Integrated driving motor without position sensor

A technology for driving motors and sensors, which is applied in the direction of connection with control/driving circuits, electronic commutation motor control, and single motor speed/torque control, etc. Large and other problems, to achieve the effect of low production cost, reduce the number of production parts, and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0083] Below in conjunction with accompanying drawing, the present invention is further described:

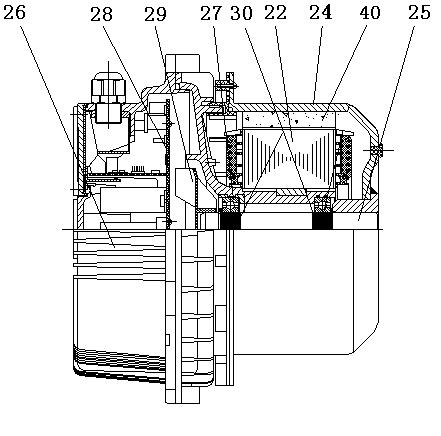

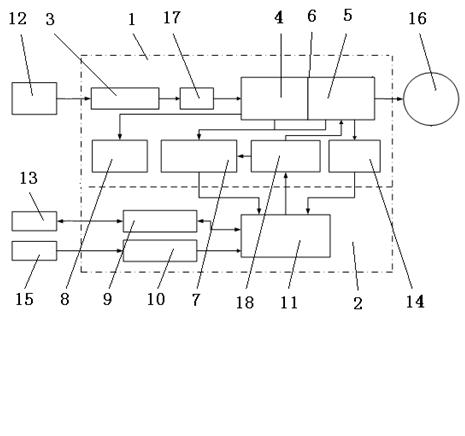

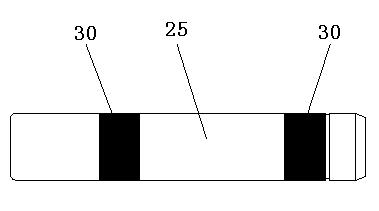

[0084] An integrated position sensorless driving motor, which is provided with a motor 16, the motor 16 is composed of a stator 22, an outer rotor 24, a rotor shaft 25, a bearing 27 and an end cover 26, and the stator is installed in the iron core slot by a multi-phase winding , the connection relationship between the stator 22 and the outer rotor 24 is the same as that of the prior art, which will not be repeated here. The outer rotor 24 is fixedly connected to the end cover 26 through the labyrinth spigot, and the motor 16 is provided with a driver 28, which is fixedly connected to the end cover 26. , the end cover 26 is connected with the stator 22 of the motor 16 to form a whole to increase the heat dissipation capacity of the module, the driver 28 is composed of a power board 1 and a control board 2, the control board 2 is fixed on the power board 1, and the power Board 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com