High-magnesium cold-working mould steel and preparation method thereof

A technology of cold working die steel and high magnesium, which is applied in the field of mold manufacturing, can solve the problems of burning loss, low yield, and low solubility, and achieve the effects of reducing costs, improving solubility, and refining grains

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

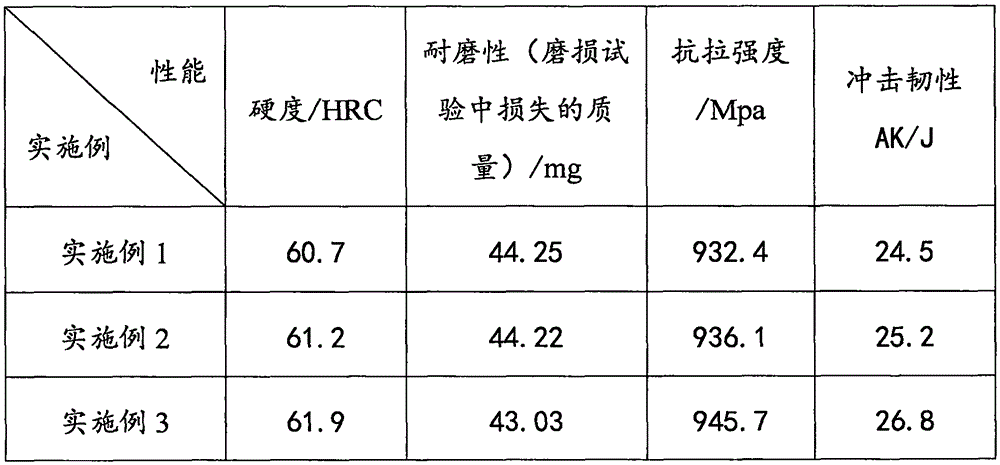

Examples

Embodiment 1

[0019] A high-magnesium cold-working die steel, wherein the weight percent of each content component is, The balance is Fe and unavoidable impurities.

[0020] A preparation method of high-magnesium cold-working die steel, comprising the following steps:

[0021] (1) Smelting raw materials including industrial pure iron, ferrosilicon, ferromanganese, ferromolybdenum and ferrovanadium are loaded into the pressurized induction furnace, and the nickel-magnesium alloy is loaded into the feed bin of the pressurized induction furnace;

[0022] (2) Start induction smelting, and at the same time start the external air extraction system to evacuate the smelting system, and control the vacuum degree within 10Pa;

[0023] (3) After the smelting raw materials are melted, pressurize to 1MPa with argon gas, add nickel-magnesium alloy in three times from the silo, add the last batch of nickel-magnesium alloy for 5 minutes, keep the furnace temperature at 1580-1620°C and start pouring;

[0...

Embodiment 2

[0027] A high-magnesium cold-working die steel, wherein the weight percentages of the components are: C: 1.50, Si: 0.40, Mn: 0.40, Cr: 12.0, V: 0.80, Mo: 0.90, Ni: 0.50, Mg: 0.07, The balance is Fe and unavoidable impurities.

[0028] A preparation method of high-magnesium cold-working die steel, comprising the following steps:

[0029] (1) Smelting raw materials including industrial pure iron, ferrosilicon, ferromanganese, ferromolybdenum and ferrovanadium are loaded into the pressurized induction furnace, and the nickel-magnesium alloy is loaded into the feed bin of the pressurized induction furnace;

[0030] (2) Start induction smelting, and at the same time start the external air extraction system to evacuate the smelting system, and control the vacuum degree within 10Pa;

[0031] (3) After the smelting raw materials are melted, argon gas is applied to pressurize to 2MPa, and nickel-magnesium alloy is added from the silo in 4 times. After the last batch of nickel-magnesiu...

Embodiment 3

[0035] A high-magnesium cold-working die steel, wherein the weight percentage of each content component is, C: 1.60, Si: 0.50, Mn: 0.50, Cr: 13.0, V: 0.80, Mo: 1.20, Ni: 0.70, Mg: 0.08, The balance is Fe and unavoidable impurities.

[0036] A preparation method of high-magnesium cold-working die steel, comprising the following steps:

[0037] (1) Smelting raw materials including industrial pure iron, ferrosilicon, ferromanganese, ferromolybdenum and ferrovanadium are loaded into the pressurized induction furnace, and the nickel-magnesium alloy is loaded into the feed bin of the pressurized induction furnace;

[0038] (2) Start induction smelting, and at the same time start the external air extraction system to evacuate the smelting system, and control the vacuum degree within 10Pa;

[0039] (3) After the smelting raw materials are melted, argon is applied to pressurize to 3MPa, and nickel-magnesium alloy is added in 5 times from the silo. After the last batch of nickel-magnes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com