Patents

Literature

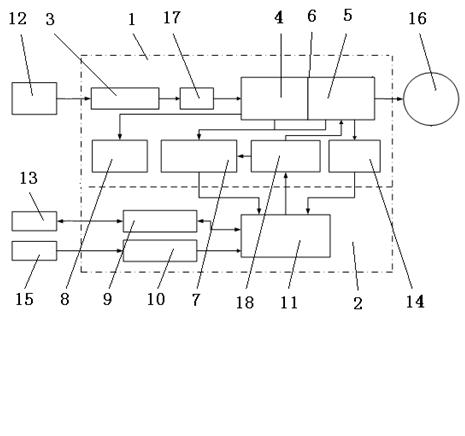

670results about "Suppressing electromagnetic interference" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

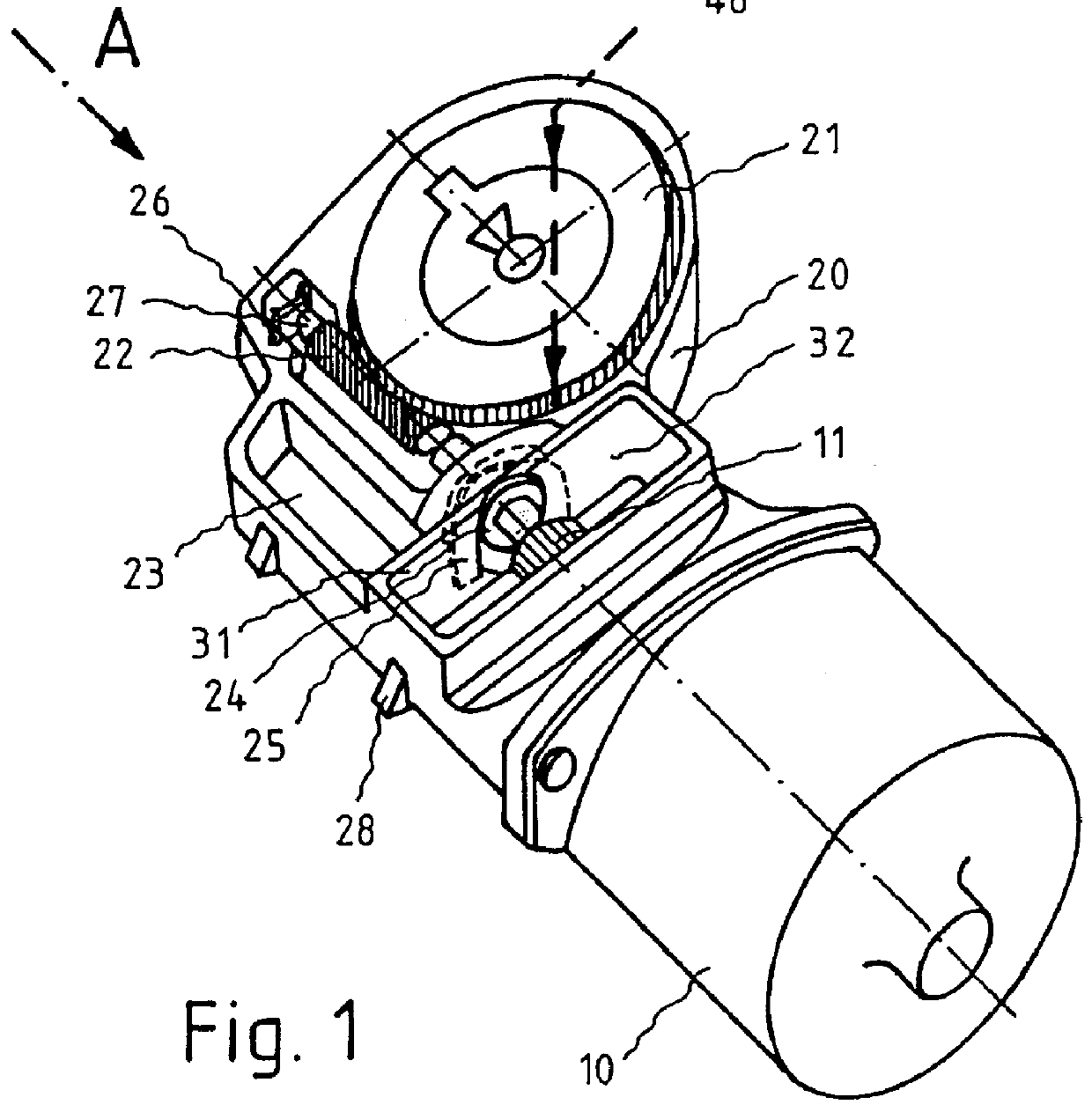

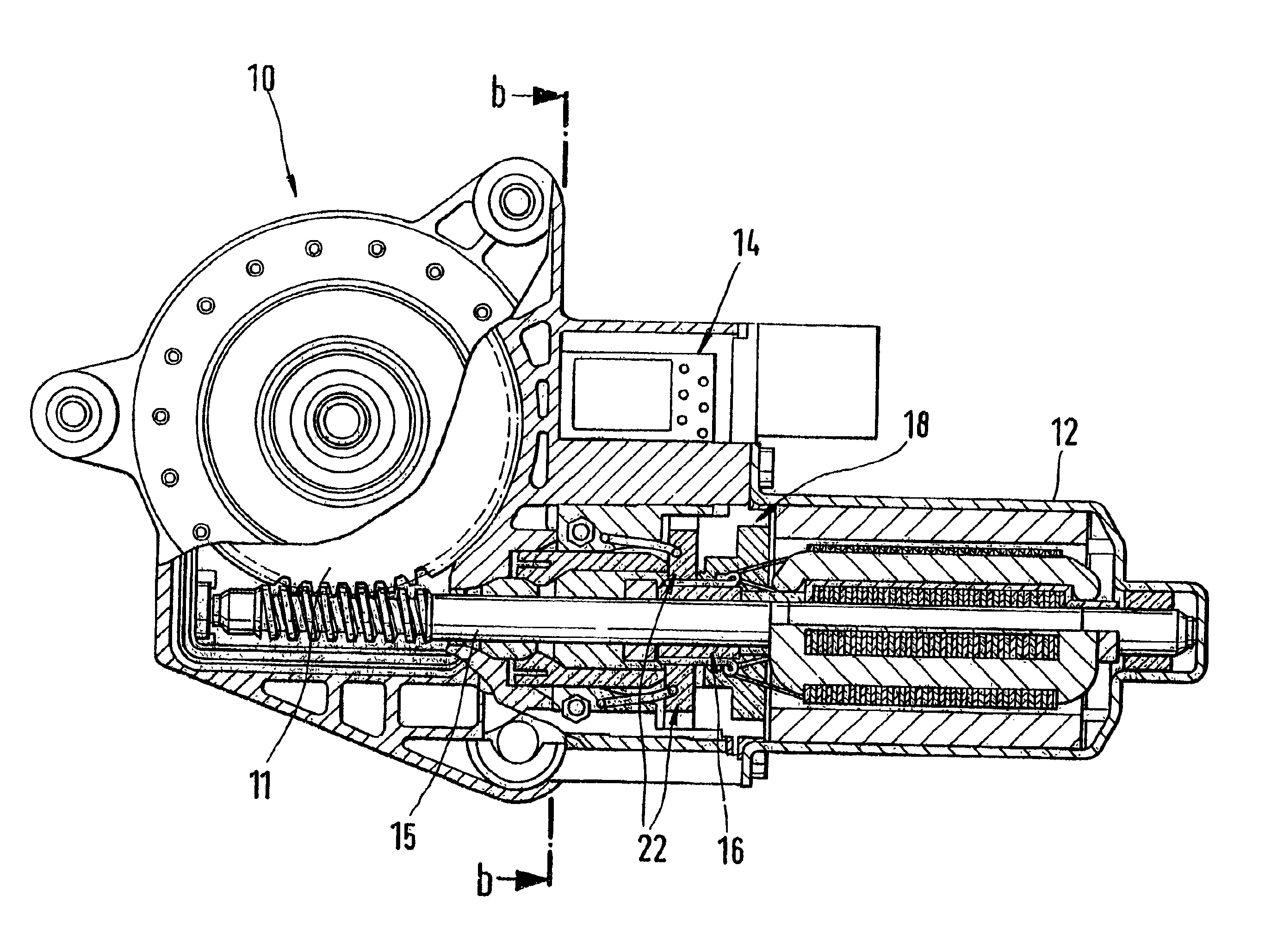

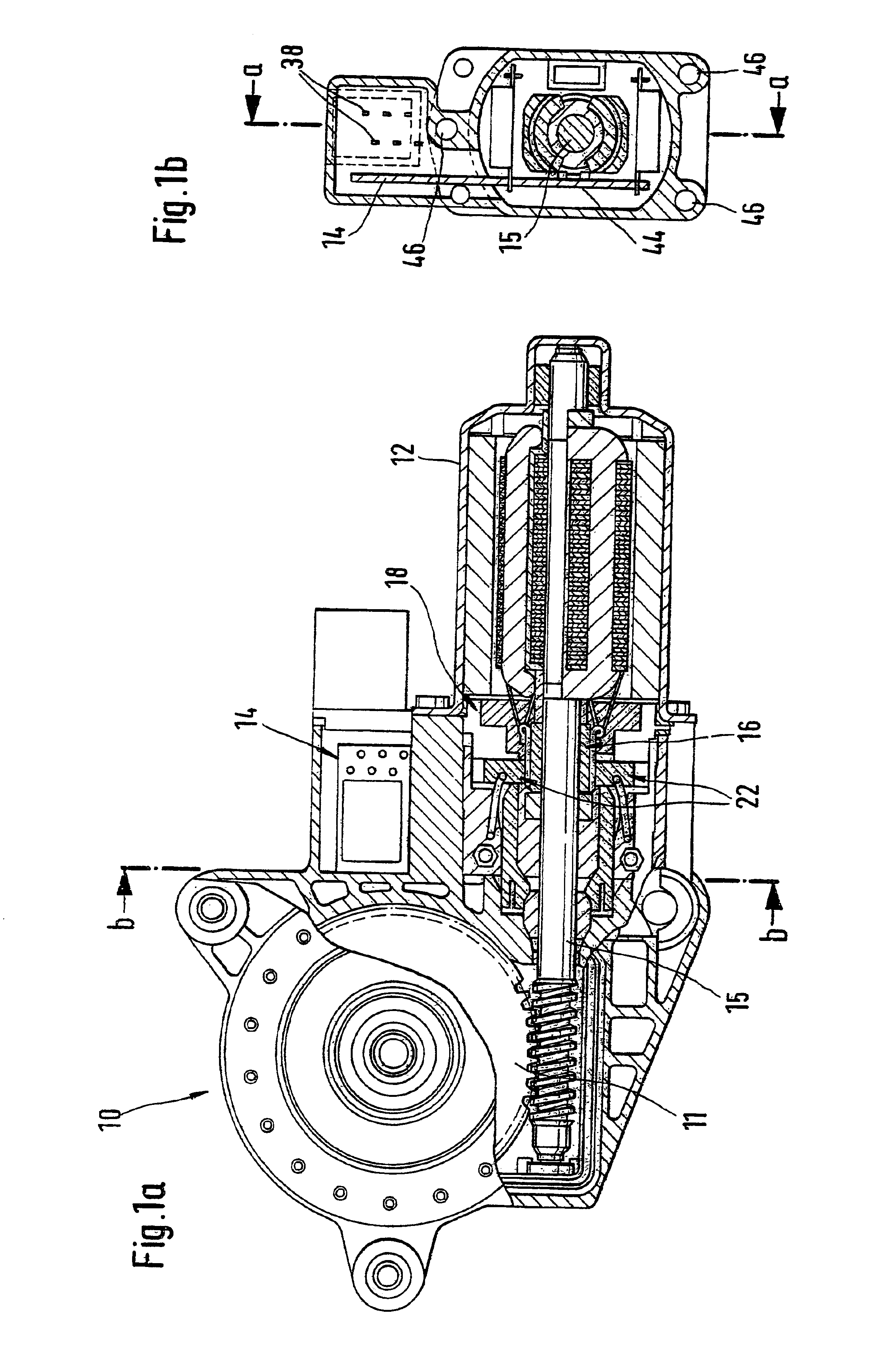

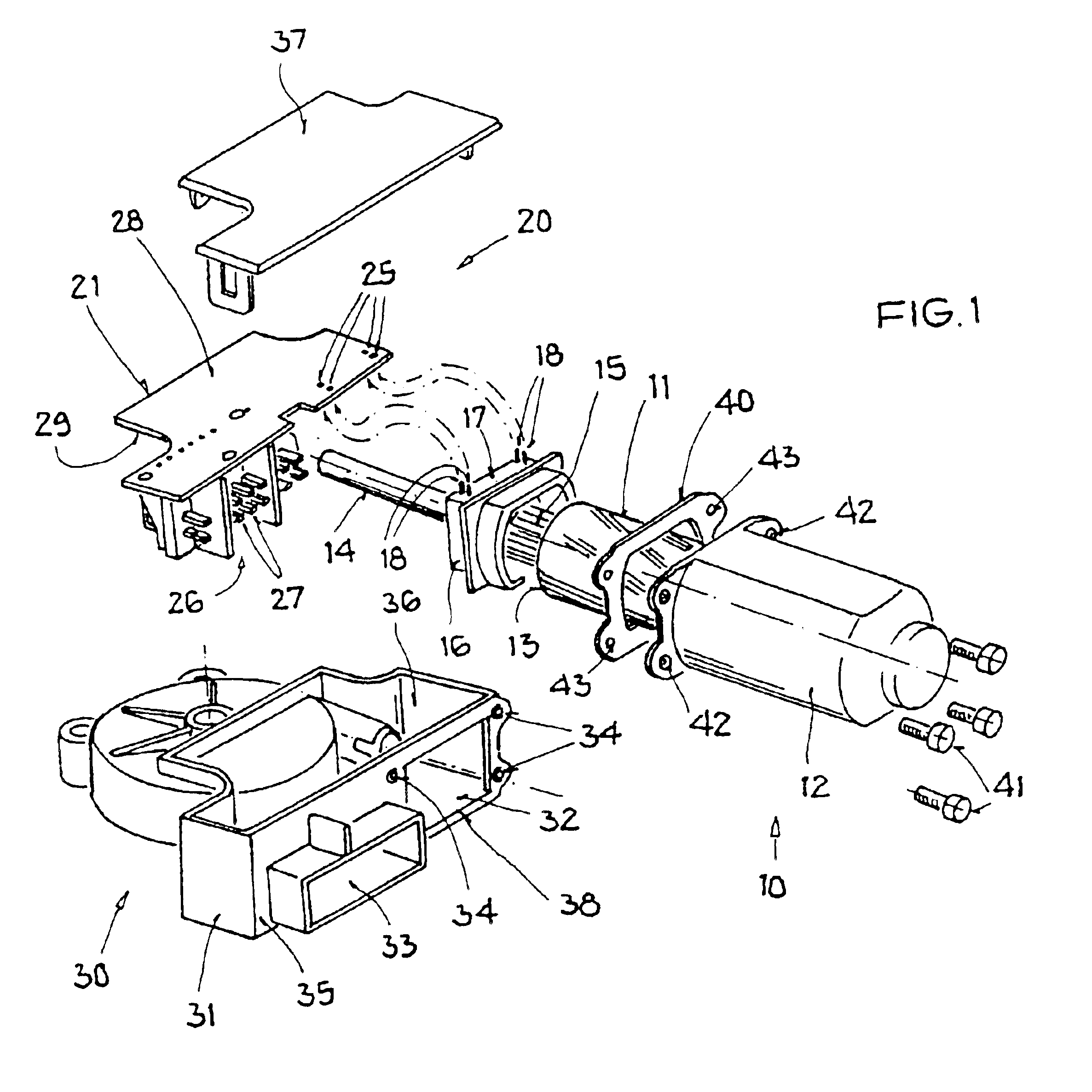

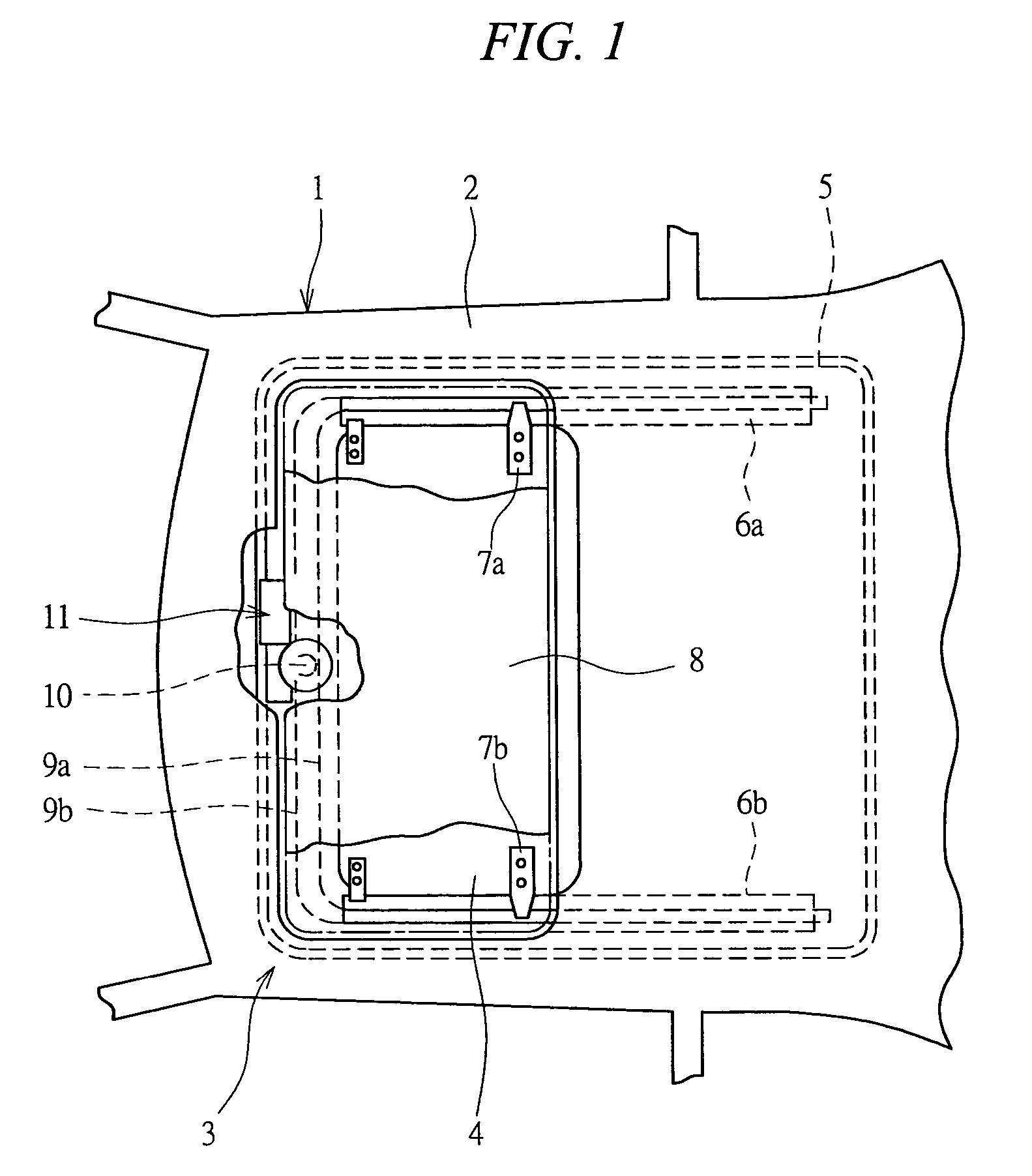

Drive device for moving a sliding sunroof of a vehicle

InactiveUS6201326B1Improve efficiencyDisassembly of the brush holderRotary current collectorToothed gearingsEngineeringPrinted circuit board

A brush holder equipped as a component on a printed circuit board and is inserted into a recess provided in a transmission housing of the drive device and thereby can be slid in the radial direction over a commutator of an already completely assembled armature. The drive device according to the invention is provided for moving a sliding sunroof of a vehicle.

Owner:ROBERT BOSCH GMBH

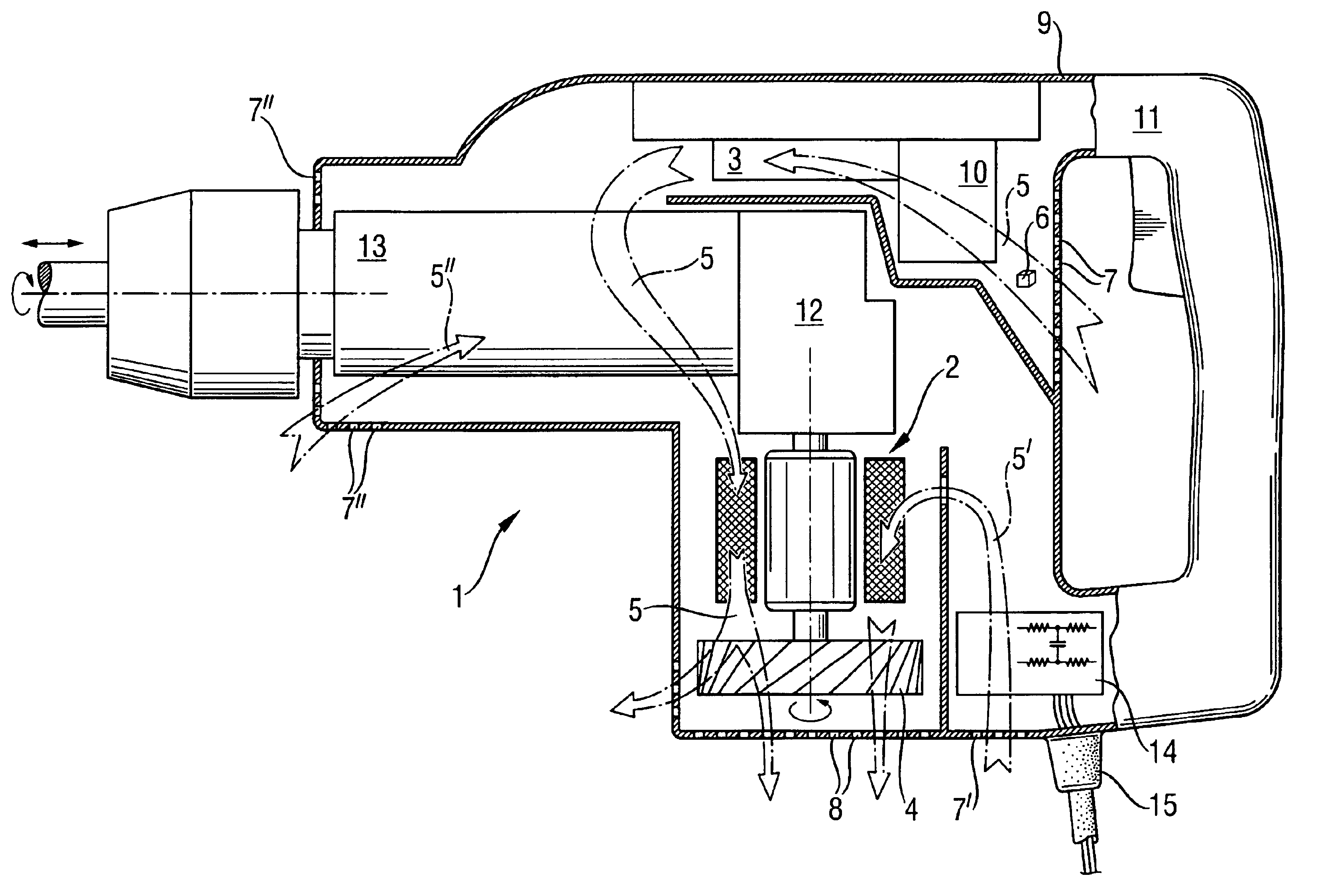

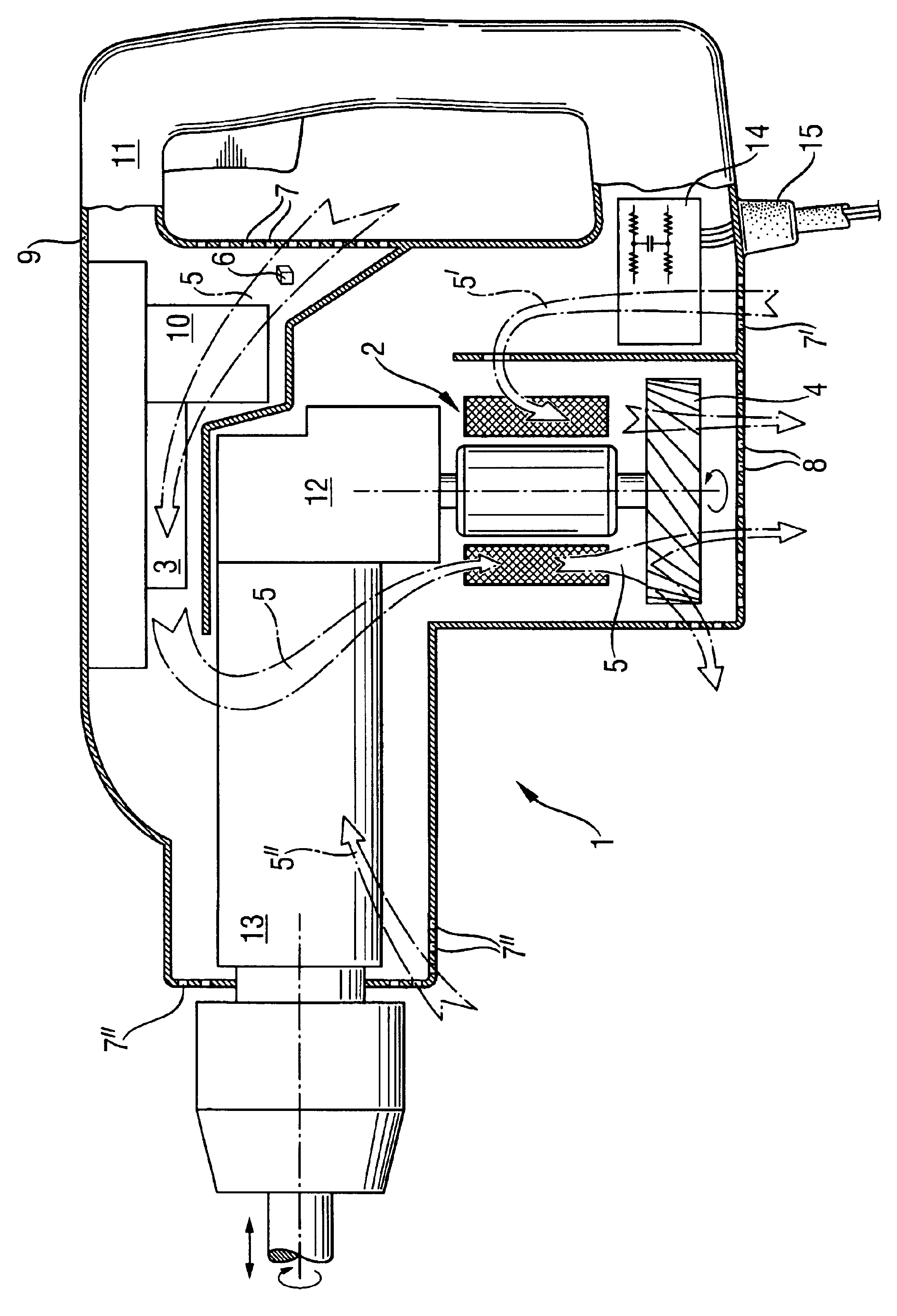

Electrical, fan-cooled tool

An electrical tool includes a housing having inlet (7) and outlet (8) openings, a brushless electric motor (2) and an inverted rectifier (3) both arranged in the housing (9) between inlet (7) and outlet (8) openings in an air stream (5) of an air volume (6), and a link condensator (10) located in the housing (9) in the air stream (5), with the inverted rectifier (3) being arranged, in the air flow direction, downstream of the link condensator (10) and upstream of the electric motor (2).

Owner:HILTI AG

Component carrier

InactiveUS7141899B2Easy to assembleLess susceptibleMultiple-port networksAnti-noise capacitorsElectrical conductorBand shape

The invention provides a structure and method of its use comprising a filtering and interference suppression device (62), particularly of the broad band type, for an electric motor (34) comprising at least a first powering brush (16) for an armature commutator of the electric motor (34), of the type comprising a capacitor (64), one terminal of which is electrically connected to a strip conductor (38) that electrically powers the first brush (16) powering the armature commutator of the electric motor (34), and the other terminal of which is electrically connected to a ground strip conductor (58), connected, in turn, to the electrical ground (60) of the electric motor (34), characterized in that the capacitor (72) of the filtering and interference suppression device (62) is of the non-inductive type, and in that each of the non-inductive capacitors (72) is directly attached to a circuit board (73) comprising strip conductors, of which are at least one powering strip conductor (38, 40) for a brush and one ground strip conductor (58).

Owner:X2Y ATTENUATORS L L C

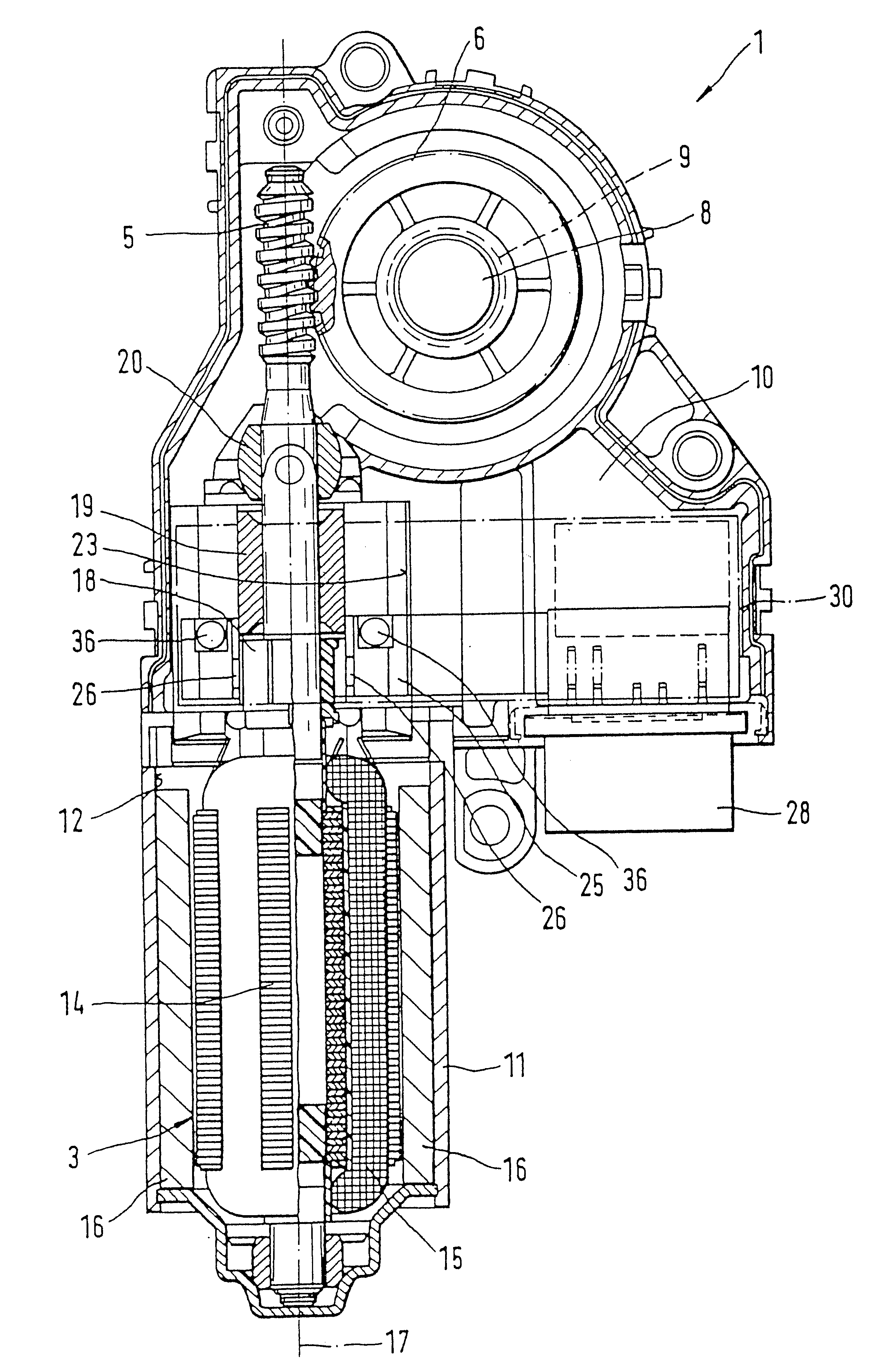

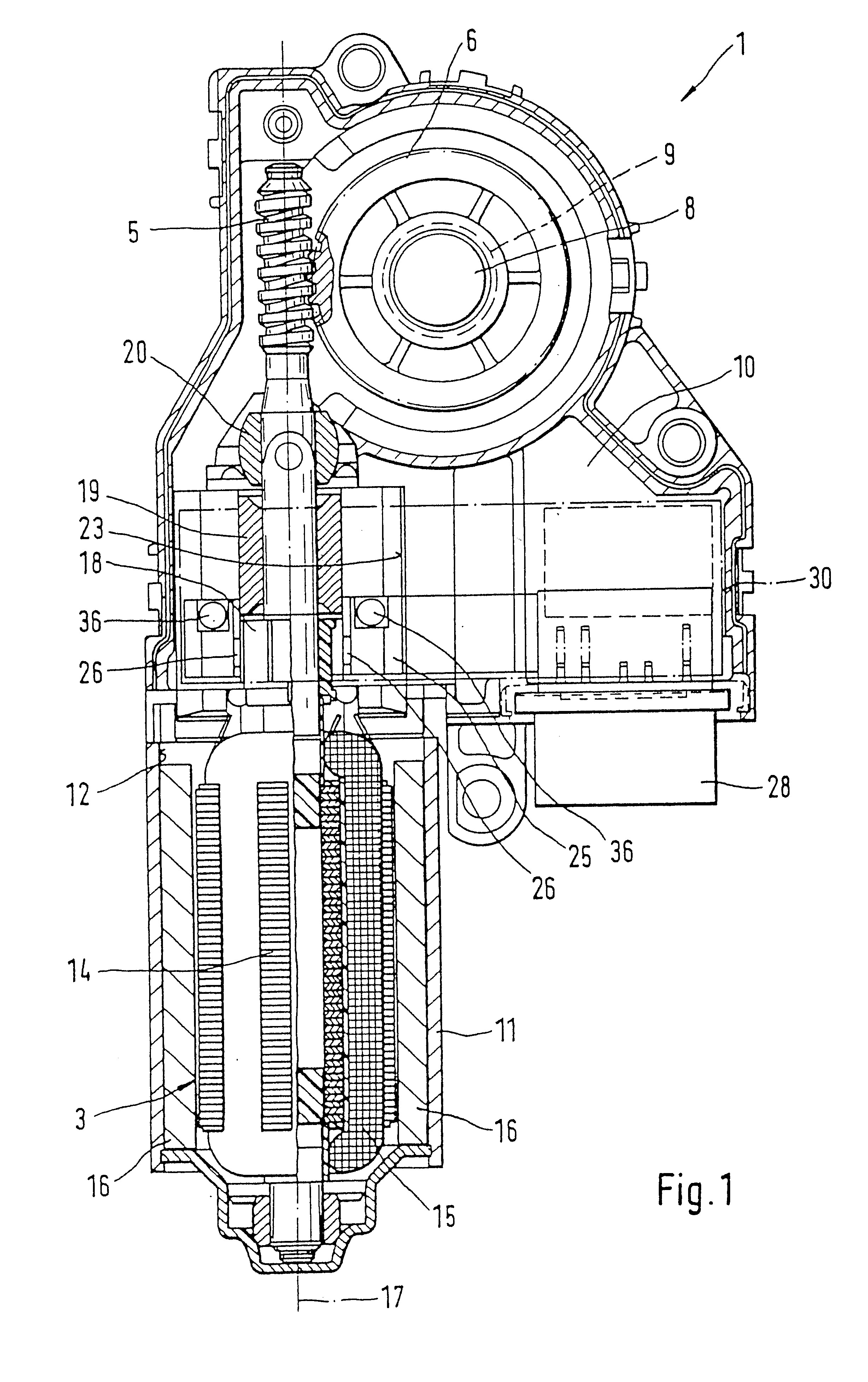

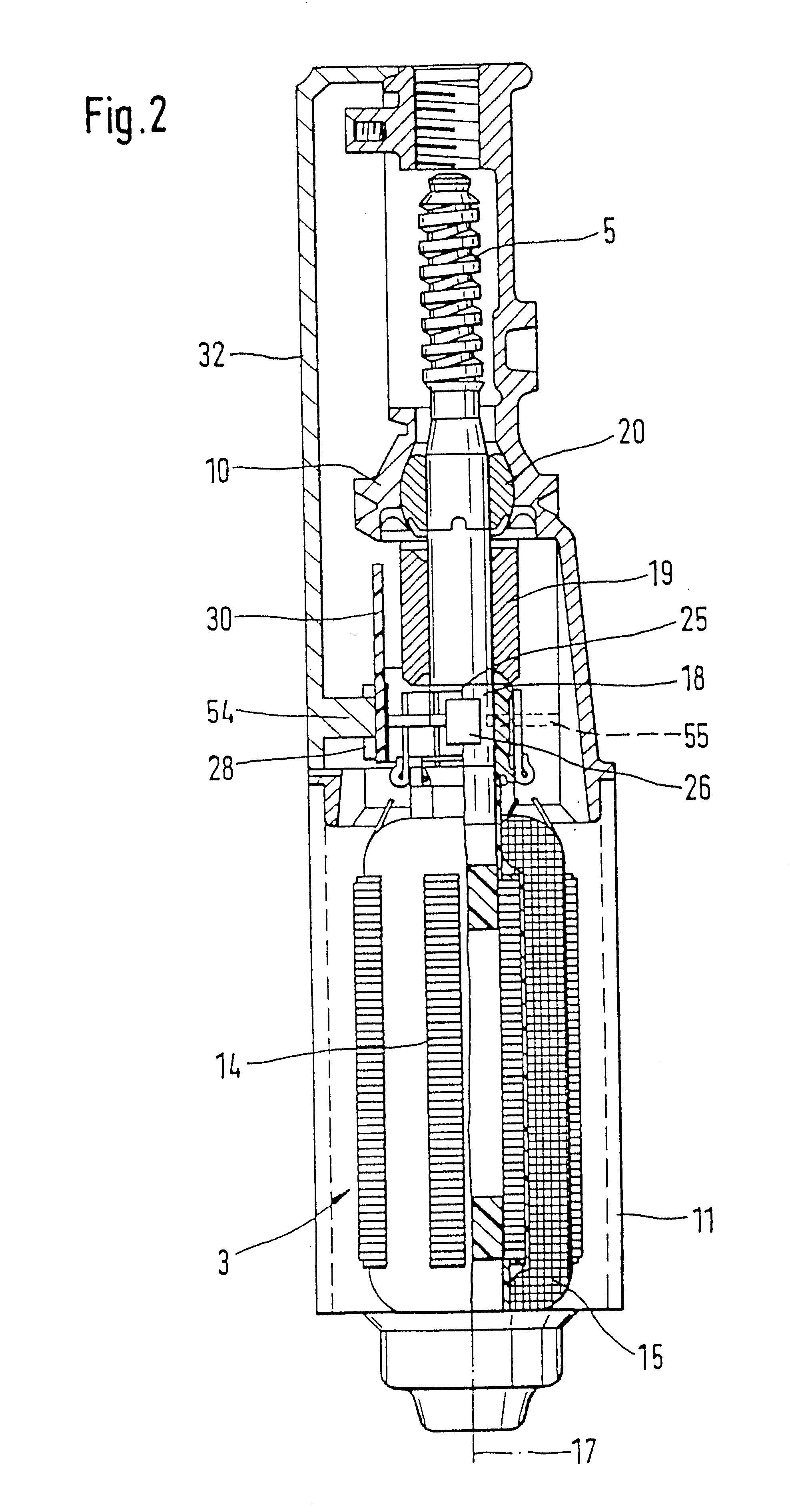

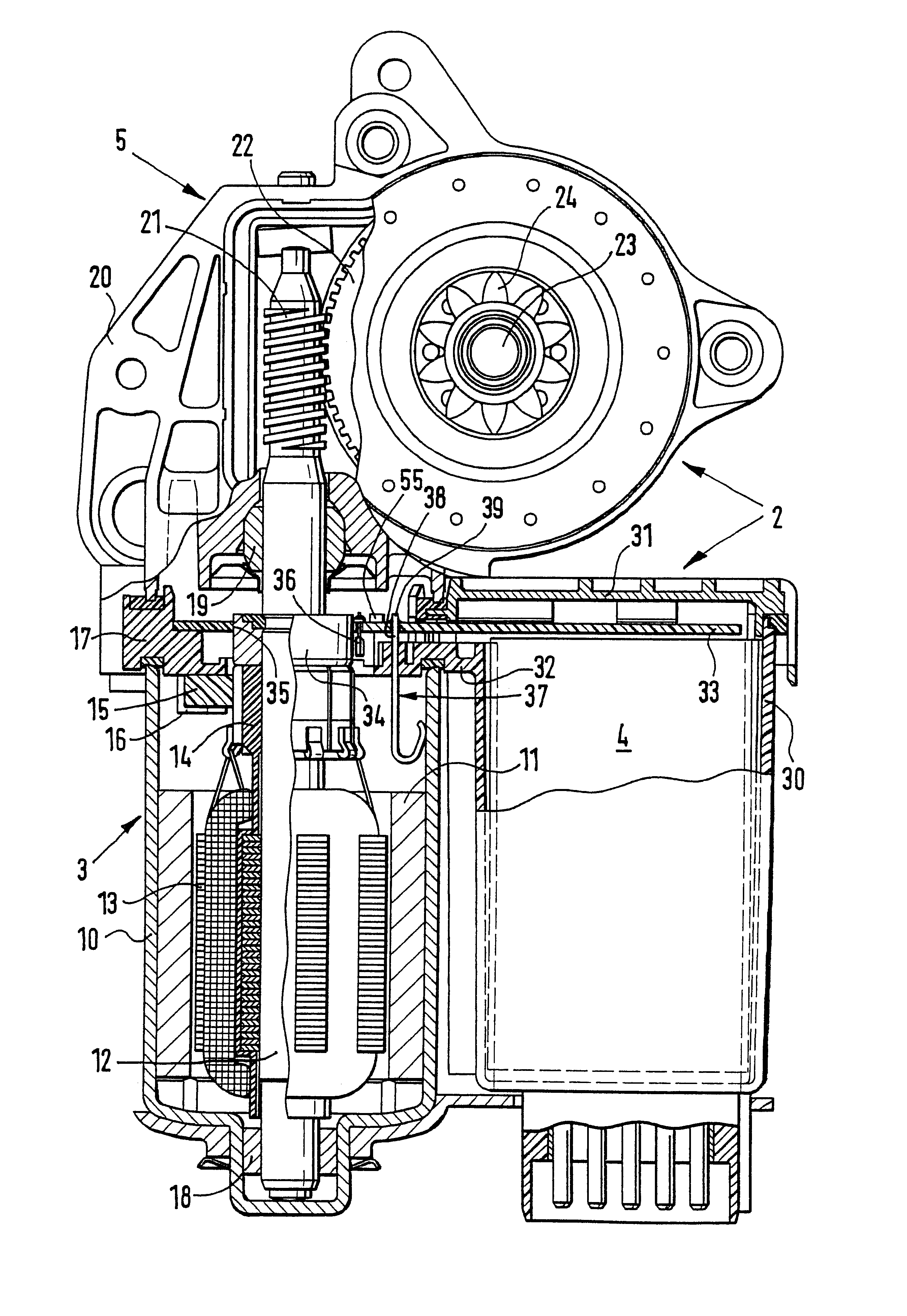

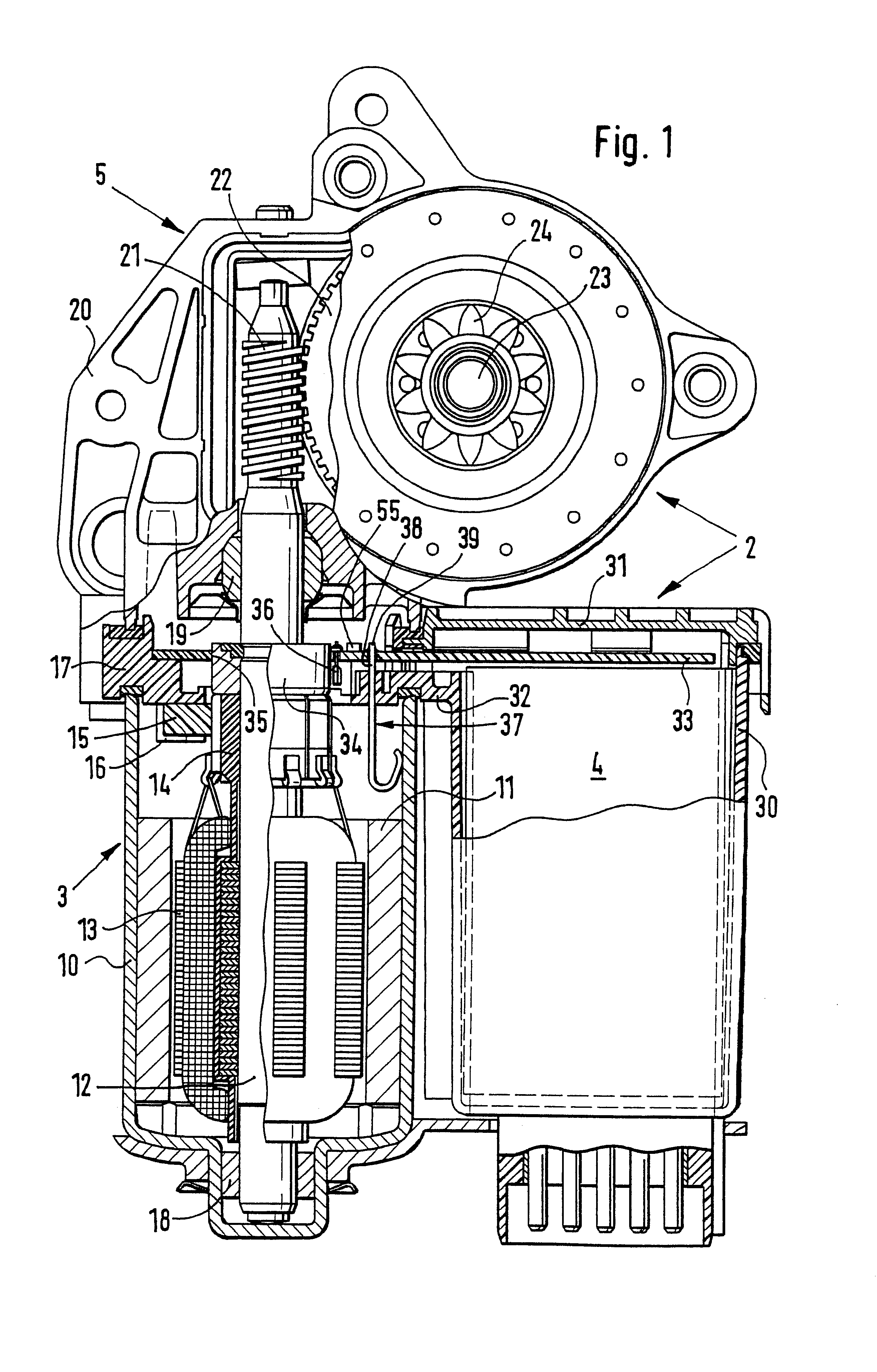

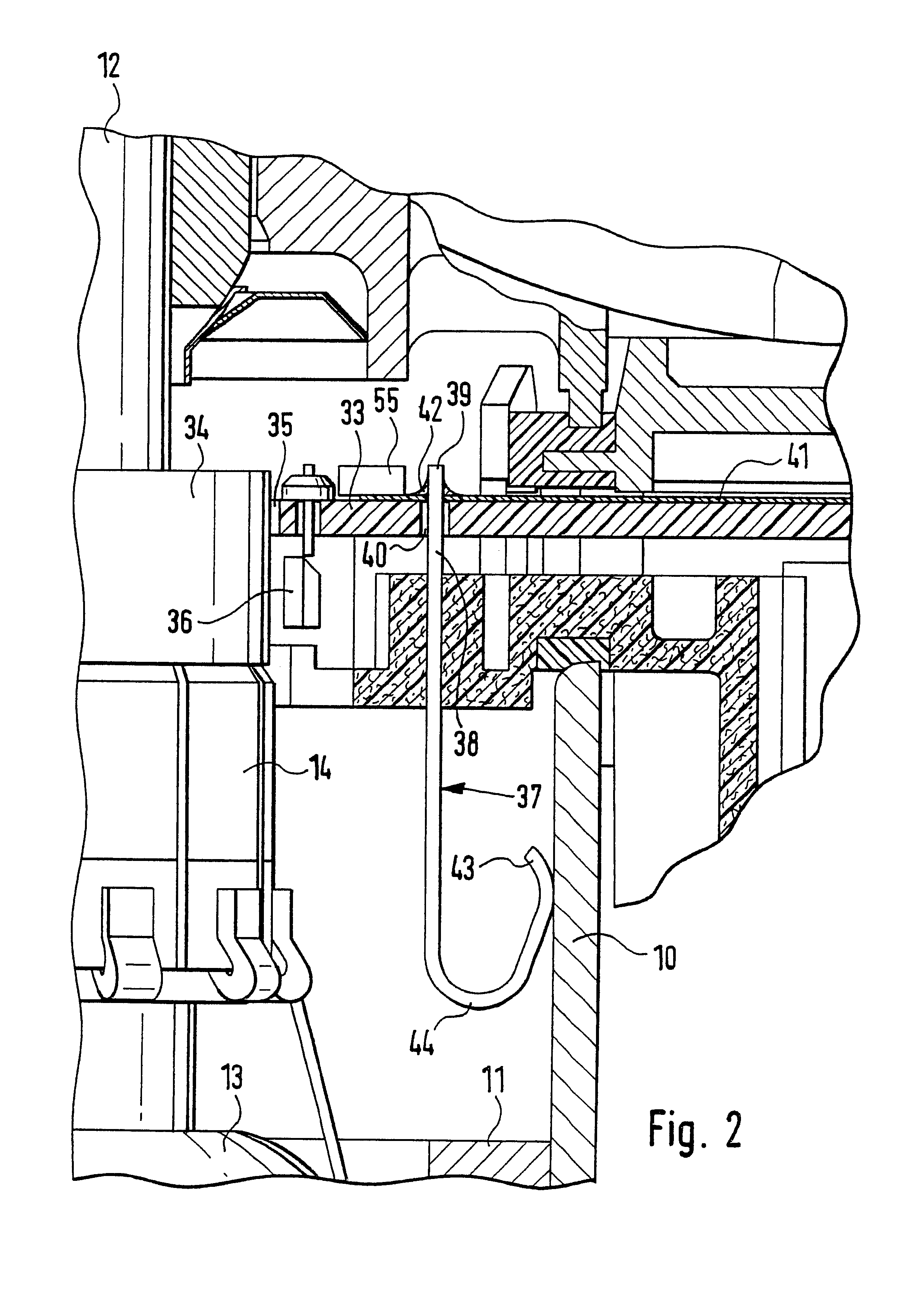

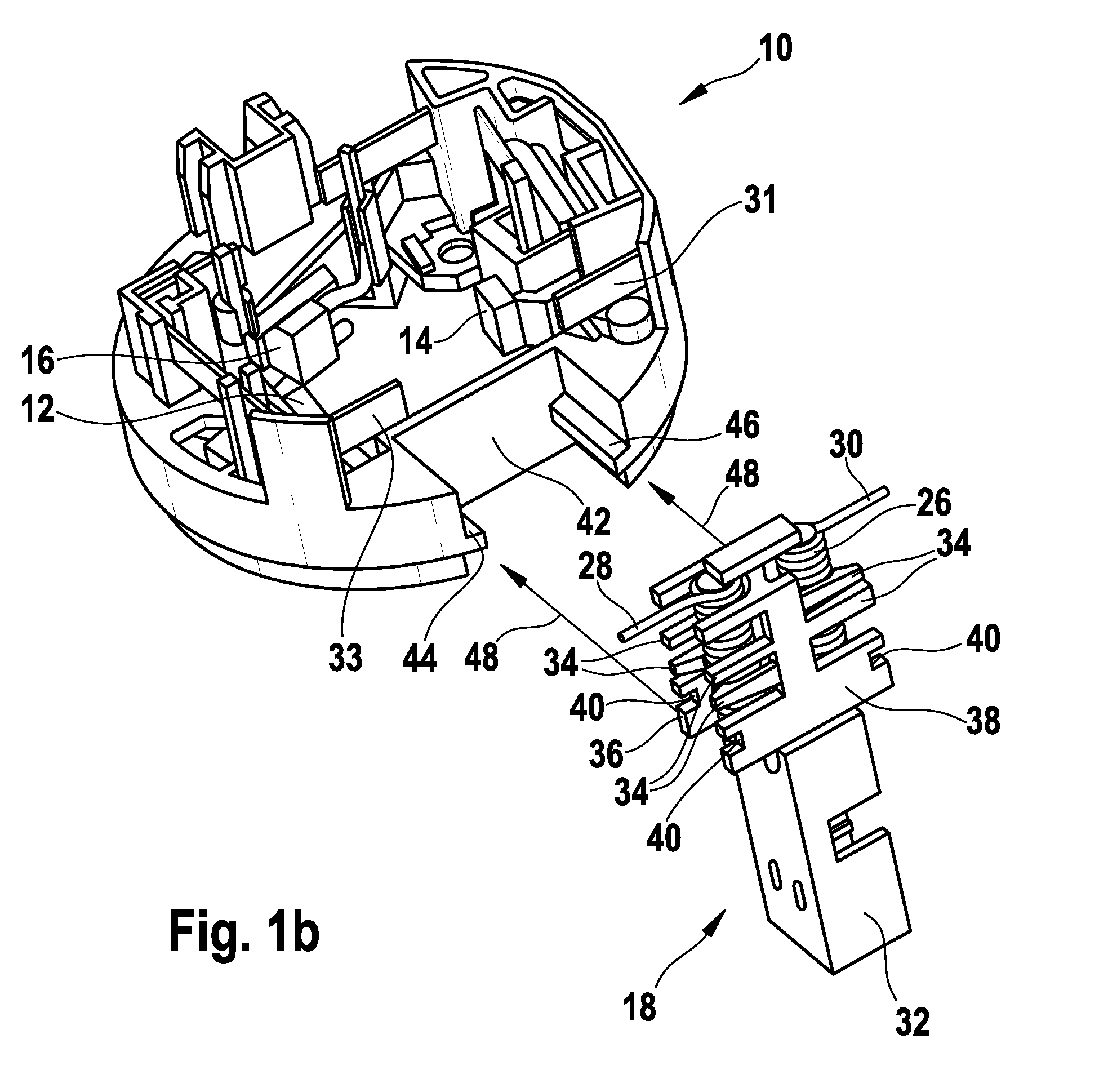

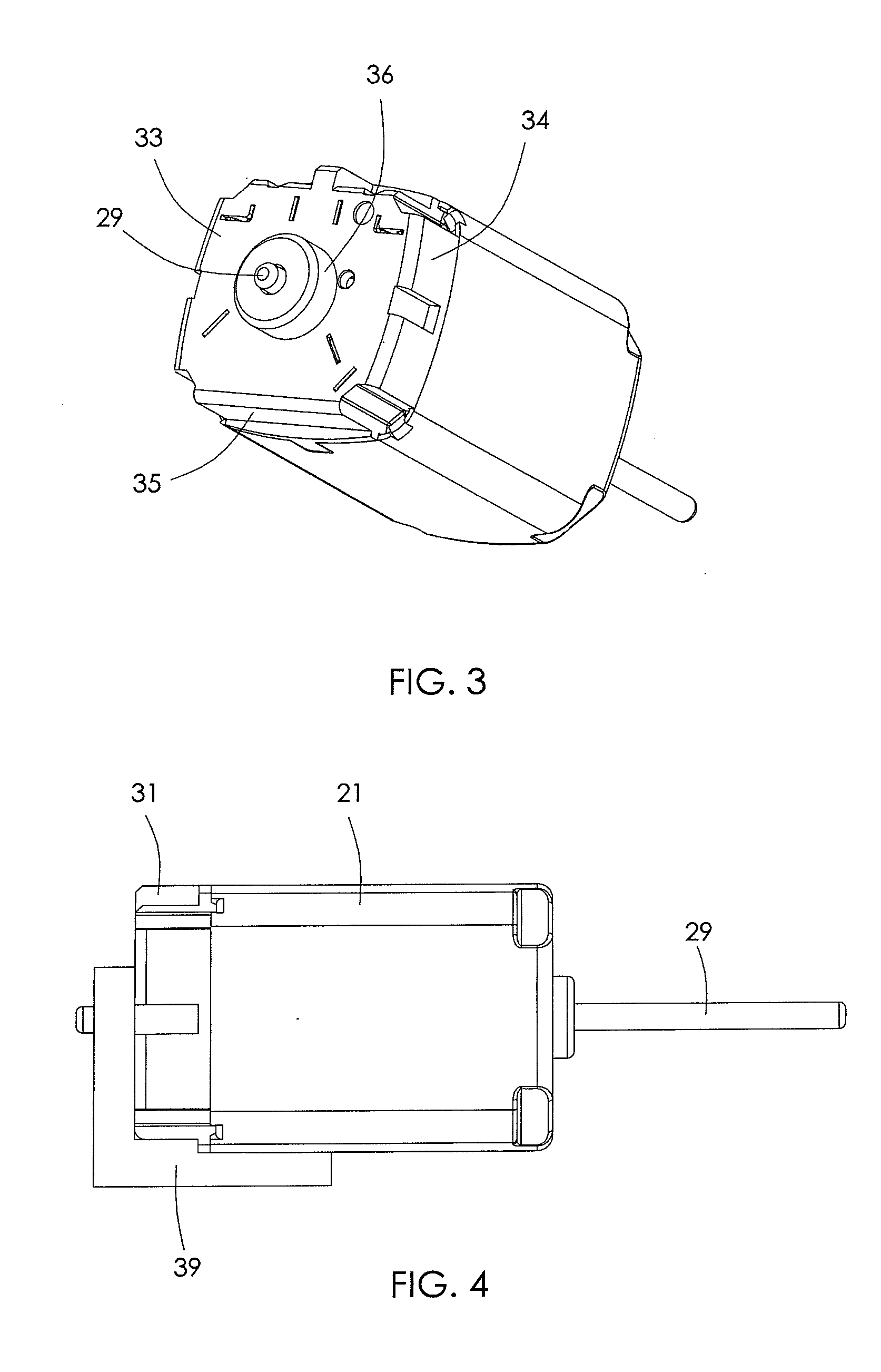

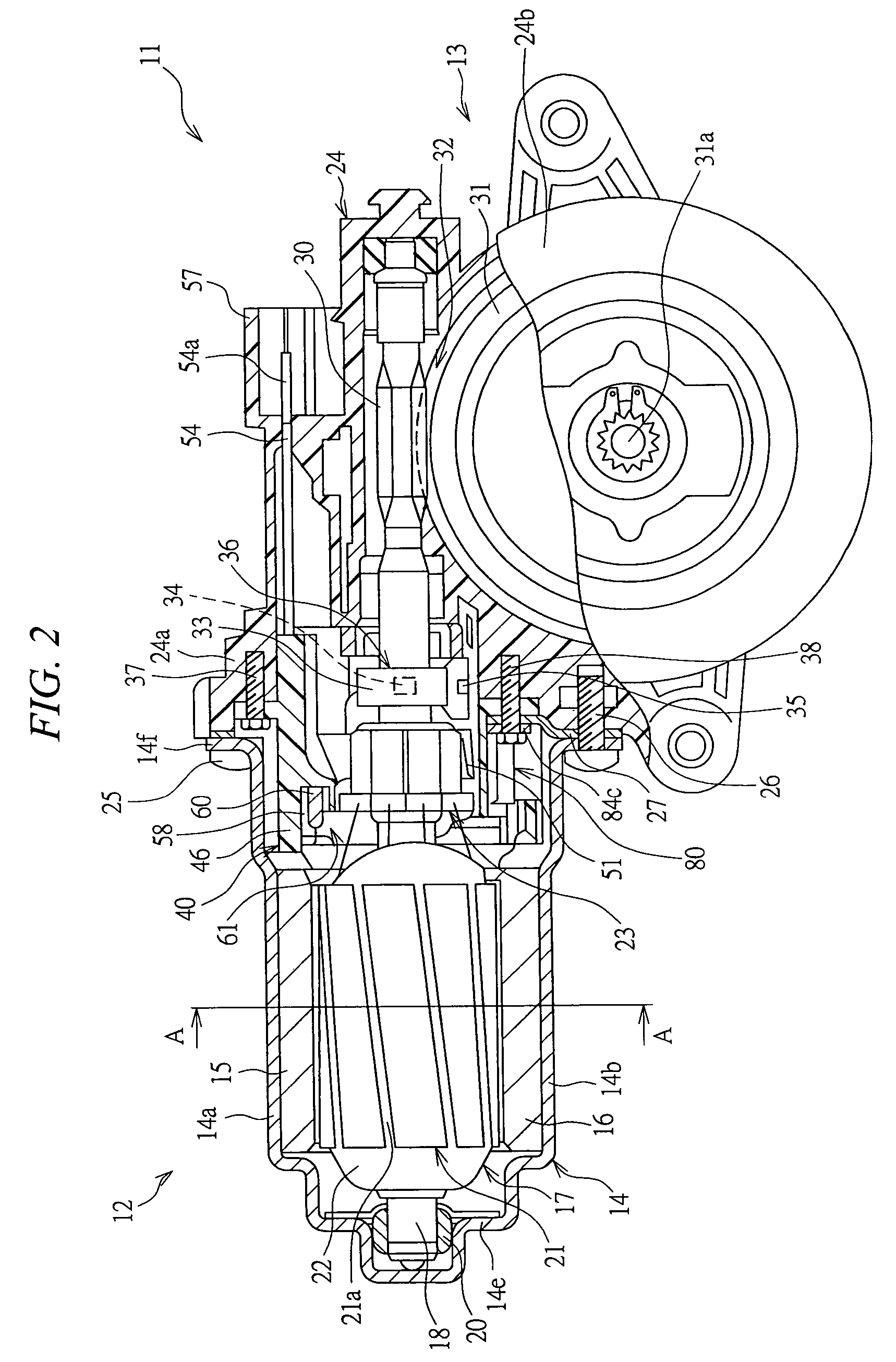

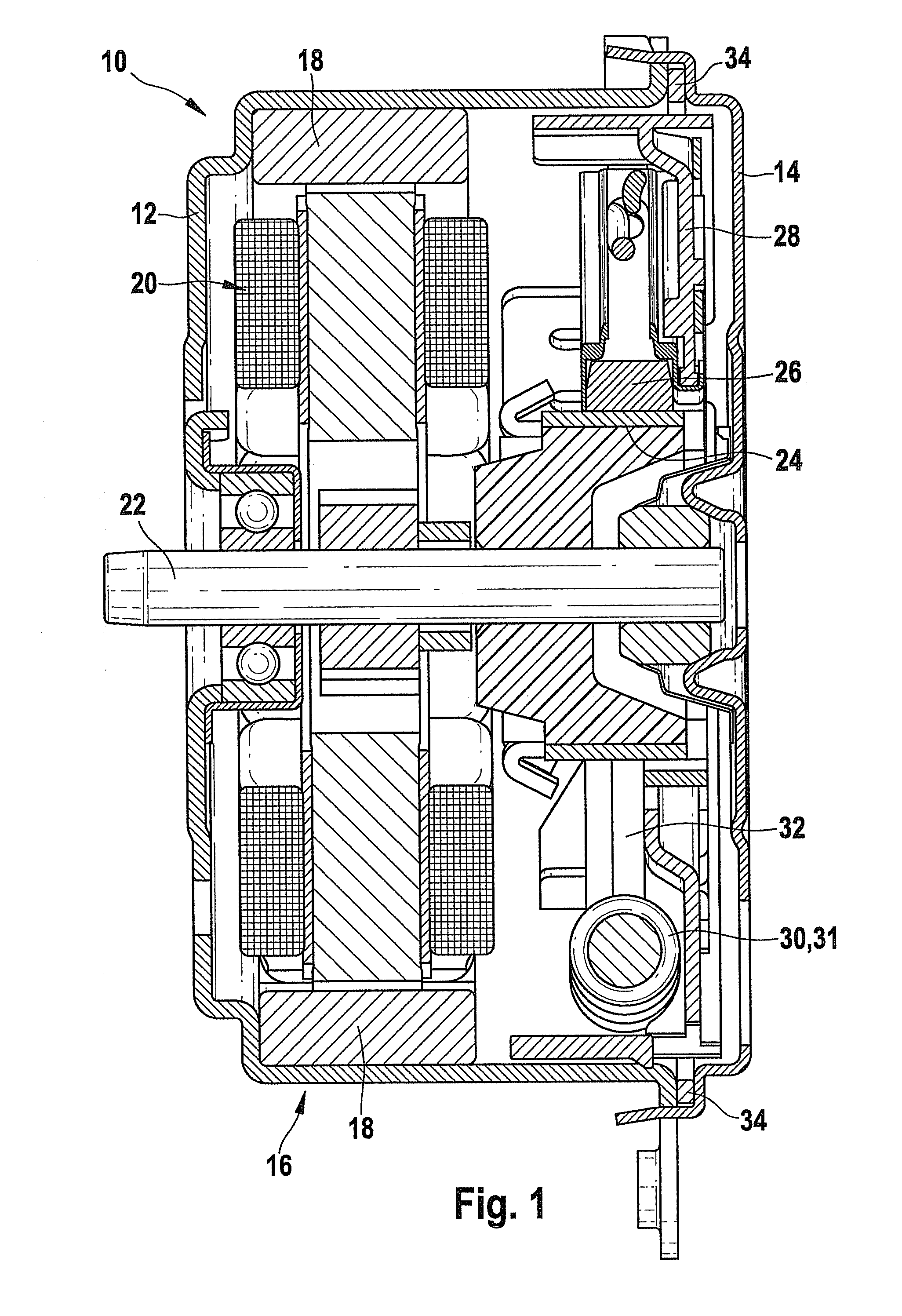

Electrical drive unit

InactiveUS6163096ARotary current collectorManufacturing dynamo-electric machinesEngineeringDrive motor

PCT No. PCT / DE98 / 01532 Sec. 371 Date Feb. 26, 1999 Sec. 102(e) Date Feb. 26, 1999 PCT Filed Jun. 5, 1998 PCT Pub. No. WO99 / 00885 PCT Pub. Date Jan. 7, 1999An electrical drive unit for windshield wipers of a motor vehicle, including a drive motor which has an armature accommodated in a substantially cup-shaped housing, and a substantially cup-shaped gearbox for receiving gear elements which is secured on a face end to the housing and is closable by a gearbox cover. A closable opening is provided in the gearbox or housing, through which opening a brush holder support that holds commutator brushes can be pushed in a radial direction onto the commutator of the drive motor.

Owner:ROBERT BOSCH GMBH

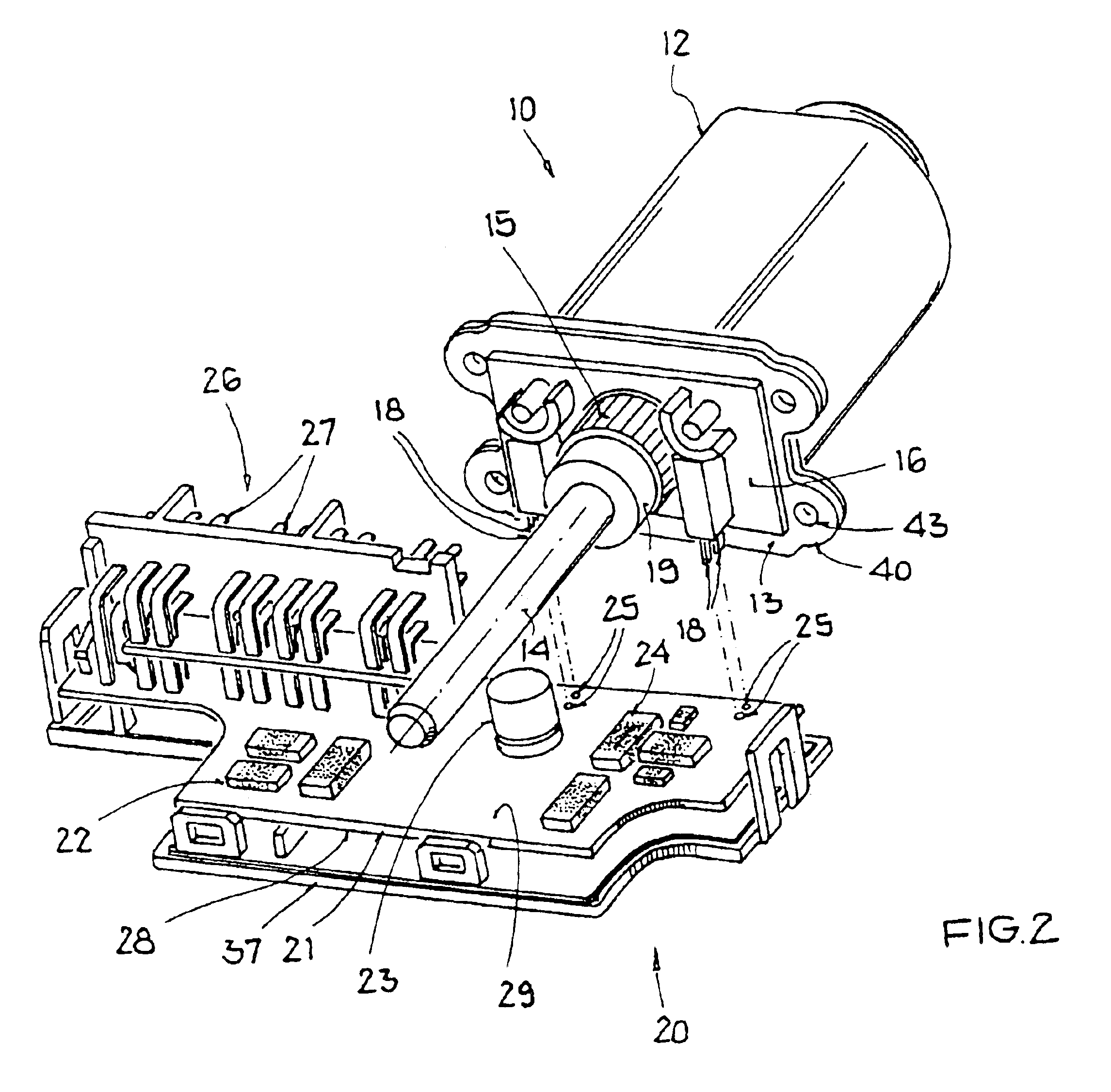

Actuating drive with an electric motor and control electronics

InactiveUS6528915B1Association with grounding devicesMechanical energy handlingElectrical conductorControl electronics

An actuating drive with an electric motor that has a metallic electric motor housing, a shaft, an armature, collector, brushes, and a brush holder plate, and control electronics. Electronic and electric components are connected to a printed circuit board and the printed circuit board protrudes at right angles to the shaft and into a cross section of the electric motor housing. Outside the electric motor housing, the electronic and electric components are protected by a control electronics housing. Radio interference suppression means, for example, can be disposed inside the actuating drive. The system includes a printed circuit board with a strip conductor and a contact spring that leads from the strip conductor and this contact spring protrudes into the electric motor housing, wherein a resilient free end of the spring rests against the electric motor housing producing an electrical contact.

Owner:ROBERT BOSCH GMBH

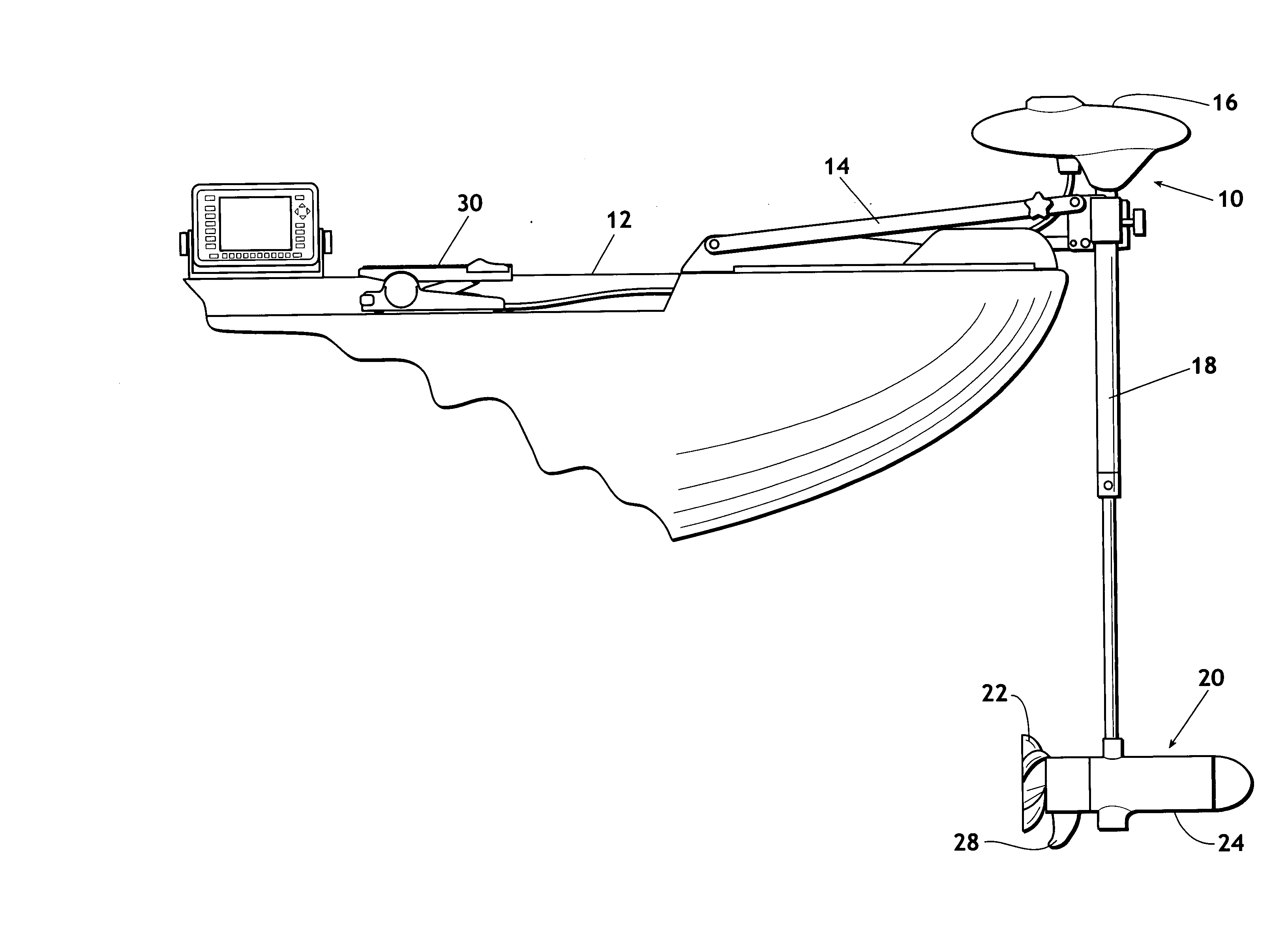

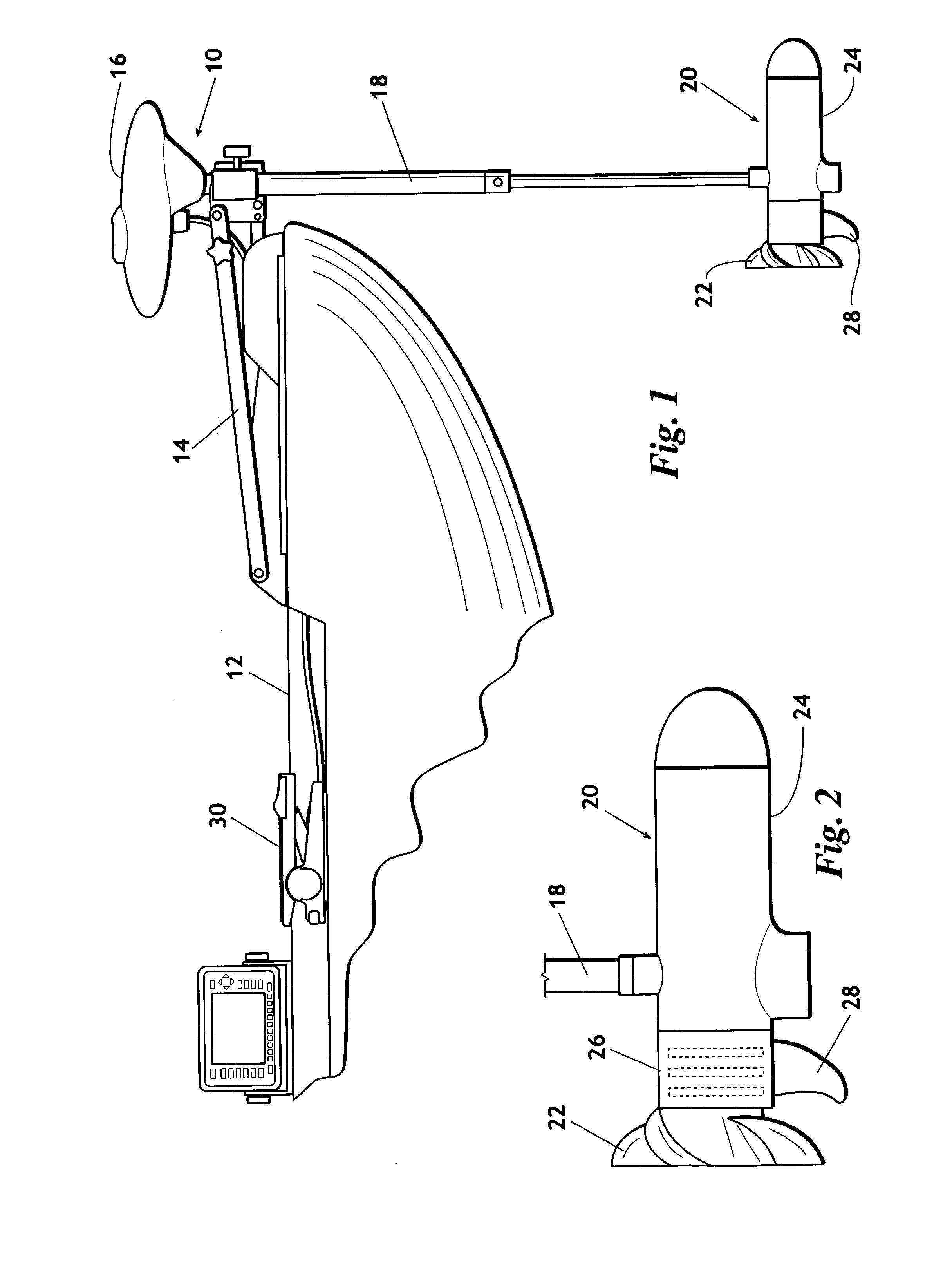

DC motor with integral controller

InactiveUS6902446B1Little and and degradationEmission reductionSteering initiationsControllers with pulse-train output signalIntegral controllerMotor controller

A DC motor having a motor housing and a motor controller housed within the motor housing. In a preferred embodiment the heat producing components of the motor controller are in thermal communication with the housing such that the majority of the heat produced by such components will be readily conducted to the environment in which the motor is operating. When incorporated into a trolling motor, the motor housing of the present invention will be submerged so that controller produced heat will be dissipated into the water in which the trolling motor is operated.

Owner:BRUNSWICK CORPORATION

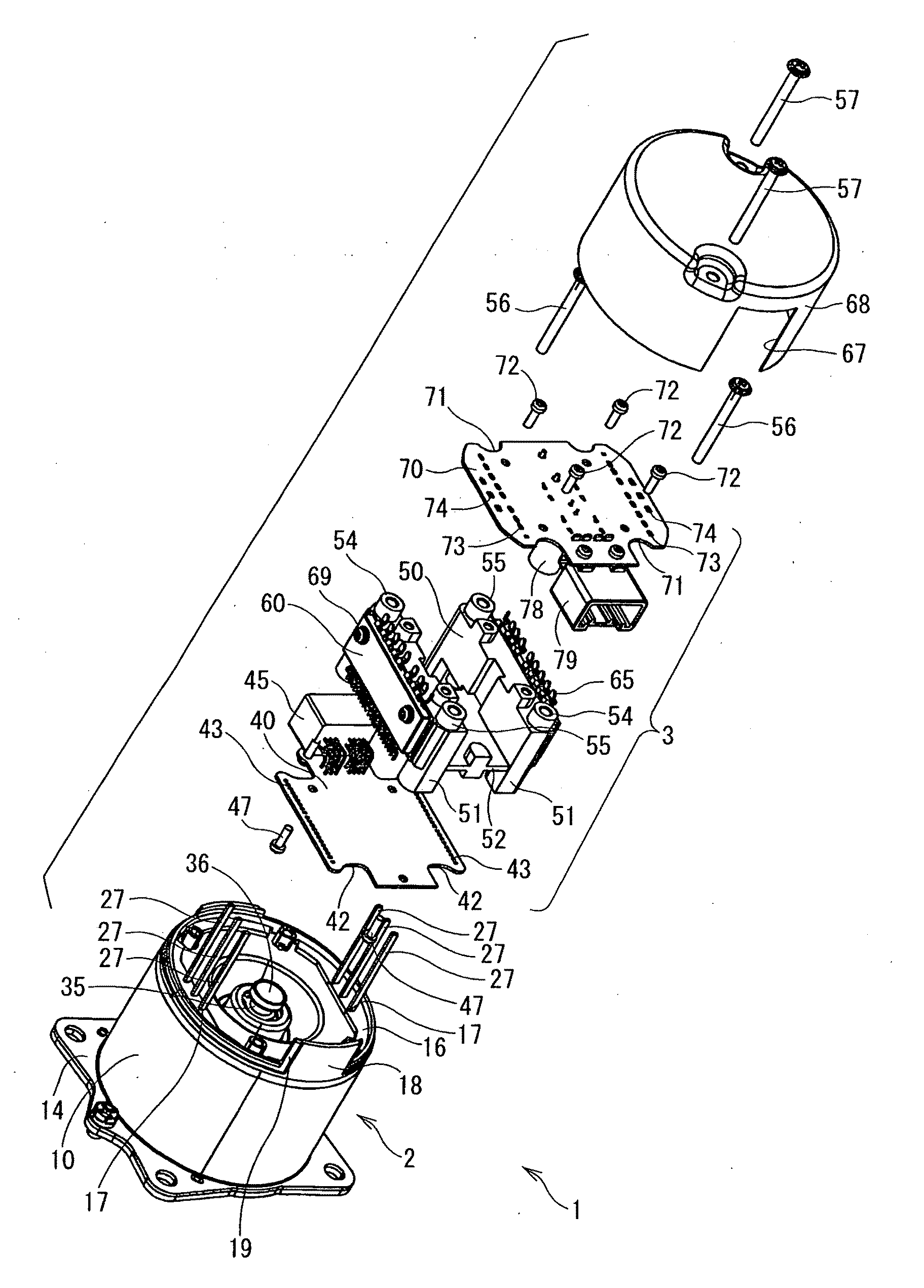

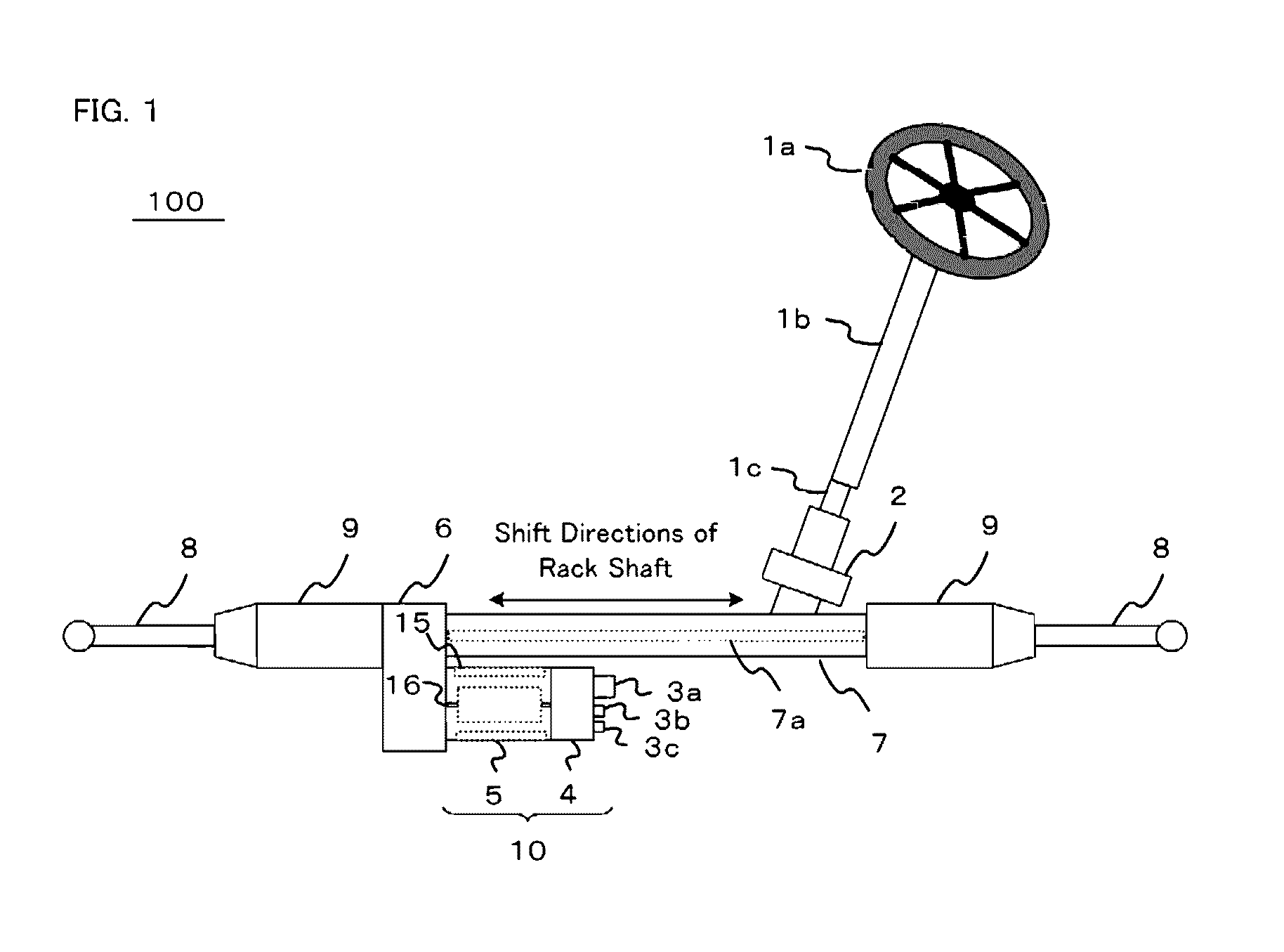

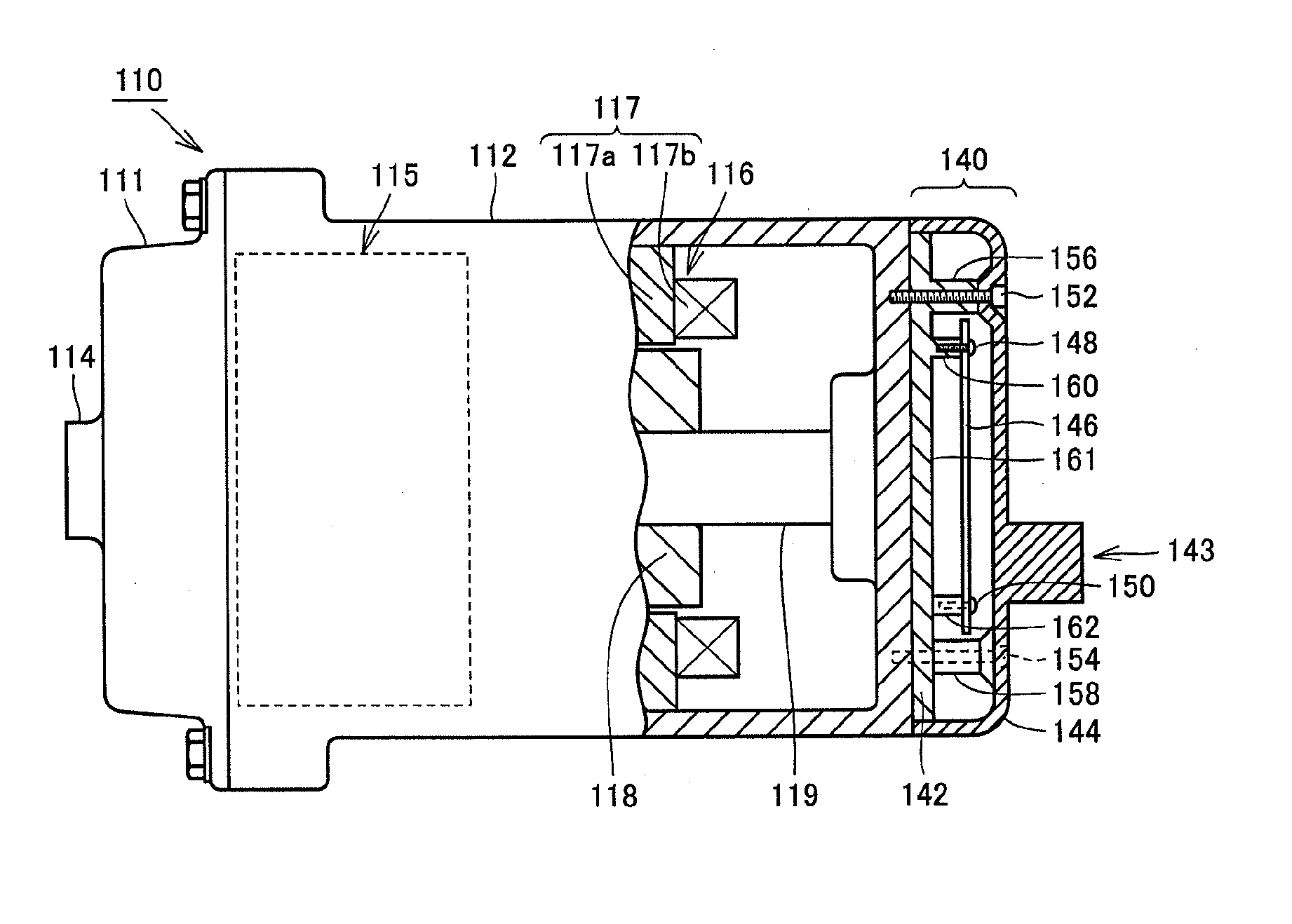

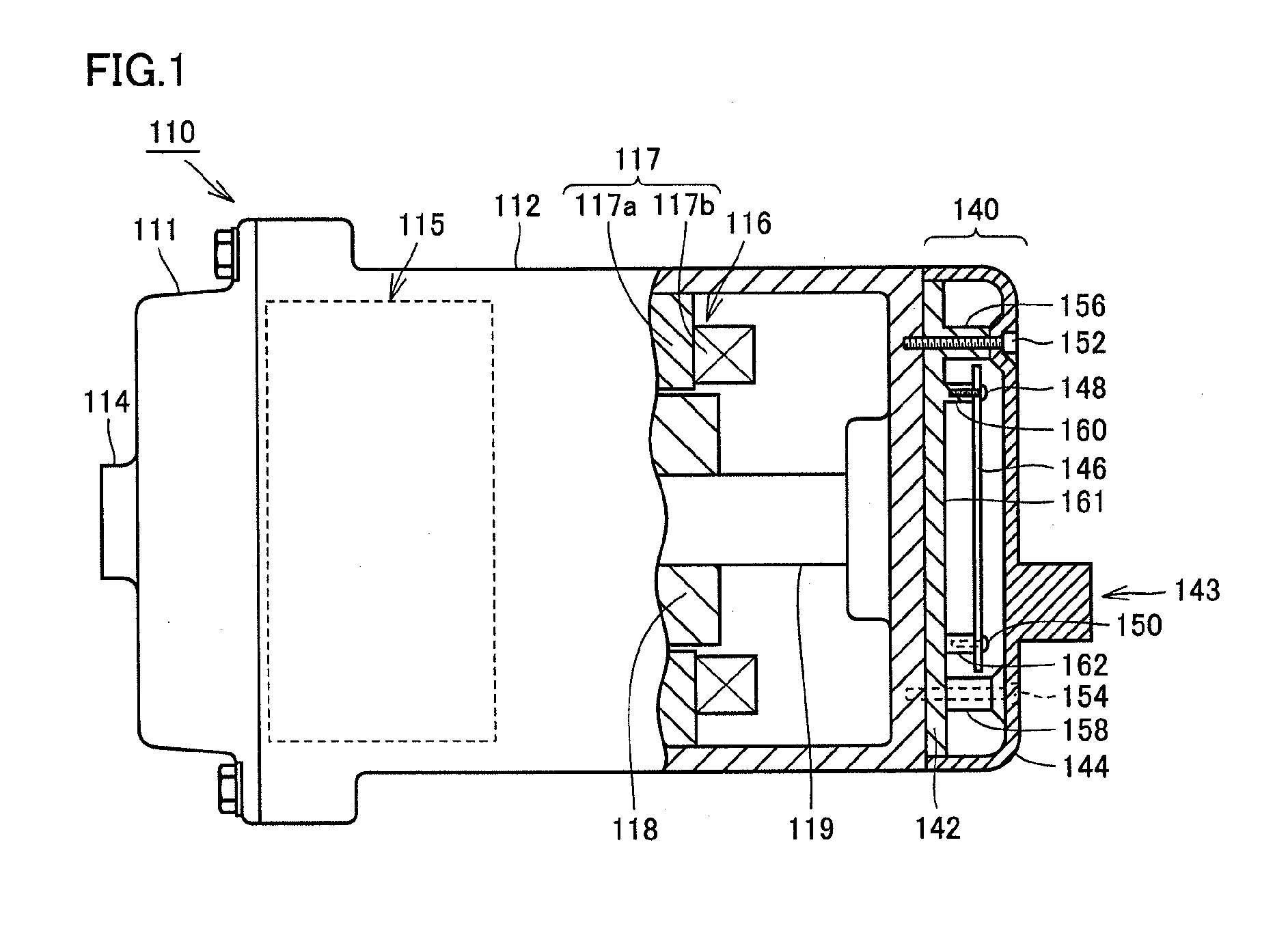

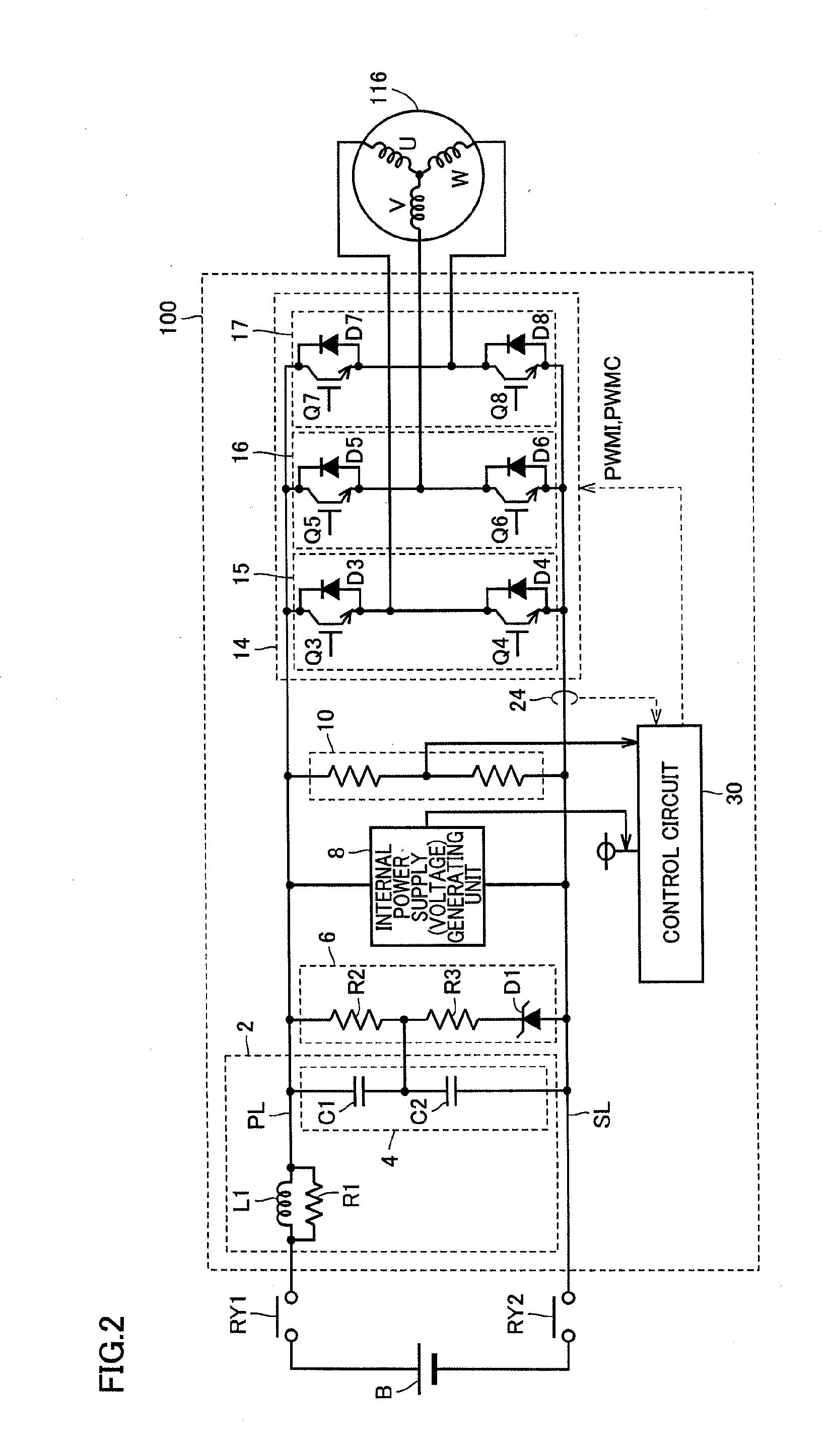

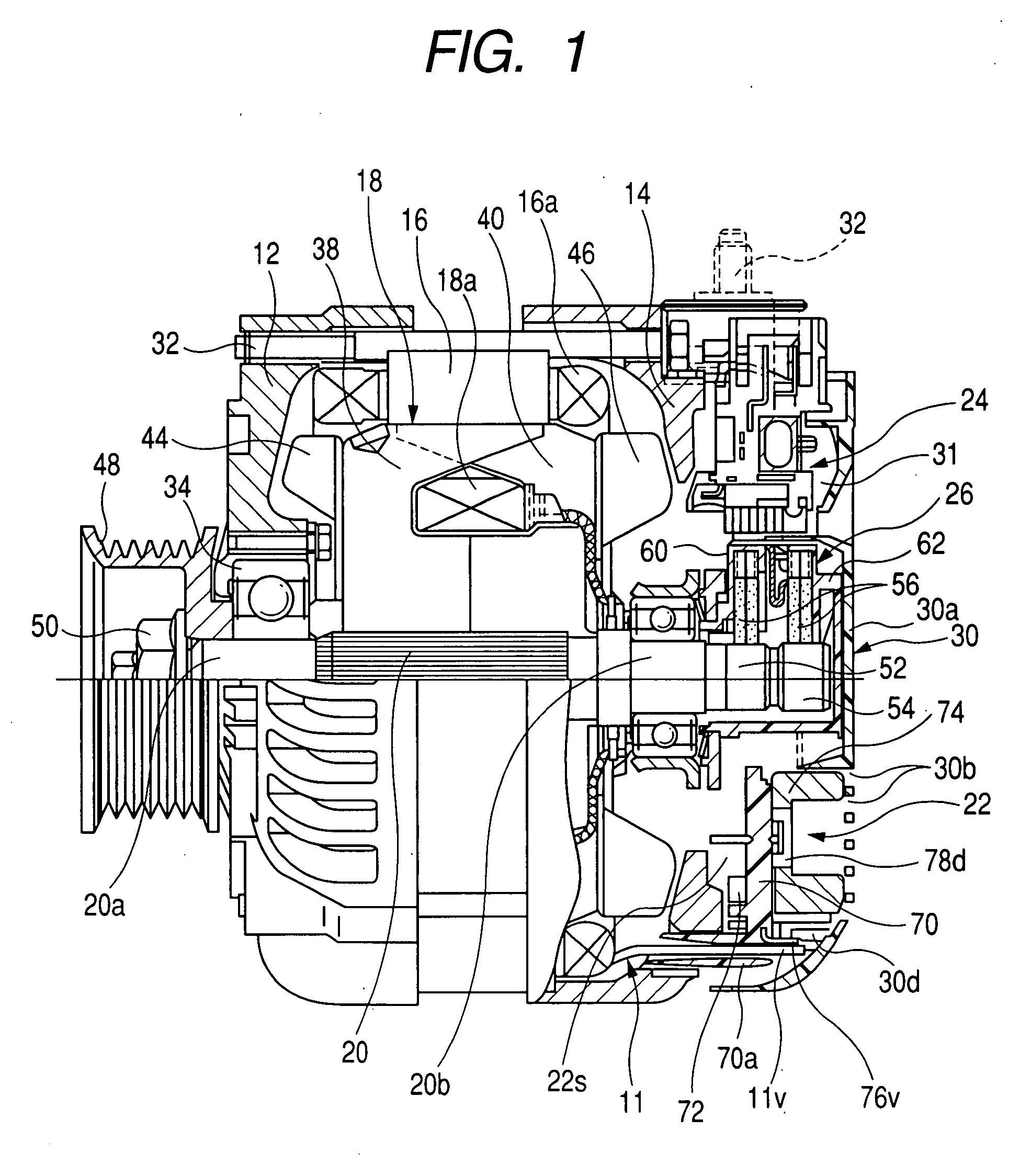

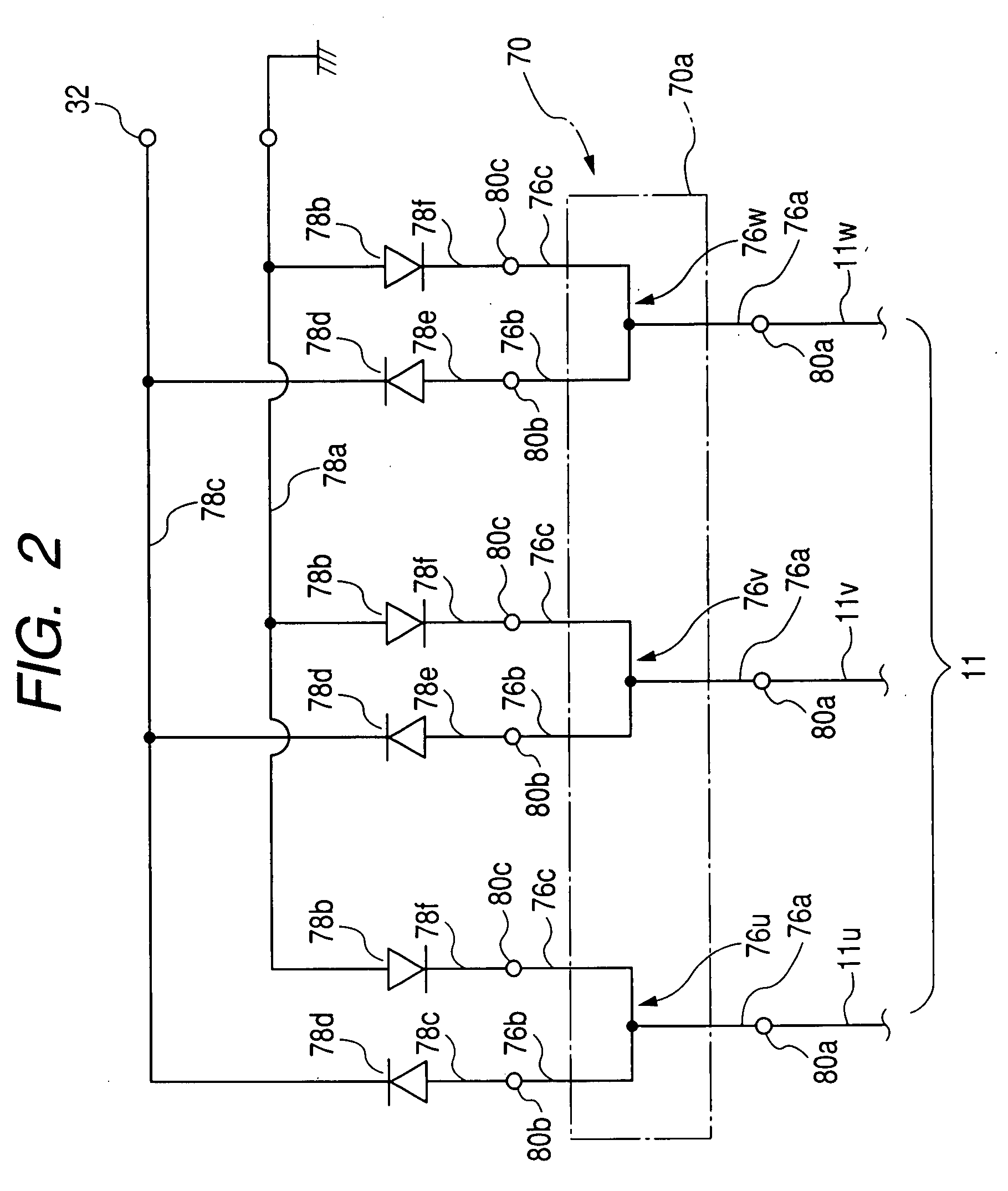

Electric drive apparatus

ActiveUS20110285223A1Small sizeReducing power source noiseSynchronous generatorsAssociation with control/drive circuitsRotational axisElectric drive

Two power modules, in which switching elements for switching over currents supplied to coils of a motor are resin-molded, are provided to face each other sandwiching a plane including a rotation axis of a shaft. A first smoothing capacitor, second smoothing capacitors and a choke coil are located between the power modules. By consolidating large-sized electronic parts between the power modules, a control unit can be reduced in size and impedance of electric conductor connecting the electronic parts and the power modules can be reduced.

Owner:DENSO CORP

Electric motor, in particular for raising and lowering disks in motor vehicles

Owner:ROBERT BOSCH GMBH

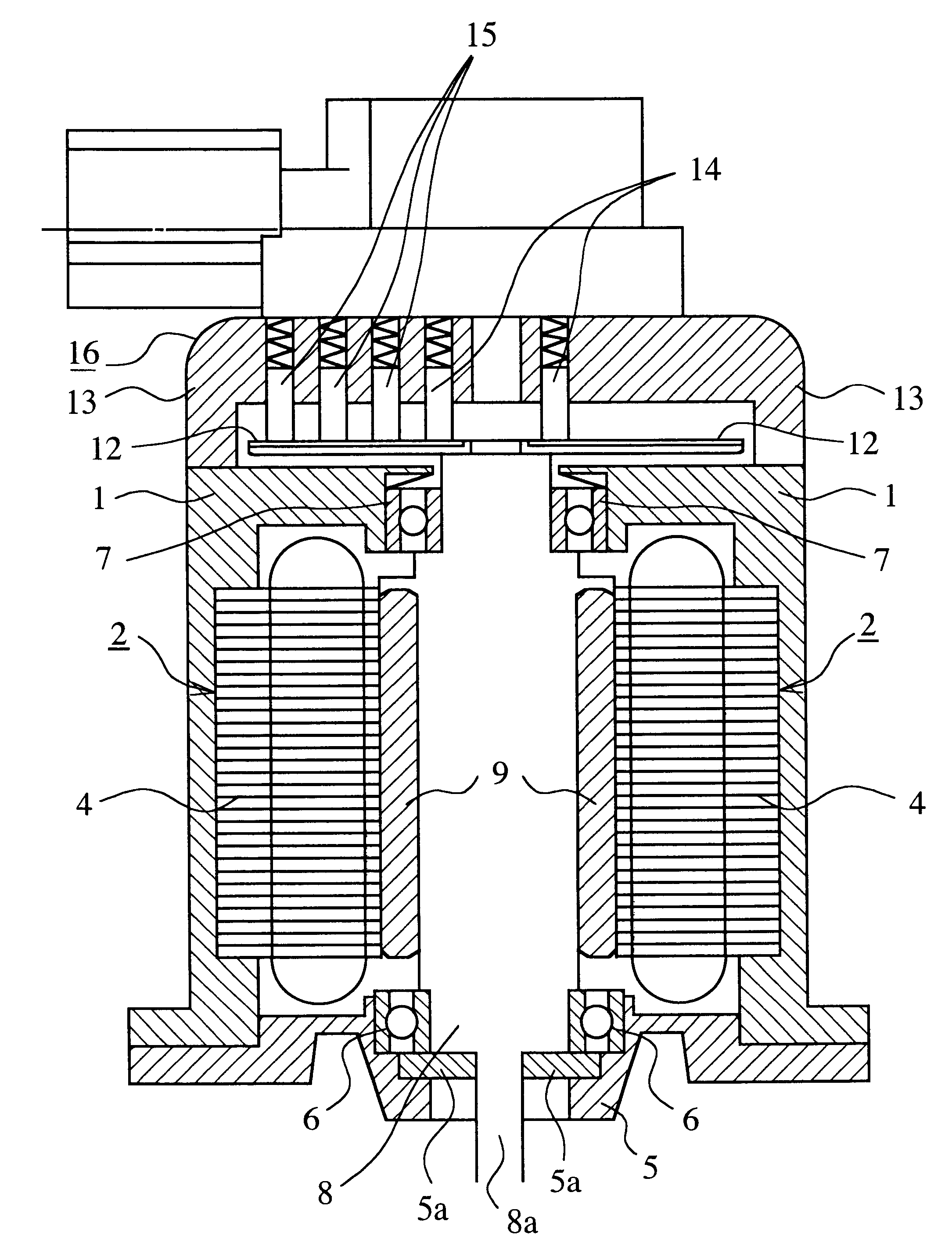

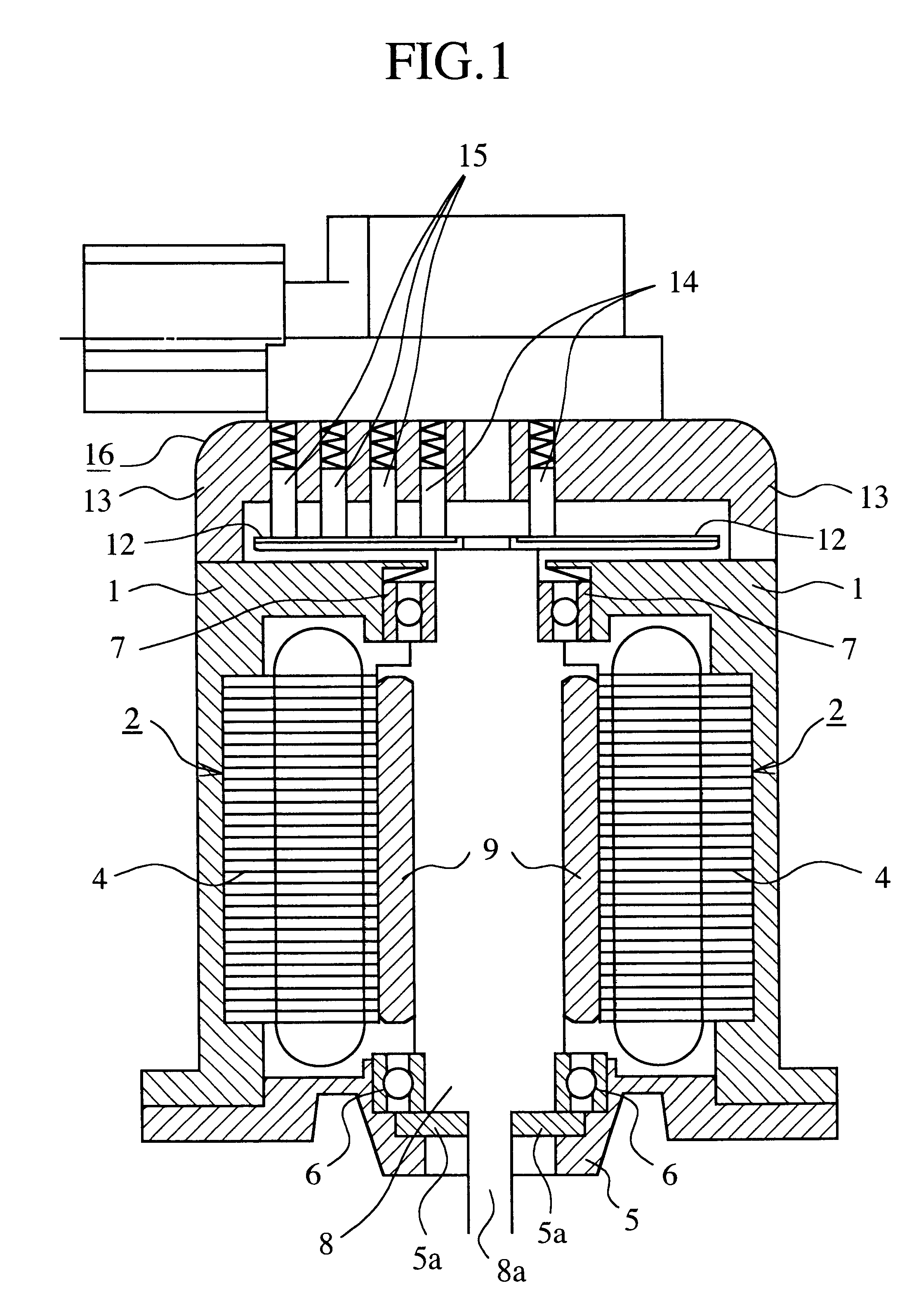

Integrated driving motor without position sensor

InactiveCN102307033AImprove efficiencyHighly integratedAssociation with control/drive circuitsMagnetic circuit rotating partsLow noiseElectric machine

The invention relates to the motor technology field, more particularly to an integrated driving motor without a position sensor. The driving motor is provided with a motor; and the motor is composed of a stator, an external rotor, a rotor spindle, and an end cover. The driving motor is characterized in that: a driver is arranged in the motor and is fixedly connected with the end cover; the end cover and the stator of the motor are mutually connected to form an integral body so as to strengthen heat radiation capability of a module; the driver is composed of a power plate and a control plate; the power plate is provided with a major loop, an inlet wire open-phase detection circuit, a bus current detection circuit, an under-voltage and over-voltage detection circuit, a counter-electromotive force detection circuit and a switch power supply circuit; and the control plate is provided with a DSP control system circuit and a communication module circuit. According to the invention, on the basis of the above-mentioned structure, the driving motor has advantages of compact structure, high-density power, high efficiency, low noise, high integrated level, and low cost and the like.

Owner:WEIHAI CREDITFAN VENTILATOR

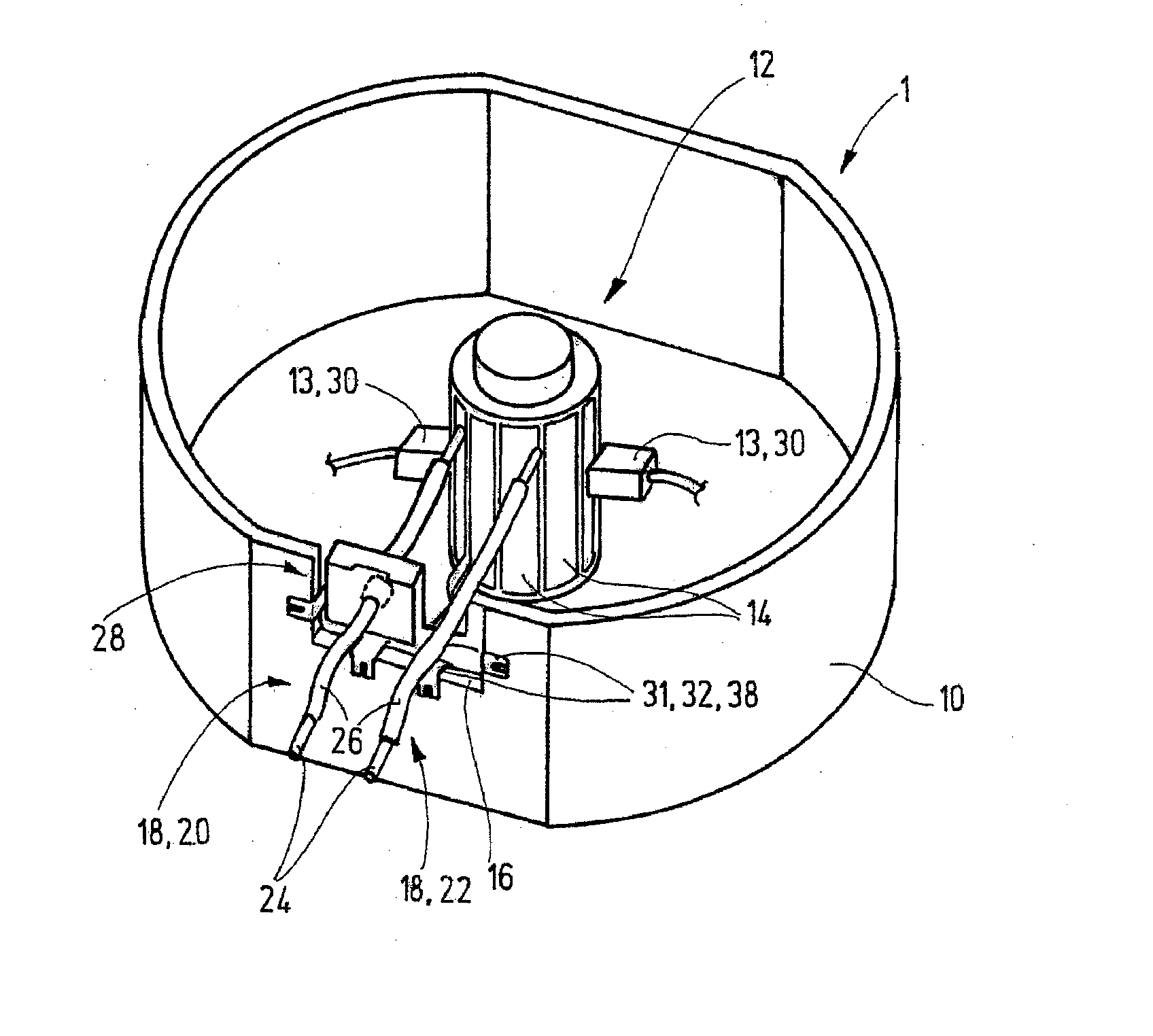

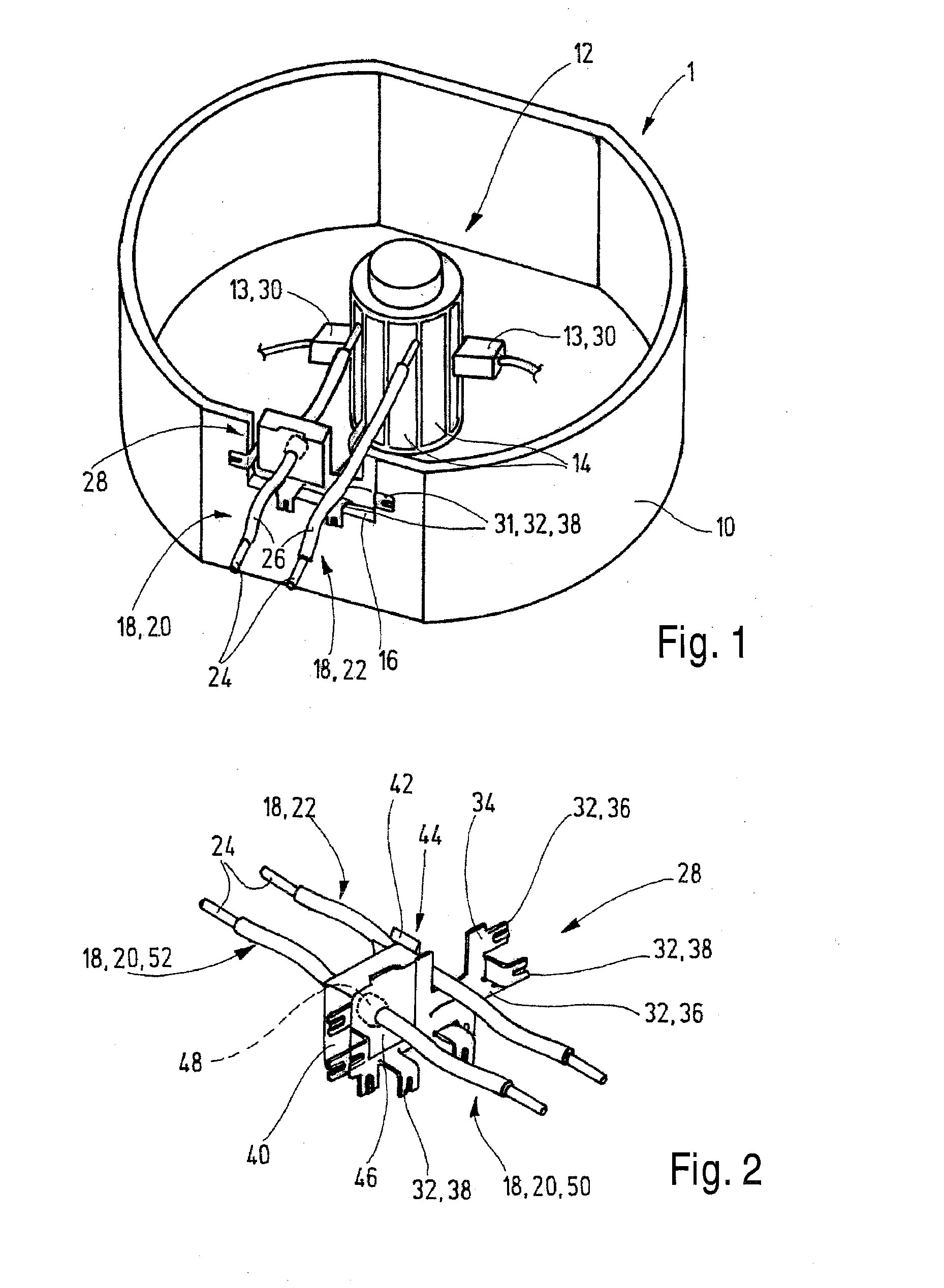

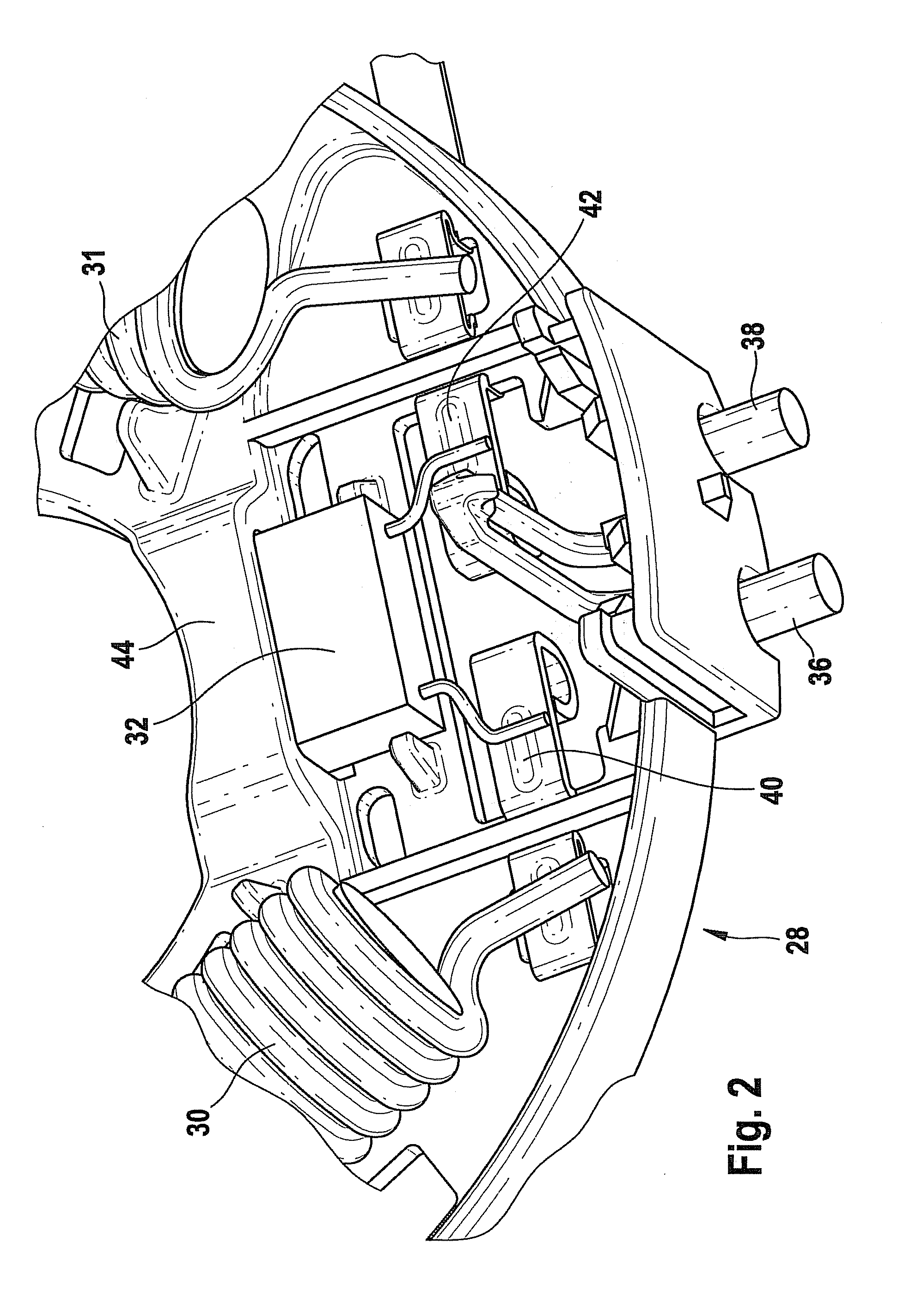

Electric drive

InactiveUS7898141B2Variety of tools andReliably producedRotary current collectorVehicle cleaningElectricityDrive shaft

An electric drive, in particular a wiper drive for vehicles, is proposed, with an electric driving motor in a motor housing (50), a brush holder (10) projecting into the motor housing (50), an anti-interference module (18) which is connected electrically and mechanically to the brush holder (10) and is intended for the electrical connection and interference protection of the motor, and with a gear mechanism (52) which is attached to the motor housing (50), at least partially accommodates the anti-interference module (18) and is designed in accordance with the predetermined position of the output shaft (53) with respect to the drive shaft (58). According to the invention, the diversity of components of the electric drive and therefore, in particular, the diversity of tools for producing the components are reduced by the anti-interference module (18) and the brush holder (10) being equipped with corresponding retaining means (40, 44) which permit the installation of a structurally identical anti-interference module (18) on the brush holder (10) in two installation positions rotated through 180°.

Owner:ROBERT BOSCH GMBH

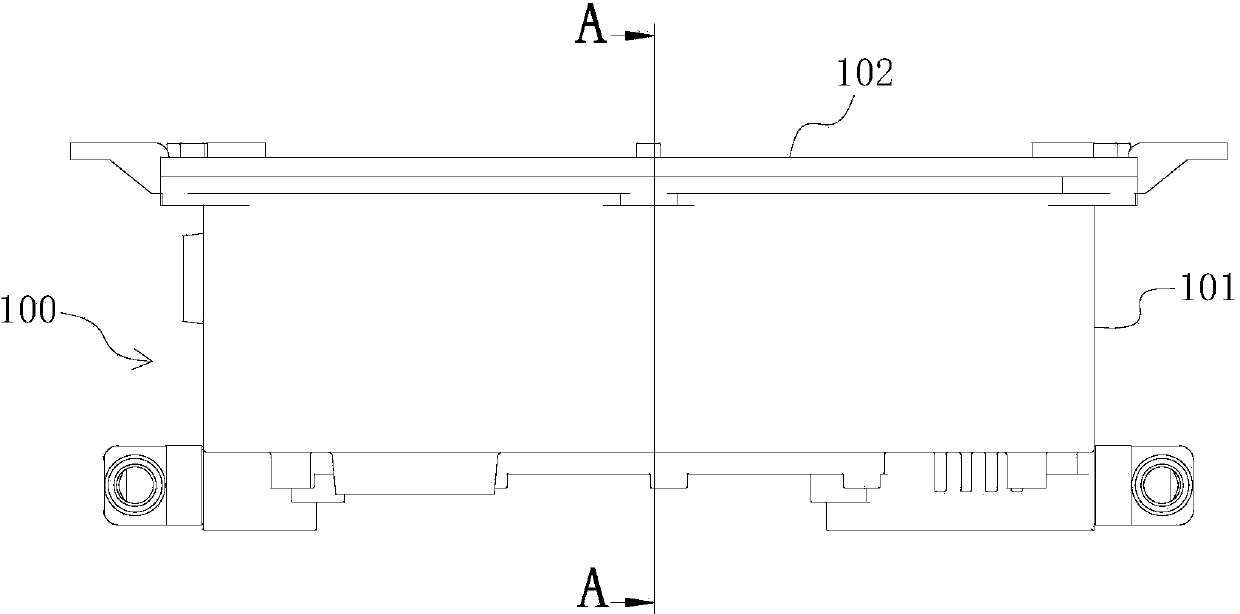

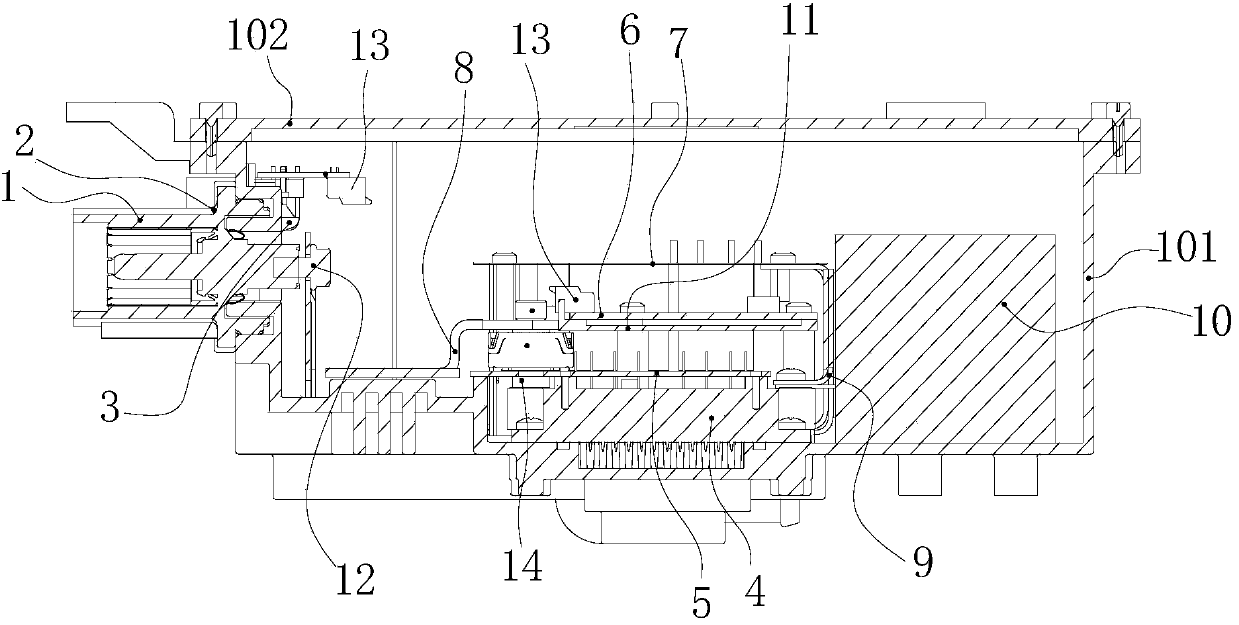

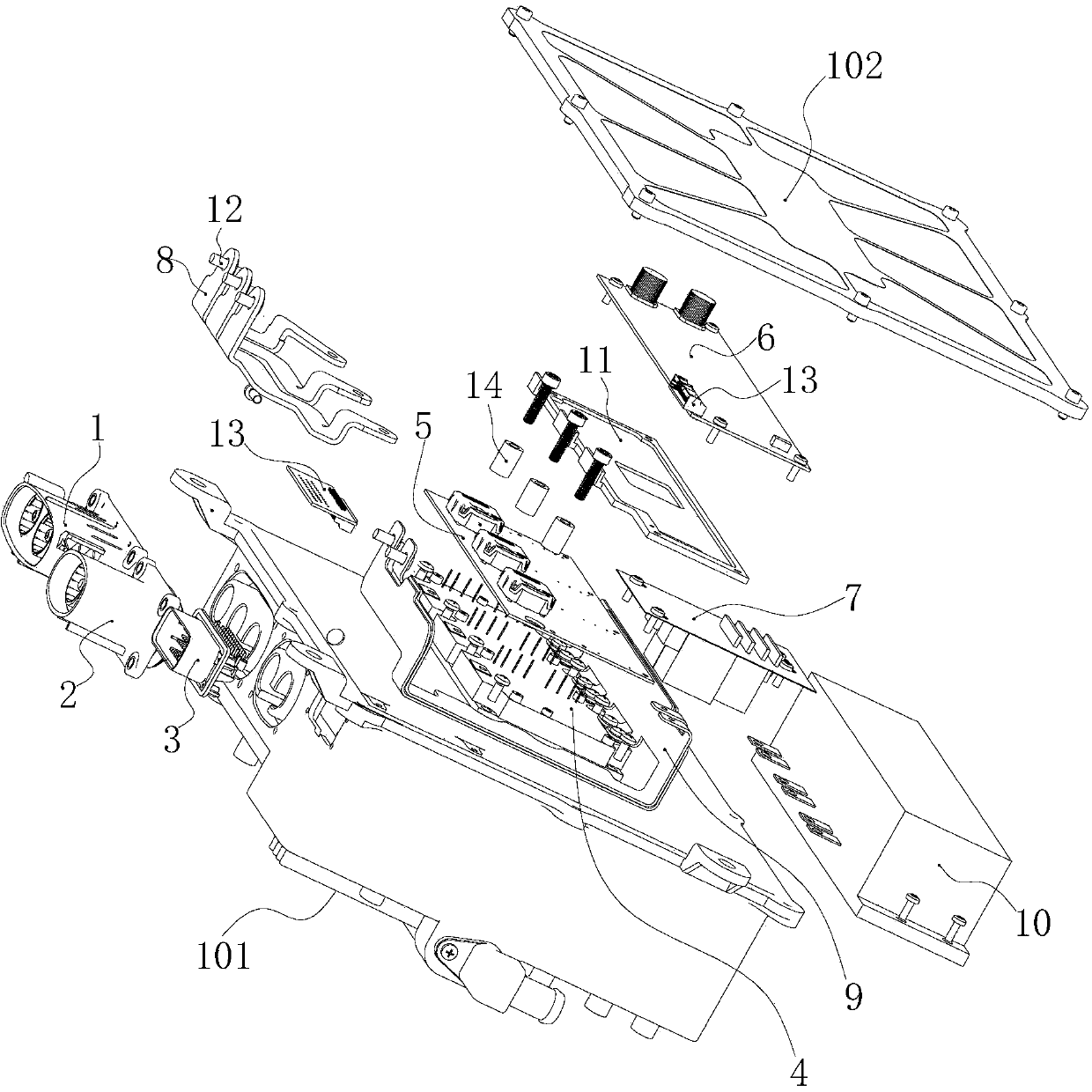

Pmdc motor

A PMDC motor, particularly for driving an automobile liftgate, comprises a stator and a rotor rotatably mounted to the stator. The stator comprises a housing and an end cap mounted to one end of the housing. The end cap comprises: a first brush, a second brush, a first terminal, a second terminal, a first choke connected in series with the first brush and the first terminal, a second choke connected in series with the second brush and the second terminal, an overcurrent protection component connected in series with the second brush, and a set of capacitors. Each of the chokes comprises an inductor core extending axially and a winding wound about the inductor core.

Owner:JOHNSON ELECTRIC SA

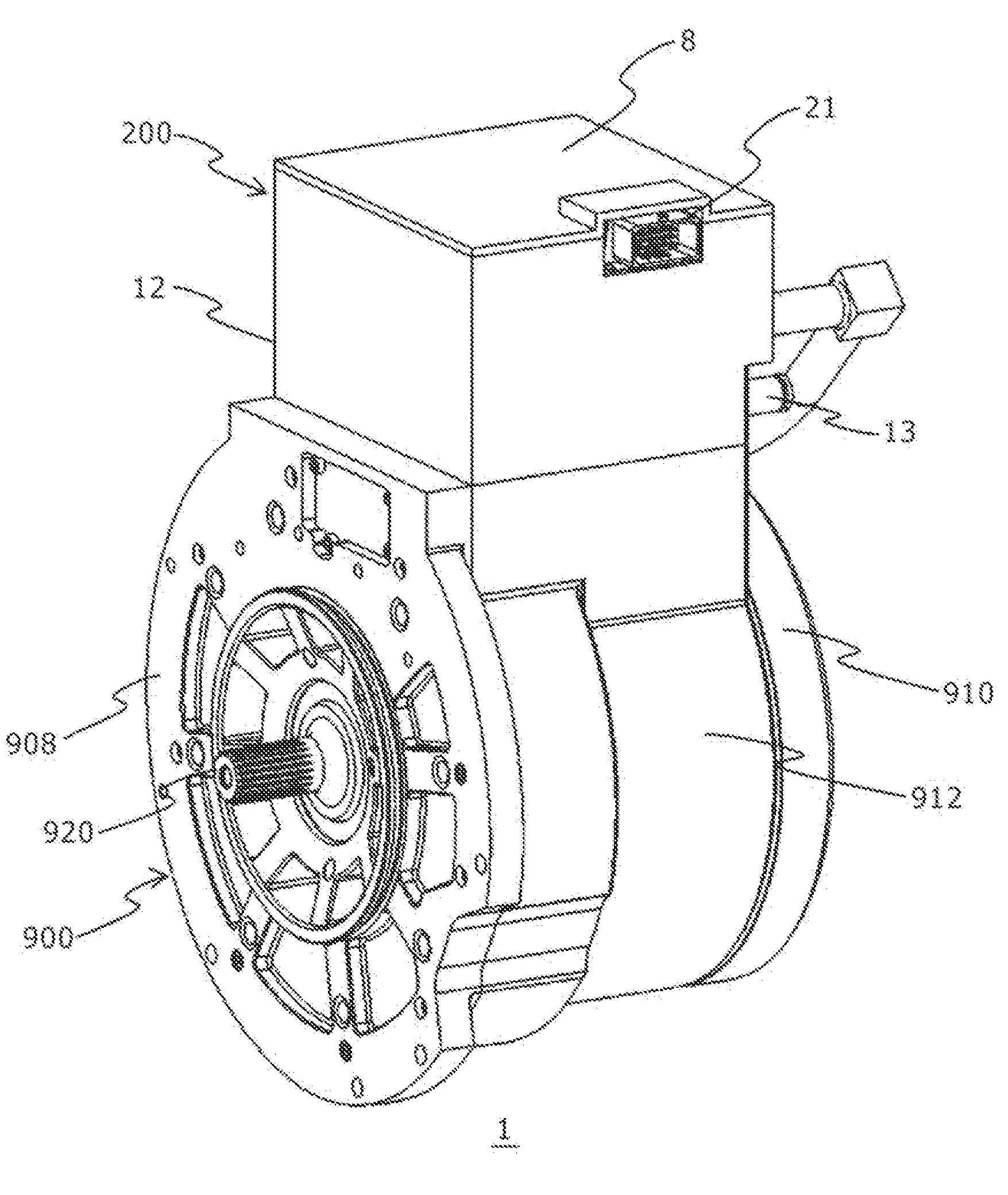

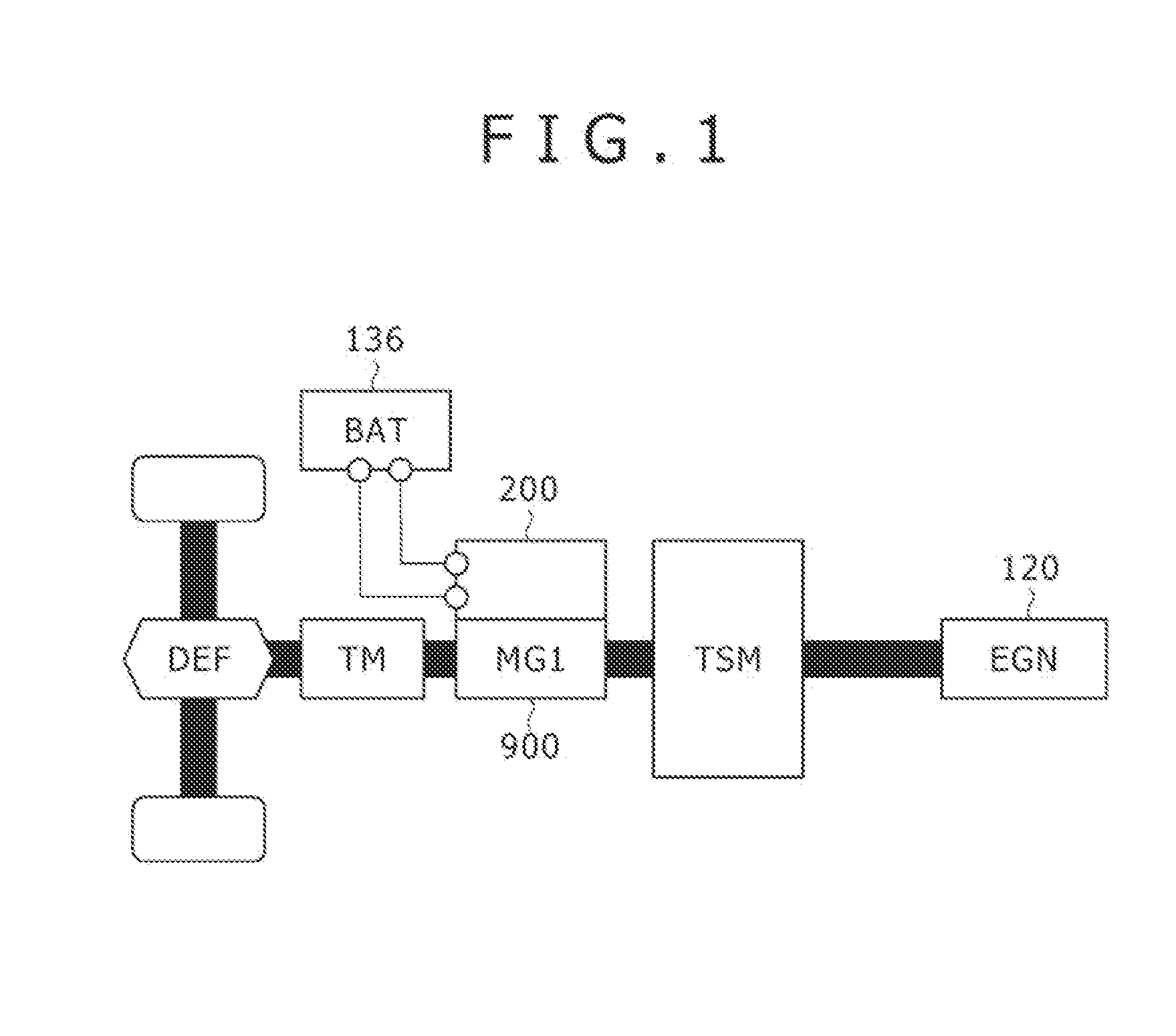

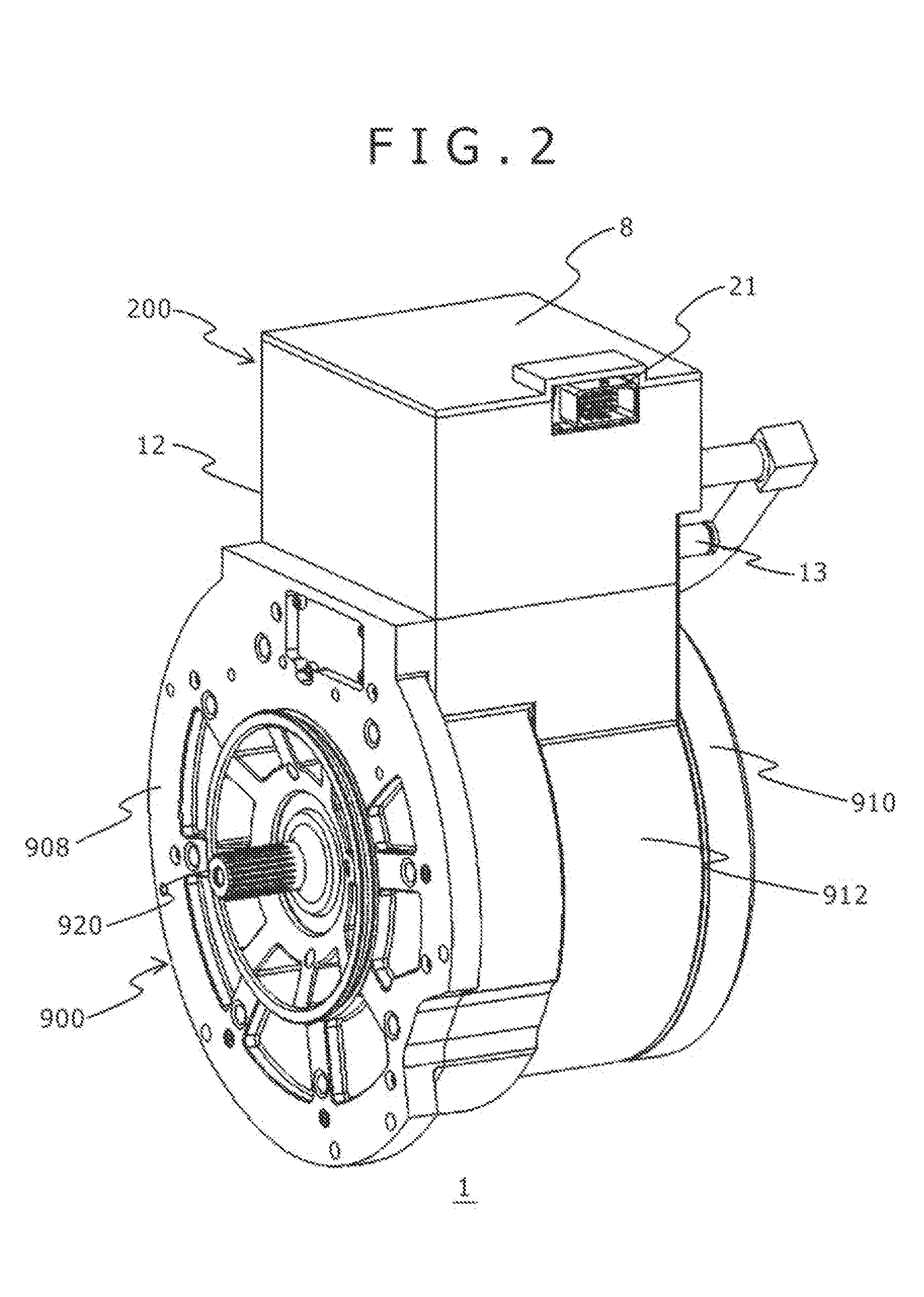

Mechanical-Electrical Integrated Electric Drive System

InactiveUS20140306563A1Inhibit bad effectsAssociation with control/drive circuitsAssociation with grounding devicesCapacitanceElectricity

Disclosed is a mechanical-electrical integrated electric drive system capable of returning common mode current from a rotary electric machine's side to a virtual neutral point of a power-conversion device inside the electric drive system, where the system comprises a rotary electric machine that includes a rotor, a stator having a stator core including armature windings, and a housing holding the stator and having AC terminals of the armature windings arranged thereon; a power conversion device that is fixed to the periphery of the housing and includes an inverter circuit and AC bus bars connecting the inverter circuit with the AC terminals; conductor rings that are arranged in contact with the stator core to collect common mode current deriving from stray capacitance of the stator; and a connection wire that connects the conductor bar to a virtual neutral point on the DC input side of the inverter circuit.

Owner:HITACHI AUTOMOTIVE SYST LTD

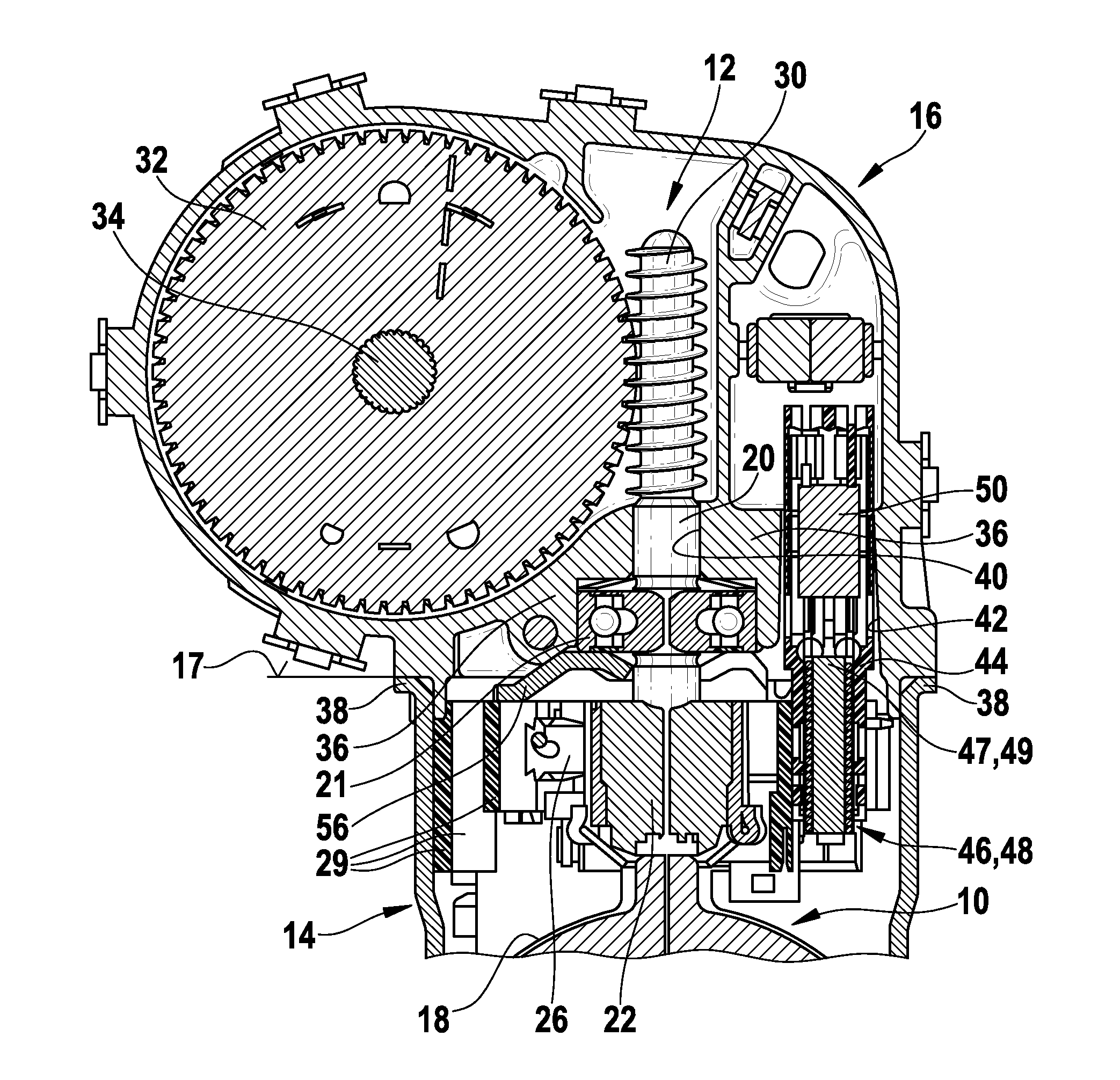

Electric drive

InactiveUS8026645B2Good interference suppression effectVehicle cleaningDC commutatorElectricityEngineering

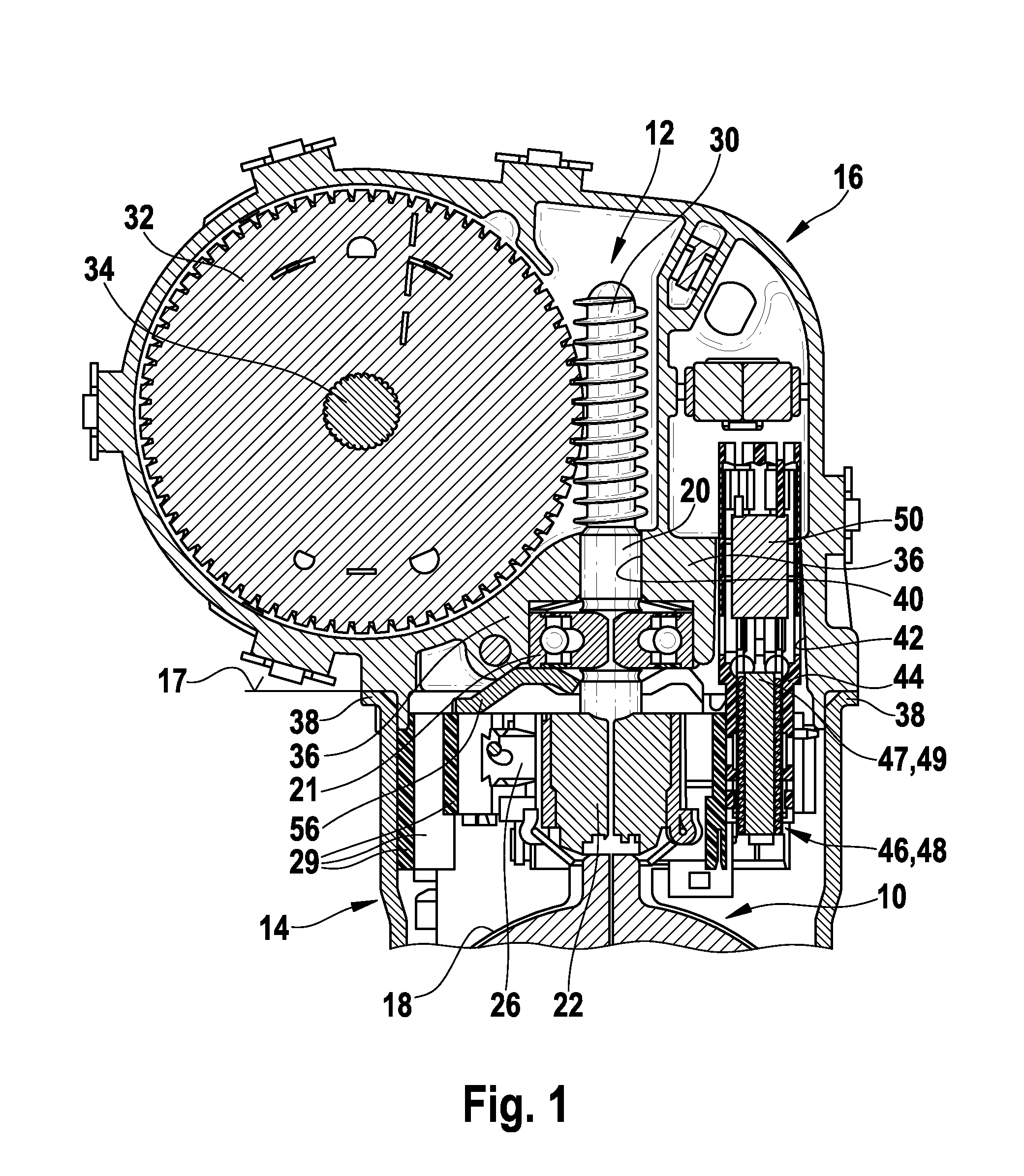

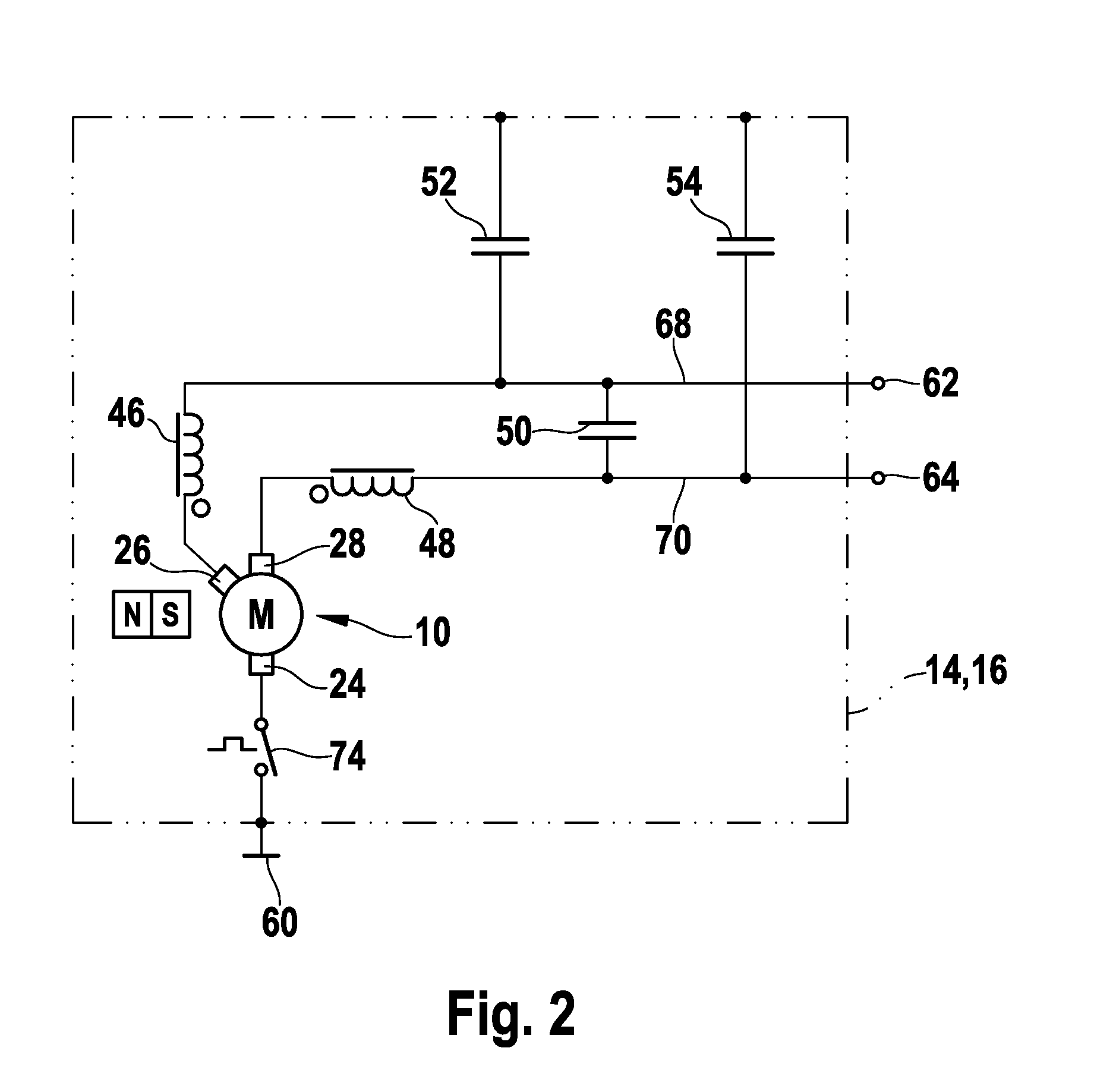

The invention relates to an electric drive, particularly a windshield wiper drive for vehicles, comprising an electric motor (10) in a crucible-shaped, preferably metal, motor housing (14), a gearbox housing (16) that is attached to the motor housing (14), and an arrangement for the interference suppression of the motor (10). According to the invention, at least one choke coil (46, 48) for the interference suppression of the motor (10) is disposed in the transition region from the motor housing (14) to the gearbox housing (16), wherein in this transition region means (36, 56) are provided in order to shield the filtered coil end (47, 49) projecting into the gearbox housing (16) from the interfering radiation produced by the motor (10).

Owner:ROBERT BOSCH GMBH

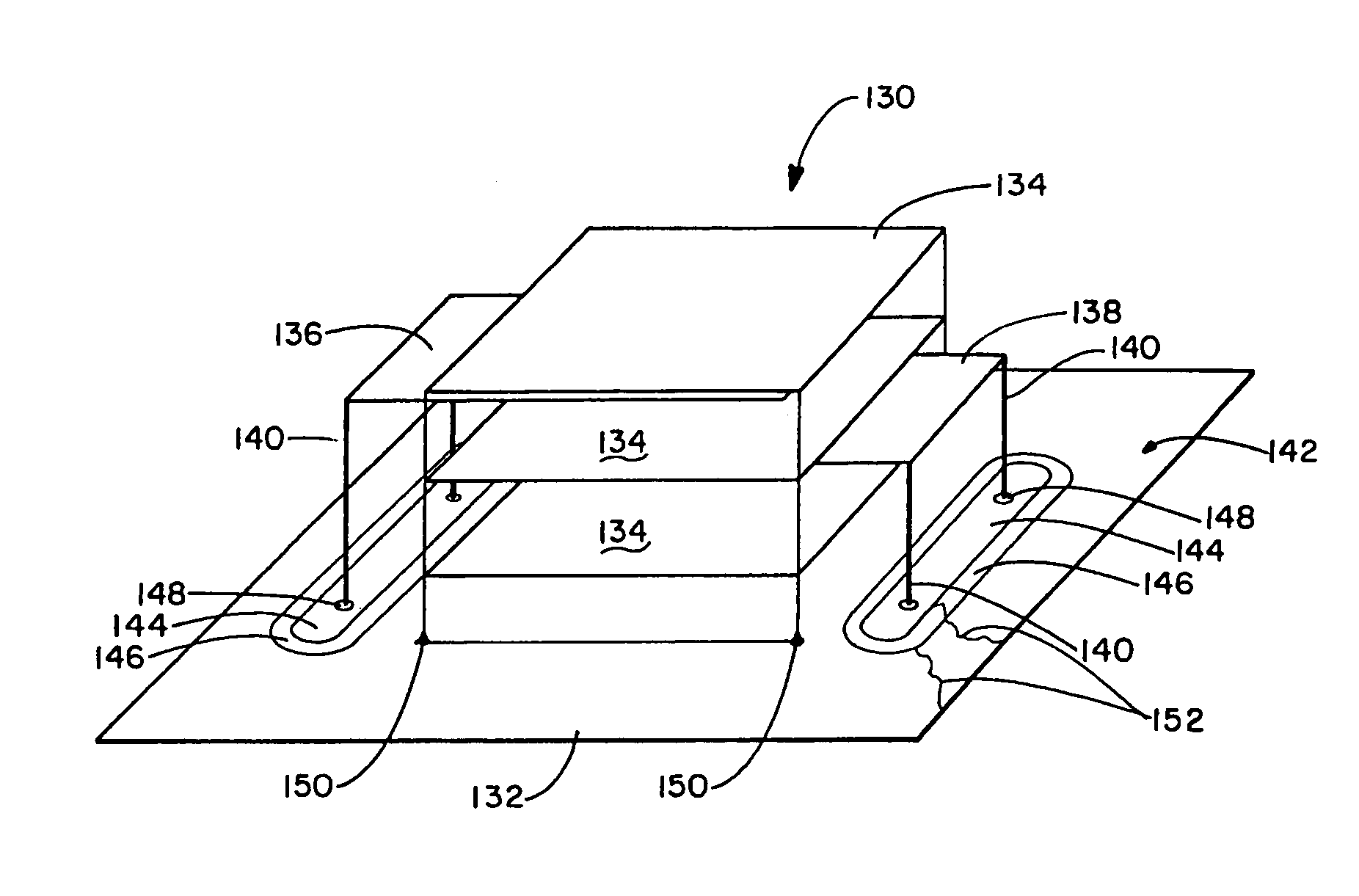

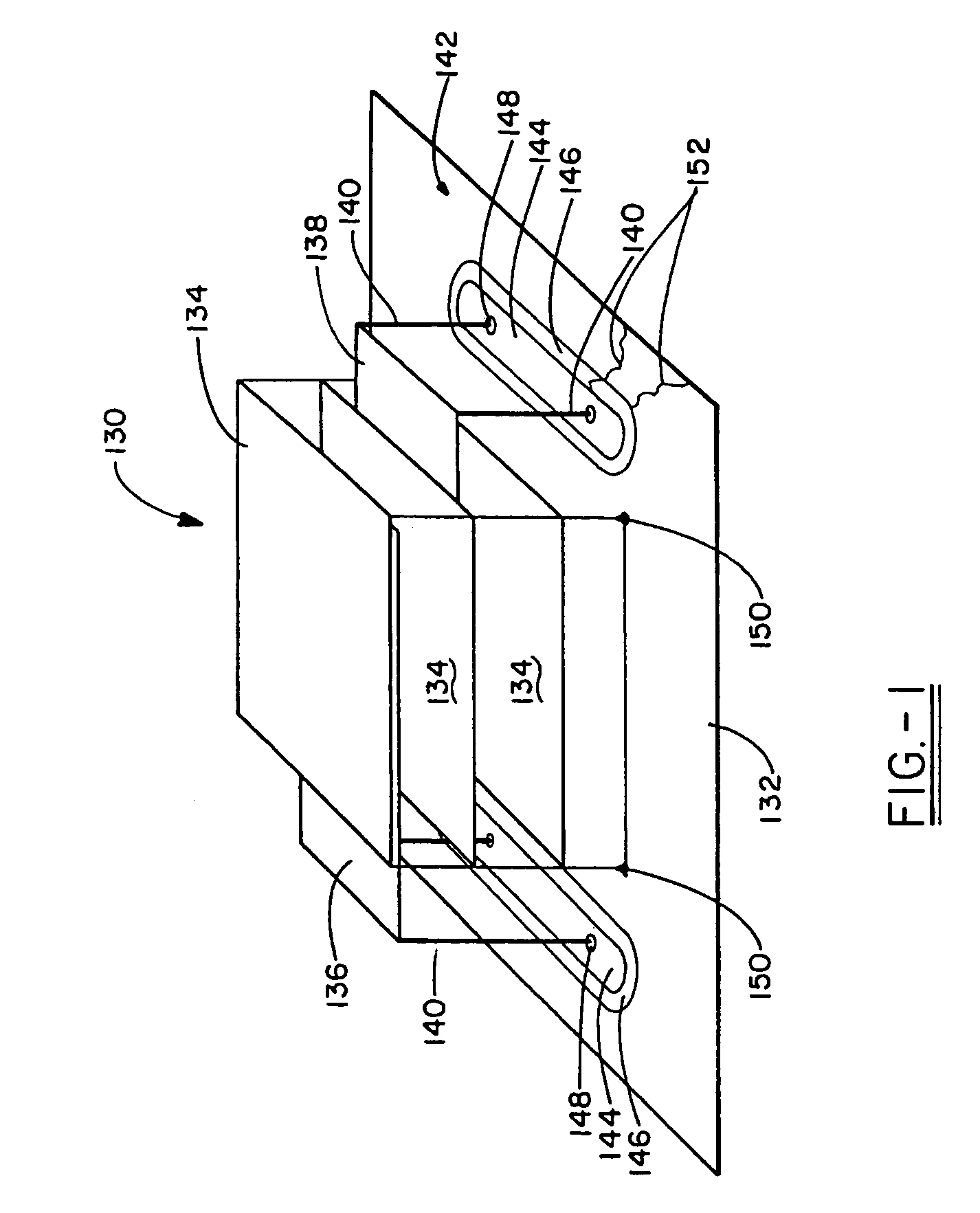

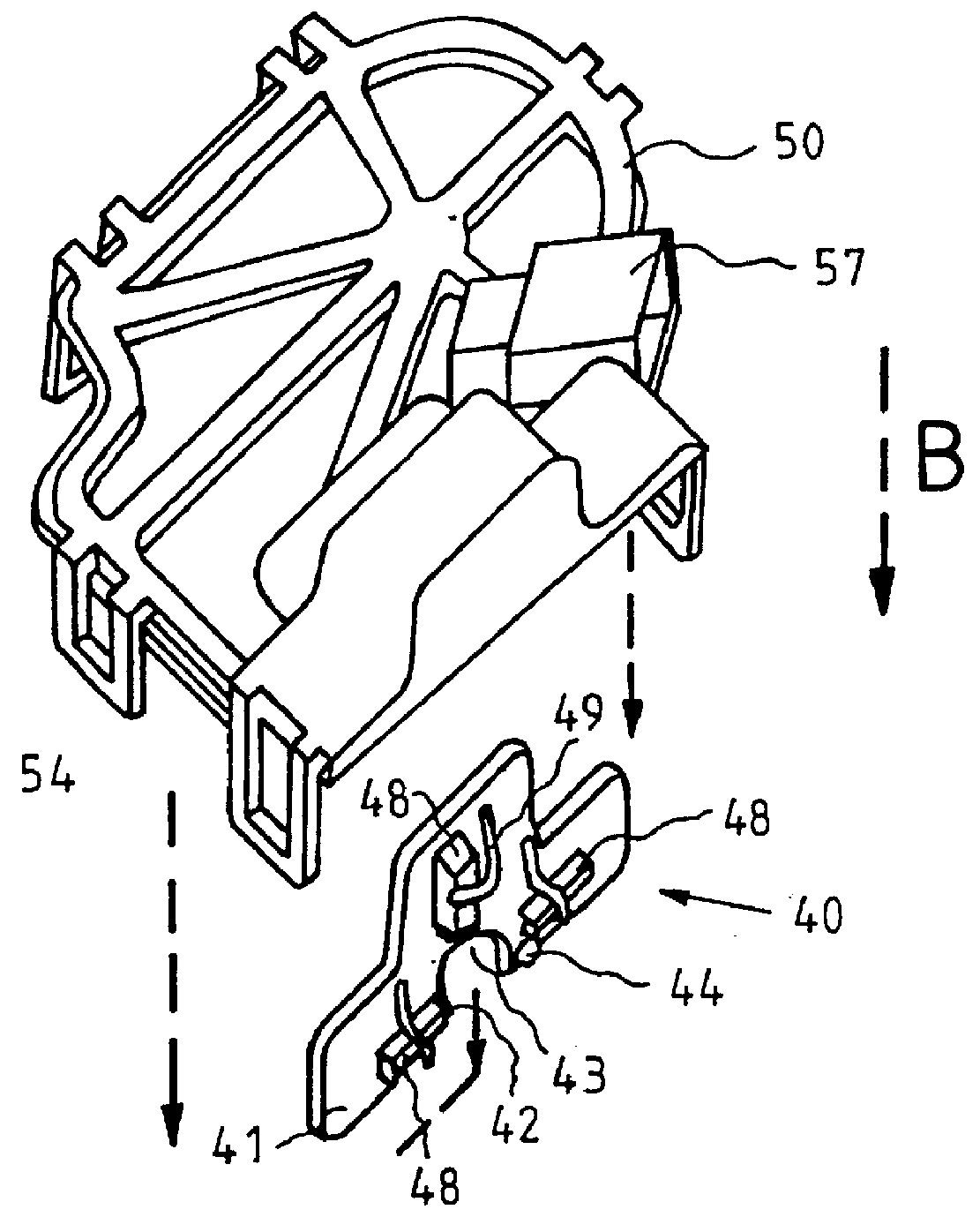

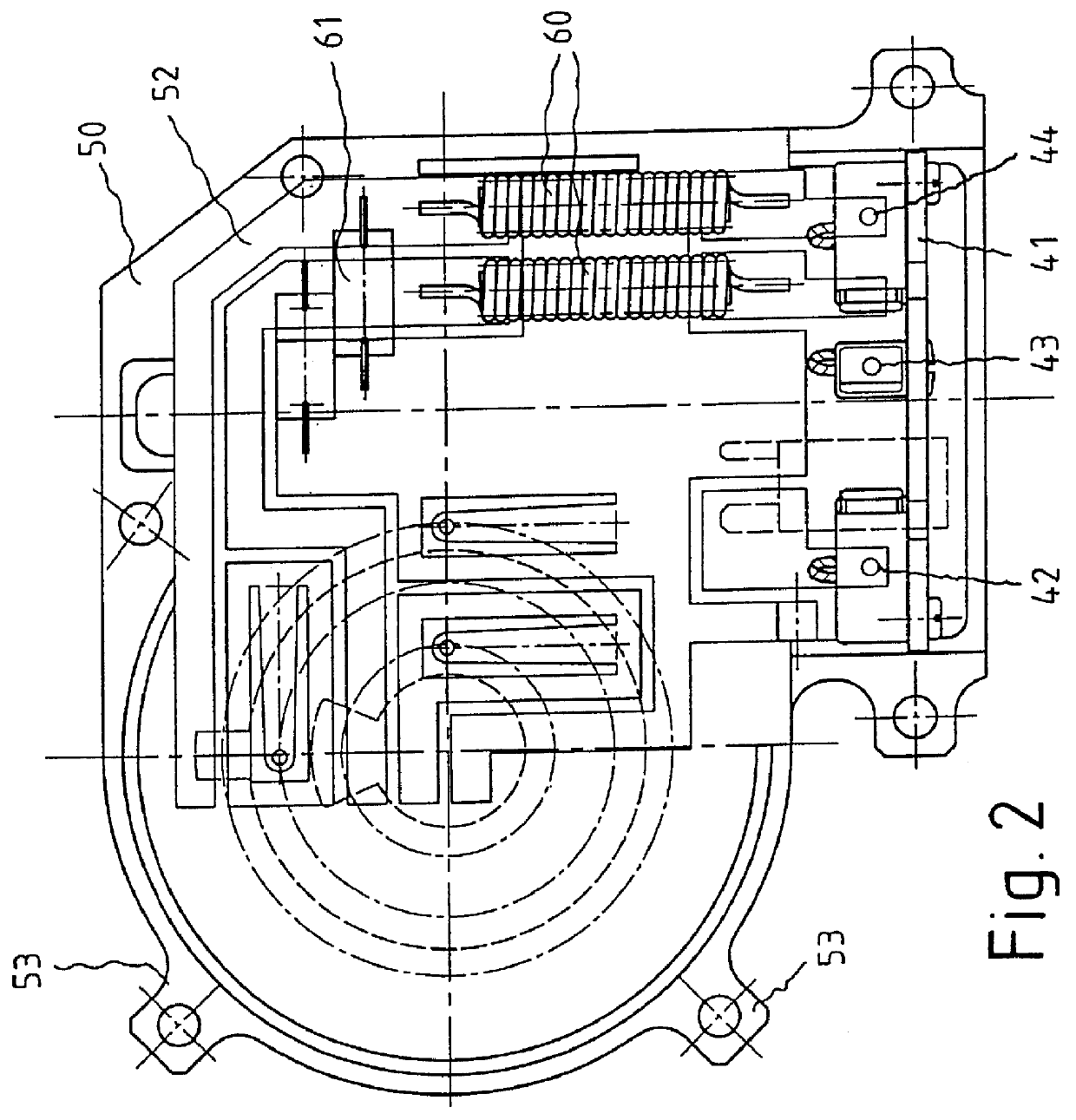

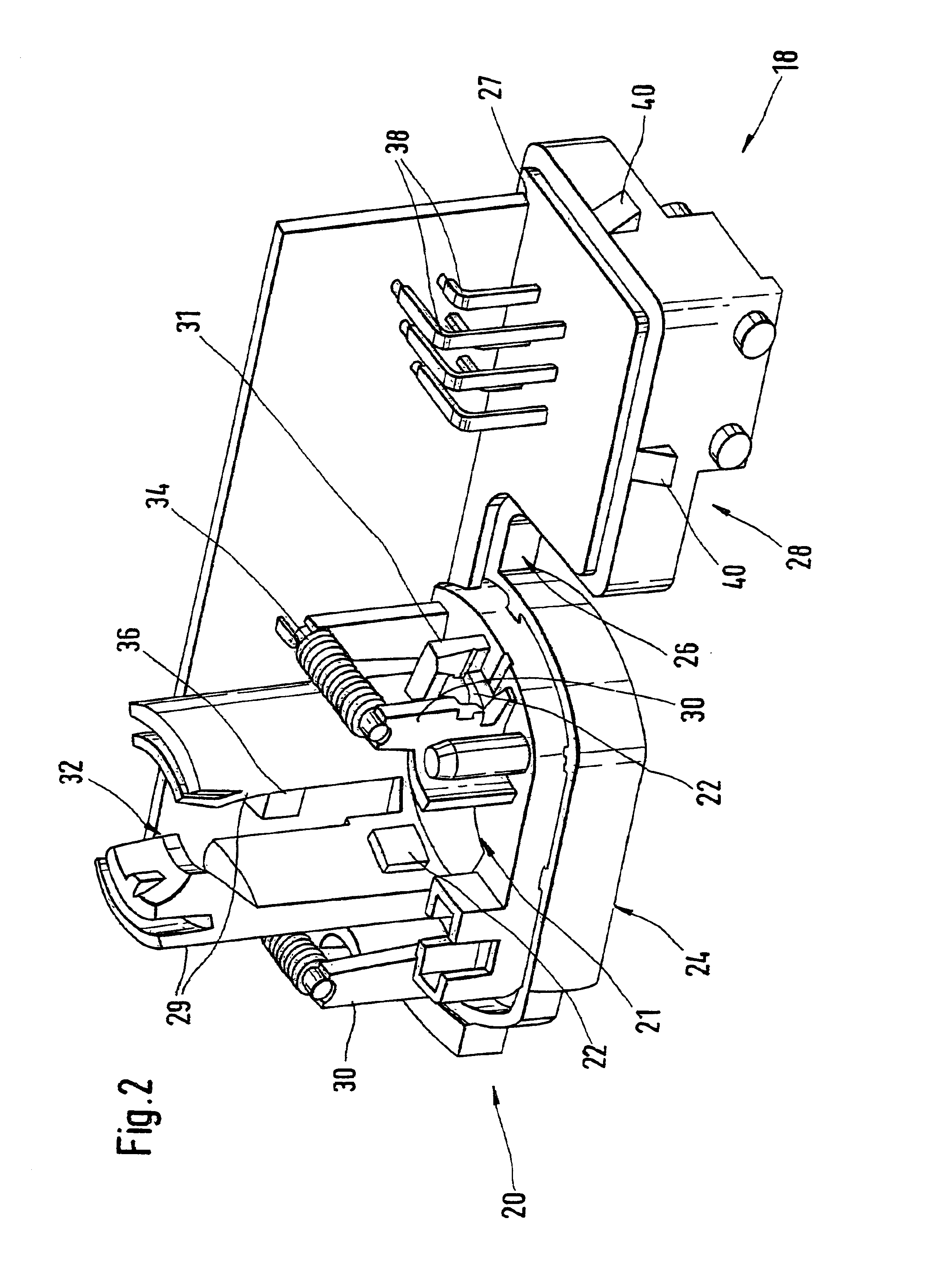

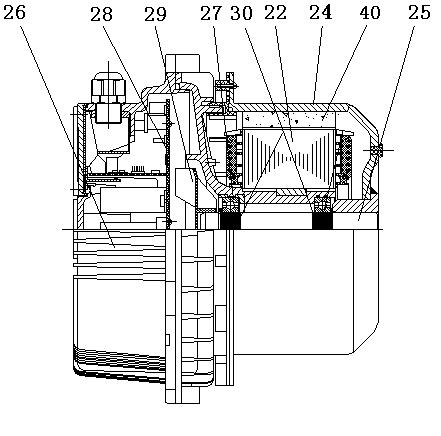

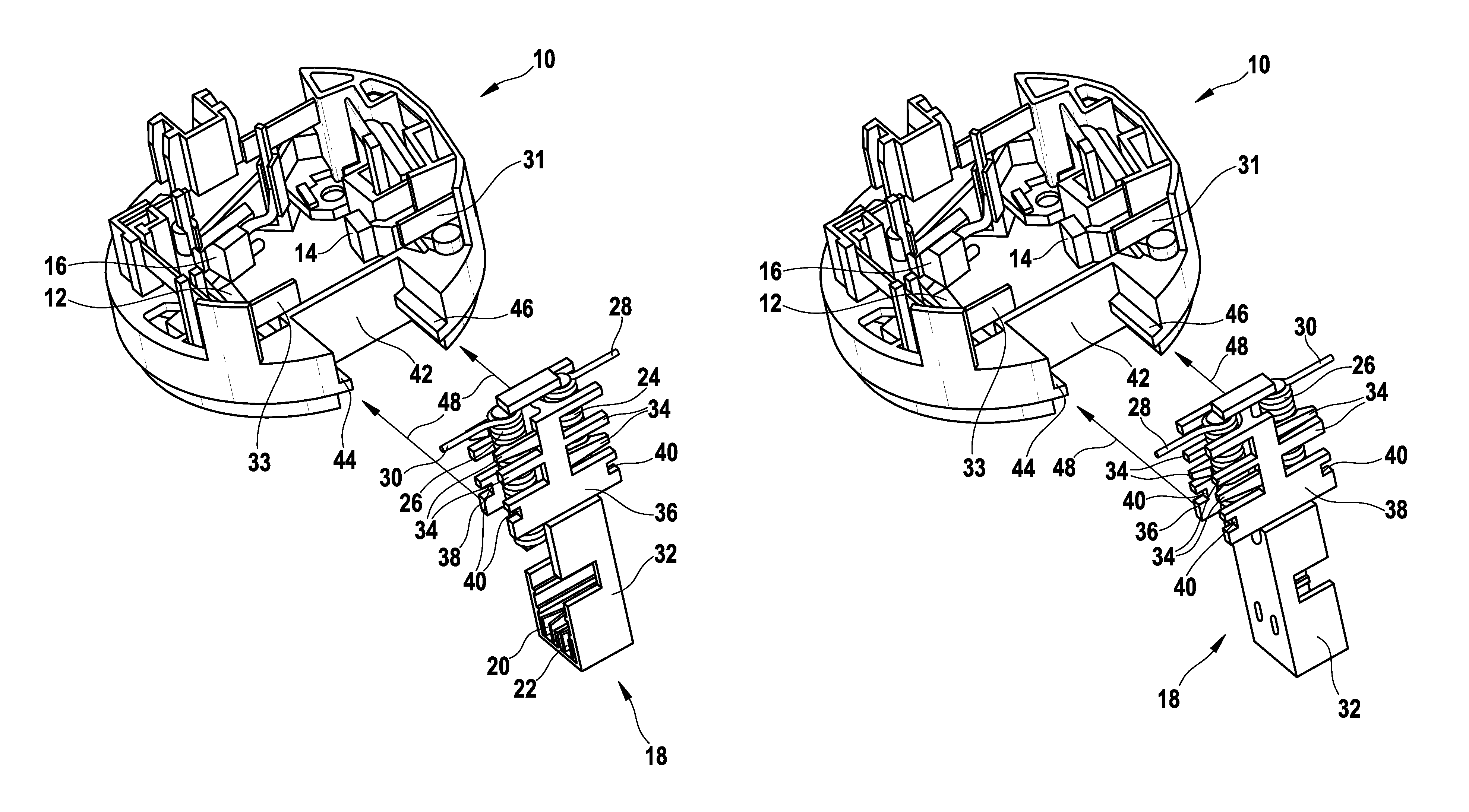

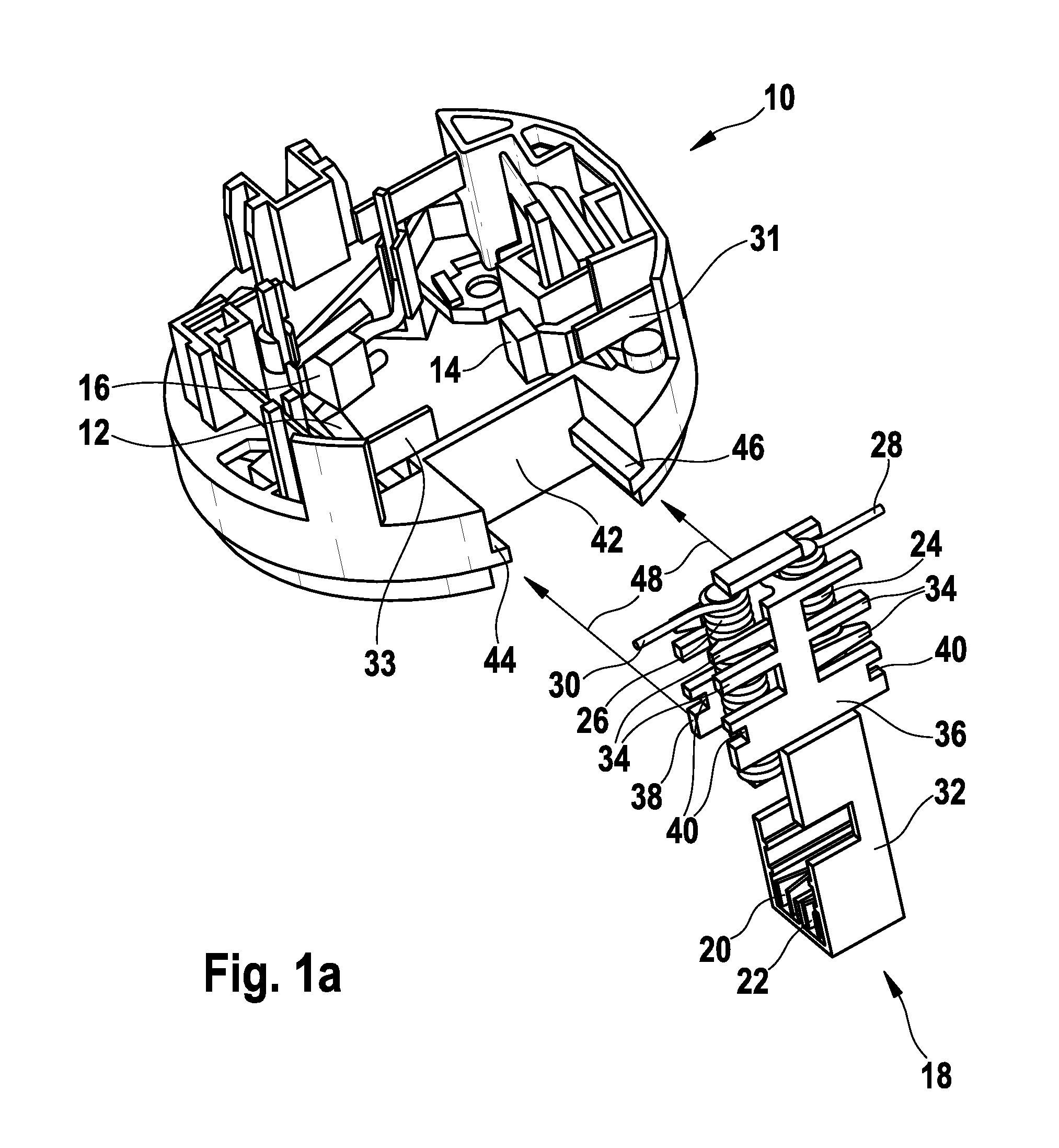

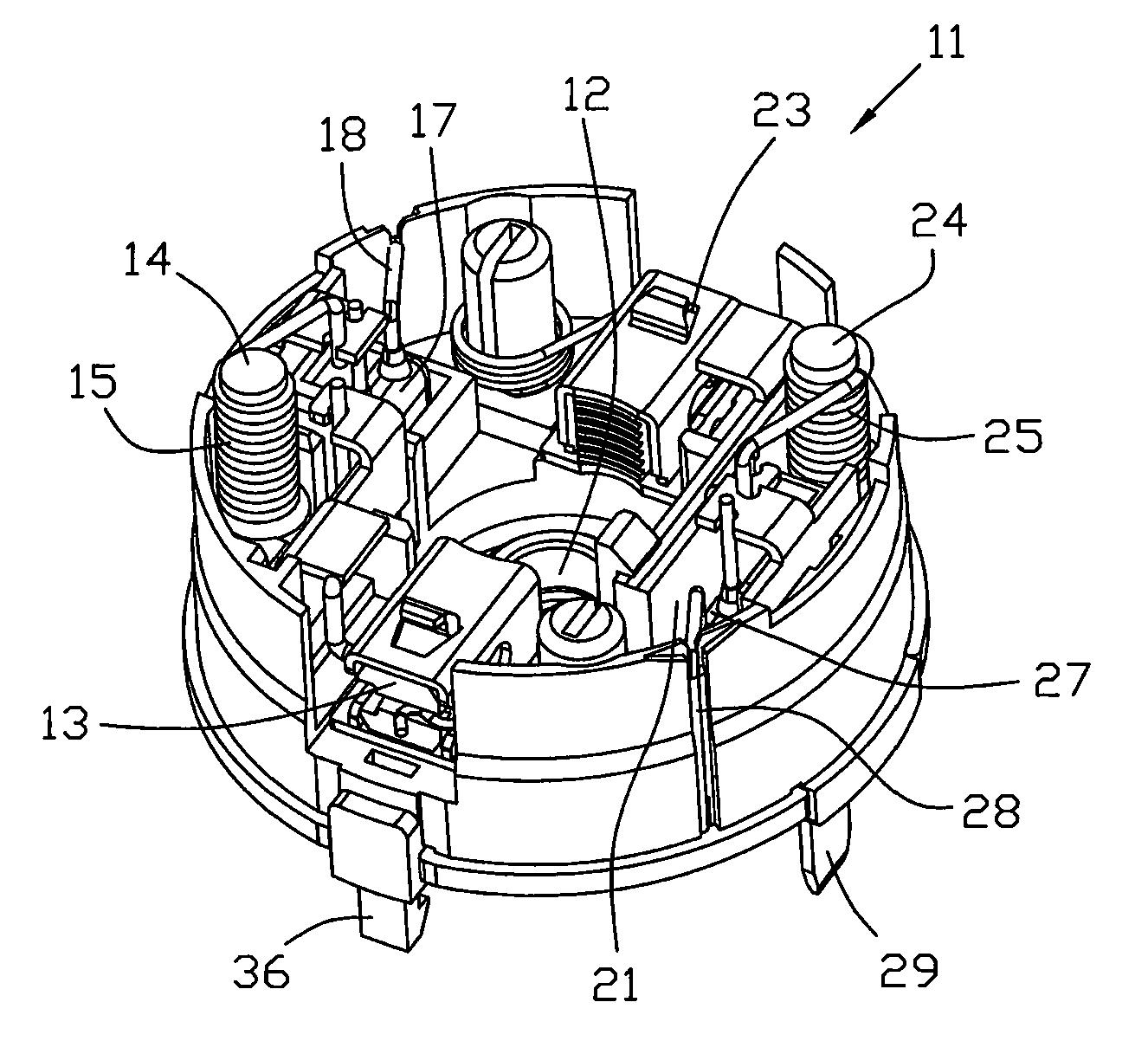

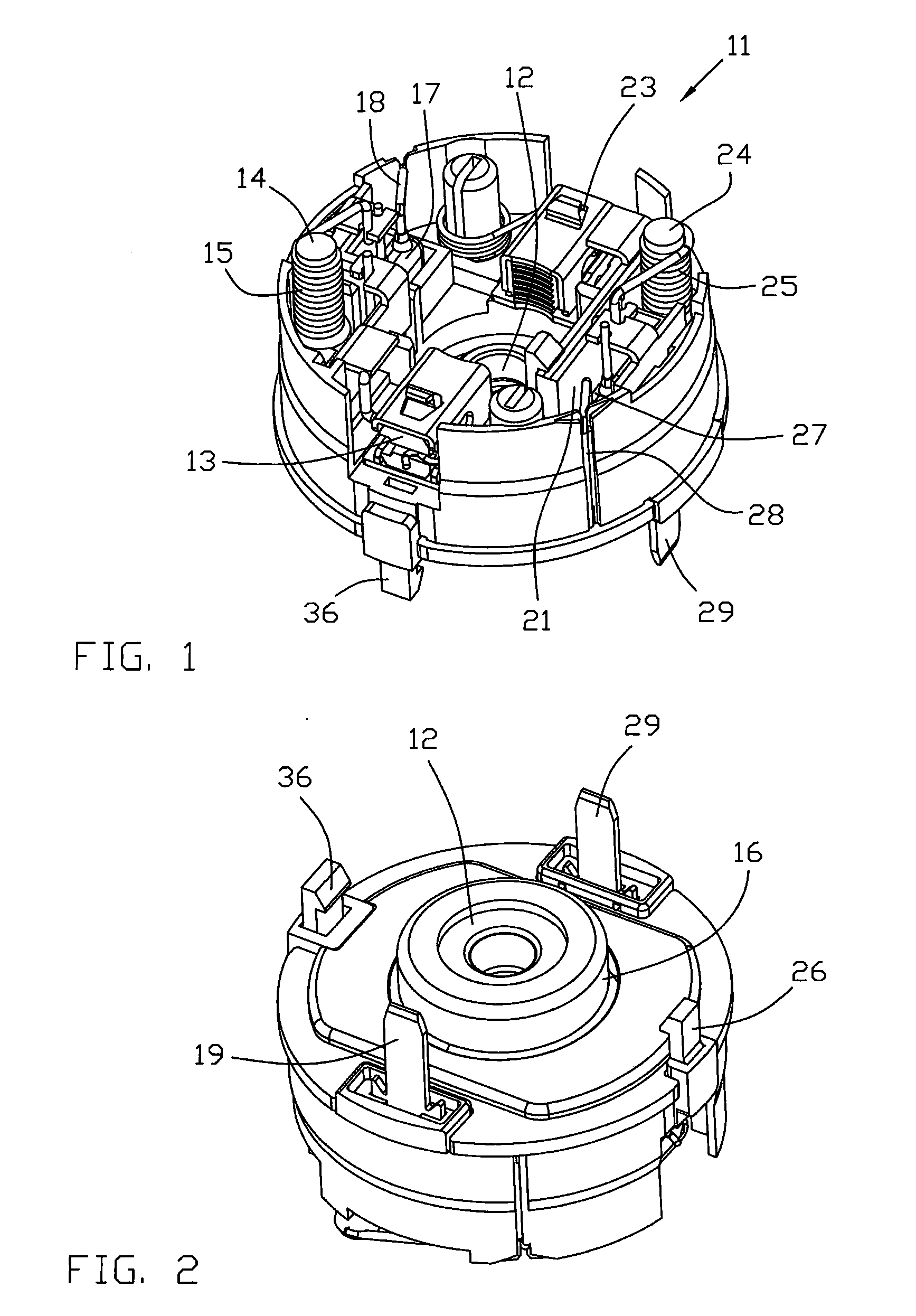

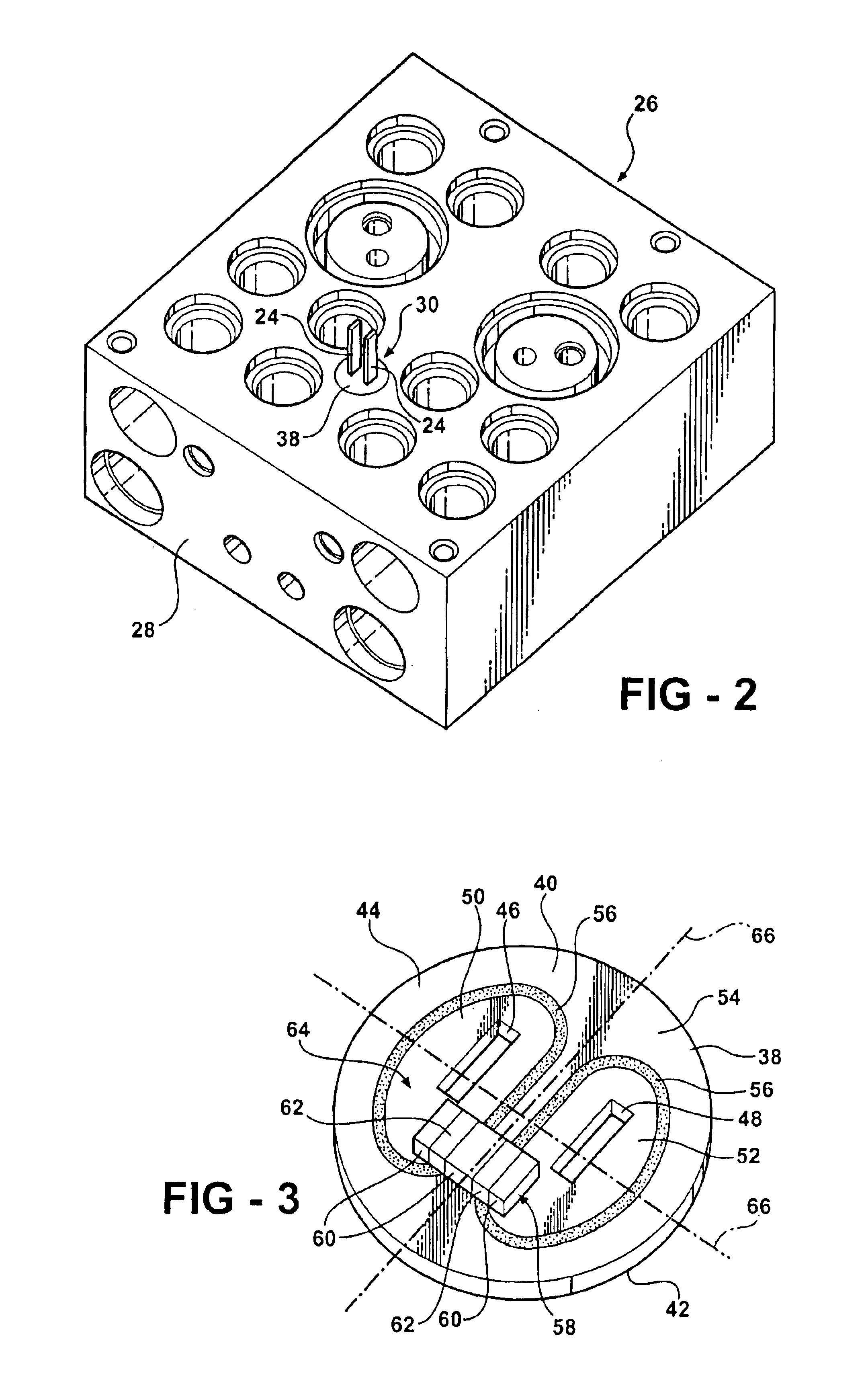

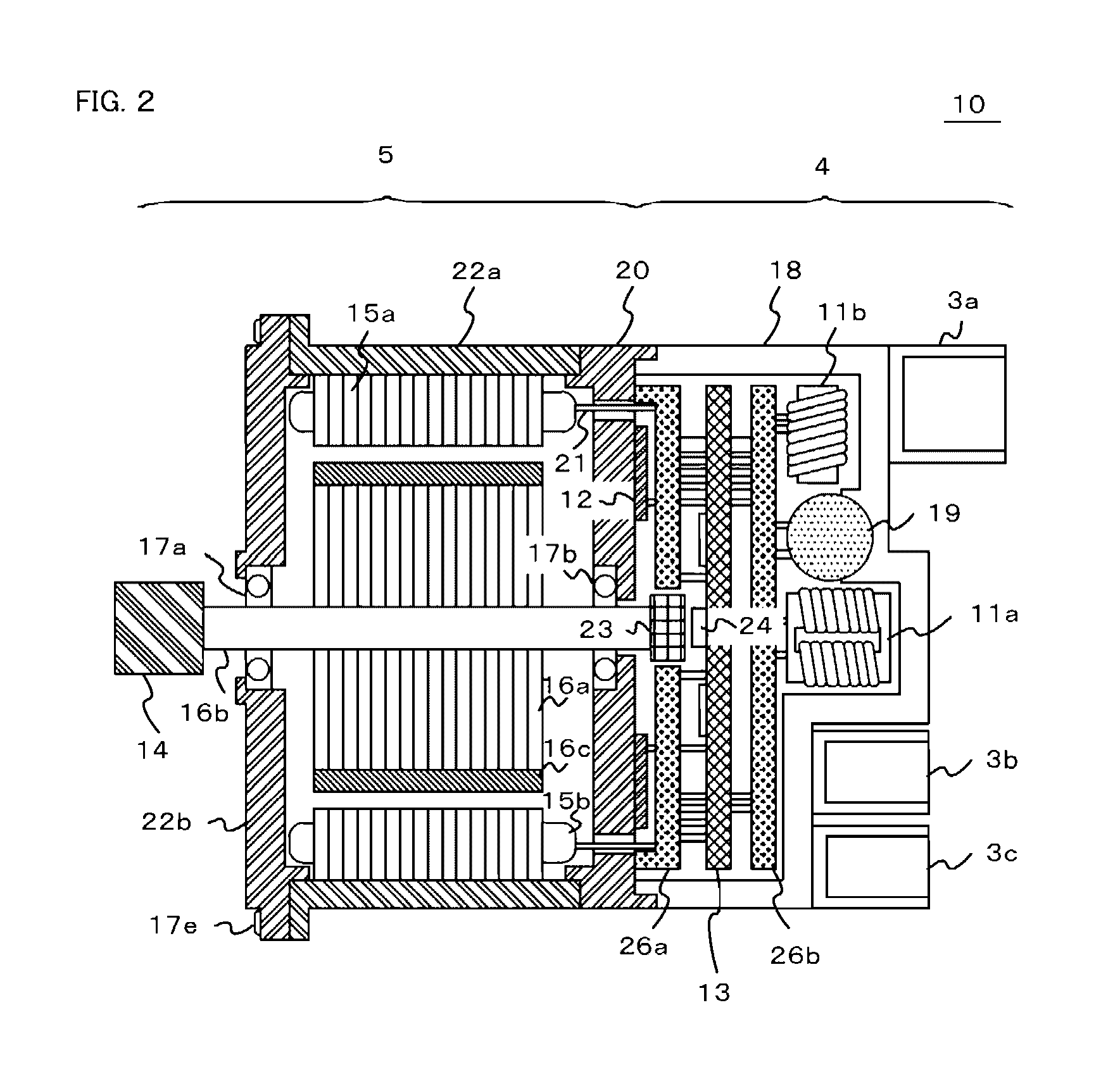

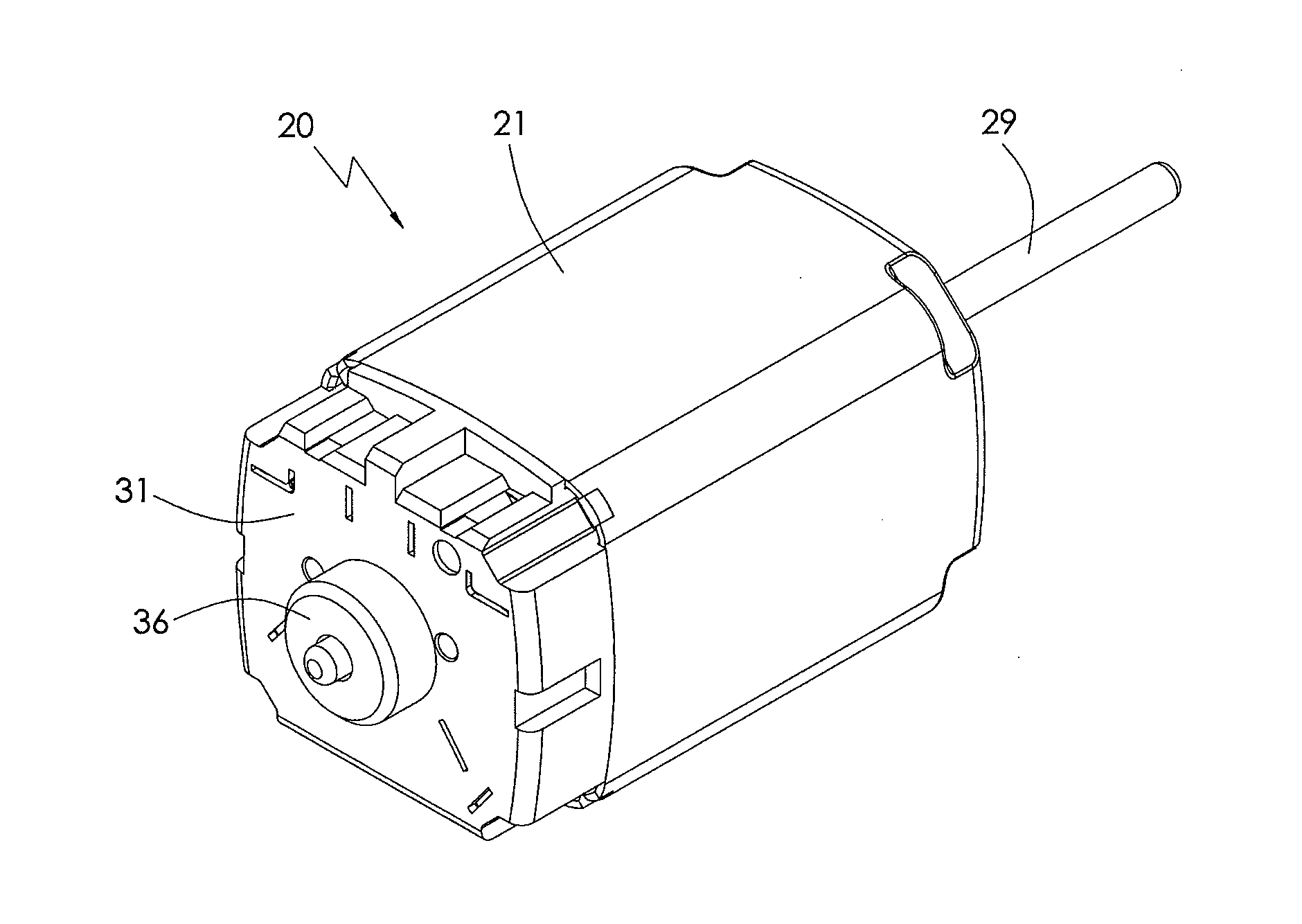

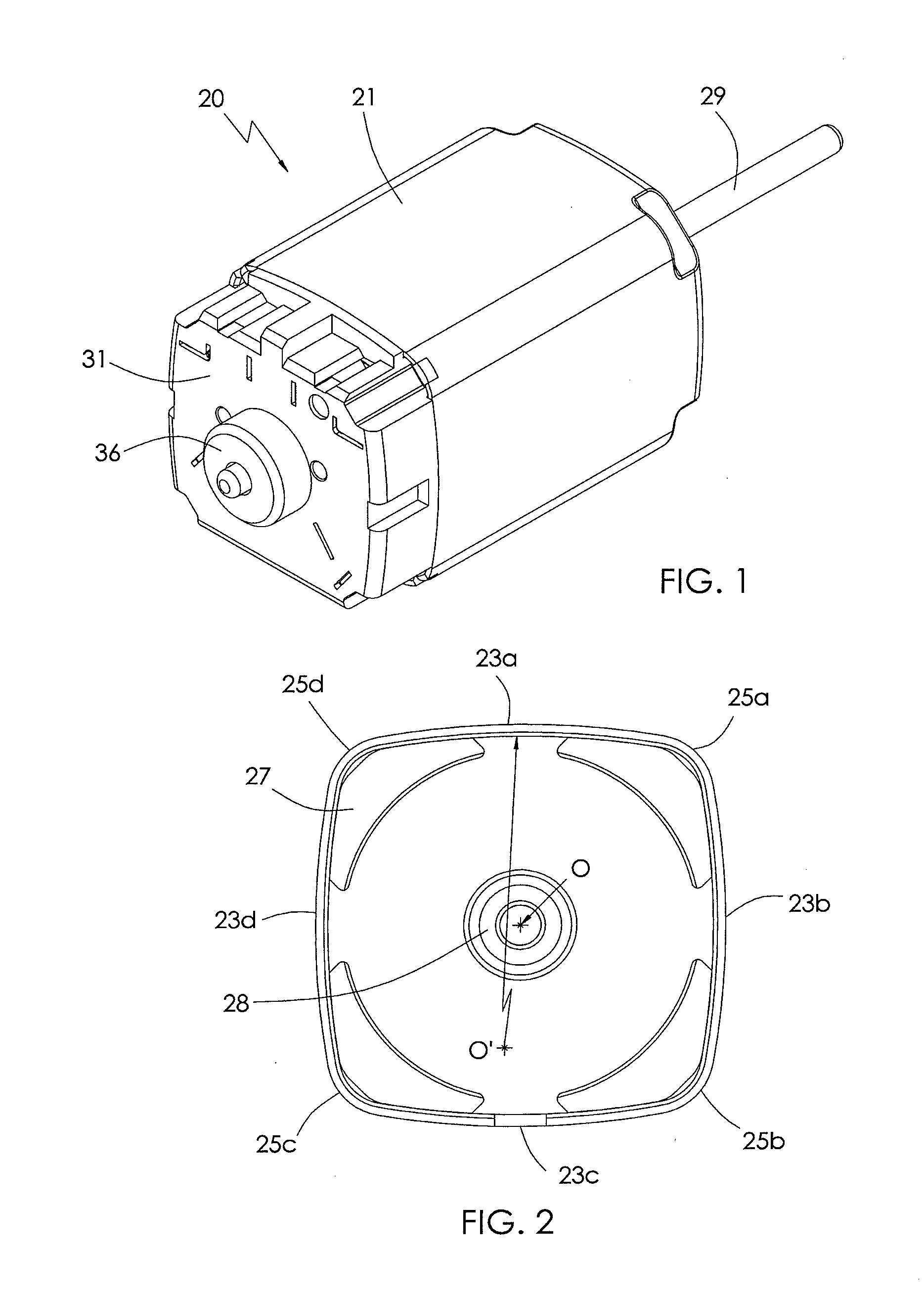

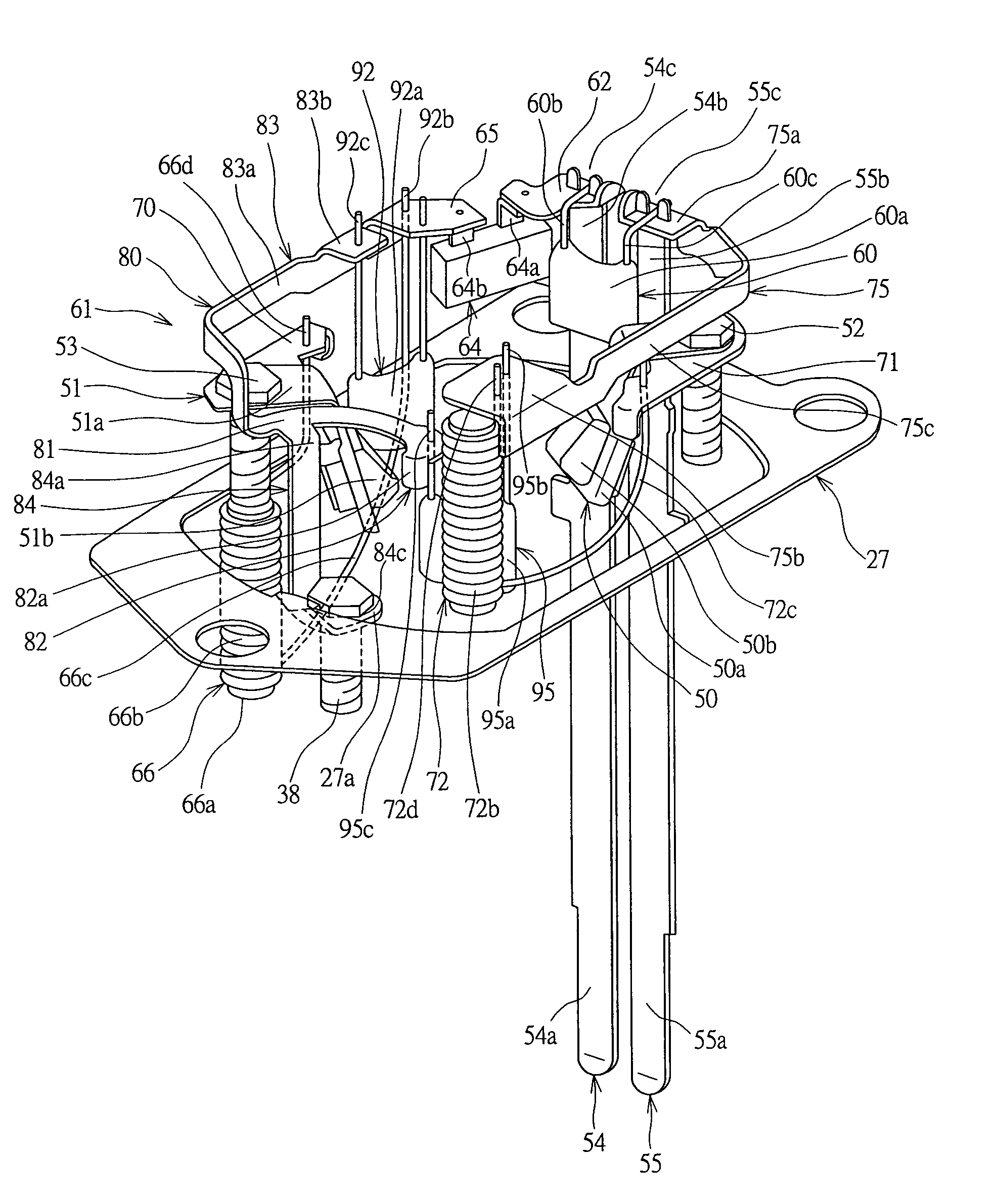

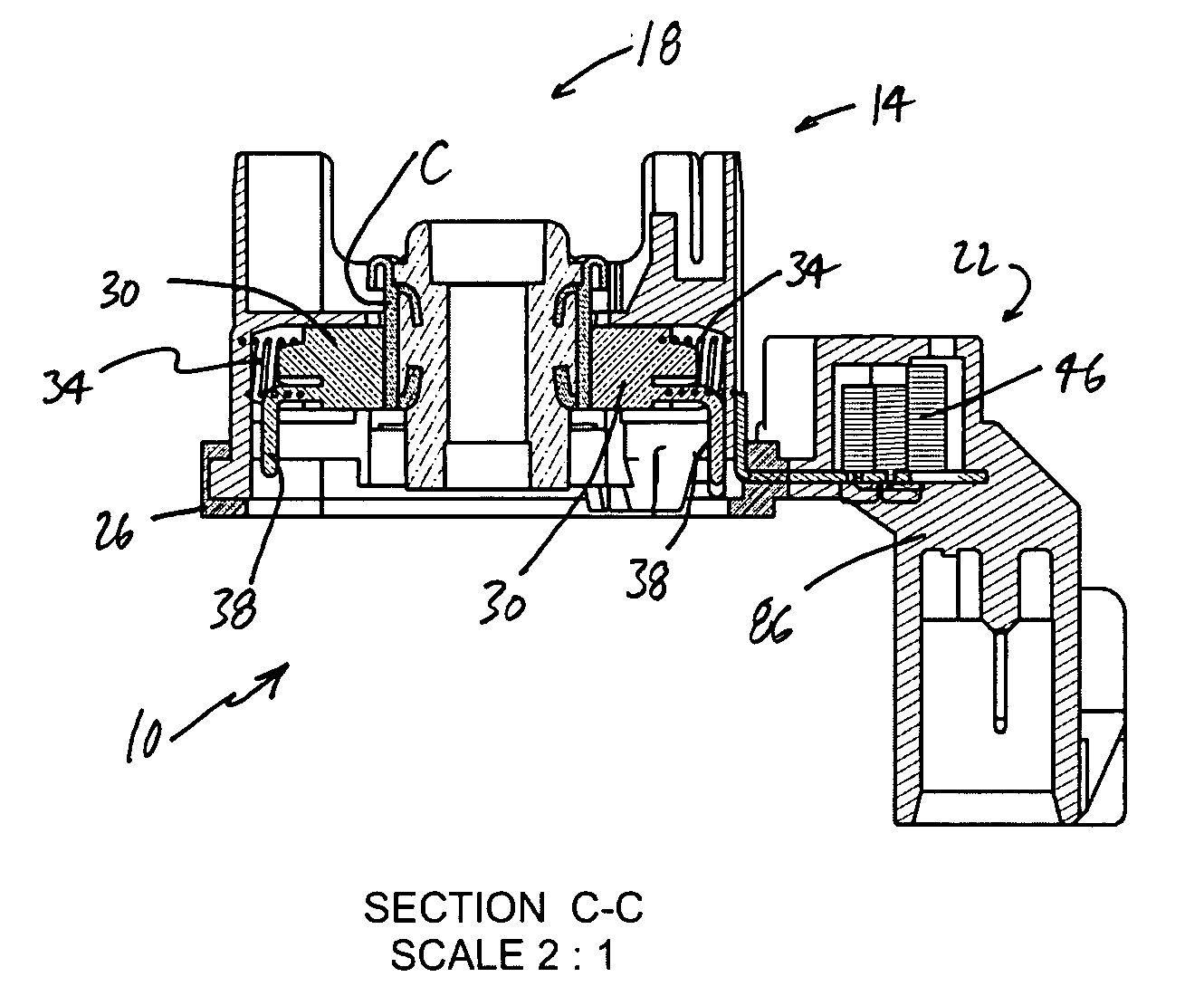

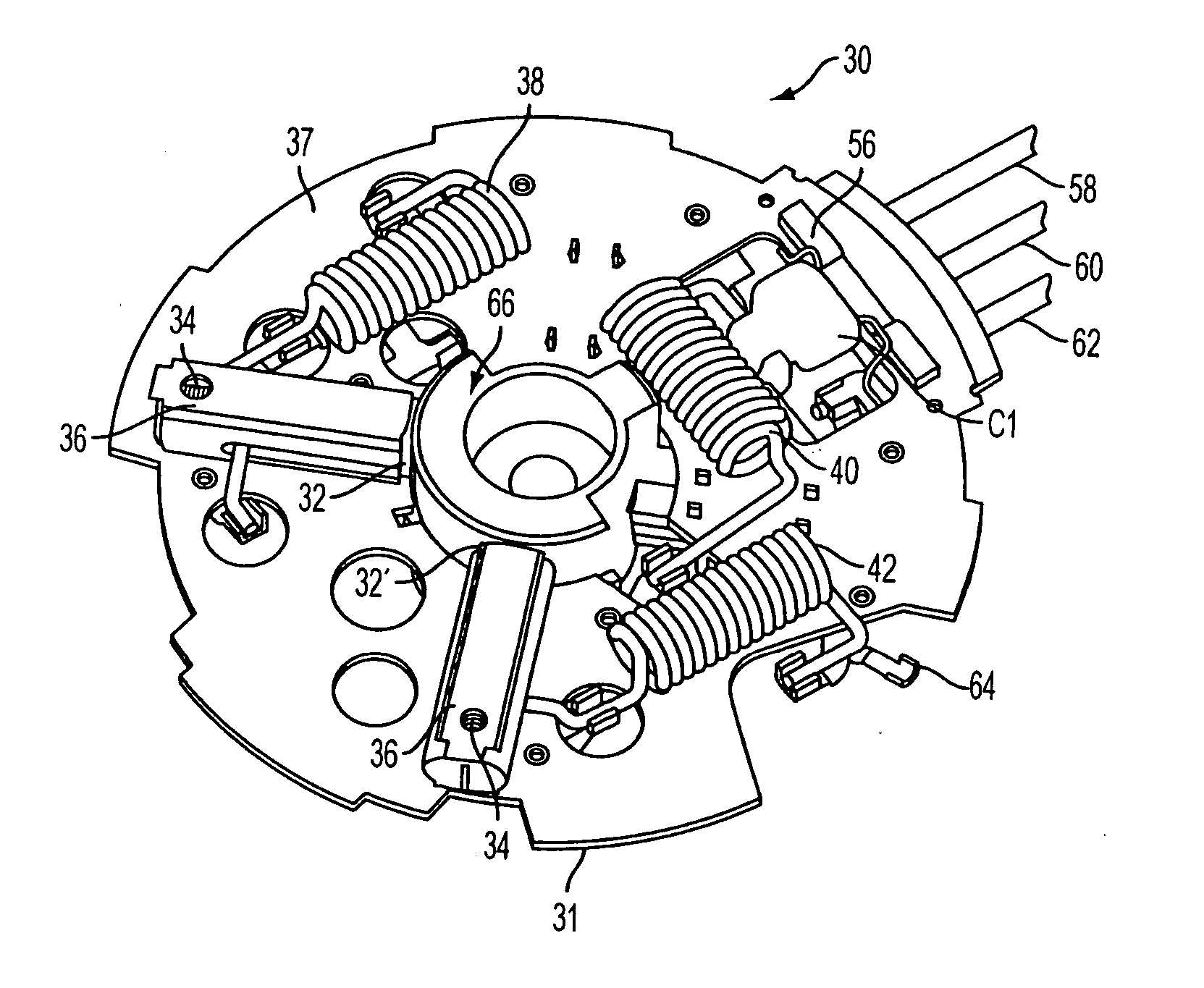

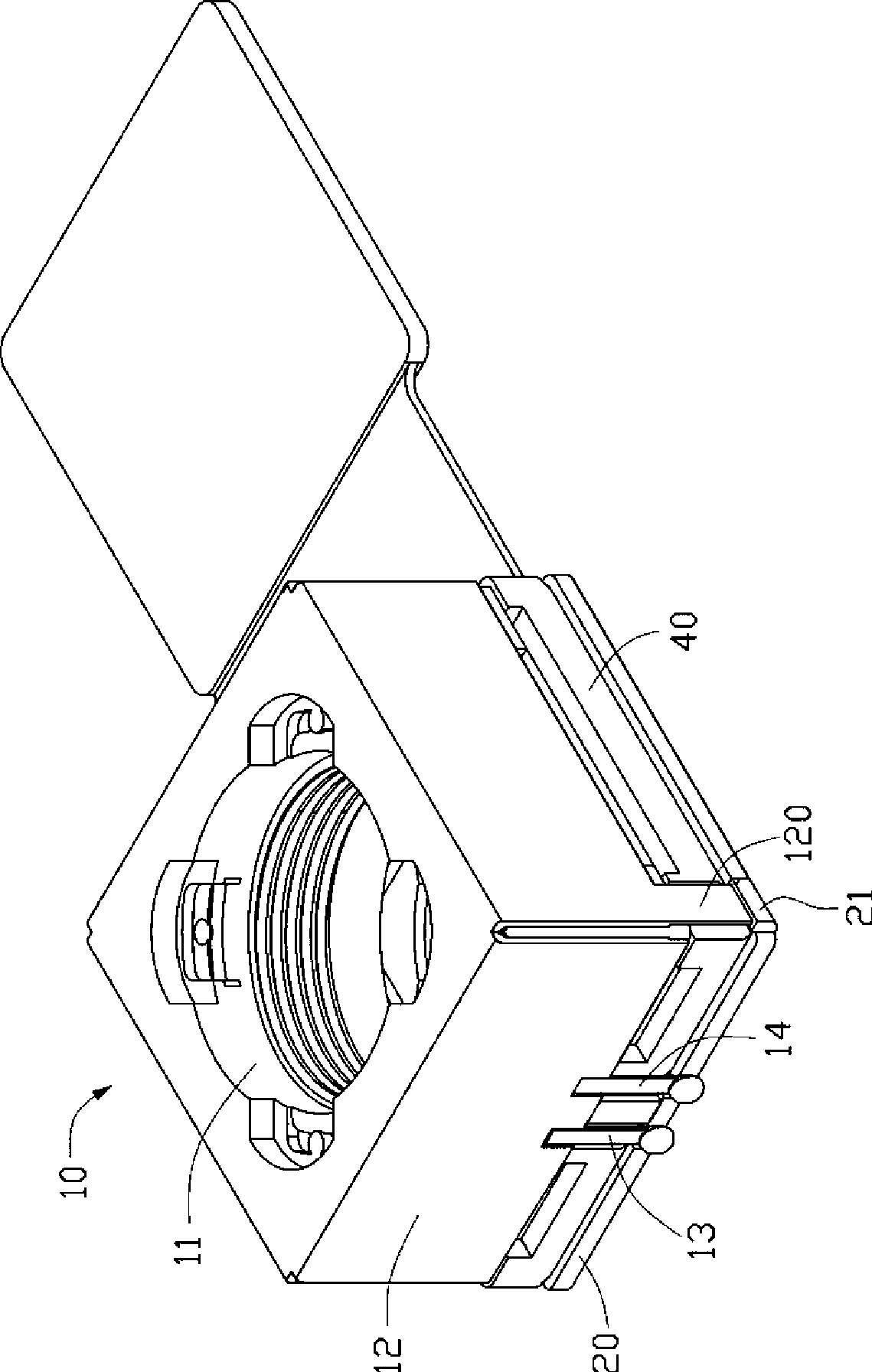

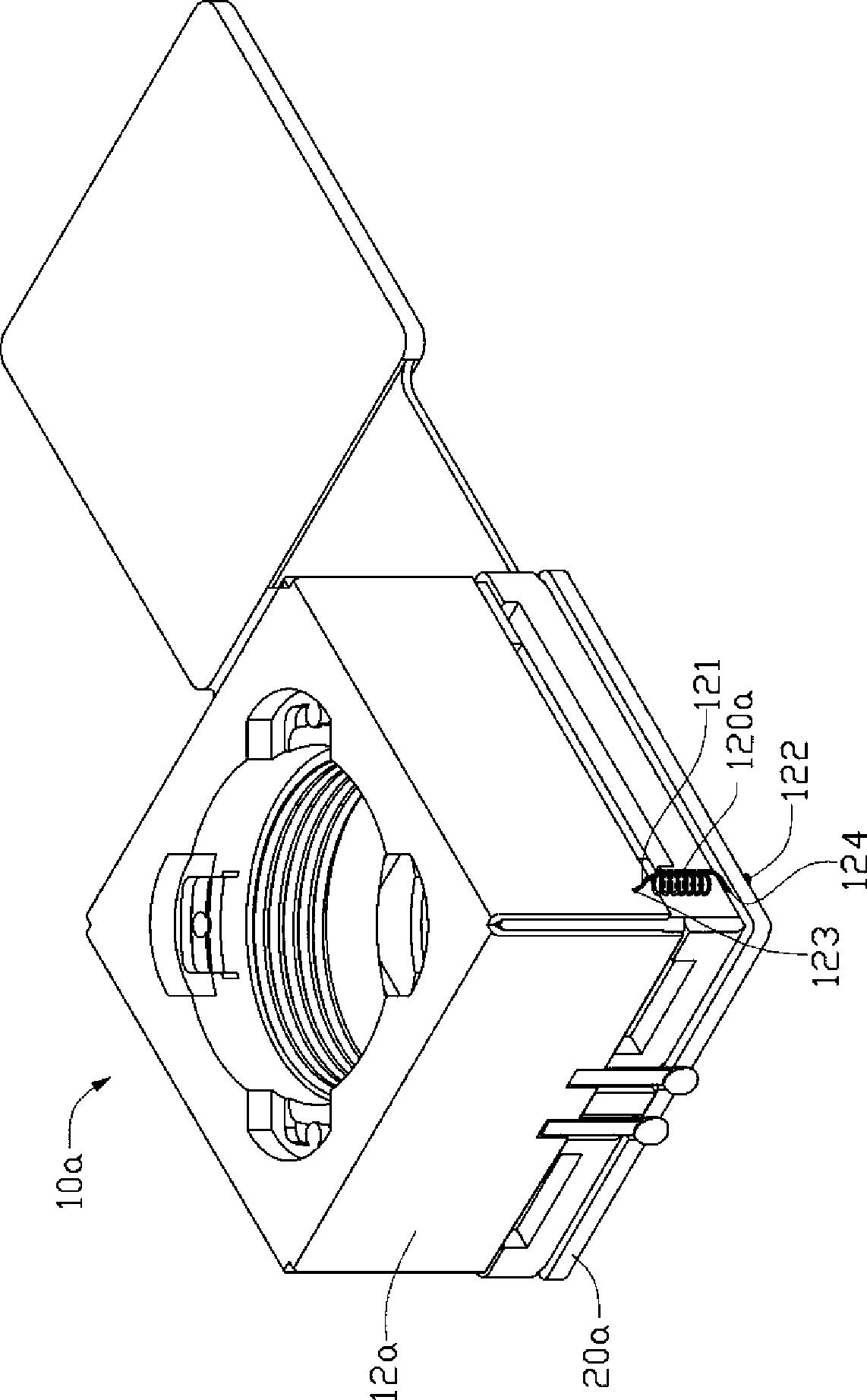

Motor assembly having improved electromagnetic noise filtering and dissipation

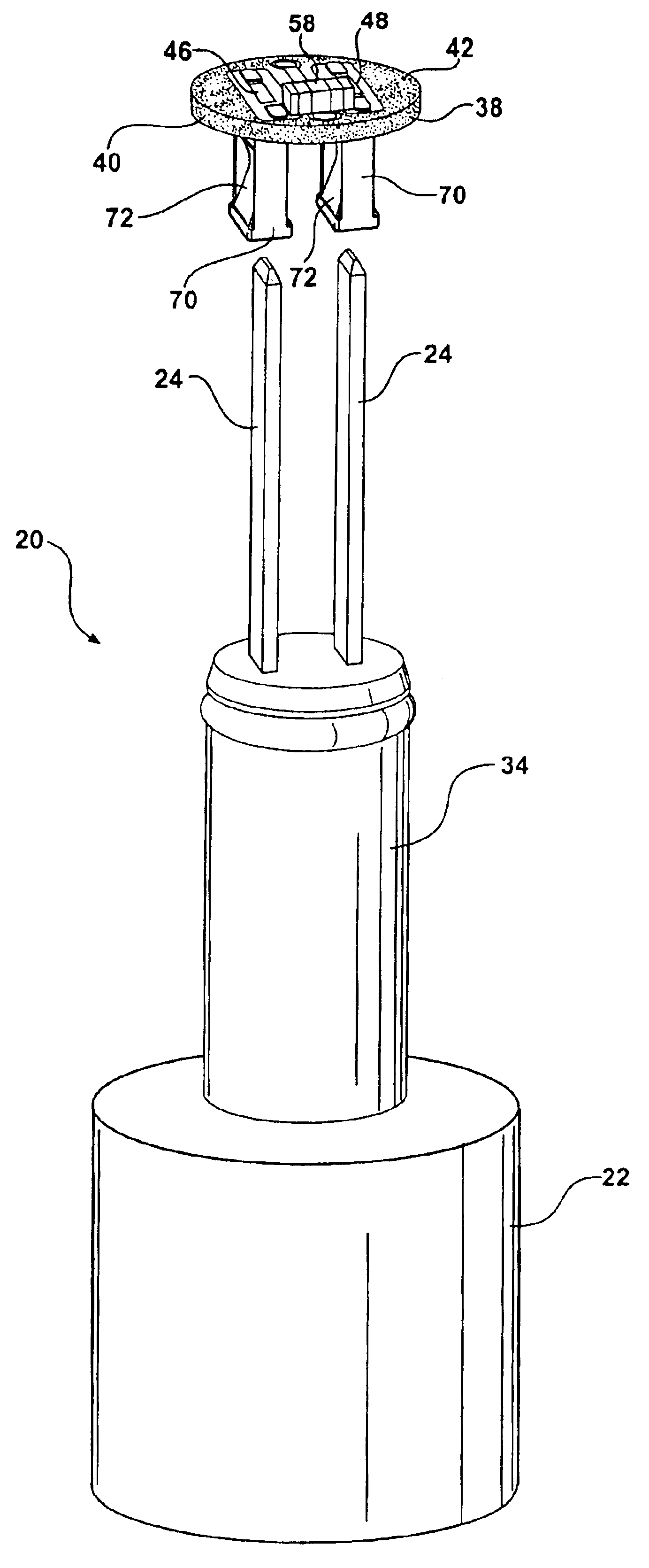

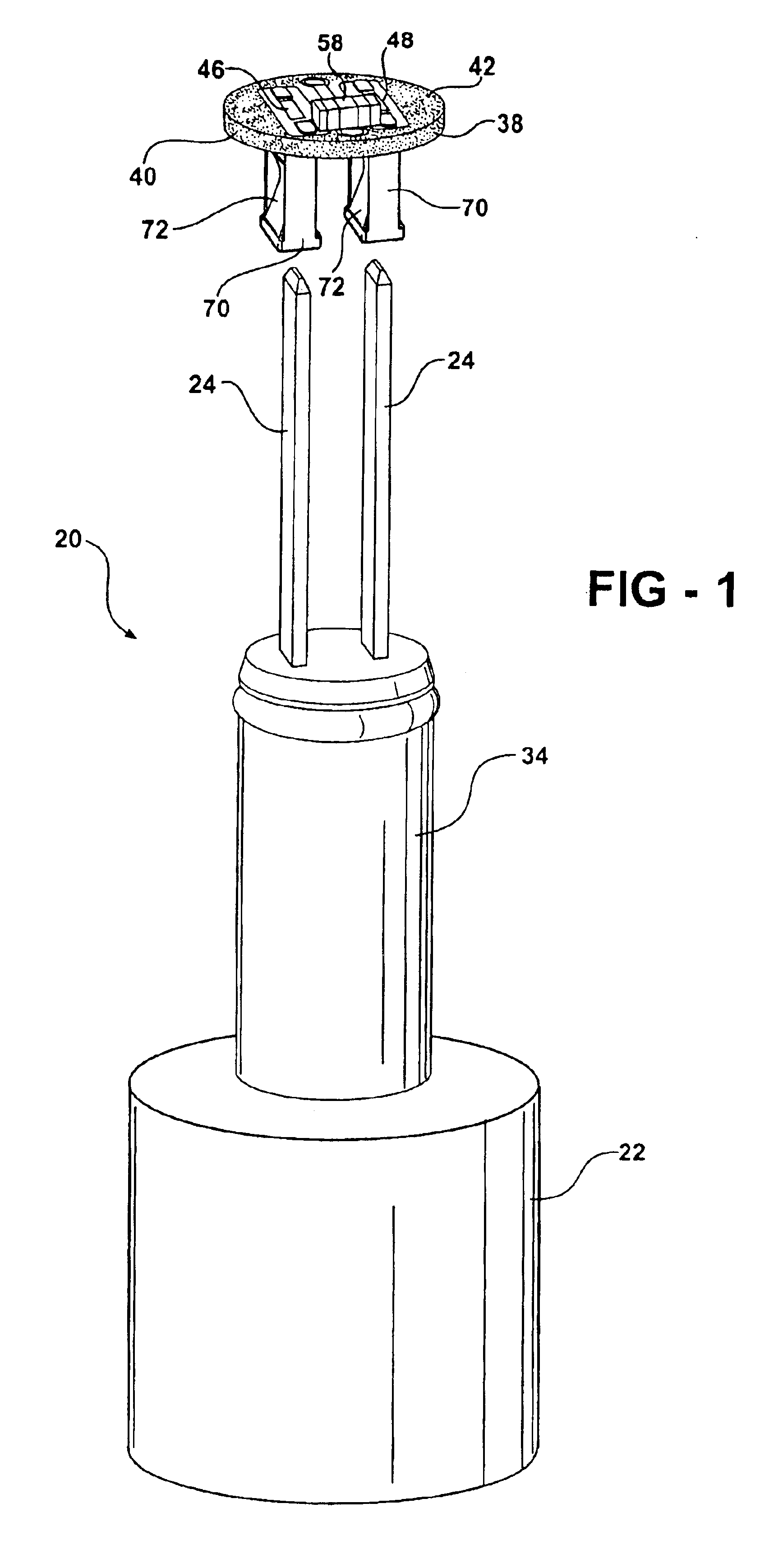

ActiveUS6888062B1Reduce circuit connectionsOvercome deficienciesAssociation with grounding devicesMagnetic/electric field screeningElectrical connectionElectromagnetic noise

The subject invention provides a motor assembly having improved electromagnetic noise or interference (EMI) filtering and dissipation and includes a motor having at least two terminals. A carrier having an upper and a lower surface with an outer periphery defines apertures for receiving the terminals. First and second conductive regions are disposed on one of the upper and the lower surfaces and adjacent the apertures for electrically connecting to the terminals. A grounding region is disposed on one of the upper and the lower surfaces for grounding the carrier to an electrical ground and insulated from the first and the second conductive regions by a first non-conductive region. A circuit extends electrically connects the first and the second conductive regions to the grounding region for filtering EMI. A biasing device urges the grounding region of the carrier into electrical connection with the electrical ground for dissipating EMI and receptacles electrically connect the first and the second conductive regions to the terminals without requiring the terminals to be soldered to the carrier.

Owner:BWI CO LTD SA +1

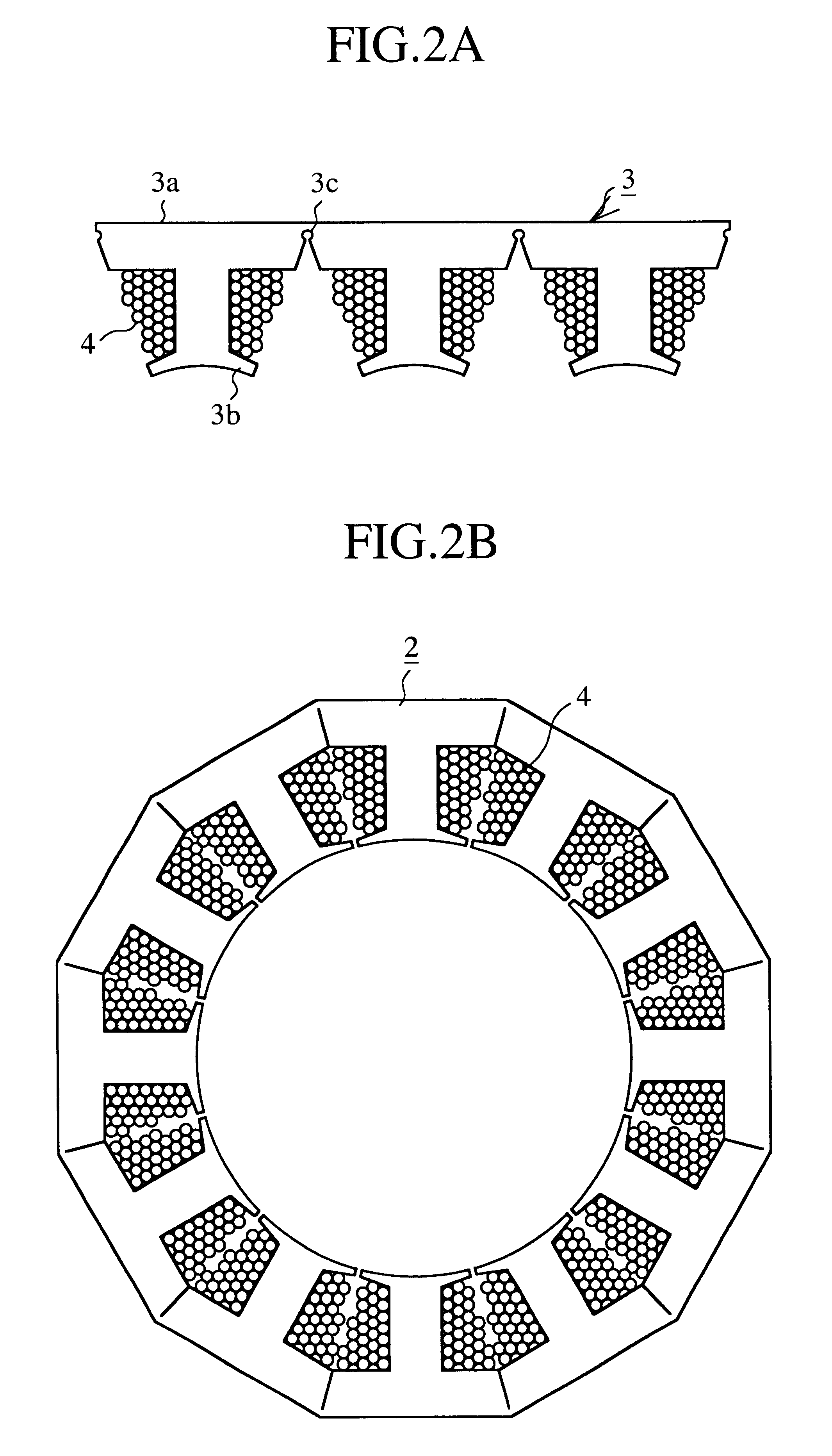

Direct current motor

A direct current motor according to the present invention is provided with a stator 2 in which coils 4 corresponding to N phases are arranged almost at equal intervals in a circle-circumferential direction of stator cores 3, a rotor 8 in which a plurality of permanent magnets 9 are respectively arranged at positions corresponding to the coils 4 of the stator 2, and a current carrying device, having a commutator 11, for commutating direct current supplied from a power source to N-phase current in cooperation with the rotor 8 and carrying the N-phase current to each coil of the stator 2. In the internal space of the current carrying device, a plurality of noise eliminating members 23 connected with a plurality of brush holding plates corresponding to the coil phases are arranged.

Owner:MITSUBISHI ELECTRIC CORP

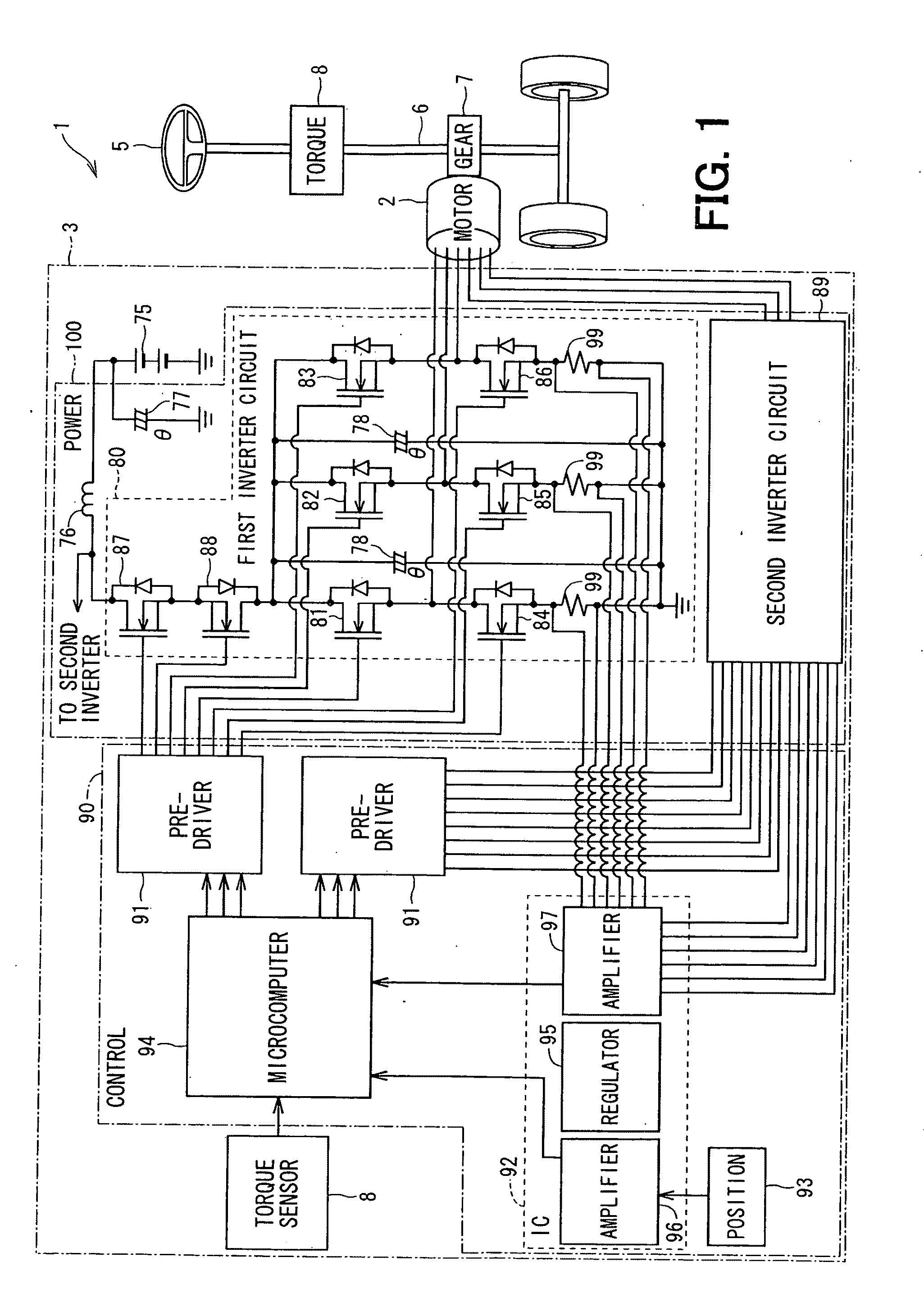

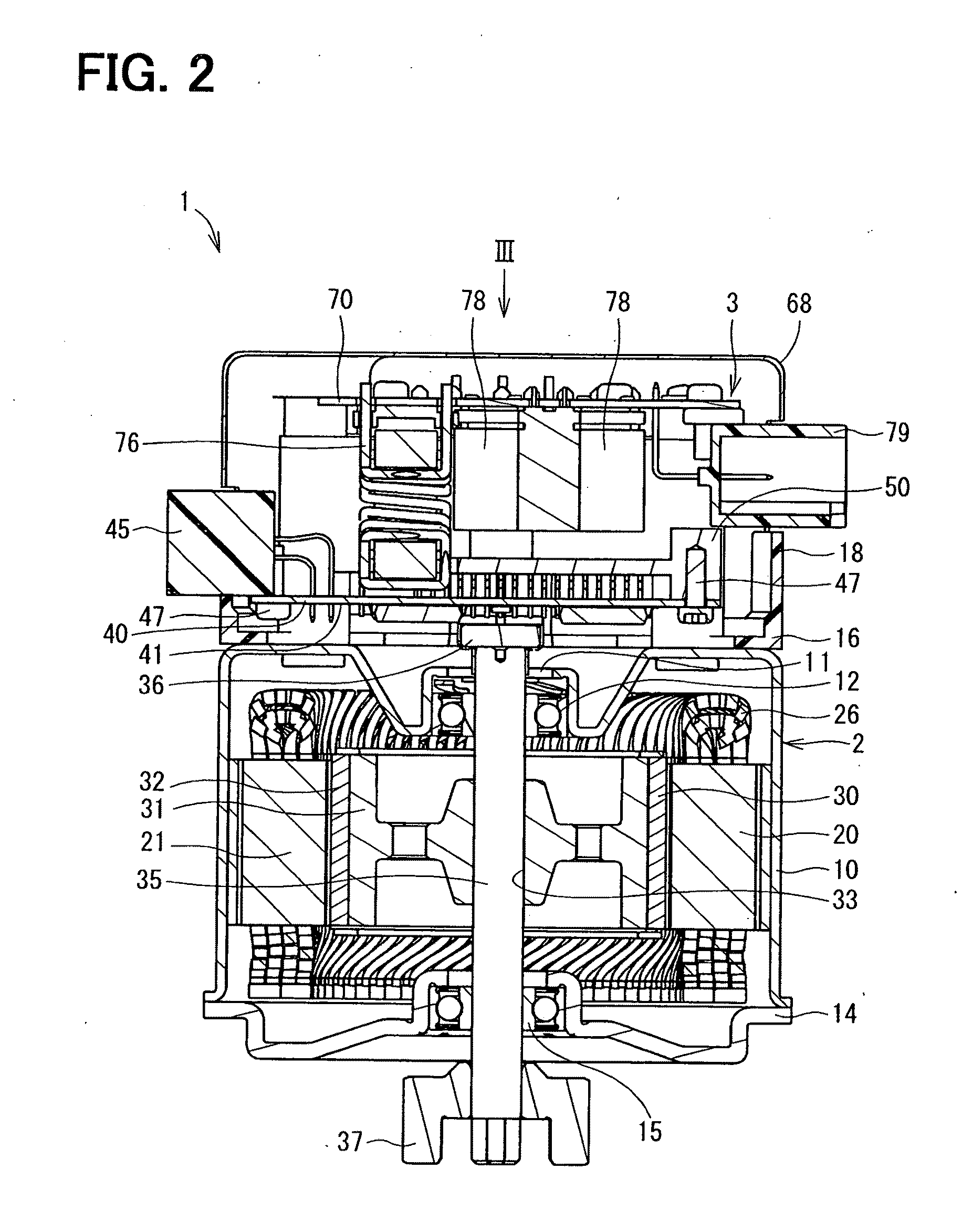

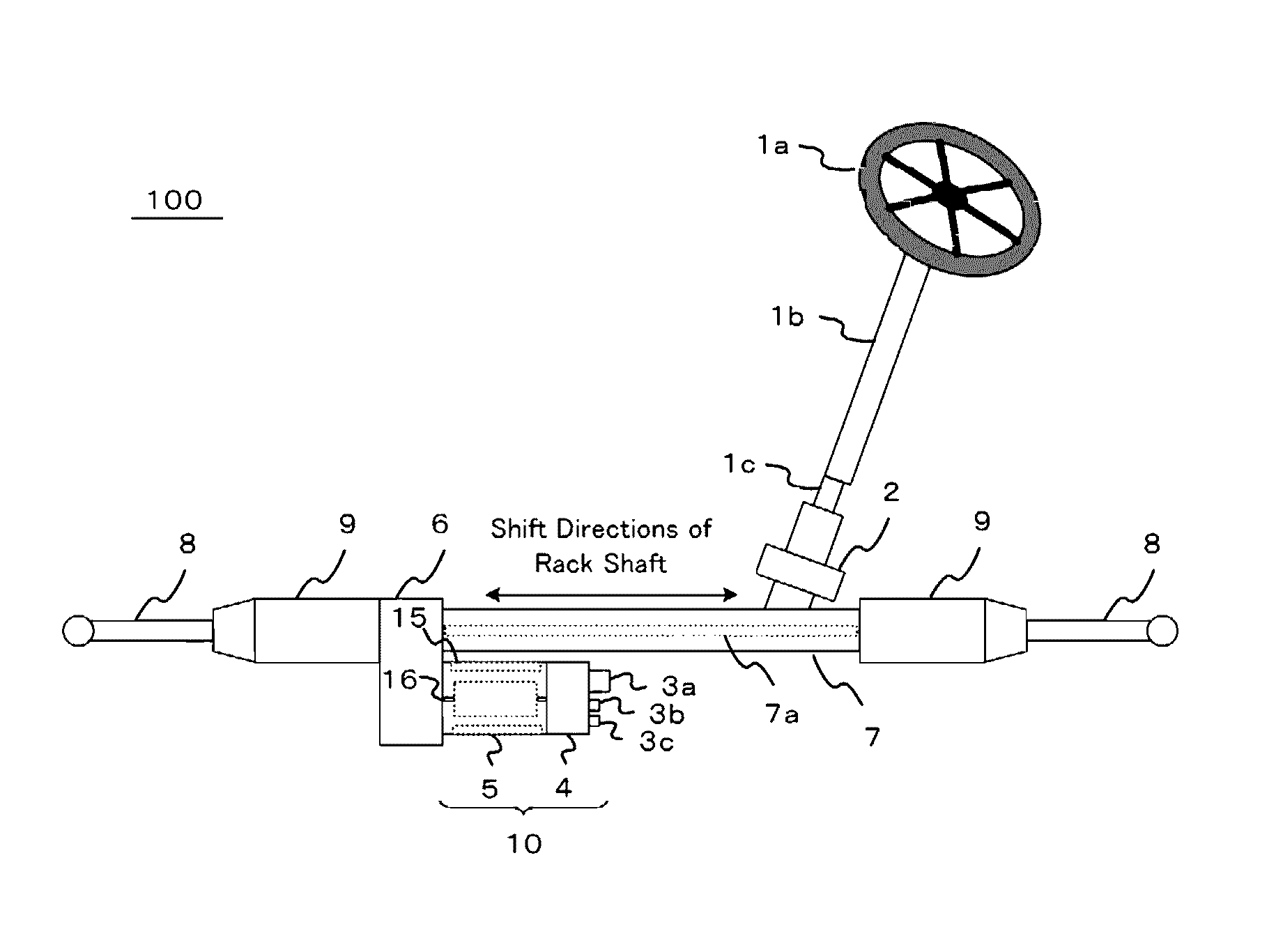

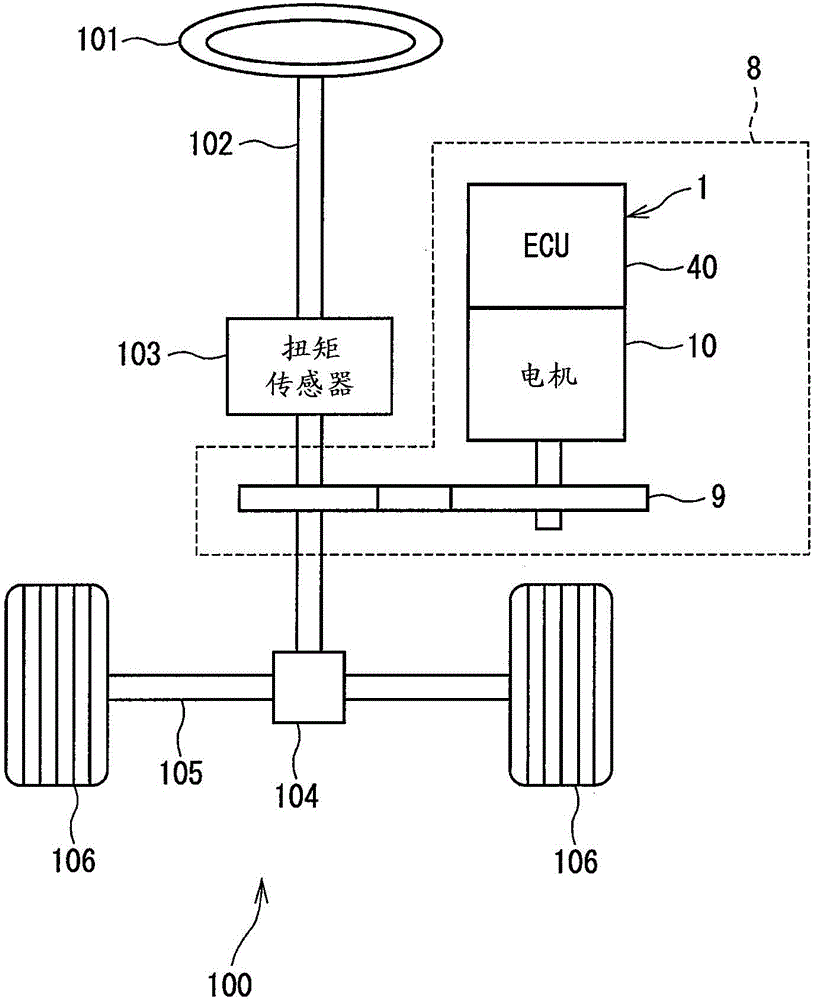

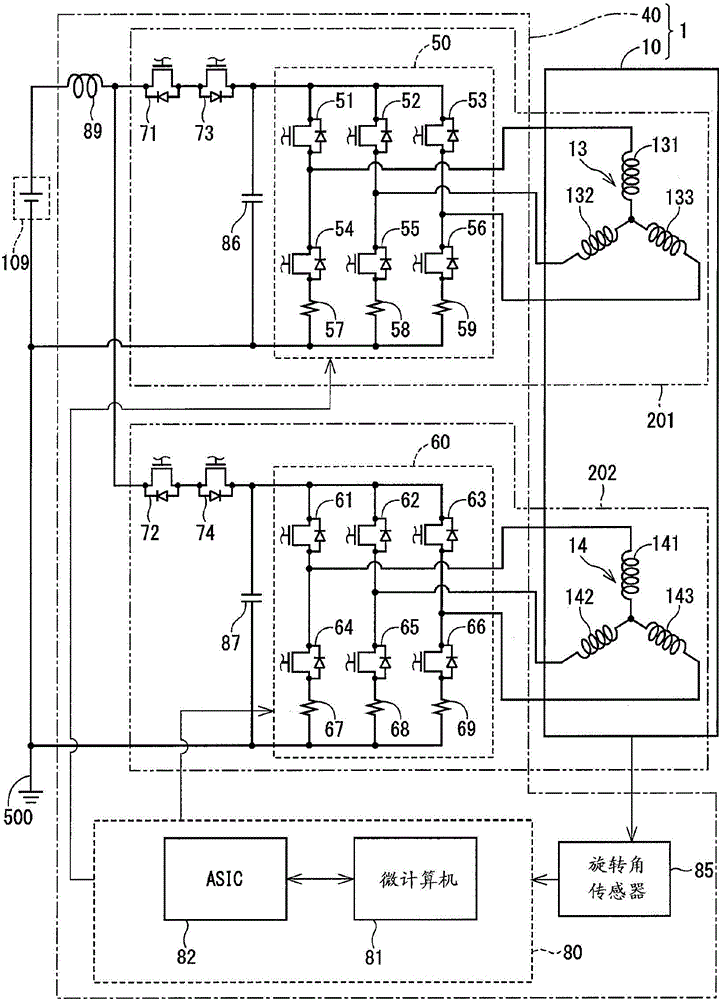

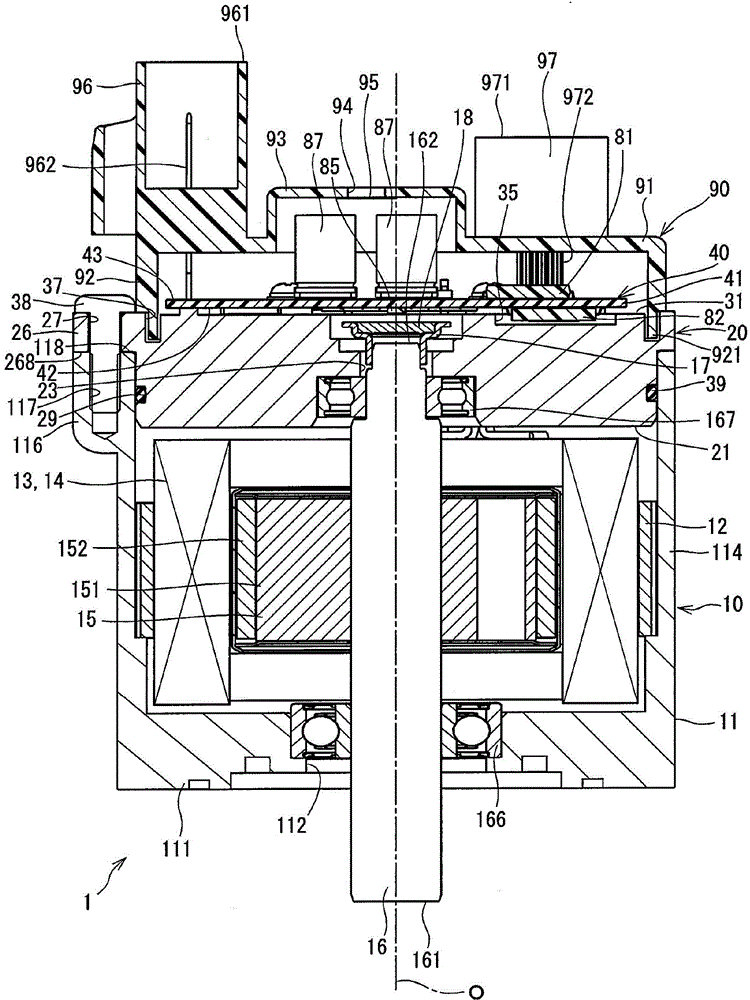

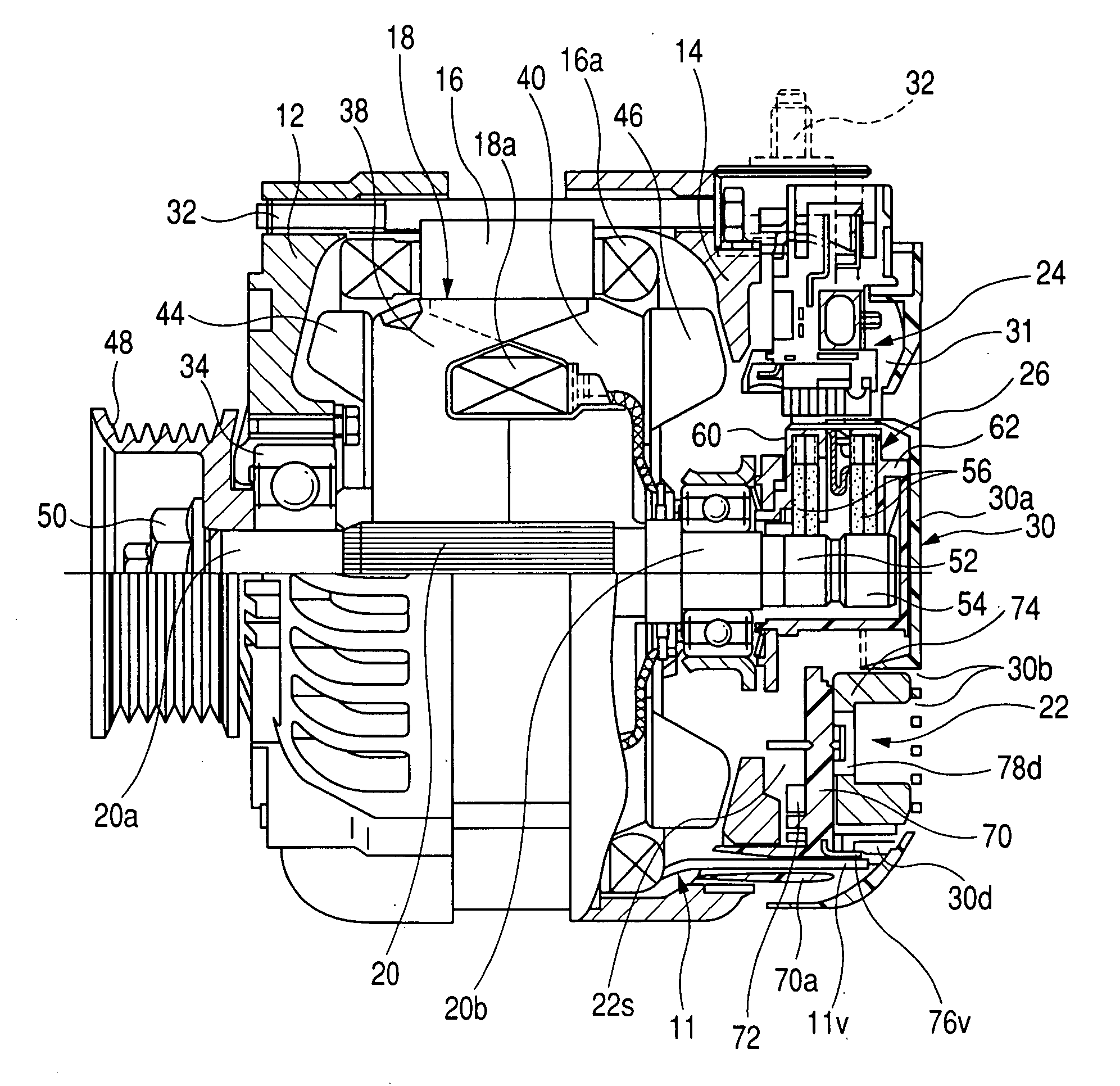

Rotating electric machine with a built-in control device and electric power assist steering system

ActiveUS20170008554A1Reduce component countLow costAssociation with control/drive circuitsElectrical steeringElectric power steeringMicrocomputer

A rotating electric machine with a built-in control device that can be downsized. The rotating electric machine with a built-in control device includes a rotor including a permanent magnet of sensor use provided on a rear side of a rotor shaft, a front side housing fixed with a first bearing supporting a front side of the rotor shaft, a motor frame including a rotor and a stator, a heat sink fixed with a second bearing supporting the rear side of the rotor shaft, a control substrate mounting a rotary sensor, a microcomputer, and a driving circuit. The microcomputer controls the driving circuit based on signals from the rotary sensor and drives a plurality of switching elements. At least one of a smoothing condenser and a noise reduction coil, connected to the switching elements, is arranged at a far rear side of the control substrate.

Owner:MITSUBISHI ELECTRIC CORP

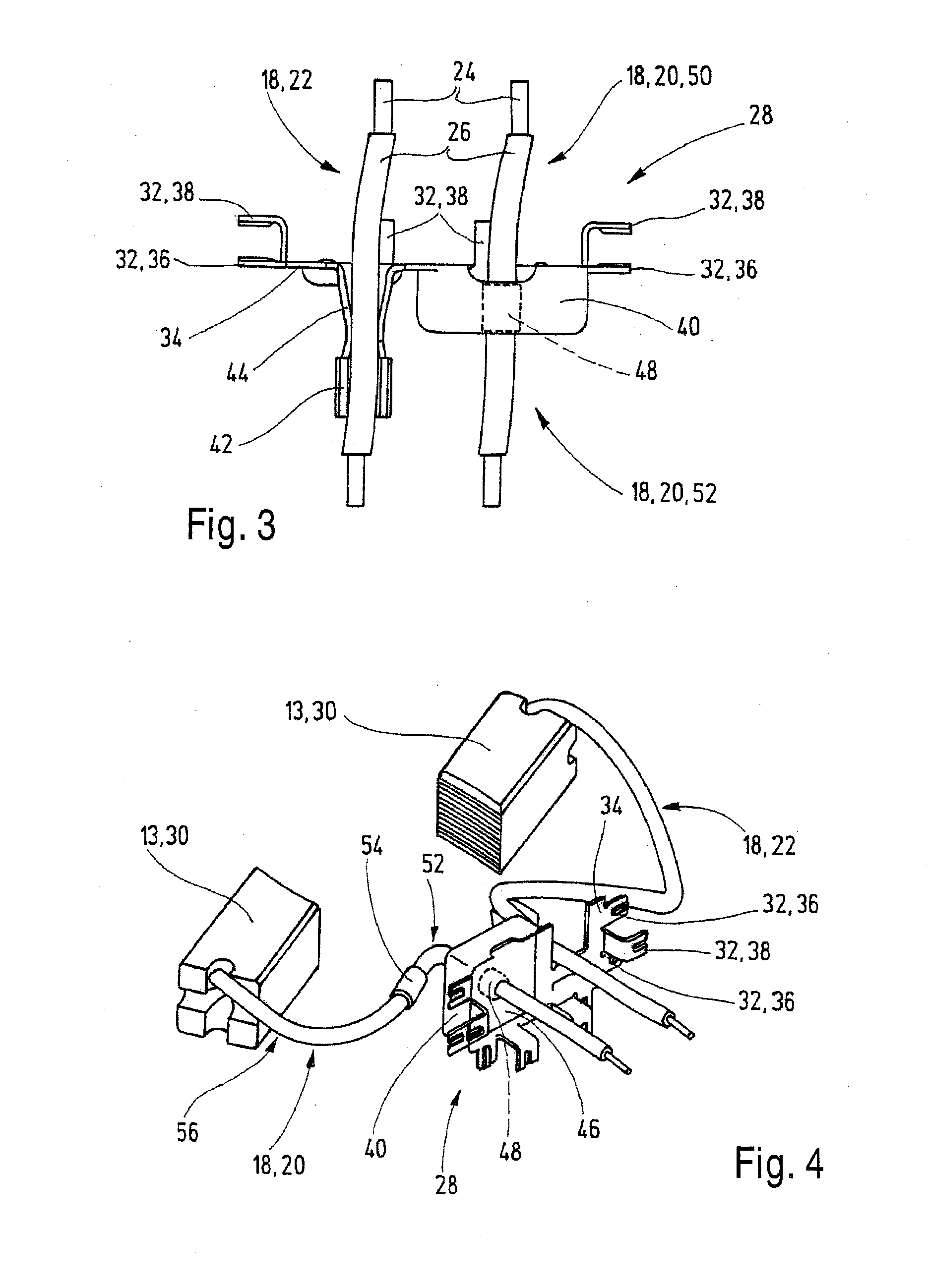

Electric drive unit consisting of an electromotor and an electronic module

InactiveUS6873076B2Eliminate the effects ofFully coupledAssociation with control/drive circuitsRotary current collectorElectricityDrive shaft

An electric drive unit provides a simple and economical electrical connection of an electric motor and an electronic module. The commutator of the electric motor, a brush rocker ring arranged on the commutator, and the drive shaft of the electric motor as well as the carrier body of the electronic module are inserted into a transmission housing. In the transmission housing, the carrier body of the electronic module is positioned so that contact elements provided on the brush rocker ring engage into contact points provided on the carrier body of the electronic module. The electric drive unit can be used for window lifter drives.

Owner:CONTI TEMIC MICROELECTRONIC GMBH

Permanent magnet motor

ActiveUS20110140554A1Magnetic circuit stationary partsSupports/enclosures/casingsPermanent magnet motorCurve line

A permanent magnet motor has a stator and a rotor rotatably mounted to the stator. The stator has a housing with n side portions and n connecting portions distributed alternately, wherein n is a integer equal to or greater than 3. Adjacent side portions are interconnected by one of the connecting portions. The radial cross section of each side portion is a convex curved line which is curved outwardly relative to a straight line passing through the two ends of the convex curve line. Permanent magnets are fixed to an inner surface of the housing. An end cap fixed to one end of the housing, has a bottom and n side walls extending from the bottom. A flat mounting surface is formed at the outer surface of a first one of the side walls.

Owner:JOHNSON ELECTRIC SA

Electric compressor

InactiveUS20150061421A1Improve reliabilityLower Level RequirementsAssociation with control/drive circuitsPositive displacement pump componentsEngineeringElectric power

An electric compressor includes: a compressing unit; an electric motor that rotates the compressing unit; and a driving circuit. The driving circuit includes a filter circuit, an inverter circuit that receives electric power from the power supply line via the filter circuit, and a circuit board on which the inverter circuit is disposed, and a base member (aluminum base) and that supports the circuit board. The filter circuit has an electromagnetic coil and a damping resistor. The damping resistor is fixed to the aluminum base in abutment with the aluminum base. Preferably, the filter circuit is mounted on the circuit board, and the damping resistor has a lead line soldered to the circuit board and is fixed to the aluminum base by a screw. With this, there can be provided the electric compressor capable of effectively cooling the damping resistor of the filter circuit.

Owner:TOYOTA IND CORP

Drive unit and electric power steering device including drive unit

ActiveCN105322724ASimplified Noise Cancellation ConfigurationAssociation with control/drive circuitsElectrical steeringElectric power steeringElectric machine

Provided are a drive unit and an electric power steering device including the drive unit. The drive unit that includes a rotating electric machine having a stator with winding wound on the stator and with a shaft rotating within the stator, and a rotor rotatable relative to the stator. The drive unit also includes a controller holding member disposed on one end of the rotating electric machine, and a controller having a substrate fixed to the controller holding member, a heat generation element mounted on a heat generation element mounting surface. The drive unit further includes a power supply connector connecting the substrate and a power supply, and a ground line coupled to a ground terminal of the power supply providing a conductive connection to the controller holding member via the substrate and the power supply connector. With this structure, the drive unit's common mode noise may be reduced.

Owner:DENSO CORP

Electric motor

ActiveUS6975059B2Improve propertiesSecure spaceAssociation with grounding devicesRotary current collectorLeaf springElectric motor

An object of the invention is to improve a layout property of members arranged on the brush holder. Power feeding terminals are formed in a flat shape extending in an axial direction of an armature shaft, and the power feeding terminal is arranged side by side in a width direction with respect to the power feeding terminal in one end portion of a brush holder. A condenser is provided between the power feeding terminals and the armature shaft. Further, a power supply circuit for electrically connecting the power feeding terminals to a leaf spring brush is electrically connected to a motor housing via a grounding stay, and a choke coil for reducing a noise generated in the power supply circuit is arranged so as to be lapped over a screw member fixing the leaf spring brush to the brush holder in the axial direction of the armature shaft.

Owner:MITSUBA CORP

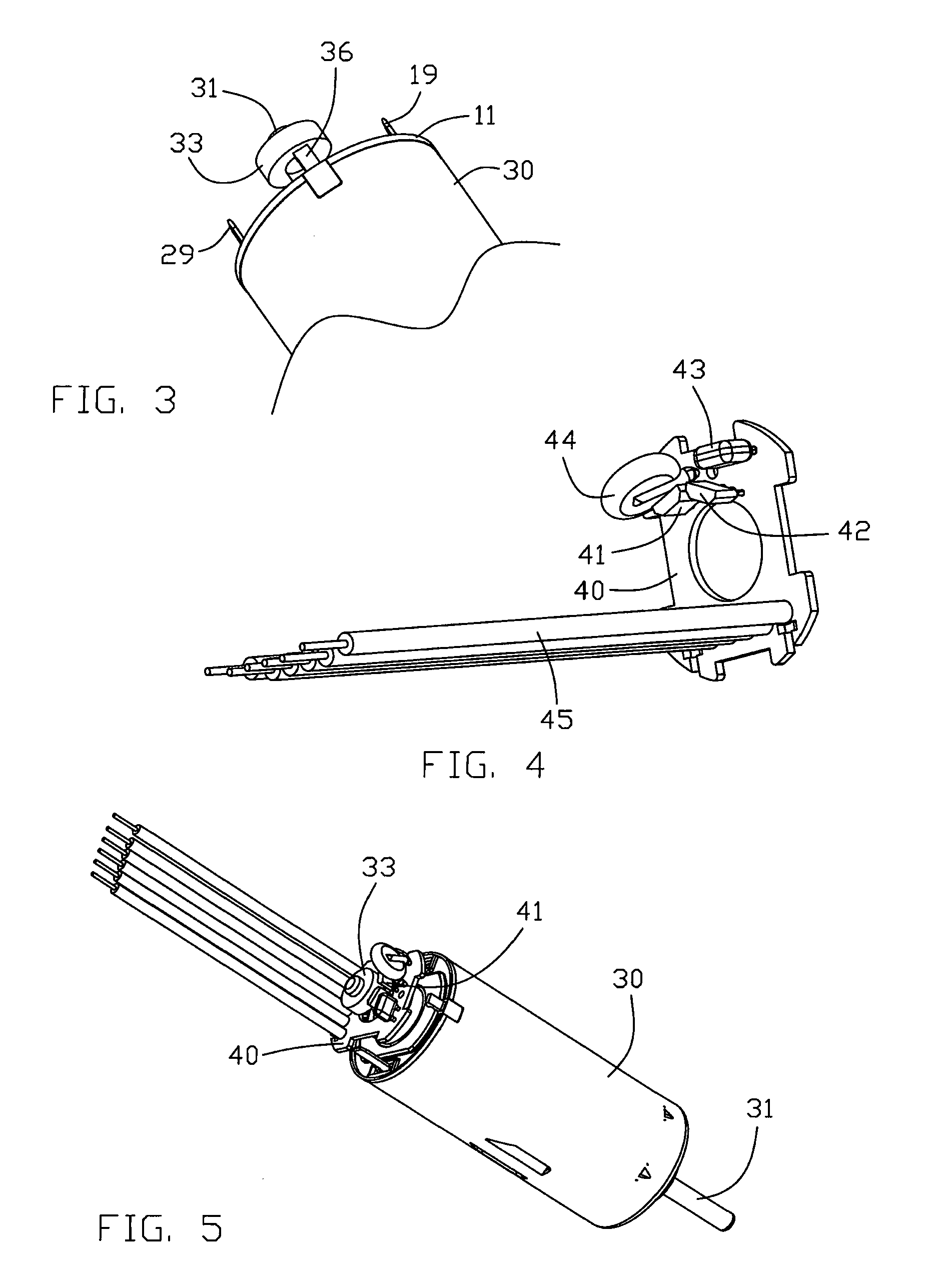

Dc Motor With Supressor

InactiveUS20070278877A1Supports/enclosures/casingsSuppressing electromagnetic interferenceSuppressorElectrical connection

A DC motor (1), in particular for a blower device of a motor vehicle, having a pole housing (10), a plurality of contact elements (13) effecting the bonding to a collector (12), a pole housing opening (16) making it possible to feed electrical connection lines (18) through into the pole housing (10), and an interference suppressor (28, 28.1) serving to reduce and / or eliminate line-conducted electrical interference signals, in which the interference suppressor (28, 28.1) has at least one leadthrough capacitor (48), which is located in an electrical path of at least one connection line (18). The invention further relates to an electrical interference suppressor (28, 28.1) for an electrical device located in a housing, in particular for a DC motor (1) in a pole housing (10), as well as to the use of a leadthrough capacitor (48, 48.1) for interference suppression in a DC motor (1).

Owner:ROBERT BOSCH GMBH

Brush assemblies

InactiveUS20050285463A1Connection securityRotary current collectorSupports/enclosures/casingsElectrical conductorLead frame

Detailed are brush assemblies for electric motors. The assemblies may include lead frames to which leaded electrical components are mounted directly. The lead frames additionally may include two or more conductors and be positioned remote from the brushes of the assemblies.

Owner:ENERGY CONVERSION SYST HLDG

Vehicle alternator with improved end cover structure

InactiveUS20080061641A1High mechanical strengthIncrease in sizeSynchronous generatorsWindingsAlternatorStator coil

A vehicle alternator is disclosed having a stator, a rotor, a frame surrounding the stator and the rotor, a bowl-shaped end cover mounted on the frame and defining an electric component-part compartment, a brush unit held in sliding contact with slip rings of a rotary shaft, and a rectifier unit. The rectifier unit includes a terminal block embedded with A.C. conductive segments for multi-phase windings of a stator coil. The end cover includes a base wall portion and protective partitioned compartments axially protruding from a base wall portion of the end cover toward the frame at circumferentially spaced positions for the multi-phase windings, respectively, for surrounding at least one circumference of a connecting portion between an exposed end portion of each A.C. conductive segment and a diode lead and a connecting portion between the exposed end portion of each A.C. conductive segment and a stator lead.

Owner:DENSO CORP

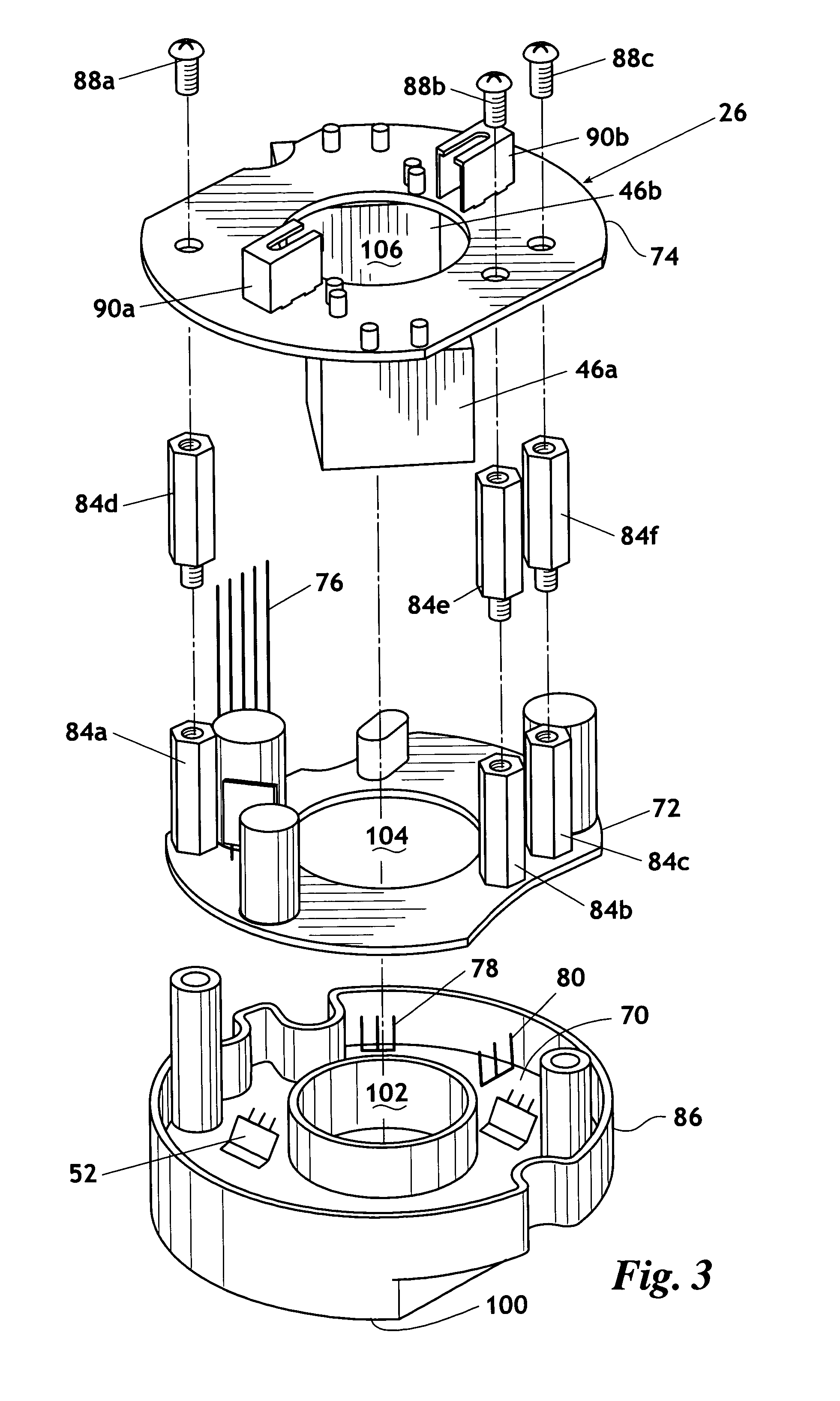

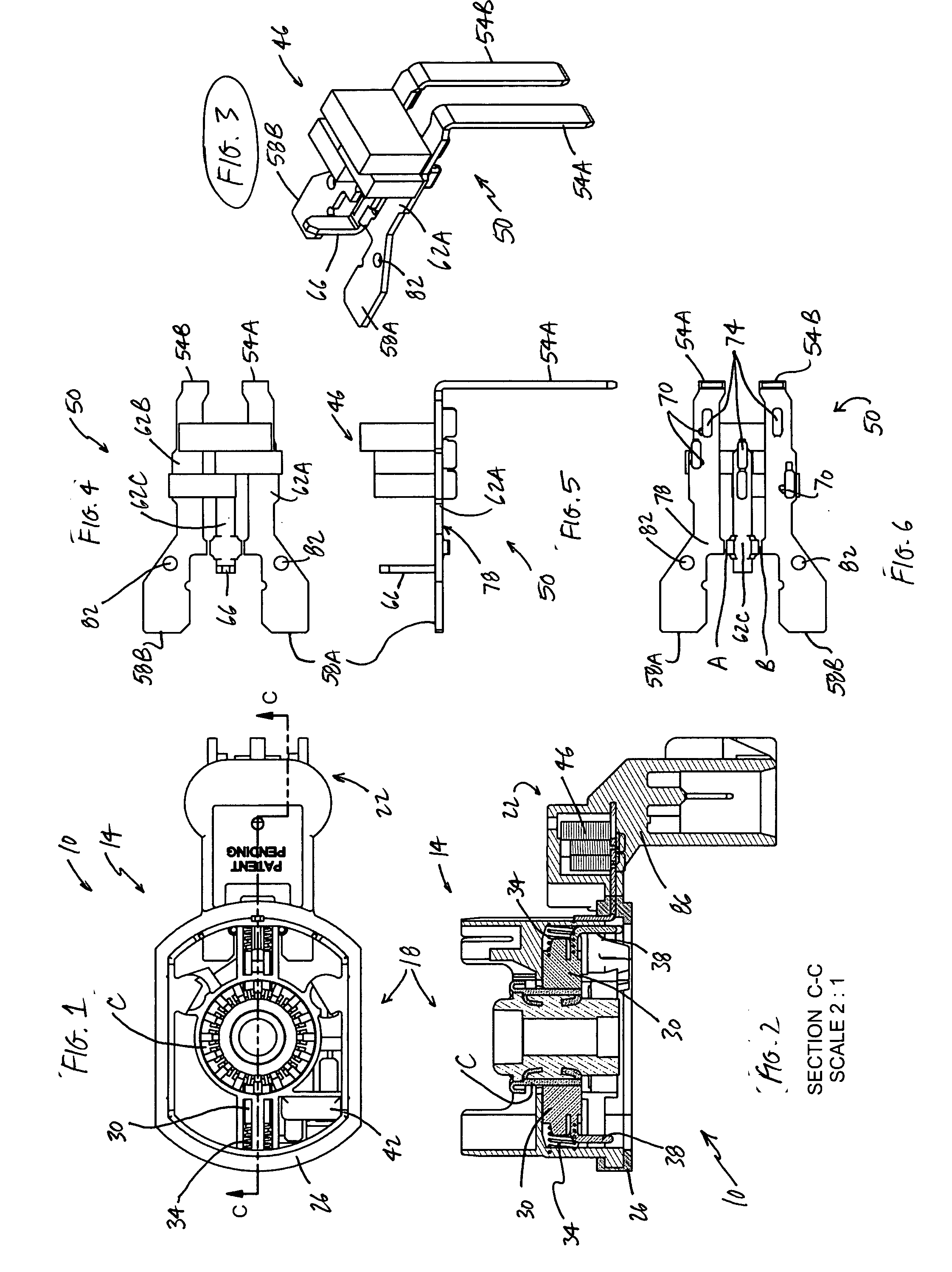

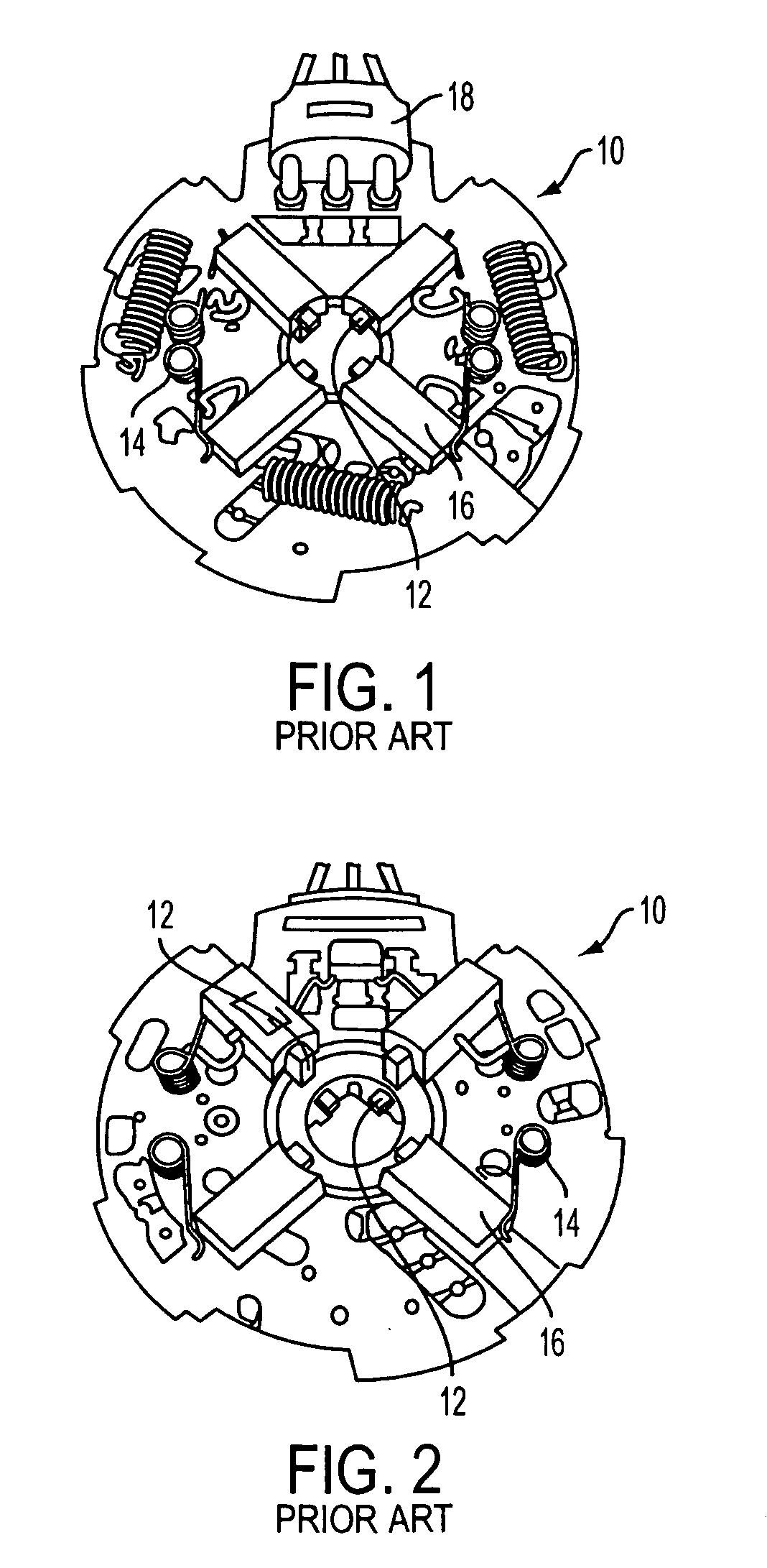

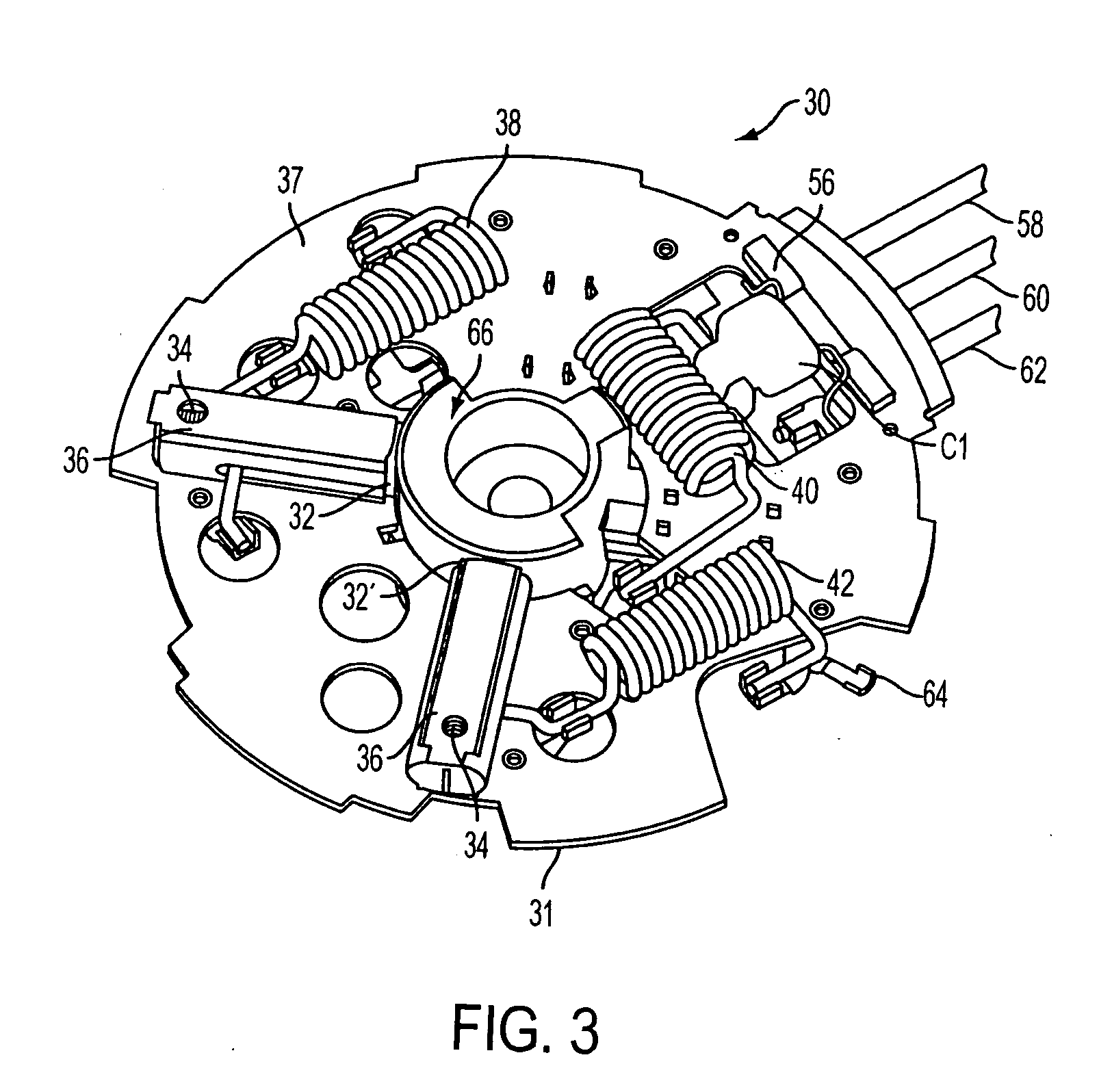

Brush card assembly with RFI suppression for two or three speed permanent magnet brush motor with link wound dual commutator and dual armature winding configuration

A brush card assembly 30 is provided for a permanent magnet brush motor 50. The motor includes a link wound, high speed side commutator 46 and an associated high speed side armature winding 44, and a link wound low speed side commutator 54 and an associated low speed side armature winding 52. The brush card assembly includes a brush card 31 including a high speed side having a positive brush 32 and a negative brush 32′ constructed and arranged to be operatively associated with the high speed side commutator 46, and a low speed side opposite the high speed side. The low speed side has a positive brush 33 and a negative brush 33′ constructed and arranged to be operatively associated with the low speed side commutator 54. The brushes are constructed and arranged with respect to the commutators to provide at least two different operating speeds of the motor.

Owner:SHUFFLE MASTER +1

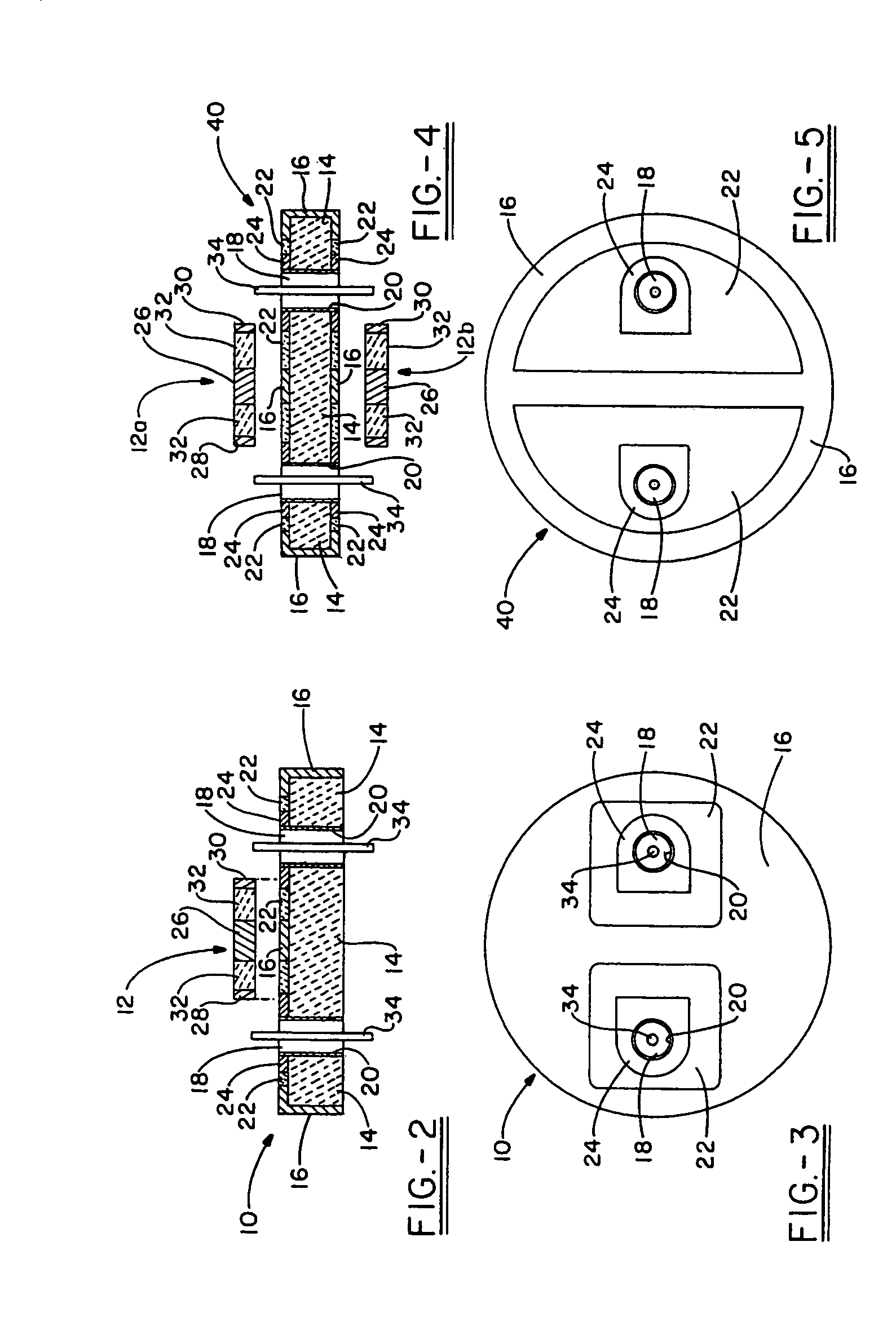

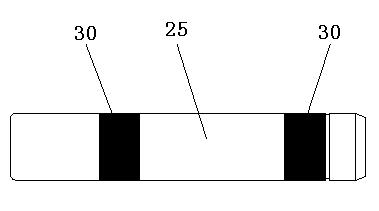

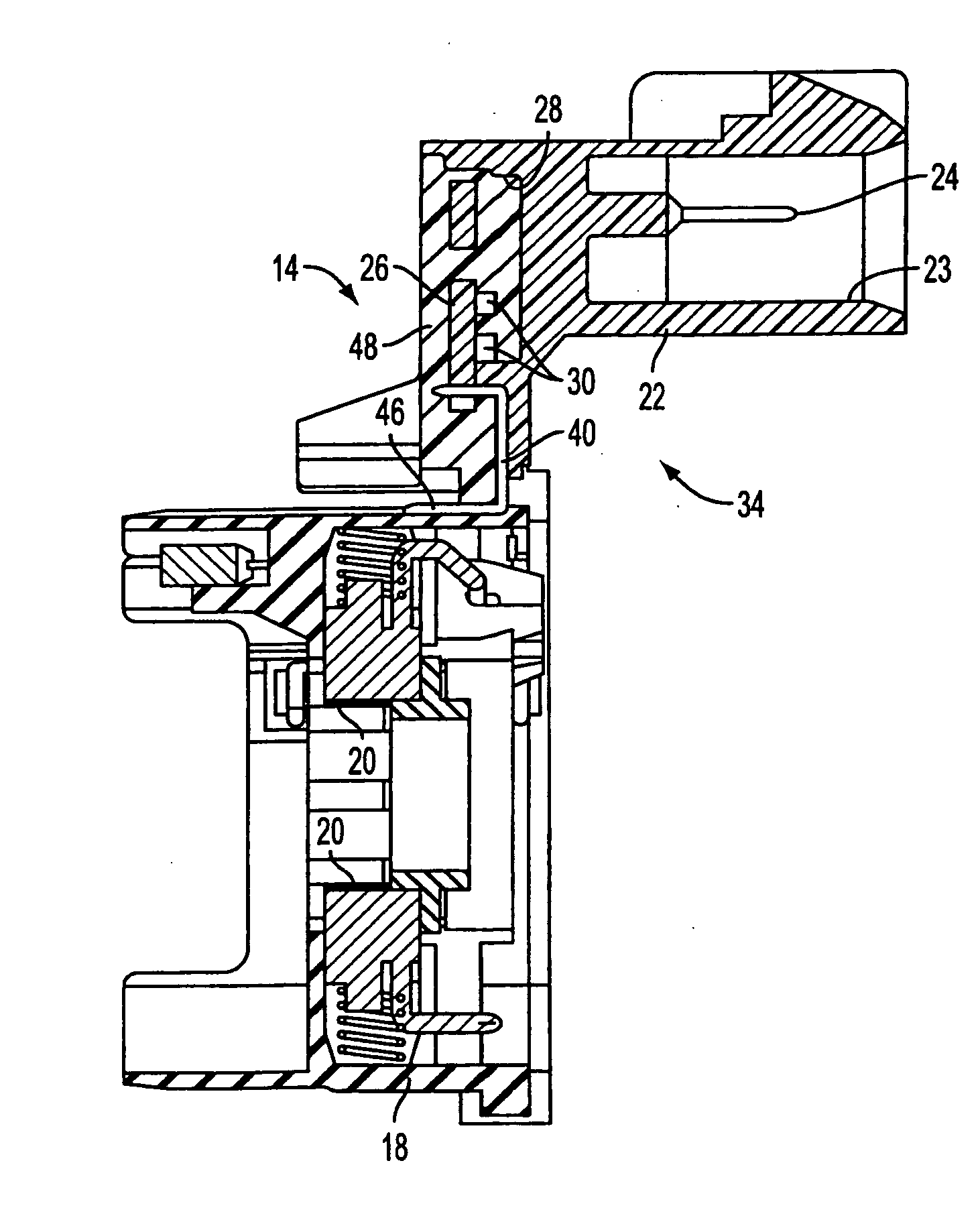

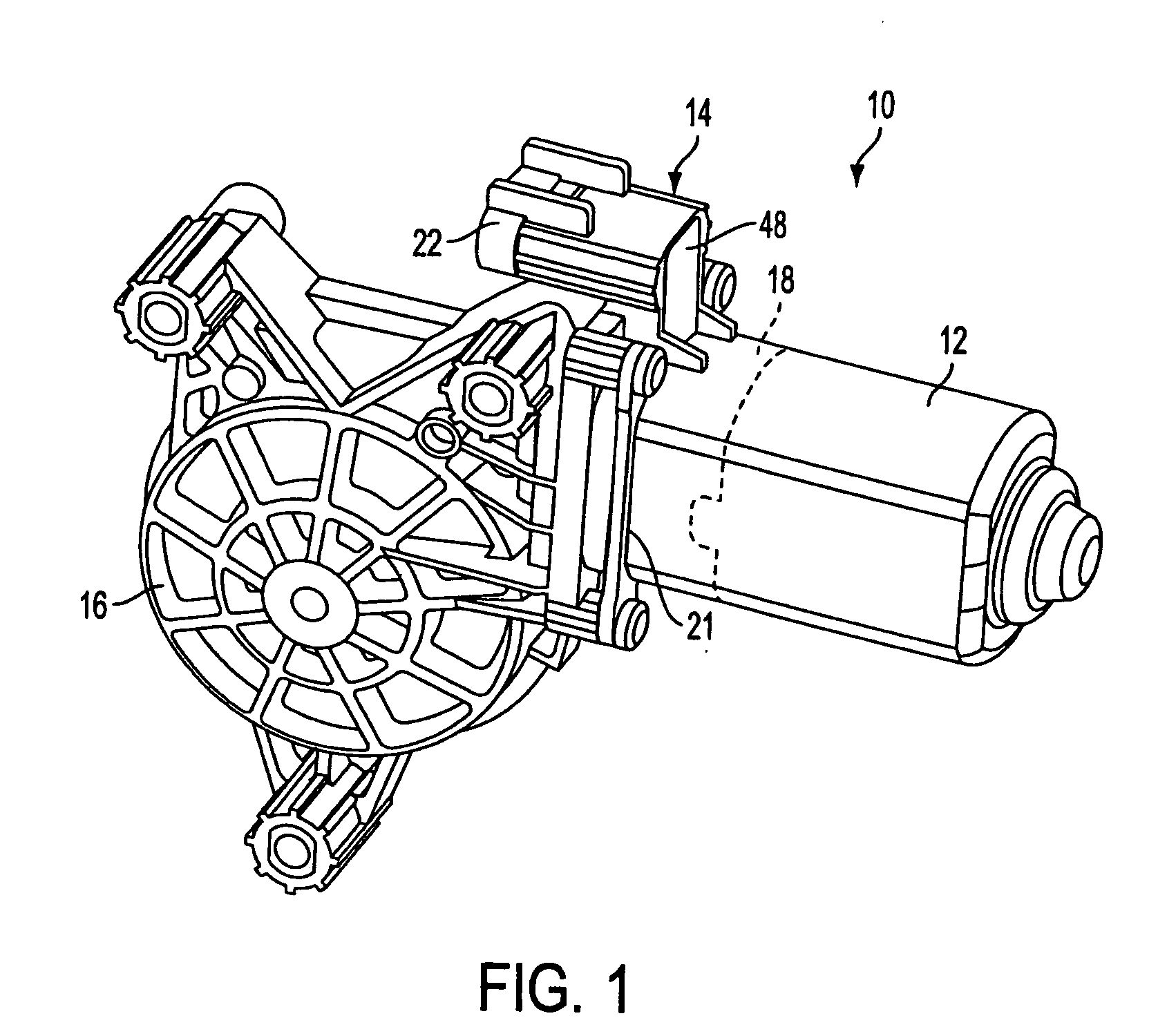

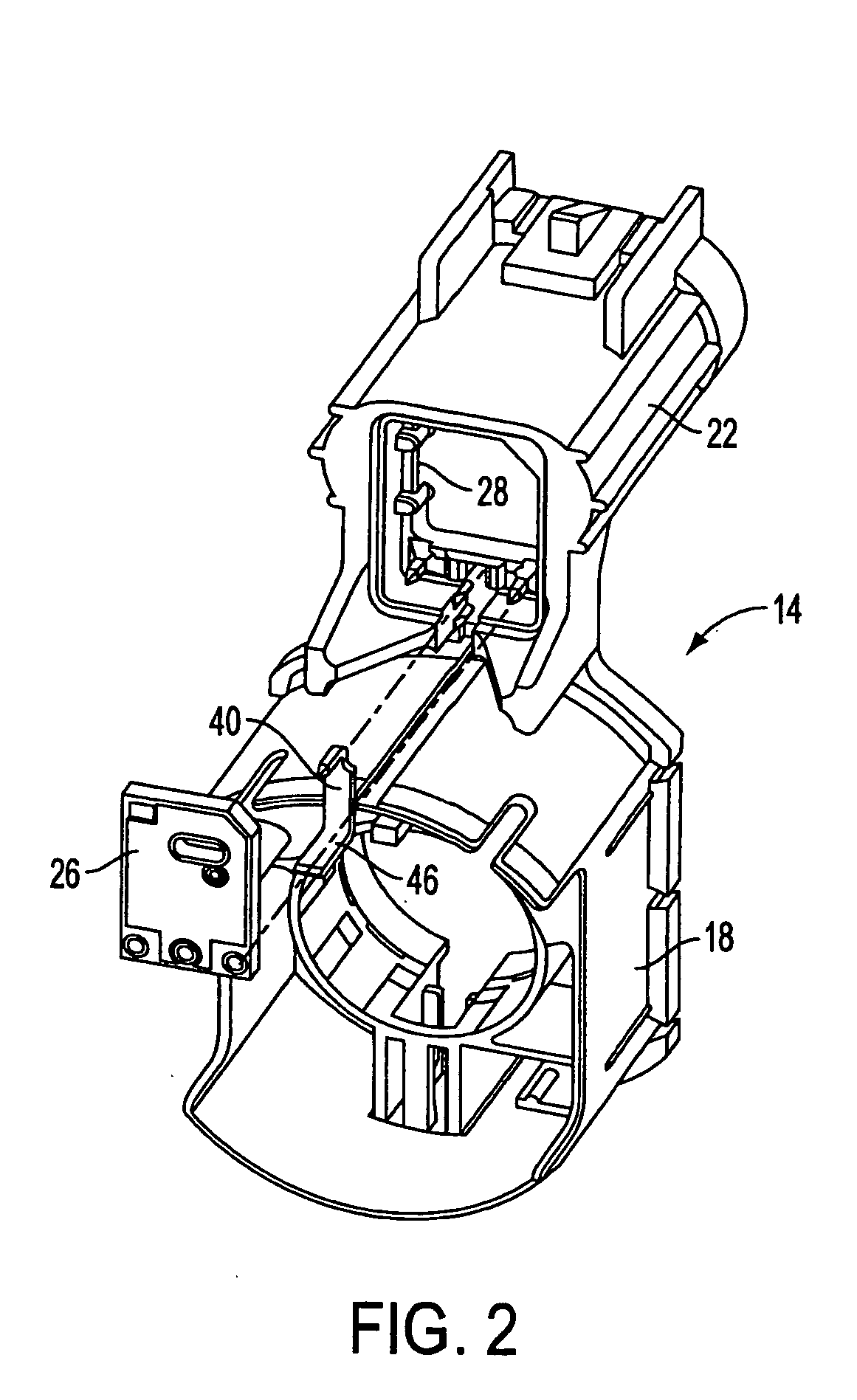

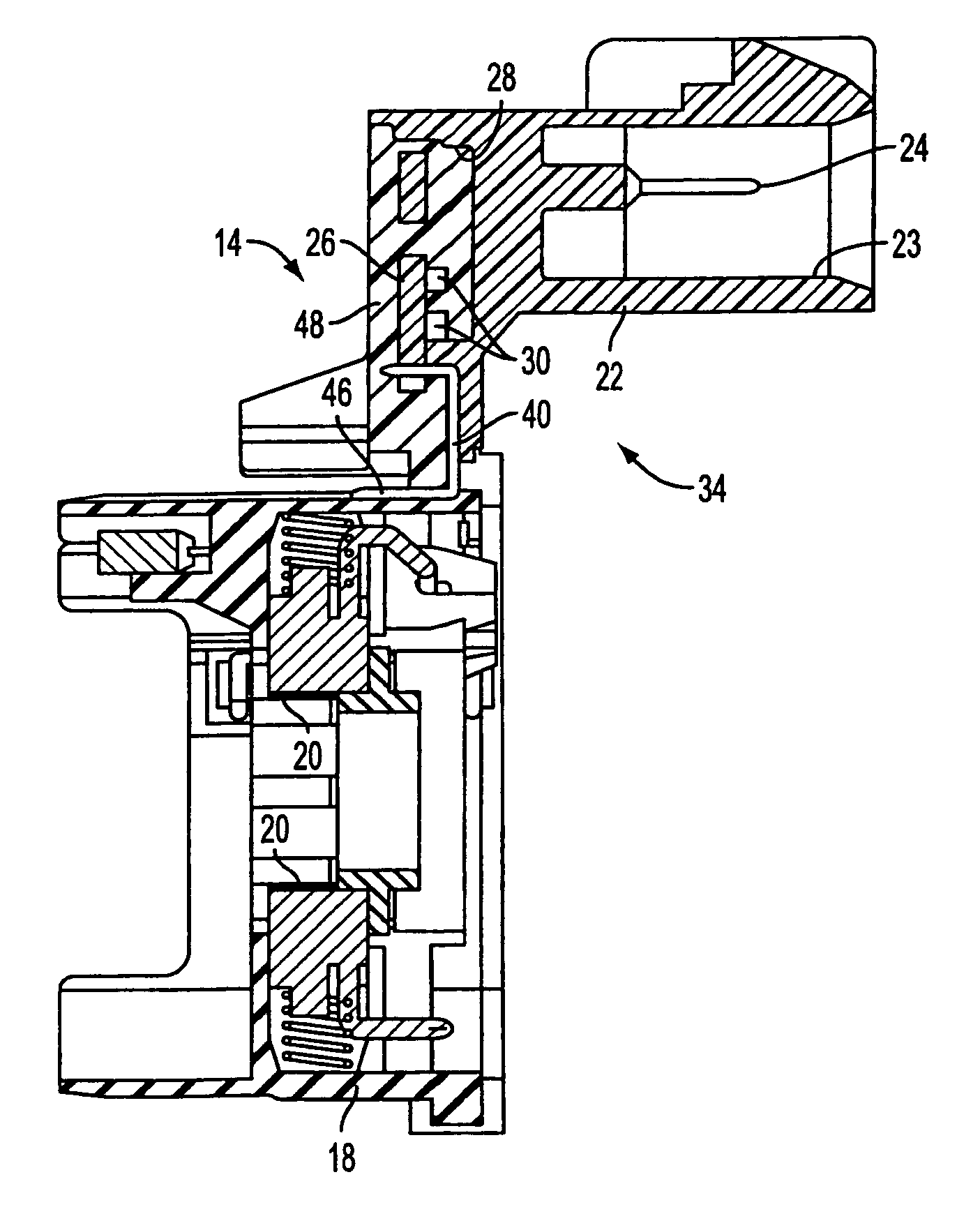

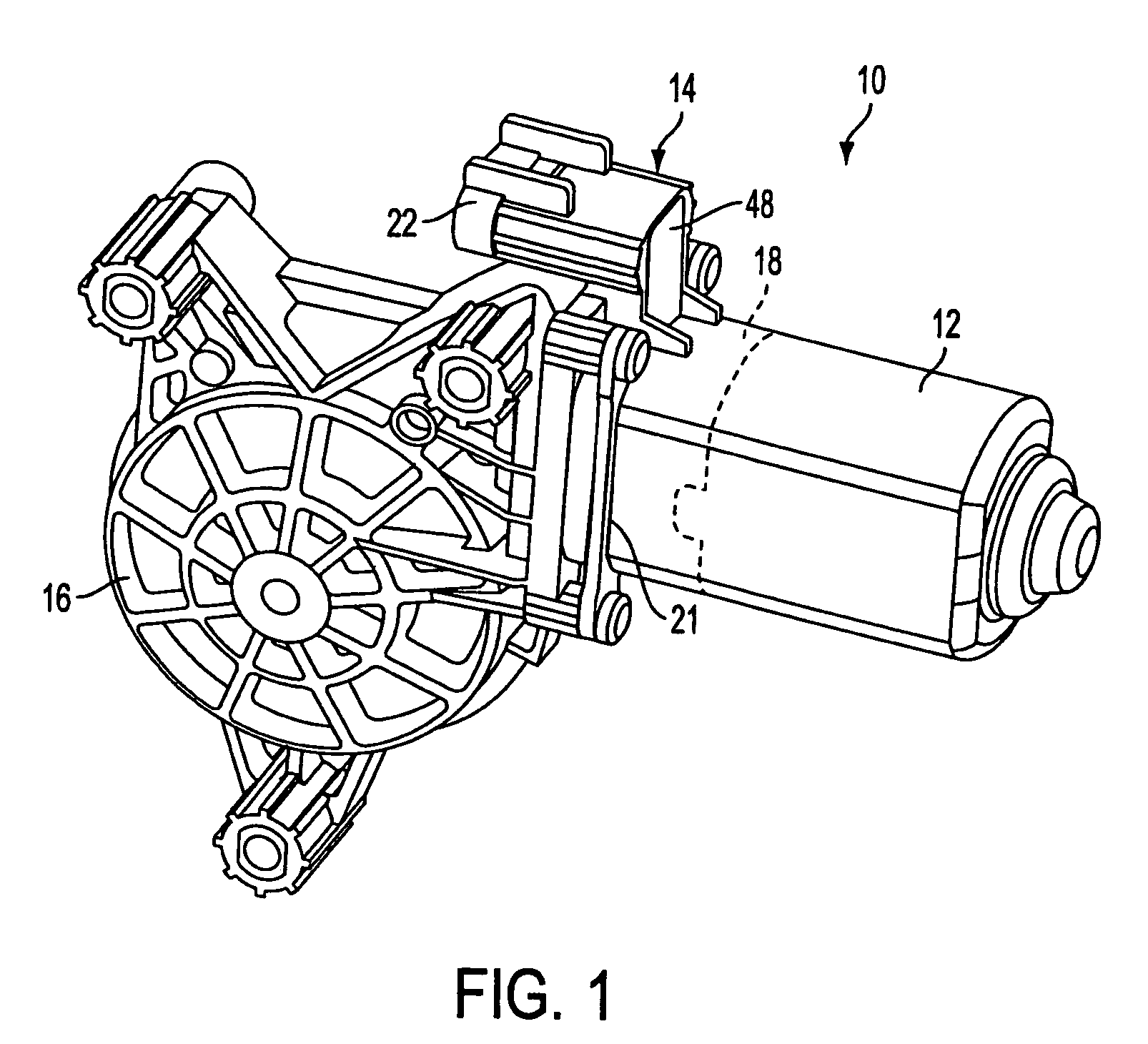

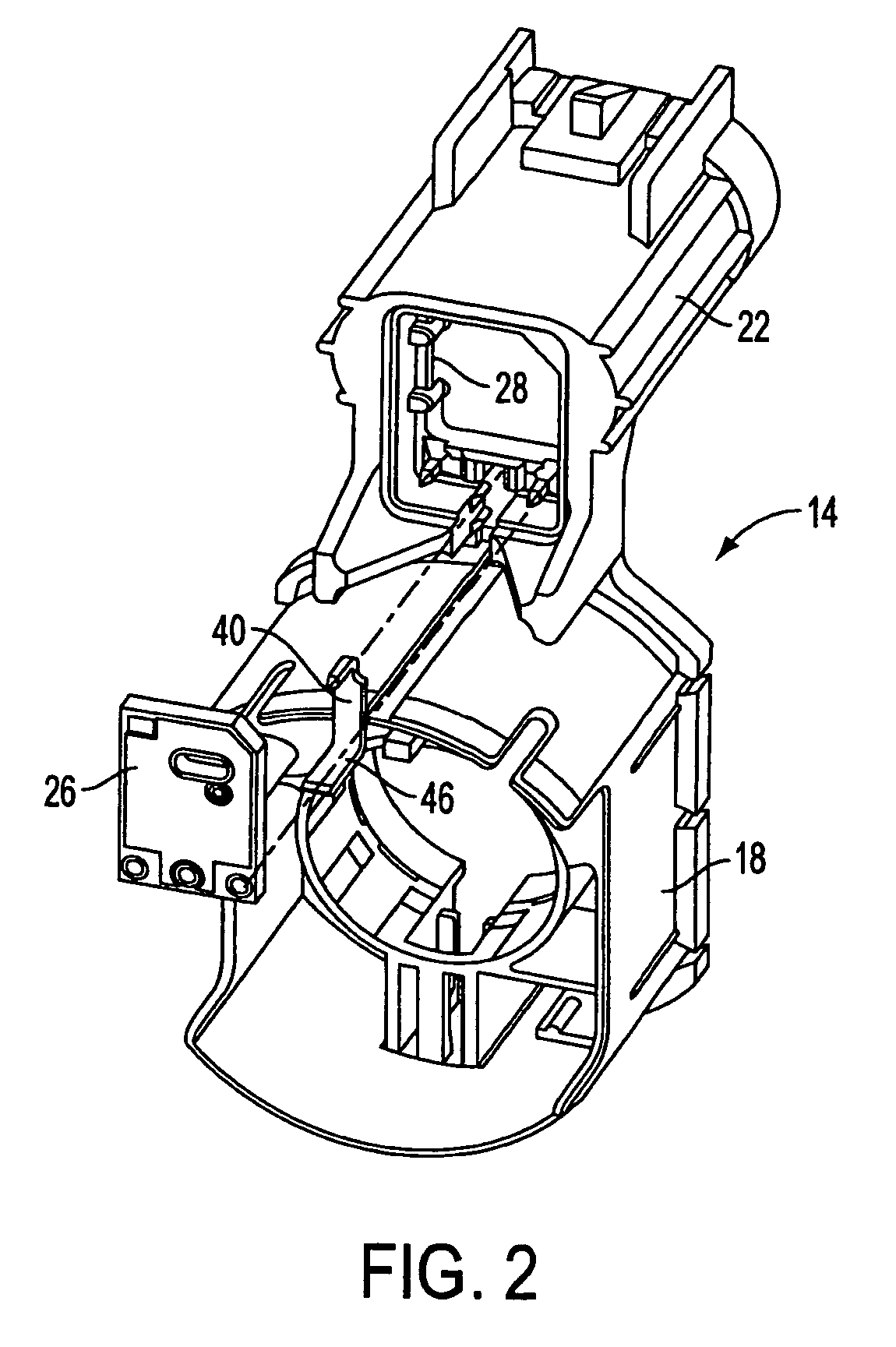

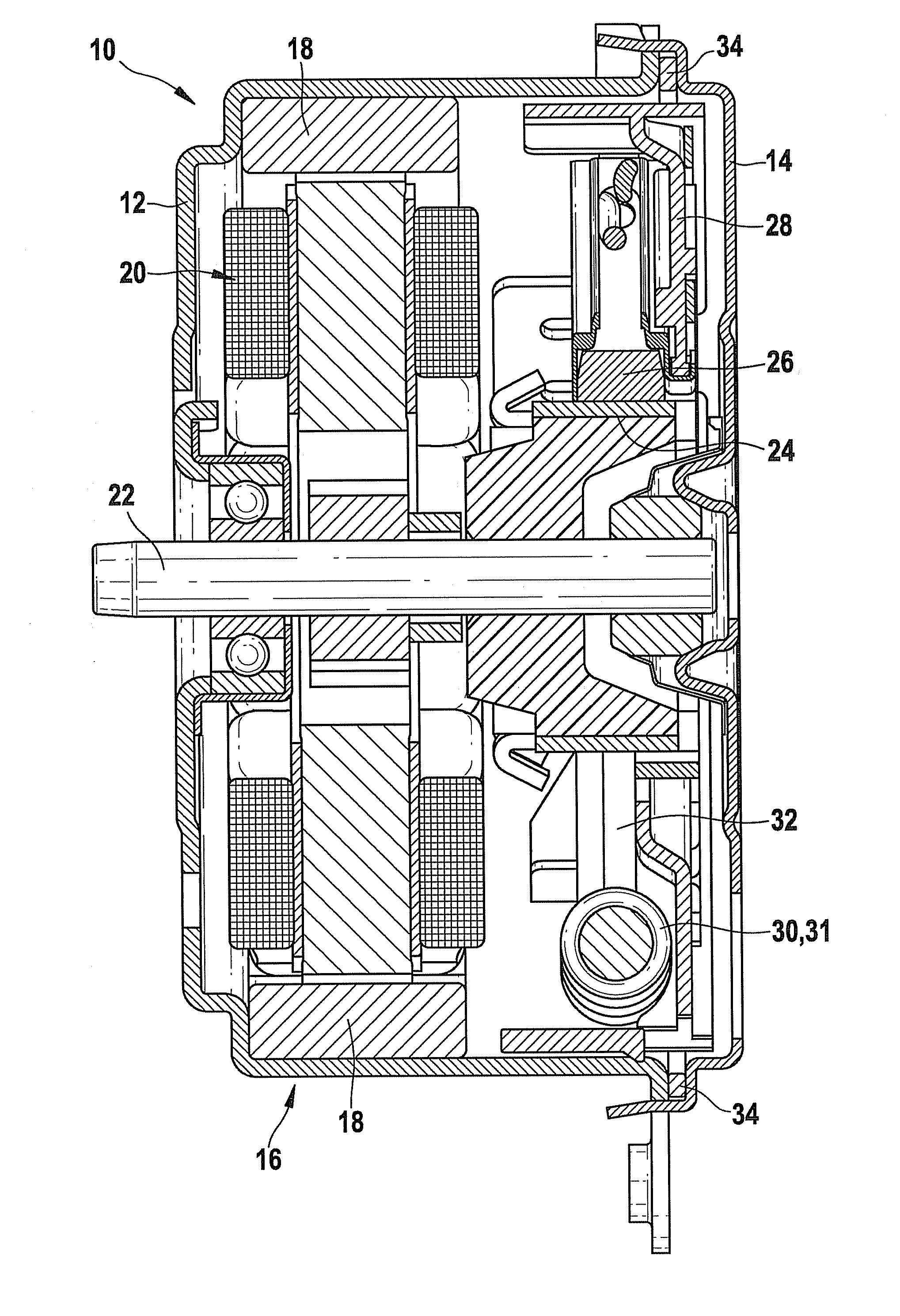

EMI suppression in permanent magnet DC motors having PCB outside motor in connector and overmolded

InactiveUS20050189829A1EMI suppressionRotary current collectorMagnetic/electric field screeningElectromagnetic interferenceEngineering

A permanent magnet DC motor 10 having electromagnetic interference (EMI) suppression includes a metal motor housing 12 and a brush card assembly 34. The brush card assembly includes brushes 20 and leads 24 constructed and arranged to be coupled with a source of power to power the motor. A brush card housing 14 has a first portion 18 housing the brushes and a second portion 22, integral with the first portion, and housing the leads. A printed circuit board 26 is mounted with respect to the second portion of the housing and carries at least one electromagnetic interference (EMI) suppression component 30 constructed and arranged to suppress EMI generated by the motor. The leads are electrically connected to the printed circuit board so that current can be provided through the printed circuit board to the brushes. A contact member 40 is electrically connected between the printed circuit board and the metal motor housing so that the at least one EMI suppression component couples the brushes to the metal motor housing thereby causing the metal motor housing to become an AC ground and EMI shield.

Owner:BROSE FAHRZEUGTEILE GMBH & CO KG HALLSTADT (DE)

EMI suppression in permanent magnet DC motors having PCB outside motor in connector and overmolded

InactiveUS6992414B2Rotary current collectorMagnetic/electric field screeningElectricityElectromagnetic interference

A permanent magnet DC motor 10 having electromagnetic interference (EMI) suppression includes a metal motor housing 12 and a brush card assembly 34. The brush card assembly includes brushes 20 and leads 24 constructed and arranged to be coupled with a source of power to power the motor. A brush card housing 14 has a first portion 18 housing the brushes and a second portion 22, integral with the first portion, and housing the leads. A printed circuit board 26 is mounted with respect to the second portion of the housing and carries at least one electromagnetic interference (EMI) suppression component 30 constructed and arranged to suppress EMI generated by the motor. The leads are electrically connected to the printed circuit board so that current can be provided through the printed circuit board to the brushes. A contact member 40 is electrically connected between the printed circuit board and the metal motor housing so that the at least one EMI suppression component couples the brushes to the metal motor housing thereby causing the metal motor housing to become an AC ground and EMI shield.

Owner:BROSE FAHRZEUGTEILE GMBH & CO KG HALLSTADT (DE)

DC machine

InactiveUS20110006636A1Improve stabilityTolerance chainRotary current collectorSupports/enclosures/casingsMobile vehicleEngineering

A DC machine, particularly a DC motor for use in a motor vehicle, includes a stator, a rotor that is supported rotatably in a pole housing having a commutator, and having a brush-holder support, made substantially of plastic, for fixing at least two brushes and further components. The brush-holder support has a device for improving the positioning of the components situated on or at it relative to the rest of the machine and / or for shortening the tolerance chain of the machine, in particular, a longtime stabilization of the overall equipment being also achieved.

Owner:ROBERT BOSCH GMBH

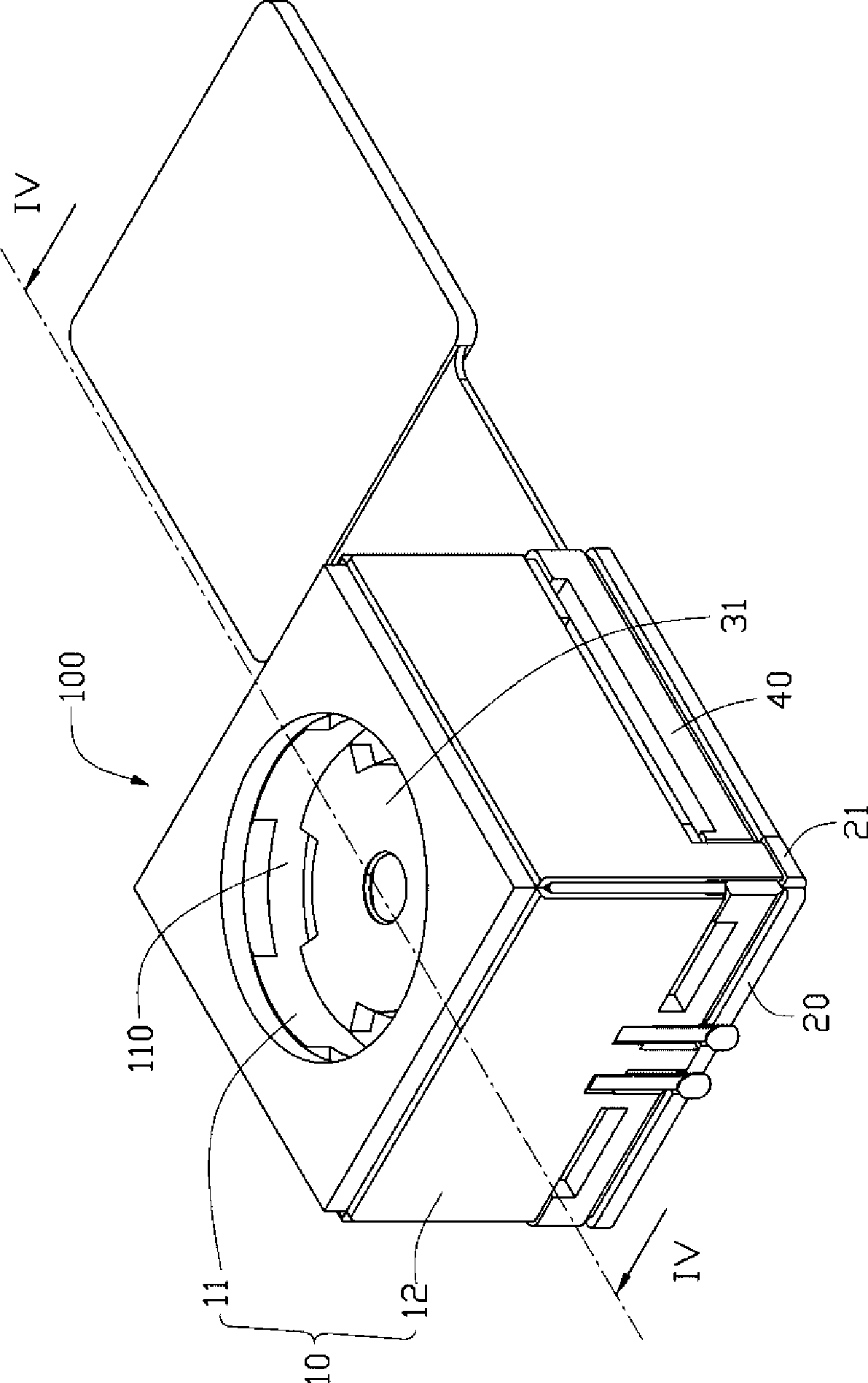

Voice coil motor and imaging device with same

InactiveCN101546936AAvoid electromagnetic interferenceProjector focusing arrangementCamera focusing arrangementConvex structureElectromagnetic interference

The invention relates to a voice coil motor comprising a body and a metal shell which coats the body, wherein the metal shell is provided with a convex structure used for electrical grounding. The convex structure of the metal shell of the voice coil motor is electrically grounded, thereby ensuring that the metal shell generates a grounded coating function to eliminate electromagnetic interference generated by the voice coil motor. The invention also relates to an imaging device with the voice coil motor.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

Motor controller

ActiveCN103730989ACompact structureEfficient signal transmissionAC motor controlSuppressing electromagnetic interferenceBusbarThree-phase

The invention discloses a motor controller which comprises a box body, a three-phase connector, a two-phase connector, a signal connector, an IGBT module and the like. The three-phase connector, the two-phase connector and the signal connector are fixed to the outer portion of the box body, and the IGBT module is fixed in the box body. The three-phase connector, the two-phase connector and the signal connector are installed on the same side wall of the box body. The IGBT module is installed on a bottom plate of the box body. A drive board, a control board and an absorbing board are sequentially arranged above the IGBT module from bottom to top. The two opposite sides of the IGBT module are provided with an AC busbar and a DC busbar respectively, the AC busbar is adjacent to the three-phase connector, and a capacitor is arranged between the DC busbar and the box body side wall adjacent to the DC busbar. According to the motor controller, due to the fact that the structure of the controller is improved, the technical problems that an existing motor controller is large in control size and low in power density are solved.

Owner:JING JIN ELECTRIC TECHNOLOGIES (BEIJING) CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com