Intelligent screening system based on numerical control processing technology for difficult-to-machine metal

A kind of processing technology and difficult-to-machine technology, applied in the field of intelligent screening system, can solve the problems of cracks, tool wear, large application requirements, etc., to achieve the effect of improving learning accuracy, long tool life, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] specific implementation plan

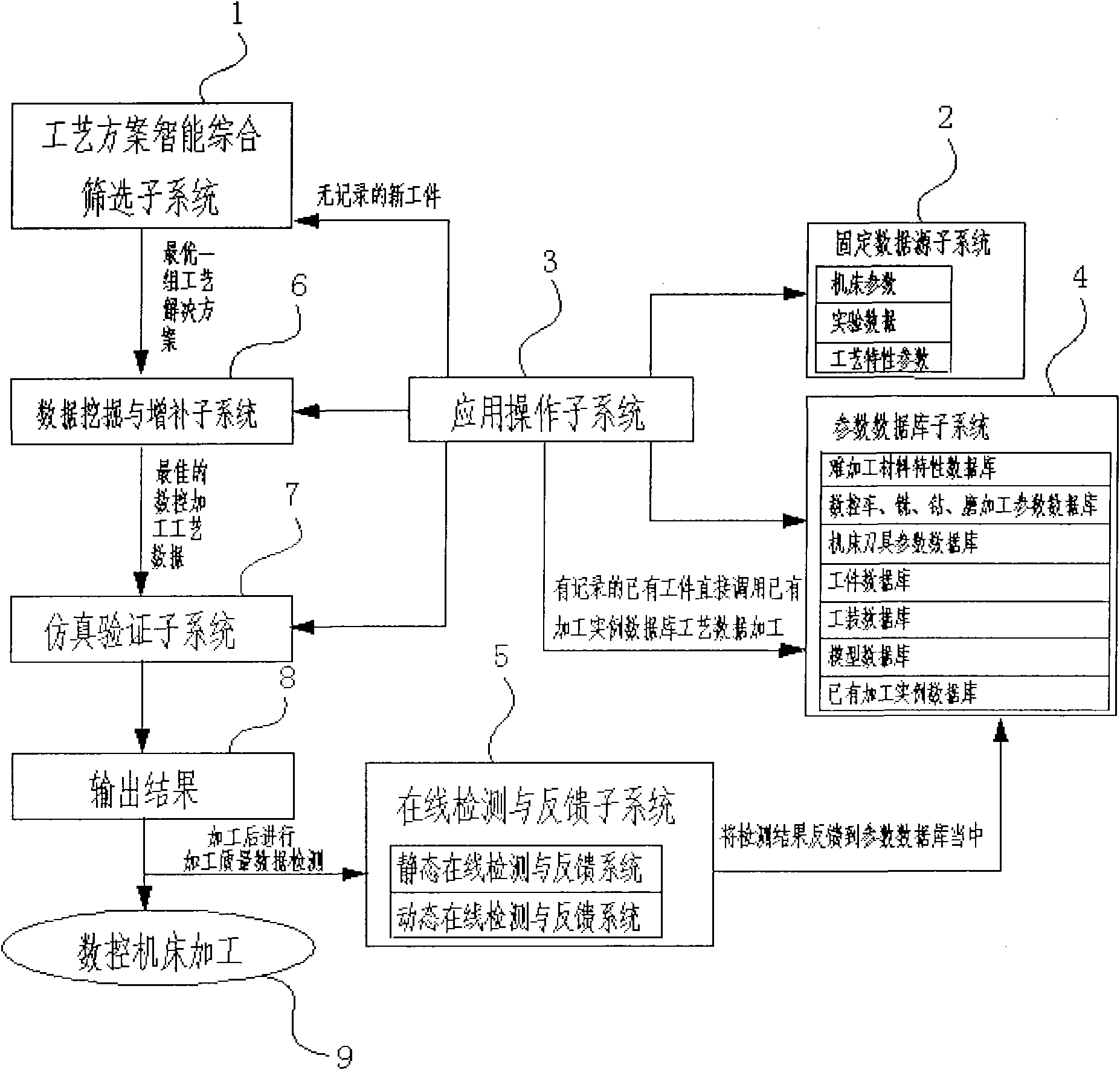

[0044] An embodiment of the system of the present invention is provided below, as figure 1 As shown, the intelligent screening system based on the NC machining process of difficult-to-machine metals includes the following seven subsystems 1-7:

[0045] A parameter database subsystem 4 for storing and extracting NC machining parameter data of difficult-to-machine materials. The parameter database subsystem 4 consists of the following seven databases:

[0046] The parameter database subsystem is composed of the following aspects of data:

[0047] 1. A difficult-to-machine material characteristic database for storing and extracting data on strength, stiffness, elasticity and plasticity, hardness, impact toughness, fracture toughness, and fatigue strength of various difficult-to-machine materials;

[0048] 2. It is used to store and extract the three elements of NC machining (turning, milling, drilling, grinding) of various difficult-to-mach...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com