Patents

Literature

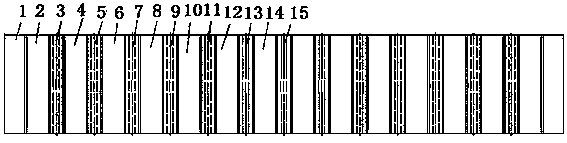

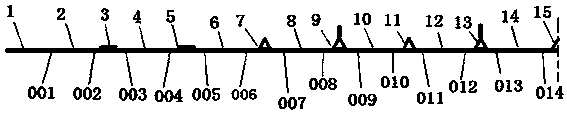

84results about How to "Welding safety" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

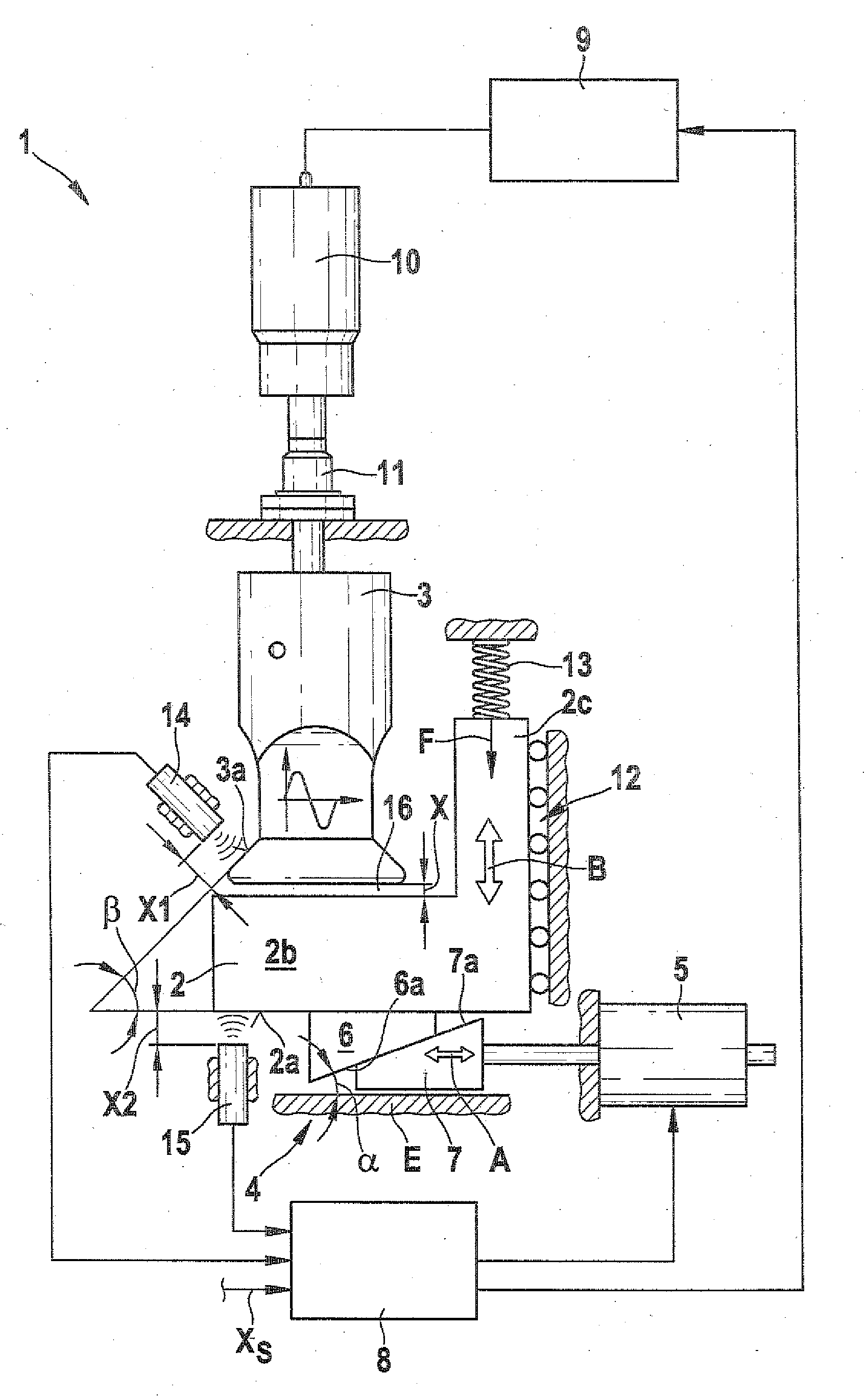

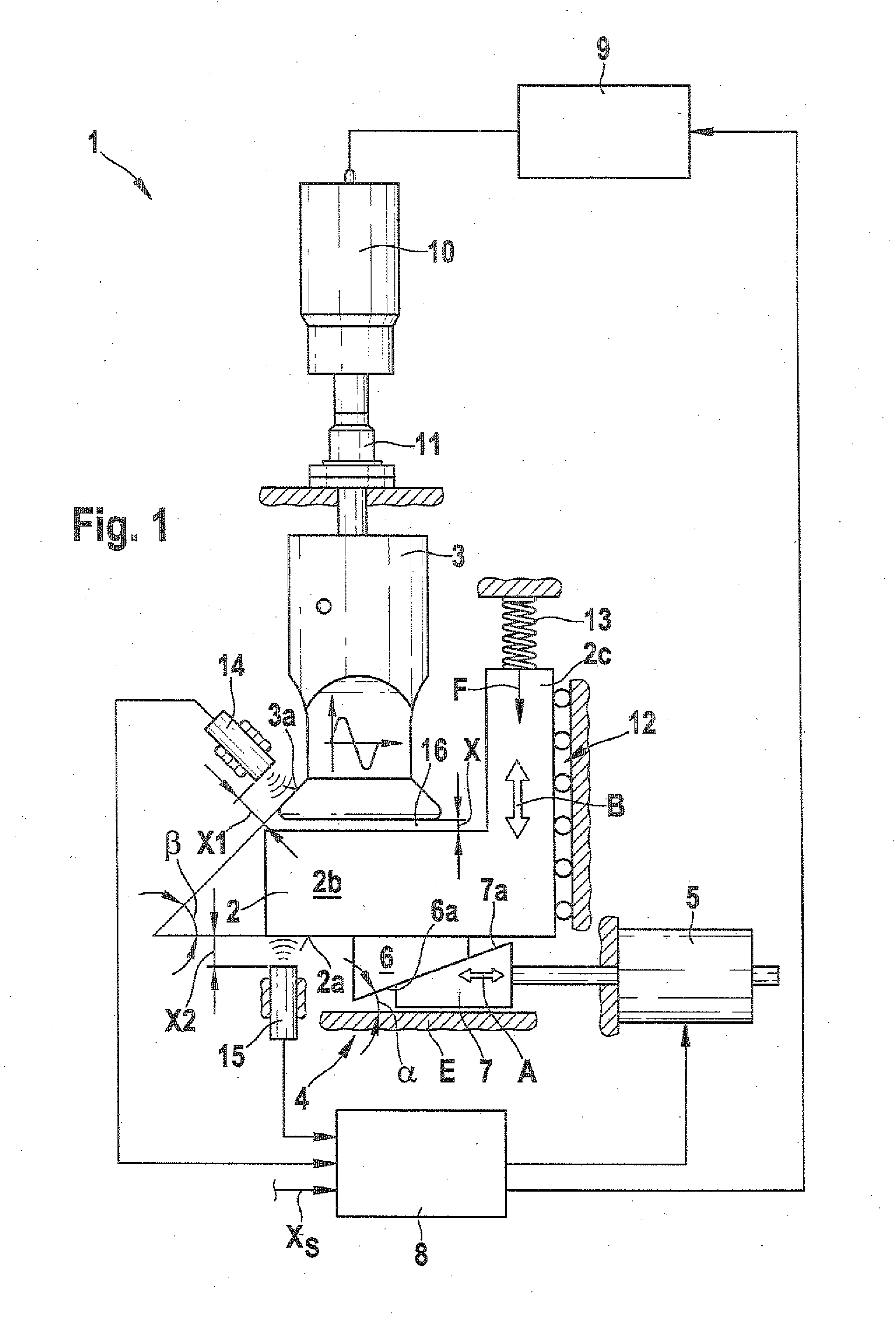

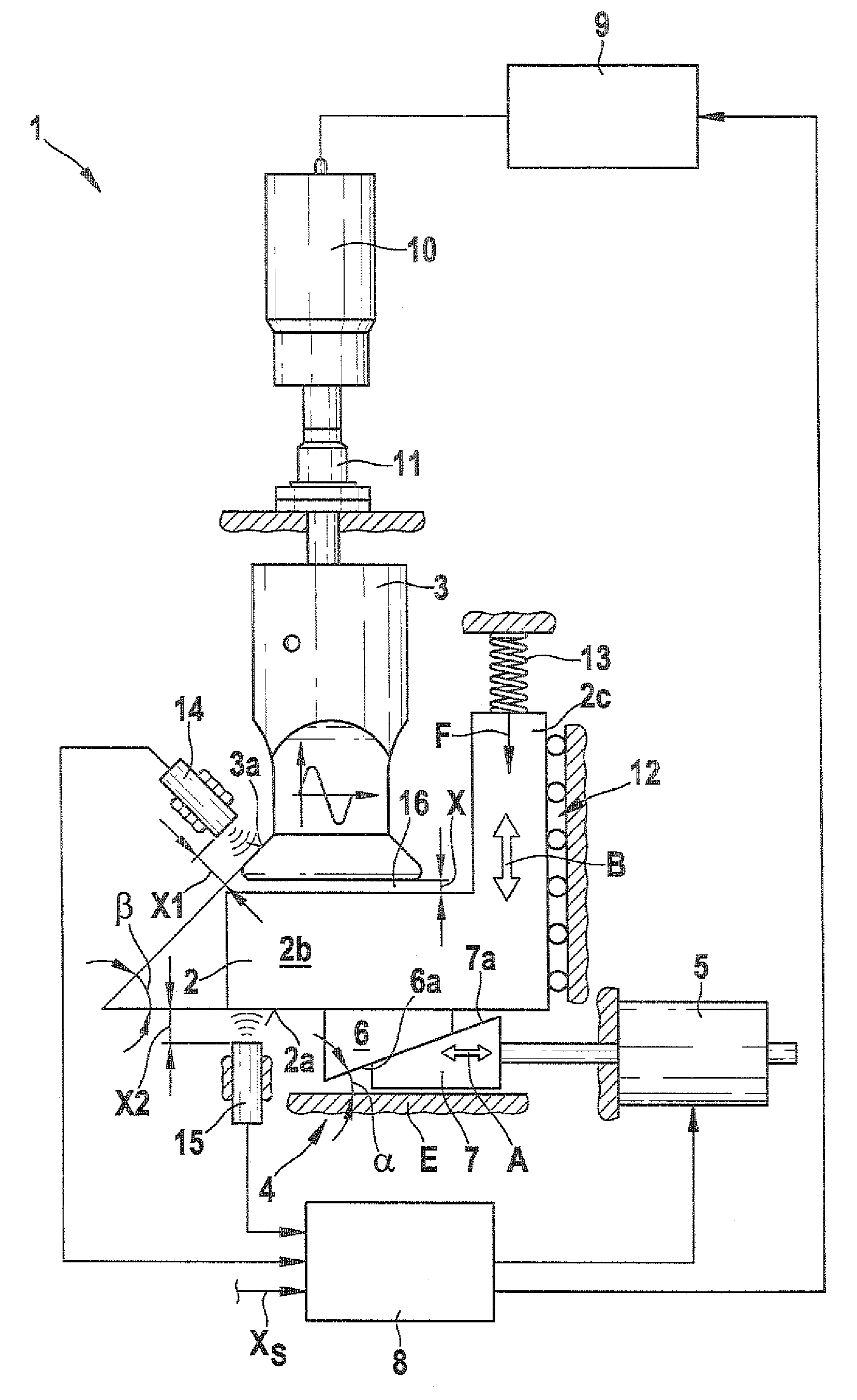

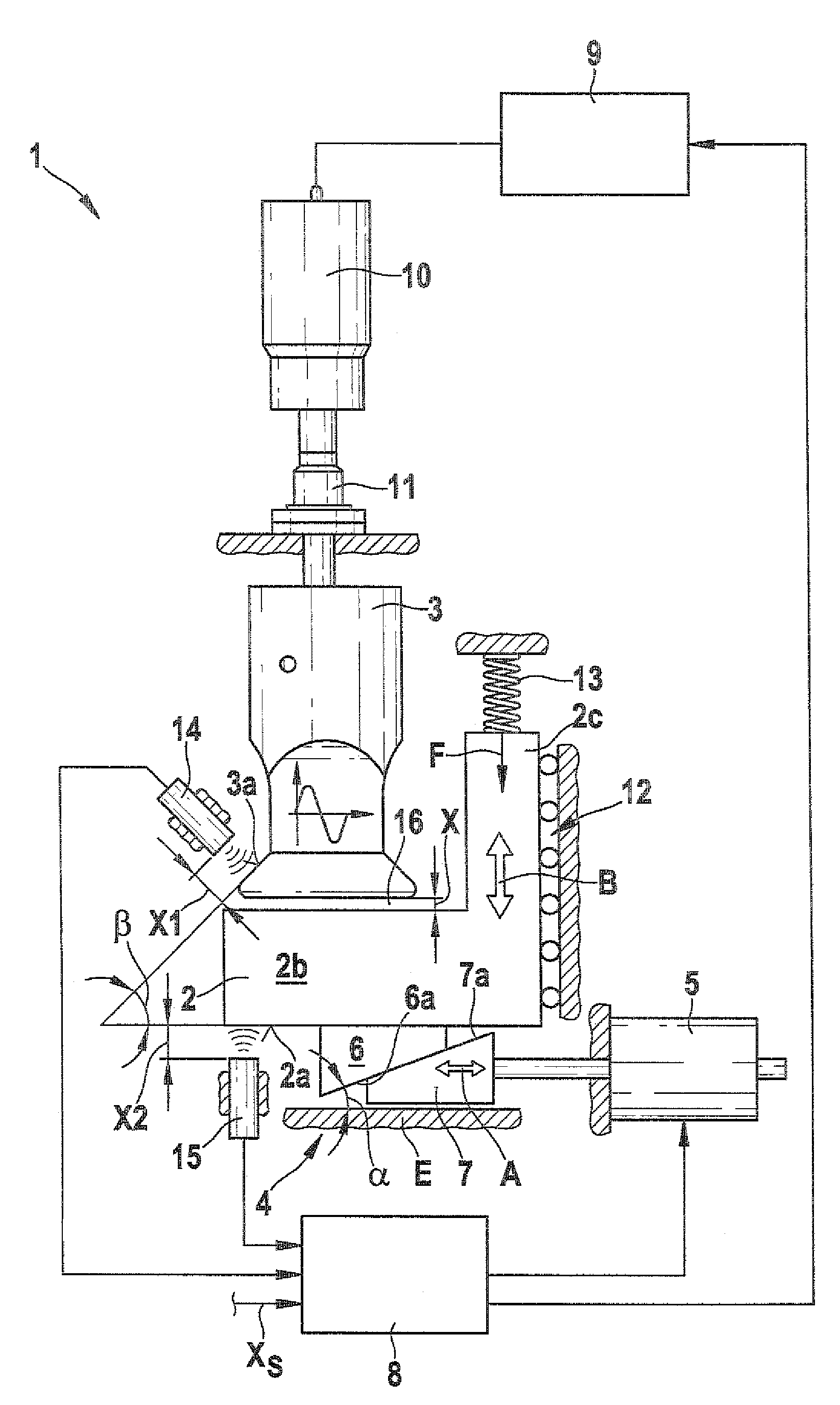

Ultrasonic welding device, and packaging machine with an ultrasonic welding device

ActiveUS20090250171A1Easy constructionAbility to be produced at a lower costControlling laminationLaminationEngineeringActuator

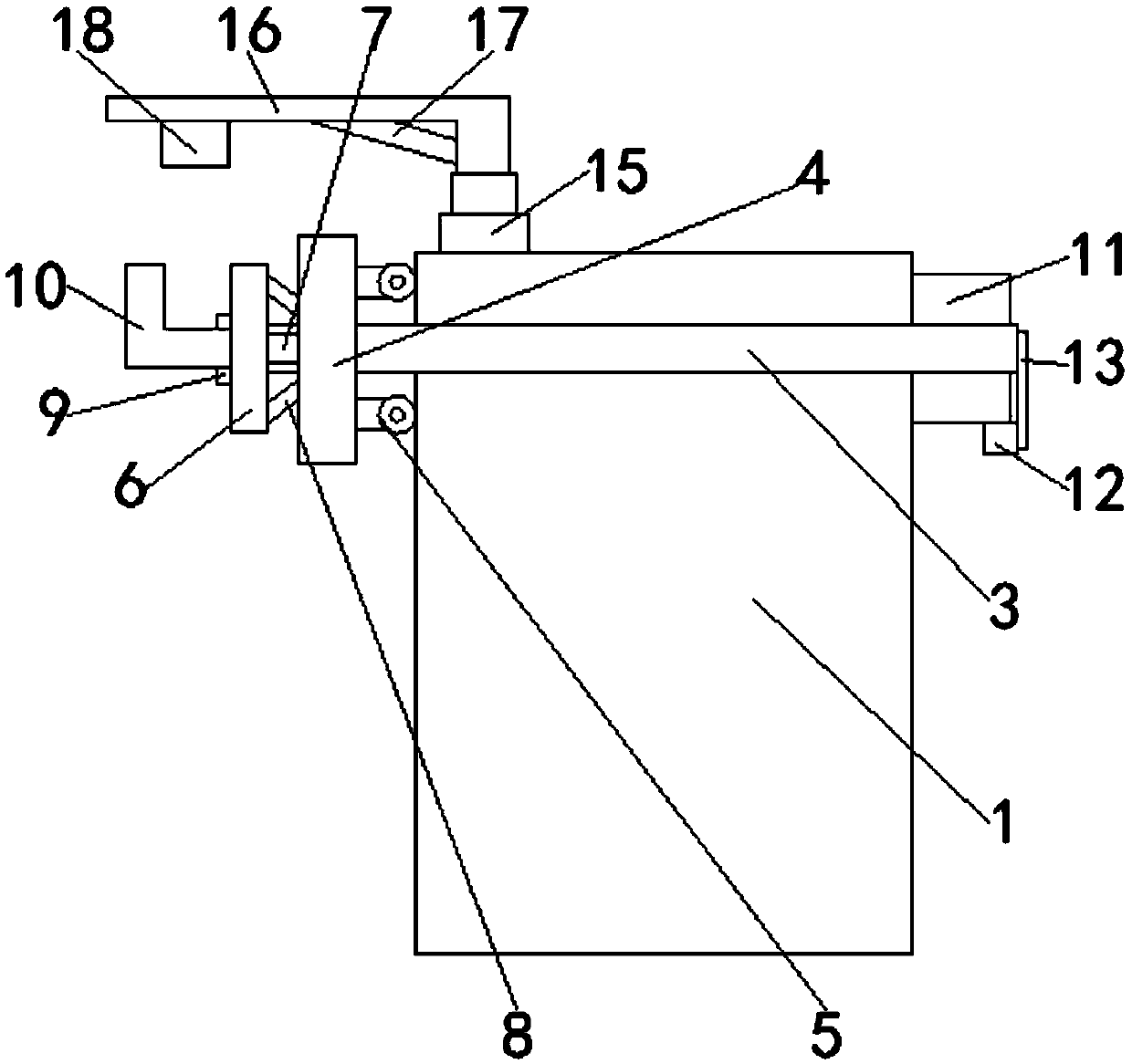

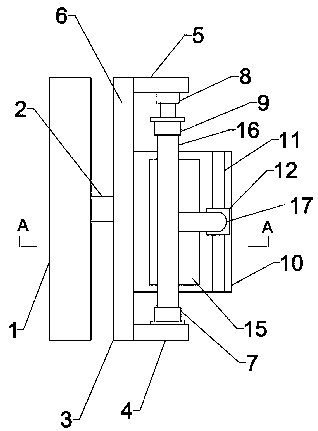

The invention relates to an ultrasonic welding device for welding foil-like materials and includes an ultrasound sonotrode, an anvil, an adjusting unit for adjusting a relative position between the ultrasound sonotrode and the anvil, and a regulating unit which regulates, via the adjustment unit, a width of a working gap between the ultrasound sonotrode and the anvil. The anvil is mounted to be movable with respect to the ultrasound sonotrode on a movable mounting. The adjusting unit has a first wedge element connected to the anvil, a second wedge element, and an actuator. The actuator is connected to the second wedge element, and the second wedge element moves relative to the first wedge element to execute a position change of the anvil relative to the ultrasound sonotrode.

Owner:SYNTEGON TECHNOLOGY GMBH

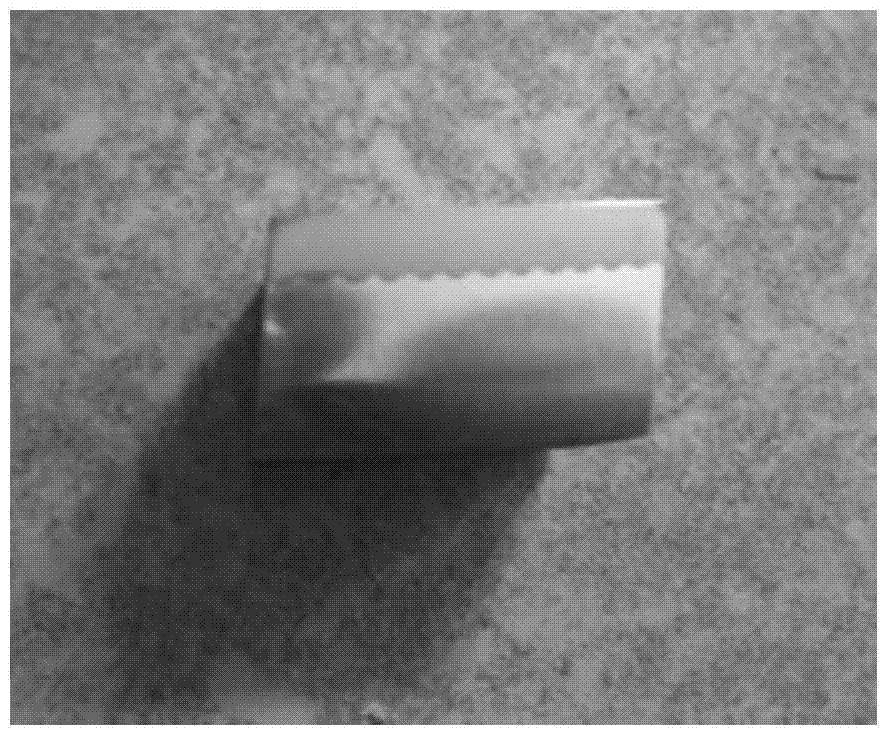

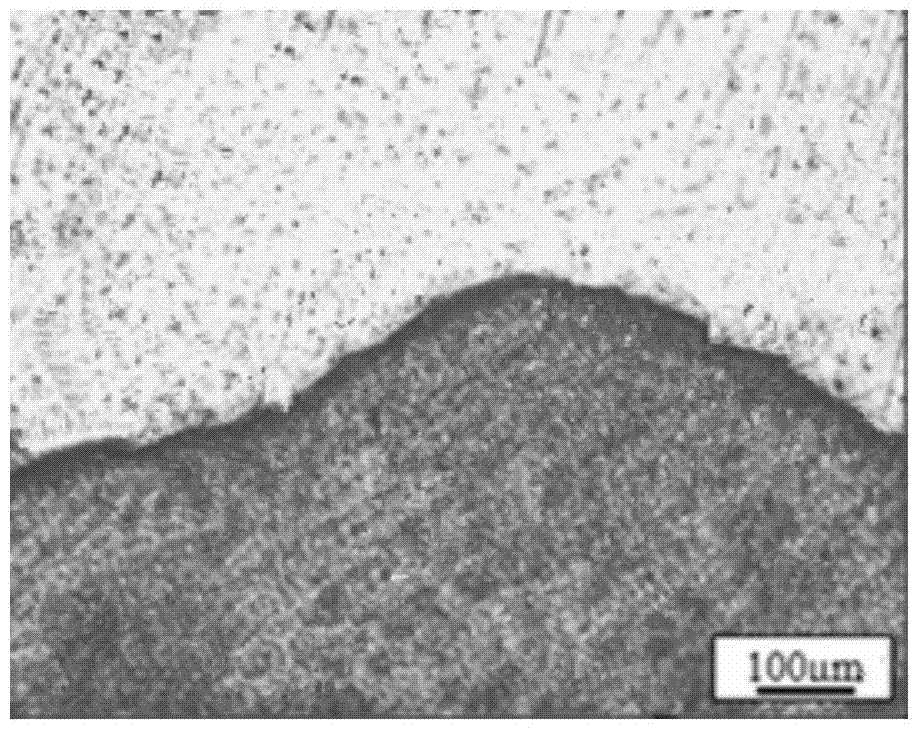

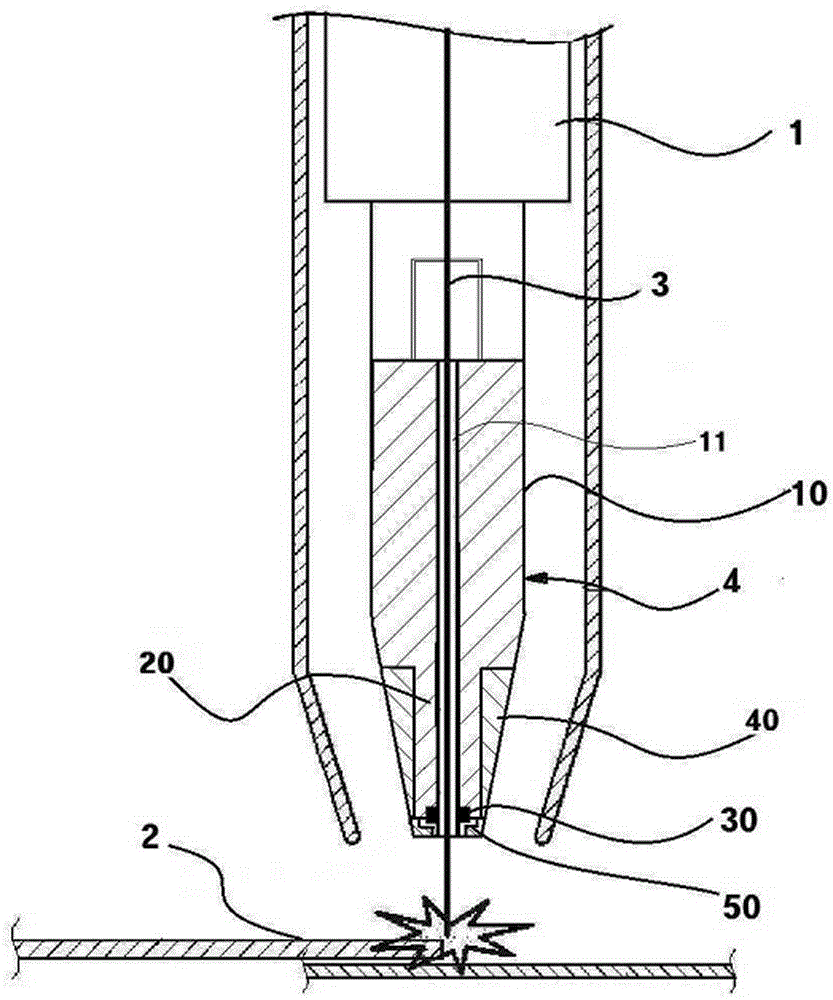

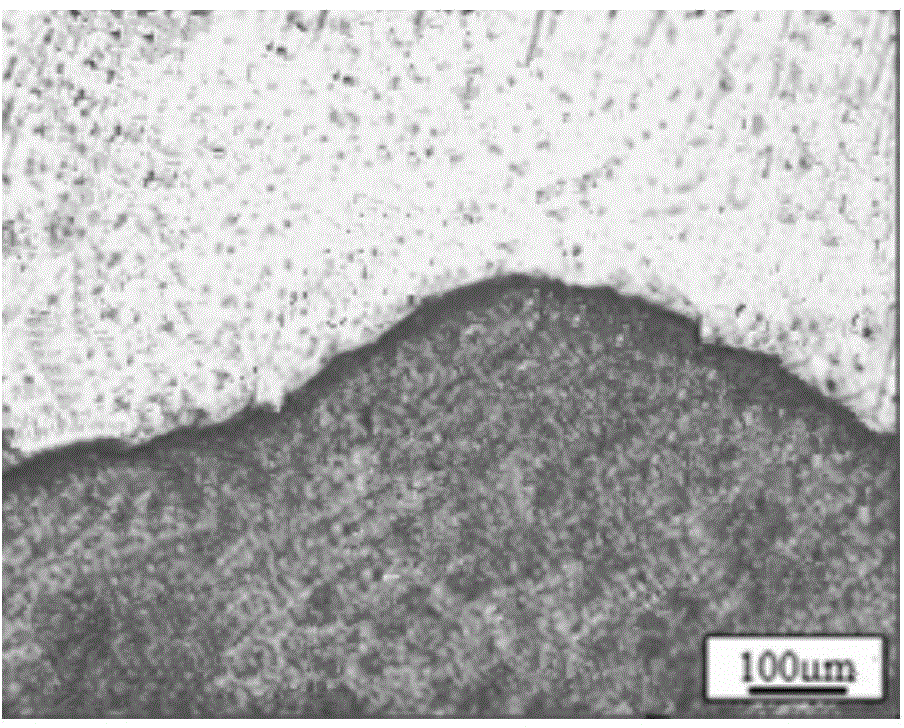

Explosive welding forming method of magnesium and aluminum alloy composite plates

InactiveCN103586574AImprove compactnessAdvancedMetal working apparatusNon-electric welding apparatusAlloy compositeFuel oil

The invention relates to an explosive welding forming method of magnesium and aluminum alloy composite plates. The explosive welding is performed according to the performance requirements of the magnesium and aluminum alloy composite plates, ammonium nitrate fuel oil mixture is adopted, and long-distance instantaneous explosive form is performed on a ground sand base. The welding method is high in forming speed, welding line is firm and is good in metallographic structure compactness, the combined rate is up to 99.5%, the interfacial shear strength is 120MPa, on the premise of strict operation, the welding process is safe and reliable, and the method is reliable and effective in magnesium and aluminum alloy composite plate production.

Owner:TAIYUAN UNIV OF TECH

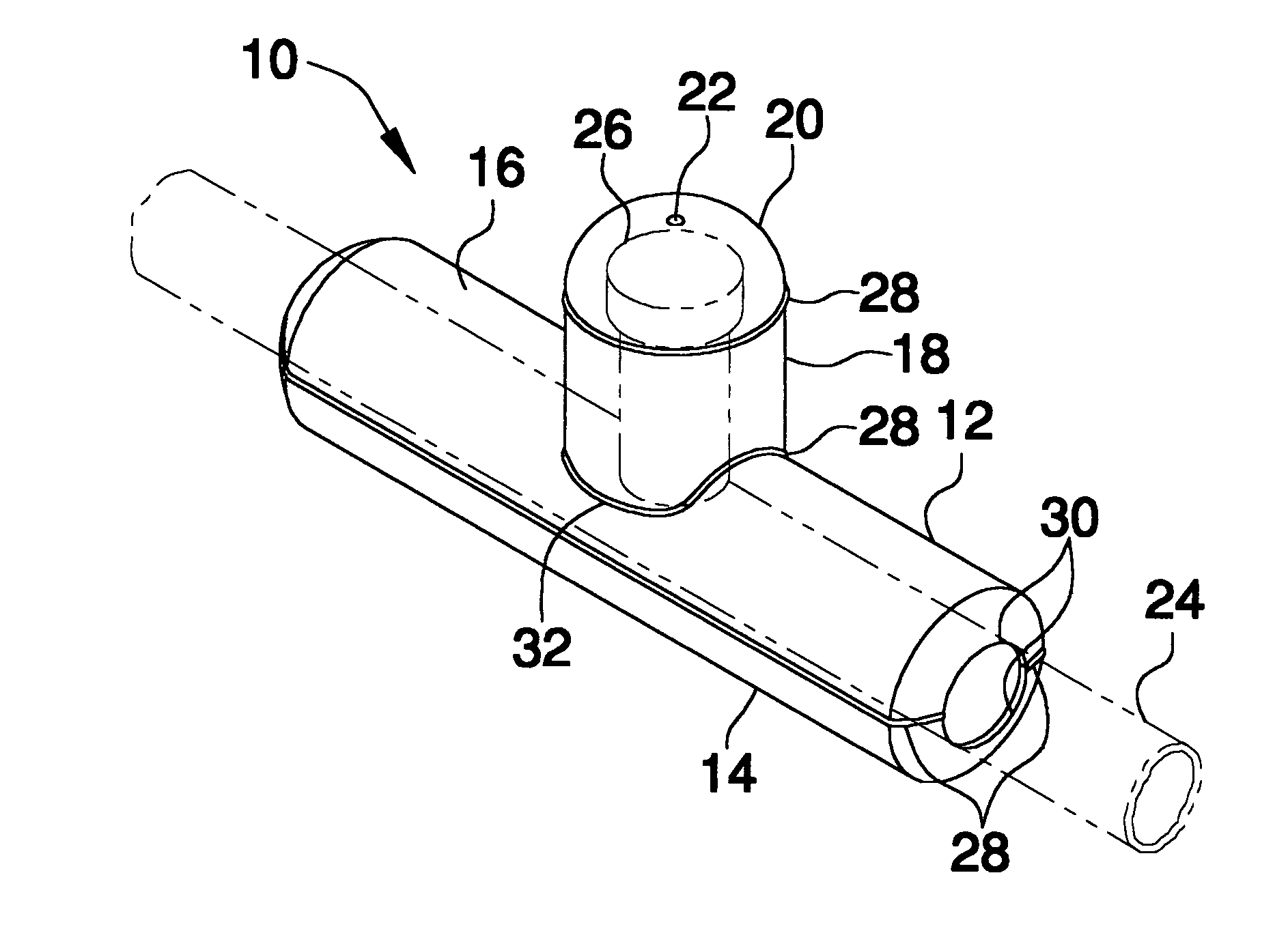

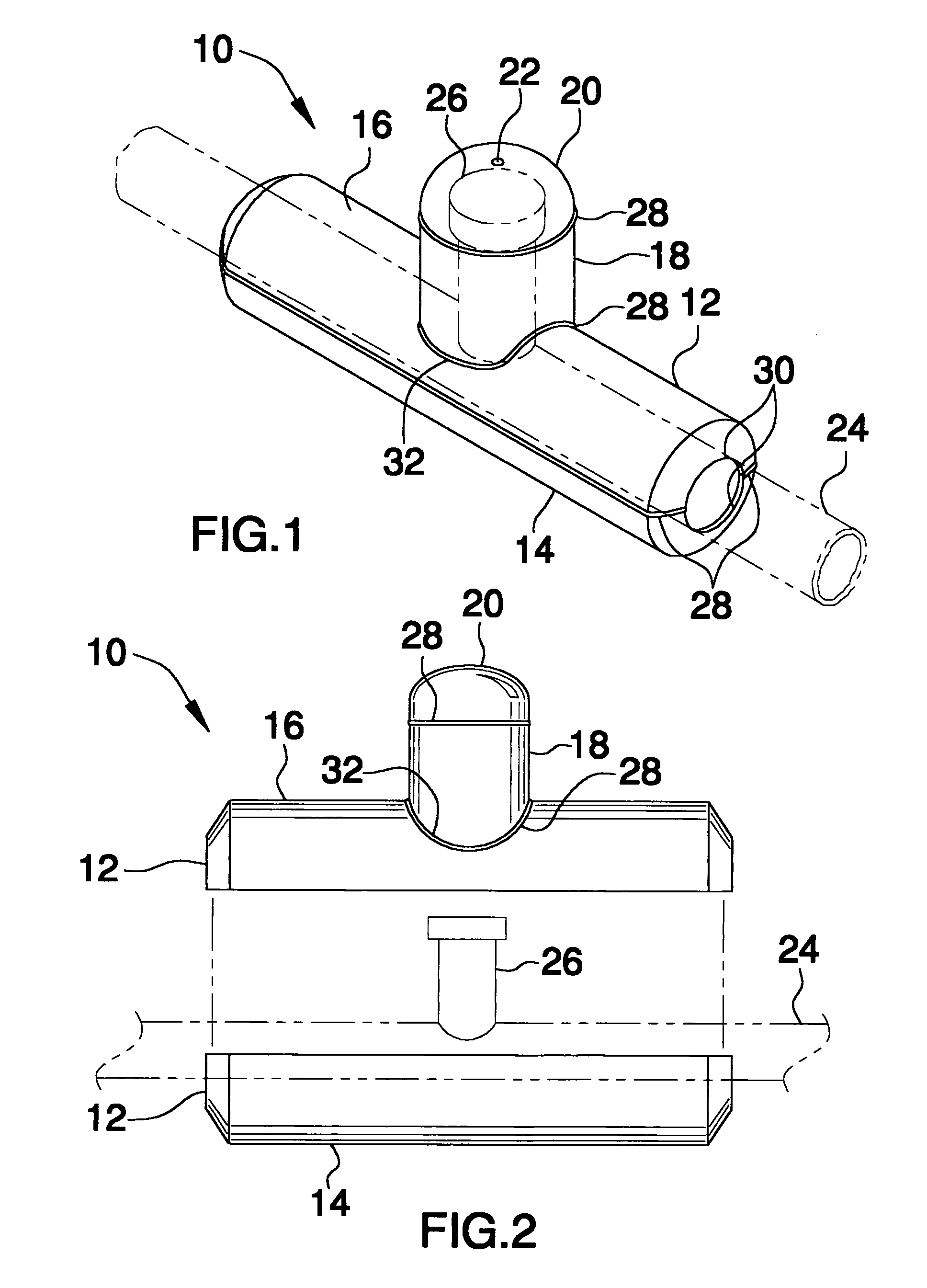

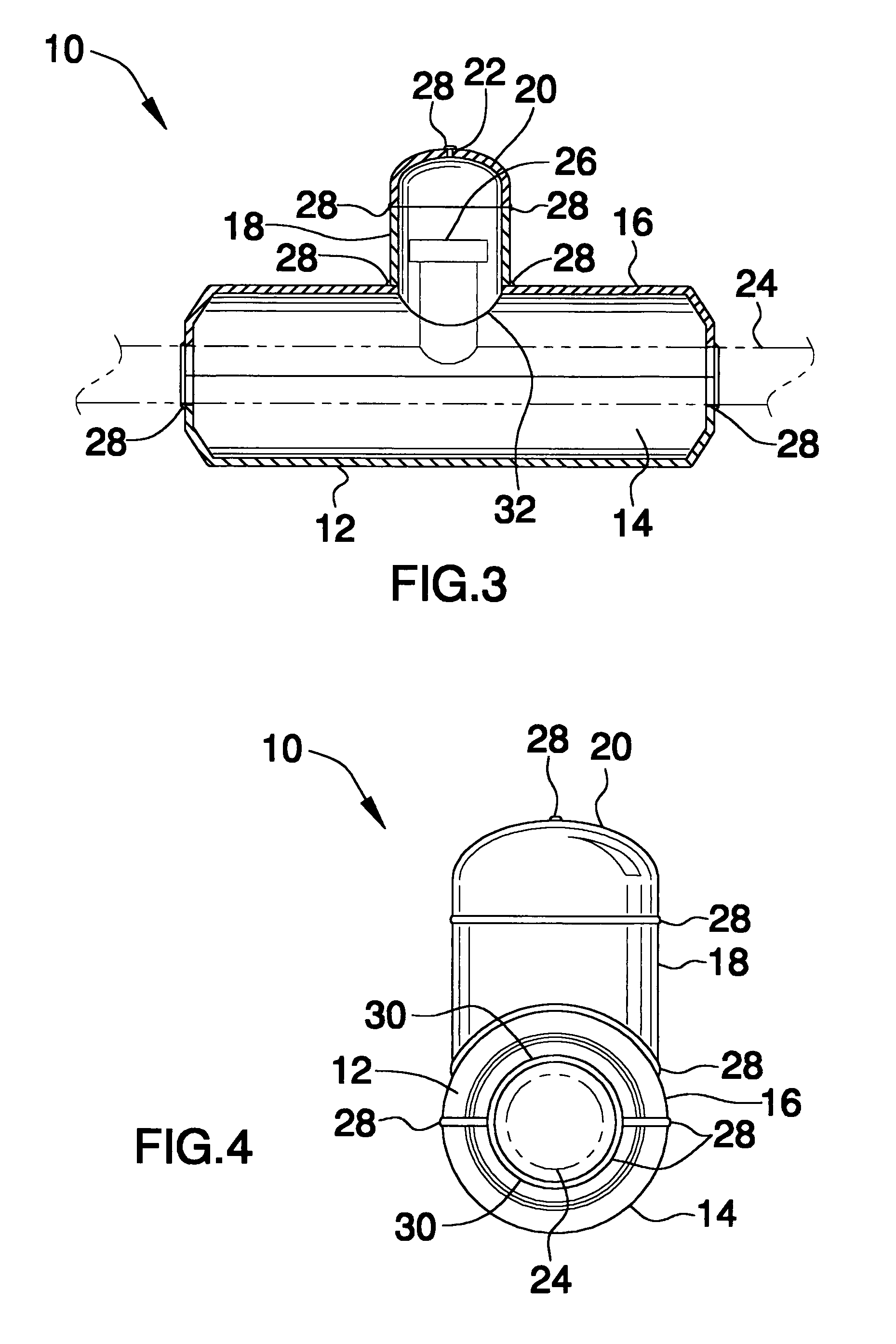

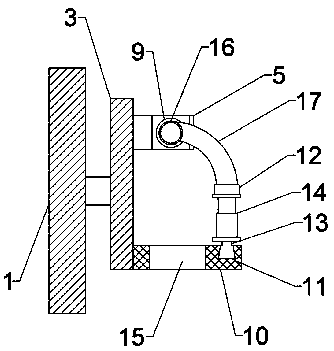

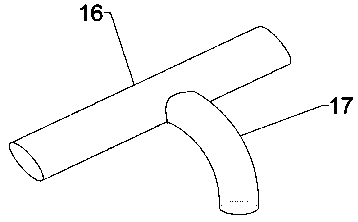

Natural gas pipe repair fitting and method

InactiveUS6901967B1Easily and efficiently manufactured and marketedLow pricePipe elementsRigid pipesProduct gasSpherical form

Natural gas pipe repair fittings and methods for using same allow safely welding a pipe repair fitting over a leaking natural gas service line “T” fitting. A bottom half and a top half are welded together to form a hollow cylinder having hemispherical ends with semicircular pipe notches in them. A hollow vertical pipe has one end welded over a pipe hole in the middle of the top half of the cylinder. A hemispherical cap is affixed to the opposing end of the vertical pipe. The cap has a cap hole in its top. A method for installing the natural gas pipe repair fitting by enclosing a leaking natural gas service line “T” fitting with the natural gas pipe repair fitting and welding the natural gas pipe repair fitting to the gas main line is also disclosed.

Owner:VERVE

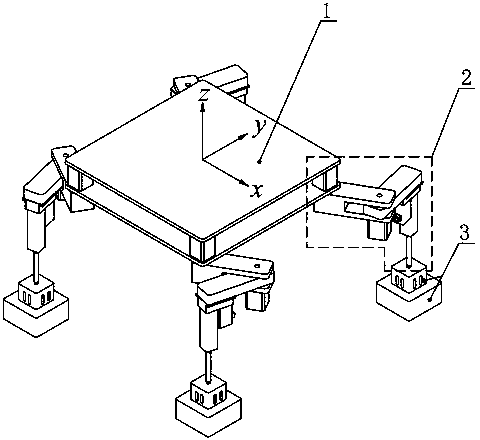

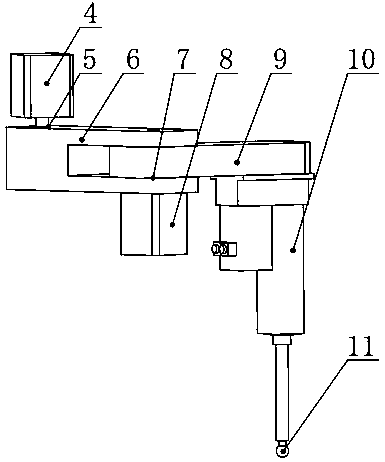

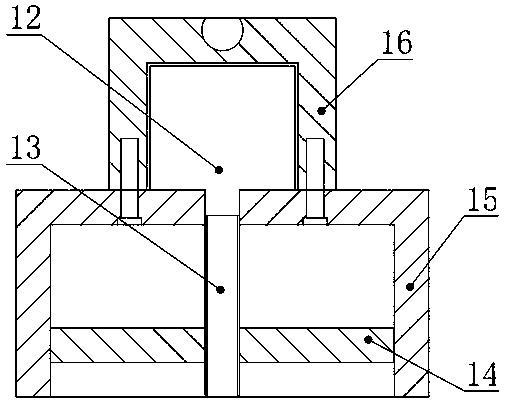

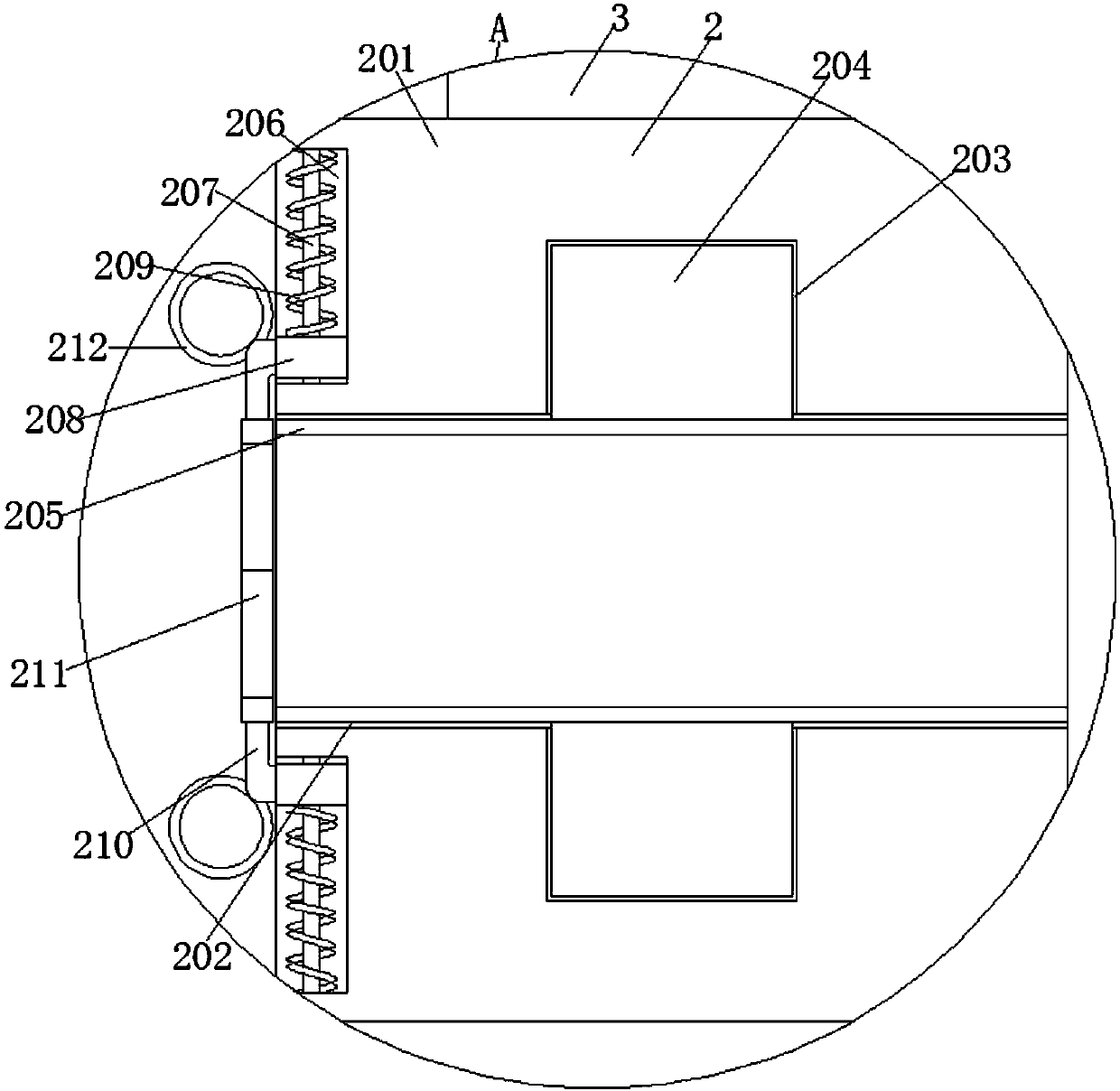

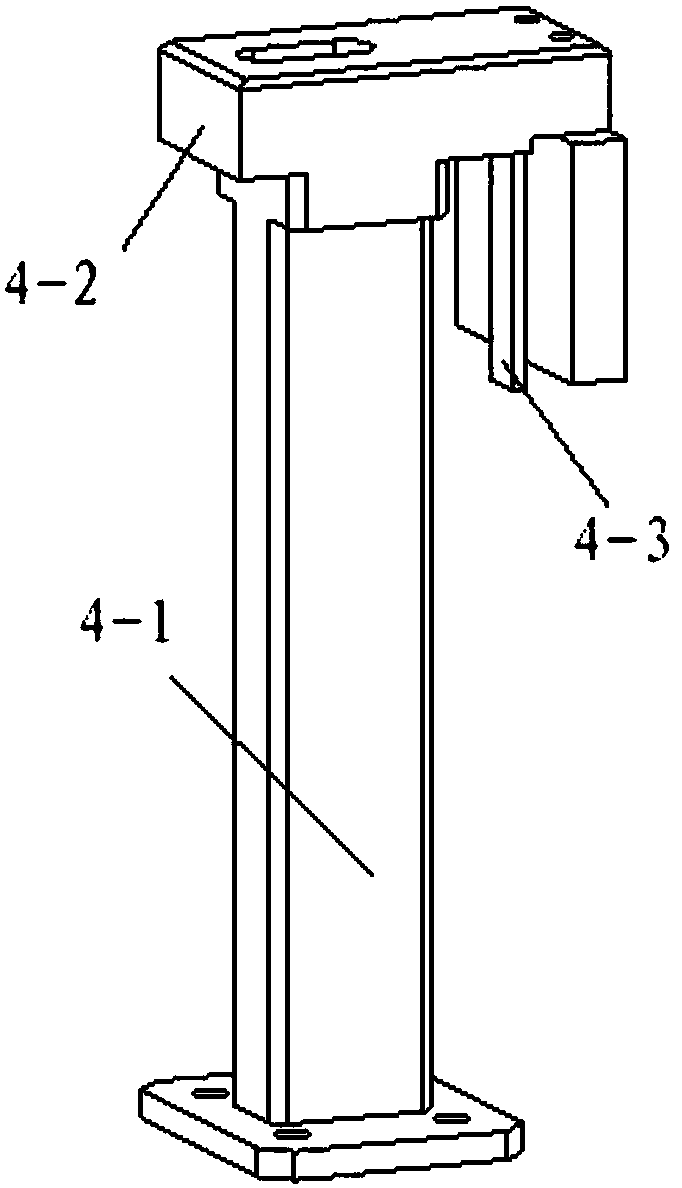

A foot-type magnetic adsorption wall climbing robot

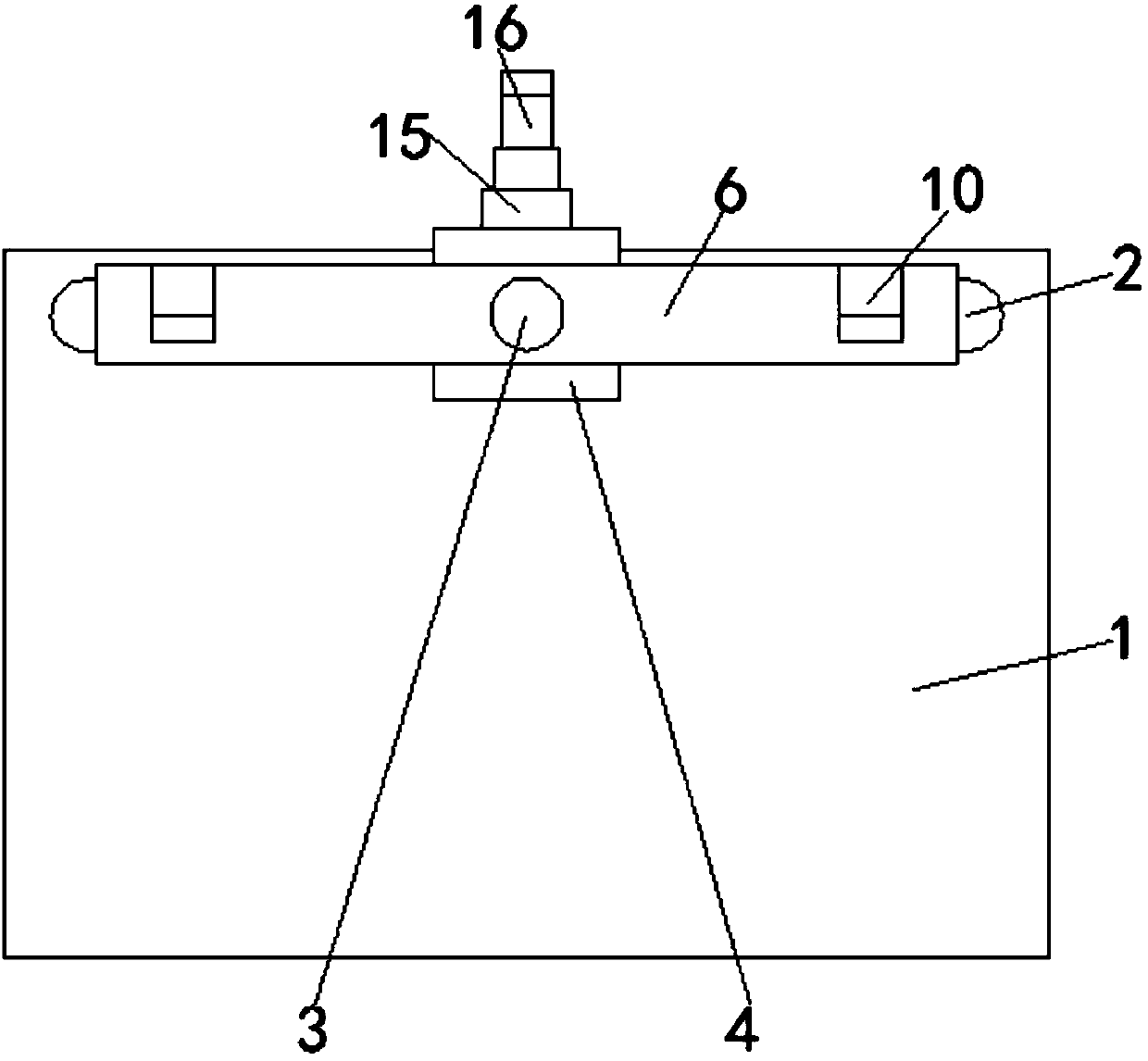

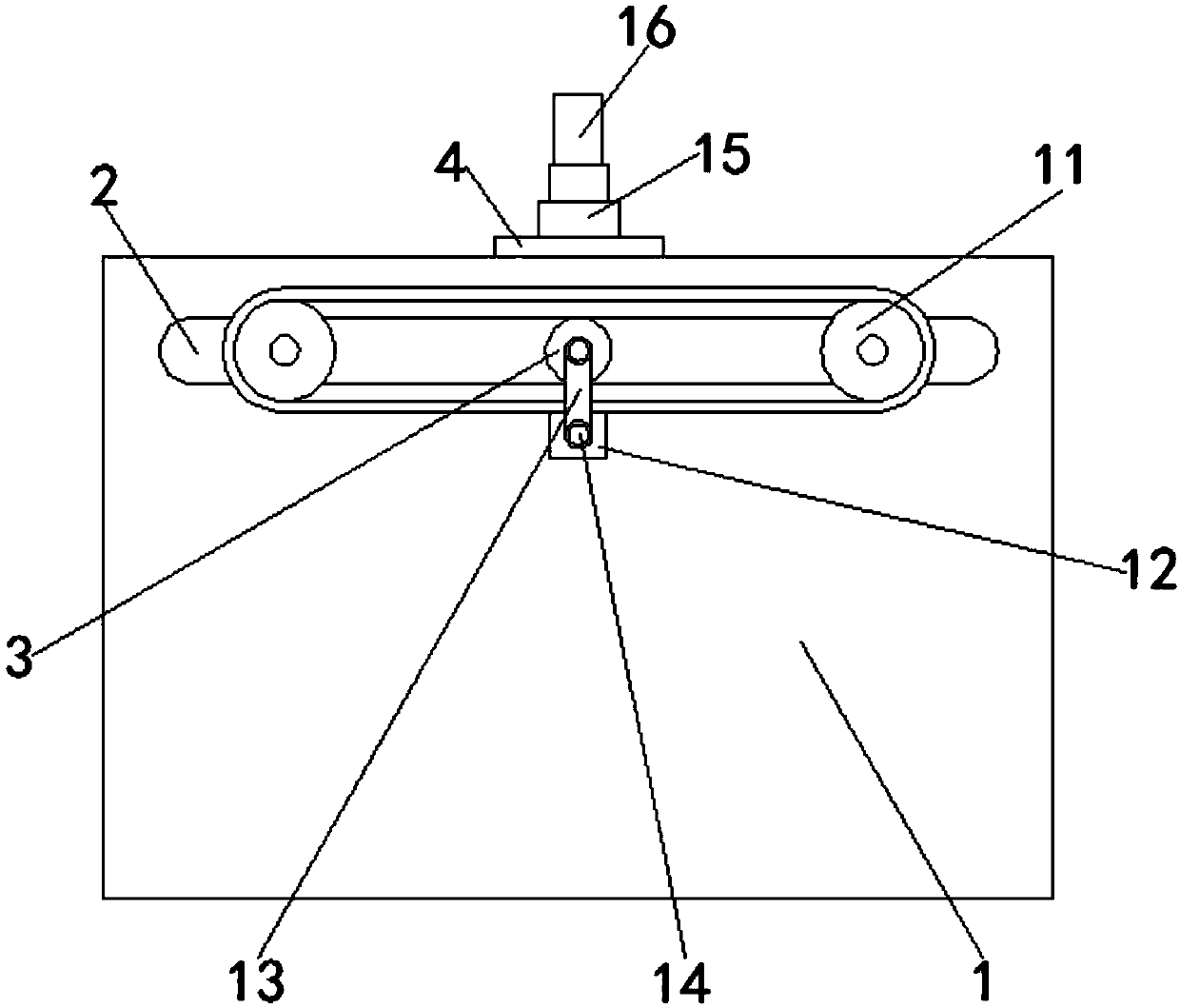

The invention belongs to the field of wall-climbing robots, in particular to a foot-type magnetic adsorption wall-climbing robot, which is composed of a carrying platform, a walking leg and an adsorption foot. Various actuators can be mounted on the carrier platform to perform various operations on the iron-based wall surface. Each walking leg comprises a two-degree-of-freedom series mechanism, aservo-electric cylinder and a ball hinge, wherein the end of each walking leg is connected and absorbed sufficiently. The suction foot adopts a screw nut mechanism to adjust the height of the permanent magnet and the wall surface so that the suction force can be adjusted. Robots can be thought of as combinations of 4-RRR Planar mechanisms and elevating mehcanisms. the movement of the two mechanisms is controlled to realize the omni-directional movement of the platform in the space. Robot can move straight, turn and adjust posture flexibly on the different curvature of the wall. The invention solves the shortcomings of unreliable adsorption and inflexible steering of the conventional magnetic adsorption wall climbing robot, and has the advantages of simple structure, strong load capacity, good obstacle-crossing ability, flexible movement and reliable adsorption.

Owner:SOUTHWEST PETROLEUM UNIV

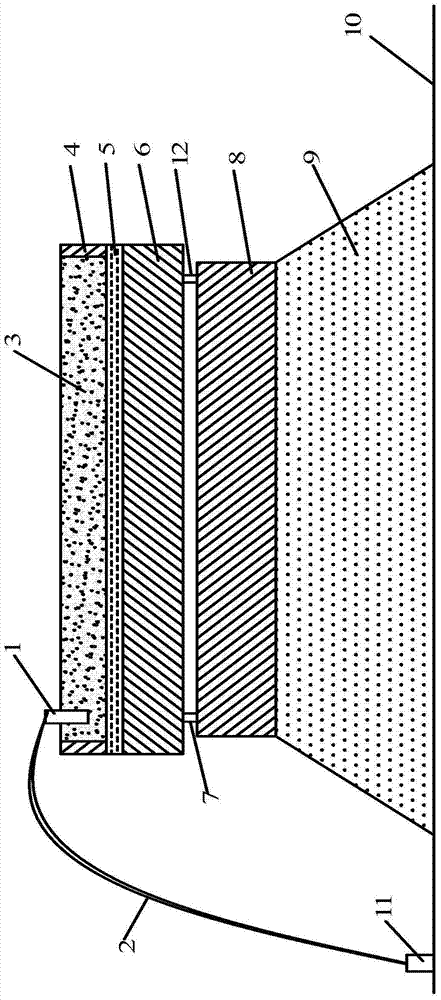

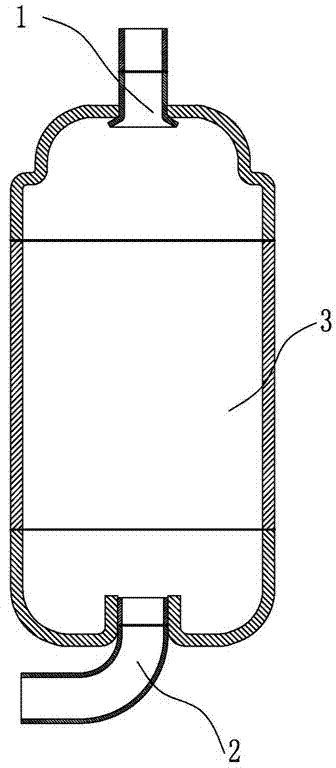

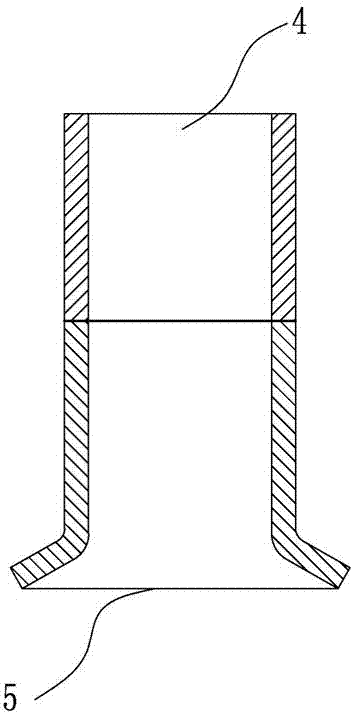

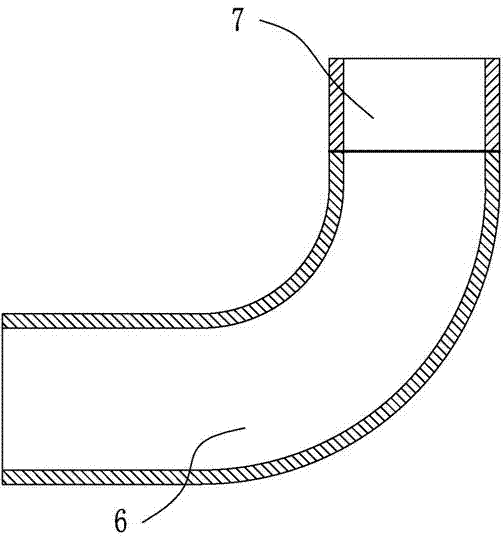

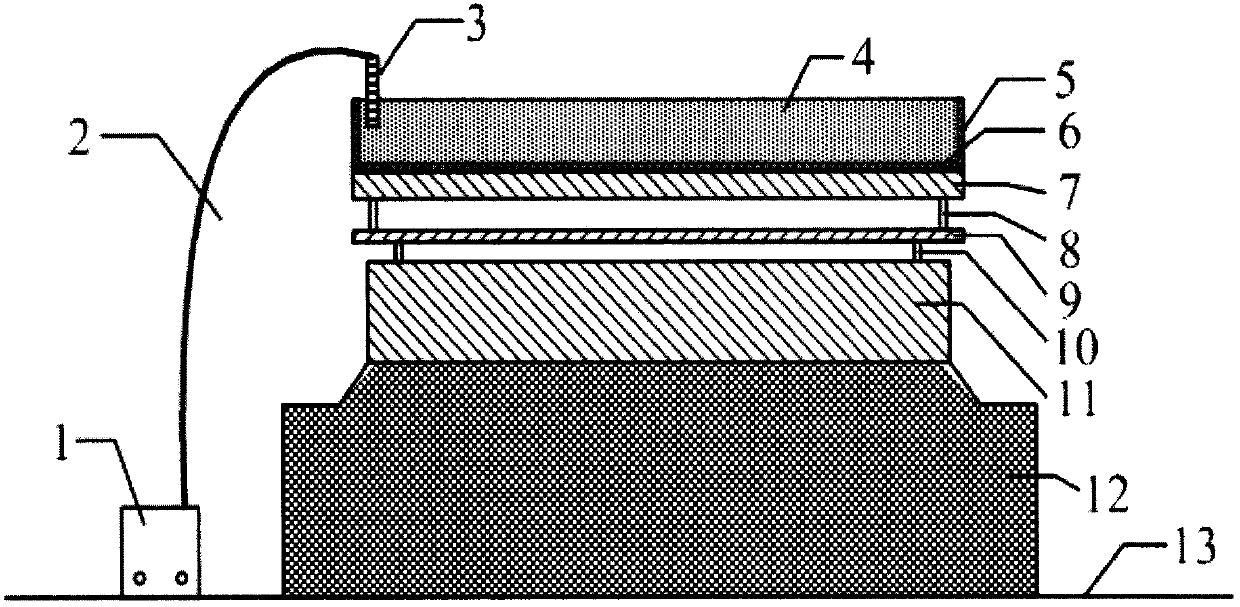

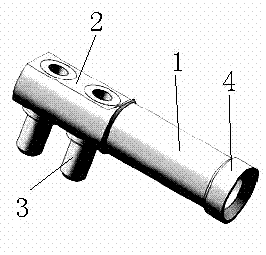

Liquid reservoir air inlet and outlet pipe and manufacturing method as well as application thereof

ActiveCN103033002ASimple structureReduce usageRefrigeration componentsResistance welding apparatusEngineeringCopper

The invention relates to the field of a compressor, in particular to a liquid reservoir air inlet and outlet pipe and application thereof. The liquid reservoir air inlet and outlet pipe comprises an air inlet pipe and an air outlet pipe, wherein the air inlet pipe is arranged on the upper part of a liquid reservoir; the air outlet pipe is arranged on the lower part of the liquid reservoir; the air inlet pipe comprises a first air inlet pipe and a second air inlet pipe; the first air inlet pipe and the second air inlet pipe are butt-welded through flash welding; the air outlet pipe comprises a first air outlet pipe and a second air outlet pipe; and the first air outlet pipe and the second air outlet pipe are butt-welded through flash welding. By using the liquid reservoir air inlet and outlet pipe of the structure, the using amount of copper is saved, and the manufacturing cost is reduced; and the second air inlet pipe and the second air outlet pipe are all connected to a housing of the liquid reservoir through the electric resistance welding free of solder. The technology of the invention is simple, the solder is saved, further the manufacture cost is reduced, meanwhile in the manufacture process exhaust gas such as carbon dioxide or the like is not generated to pollute the environment.

Owner:DONGGUAN JINRUI HARDWARE PROD

Welding technology for steel plates

InactiveCN104588850AWelding safetyGuarantee welding qualityArc welding apparatusSheet steelEngineering

The invention discloses a welding technology for steel plates, and relates to the technical field of welding technologies. The welding technology includes the four steps of pre-welding preparing, temporary tack welding, welding and post-welding processing. By means of the welding technology for the steel plates, the welding steps are simplified, the welding mode is simple, standard specifications are selected for materials, and the steel tube welding quality can be guaranteed; a regular welding mode is provided for the steel plates which are 3 mm in thickness, and rapid and safe welding of the steel plates which are 3 mm in thickness is facilitated.

Owner:WUHU CIMC RUIJIANG AUTOMOBILE

Welding technology for steel plate

The invention discloses a welding technology for a steel plate and relates to the technical field of welding technologies. The welding technology includes four steps of preparing before welding, tack welding, welding and processing after welding. According to the welding technology for the steel plate, the welding steps are simplified, the welding mode is simple, material selection is accurate and standard, the welding quality of a steel pipe can be ensured, a standard welding mode is provided for the steel plate 1 millimeter in thickness, and the steel plate which is 1 mm in thickness can be easily, rapidly and safely welded.

Owner:WUHU CIMC RUIJIANG AUTOMOBILE

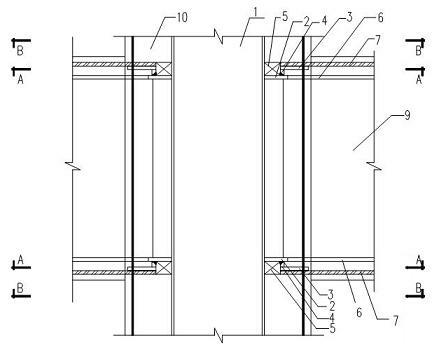

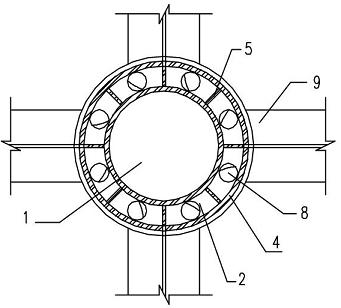

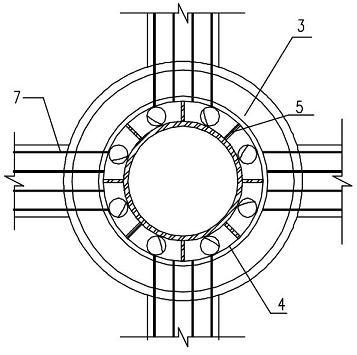

Connecting joint of steel pipe concrete column and profile steel concrete beam

ActiveCN102619286AGuaranteed longitudinal reinforcement anchorageShorten the lengthBuilding constructionsPunchingConcrete beams

The invention discloses a connecting joint of a steel pipe concrete column and a profile steel concrete beam. The intersection between a steel pipe in the steel pipe concrete column and a flange girth of the profile steel concrete beam is provided with a pair of large and small annular plates of different diameters; the horizontal and vertical positions of the two annular plates are staggered away from each other; the small annular plate is welded with a steel beam flange girth in the profile steel concrete beam; the large annular plate is welded with a longitudinal bar in the profile steel concrete beam; a steel pipe is arranged between the annular plates for welding the large and small annular plates into a whole; and the steel pipe of the steel pipe concrete column and the steel pipe for connecting the two annular plates are connected into a whole through a vertical rib. The connecting joint of the steel pipe concrete column and the profile steel concrete beam disclosed by the invention has the advantages that: 1, a large quantity of steel bar holes are not required to be formed on a steel pipe in a steel pipe concrete column; 2, damages to the section of a profile steel concrete column caused by steel pipe punching are avoided; and 3, convenience is brought to construction casting and compacting of concrete.

Owner:CHINA NERIN ENG

Explosive welding forming method of titanium-pure aluminum-aluminum alloy composite plate

InactiveCN107627019AAdvancedApparent molding speedNon-electric welding apparatusAlloy compositeFuel oil

The invention provides an explosive welding forming method of a titanium-pure aluminum-aluminum alloy composite plate. The explosive welding forming method of the titanium-pure aluminum-aluminum alloycomposite plate performs explosive welding forming according to the performance requirements of a titanium plate, an aluminum plate and an aluminum alloy plate; and an ammonium nitrate fuel oil mixture is adopted, and remote instantaneous explosive welding forming is performed on a ground sand grain substrate. Compared with the related art, the explosive welding forming method of the titanium-pure aluminum-aluminum alloy composite plate is high in speed, firm in interface bonding, good in interface shearing strength and high in bonding rate, the shearing strength of the titanium-pure aluminum-aluminum alloy composite plate reaches 230 MPa, the explosive welding bonding rate is 99%, controllability is good, the welding process is safe and reliable, and the explosive welding forming methodof the titanium-pure aluminum-aluminum alloy composite plate is a reliable and effective method for preparing the titanium-pure aluminum-aluminum alloy composite plate.

Owner:XIAN AERONAUTICAL UNIV

Aluminum plate welding process

InactiveCN104439641AWelding safetyChoose accurate specificationArc welding apparatusWelding/soldering/cutting articlesEngineeringSteel tube

The invention discloses an aluminum plate welding process, and relates to the technical field of welding processes. The aluminum plate welding process mainly includes the four steps of pre-weld preparation, tack weld, welding and post-weld treatment. By the adoption of the aluminum plate welding process, welding steps are simplified, the welding mode is simple, materials are accurately and standardly selected and used, the welding quality of steel pipes can be guaranteed, the standard welding mode is provided for aluminum plates with the thickness being 4 mm, and quick and safe welding of the aluminum plates with the thickness being 4 mm is facilitated.

Owner:WUHU CIMC RUIJIANG AUTOMOBILE

Ultrasonic welding device, and packaging machine with an ultrasonic welding device

ActiveUS8156984B2Easy constructionLow costControlling laminationLaminationUltrasonic weldingEngineering

The invention relates to an ultrasonic welding device for welding foil-like materials and includes an ultrasound sonotrode, an anvil, an adjusting unit for adjusting a relative position between the ultrasound sonotrode and the anvil, and a regulating unit which regulates, via the adjustment unit, a width of a working gap between the ultrasound sonotrode and the anvil. The anvil is mounted to be movable with respect to the ultrasound sonotrode on a movable mounting. The adjusting unit has a first wedge element connected to the anvil, a second wedge element, and an actuator. The actuator is connected to the second wedge element, and the second wedge element moves relative to the first wedge element to execute a position change of the anvil relative to the ultrasound sonotrode.

Owner:SYNTEGON TECHNOLOGY GMBH

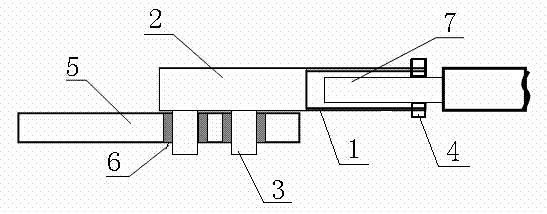

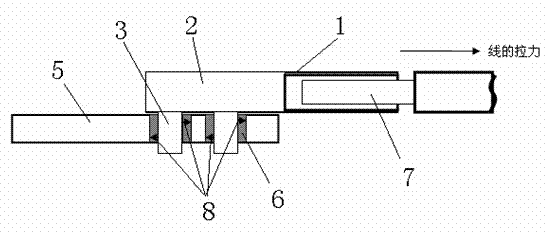

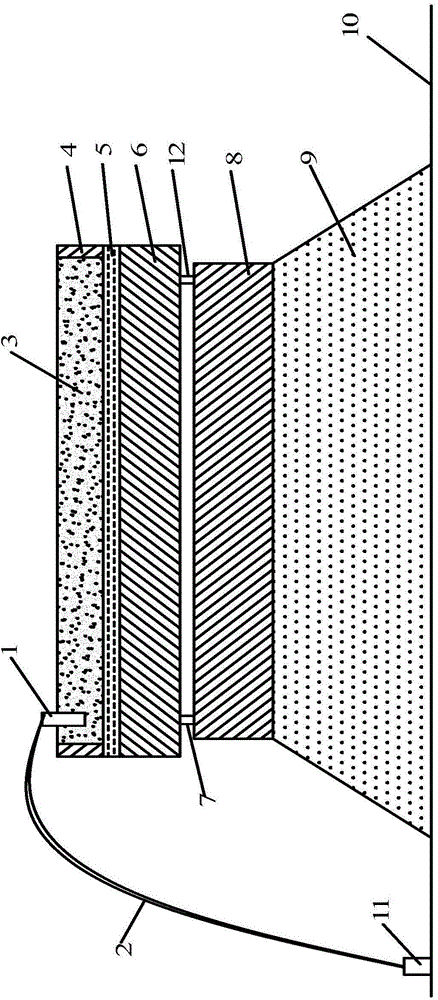

Connection method for crimping-to-welding circuit board, and connecting terminal

InactiveCN104124543AEasy connectionImprove reliabilityLine/current collector detailsConnections effected by permanent deformationEngineeringShock resistance

The invention discloses a connection method for a crimping-to-welding circuit board, and a connecting terminal, wherein a crimping-to-welding device is added between a circuit board welding pad and a connecting line which need to be connected, and the connecting line is connected with the circuit board welding pad through the crimping-to-welding device; the connecting line is connected with the crimping-to-welding device by means of crimping, and the crimping-to-welding device is connected with the circuit board welding pad by means of welding; thus the connecting line is connected by means of the most reliable crimping, and the circuit board is connected by means of the simplest and the most convenient welding. The problems of inconvenience operation, unreliable welding spots, unstressed welding spots, the need of carrying out other treatments, and the like during the direct welding of the line and the circuit board (in particular in case of a thick line) are avoided, and compared with other common screw crimping-to-welding connecting terminals, the occupied space volume and the operation difficulty are reduced, and the shock resistance and the connection reliability are improved.

Owner:株洲天利铁路机车车辆配件有限公司

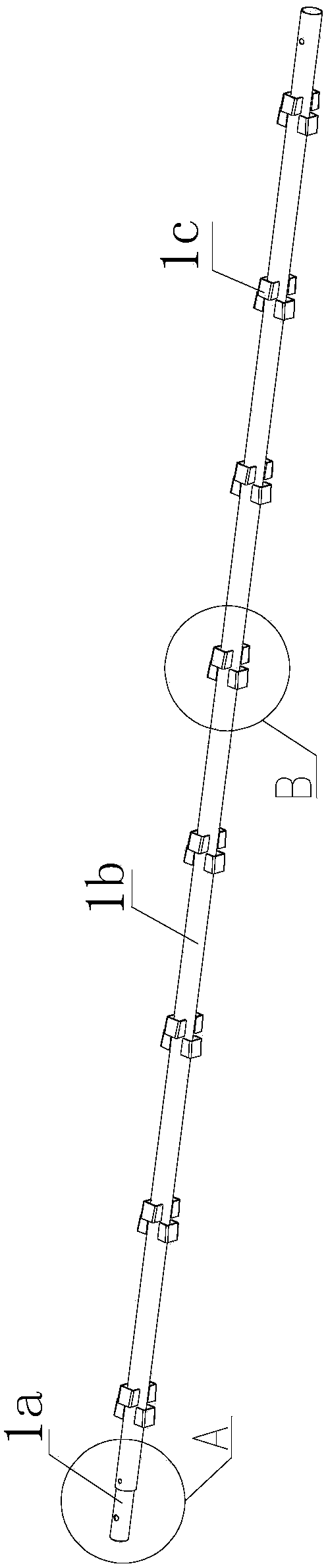

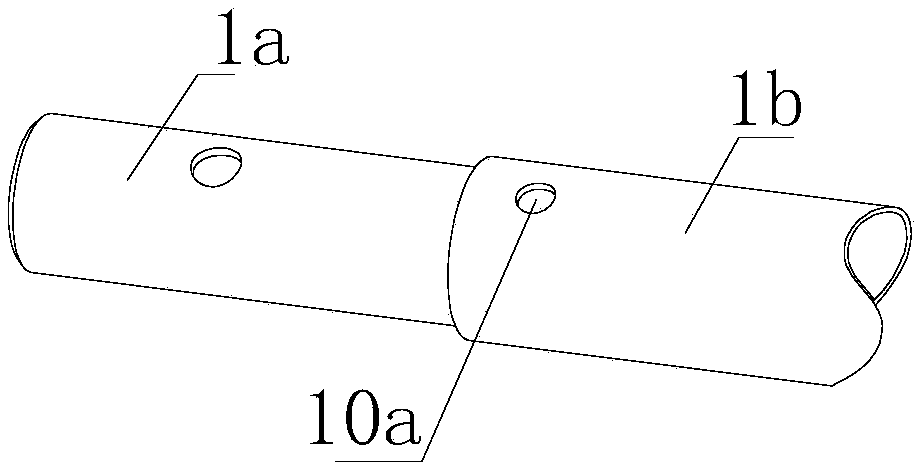

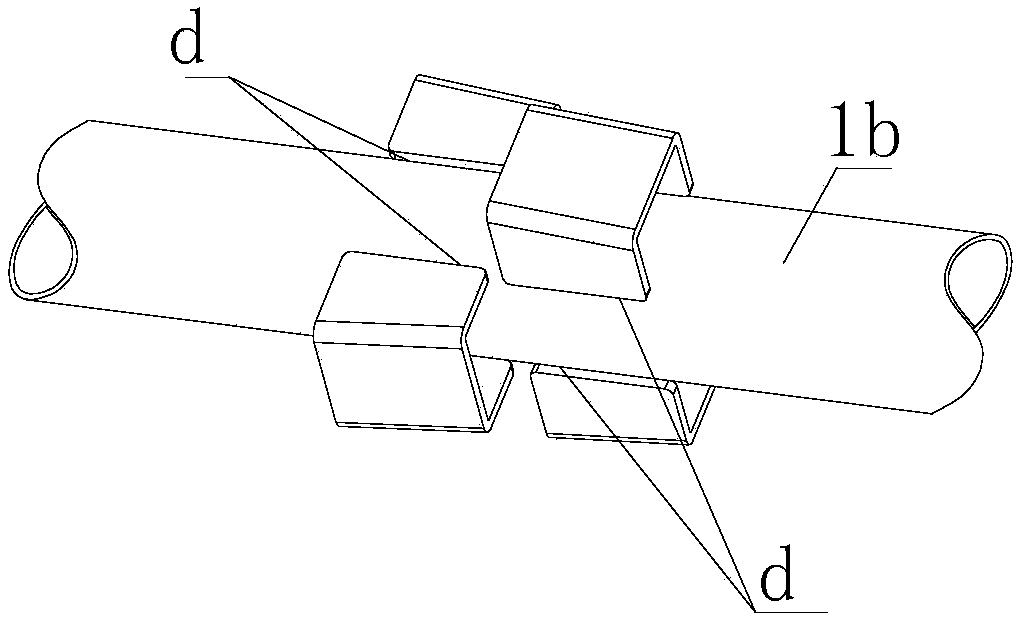

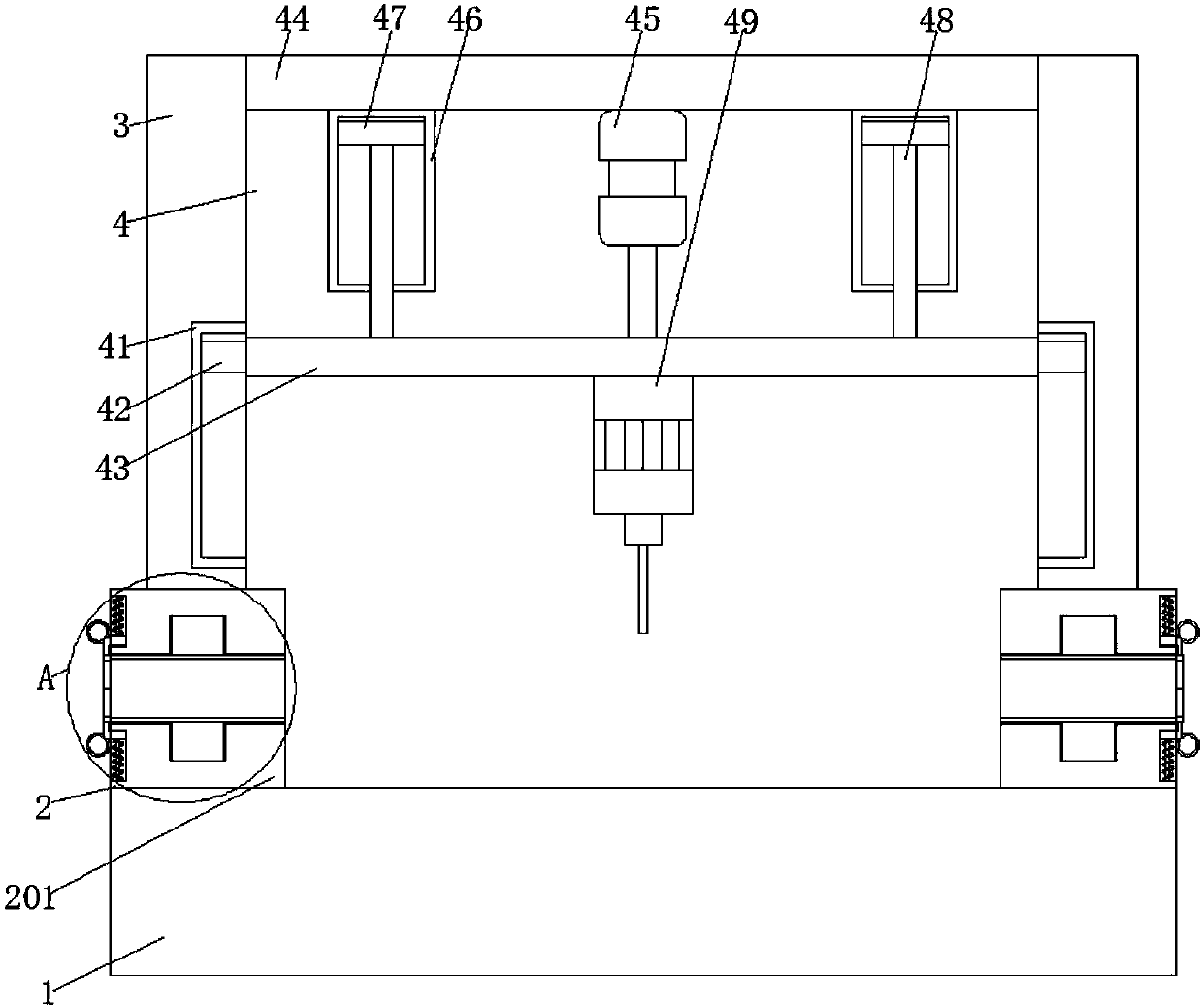

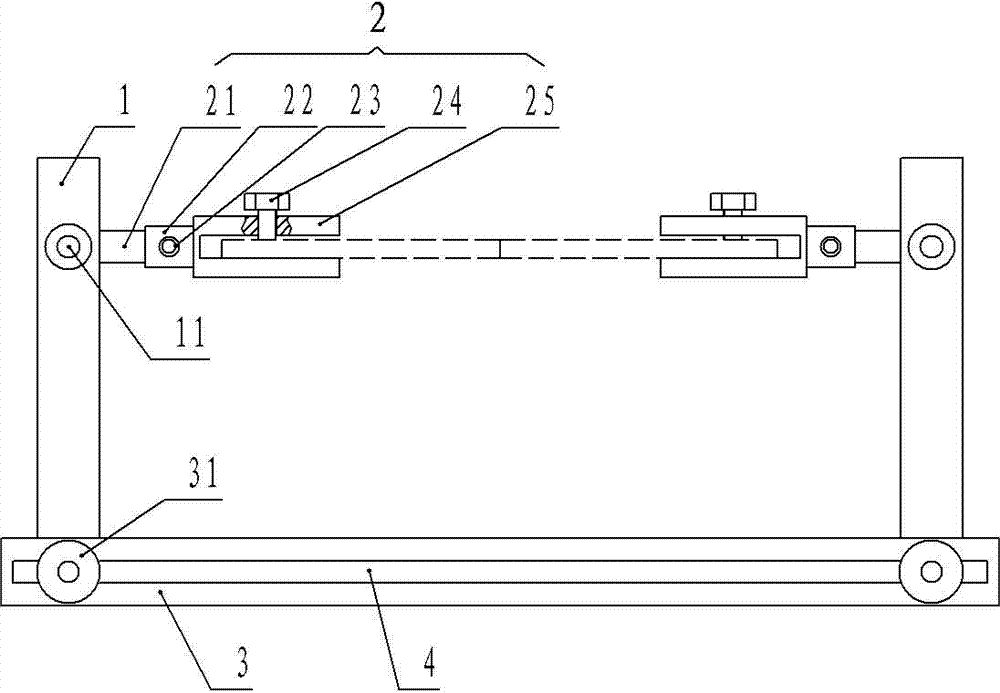

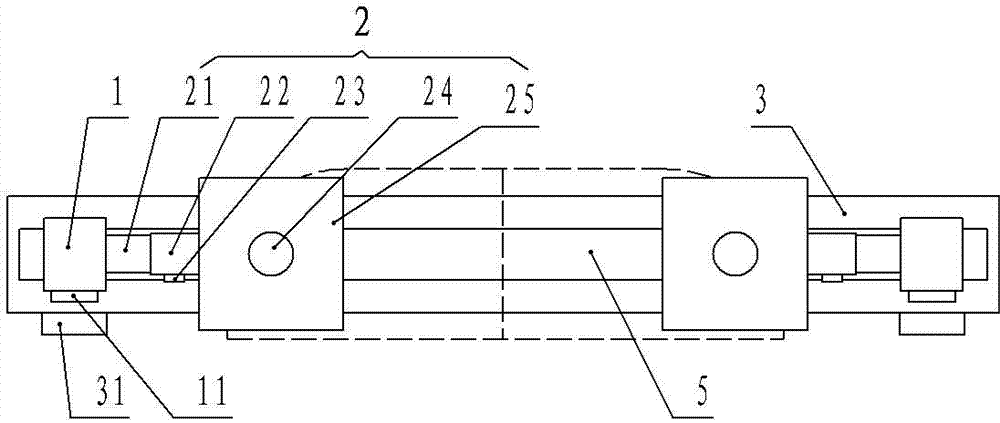

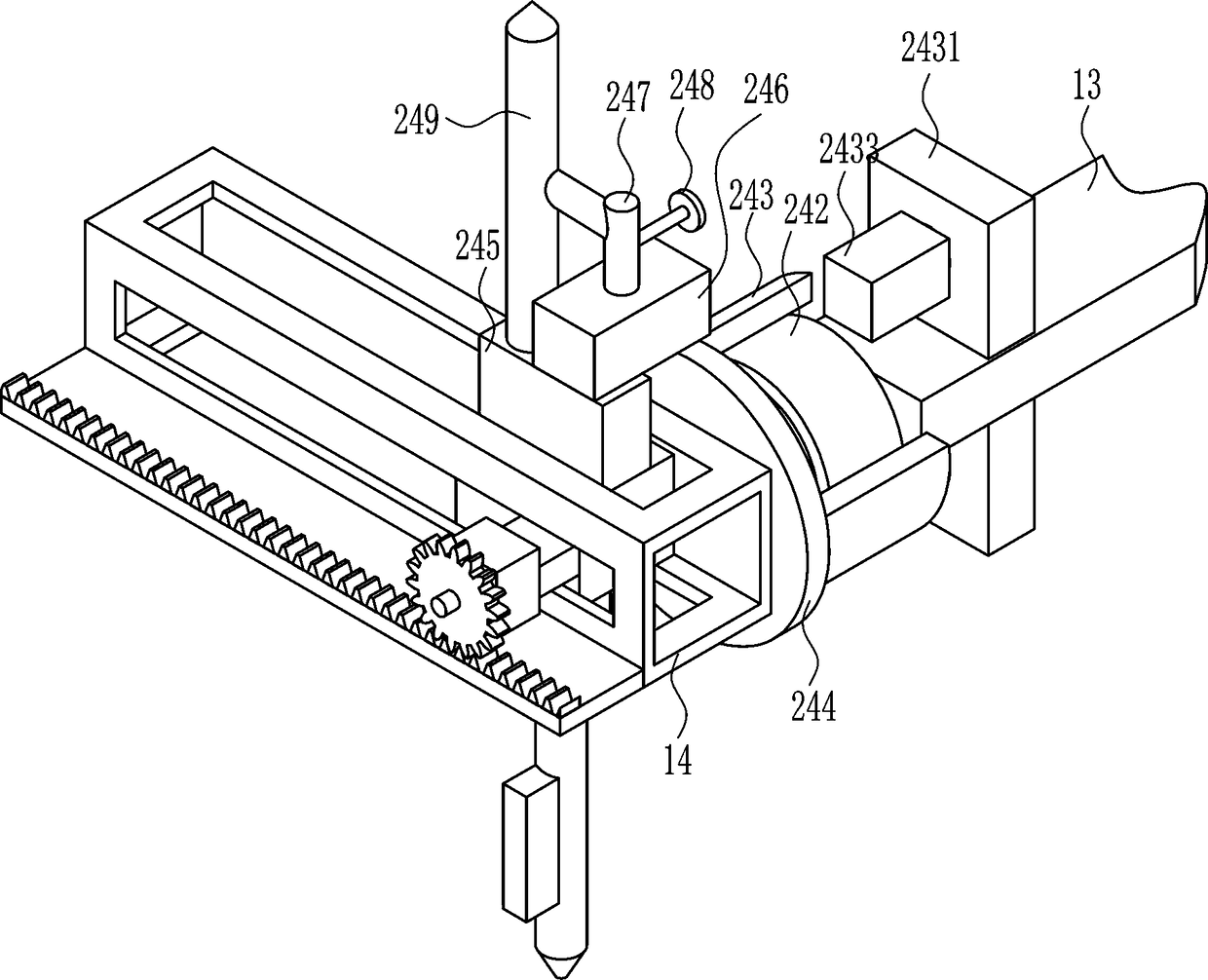

Automatic scaffold welding machine and welding method thereof

ActiveCN108098126AFast solderingEasy to replaceResistance electrode holdersWelding/soldering/cutting articlesEngineeringSpot welding

The invention provides an automatic scaffold welding machine. The welding machine is used for automatic welding of a main steel pipe serving as a vertical rod in a steel pipe scaffold with socket andspigot joints and a socket pipe and an U-shaped socket part. The welding machine comprises a base, the front side of the base is provided with a three-shaft position-changing device for switching a feeding station with a workpiece to be welded and a welding station and realizing rapid welding of the two surfaces of the workpiece to be welded through 180-degree-rotation of the welding station; twogantry type welding gun supports which are vertically arranged are installed on the two sides of the rear side of the base, a cross frame beam is arranged between the two welding gun supports, and thecross frame beam is provided with a spot welding mechanism which is used for carrying out spot welding on the socket pipe which is at the welding station of the three-shaft position-changing device and fixed on the main steel pipe and a multiple sets of double-gun welding mechanisms which are used for simultaneously welding weld joints of all U-shaped socket parts; and one end of the cross framebeam is provided with a welding gun walking mechanism which is used for pulling the multiple sets of double-gun welding mechanisms to move at the same time to carry out welding on the welding joints of all the U-shaped socket parts correspondingly. The invention further provides a welding method of the automatic scaffold welding machine.

Owner:ZHUHAI RUILING WELDING AUTOMATION CO LTD

Tungsten electrode inert gas shielded welding process of aluminum plate

InactiveCN104526128AWelding safetyGuarantee welding qualityArc welding apparatusWelding/soldering/cutting articlesSpot weldingMaterials science

The invention discloses a tungsten electrode inert gas shielded welding process of an aluminum plate and relates to the welding process technical field. The tungsten electrode inert gas shielded welding process mainly comprises four steps of preparation before welding, temporary spot welding, welding and treatment after the welding. According to the tungsten electrode inert gas shielded welding process of the aluminum plate, the welding steps are simplified, the welding method is simple, the material selection is accurate and standard, the welding quality of the aluminum plate can be ensured, a standard welding way is provided for the aluminum plate, and the rapid and safe welding on the aluminum plate is facilitated.

Owner:WUHU CIMC RUIJIANG AUTOMOBILE

Metal tube welding device safe and convenient to use

InactiveCN107914104AImprove overall qualityEasy to useWelding/cutting auxillary devicesAuxillary welding devicesTelescopic cylinderRisk factor

The invention relates to the technical field of metal pipe processing equipment, in particular to a safe and convenient metal pipe welding device. The technical problem to be solved by the present invention is that the use of the electric welding device has a large risk factor, poor quality and inconvenient use. In order to solve the above technical problems, the present invention provides a safe and convenient welding device for metal pipes, which includes a base, two adjustment devices, two vertical plates and a welding device. Both sides of the upper surface of the base are fixedly connected with An adjustment device, and the tops of the two adjustment devices are fixedly connected with vertical plates, and the opposite sides of the two vertical plates are connected by a welding device. By improving the welding device, the invention can make the electric welding machine move up and down stably when the telescopic cylinder is started, thereby improving the overall quality of welding, and is convenient to use, and two sets of semicircular splints can fasten the metal pipe, enabling two Or stable welding, at this time, the staff can stay away from the welding machine.

Owner:XINCHANG GREAT WALL AIR CONDITION PARTS

0Cr18Ni9 stainless steel plate welding process

InactiveCN104439616AWelding safetyGuarantee welding qualityArc welding apparatusMetallurgyMaterial selection

The invention discloses a 0Cr18Ni9 stainless steel plate welding process, and relates to the technical field of welding processes. The 0Cr18Ni9 stainless steel plate welding process mainly includes the steps of preparation before welding, tack weld, welding and treatment after welding. By means of the 0Cr18Ni9 stainless steel plate welding process, the welding steps are simplified, a welding mode is simple, material selection is precise and standard, the welding quality of 0Cr18Ni9 stainless steel plates can be guaranteed, the standard welding mode is provided for the 0Cr18Ni9 stainless steel plates, and quick and safe welding of the 0Cr18Ni9 stainless steel plates is facilitated.

Owner:WUHU CIMC RUIJIANG AUTOMOBILE

16 Mn steel plate argon arc welding process

InactiveCN104439643AWelding safetyGuarantee welding qualityArc welding apparatusWelding/soldering/cutting articlesEngineeringMaterial selection

The invention discloses a 16 Mn steel plate argon arc welding process, and relates to the technical field of welding processes. The 16 Mn steel plate argon arc welding process mainly includes the steps of preparation before welding, tack weld, welding and treatment after welding. By means of the 16 Mn steel plate argon arc welding process, the welding steps are simplified, a welding mode is simple, material selection is precise and standard, the welding quality of 16 Mn steel plates can be guaranteed, the standard welding mode is provided for the 16 Mn steel plates, and quick and safe welding of the 16 Mn steel plates is facilitated.

Owner:WUHU CIMC RUIJIANG AUTOMOBILE

Welding tool for rear baffle of vehicle body

InactiveCN104759812AWelding safetyImprove work efficiencyWelding/cutting auxillary devicesAuxillary welding devicesCar manufacturingEngineering

The invention discloses a welding tool for a rear baffle of a vehicle body, and belongs to the technical field of manufacturing of automobiles. The welding tool comprises at least two supporting rods, wherein the at least two supporting rods pass through sliding blocks at the lower end and are oppositely vertically arranged into a chute in a base; the chute is in the same direction as the length direction of the base; workpiece clamps oppositely extend out from the upper ends of the supporting rods and are glidingly connected with the supporting rods through workpiece clamp locking screws. The welding tool can solve the problems of difficult overturning of cylinder, inconvenient operation and high cost in welding of the rear baffle of the existing vehicle body.

Owner:陈巧兰

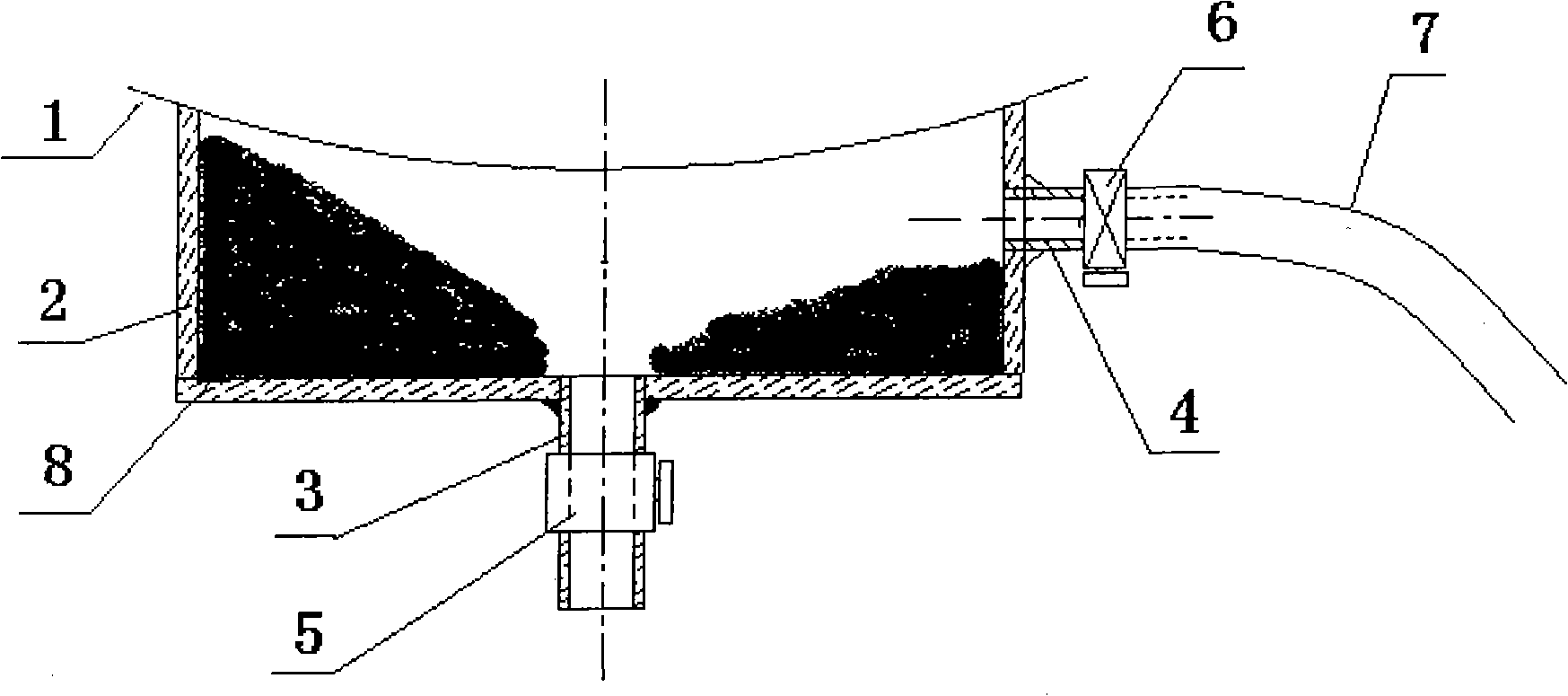

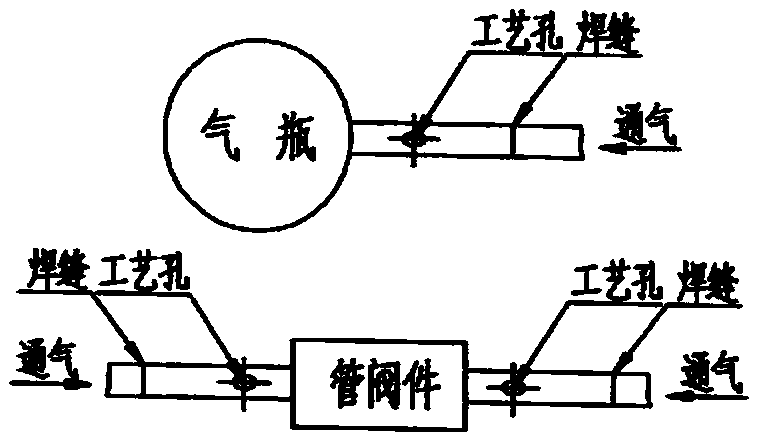

Gas pipeline leakage can repairing method

The invention provides an iron box wrapping-repairing method for gas pipe leakage; the method includes the following steps of: 1) making a wedge-shaped wooden plug the diameter of which is similar to that of a leak source and driving the wooden plug into the leak source; 2) coating sealant on a slit between the wooden plug and the leak source; 3) making an iron box the opening of which can be matched with a pipe line according to the size of the leak source, arranging an air inlet and an air outlet on the iron box simultaneously and installing one air intake valve and one drain tap on the air inlet and the air outlet respectively; 4) filling paste with volume no more than 3 / 4 that of the iron box into the iron box in advance, and covering the iron box on the leak source in an inverted way; 5) introducing nitrogen in from the air intake valve, opening the drain tap simultaneously, installing a rubber tube on the drain tap, and drawing the rubber tube far away from the area of the leak source; 6) coating the sealant in the slit between the iron box and the pipe line to completely cut off the coal gas at a welding position; 7) welding the iron box and the pipe line after confirming that the concentration of CO at the area of the leak source is less than 30ppm; and 8) after welding, cutting nitrogen off, and closing the air intake valve and the drain tap.

Owner:武钢集团有限公司

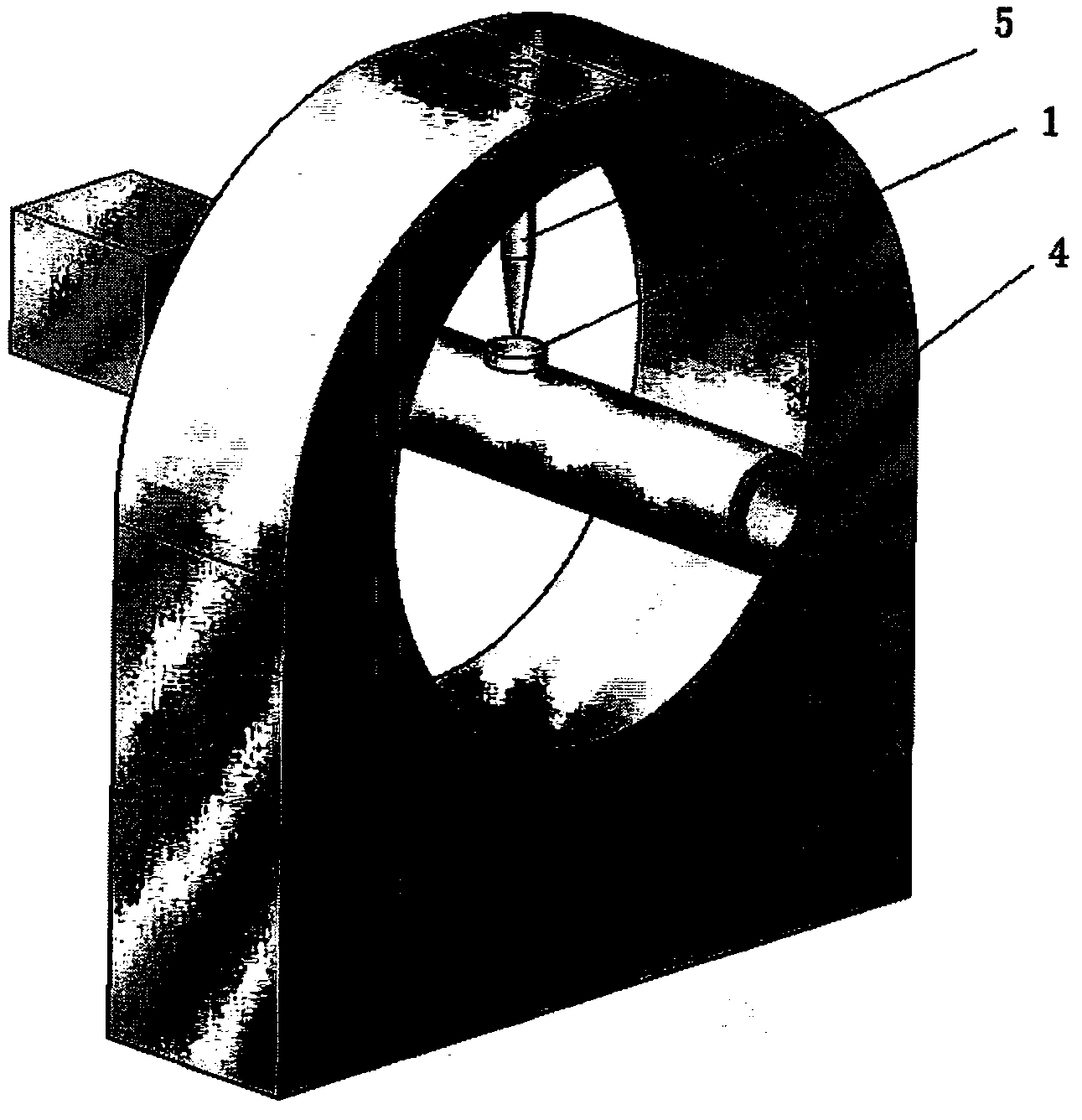

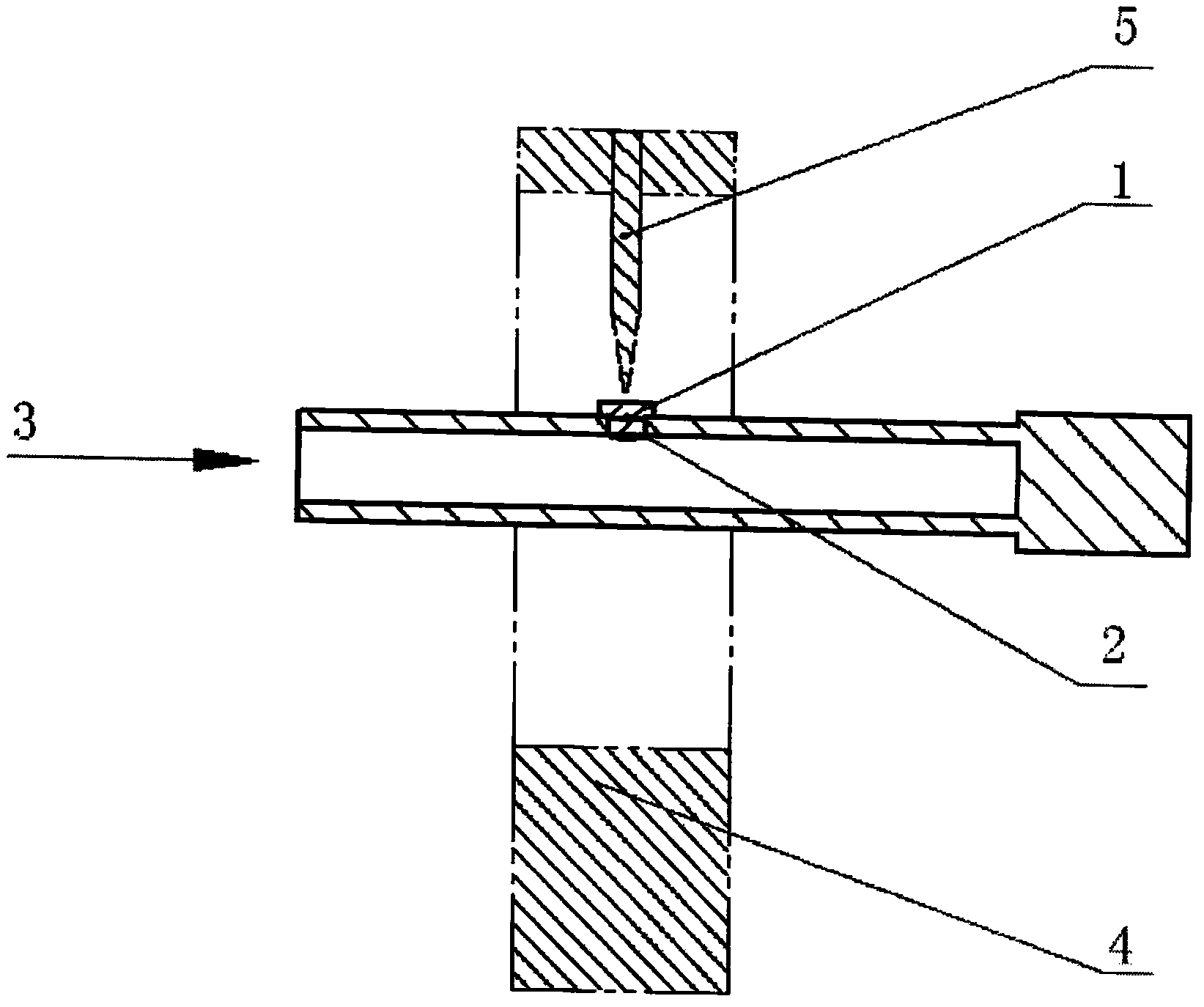

Anti-oxidation automatic welding method for process holes of titanium alloy pipelines in satellite propulsion system

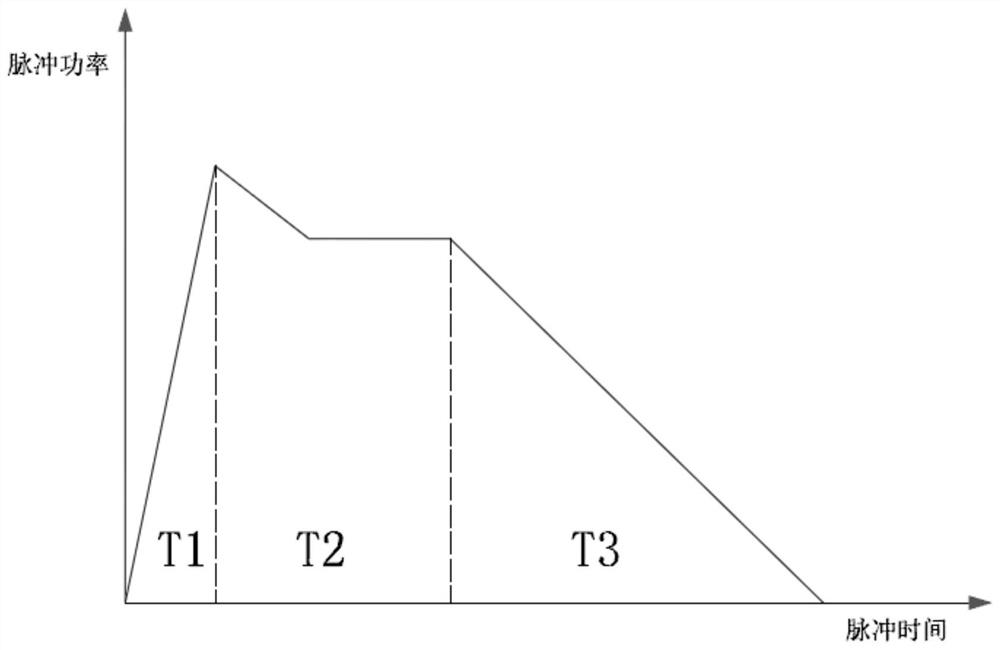

ActiveCN106134324BSolve Oxidation ProblemsAvoid inclusionsArc welding apparatusPower flowWelding power supply

The steps of the anti-oxidation automatic welding method for titanium alloy pipeline process holes in satellite propulsion system are as follows: (1) according to the size of the process hole, a process plug with a small through hole in the center is equipped to block the process hole; (2) before welding, the pipe A small amount of inert protective gas is passed through the inside of the road, and the gas escapes through the tiny through hole in the center of the process plug, forming a partial protection zone for flow on the inner wall of the process hole; (3) Place the welded pipe clamp on the all-position automatic welding equipment on the On the process hole of the plug, the precision welding power source of the all-position automatic welding equipment is used to complete the welding with high current in a short time, so that the oxidation time of the weld is greatly shortened, and the weld metal solidifies quickly. The invention overcomes the limitation of placing the product in a vacuumized inert gas protection container for anti-oxidation welding, and can be used for products of satellite propulsion systems of any size to carry out anti-oxidation welding of pipeline process holes at any part of the whole star. It has been used in Welding of dozens of satellites including my country's new generation of large-scale communication satellites.

Owner:BEIJING SATELLITE MFG FACTORY

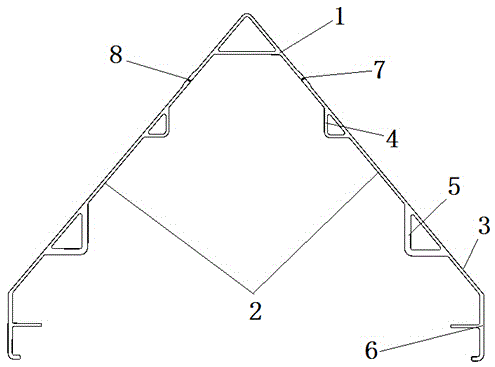

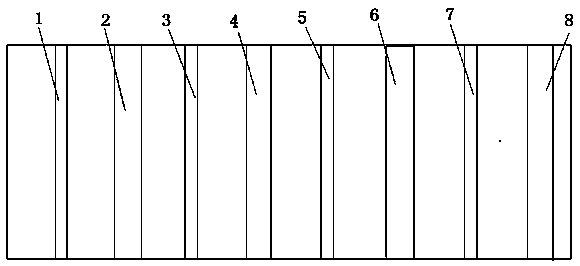

Railway aluminium alloy truck upper funnel ridge and friction stir welding production method

ActiveCN104889563AStable structureHigh strengthHopper carsWelding/soldering/cutting articlesTruckUltimate tensile strength

The invention relates to a railway aluminium alloy truck upper funnel ridge and friction stir welding production method. The whole upper funnel ridge is formed by splicing aluminium alloy sections; according to the shape of the upper funnel ridge on a truck body and requirements, different aluminium alloy sections are adopted, the aluminium alloy sections are mutually welded by friction stir welding, and the whole aluminium alloy truck upper funnel ridge is formed. The friction stir welding comprises the steps of arranging the aluminium alloy sections forming the railway aluminium alloy truck upper funnel ridge in sequence, and welding to connect all the aluminium alloy sections together by friction stir welding, thus forming the whole railway aluminium alloy truck upper funnel ridge. The railway aluminium alloy truck upper funnel ridge has the characteristics of stable structure, high strength and attractive appearance by adopting the aluminium alloy sections to form a wallboard, compared with an original method of riveting on a frame by using a board, the overall strength is enhanced greatly, and the appearance is very attractive.

Owner:株洲春华实业有限责任公司

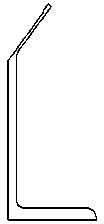

Sidewall plate of railway hopper wagon made by aluminum alloy and friction-stir welding method thereof

ActiveCN104908761AStable structureHigh strengthAxle-box lubricationHopper carsUltimate tensile strengthFriction stir welding

Provided is a sidewall plate of a railway hopper wagon made by aluminum alloy and a friction-stir welding method thereof. The sidewall plate is integrally formed by splicing of aluminum alloy sections. According to the shape and the requirement for the sidewall plate of a wagon body, different aluminum alloy sections are adopted and welded together by friction-stir welding in order to form the overall sidewall plate made by aluminum alloy.The friction-stir welding is realized by arraying the aluminum alloy sections forming the sidewall plate of the railway hopper wagon according to the sequence. All the aluminum alloy sections are welded for connection by means of friction stir welding. Therefore, the overall sidewall plate of the railway hopper wagon is formed.The aluminum alloy sections are adopted for forming the wall plate featuring a stable structure, high strength and attractive external appearance. Compared with the mode that plates are utilized for being riveted onto a framework, the overall strength is improved a lot; and the appearance looks attractive.

Owner:株洲春华实业有限责任公司

End wall of railway wagon made by aluminum alloy and manufacturing method thereof utilizing friction stir welding

ActiveCN104908762AStable structureHigh strengthAxle-box lubricationHopper carsUltimate tensile strengthTruck

Provided is an end wall of a railway wagon made by aluminum alloy and a manufacturing method thereof utilizing friction stir welding. The overall end wall is formed by splicing of aluminum alloy sections. According to the shape and the requirement for the end wall of a wagon body, the aluminum alloy sections are welded by friction stir welding in order to form the overall block of the end wall made by aluminum alloy.The friction stir welding is realized by arraying the aluminum alloy sections forming the end wall of a railway hopper wagon according to the sequence. All the aluminum alloy sections are welded for connection by means of friction stir welding. Therefore, the overall end wall of the railway hopper wagon is formed. The end wall of the railway wagon made by aluminum alloy and the manufacturing method thereof utilizing friction stir welding have following beneficial effects: a wall plate is formed by the aluminum alloy sections and is featured by being stable in structure, high in strength and attractive in external appearance; compared with a conventional mode that plates are utilized for being riveted onto a framework, the overall strength is improved a lot; and the appearance looks attractive.

Owner:株洲春华实业有限责任公司

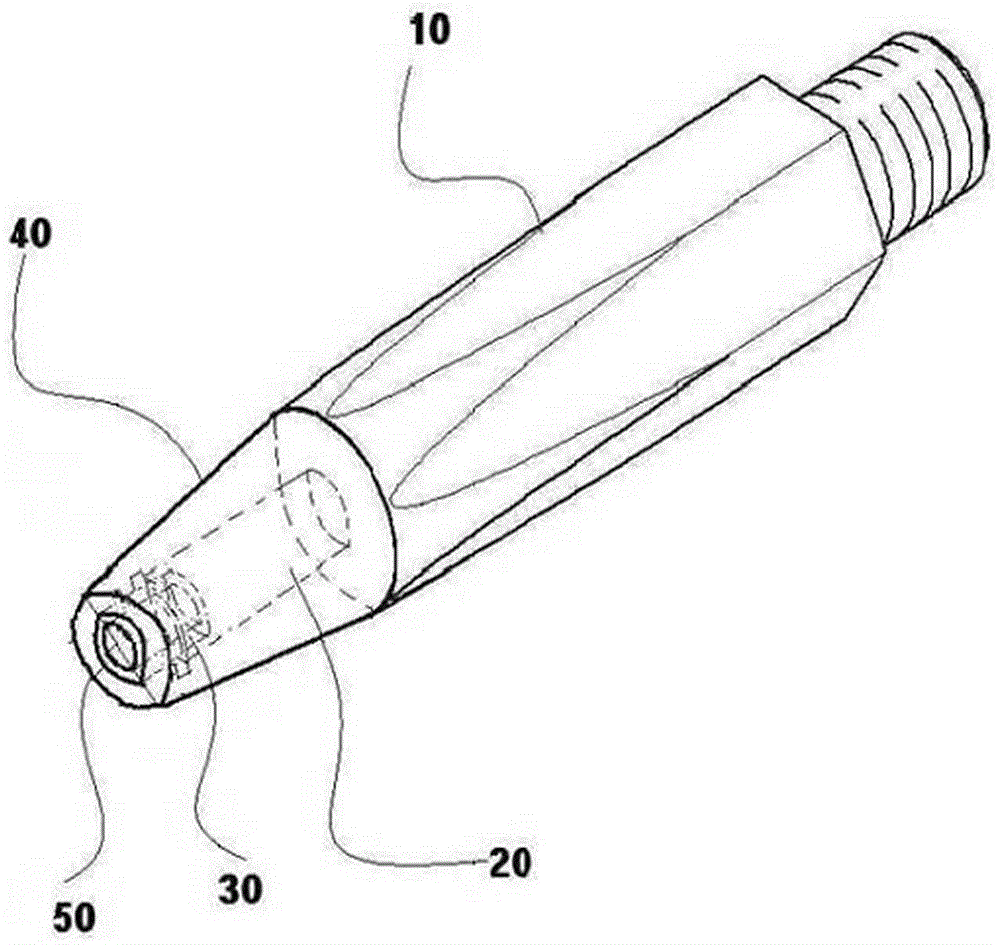

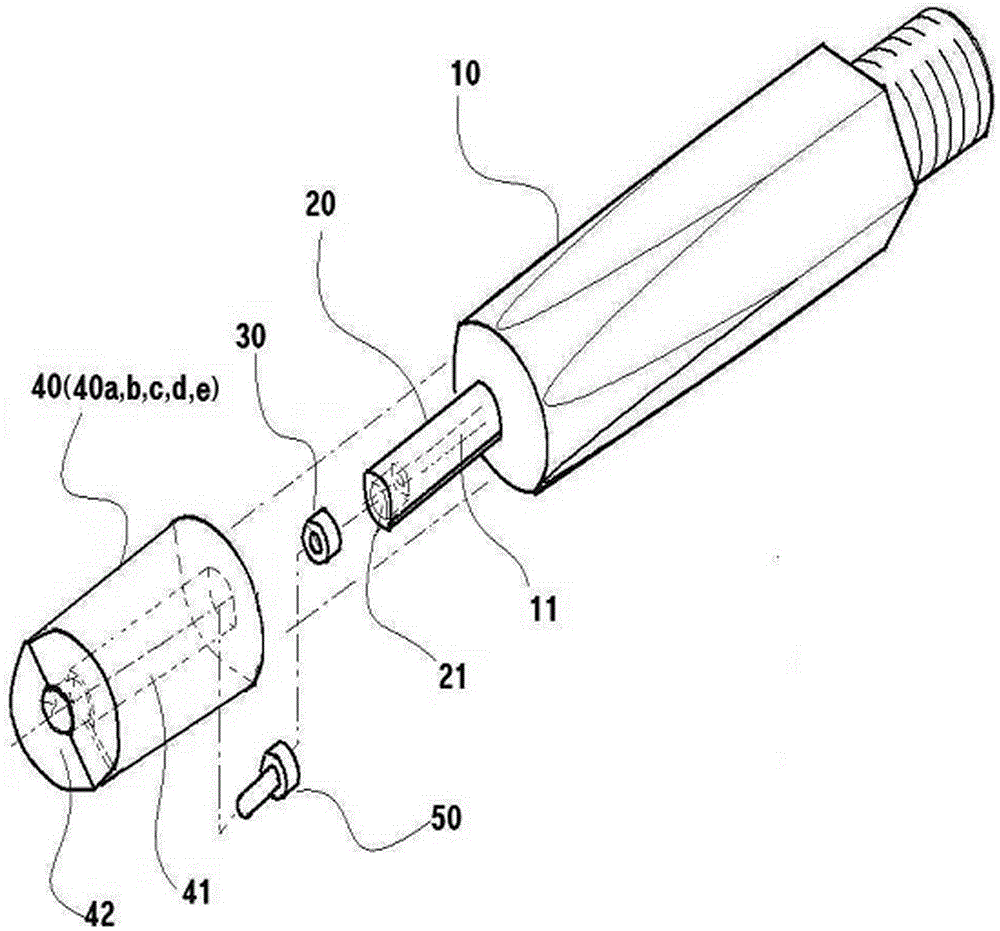

GMA welding contact tip having bushing

InactiveCN105252124AExtended service lifeLower purchase costElectrode accessoriesWelding accessoriesEngineeringCopper

The invention discloses a Gas Metal-arc (GMA) welding contact tip having a bushing made of a copper material. The invention is characterized in that the GMA welding contact tip is installed on a front end of a GMA welding machine which receives welding wires at a predetermined speed and forms a molten according to the welding arc generated between the contact tip and parent metals, and welding current is transmitted to the welding wires so as to guide the bath. The GMA welding contact tip includes a copper tip main body installed on the welding machine; an energization connection part integrally connected to the front of the tip main body in a conducting manner, the energization connection part being narrower than the periphery of the tip main body (10); the cylindrical bushing made of materials stronger than the copper and installed in the front of the energization connection part, and preventing burn back caused by the wielding arc and the diameter expansion of the tip; and a front reinforcement mouth around the energization connection part and the periphery of the bushing.

Owner:郑来植

Explosive welding forming method of magnesium-aluminum alloy composite plate

InactiveCN103586574BImprove compactnessAdvancedMetal working apparatusNon-electric welding apparatusAlloy compositeUltimate tensile strength

The invention relates to an explosive welding forming method of magnesium and aluminum alloy composite plates. The explosive welding is performed according to the performance requirements of the magnesium and aluminum alloy composite plates, ammonium nitrate fuel oil mixture is adopted, and long-distance instantaneous explosive form is performed on a ground sand base. The welding method is high in forming speed, welding line is firm and is good in metallographic structure compactness, the combined rate is up to 99.5%, the interfacial shear strength is 120MPa, on the premise of strict operation, the welding process is safe and reliable, and the method is reliable and effective in magnesium and aluminum alloy composite plate production.

Owner:TAIYUAN UNIV OF TECH

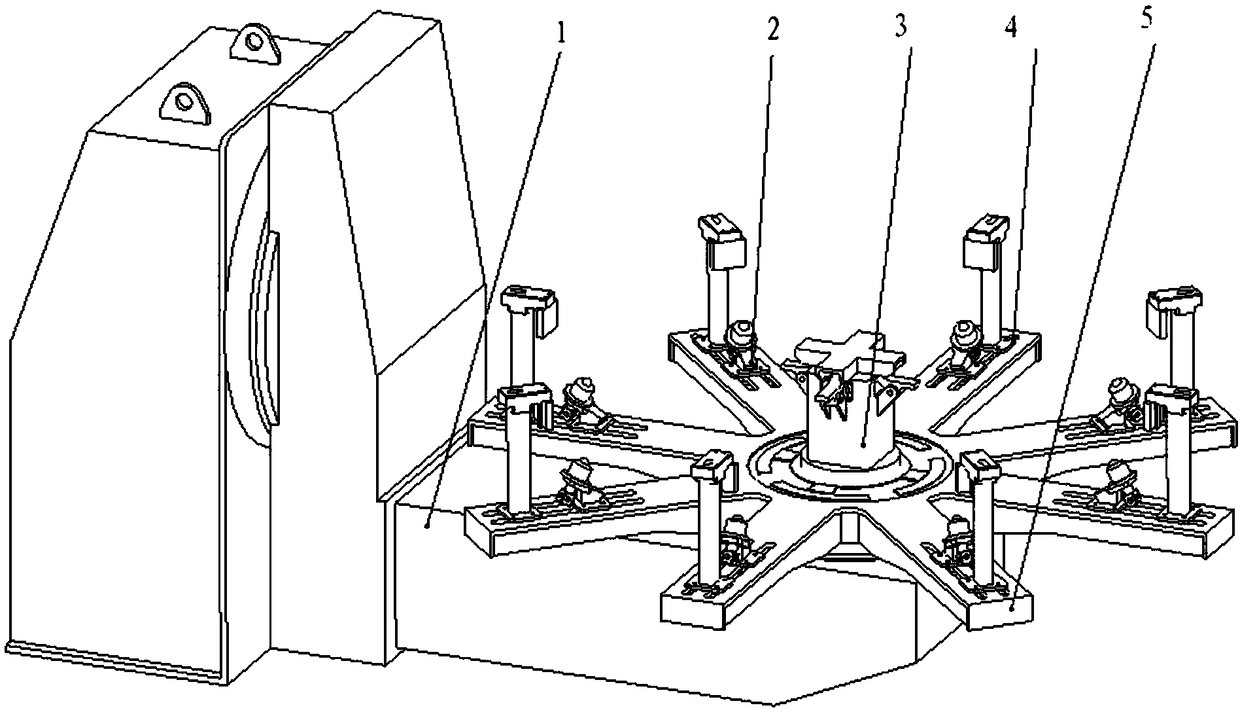

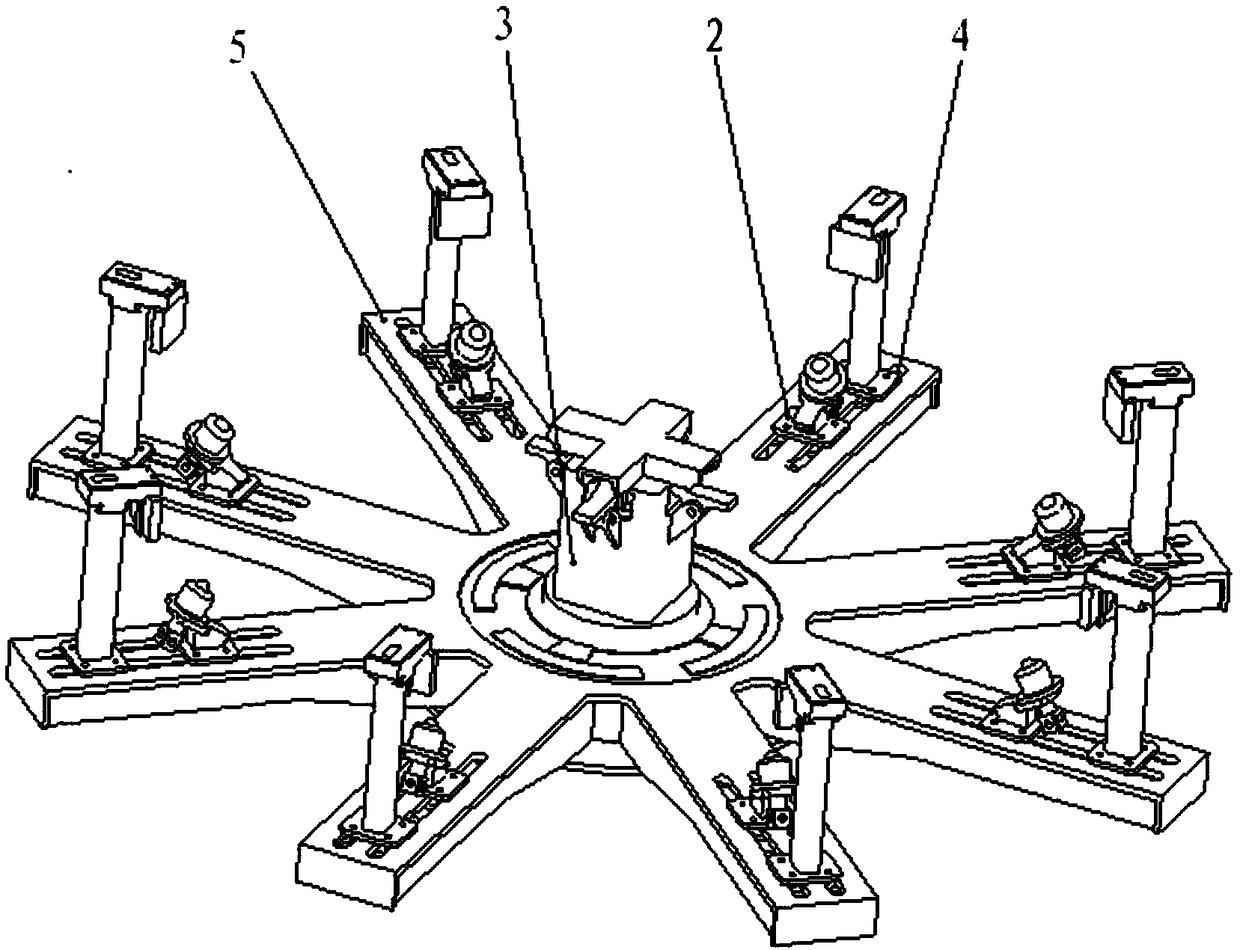

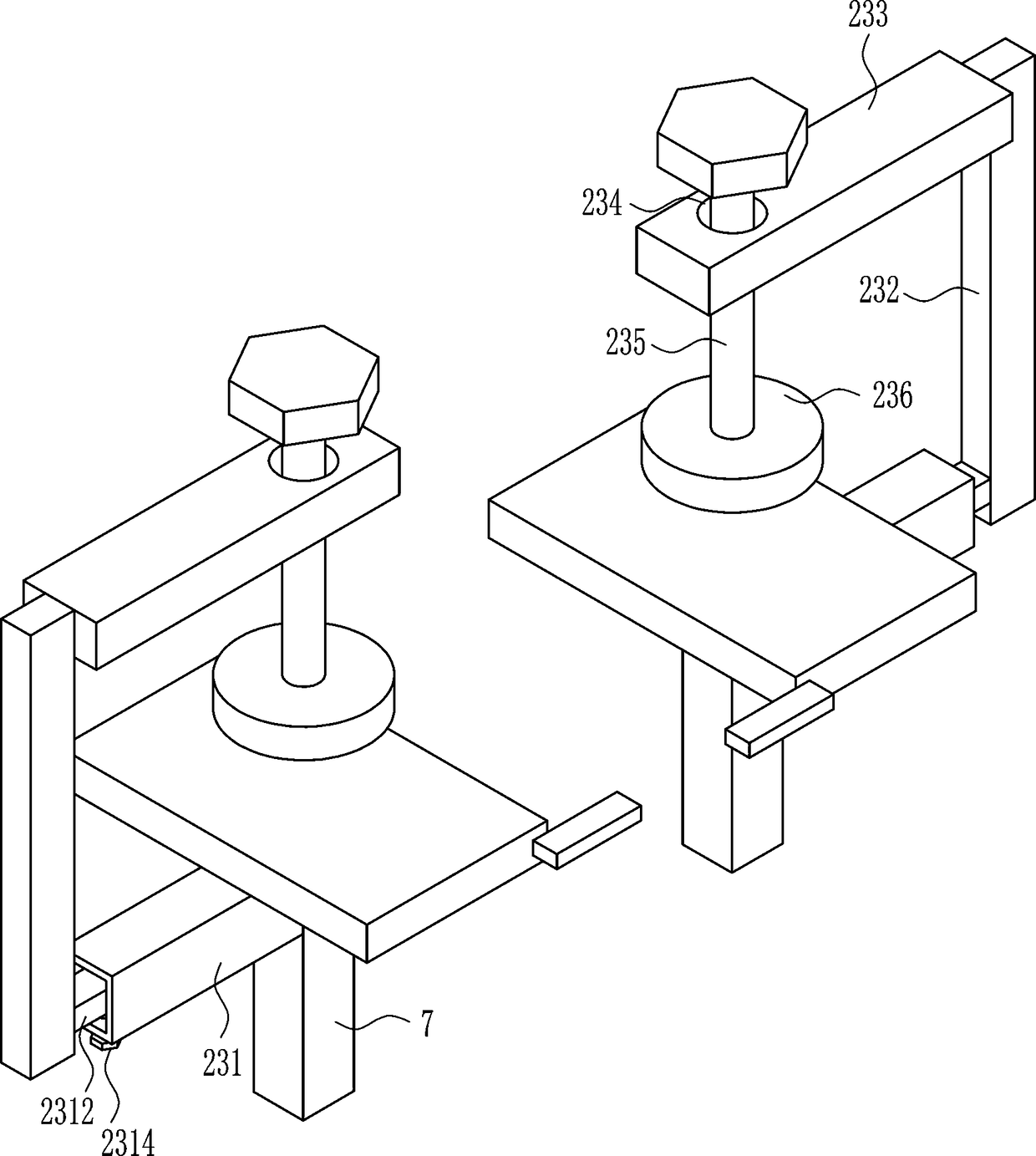

Positioning and clamping device for butt welding of mixer head group and its operation method

ActiveCN106216919BUnified standardHigh positioning accuracyWelding/cutting auxillary devicesAuxillary welding devicesSize differenceEngineering

The invention discloses a locating and clamping device for mixer truck end socket assembling and welding and an operation method thereof. The locating and clamping device for mixer truck end socket assembling and welding comprises ball supports, a pneumatic pressing device, pressing blocks and an upper platform. The ball supports, the pneumatic pressing device and the pressing blocks are arranged on the upper platform. The upper platform is in a spoke shape, a round platform is arranged in the middle, and a plurality of cantilevers distributed uniformly in the circumferential direction are radiated outwards from the outer circle of the round platform. Each cantilever is provided with one pressing block and one ball support. The pneumatic pressing device is arranged in the center of the round platform of the center of the upper platform. For end sockets of the same type with the machining allowance and end sockets of the different types with a little size difference, the locating and clamping device can be used for locating and clamping the end sockets, thus, the universality is improved, the working efficiency is further improved, and workloads of workers are reduced.

Owner:ANHUI XINGMA SPECIAL PURPOSE VEHICLE

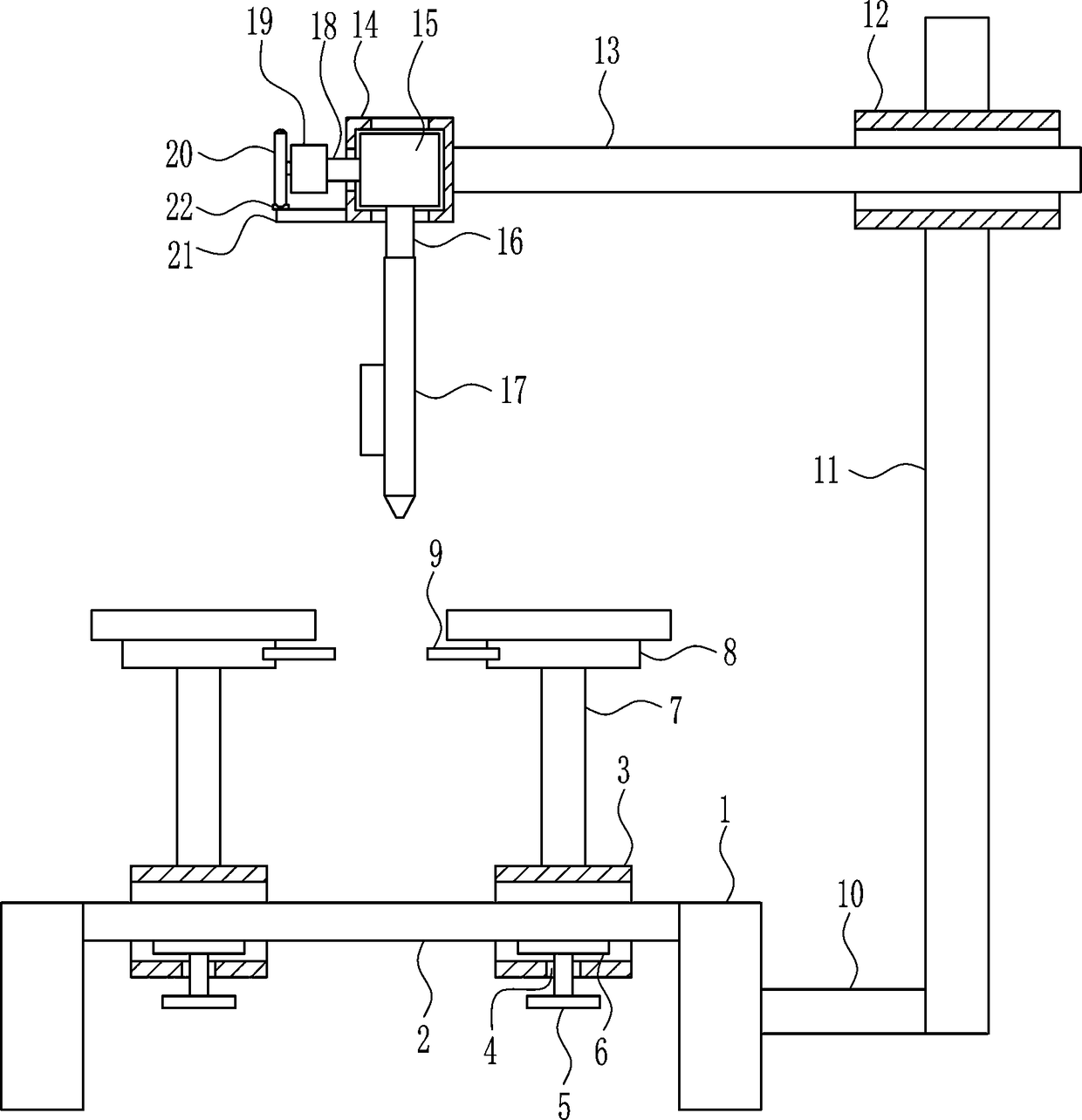

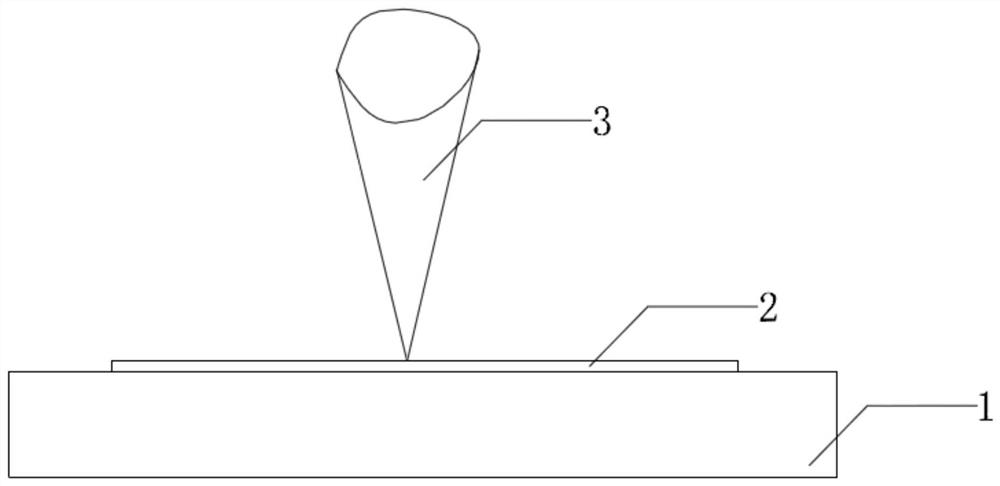

A kind of laser welding equipment with smearable coating for plate metal parts

ActiveCN107234339BReduce riskImprove welding qualityLaser beam welding apparatusEngineeringSoldering process

The invention relates to laser welding equipment, in particular to laser welding equipment capable of achieving coating painting of sheet metal parts. The laser welding equipment capable of achieving coating painting for the sheet metal parts aims at achieving the technical effects that the welding process risk is low, welding joint compactness and welding quality are high and the welding process saves time and labor. In order to achieve the technical effects, the laser welding equipment capable of achieving coating painting of the sheet metal parts comprises supports, a first guide rail, a first guide sleeve, a first screw rod, a first pressing block, a supporting rod, a placing plate, a check block, a connection rod, a supporting plate, a second guide sleeve and the like. The first guide rail is installed on the inner sides of the two supports in a welded mode, and the first guide sleeve is in sliding connection with the first guide rail. The effects that the welding process risk is low, welding joint compactness and welding quality are high and the welding process saves time and labor.

Owner:扬州亚联机械科技有限公司

Safe-to-use welding mechanism for solar photovoltaic bracket production

InactiveCN107695573AEasy to moveWelding safetyWelding/cutting auxillary devicesAuxillary welding devicesInsertion stentArchitectural engineering

The invention relates to the technical field of power, and discloses a safe-to-use welding mechanism for solar photovoltaic bracket production. The welding mechanism comprises a base; a sliding grooveis formed in the left surface of the base; a round rod is movably arranged in an inner cavity of the sliding groove; the outer surface of the round rod is sleeved and connected with a vertical platelocated on the left side of the base; pulleys connected with the base are fixedly arranged on the right surface of the vertical plate; the outer surface of the round rod is sleeved and connected witha holding plate located on the left side of the vertical plate; and first inclined rods located in front of the round rod are fixedly arranged on the right surface of the holding plate. According to the safe-to-use welding mechanism for the solar photovoltaic bracket production, the round rod is arranged in the inner cavity in the upper part of the base, and the round rod can be forced to move left and right through a conveying belt, a movable plate and a bottom block which are arranged at the right end of the round rod, so that the welding is very convenient and safe; in addition, the left end of the outer surface of the round rod is sleeved and connected with the vertical plate and the pulleys, so that the round rod is more convenient to move.

Owner:扬州申威光电器材有限公司

Tube welding and locating device for production

InactiveCN108971879AEasy positioningAchieve positioningWelding/cutting auxillary devicesAuxillary welding devicesFixed frameEngineering

The invention provides a tube welding and locating device for production. The tube welding and locating device for production comprises a fixing frame, a supporting plate, a first tube locating piece,a second tube locating piece and a third tube locating piece. The fixing frame comprises a first fixing plate and a second fixing plate which are parallel. A connection plate is perpendicularly and fixedly connected between the first fixing plate and the second fixing plate. One side of the connection plate is fixedly connected with the supporting plate. The first tube locating piece is arrangedinside the first fixing plate. The second tube locating piece driven by a lifting drive mechanism is arranged inside the second fixing plate. The upper surface of the end, far away from the connectionplate, of the supporting plate is provided with a sliding groove. The sliding groove is parallel with the connection plate. A sliding block is arranged in the sliding groove in a penetrating manner.A supporting rod used for supporting the third tube locating piece is arranged on the upper side of the sliding block. The top end of the supporting rod is detachably and fixedly connected with the third locating piece. The tube welding and locating device for production is convenient to use, capable of conducting welding and locating on tubes of different specifications, good in welding accuracyand good in welding effect.

Owner:XUZHOU UNIV OF TECH

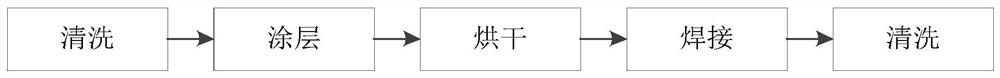

Low-frequency and low-power laser welding method for oxygen-free copper

PendingCN112222619AAvoid uniformityAvoids the problem of penetration into weld seamsLaser beam welding apparatusGraphiteLaser soldering

The invention discloses a low-frequency and low-power laser welding method for oxygen-free copper, and belongs to the technical field of welding. The method comprises the technological processes of cleaning, coating, drying, welding recleaning and the like. According to the method, the oxygen-free copper welding problem of low-frequency and low-power laser equipment is solved, the welding processis safe and reliable, the conditions of uniform coating of a graphite coating and welded joint penetration before and after welding are well controlled, and welded joints are flat, attractive and goodin comprehensive performance.

Owner:中国船舶集团有限公司第七二四研究所

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com