A kind of preparation method of aluminum-based boron carbide neutron absorbing plate

A neutron-absorbing plate, aluminum-based boron carbide technology, applied in the field of reinforcement, non-ferrous metal powder metallurgy and plate forming, can solve the problems of low secondary ray energy, low boron content in boron steel, high thermal neutron capture cross section, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] The present invention will be further described below in conjunction with accompanying drawing:

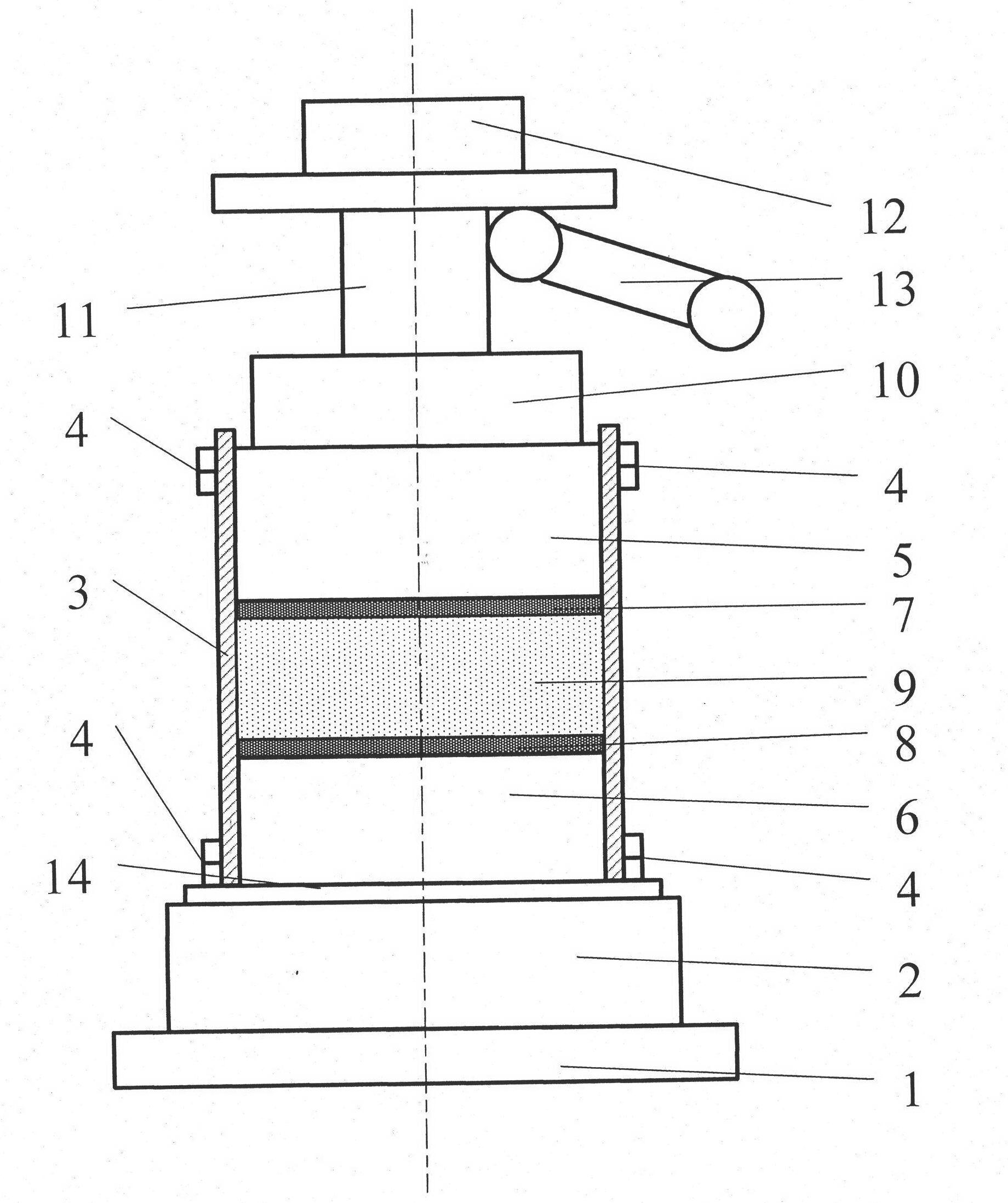

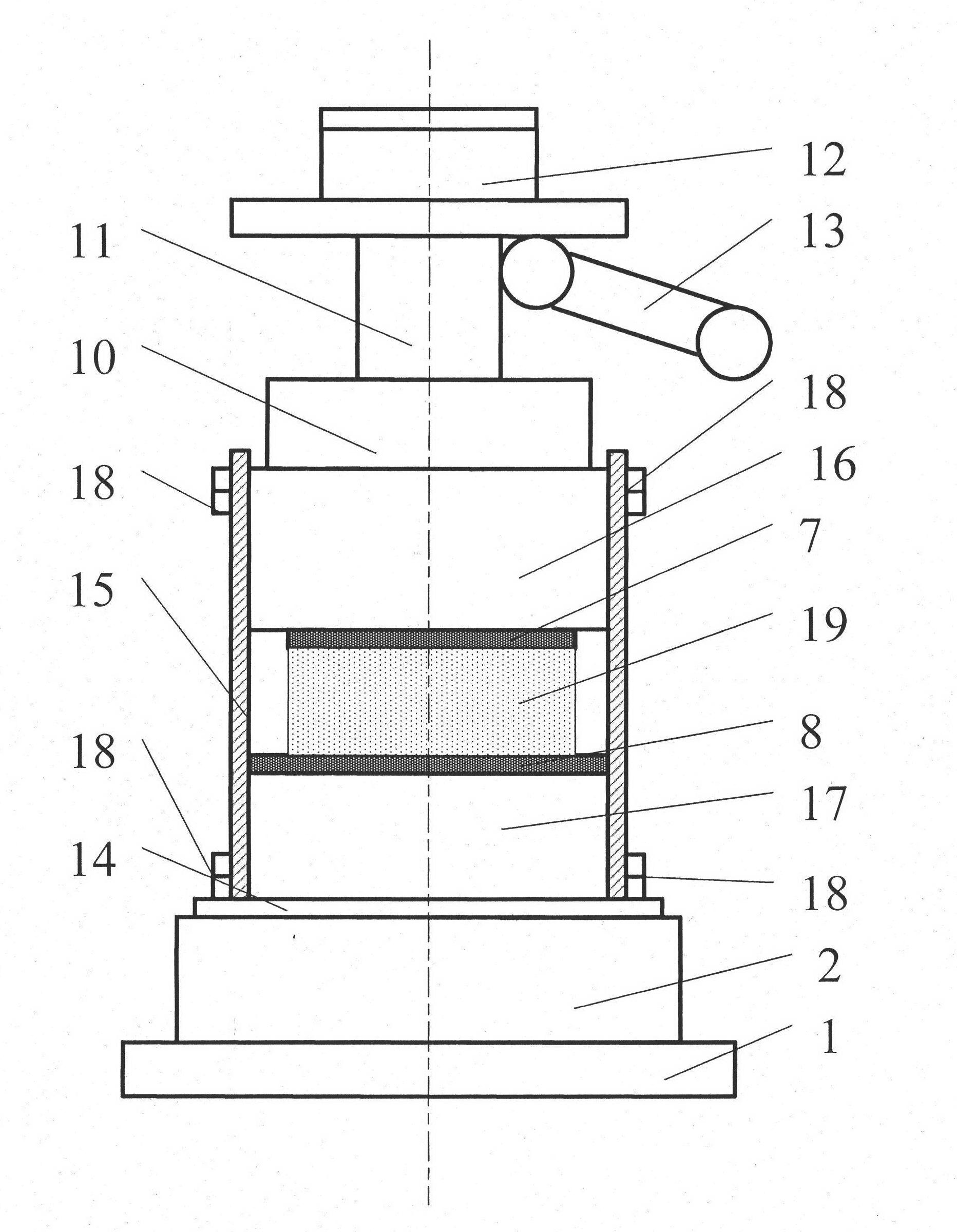

[0060] figure 1 As shown, it is the powder metallurgy state diagram of the aluminum-based boron carbide neutron absorbing plate. The amount of powder metallurgy materials used in the preparation is determined according to the preset range, and the unit of measurement is grams.

[0061] The preparation is completed on a press machine in a split stainless steel mold. The position and connection relationship of each part must be correct, proportioned according to quantity, and operated in sequence.

[0062] On the upper part of the press base 1 is a heater 2, on the upper part of the heater 2 is a backing plate 14, and a metallurgical powder mold 3 is placed on the top of the backing plate 14, and the mold 3 is opened and closed by the opening and closing frame 4. Inside the metallurgical powder mold 3 The bottom is the lower template 6, and a layer of graphite paper 8 is laid ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Microhardness | aaaaa | aaaaa |

| Microhardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com