Automatic scaffold welding machine and welding method thereof

An automatic welding machine and automatic welding technology, applied in the direction of welding/welding/cutting items, welding equipment, resistance welding equipment, etc., can solve problems such as low production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

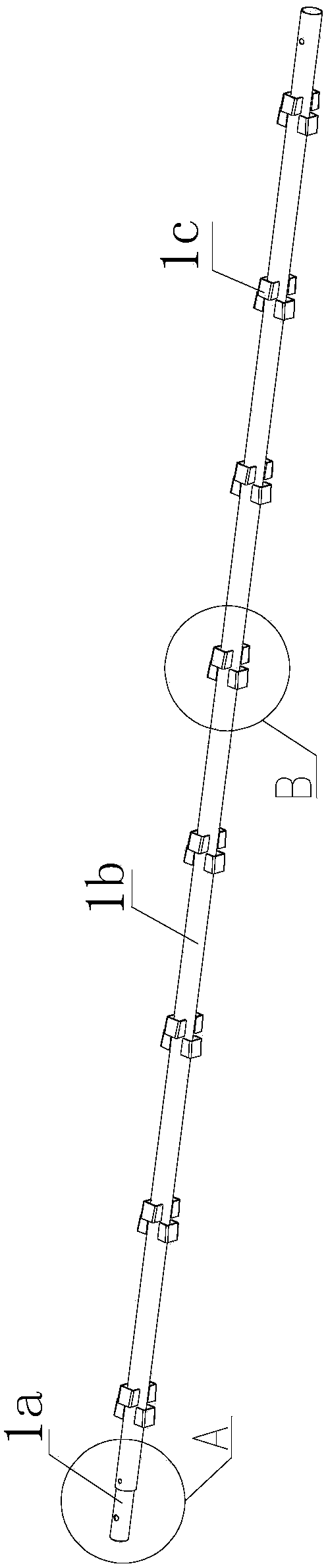

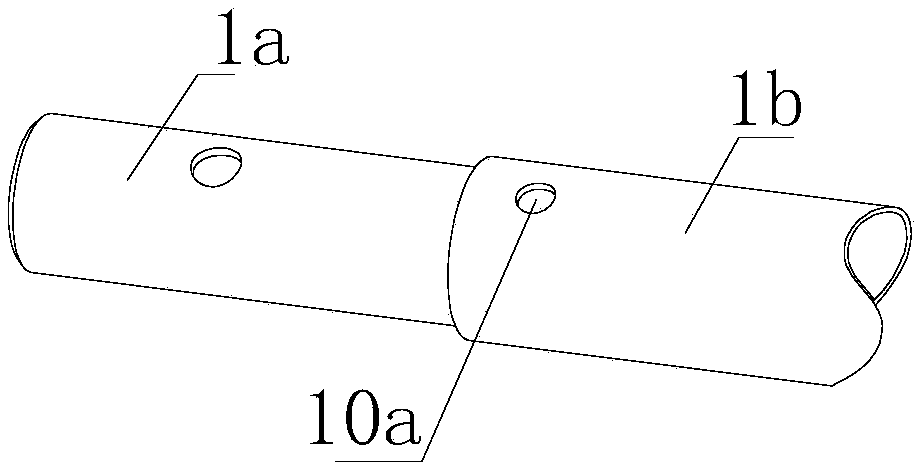

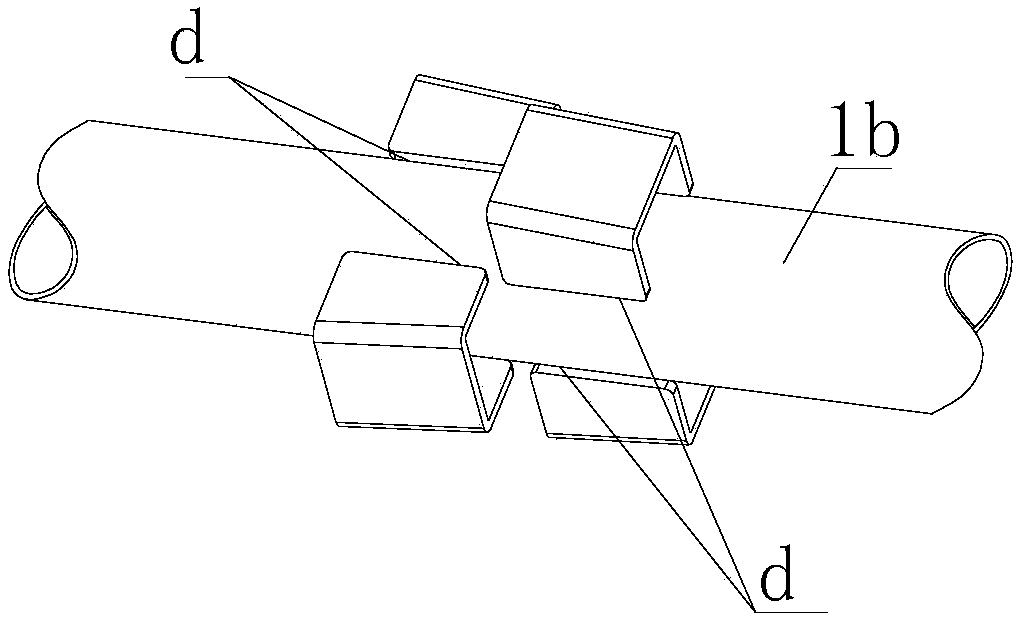

[0082] Scaffold automatic welding machine, such as Figure 4 to Figure 6 As shown, it is used for the automatic welding of a main steel pipe 1 used as a vertical pole in a socket-type steel pipe scaffolding, a socket pipe 2, and eight groups of thirty-two U-shaped sockets 3, including a horizontally arranged base 4, On the front side of the base 4, there is a circumferential rotation of 180° to switch between the loading station and the welding station of the main steel pipe 1 to be welded, the socket pipe 2 and the U-shaped socket 3, and the welding station itself rotates. 180° realizes the three-axis displacement device 5 for quick welding on both sides of the main steel pipe to be welded respectively; on both sides of the rear side of the base 4, two vertically arranged gantry-type welding torch brackets 6 are fixed, and a horizontal torch bracket 6 is arranged between the two welding torch brackets 6 The frame beam 7 and the cross frame beam 7 are equipped with a spot weld...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com