Explosive welding forming method of titanium-pure aluminum-aluminum alloy composite plate

An explosive welding and forming method technology, applied in welding equipment, non-electric welding equipment, metal processing equipment, etc., can solve the problems of different chemical properties, size and shape specifications are not restricted by equipment, and the compounding method is difficult, etc., to achieve the interface Good shear strength, safe and reliable welding process, and firm interface bonding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

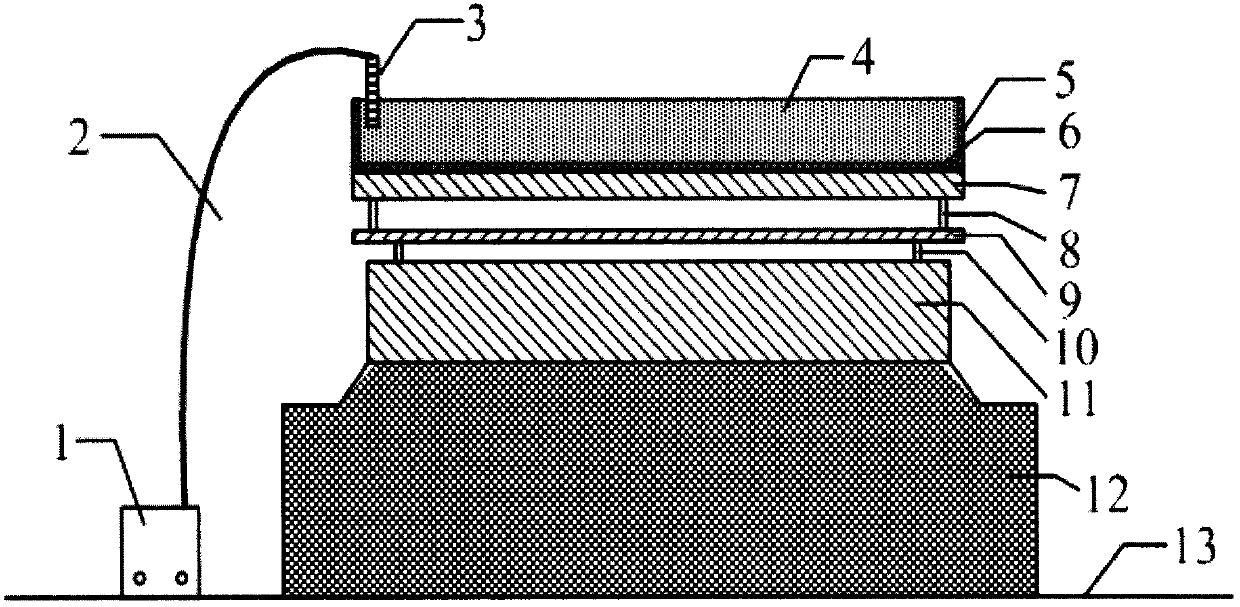

[0029] The present invention will be described in detail below with reference to the accompanying drawings and examples.

[0030] The invention provides an explosive welding forming method of a titanium-pure aluminum-aluminum alloy composite plate. The chemical materials used are titanium plate, pure aluminum plate, aluminum alloy plate, ammonium oil explosive, detonator, lead wire, aluminum foil, butter, Sandpaper, sand grains and absolute ethanol, its combined preparation dosage is as shown in Table 1:

[0031] Table 1 Combination ratio of chemical substances and materials

[0032] Titanium plate: TAl

500mm×300mm×1mm

Pure aluminum plate: Al1060

550mm×350mm×1mm

Aluminum alloy plate: Al5020

550mm×350mm×6mm

Ammonium oil explosives:

2060g±50g

Diameter 6mm×40mm

Lead wire: shielded cable

50000mm

Aluminum foil: Al

10mm×6m×0.5mm 15 pieces

Butter: General Purpose Lithiu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com