a wire feeder control system is directly connected with the arc welding power by the welding cable, the energy of an electric arc is directly utilized to drive a wire feed motor, and the programme control of an automatic welding process can be realized. The wire feed method dispenses with the control cable or the carrier cable. By connecting the welding cable used for transporting electric arc energy with the far wire feed system, the programme control of the wire feed motor and the automatic welding process is realized, and the stable working of the welding system is guaranteed. As automatic wire feed consumable electrode electrical arc welding equipment dispenses with the control cable or the carrier cable connected between the electrical arc welding power and the wire feeder, the welding method can be much more convenient, and the service reliability and the stability of the welding equipment are improved. Besides, the invention also discloses a system for realizing the method.

Owner:HANGZHOU KAIERDA ELECTRIC WELDING MACHINE

Method for welding and repairing copper surface defect of aluminum-copper composite board transition joint

ActiveCN102059430AStrong penetrating powerHigh thermal efficiencyArc welding apparatusWorking environmentHeat losses

The invention relates to a method for welding and repairing copper surface defects of an aluminum-copper composite board transition joint. The method comprises the following steps of: before welding, preheating a part to be welded at the temperature of 20020 DEG C so as to slow down heat loss of a welding area; filling and welding pit defects on a copper surface by utilizing an inert gas arc welding method, wherein the inert gas is a mixed gas of argon and helium; and introducing cooling water to an aluminum surface of the aluminum-copper composite board transition joint so as to reduce the heat introduced to a combination area interface of the aluminum-copper composite board transition joint. The welding method of the invention is simple and practical, not only improves the work environment, reduces the labor intensity of workers and the production cost, but also ensures that the partial peeling phenomenon does not occur in the welded aluminum-copper composite board transition joint.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

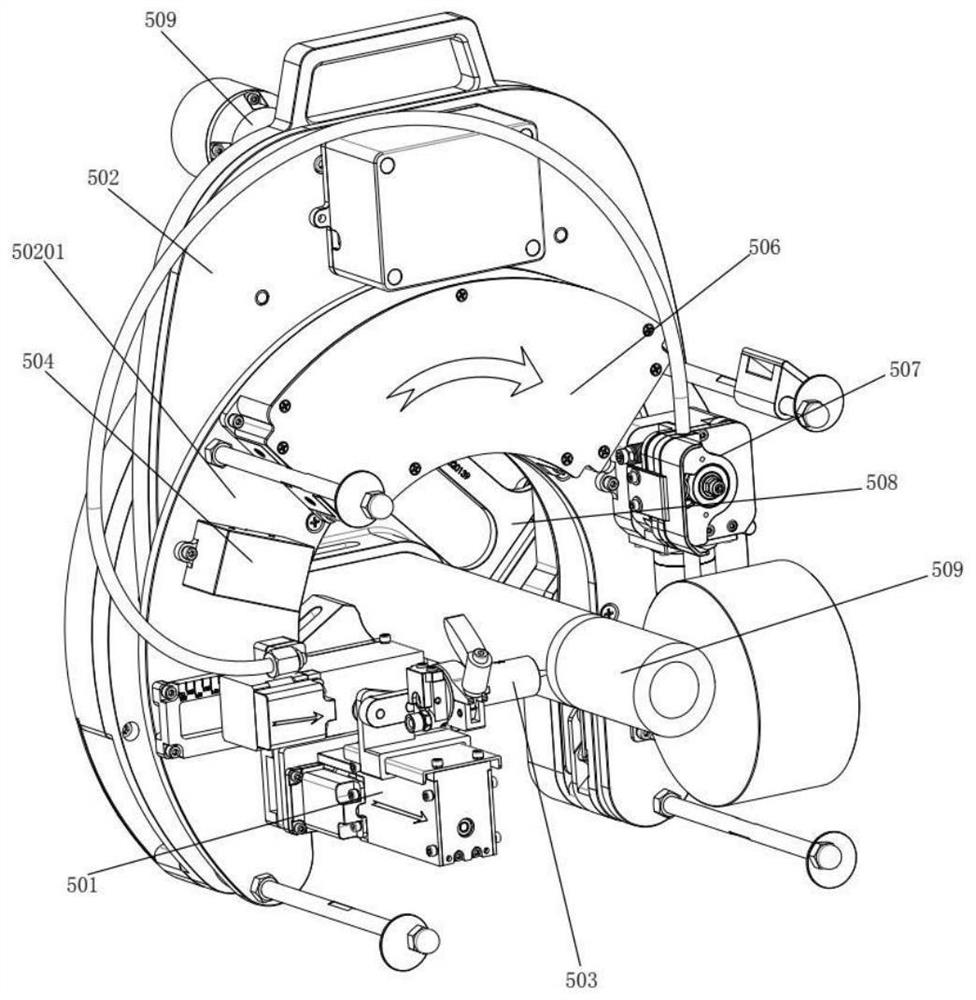

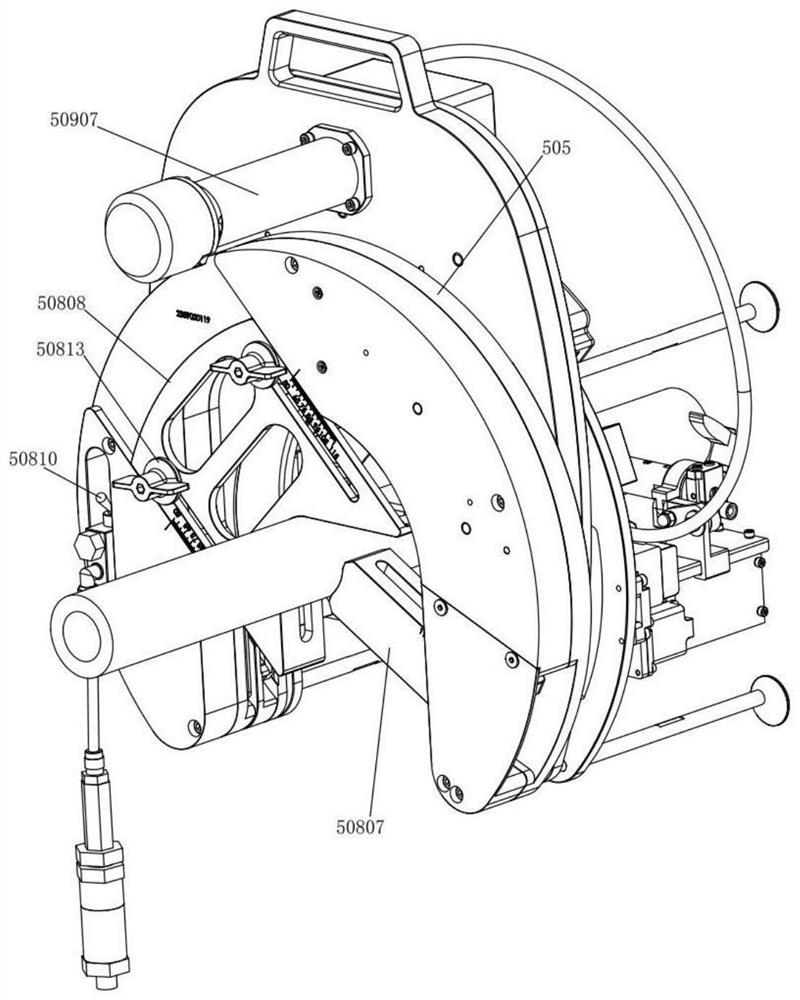

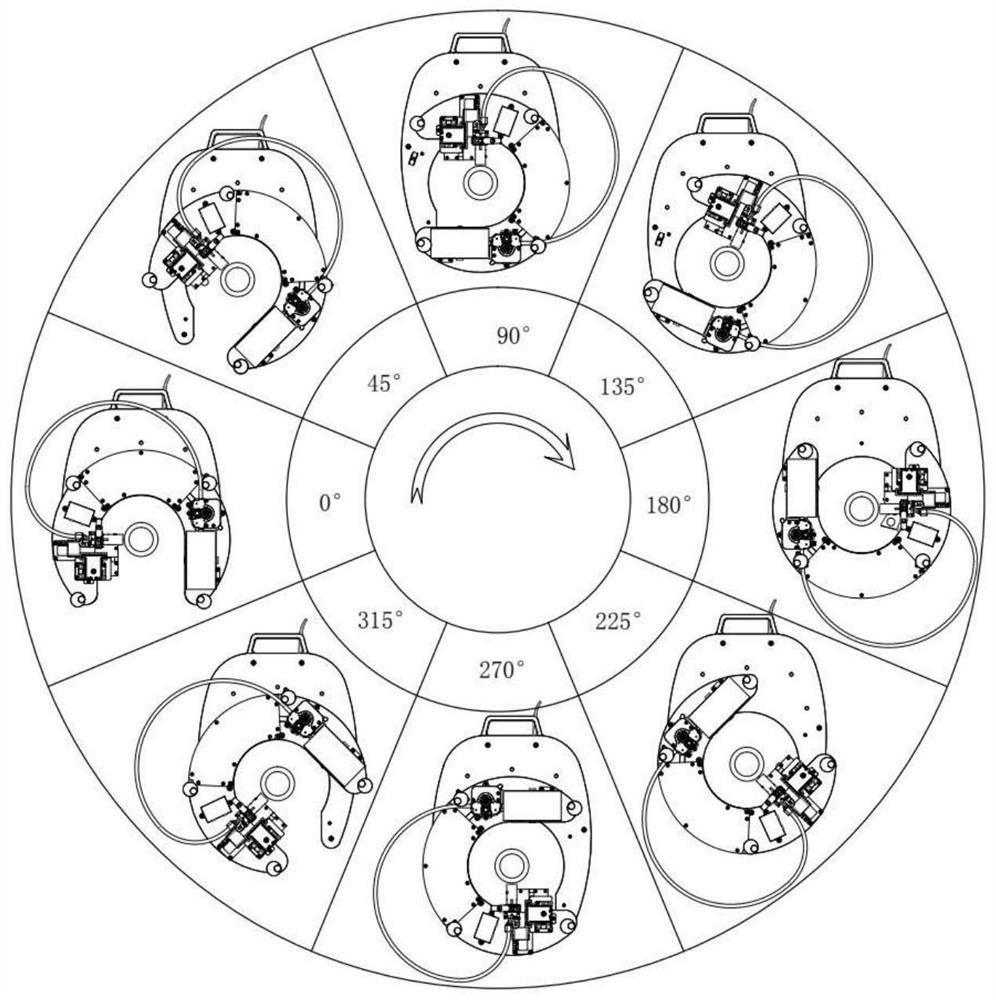

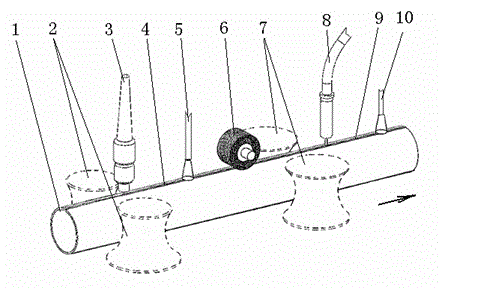

Welding system and welding method for all-position automatic welding of small-diameter pipeline

ActiveCN113385786AMeet the needs of high-quality and efficient production operationsGuarantee welding qualityWelding accessoriesPipe fittingPipe welding

The invention discloses a welding system and a welding method for all-position automatic welding of a small-diameter pipeline, and relates to the technical field of pipe welding. The welding system comprises a supporting main body with an opening, wherein a rotating disc and a clamp holder base are arranged on the supporting main body, and the rotating disc can rotate on the supporting main body; a welding gun is further arranged on the rotating disc; and a rapid clamping device is arranged on the clamp holder base and comprises clamping positioning angle blocks and clamping rotating blocks which are oppositely arranged around the rotating circle center of the rotating disc, and the clamping positioning angle blocks and the clamping rotating blocks can move relative to each other. The welding system can effectively meet the requirements of factory sites and other pipeline systems with small pipe diameters, high pipeline concentration, multiple pipeline turning points, multiple crossed positions and narrow construction space, and welding equipment is small in size and convenient to assemble and disassemble.

Owner:CHENGDU XIONGGU JIASHI ELECTRICAL

Aluminum plate welding process

InactiveCN104439641AWelding safetyChoose accurate specificationArc welding apparatusWelding/soldering/cutting articlesEngineeringSteel tube

The invention discloses an aluminum plate welding process, and relates to the technical field of welding processes. The aluminum plate welding process mainly includes the four steps of pre-weld preparation, tack weld, welding and post-weld treatment. By the adoption of the aluminum plate welding process, welding steps are simplified, the welding mode is simple, materials are accurately and standardly selected and used, the welding quality of steel pipes can be guaranteed, the standard welding mode is provided for aluminum plates with the thickness being 4 mm, and quick and safe welding of the aluminum plates with the thickness being 4 mm is facilitated.

Owner:WUHU CIMC RUIJIANG AUTOMOBILE

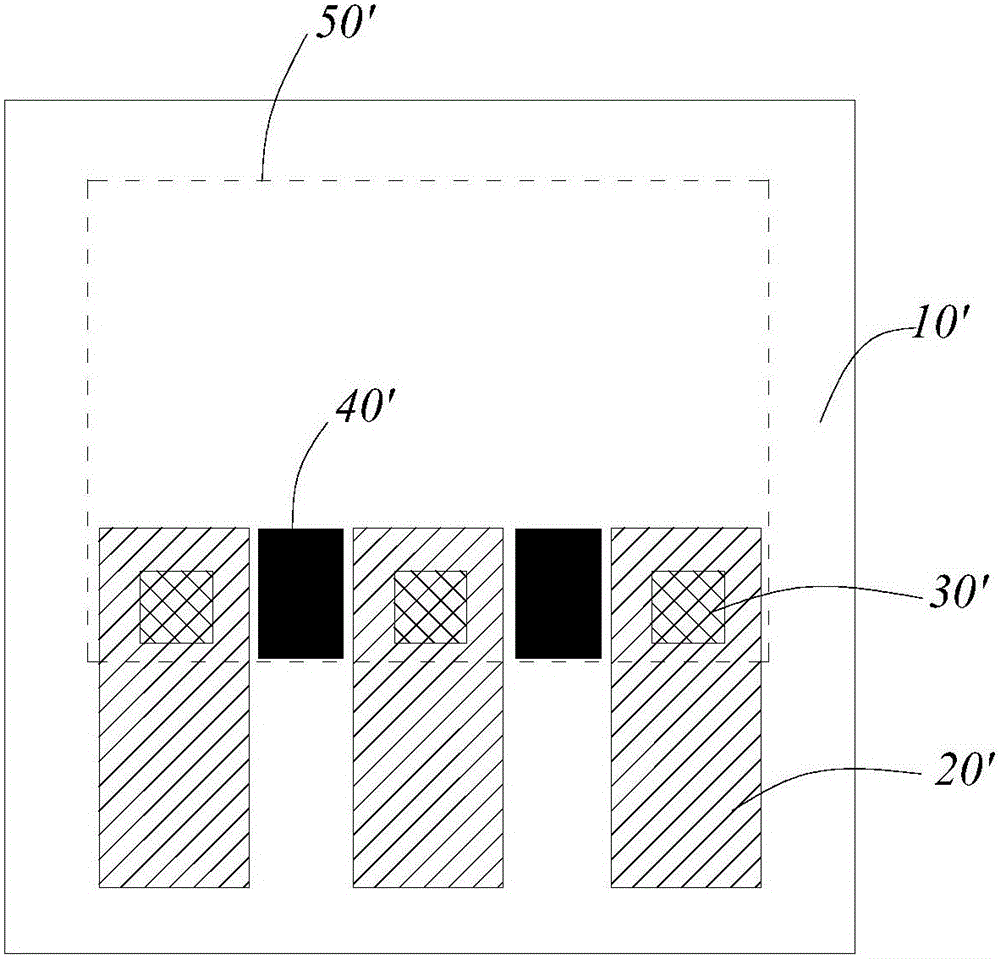

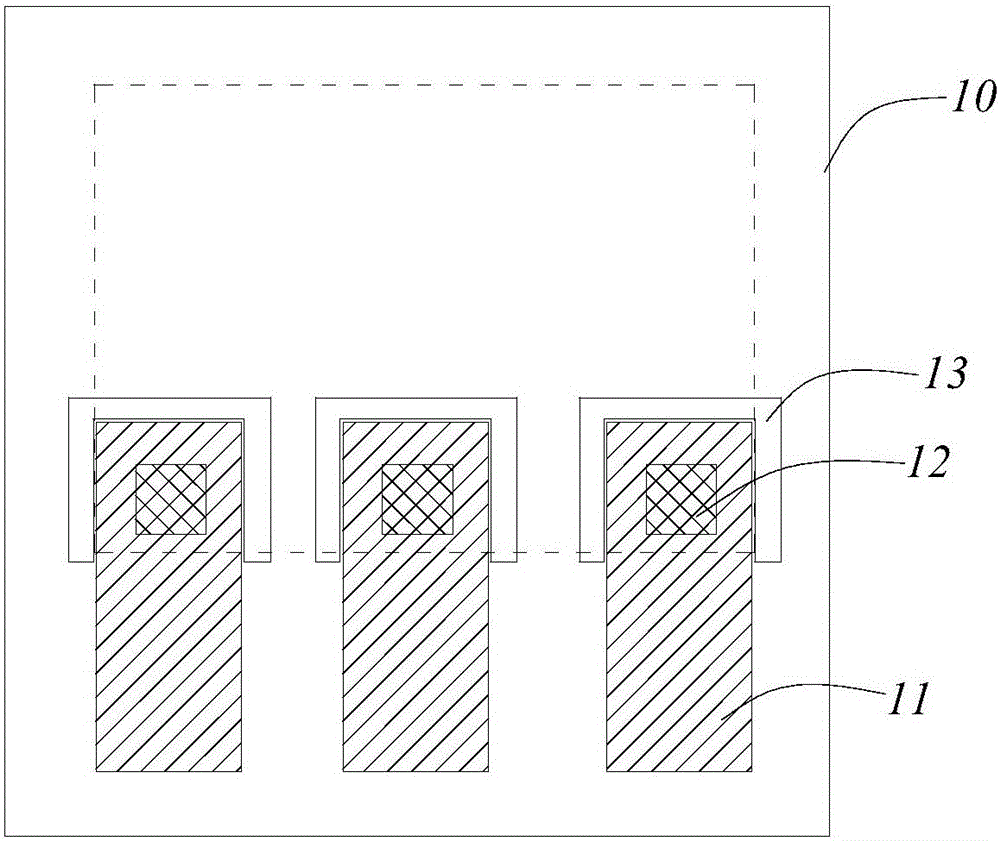

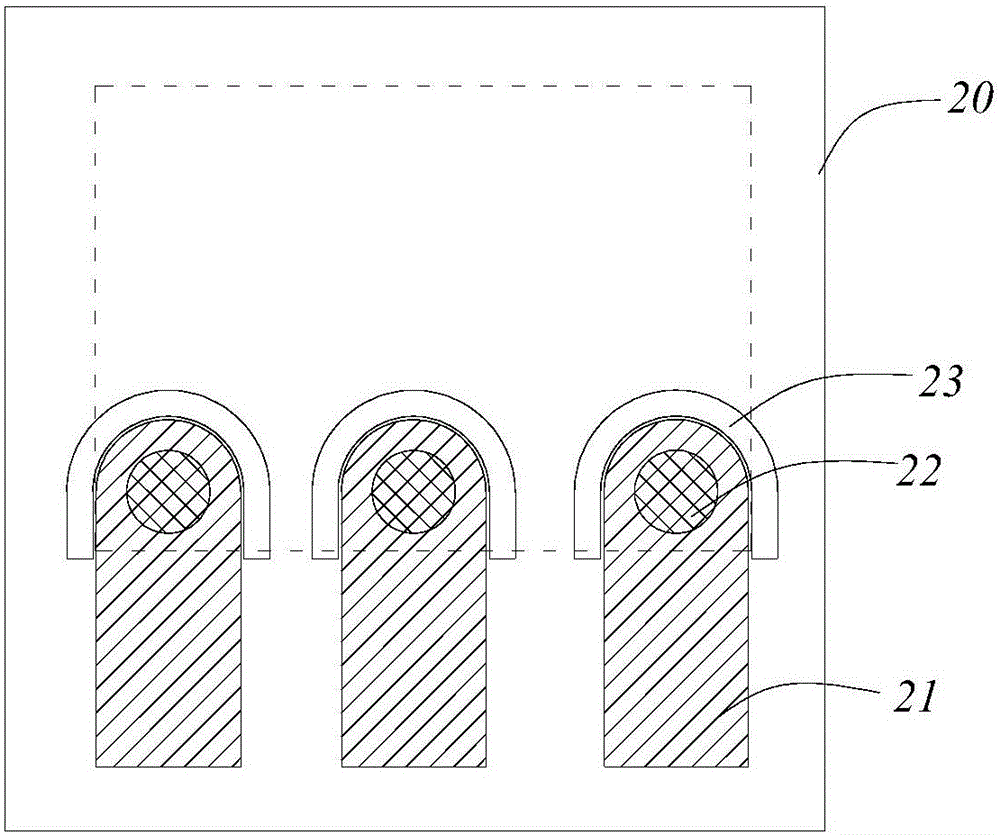

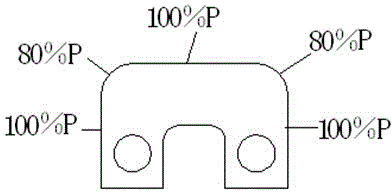

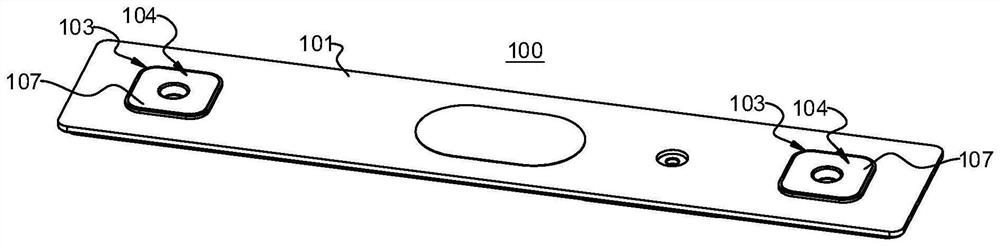

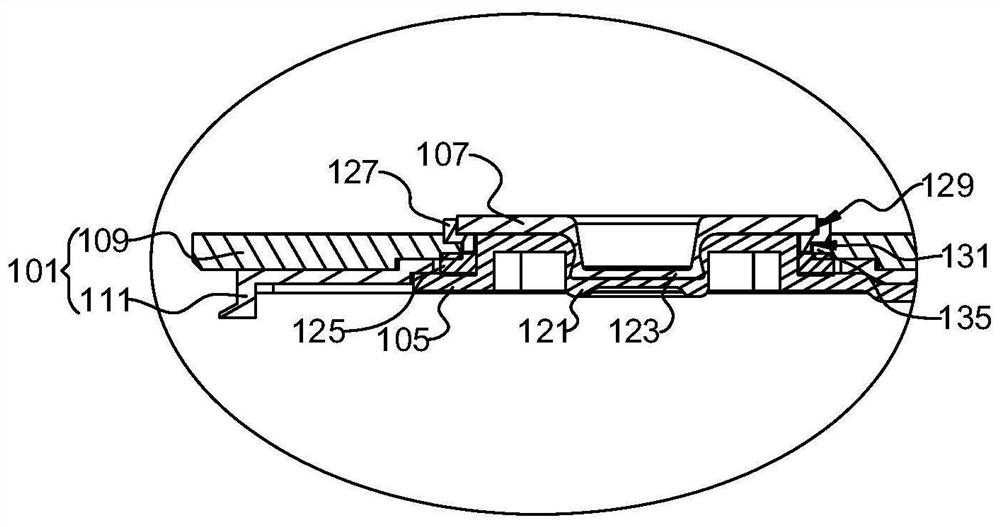

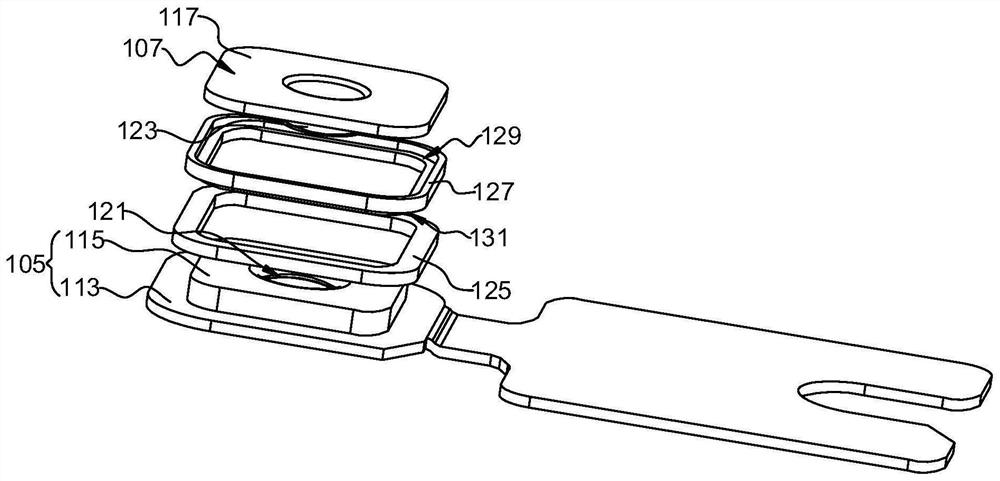

Substrate and substrate-applying welding structure and welding method

InactiveCN106356353APrevent overflowReduce manufacturing costSemiconductor/solid-state device detailsSolid-state devicesEngineeringElectric signal

The invention discloses a substrate and a substrate-applying welding structure and a welding method. The substrate is a semiconductor substrate, wires and bonding pads are arranged on the semiconductor substrate, the wires are used for transmitting electric signals, the bonding pads are electrically connected with the wires and used for welding of external devices, and the semiconductor substrate is provided with welding-resistant grooves close to outer sides of the bonding pads. By the welding-resistant grooves in the outer sides of the bonding pads, excessive welding flux can be absorbed by the welding-resistant grooves in a welding process, so that overflowing of the welding flux is prevented. The semiconductor substrate is adopted, high-precision welding-resistant grooves can be made by means of photoetching and etching, and applicability to substrates with wire spacing being 50micron or below is realized.

Owner:INNOLIGHT TECHNOLOGY (SUZHOU) LTD

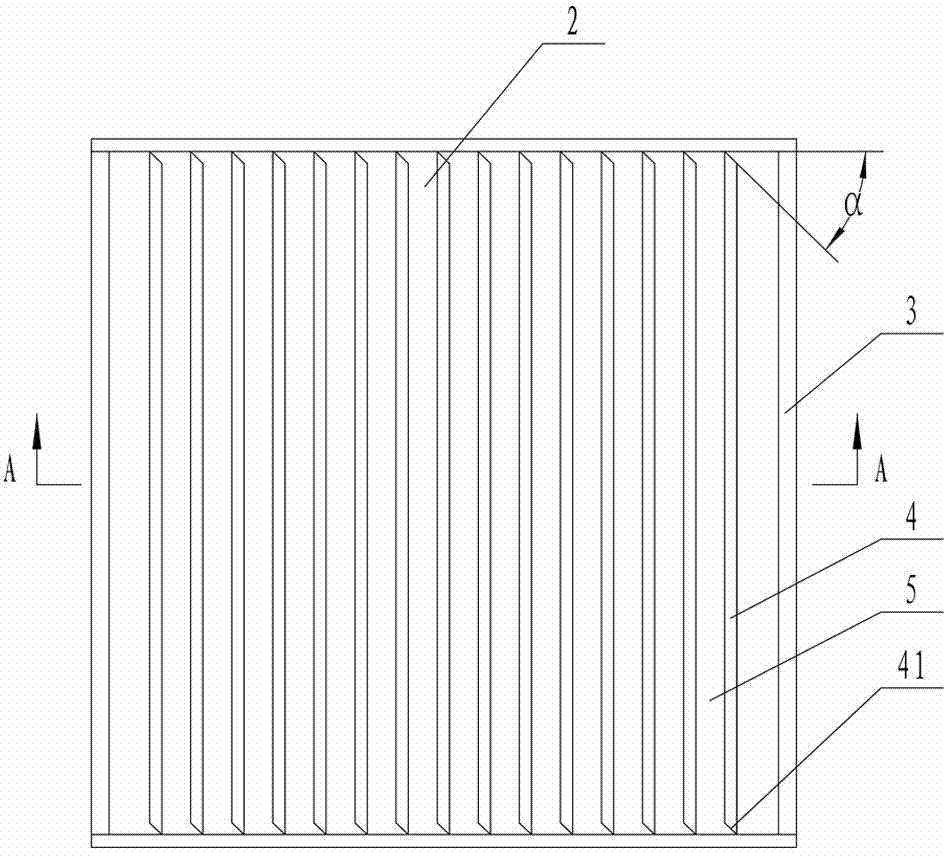

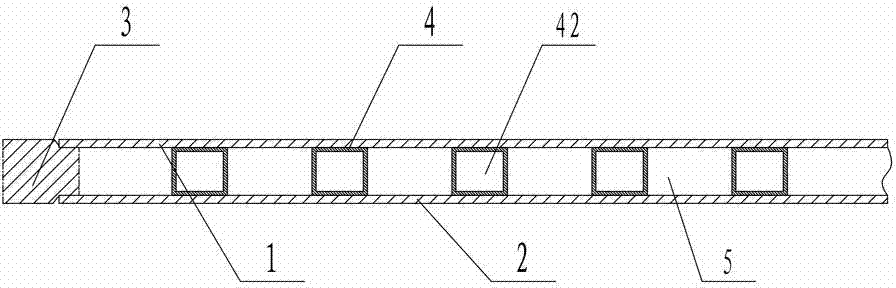

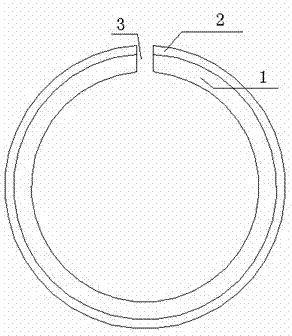

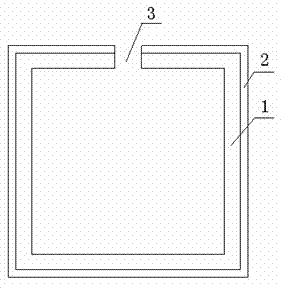

Welding method for freeze drier board layer and freeze drier board layer

ActiveCN104708176AEasy to operateReduce material usageArc welding apparatusDrying chambers/containersEngineeringPlasma arc welding

The invention discloses a welding method for a freeze drier board layer. The board layer comprises an upper board, a lower board, edge steel and square tubes. The square tubes are welded between the upper board and the lower board, and the upper board, the lower board and the square tubes are welded and fixed through a plasma arc welding method. The freeze drier board layer manufactured through the welding method comprises the upper board, the lower board and the edge steel. The four pieces of edge steel is arranged at the ends between the upper board and the lower board, the upper board and the lower board are welded and fixed through the edge steel to form a body of the board layer, the square tubes are arranged between the upper board and the lower board and provided with inner cavities, the ends, connected with the edge steel, of the square tubes are provided with slopes making the inner cavities communicated with the external environment, and multiple circulating cavities are formed in the body.

Owner:TRUKING TECH LTD

Tubulation welding method of stainless steel outer composite tube

ActiveCN104607773AImprove welding strengthImprove anti-corrosion performanceArc welding apparatusWelding/cutting media/materialsGas metal arc weldingComposite plate

The invention discloses a tubulation welding method of a stainless steel outer composite tube. The lower portion of the gap of tube blanks formed by bending a stainless steel composite plate is directly welded in an argon tungsten-arc welding mode, basic layer carbon steel of the stainless steel composite plate is welded and then automatically forms a downwards concave welding joint, after the welding joint is forcedly cooled with water, capping welding is directly carried out on the welding joint in a gas metal arc welding mode until the surplus height of the welding joint is 1-1.50 mm, then water is sprayed for cooling, and tubulation welding of the stainless steel outer composite tube is finished. The tubulation welding method is simpler than an existing method, the stainless steel outer composite tube does not need to be grooved, forming is realized one time, and as the protective atmosphere is gas, good corrosion resistance is realized, and the cost is lower compared with other welding methods. The tubulation welding method of the stainless steel outer composite tube guarantees that the strength of the welding joint of the stainless steel outer composite tube is higher than that of parent metal, and also guarantees that the welding joint of the stainless steel composites has good anti-corrosion performance.

Owner:云南昆钢新型复合材料开发有限公司

Welding method for H-shaped steel parts

InactiveCN107931797ASimple welding methodFlat surfaceWelding/cutting auxillary devicesArc welding apparatusSlagEngineering

The invention discloses a welding method for H-shaped steel parts. The welding method comprises the following steps of (1) carrying out blanking on the parts; (2) carrying out assembling; (3) carryingout welding; (4) shoveling slags; (5) carrying out conveying; (6) carrying out correction; (7) carrying out cutting-off operation; and (8) carrying out polishing. The welding method for the H-shapedsteel parts has the advantages of being simple, and the machined H-shaped steel is smooth in surface, accurate in size and good in consistency.

Owner:ANHUI KINGYOUNG STRUCTURAL METAL WORK

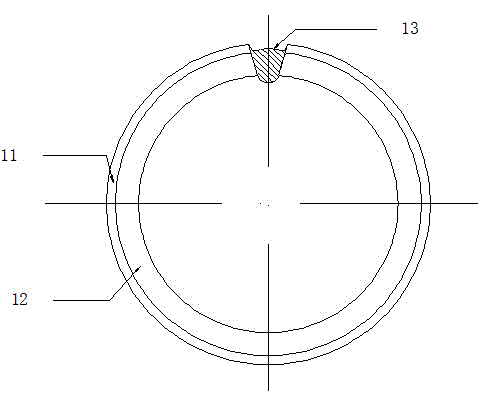

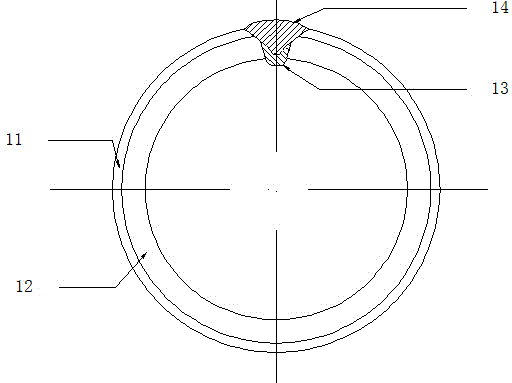

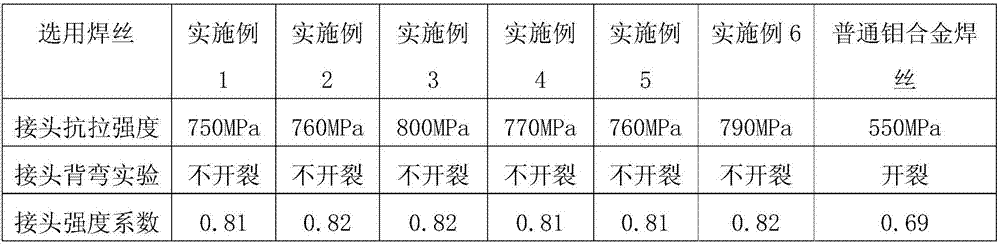

Method for welding molybdenum alloy

ActiveCN106862732AInhibition of sensitization tendencySmall mechanical propertiesArc welding apparatusWelding/cutting media/materialsActive agentDirect current

The invention discloses a method for welding molybdenum alloy, belonging to the technical field of metal welding. The method comprises the steps: (1) after cleaning, drying the welding area of molybdenum alloy; (2) manufacturing a special welding wire for the molybdenum alloy; (3) degassing at high temperature; (4) taking out a molybdenum alloy workpiece, spraying an active agent until the thickness is 0.2-0.8mm on the he welding area of molybdenum alloy, heating the special welding wire for the molybdenum alloy to dry, and then welding the molybdenum alloy workpiece, wherein the welding method adopts TIG wire filling welding, adopts a direct-current straight polarity power supply and determines welding process parameters; (5) cooling; (6) inspection. The method can reduce the quantity of joint holes, improve weldability, reduce cracks, refine parent crystalline grains so as to improve the tensile property of welded joints, and obtain good welding quality.

Owner:宝鸡市蕴杰金属制品有限公司

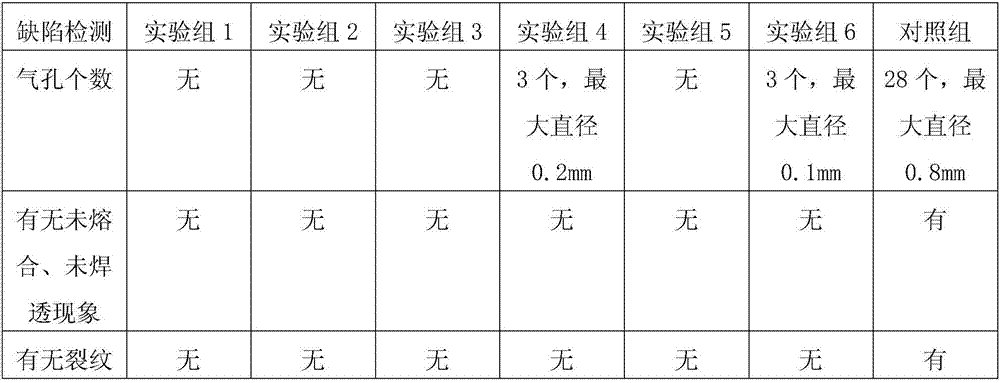

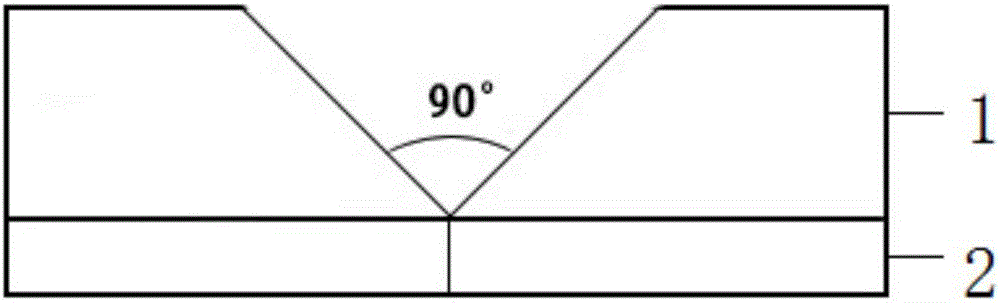

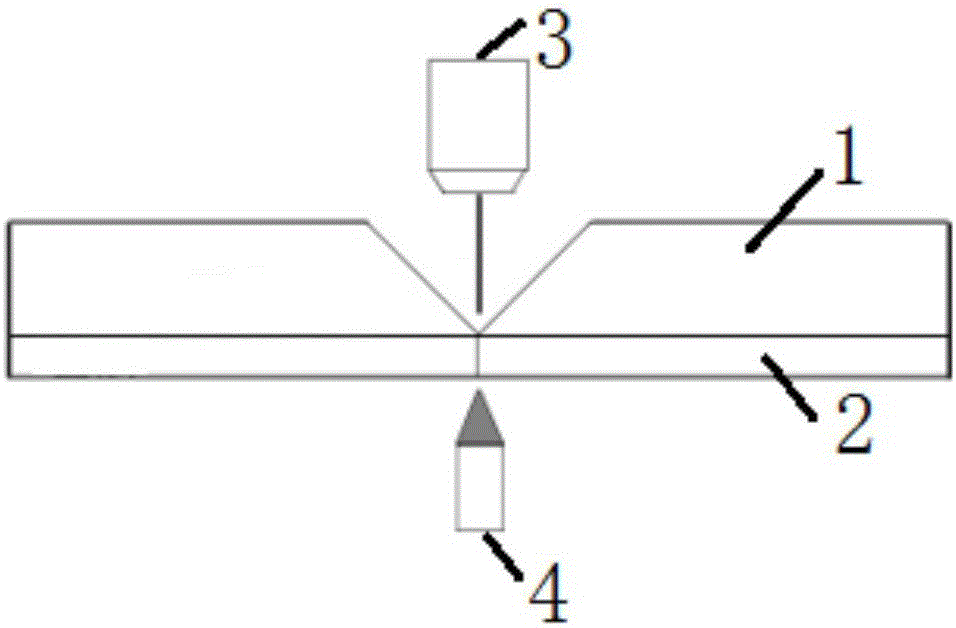

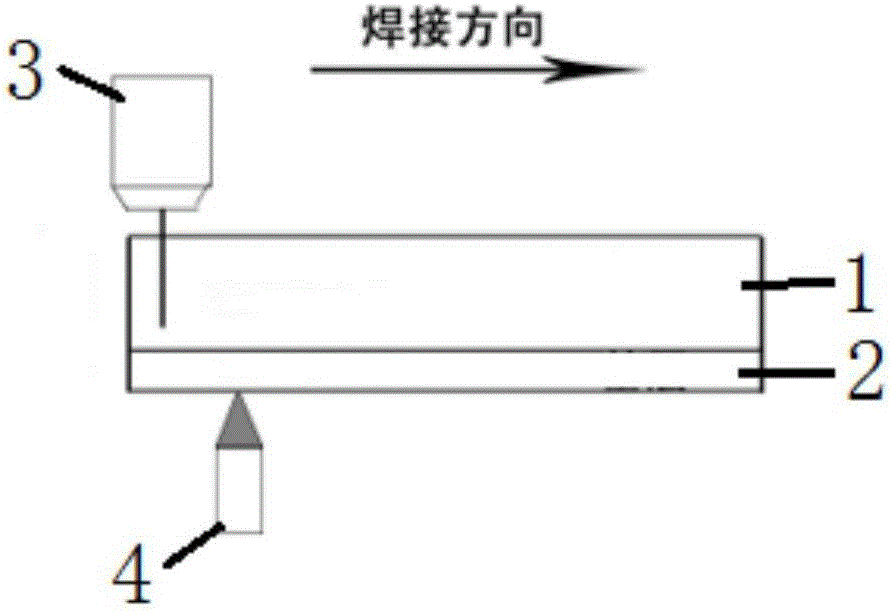

MIG+TIG double-faced welding method for butt joint of stainless steel composite tube or composite plate

ActiveCN106808068ASimple welding methodImprove automationArc welding apparatusButt jointComposite plate

The invention discloses an MIG+TIG double-faced welding method for a butt joint of a stainless steel composite tube or a composite plate. The method comprises the following steps that a base layer is provided with an oblique plane notch, and a stainless steel compound layer keeps the original thickness; secondly, an MIG welding gun is used for welding the base layer, a TIG welding gun is used for welding the stainless steel compound layer, the MIG welding gun and the TIG welding gun carry out welding in the same direction, and the TIG welding gun starts to carry out welding ahead of the MIG welding gun. By means of the MIG+TIG double-faced welding method for the butt joint of the stainless steel composite tube or the composite plate, a weld joint of the stainless steel composite tube has good corrosion resistant performance and also has good comprehensive mechanical performance.

Owner:SHANGHAI JIAO TONG UNIV

Impeller for centrifugal pump

The invention discloses an impeller for a centrifugal pump. The traditional impeller is easy to wear and lock and has high manufacturing cost. In the impeller for the centrifugal pump, a front cover plate, a rear cover plate and blades are made of stainless steel materials, the plurality of blades are radially arranged between the front cover plate and the rear cover plate, the blades, the front cover plate and the rear cover plate are welded, the edge of a through hole of the front cover plate is provided with a plastic opening ring, the external diameter of the plastic opening ring is larger than the inner diameter of a center hole of a guide blade cover plate, a hub is made of plastics and assembled on the rear cover plate, the front end of the hub extends into the plastic opening ring, a radial clearance is kept between the front end of the hub and the plastic opening ring to form an impeller inlet, and a structure which can move along a pump shaft is adopted in an inner hole of the hub. When the pump is assembled, the front end surface of the plastic opening ring contacts the guide blade cover plate, the impeller can float on the pump shaft through the hub to automatically regulate the size of an axial clearance, thereby the problems of impeller wear and locking caused by silt can be solved to a certain extent. Moreover, by adopting the impeller with the assembly structure, the processing difficulty and the construction cost are reduced.

Owner:新界泵业(浙江)有限公司

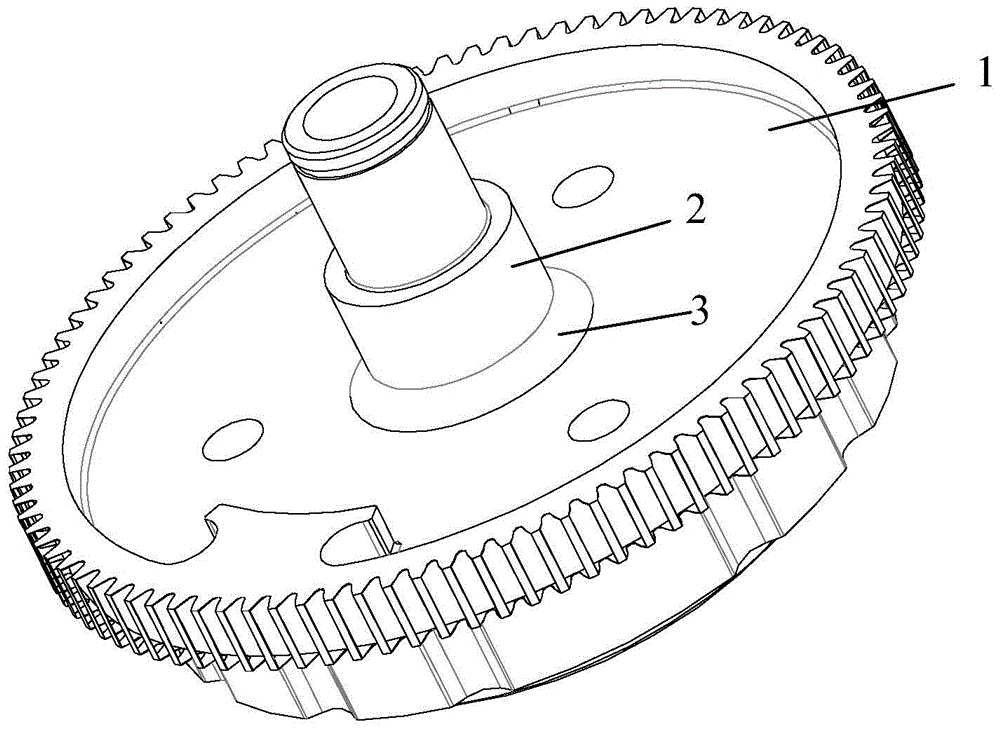

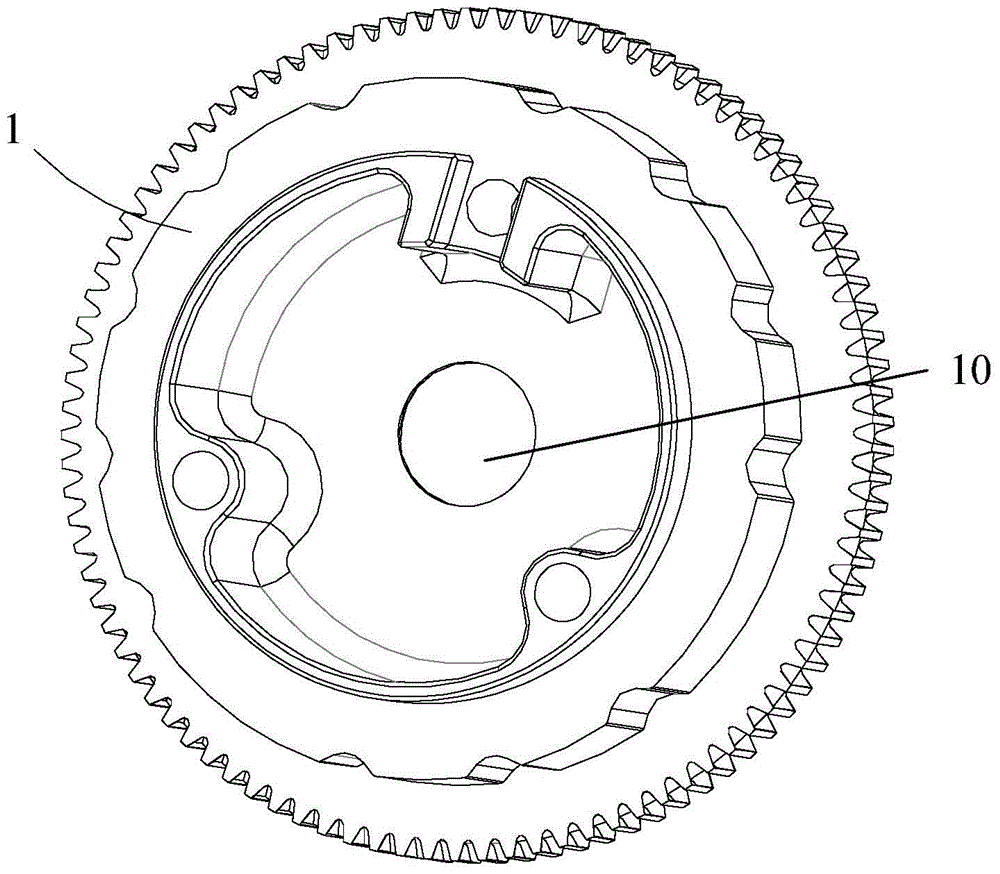

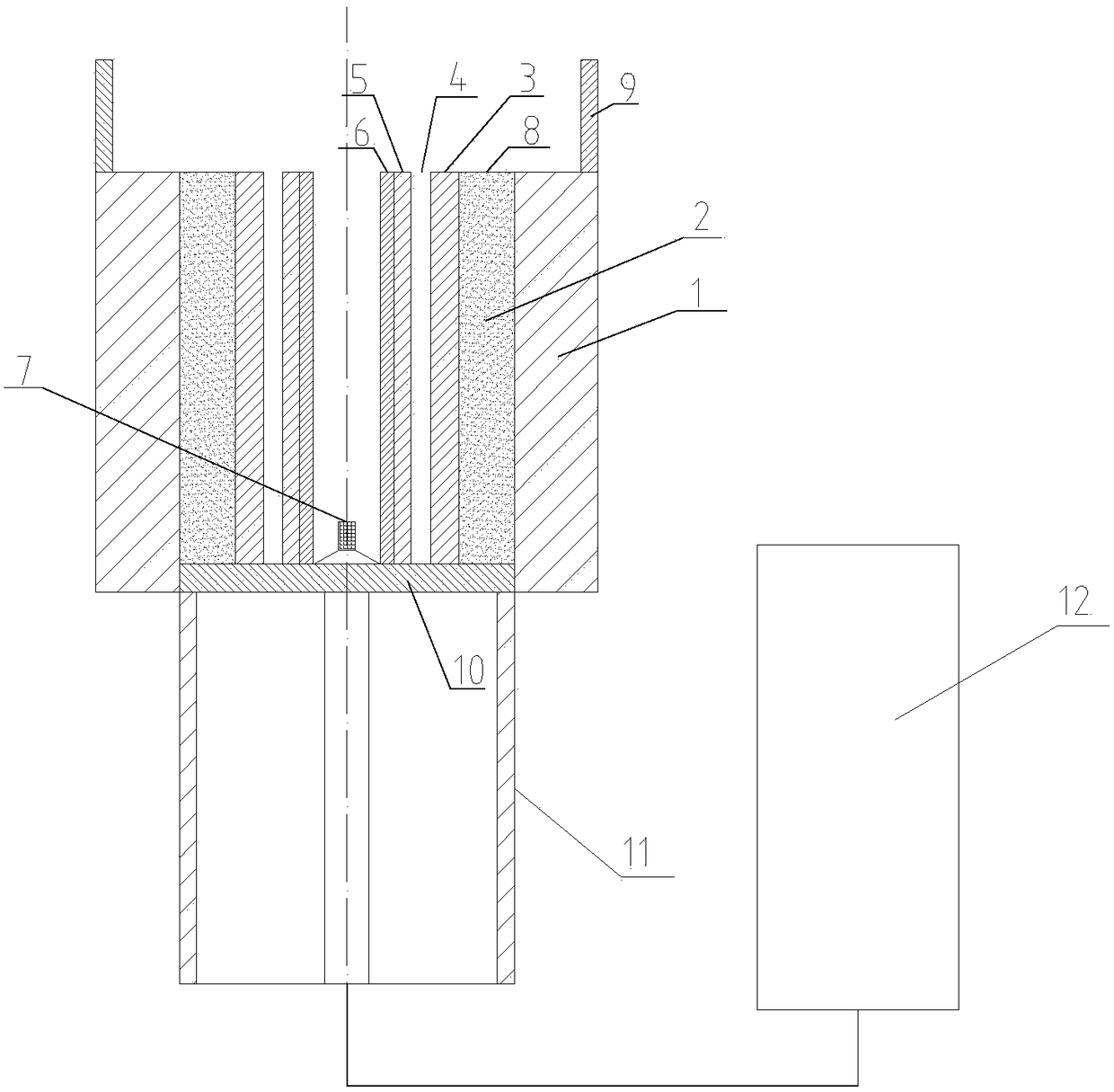

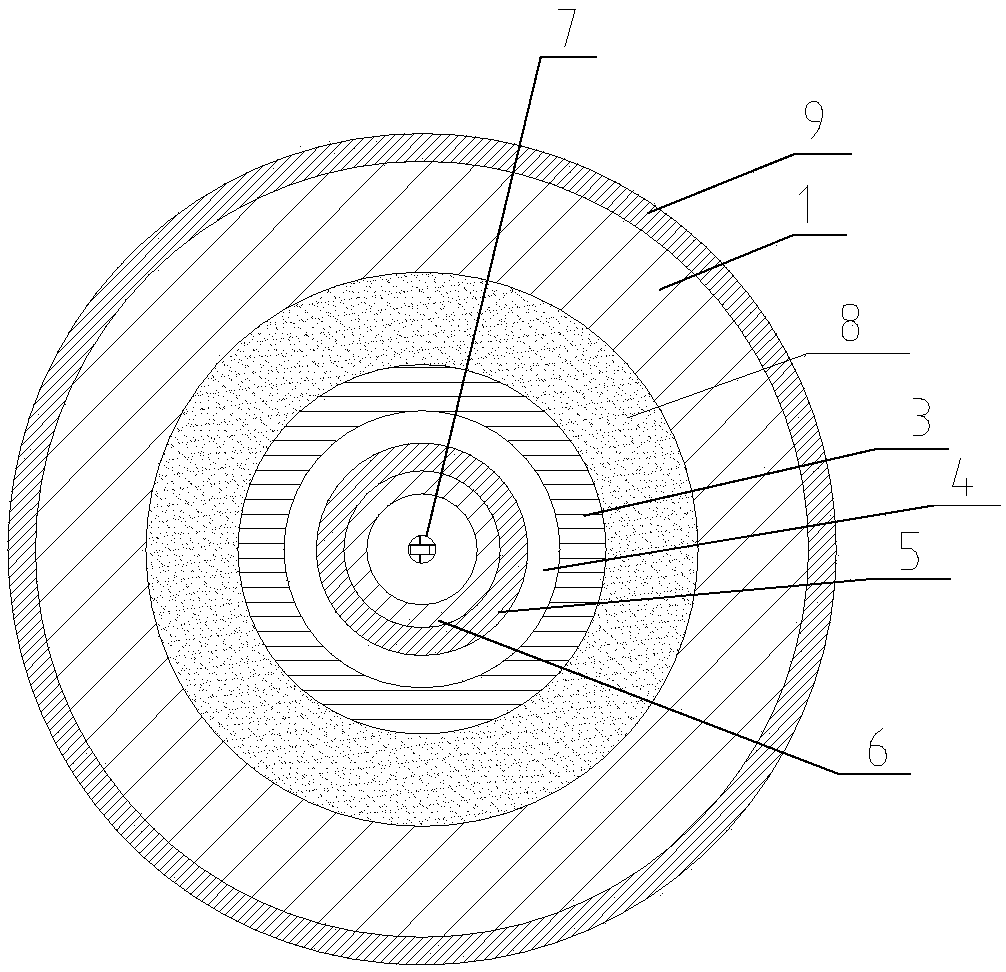

Preparation method for powder metallurgy rotating hub gear

InactiveCN105665711AStable structureImprove connection strengthState of artHigh volume manufacturing

The invention relates to a preparation method for a powder metallurgy rotating hub gear. The method comprises a process of designing material composition, a pressing process and a sintering welding process, wherein a brand-new welding method of connecting a rotating hub gear substrate with a rotating hub gear shaft together is employed in the sintering welding process; compared with a method for integrally forming the rotating hub gear in the prior art, the preparation method disclosed by the invention does not need to prepare a mold with a complicated structure, and does not need to specially equip high-end equipment, so that production cost is reduced; a sintering welding manner is adopted by the preparation method disclosed by the invention instead of a common welding manner in the prior art, and soldering flux is introduced into a connection gap through diversion trenches, and welded connection is reinforced from three parts, so that connection strength and positioning accuracy of the rotating hub gear substrate and the rotating hub gear shaft are increased, and the prepared rotating hub gear is firm in structure; and moreover, the preparation method disclosed by the invention is simple, and is convenient for performing mass production.

Owner:NBTM NEW MATERIALS GRP

Tungsten electrode inert gas shielded welding process of aluminum plate

InactiveCN104526128AWelding safetyGuarantee welding qualityArc welding apparatusWelding/soldering/cutting articlesSpot weldingMaterials science

The invention discloses a tungsten electrode inert gas shielded welding process of an aluminum plate and relates to the welding process technical field. The tungsten electrode inert gas shielded welding process mainly comprises four steps of preparation before welding, temporary spot welding, welding and treatment after the welding. According to the tungsten electrode inert gas shielded welding process of the aluminum plate, the welding steps are simplified, the welding method is simple, the material selection is accurate and standard, the welding quality of the aluminum plate can be ensured, a standard welding way is provided for the aluminum plate, and the rapid and safe welding on the aluminum plate is facilitated.

Owner:WUHU CIMC RUIJIANG AUTOMOBILE

Hot dip galvanized thin plate butt welding method

InactiveCN102029464AThe welding method is simple and easy to operateImprove welding qualityArc welding apparatusVoltElectric arc

The invention discloses a hot dip galvanized thin plate butt welding method. The method is characterized by comprising the following steps of: 1, adjusting the horizontal distance between double electrodes to be 3 to 4 millimeters; 2, connecting welding protective gas; 3, directly placing and fixing a thin plate to be welded on a horizontal motion platform without reserving gaps; 4, adjusting the welder current of a master electric arc welder to be 90 amperes, adjusting the current of a slave electric arc welder to be 120 amperes or 26 volts, adjusting the wire feeding speed to be 0.4 meter per minute, and adjusting the motion speed of the workpiece platform to be 0.5 meter per minute; 5, introducing the protective gas for 3 seconds, then starting a master electric arc and a slave electric arc, starting the motion platform after 1 second to drive the workpiece to move, and starting welding; 6, when the welding is finished, switching off a slave electric arc switch, and then switching off a master electric arc switch and a motion platform switch; and 7, switching off a protective gas switch after 5 seconds, meanwhile closing water cooling equipment, and finishing welding. The welding method is simple and easy to operate, improves the welding quality, and is particularly suitable for complete penetration welding of butt welding of thin plates with thickness of 2.5 millimeters.

Owner:马国红

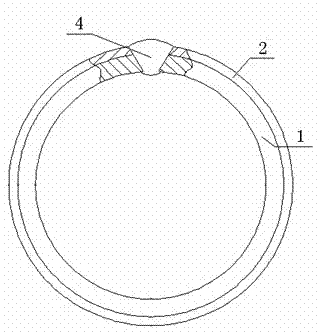

Steel-stainless steel mining gas drainage pipe exploding welding device and welding method

PendingCN108356404AImprove versatilityReduce manufacturing costWelding/soldering/cutting articlesNon-electric welding apparatusSolid particleAir layer

The invention relates to a steel-stainless steel mining gas drainage pipe exploding welding device and welding method. The welding device comprises a stainless steel inner composite pipe, a steel basepipe and a restraining pipe mold which are vertically and coaxially arranged from inside to outside; explosive layers are uniformly arranged on the inner side face of the stainless steel inner composite pipe; an air layer is arranged between the stainless steel inner composite pipe and the steel base pipe; and the position between the steel base pipe and the restraining pipe mold is filled with arestraining layer composed of liquid or solid granular materials. According to the steel-stainless steel mining gas drainage pipe exploding welding device, the position between the steel base pipe and the restraining pipe mold is filled with the dispersible restraining layer, universality of the pipe mold is widened, and one pipe mold is adopted and can be used for preparing steel-stainless steelcomposite pipes in a series of pipe diameters. The steel-stainless steel composite steel pipes prepared through the welding method are free of the surface defects of cracks, scratches, pits and the like according to quality test, the combining rate of the steel base pipe and a stainless steel inner composite pipe combining area is higher than 96%, and requirements are met.

Owner:CHINA COAL TECH & ENG GRP HUAIBEIBLASTING TECHN RES INST

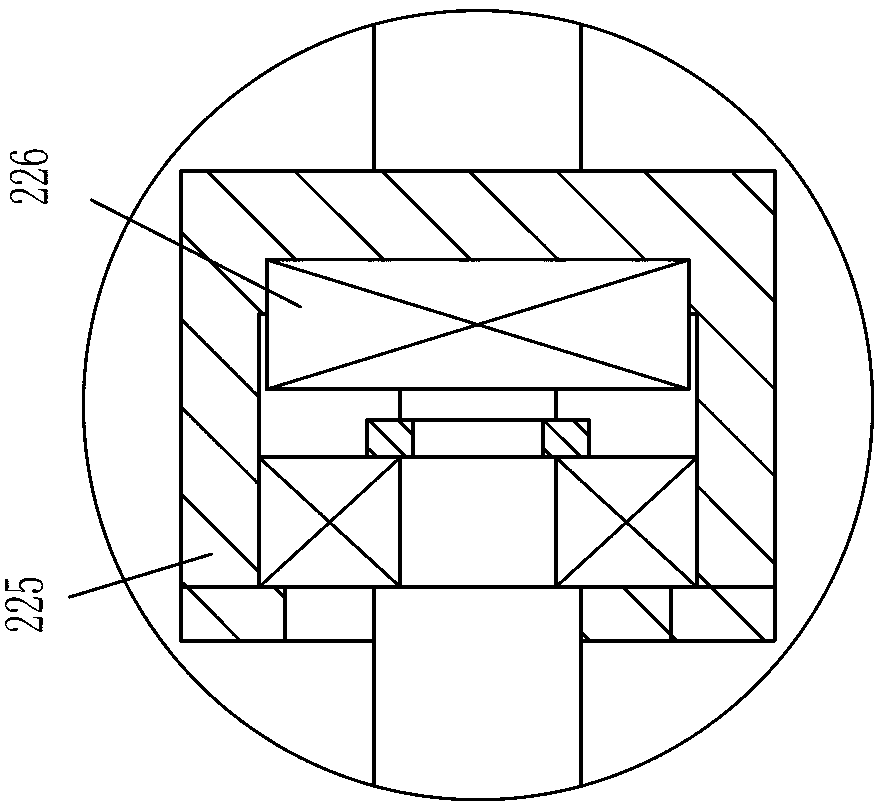

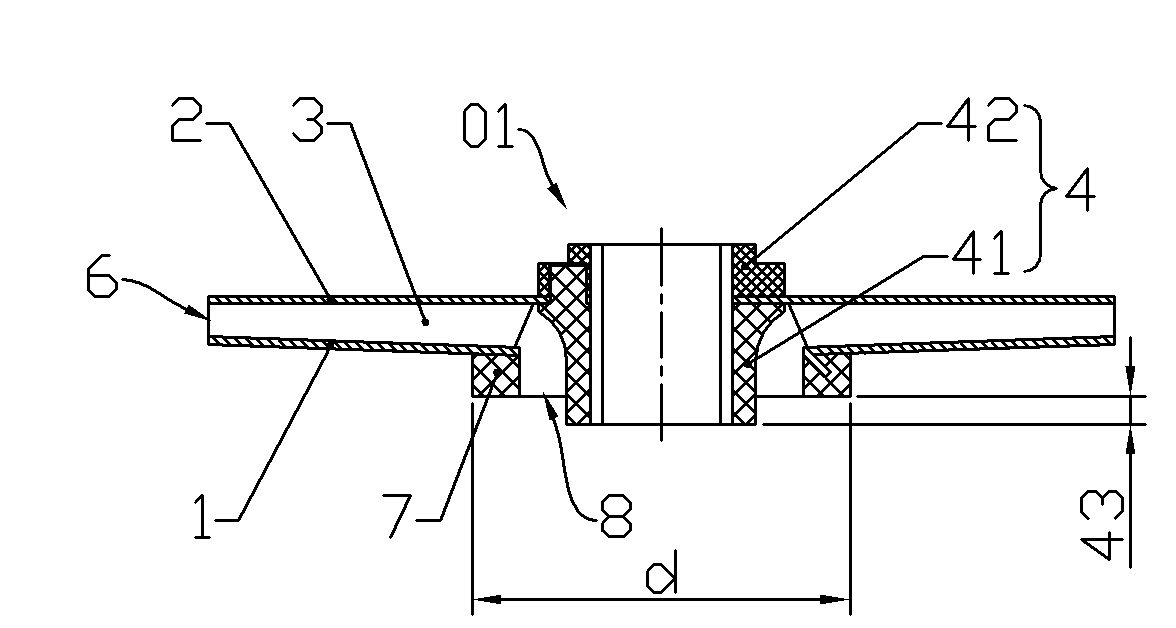

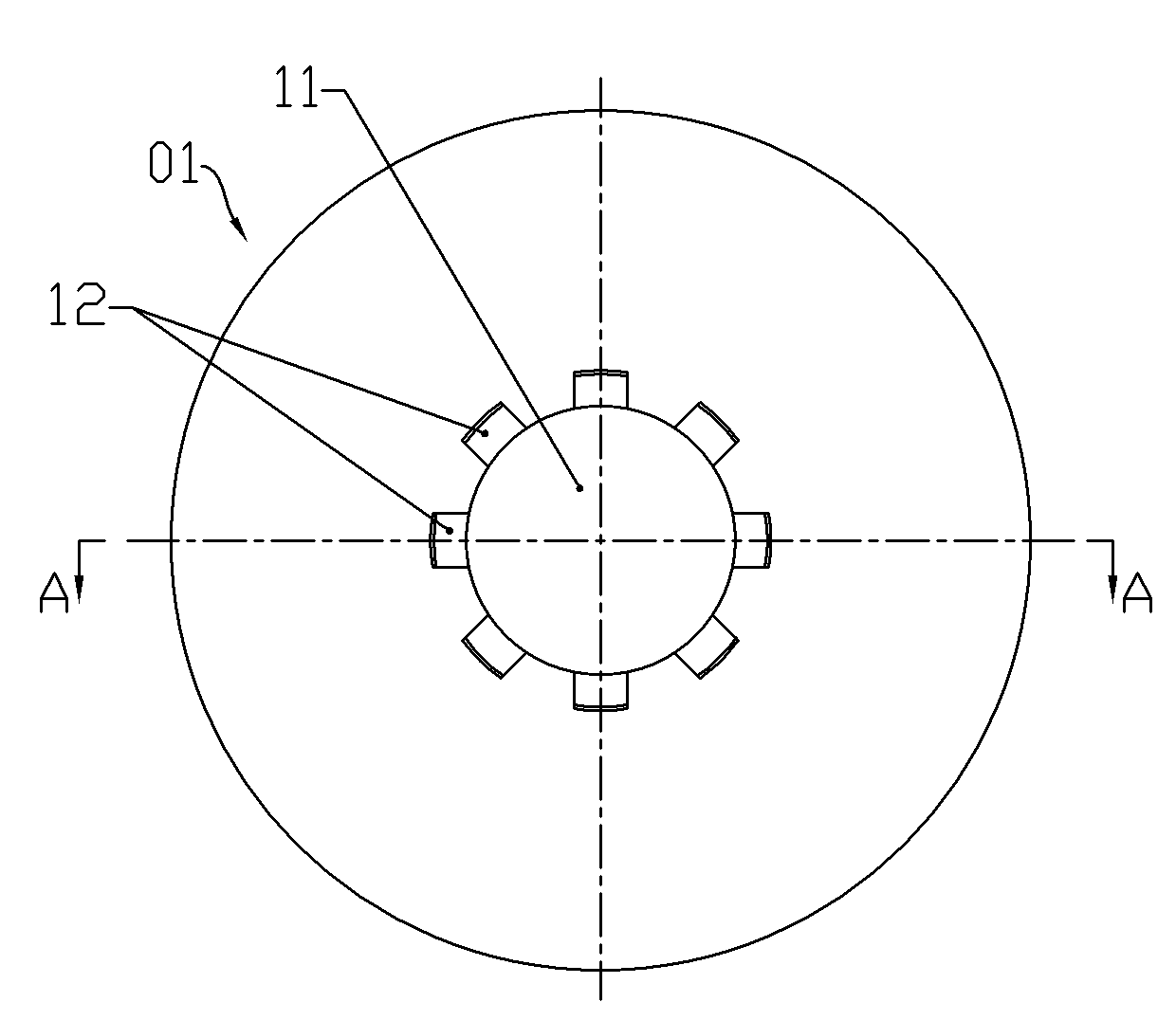

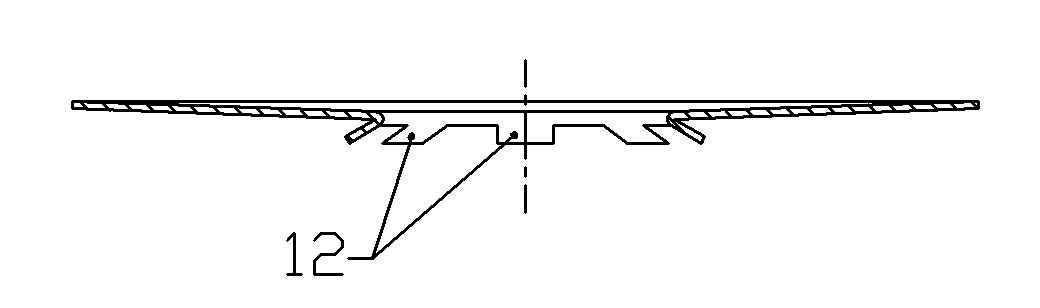

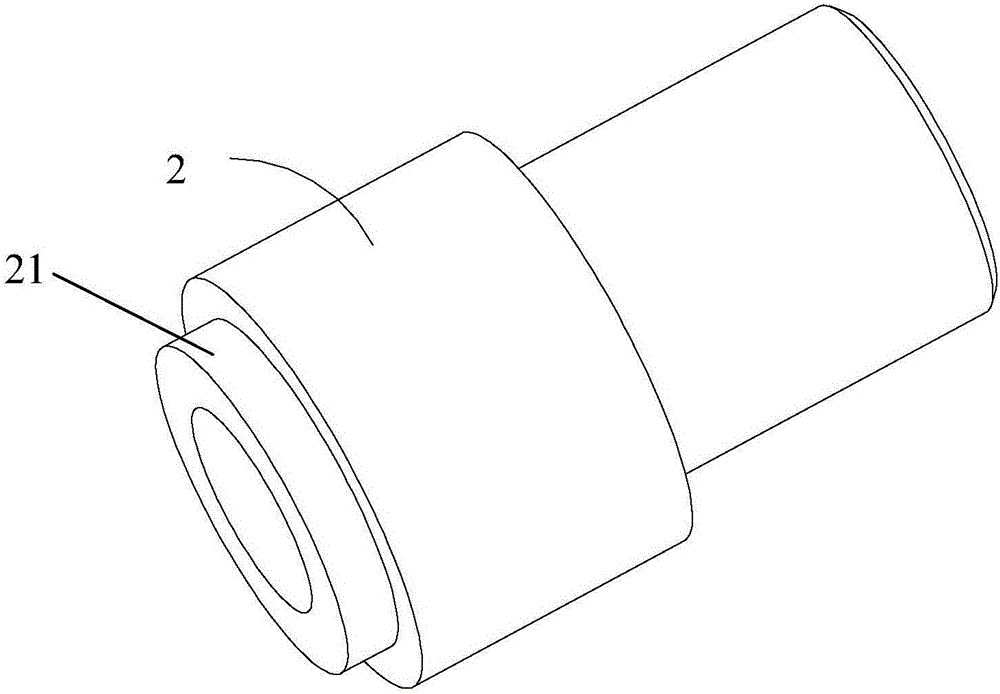

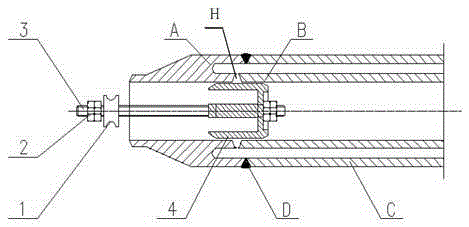

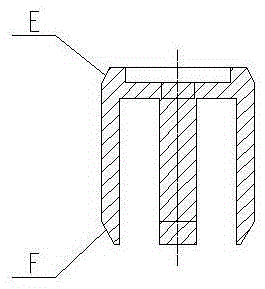

Inner pipe shallow hole welding assembly device of jacket heat exchanger jacketed pipe, jacket heat exchanger and welding method of jacketed pipe

ActiveCN105397396ASimple structureSolve the problem of eccentricity and wrong sideWelding/cutting auxillary devicesAuxillary welding devicesPipe fittingStraight tube

The invention discloses an inner pipe shallow hole welding assembly device of a jacket heat exchanger jacketed pipe, a jacket heat exchanger and a welding method of the jacketed pipe. The assembly device is used for seamless assembly between an inner pipe of the jacketed pipe and connecting grooves of end connecting pieces of the jacketed pipe and structurally comprises a claw type locator, a rotating pull rod, a lock nut and a beating handle. One end of the rotating pull rod penetrates the center axis of the claw type locator and is fixedly connected through a bolt and a nut. The beating handle is arranged at the other end of the rotating pull rod and limited through the lock nut. The assembly device is used on the inner pipe of the straight jacketed pipe and the inner sides of the grooves of the connecting pieces, and the problem of the eccentric misalignment of a pipe fitting during assembly of the inner pipe and the grooves is solved through assembly and spot welding of the assembly device. The concentricity of the inner pipe and the grooves is controlled by controlling the linearity deviation of the locator, and the wrong variable of the inner pipe and the grooves is controlled by controlling the outer diameter deviation of the locator. The assembly device is of a detachable structure and is simple and easy to detach. The assembly device can be recycled, and the assembly device is suitable for sleeve type equipment with inner pipes of the same type.

Owner:THE CHALLENGE PETROCHEM MACHINERY CORP

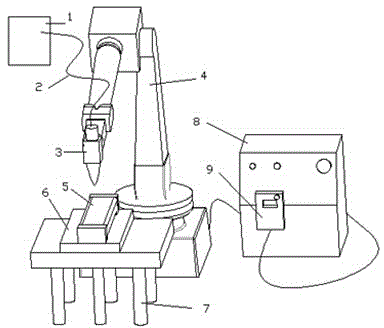

Laser welding method for automobile skylight guide rail

InactiveCN104607799AReduce burnoutControl weld surface topographyLaser beam welding apparatusEngineeringMachining

A laser welding method for an automobile skylight guide rail comprises the following steps of (1), designing a tool coordinate system, (2), fixing workpieces, (3), starting mechanical arm demonstration, (4), placing a height standard block, (5), lowering power at corners of the workpieces, (6), setting parameters, and (7), carrying out welding. According to the method, the surface appearance of weld joint can be controlled precisely, the burning loss phenomenon at the corners of the workpieces can be reduced, the weld joint is even and attractive after welding, secondary machining is not needed, and the welding method is simple and easy to achieve.

Owner:JIANGSU ZHONGKESIXIANG LASER TECH

0Cr18Ni9 stainless steel plate welding process

InactiveCN104439616AWelding safetyGuarantee welding qualityArc welding apparatusMetallurgyMaterial selection

The invention discloses a 0Cr18Ni9 stainless steel plate welding process, and relates to the technical field of welding processes. The 0Cr18Ni9 stainless steel plate welding process mainly includes the steps of preparation before welding, tack weld, welding and treatment after welding. By means of the 0Cr18Ni9 stainless steel plate welding process, the welding steps are simplified, a welding mode is simple, material selection is precise and standard, the welding quality of 0Cr18Ni9 stainless steel plates can be guaranteed, the standard welding mode is provided for the 0Cr18Ni9 stainless steel plates, and quick and safe welding of the 0Cr18Ni9 stainless steel plates is facilitated.

Owner:WUHU CIMC RUIJIANG AUTOMOBILE

16 Mn steel plate argon arc welding process

InactiveCN104439643AWelding safetyGuarantee welding qualityArc welding apparatusWelding/soldering/cutting articlesEngineeringMaterial selection

The invention discloses a 16 Mn steel plate argon arc welding process, and relates to the technical field of welding processes. The 16 Mn steel plate argon arc welding process mainly includes the steps of preparation before welding, tack weld, welding and treatment after welding. By means of the 16 Mn steel plate argon arc welding process, the welding steps are simplified, a welding mode is simple, material selection is precise and standard, the welding quality of 16 Mn steel plates can be guaranteed, the standard welding mode is provided for the 16 Mn steel plates, and quick and safe welding of the 16 Mn steel plates is facilitated.

Owner:WUHU CIMC RUIJIANG AUTOMOBILE

Composite pole column, top cover and battery

PendingCN113629329AGuaranteed stiffnessGuaranteed electrical conductivityCell sealing materialsStructural engineeringSoldering

The invention discloses a composite pole column, a top cover and a battery, and relates to the technical field of batteries. The composite pole column comprises an inner pole column and an outer pole column, wherein the inner pole column is provided with a first matching part, the outer polecolumn is provided with a second matching part matched with the first matching part, one of the first matching part and the second matching part is a concave groove, the other one of the first matching part and the second matching part is a protrusion, and when the first matching part is matched with the second matching part, the circumferential edge of the protrusion is attached to the circumferential edge of the groove inner wall of the concave groove, and the end face of the protrusion is attached to the groove bottom of the concave groove. According to the invention, the pole column does not need to be connected in a welding mode, pseudo soldering does not exist, only the concave groove and the protrusion need to be matched in a stamping mode and the like, and the pole has the advantages of being simple in matching mode, reliable and low in cost; and the concave groove and the protrusion can form a tightly attached composite structure, and the rigidity, the conductivity and the air tightness of the pole column can be ensured, so that the quality, the use performance and the safety performance of the pole column are ensured.

Owner:JIANGSU ZENIO NEW ENERGY BATTERY TECH CO LTD

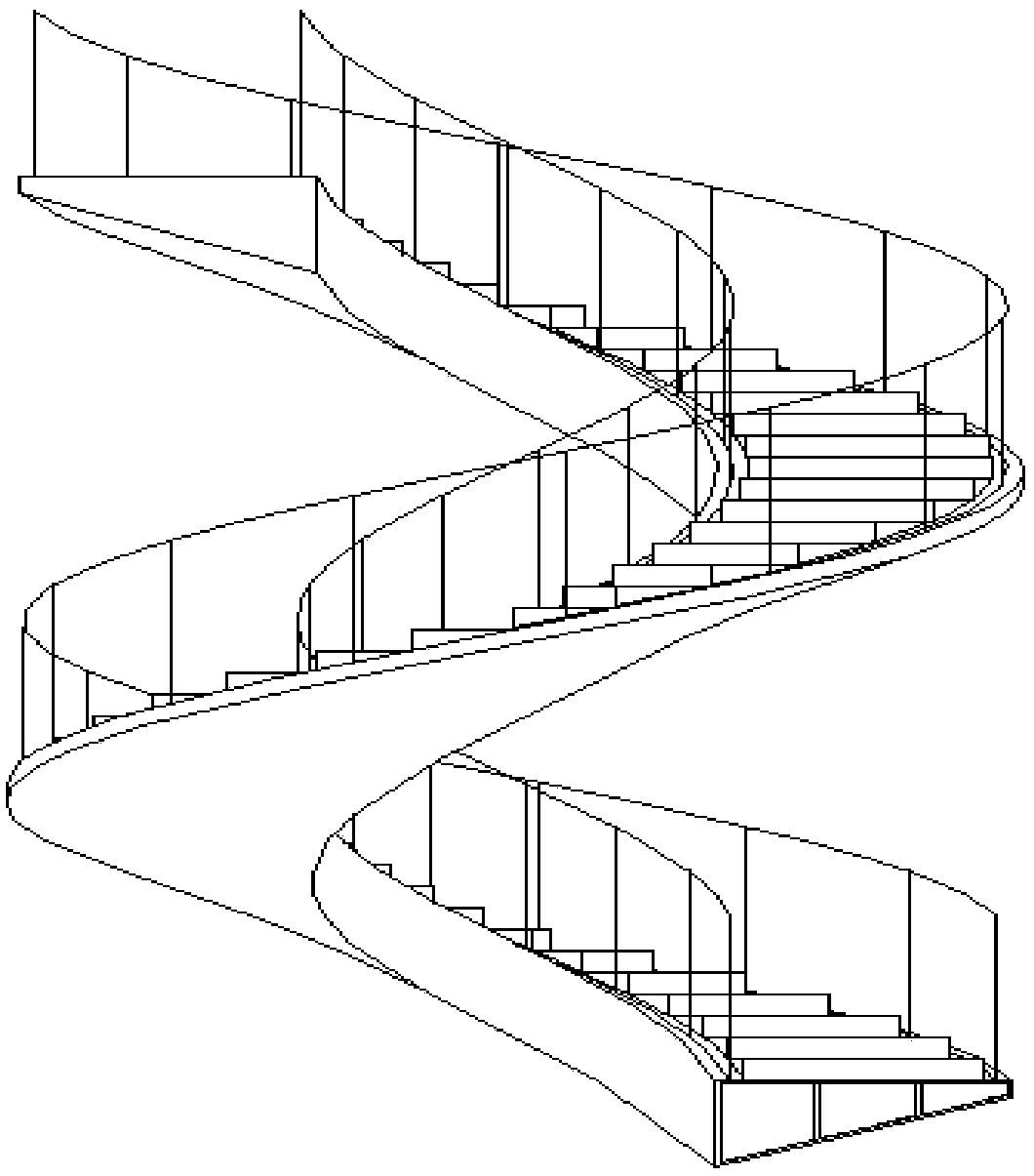

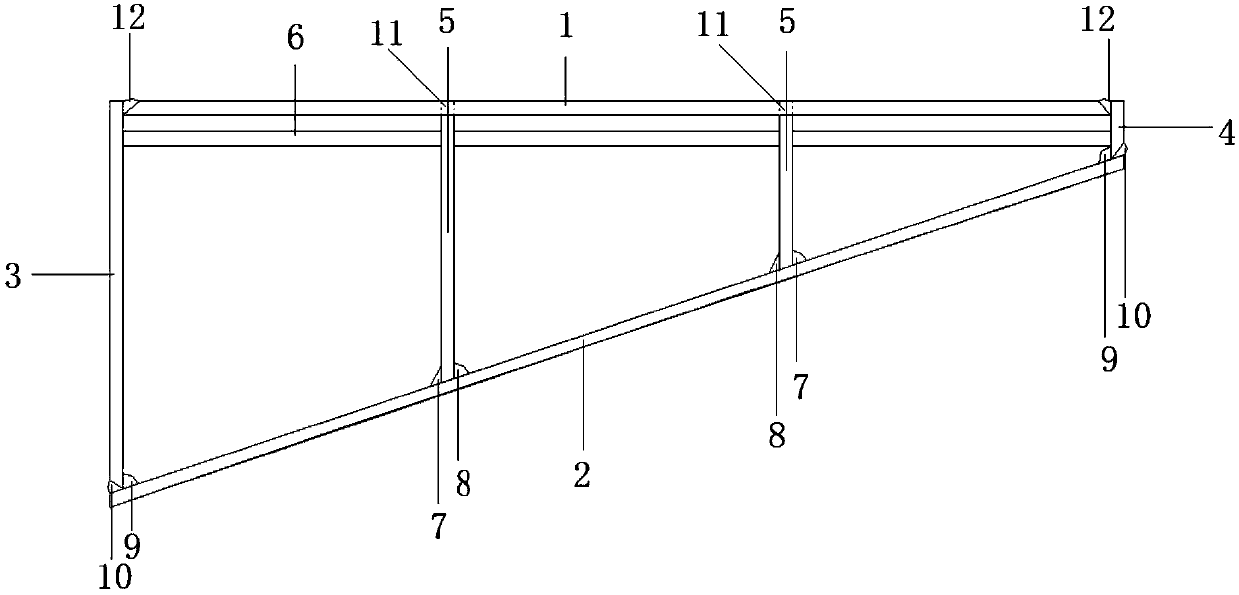

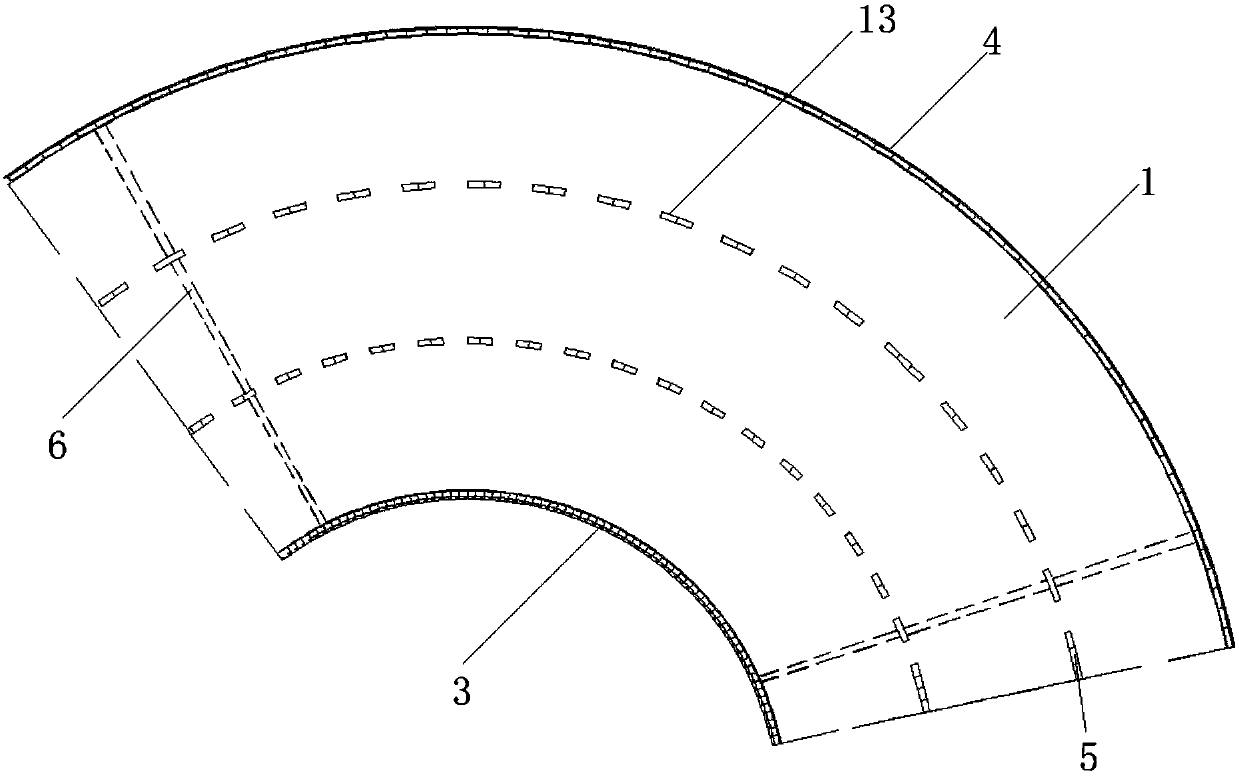

Welding method for large-curvature thick plate box type rotary steel ladder box body

ActiveCN107649803AReduce welding difficultyNo flip welding requiredWelding/cutting auxillary devicesAuxillary welding devicesThick plateLarge deformation

The invention provides a welding method for a large-curvature thick plate box type rotary steel ladder box body. The welding method is characterized in that the rotary steel ladder box body comprisesa cover plate, a bottom plate, an inner side plate and an outer side plate which are formed in a pressed mode according to the sizes of a design drawing; a plurality of separating plates are arrangedbetween the inner side plate and the outer side plate; and anti-deformation supports are arranged between the separating plates and the inner and outer side plates as well as between the separating plates. According to the welding method, through the measures of setting of grooves of assembled steel plates, supporting and reinforcement before welding, reasonable arrangement of the welding joint welding sequence, adoption of symmetrical welding and the like, the problems of large deformation, difficult control and the like prone to occurring during welding of thick plates are reduced, deformation correction in the later period is reduced, and therefore the purpose of lowing manufacturing cost is realized. By means of the welding method, the welding difficulty can be lowered, turning over isnot needed during component welding, a welding joint can be formed at a time, the thermal contraction deformation is small, and the accuracy and quality of manufacturing of a rotary steel ladder areimproved.

Owner:CHINA FIRST METALLURGICAL GROUP

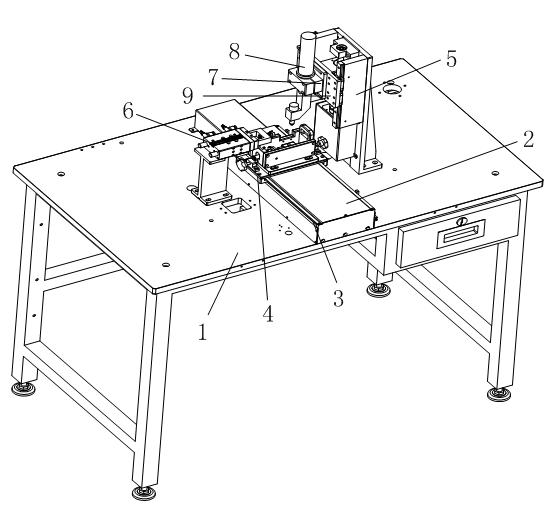

Automatic welding equipment

InactiveCN102366863AReduce wasteIncreased welding outputWelding/cutting auxillary devicesAuxillary welding devicesAutomatic test equipmentProtection mechanism

The invention relates to automatic welding equipment. A sliding table is arranged on an operating platform, the sliding table is fixed in an operating region of the operating platform, grooves are formed on the two sides of the sliding table, and a movable fixed seat is mounted on the sliding table by virtue of the grooves; a welding machine grounding protection mechanism is arranged on one side of the sliding table, where the groove is located, a welding gun sliding table mechanism vertical to the sliding table is arranged on the other side of the sliding table, where the groove is located, the welding machine grounding protection mechanism and the welding gun sliding table mechanism are arranged at a center line of the sliding table and are fixed on the operating platform of the sliding table, and spaces from the welding machine grounding protection mechanism and the welding gun sliding table mechanism to the two sides of the sliding table are equal, and the welding gun grounding protection mechanism is aligned to the welding gun sliding table mechanism; and a welding gun mechanism which slides up and down is arranged on the welding gun sliding table mechanism, and the welding gun mechanism is in contact with a welding device on the movable fixed seat by virtue of a track on the welding gun sliding table mechanism. The movable fixed seat on the sliding table is controlled to move back and forth by virtue of a program, and the coordinate with a welding gun is utilized for realizing automatic welding, thereby improving yield and being simple in welding way.

Owner:SUZHOUSCON AUTOMATION TECH

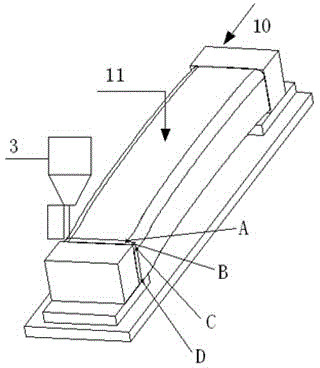

One-step forming straight welding method for stainless steel outer composite tubes

ActiveCN103537776ASimple welding methodReduce dosageArc welding apparatusWelding/soldering/cutting articlesChromiumVoltage

The invention provides a one-step forming straight welding method for stainless steel outer composite tubes. The method is characterized in that one-step welding is performed on shaped bevels of tube blanks, with welding wires having higher nickel and chromium content than stainless steel composite layers and solder having higher nickel and chromium content than the stainless steel composite layers, under the conditions: 0.5-2.5mm spacing of shaped bevels of the tube blanks, 13-23mm spacing H between a welding torch contact nozzle and a tube, 1.0-2.0mm distance h between the welding wires and the tube, 200-350A welding current, 20-50V welding voltage, 0.5-1.5m / min welding speed, and 10-30m / min feeding speed of welding wires. Finished welds of the stainless steel outer composite tubes are subjected to salt spray test for 125 hours, and the test results show no rust; the method is simpler than the existing methods, available for one-step forming, fewer welding wires and solder are used, and the cost is low.

Owner:云南昆钢新型复合材料开发有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com