Laser welding method for automobile skylight guide rail

A technology for automotive sunroofs and laser welding, which is applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve problems such as weld surface defects, difficulties, and difficulties in meeting production needs, and achieve reduced workpiece burns and uniform weld seams The effect of beautiful appearance and simple and easy welding method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

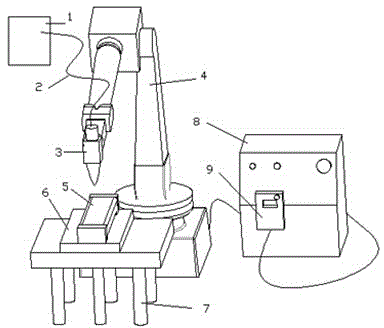

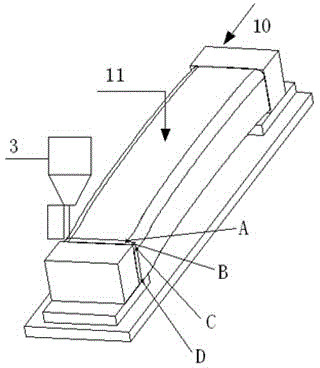

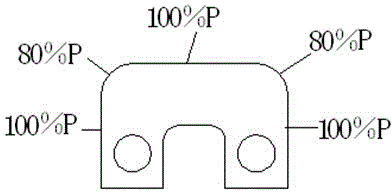

[0018] combine figure 1 , figure 2 , a kind of laser welding method of automobile sunroof guide rail, the steps are as follows:

[0019] 1. Design the tool coordinate system: connect the laser 1 to the laser head 3 through the optical fiber 2, use the robot 4 tool coordinates to set a new coordinate system and coordinate origin, and set the focus position of the laser spot focused by the laser head 3 as the tool coordinates of the robot The origin, the 3 axis of the laser head is the Z axis, and the vertical plane of the laser head 3 is used as the XY plane. Set this coordinate system to solve the tracking problem of U-shaped welds. This method can also solve the problem of special welds whose weld surface is not on the horizontal plane. Welding problem; laser 1 is a fiber laser, carbon dioxide laser, disk laser, semiconductor-pumped all-solid-state laser or lamp-pumped laser.

[0020] 2. Fix the workpiece: fix the workpiece 5 on the base 7 with self-made tooling 6, support...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com