Method and system for realizing electric arc wire feeding for arc welding power source

A technology of arc welding power supply and power circuit, which is applied in the direction of arc welding equipment, welding equipment, manufacturing tools, etc., which can solve the problems of welding failure, operation difficulty, and the limitation of the application range of automatic welding process of arc welding power supply, etc., and achieves the convenience of welding method, The effect of improving the reliability and stability of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention is achieved through the following technical solutions:

[0010] A method for arc welding power supply to realize arc wire feeding. The method is to introduce arc voltage as the power supply of the wire feeding device during the welding process, and adopt different methods to drive the wire feeding motor according to the different characteristics of the arc welding power source. The automatic wire feeding system for MIMA welding works stably.

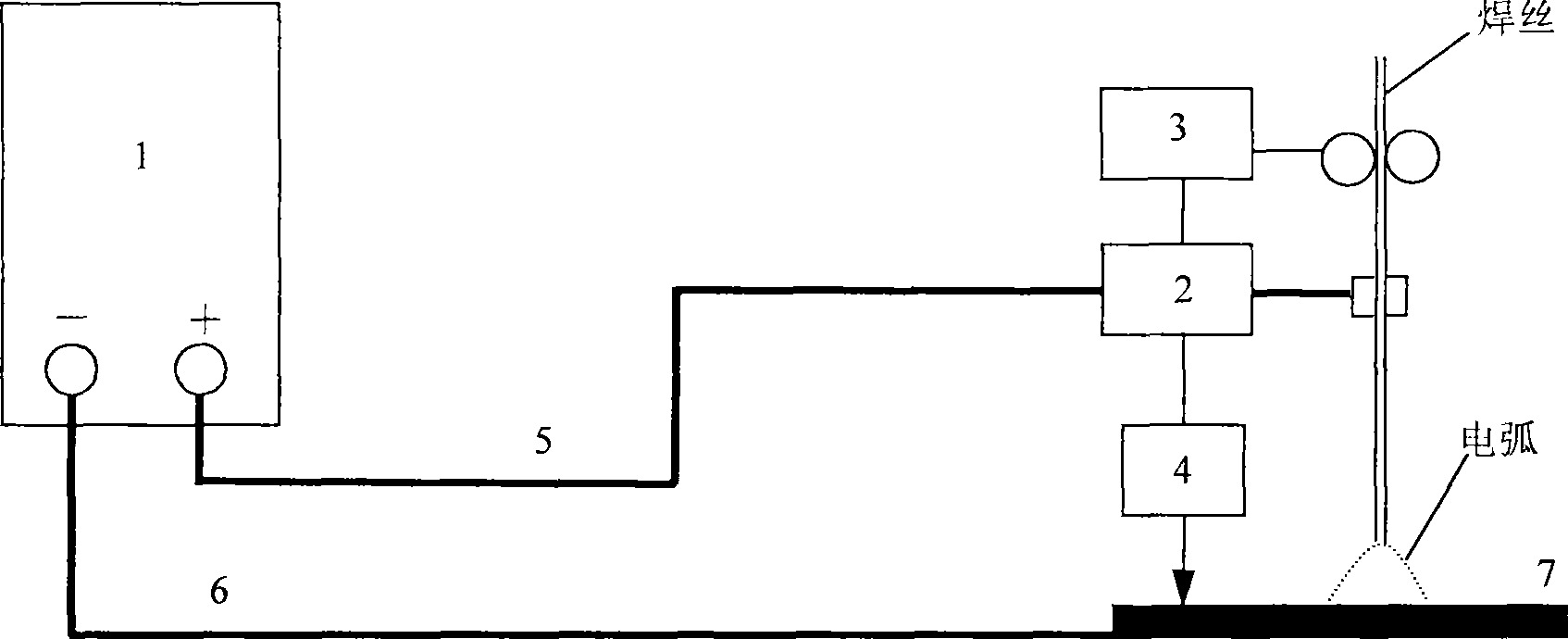

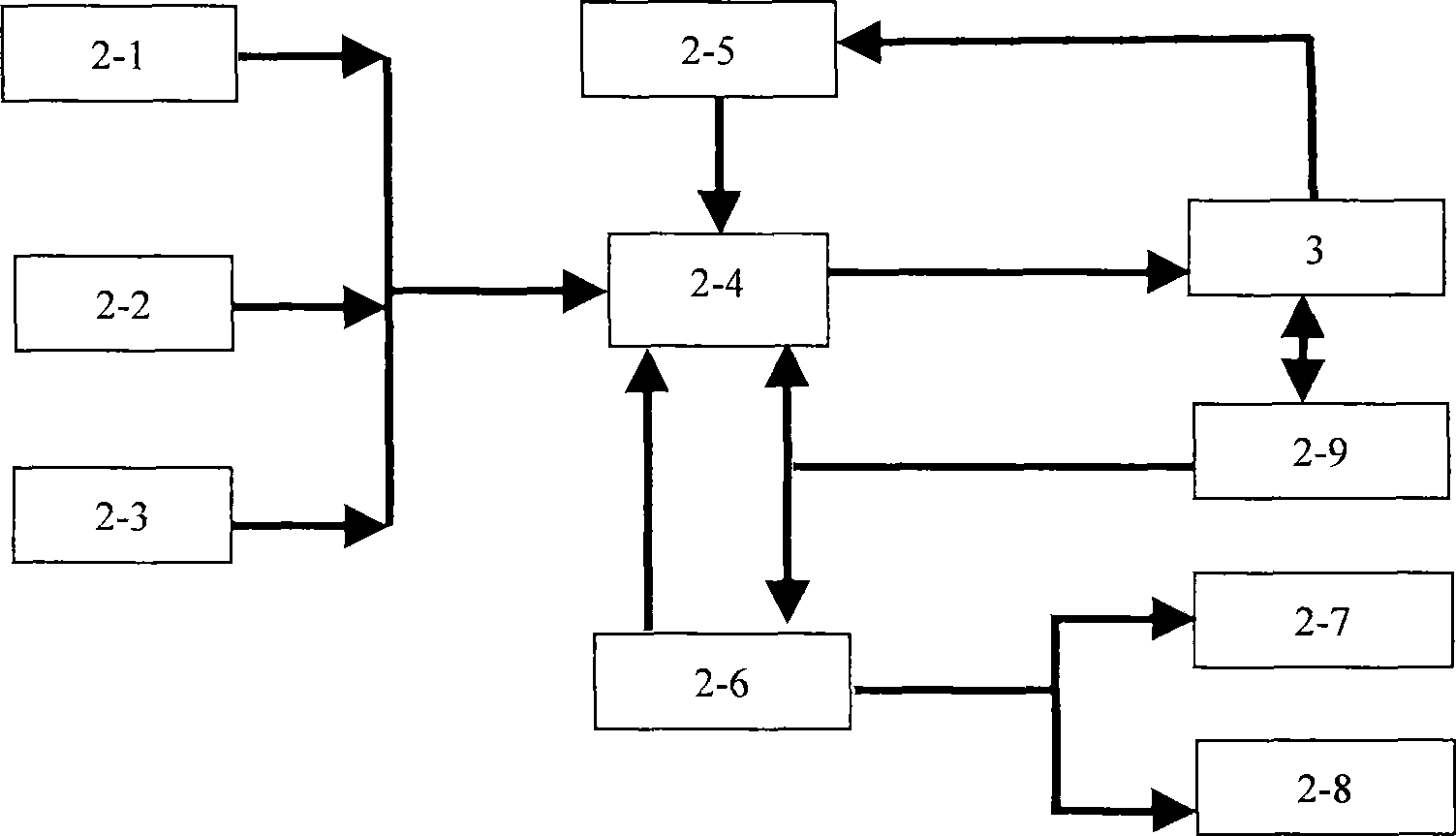

[0011] The present invention also provides a system for realizing the above method. Such as figure 1 As shown, the positive pole of the arc welding power supply (1) is connected to the arc wire feeding controller (2) through the positive pole welding cable (5), and the negative pole of the arc welding power supply (1) is connected to the welding workpiece (7) through the negative pole welding cable (6). ), one end of the controller power supply circuit (4) is connected to the workpiece (7) and the other end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com