Patents

Literature

88 results about "Self reduction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

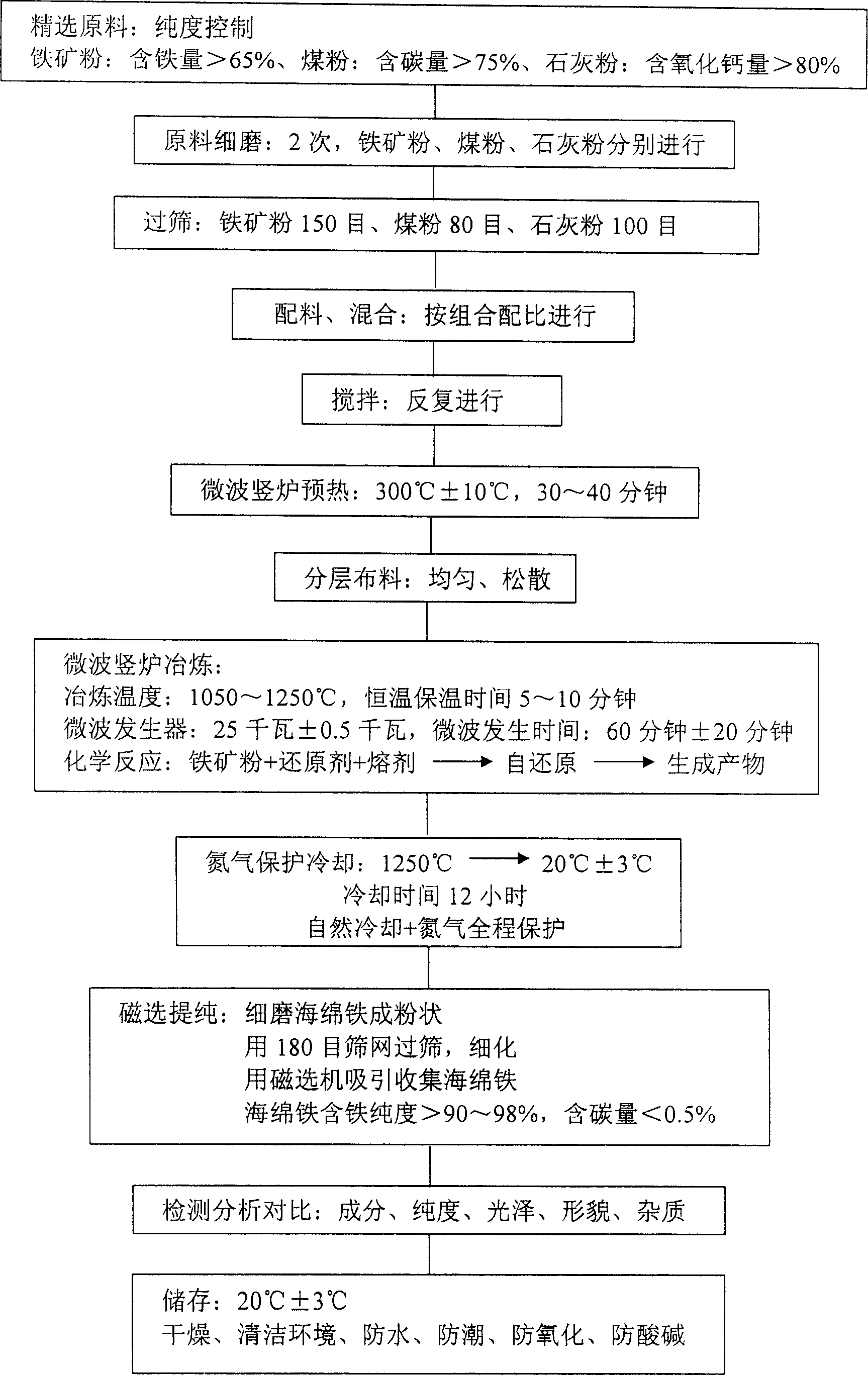

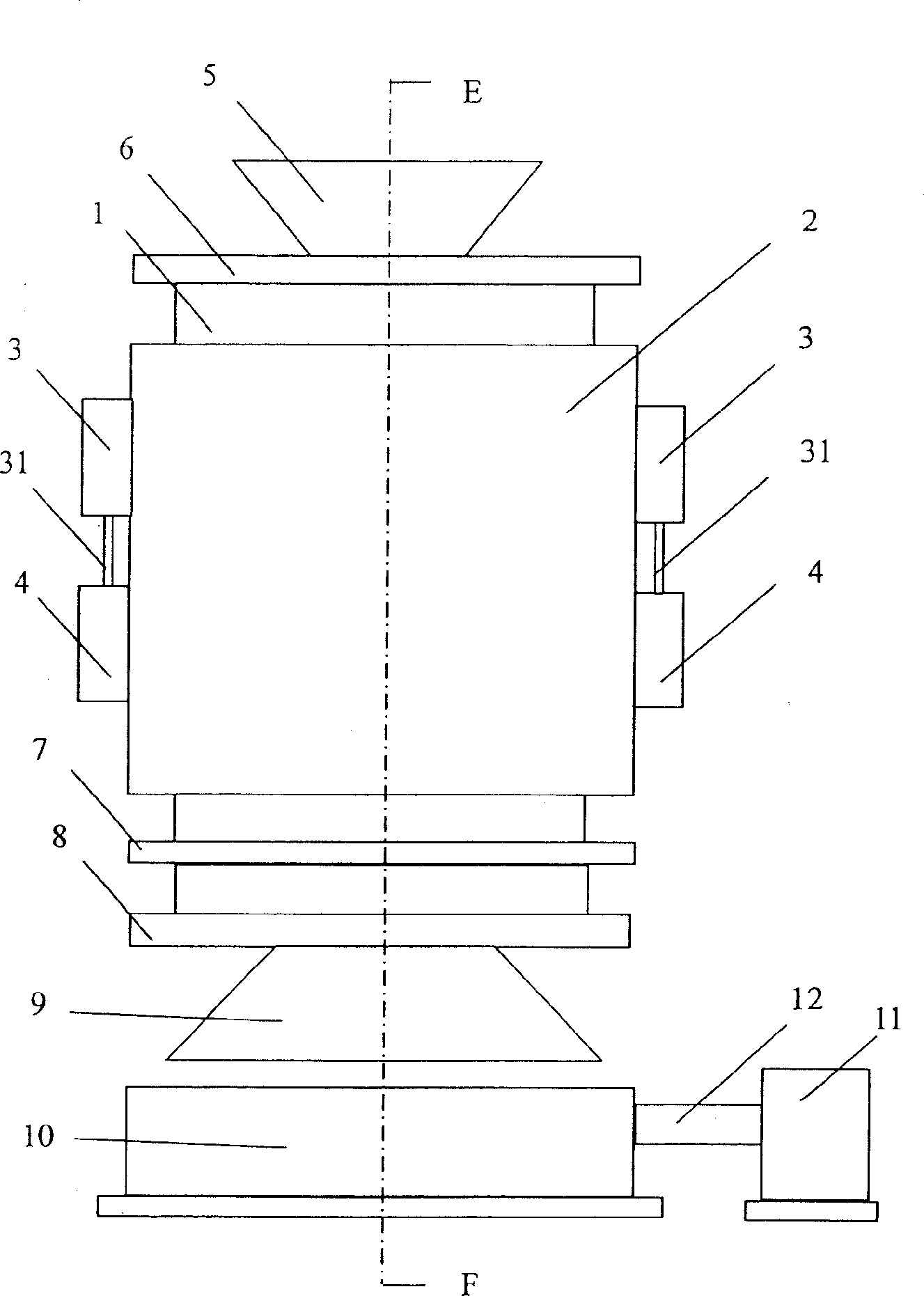

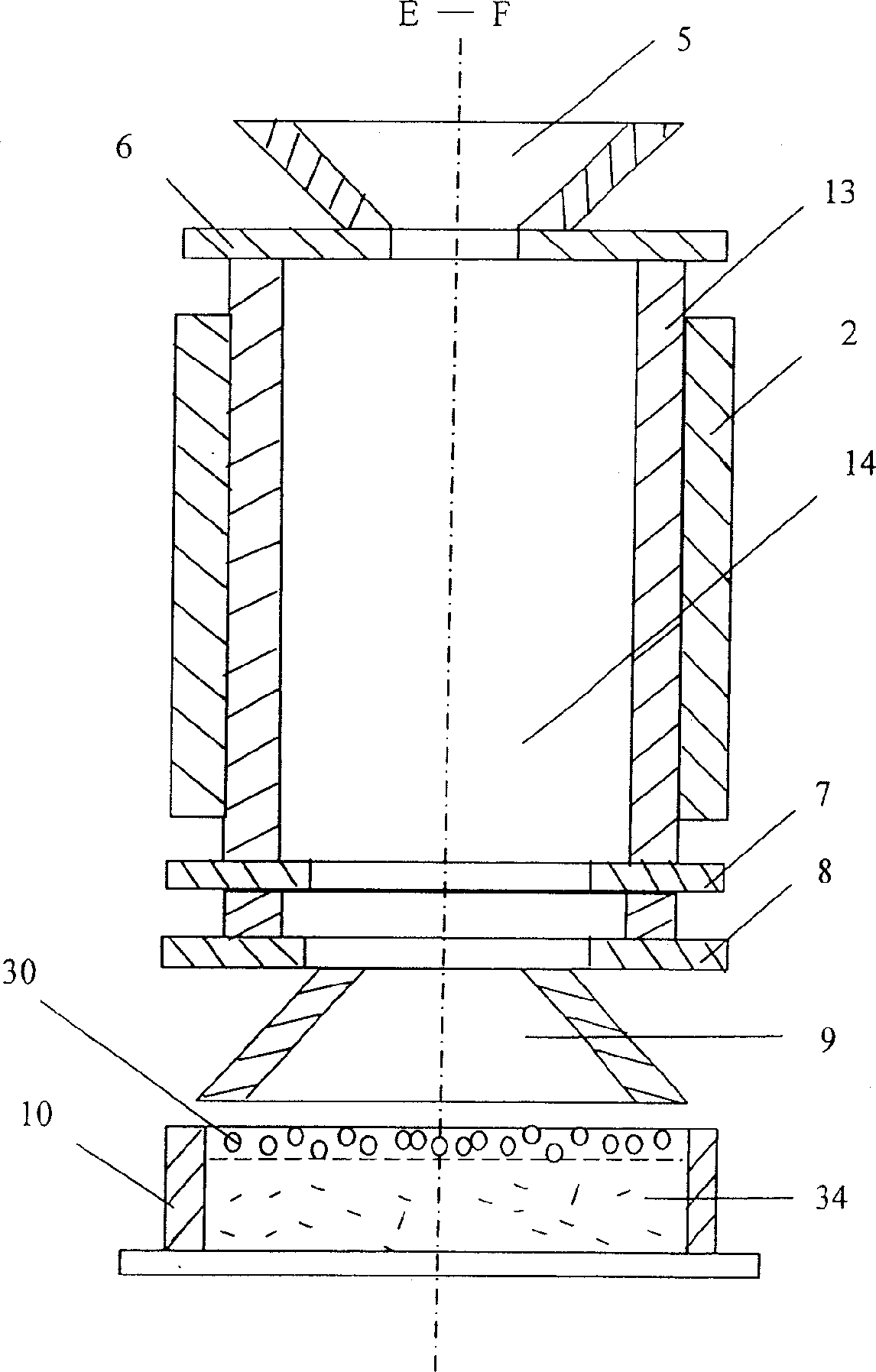

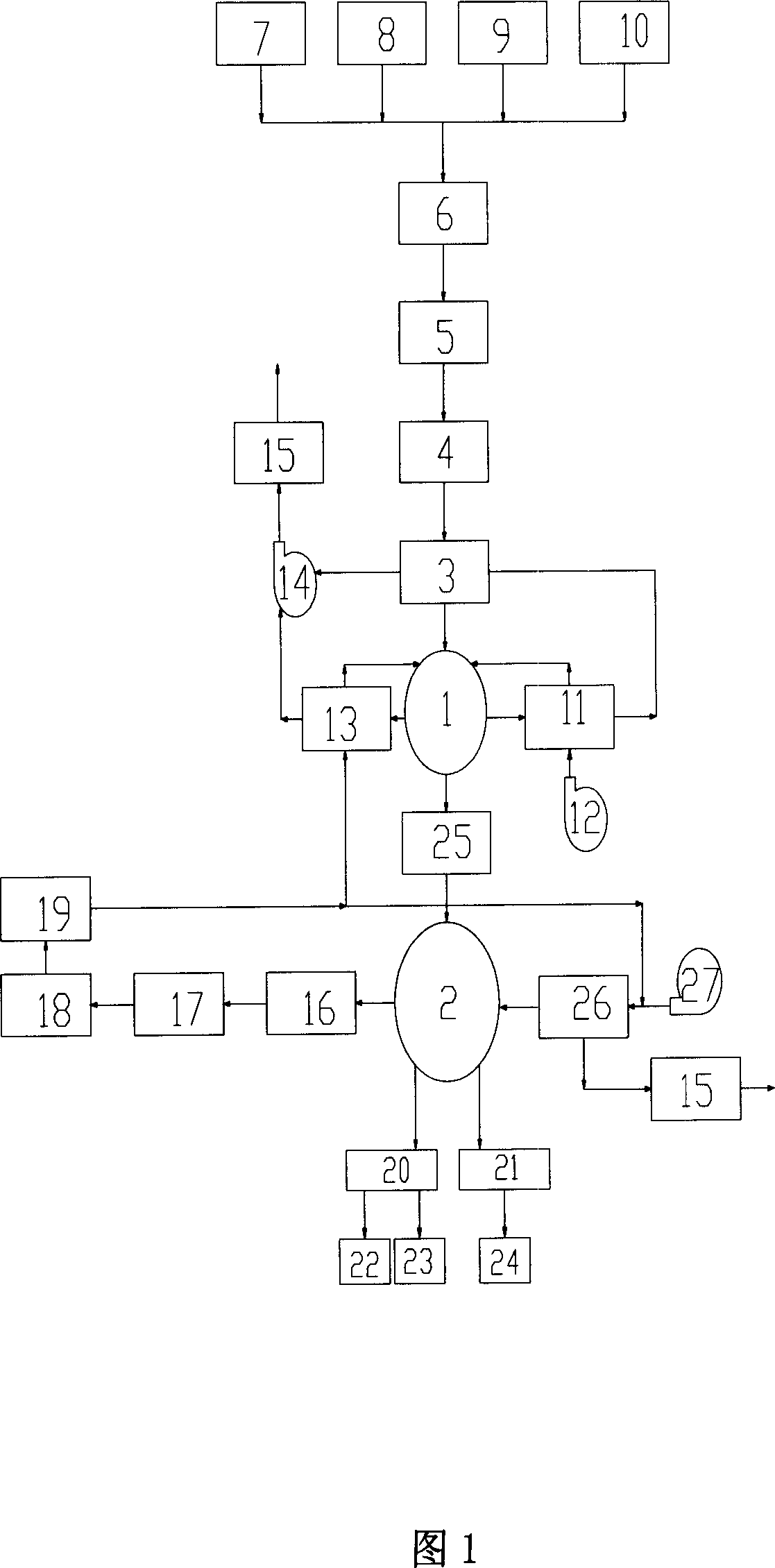

Method of manufacturing low carbon sponge iron using microwave vertical furnace

The invention relates to a method to make low carbon sponge iron by microwave shaft furnace. It adopts iron ore powder as raw material, common soft coal dust or anthracite dust as reducer to gain high quality low carbon sponge. It uses the feature that the iron ore powder, carbon powder, and lime powder has selective absorbing to microwave. Under the condition of sealing and high temperature, and under the effect of microwave generator, heater, and adjustor, it would take carbon heat self-reduction by absorbing the heat produced by microwave generator to gain low carbon sponge iron. The method has simple technology, shortens the reduction time period, saves coking coal and coke resource, and reduces environment pollution. The degree of metallization could reach 90-98%, and the carbon content could be lower than 0.5%. It is the ideal method to make low carbon sponge iron.

Owner:TAIYUAN UNIV OF TECH

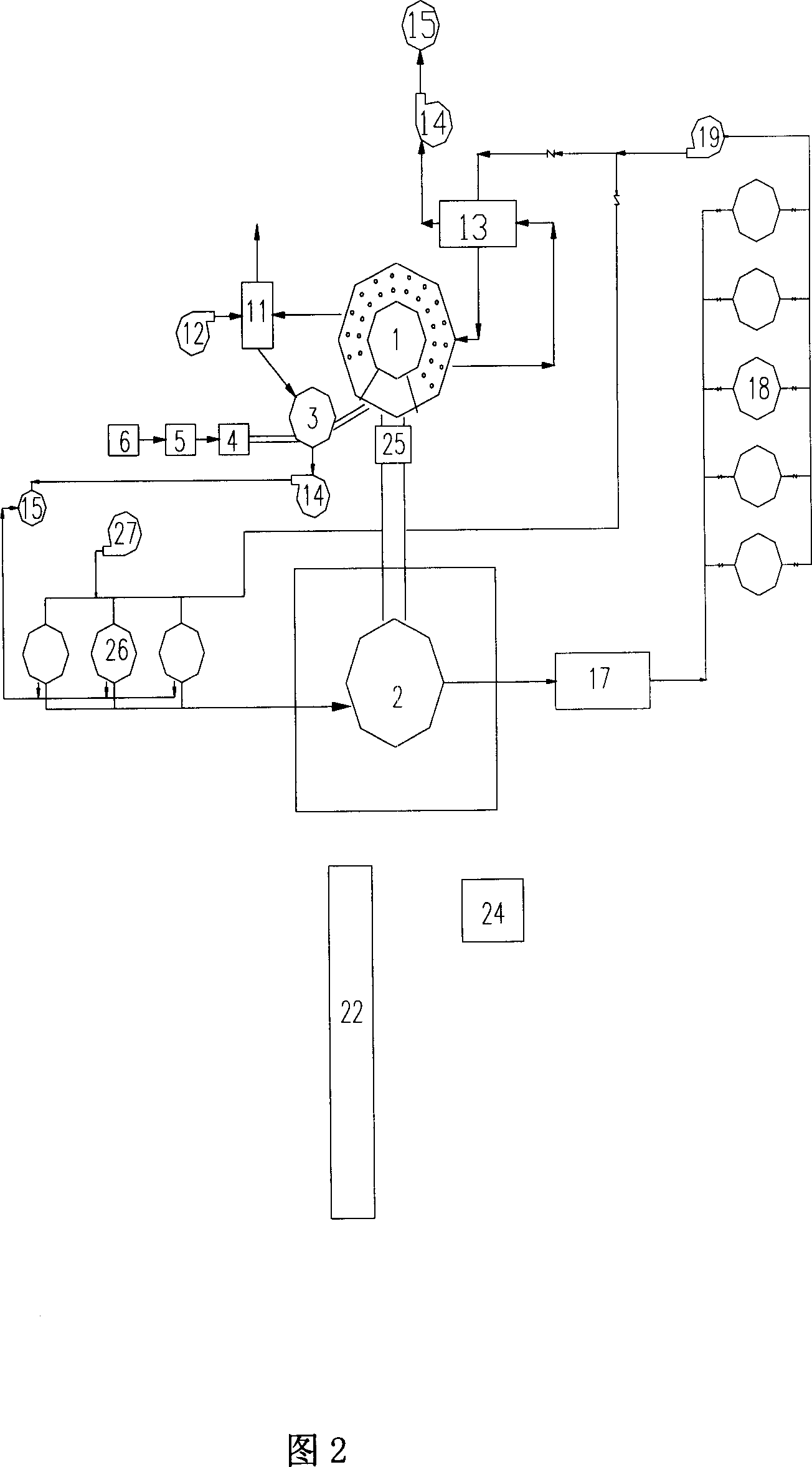

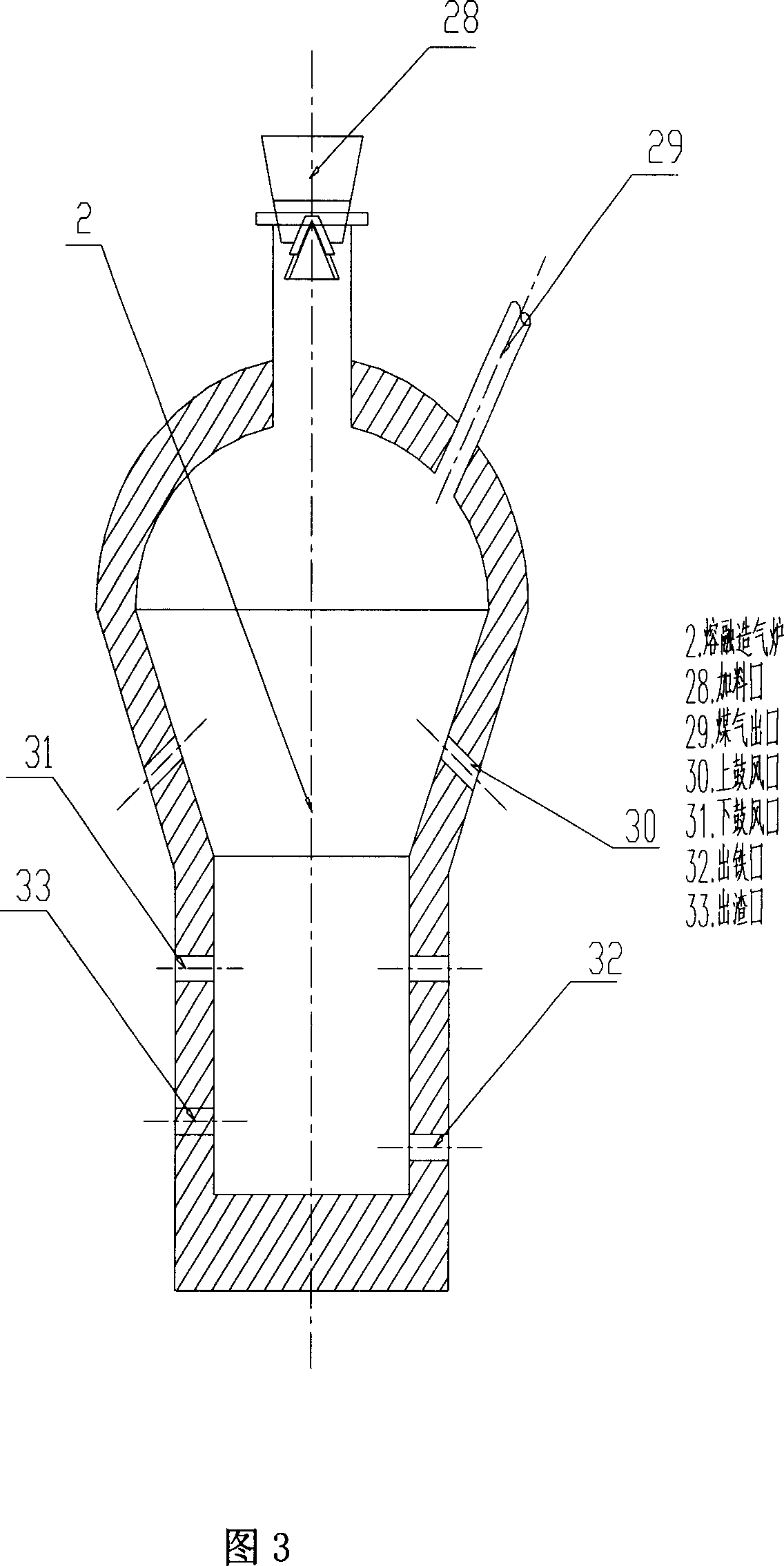

Fuse reducing iron-smelting process for rotating furnace

InactiveCN1940092ALatent heat utilizationReduce energy consumptionRotary drum furnacesGas emission reductionSmelting processSelf reduction

An iron smelting process by rotating-furnace melt and reduction is carried out by mixing iron-mine powder with powdered coal to obtain self-reduction palletizing, taking it as raw material, pre-reducing by rotating-furnace to obtain metal pellet with conversion rate >80%, heating, packing it into melt gas maker, finally reducing and melting while separating out iron slag to obtain liquefied iron and gas and utilizing it for hot-air furnace and rotating-furnace gas. It has no environmental pollution, and no need for oxygen and natural gas.

Owner:万天骥

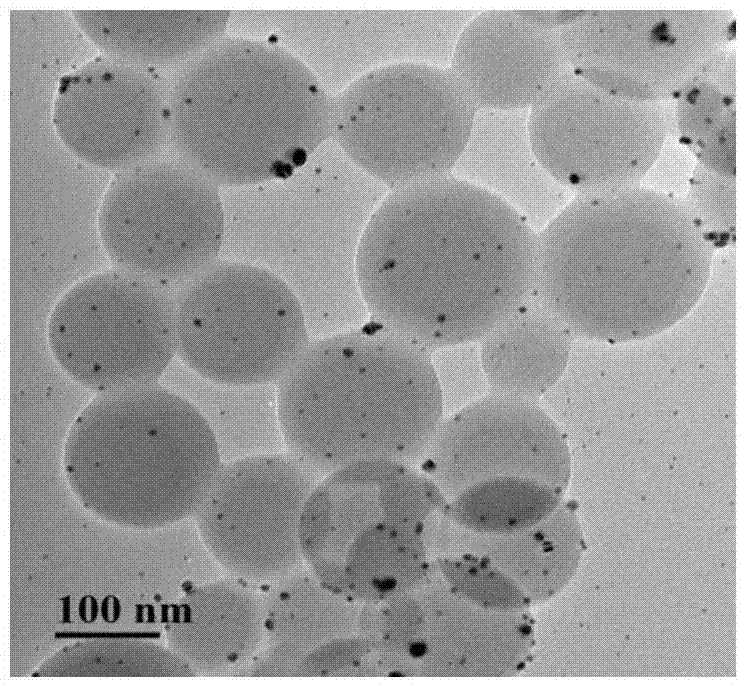

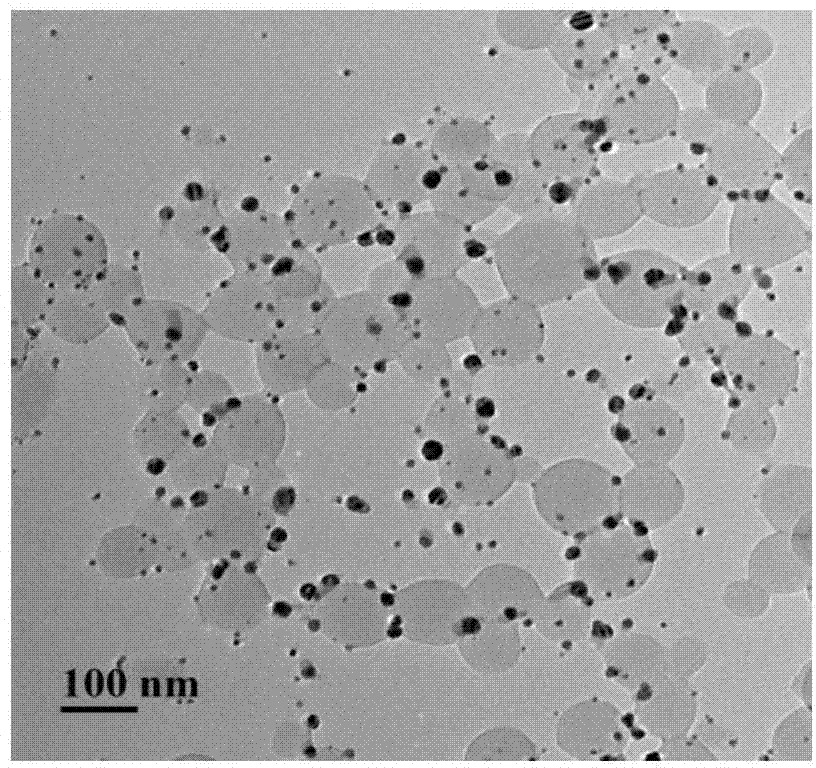

Graphene loaded high-dispersion nano Ni catalyst as well as preparation method and application thereof

InactiveCN103301841AGood dispersionGood catalytic hydrogenation performanceOrganic compound preparationCarbonyl compound preparationNano catalystSelf reduction

The invention provides a graphene loaded high-dispersion nano Ni catalyst as well as a preparation method and application thereof. The catalyst is obtained by loading high-dispersion Ni nano-metal on the surface of graphene, and doping less amorphous Al2O3, wherein the mass percent content of graphene is 40-67%, the mass percent content of Ni is 10-40%, the mass percent content of amorphous Al2O3 is 2-8%, the size distribution of Ni particles is 8-13nm, and the specific area of the catalyst is 155-200 m<2> / g. The preparation method comprises the following steps of: preparing a graphene / lamellar bimetal hydroxide composite material in one step through the hydroxide precipitation and reduction effect, and then preparing the graphene loaded high-dispersion metal Ni nano catalyst through an in-situ self-reduction method by using the reducibility of graphene. The catalyst is used for selectively hydrogenating the cinnamyl aldehyde to synthesize the benzenepropanal, and the conversion rate and the benzenepropanal selectivity are respectively 86-100% and 88-96%.

Owner:BEIJING UNIV OF CHEM TECH

Self-reduction utilization process for steel rolling oily sludge and blast furnace gas dust

ActiveCN105695735AValue maximizationReduce investmentRecycling and recovery technologiesProduction lineSlag

The invention discloses a self-reduction utilization process for steel rolling oily sludge and blast furnace gas dust. Limestone powder with the grain size smaller than 2mm is purchased and conveyed to a pelletizing production line for use, and an opposite-roll cold pressing pelletizing machine production line is adopted by the pelletizing production line; meanwhile, the steel rolling oily sludge and blast furnace gas dust are conveyed to the pelletizing production line for use; the limestone powder, the blast furnace gas dust and the steel rolling oily sludge are added into an ordinary vertical mixer to be stirred and mixed uniformly according to mass percentages of 10:75:15; after a mixture obtained in the previous step is mixed uniformly, the mixture is compacted into pellets with the diameters of 30-50 mm on an opposite-roll cold pressing pelletizing machine, and then the pellets are conveyed to a converter production line for use; during a converter deslagging process, the pellets are added into a slag tank along with steel slags, or the pellets are added into the slag tank containing molten steel slags from the top, and the mass ratio of the added pellets to the steel slags is 1:10; and after the pellets are added, the slag tank stands for 60+ / -20 min, and then the steel slags can be processed according to a normal slag hot disintegration process.

Owner:XINJIANG BAYI IRON & STEEL

Method and apparatus for preparing blue tungsten oxide by ammonium paratungstate self-reduction

InactiveCN1594107AGood catalytic propertiesReduce pollutionTungsten oxides/hydroxidesAmmonium paratungstateWater vapor

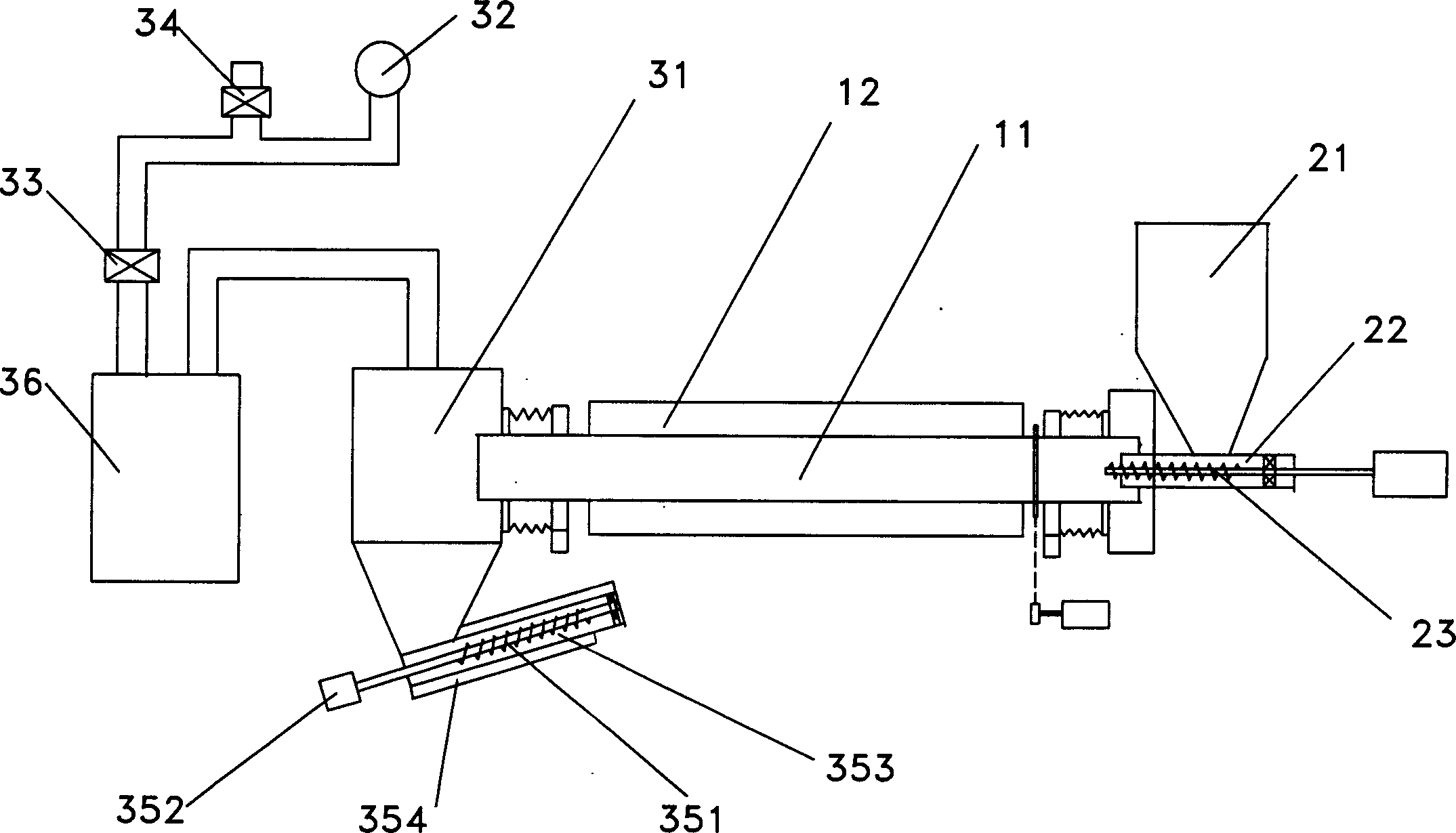

The invention discloses a method and apparatus for preparing blue tungsten oxide by ammonium paratungstate self-reduction, wherein the discharging end of the preparing apparatus is provided with sealed discharger, a cooling device, an air exhaust fan and an air vent, the preparation comprises loading the ammonia paratungstate into the furnace tube of the preparing apparatus, heating the furnace tube, so as to decompose the ammonia paratungstate into WO3, ammonia gas NH3 and water vapor H2O, further decomposing the NH3 into nitrogen N2 and hydrogen H2, controlling the reaction temperature and combustion gas pressure so as to deacidize the tungsten trioxide WO3 into blue tungsten oxide.

Owner:XIAMEN GOLDEN EGRET SPECIAL ALLOY

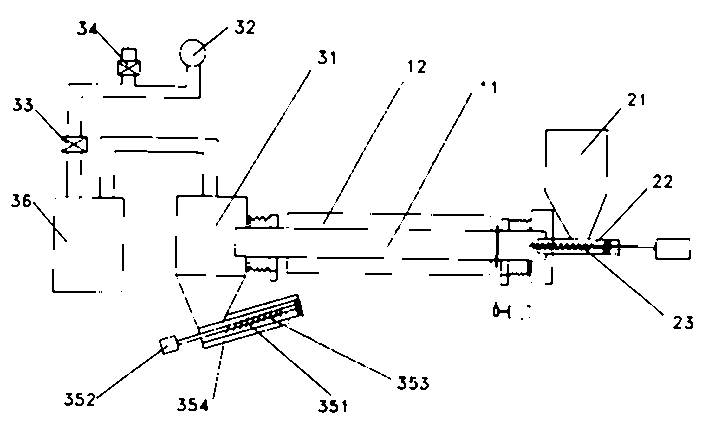

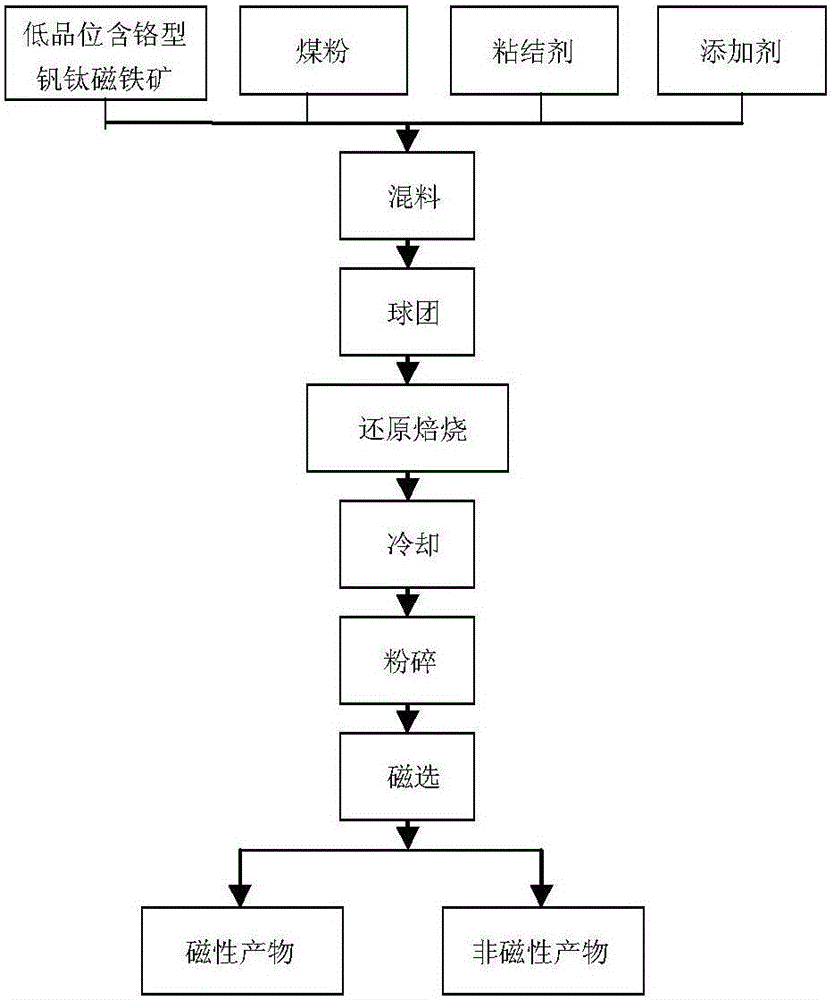

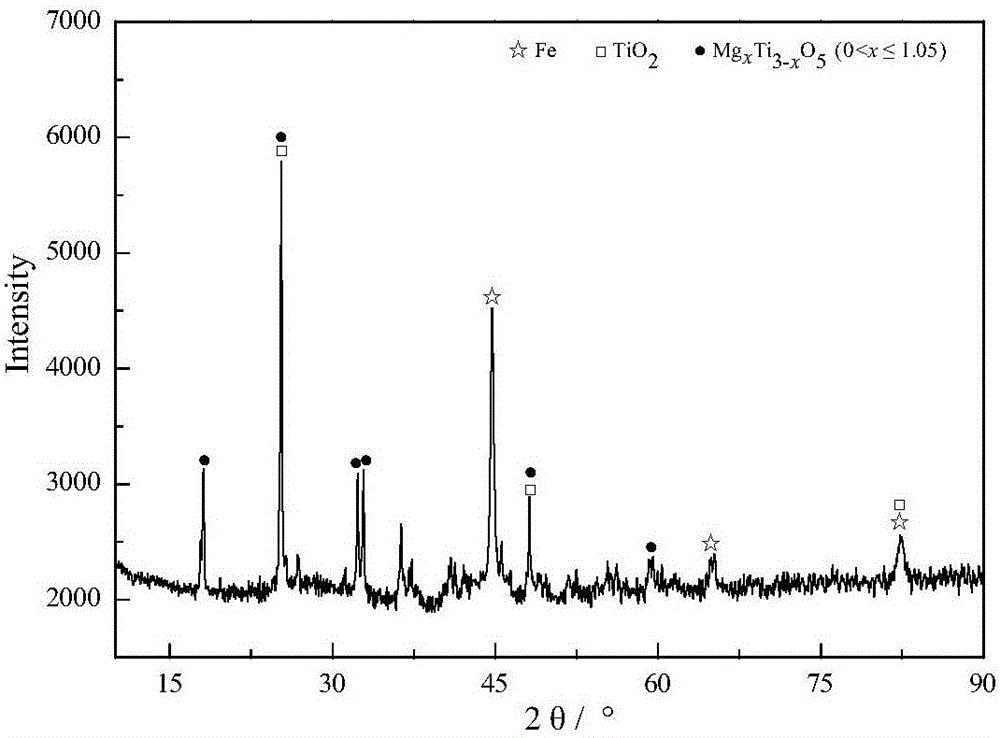

Magnetic separation method for low-grade chromium-containing vanadium titanium magnetite metalized pellet

The invention discloses a magnetic separation method for a low-grade chromium-containing vanadium titanium magnetite metalized pellet, belonging to the technical field of non-blast furnace smelting in comprehensive utilization methods of low-grade chromium-containing vanadium titanium magnetite powder. The method is carried out through the following steps of (1) mixing low-grade chromium-containing vanadium titanium magnetite powder, reduced pulverized coal, a binder and an additive by weighing; (2) preparing a pellet from the mixture, and drying; (3) carrying out coal-based pellet self-reduction high-temperature roasting on the dried pellet; (4) cooling the metalized pellet subjected to high-temperature roasting; and (5) smashing the cooled metalized pellet to obtain metalized pellet powder, and then, carrying out magnetic separation by using a magnetic separation tube to obtain an iron-enriched magnetic matter and titanium-enriched nonmagnetic matters. By using the method, the utilization ratios of strategic metal vanadium, titanium and chromium are maximized on the premise that the metallization ratio and iron recovery ratio for coal-based forced reduction of the low-grade chromium-containing vanadium titanium magnetite metalized pellet are increased.

Owner:NORTHEASTERN UNIV

Production method of fluxed composite carbon-containing pellets used in blast furnace

The invention provides a production method of fluxed composite carbon-containing pellets used in a blast furnace, wherein a mixture A is composed of 65-80% of iron ore concentrate, 1-2% of a binding agent and 10-20% of a carbon-containing material with addition of a flux to enable the ratio of (CaO+MgO) / SiO2 of the mixture A to be 1-1.4. The mixture A is added with water and is mixed uniformly to form self-fluxing pellet cores being 5-7 mm in granularity. A mixture B is composed of 75-85% of the iron ore concentrate, 1-2% of the binding agent and 5-15% of the carbon-containing material, wherein a flux is added until the ratio of (CaO+MgO) / SiO2 of the mixture A is 0.2-0.5. The production method includes the steps of placing the self-fluxing pellet cores in a pelletizer, adding the mixture B for performing pelletizing continuously to obtain raw carbon-containing pellets being 10-16 mm in granularity, and roasting the raw carbon-containing pellets to obtain the fluxed composite carbon-containing pellets. The method solves the problems of roast bonding of the fluxed pellets and internal self-reduction delay of the carbon-containing pellets, enables the alkalinity and reduced carbon in the pellets to be distributed in a gradient manner, can greatly improve high-temperature metallurgical performances of the carbon-containing pellets, can reach 2081 N / pellet in compressive strength and is 40% in metallization rate.

Owner:ANGANG STEEL CO LTD

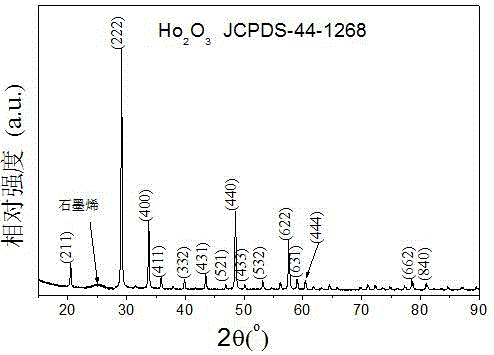

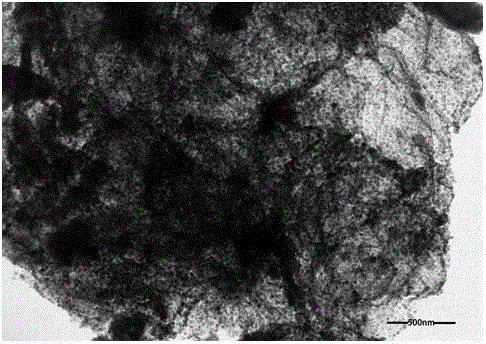

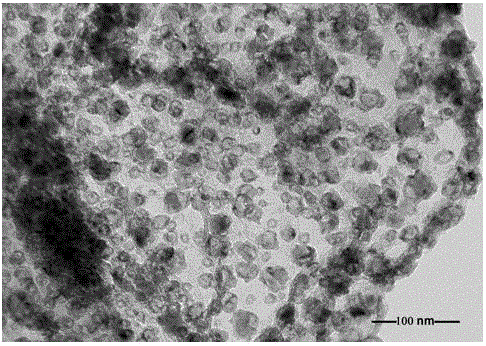

Preparation method of rare earth oxide and graphene nanocomposite material

ActiveCN106219590ASynthesis temperature is lowEasy to implementRare earth metal oxides/hydroxidesMaterial nanotechnologyGraphene nanocompositesRare earth

Provided is a preparation method of a rare earth oxide and graphene nanocomposite material. The method comprises the following steps that 1, an aqueous solution containing needed amount of rare earth nitrate is prepared according to the loading capacity of rare earth oxide on graphene and the preparation quantity of a target product and added into a certain volume of graphene oxide dispersing agent of which the concentration ranges from 0.5 g / L to 5 g / L; 2, an appropriate amount of organic fuel is added into the dispersing agent in the first step, stirring and ultrasound are conducted, and a uniform dispersing agent is obtained; 3, the dispersing agent in the first step is heated and concentrated to be thick, the heated and concentrated dispersing agent is put into a heating furnace of 300 DEG C-900 DEG C for ignition, and after burning is conducted, cooling is conducted to room temperature. The preparation method of the rare earth oxide and graphene nanocomposite material is low in synthesis temperature, short in time, easy to carry out and low in cost, a reducing agent does not need to be additionally added, and graphene oxide is subjected to self reduction to obtain graphene; meanwhile, rare earth oxide is small in particle size and uniform in size, and the uniform dispersibility on graphene is achieved. The preparation method of the rare earth oxide and graphene nanocomposite material is rapid, efficient, high in yield, green, environmentally friendly and suitable for industrial production.

Owner:NANCHANG UNIV

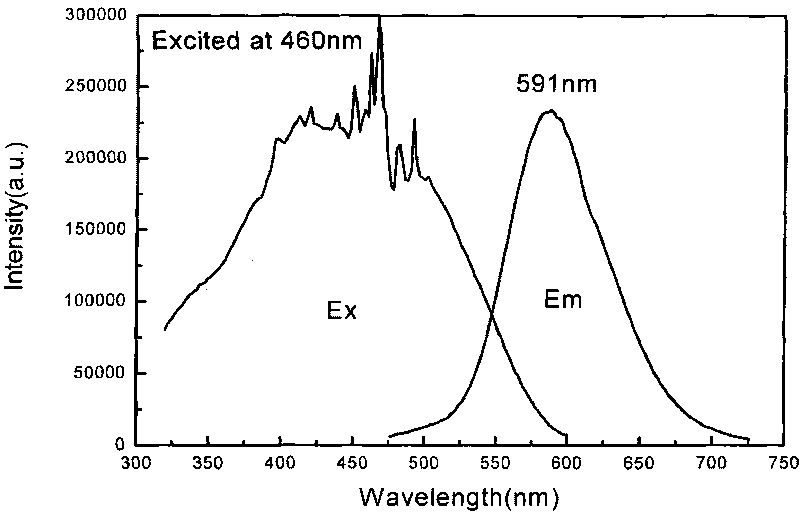

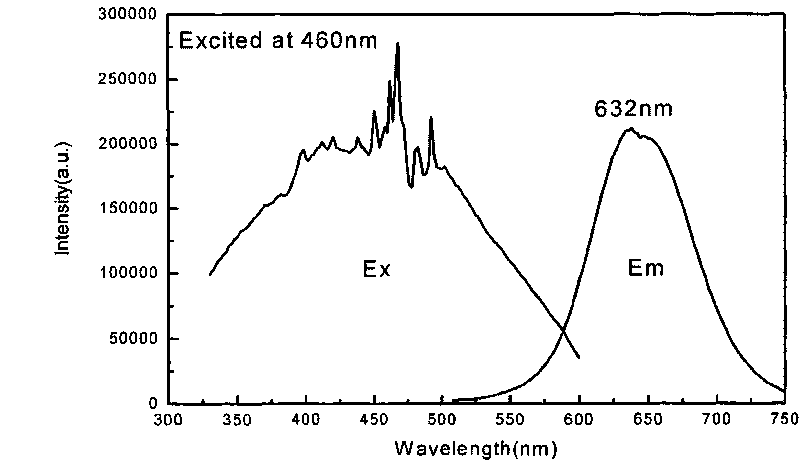

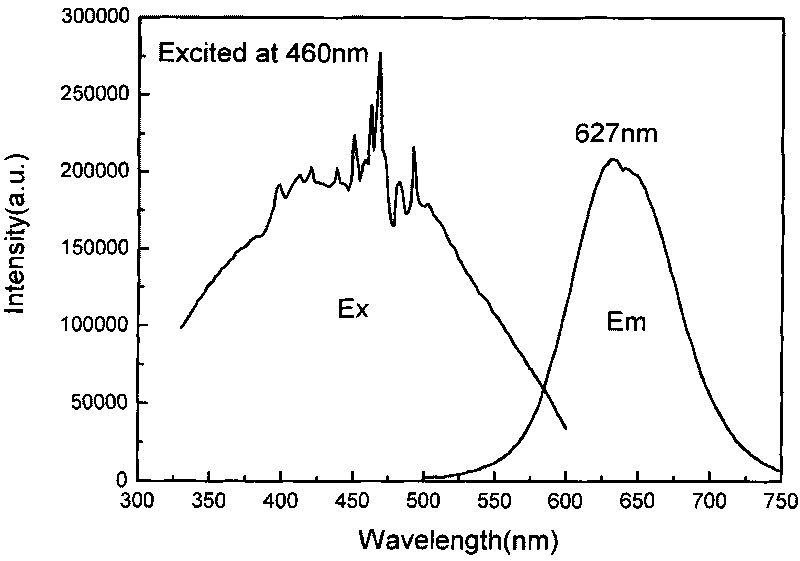

Red luminous silicon-oxygen nitride fluorescent material, preparation method and light emitting device using same

InactiveCN101724401AAdjust emission wavelengthEnhanced emission wavelengthGas discharge lamp usageLuminescent compositionsSr elementSynthesis methods

The invention relates to red luminous silicon-oxygen nitride fluorescent material, preparation method and light emitting device using same. The general formula of the fluorescent material is MIuMIIv(Sil-alphaAalpha)wO deltaN(2 / 3(u+v)+4 / 3w-2 / 3delta): Eux, Ry, Dz, wherein MI is a Ca or Sr element; MII is selected from at least one element of Sr or Ca, Ba and Zn; A is selected from at least one element of Ge, Al, Ca and In; R is selected from at least one element of Nd, Dy, Ho, Tm, Ce, Er, Pr, Bi, Sm, Yb, Lu, Gd, Tb and Mn; D is selected from at least one ion of F-, Cl-, Br- and I-; and u, v, w, alpha, delta, x, y and z are molar coefficients. The fluorescent material capable of being excited by ultraviolet-blue-green light and emitting red light is prepared by adopting a normal pressure self-reduction synthesis method and applied to manufacture LED devices.

Owner:DALIAN LUMINGLIGHT SCIENCE & TECHNOLOGY CO LTD

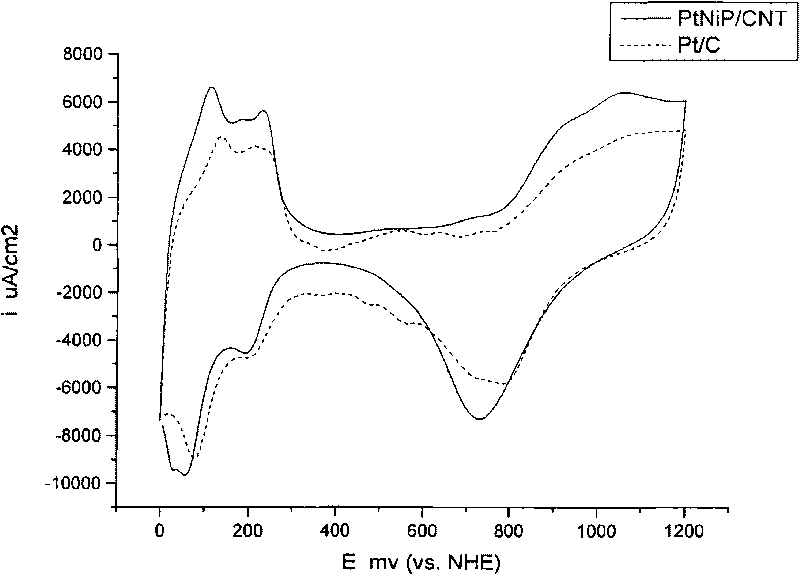

Preparation method of fuel-cell catalyst

InactiveCN101733134AAvoid corrosionReduced oxygen reduction currentCell electrodesMetal/metal-oxides/metal-hydroxide catalystsAlloyDirect development

The invention relates to a preparation method of a fuel-cell catalyst, belonging to the field of catalysts. The preparation method of the fuel-cell catalyst comprises the following steps of: using a CNT as a vector; adding sodium phosphite to a nickel sulfate and chloroplatinic acid solution; controlling the pH value and the temperature of the solution; hydrolyzing the sodium phosphite to release P; forming an alloy solid solution by the P generated through the self reduction of the sodium phosphite and reduced Pt and Ni, wherein the addition of Ni stops the remove of platinum particles of the fuel-cell catalyst, the addition of P inhibits the corrosion of non-noble metal, the formation of the alloy realizes the fining and the decentralization of the Pt particles, and the particle diameters of the fuel-cell catalyst are uniformly distributed. A test result shows that the fuel-cell catalyst has excellent property. The method is convenient and easy to operate, reduces the cost by doping Ni to noble metal, also effectively inhibits the corrosion of the non-noble metal and meets the requirements of the direct development and the utilization of the field of direct methanol fuel cells and the like.

Owner:BEIJING UNIV OF TECH

Method for extracting zinc from blast furnace gas mud

ActiveCN105087947AShort processing cycleHarm reductionProcess efficiency improvementNitrogen gasShaft furnace

The invention discloses a method for extracting zinc from blast furnace gas mud. The method comprises the steps of drying the gas mud to obtain gas ash, placing screened gas ash in a shaft furnace, introducing nitrogen to the shaft furnace for protection, and heating the shaft furnace to a temperature between 1050 DEG C and 1200 DEG C from room temperature; conducting reduction reaction to obtain gas containing zinc; introducing the gas to a sedimentation chamber for dust removal; obtaining polymorphic zinc mixed gas, and introducing the mixed gas to a coiled cooling pipe to be cooled so that a crude zinc product can be obtained. Through self-reduction reaction of fixed carbon contained in the gas mud at the temperature of 1050-1200 DEG C, the number of procedures is reduced, the gas mud processing cycle is shortened, and production cost is reduced; meanwhile, the requirement for the amount of reduction carbon and heating carbon required by reducing zinc in the gas mud can be met, complete reduction of zinc in the gas mud is guaranteed, and then harm to iron making equipment and iron production caused by zinc existing during gas mud recycling is greatly relieved.

Owner:武汉钢铁有限公司

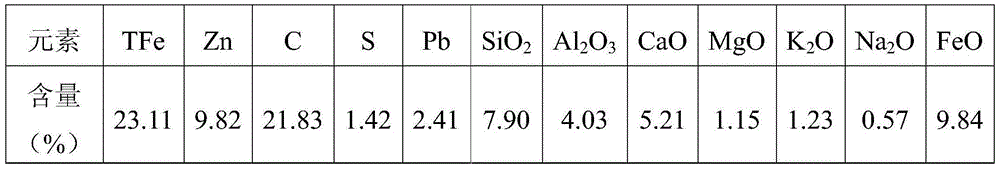

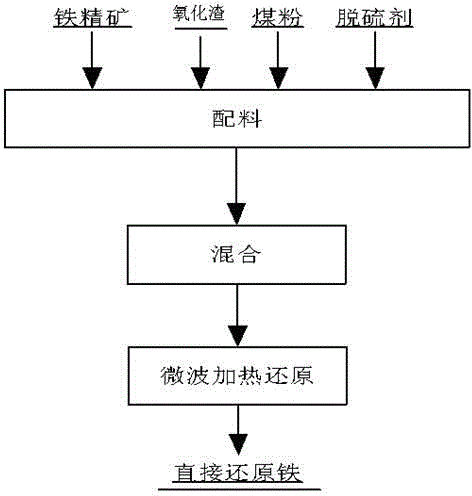

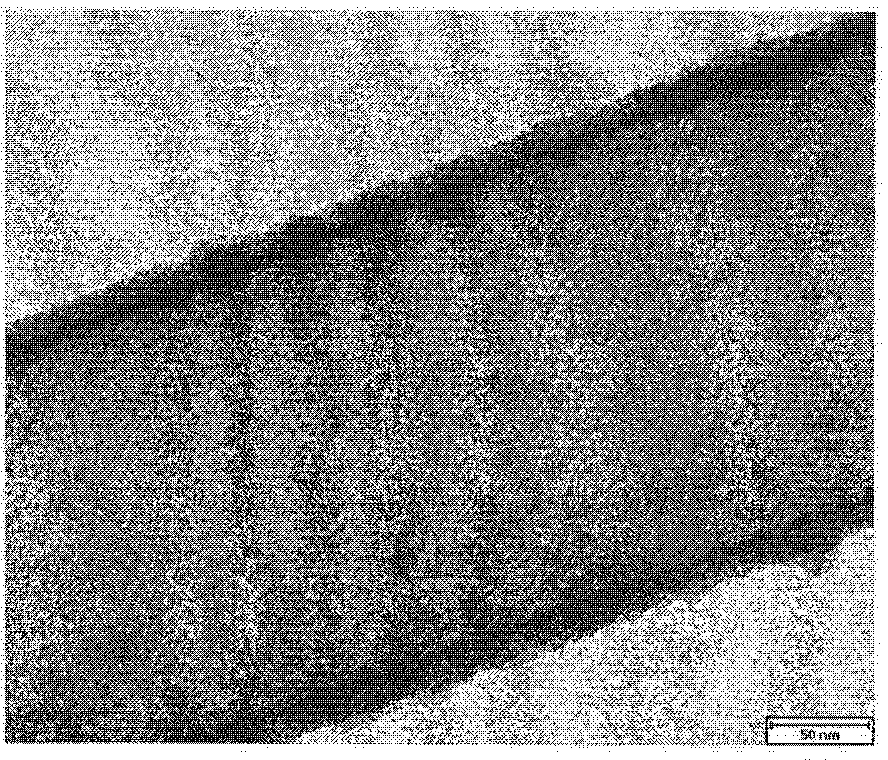

Method for preparing direct-reduction iron by reducing carbon-containing iron ore powder in microwave heating manner

The invention relates to a method for preparing direct-reduction iron by reducing carbon-containing iron ore powder in a microwave heating manner. A microwave heating manner is induced to a coal-based method direct-reduction iron preparation so as to replace the traditional coal heating manner, and high-quality direct-reduction iron is produced by utilizing self-reduction characteristics of iron ore powder, oxidizing slag and the like with coal powder. Through the method for preparing the direct-reduction iron by reducing the carbon-containing iron ore powder, the defects that the reduction time is long, the product quality is unlikely to control, the investment is large, the floor space is large and the like in a process of producing the direct-reduction iron by a coal-based tunnel kiln canning external carbon method can be effectively overcome, the production flow is simplified, the reduction time is largely shortened, the manual cost is reduced, and the certain energy-saving and emission reduction effect can be obtained.

Owner:WUKUN STEEL

Chrome-molybdenum metal self reduction pellet and preparation and direct steel liquid alloying methods thereof

The invention relates to alloy steel smelting, and particularly relates to a chrome-molybdenum metal self reduction pellet and preparation and direct steel liquid alloying methods thereof. The pellet comprises the following components according to mass percentage: 40-65 percent of high-carbon ferrochrome powder, 15-40 percent of molybdic oxide powder, 5-15 percent of a reductant and 3-5 percent of a flux. The self reduction pellet product is added to a ladle during electric furnace or convertor tapping, under the action of high-temperature molten steel and a pellet inner reductant, metal elements in the pellet are effectively reduced, as a result, the molten steel is directly alloyed; the self reduction pellet product is applied in alloy steel including stainless steel, wear resistant steel and the like, which contain elements Cr and Mo, and not only is the procedure for the production of ferro molybdenum saved, but also the elements Cr and Mo can be added at one time, so that the cost of adding alloy elements is lowered, the smelting cycle is shortened, meanwhile, the use range of high-carbon ferrochrome is widened, and furthermore, the problem that the element Mo is difficult to add and settle and great in volatilization during the steel smelting is solved.

Owner:JIANGSU UNIV

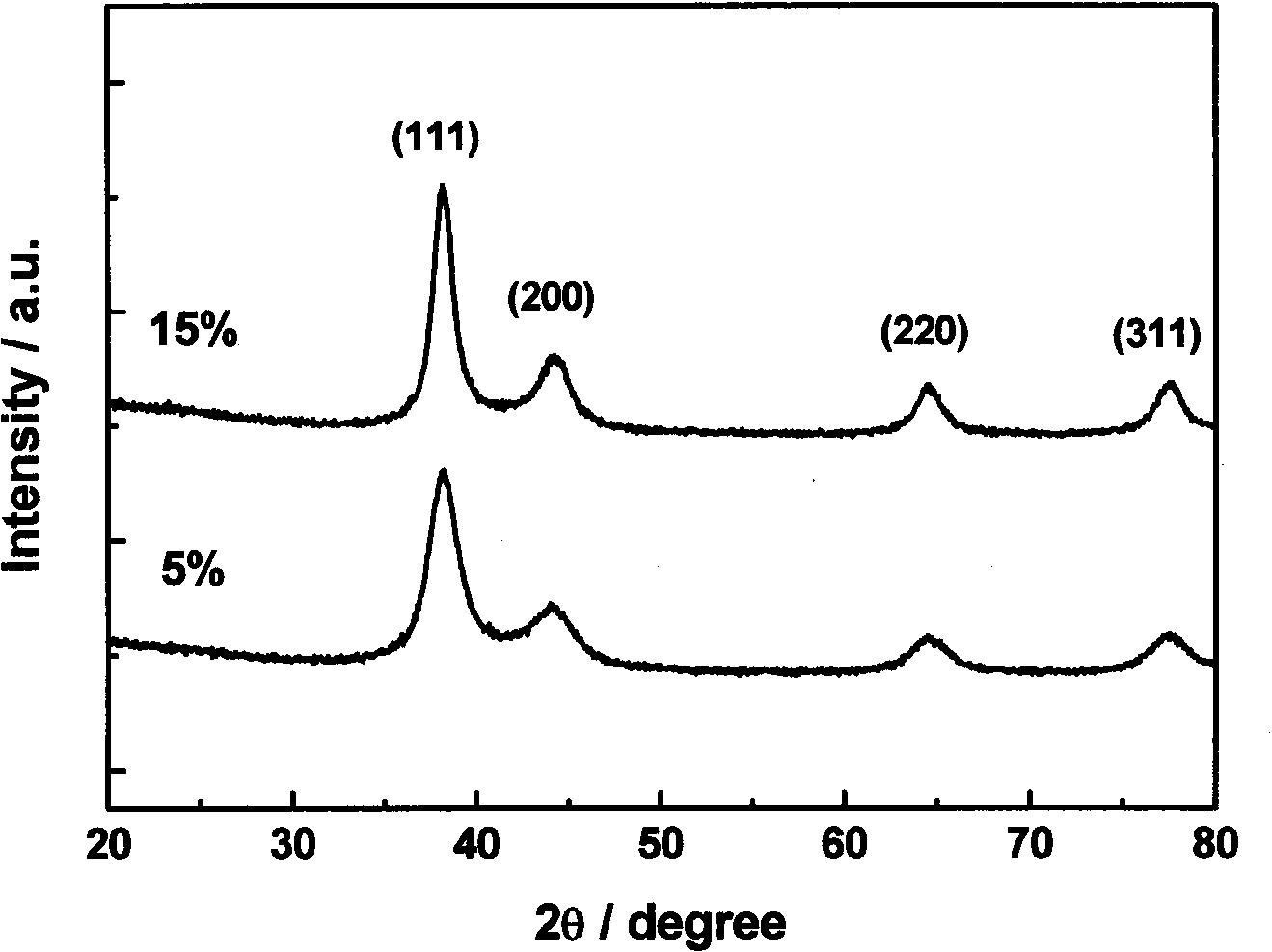

Method for preparing high-loading catalyst Pt/CNTs

InactiveCN101716529AOrderly rowsIncrease loadOrganic-compounds/hydrides/coordination-complexes catalystsCell electrodesCarbonizationOxygen

The invention belongs to the field of fuel cells, and relates to a method for preparing a high-loading catalyst Pt / CNTs, which comprises the following steps of: preparing 50g / l solution of glucose; transferring the prepared solution of glucose into a reaction kettle, adding an AAO template into the reaction kettle, reacting for 8h at the temperature of 160 DEG C, taking the template out, repeatedly washing the template to be clean with distilled water, then performing carbonization treatment on the template for 3 hours in nitrogen atmosphere at the temperature of 700 DEG C, and dissolving the template in solution of NaOH to obtain CNTs with two open ends and regular arrangement; and mixing the prepared CNTs and 10g / l H2PtCl6 in the mass ratio of 26 to 1, uniformly stirring the mixture, standing the mixture for 2 to 32 days, and then performing heating reflux for 4h to obtain the high-loading catalyst Pt / CNTs. The method realizes the self-reduction, reduces Pt metal salt to Pt nano-particles, and prepares the high-loading catalyst Pt / CNTs by adjusting standing time; and the catalyst has good electro-catalytic performance on the reduction of oxygen.

Owner:BEIJING UNIV OF TECH

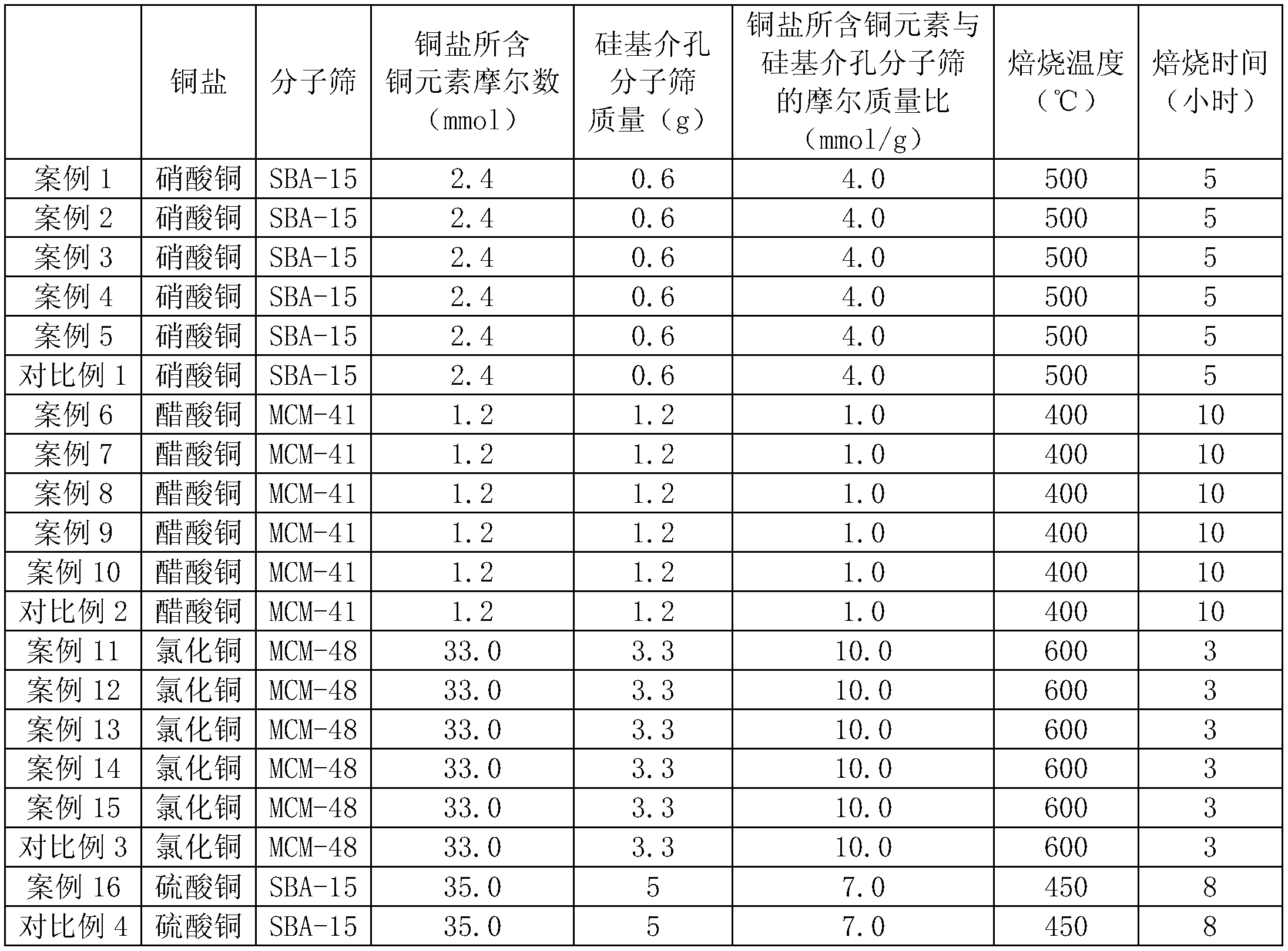

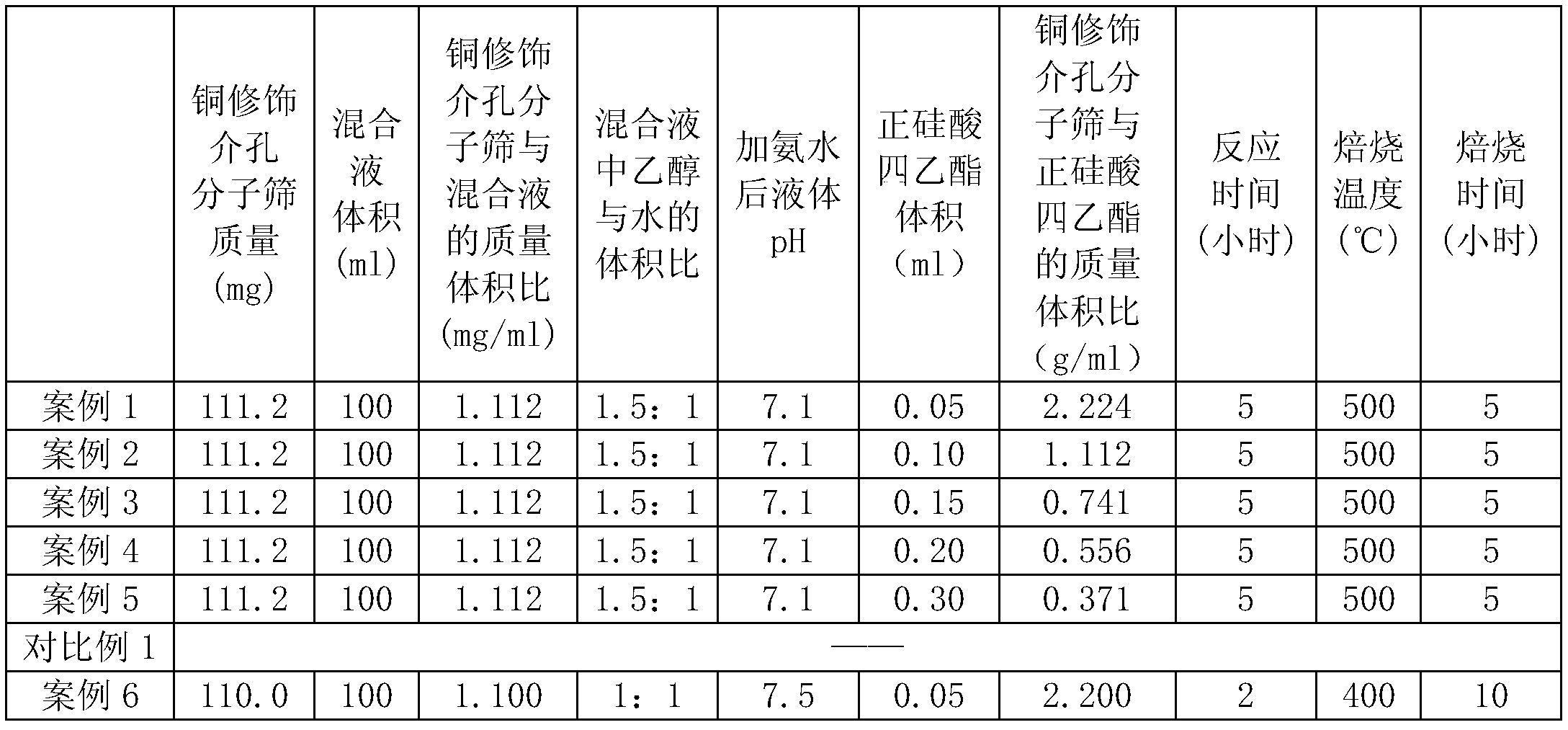

Cooper-containing mesoporous adsorbent preparation method, and prepared adsorbent and applications thereof

ActiveCN103230774AAvoid gatheringImprove adsorption capacityOther chemical processesDispersed particle separationSorbentProtection layer

The present invention relates to a copper-containing mesoporous adsorbent preparation method, and the prepared adsorbent and applications thereof. The method comprises: 1, taking a copper salt, grinding, adding a silicon base mesoporous molecular sieve, and completely grinding to obtain a mixture; carrying out calcination on the mixture to prepare a copper-modified mesoporous molecular sieve; 2, dispersing the copper-modified mesoporous molecular sieve in a mixing solution of ethanol and water, then adding ammonia water to adjust the pH value of the solution, adding tetraethyl orthosilicate to carry out a reaction, filtering the obtained reaction liquid to obtain a solid, and carrying out drying and calcination on the solid to obtain an intermediate product; and 3, carrying out calcination on the intermediate product in an inert atmosphere to obtain the adsorbent finished product. The adsorbent prepared by the method can be used for adsorbing ethylene or carbon monoxide. According to the present invention, the tetraethyl orthosilicate is adopted to plate a protection layer on the copper-modified mesoporous molecular sieve, such that cuprous oxide aggregation generated on the carrier during high temperature self-reduction can be avoided so as to improve an absorption performance of the adsorbent.

Owner:NANJING UNIV OF TECH

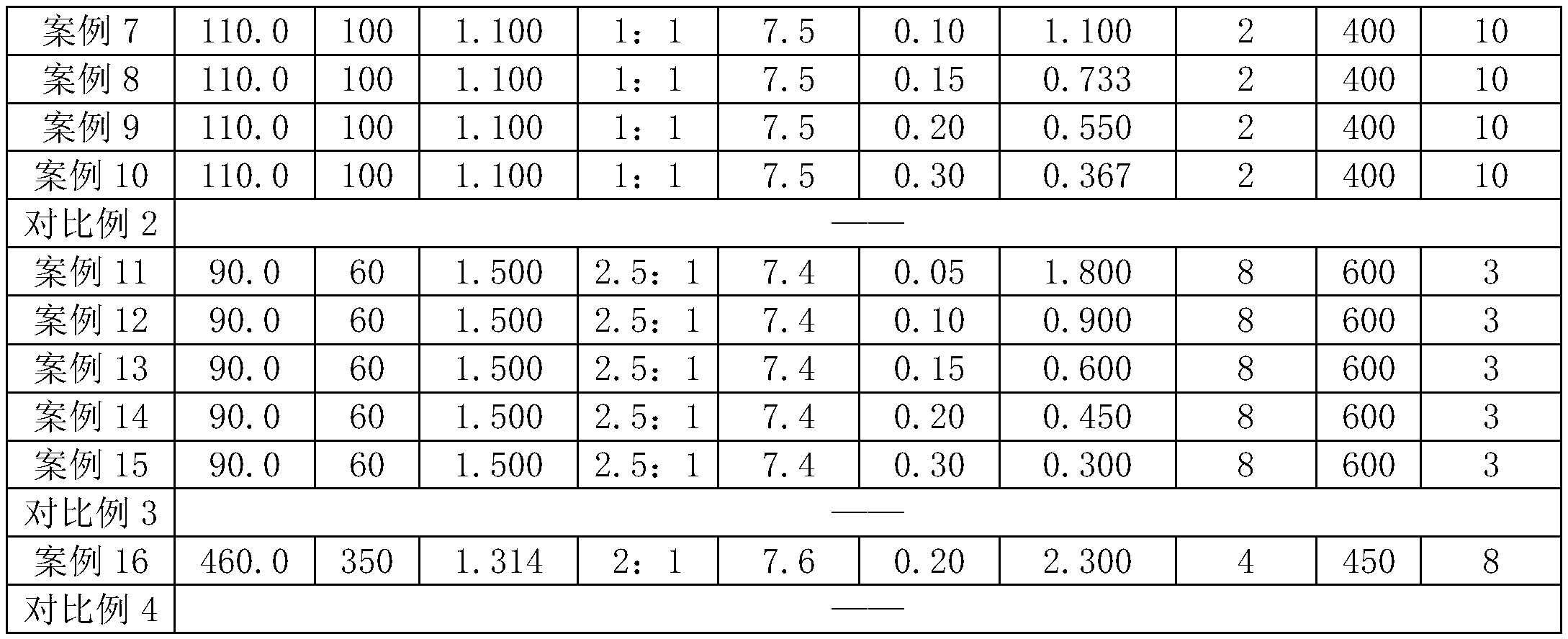

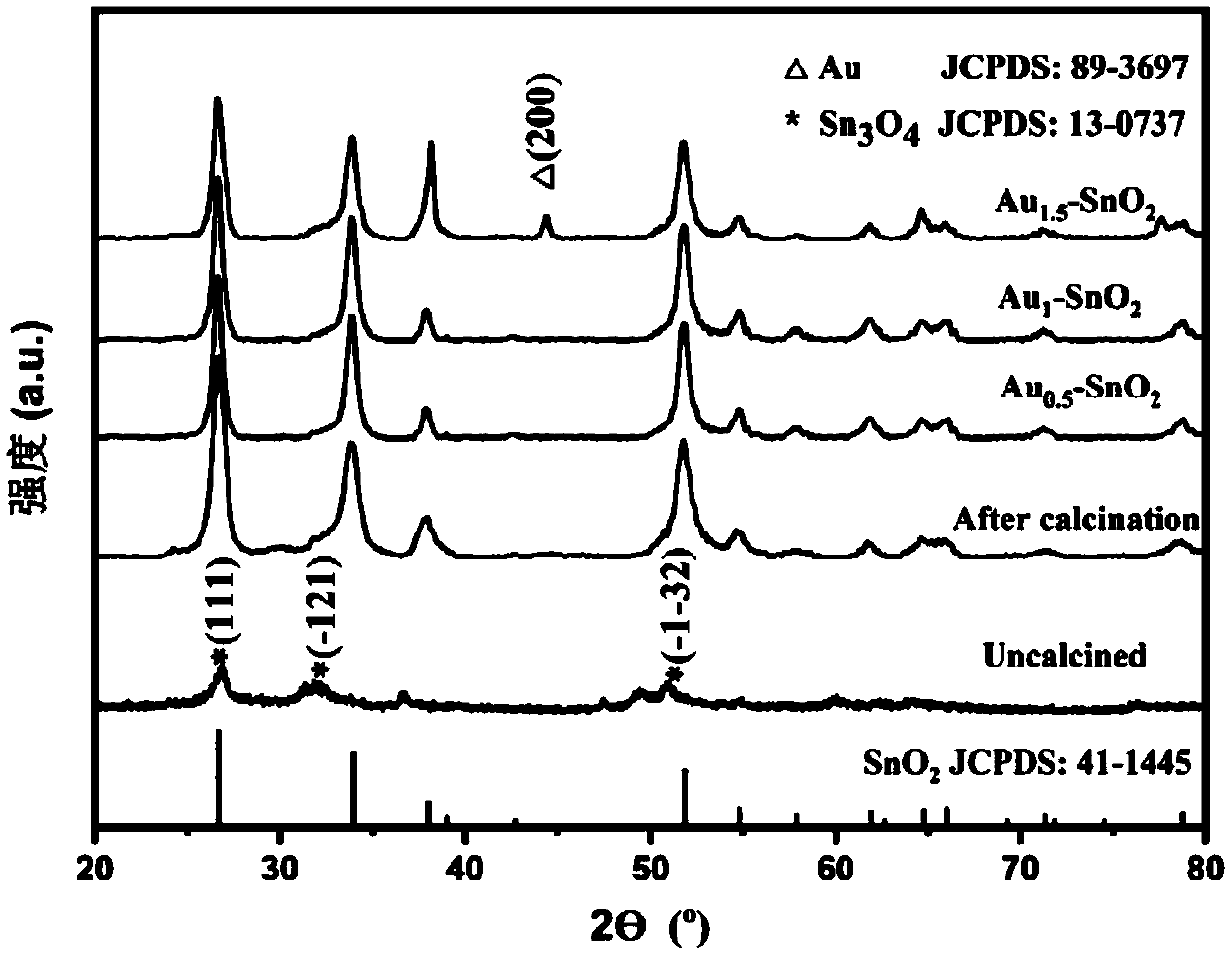

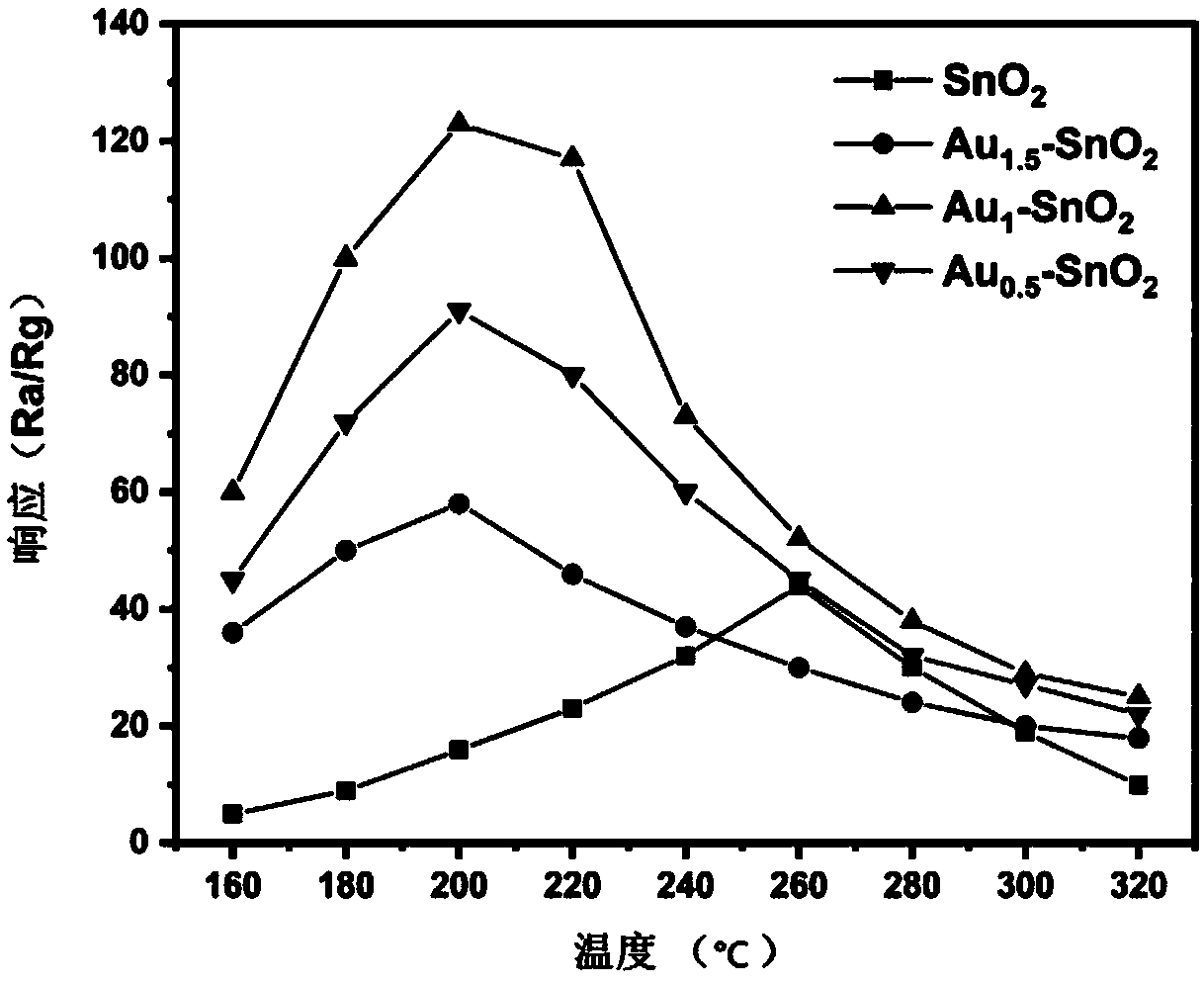

Self-reduction preparation method of gold nanoparticle loaded tin dioxide nanoflower gas-sensing material

ActiveCN109682865AHigh catalytic activityImprove adsorption capacityOther chemical processesNanotechnologyTin dioxideGold particles

The invention discloses a self-reduction preparation method of gold nanoparticle loaded tin dioxide nanoflower gas-sensing material. The method comprises the steps that a citrate sodium aqueous alkaline solution is mixed with a stannous chloride ethanol solution and placed in a reaction kettle to be heated to reach 180 DEG C, reaction is conducted for 12 hours, and floral stannic oxide powder is obtained after a product is washed and dried. The powder is dispersed in deionized water, a chloroauric acid solution is added, the reduction of the stannous oxide is used for reducing the chloroauricacid solution into gold nanoparticles, and the product is washed and dried after being stirred. Finally the gold nanoparticle loaded tin dioxide nanoflower gas-sensing material is obtained after calcination processing is conducted. The method has the advantages that the method is simple, the reaction conditions are mild, the method can be industrialized, prepared tin dioxide nanoflowers have the advantages of uniform size and large specific surface area, the experimental steps are simplified and the cost is reduced compared with a traditional method, the loaded gold nanoparticles have the advantages that the size is uniform, the distribution is uniform and nanoparticles do not aggregate, and more excellent gas-sensing performance on ethanol is shown by the gold particle loaded tin oxide nanoflowers.

Owner:BEIJING UNIV OF TECH

Method for preparing Pt catalyst with carbon carrier as carrier

InactiveCN101596453ASmall sizeEvenly dispersedCell electrodesCatalyst activation/preparationMass ratioOxygen

The invention belongs to the technical field of fuel cell. The invention relates to a method for preparing a Pt catalyst with a carbon carrier as a carrier, comprising the following steps: preparing glucose solution with concentration being 50g / l, adding XC-72 with the concentration being 0.433-1.677g / l to the glucose solution so that the mass ratio of the two can be 30-100, switching the mixture into a reaction kettle to react for 12h at the temperature of 160 DEG C, and rinsing the product repeatedly and cleanly with distilled water to obtain the composite carrier C / XC-72; mixing the prepared composite carrier C / XC-72 and H2PtCl6 with the concentration being 10g / l according to mass ratio of 0.5-2, adding polyvinylpyrrolidone as protective agent with the mass ratio of polyvinylpyrrolidone to C / XC-72 being 1:4, stirring uniformly followed by heating and refluxing for 4h to obtain catalyst Pt / C / XC-72. The invention can realize self reduction by the characteristic of carrier C / XC-72, reduce Pt metal salt into Pt nano particles and have good electro-catalysis performance for oxygen reduction.

Owner:BEIJING UNIV OF TECH

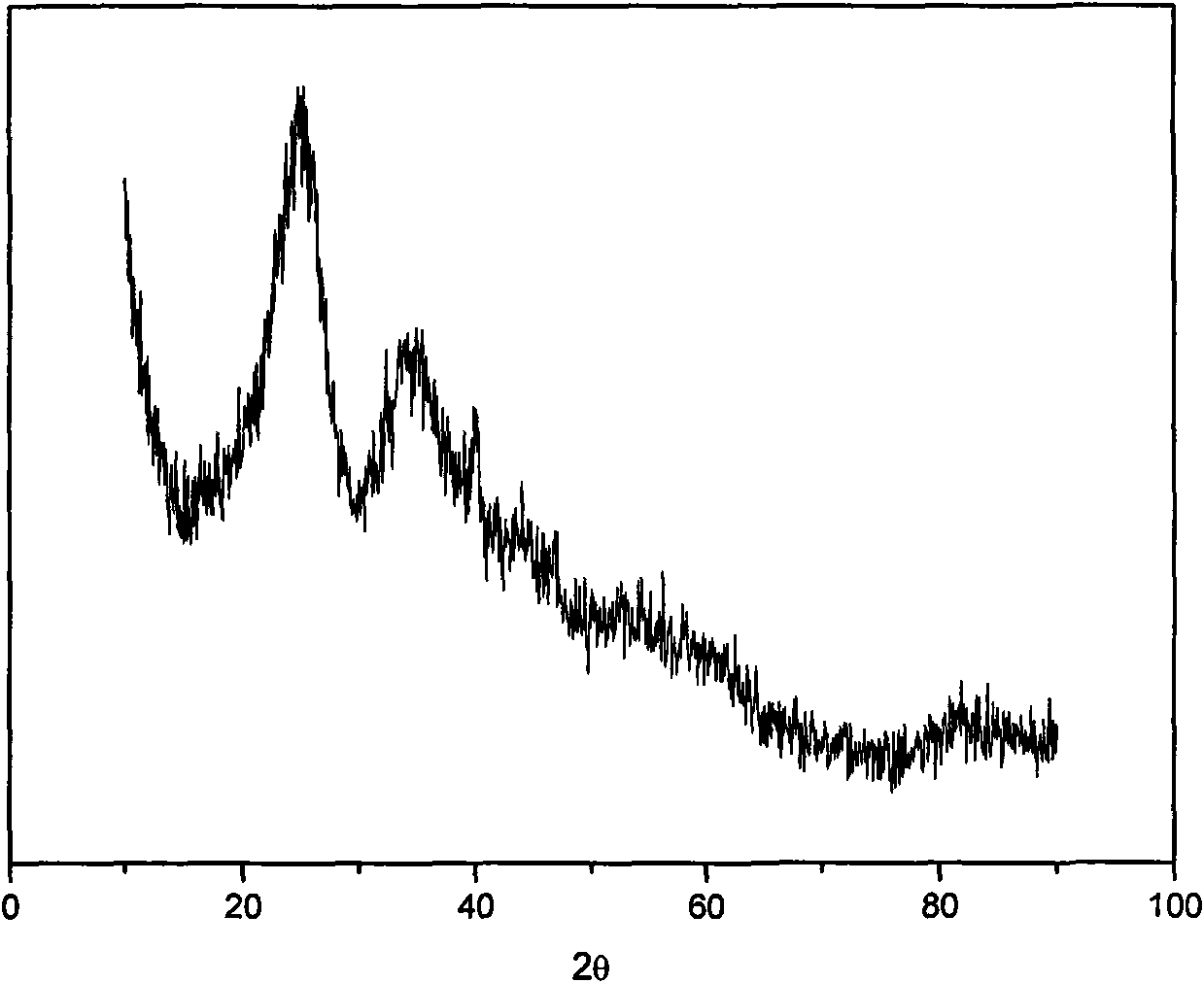

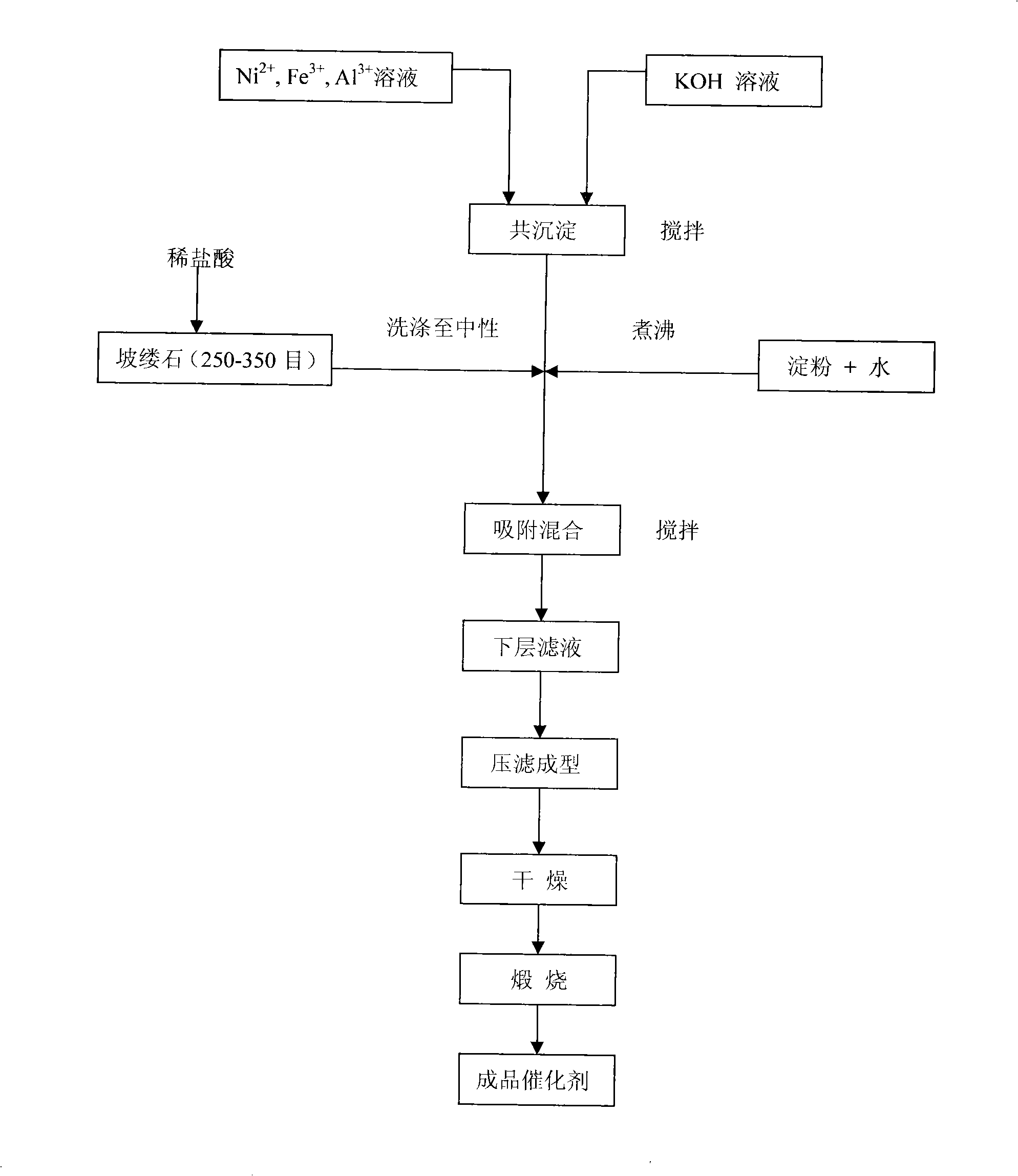

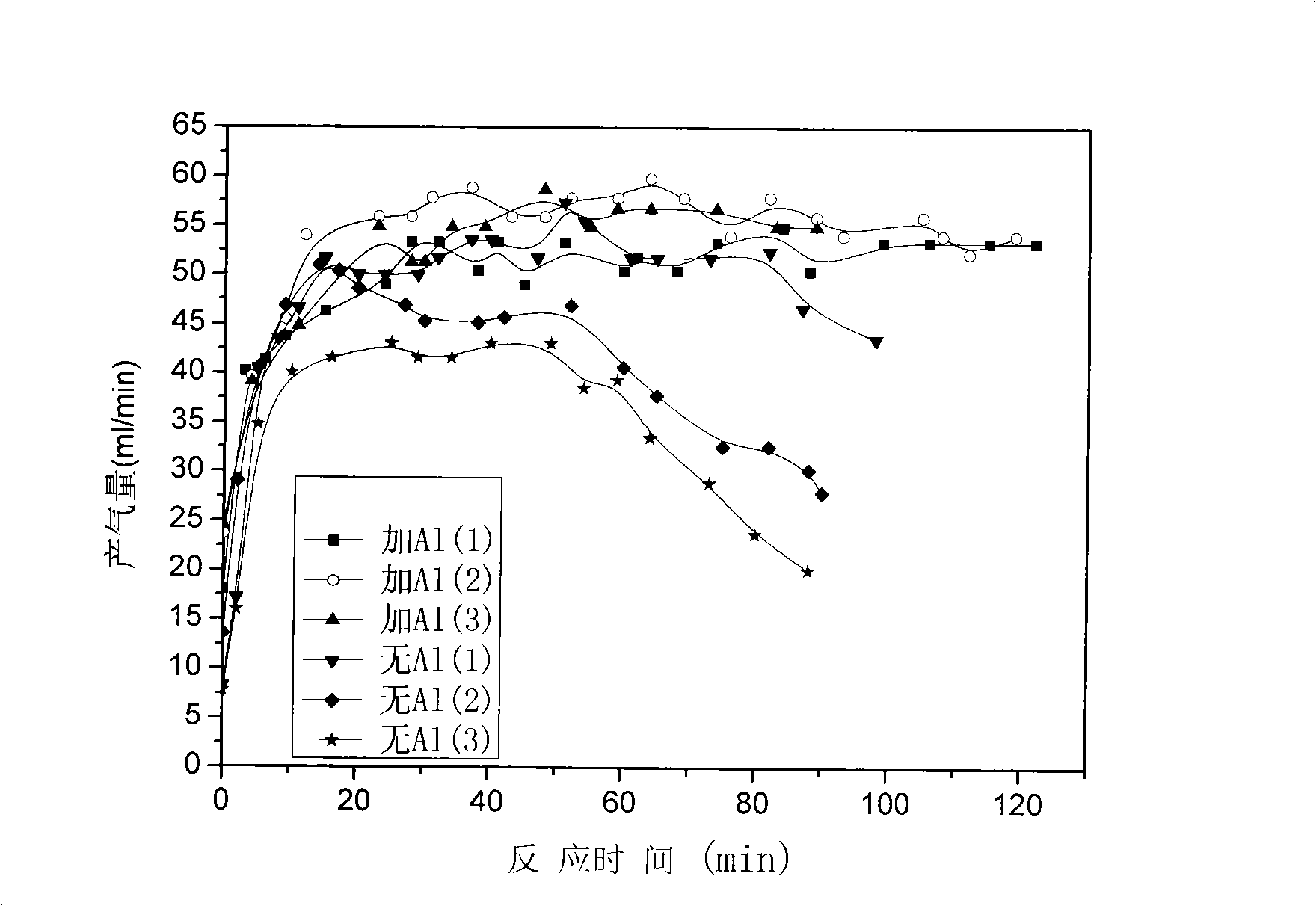

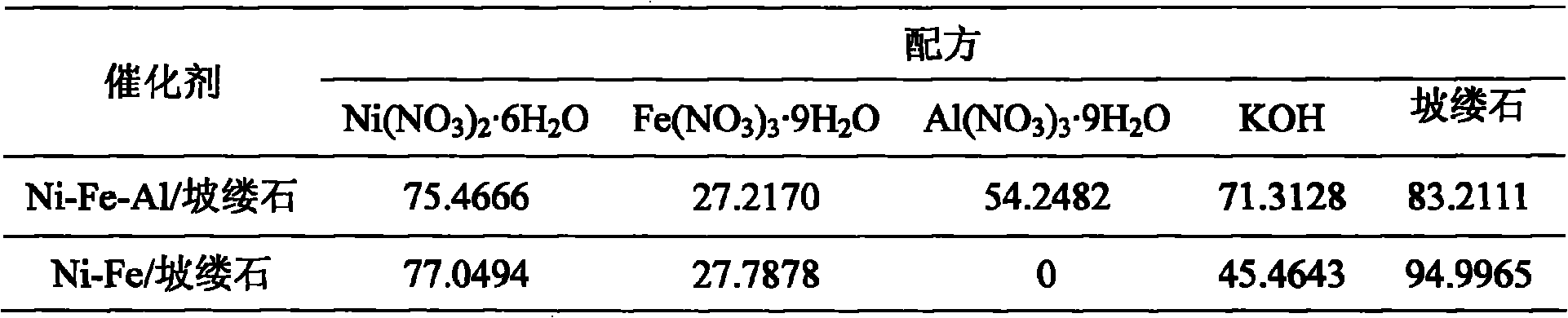

Biomass gasification tar vapor translation hydrogen making catalyst and preparation method thereof

InactiveCN101332428AImprove stabilityHydrogenMetal/metal-oxides/metal-hydroxide catalystsSteam reformingChemical industry

The invention belongs to the filed of energy sources and chemical industry and in particular relates to a catalyst used for hydrogen production from biomass gasified tar steam reforming and a preparation method thereof. The catalyst takes palygorskite as a carrier and nickel as a main active component for the steam reforming, and contains the promoter components such as iron, potassium, aluminum and the like, and the mass percentage of each component is as follows: the content of NiO is 3 - 30%, that of Fe2O3 is 3 - 20%, that of Al2O3 is 3 -2 5%, and that of K2O is 1 - 10%; the mass percentage of the palygorskite is 60 - 95%. The catalyst is prepared by a co-precipitation absorption method, in which the active components of nickel, iron, aluminum and potassium are loaded on the surface of the palygorskite in the manner of co-precipitation and absorption, and then are filtered, shaped, dried and calcined to obtain a finished catalyst. The catalyst has good activity stability and self-reduction property at the high temperature of 800 DEG C, is applicable to the steam reforming process of tar with biomass or coal gasified gas as a catalyst, and can also be used for hydrogen production reaction via hydrocarbon steam reforming.

Owner:DALIAN UNIV OF TECH

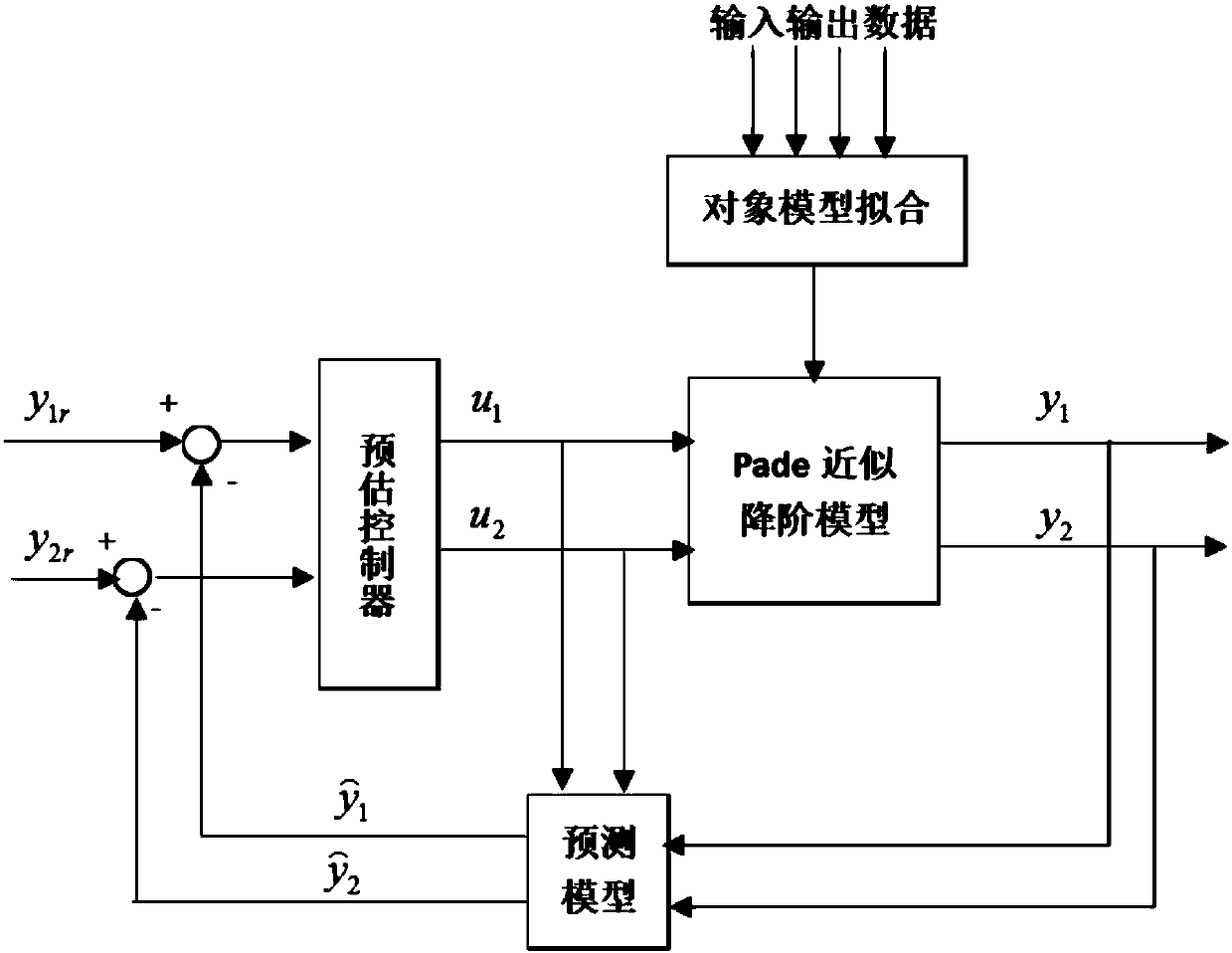

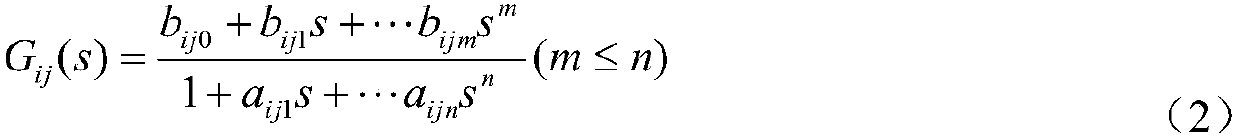

Self-reduction multi-loop centralized predictive control system for reheat steam temperature of secondary reheat unit

The invention discloses a self-reduction multi-loop centralized predictive control system for reheat steam temperature of a secondary reheat unit. The system is composed of a flue gas recirculation fan rotation speed control loop and a flue gas damper opening degree control loop. The deviation of the primary reheat steam temperature and the secondary reheat steam temperature from a set value is sent to a predictive controller. The optimized values of the flue gas recirculation fan rotation speed and the flue gas damper opening degree are calculated to ensure that the primary reheat steam temperature and the secondary reheat steam temperature of the unit are maintained within a reasonable and safe range. According to the invention, predictive control is used to easily handle the optimization of a large inertia multivariable system; the calculation process is clear and simple; during engineering application, programming is easy to implement; the corresponding control amount can be adjusted in time for the prediction of future output deviation; the primary reheat steam temperature and the secondary reheat steam temperature are stable within a reasonable range, which ensures the stability and safety of the unit; and the control system has a better control effect than traditional PID control.

Owner:SOUTHEAST UNIV

Carbon containing pellet for producing low-sulfur grained iron

The invention provides a carbon containing pellet for producing low-sulfur grained iron, the carbon containing pellet comprises the following components: 50%-70% of an iron containing raw material, 15%-35% of a carbon containing raw material, 2%-5% of an additive and 0%-5% of a binder, wherein the molar ratio of fixed carbon in the total pellet raw materials to iron oxide oxygen atoms in the iron containing raw material is controlled to satisfy (C / O) = 1.1-1.2, the carbon containing pellet also comprises 5%-15% of one of CaO containing substances and 0%-3% of one of MgO containing substances, and ([CaO]+ [MgO]) / ([SiO2] + [Al2O3]) = 0.95-1.20 and [MgO] / [Al2O3] = 0.85-1.15 are satisfied. The self-reduction carbon containing pellet of the invention is used for horizontal-moving-bed reducing process, is low in baking temperature, can effectively reduce the energy consumption and equipment maintenance costs, and can obtain the low-sulfur grained iron with the sulfur content of less than 0.04% so as to further improve the quality of a product.

Owner:ANGANG STEEL CO LTD

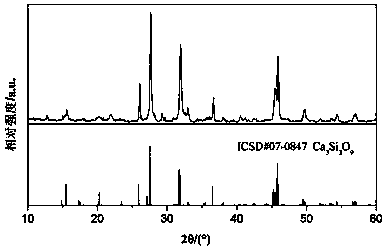

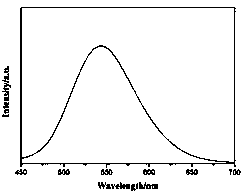

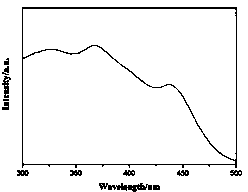

Nitrogenous silicate yellow green luminescent material for white light LED (light-emitting diode) and preparation thereof

InactiveCN103450893AHigh luminous intensityEasy to prepareLuminescent compositionsGreen-lightTwo step

The invention relates to a novel divalent europium doped nitrogenous silicate solid solution base luminescent material and a self reduction preparation method. The chemical composition of the luminescent material is shown as follows: Ca3Si3 (O9-xNx):Eu<2+>. The preparation method comprises two steps of (1) preparing a Ca2SiO4:Eu<3+> product through a sol-gel method; (2) roasting the Ca2SiO4:Eu<3+> product and a silicon nitride mixture in a non reducing atmosphere, thus obtaining the final product by the self reducing action of the Si3N4, wherein the used materials comprise calcium nitrate (CaN2O6.4H2O), europium nitrate (EuN3O9.6H2O), ethyl orthosilicate (C8H20O4Si), and Si3N4. The luminescent material has broad band (300-450nm) to absorb near ultraviolet and blue light and gives out yellow green light (534-544nm). The obtained product has high light intensity and has stable properties. The preparation process can be finished only in protection atmosphere of nitrogen and needs no other reduction atmosphere and other reduction methods, so that the preparation method is simple and safe.

Owner:SICHUAN UNIV

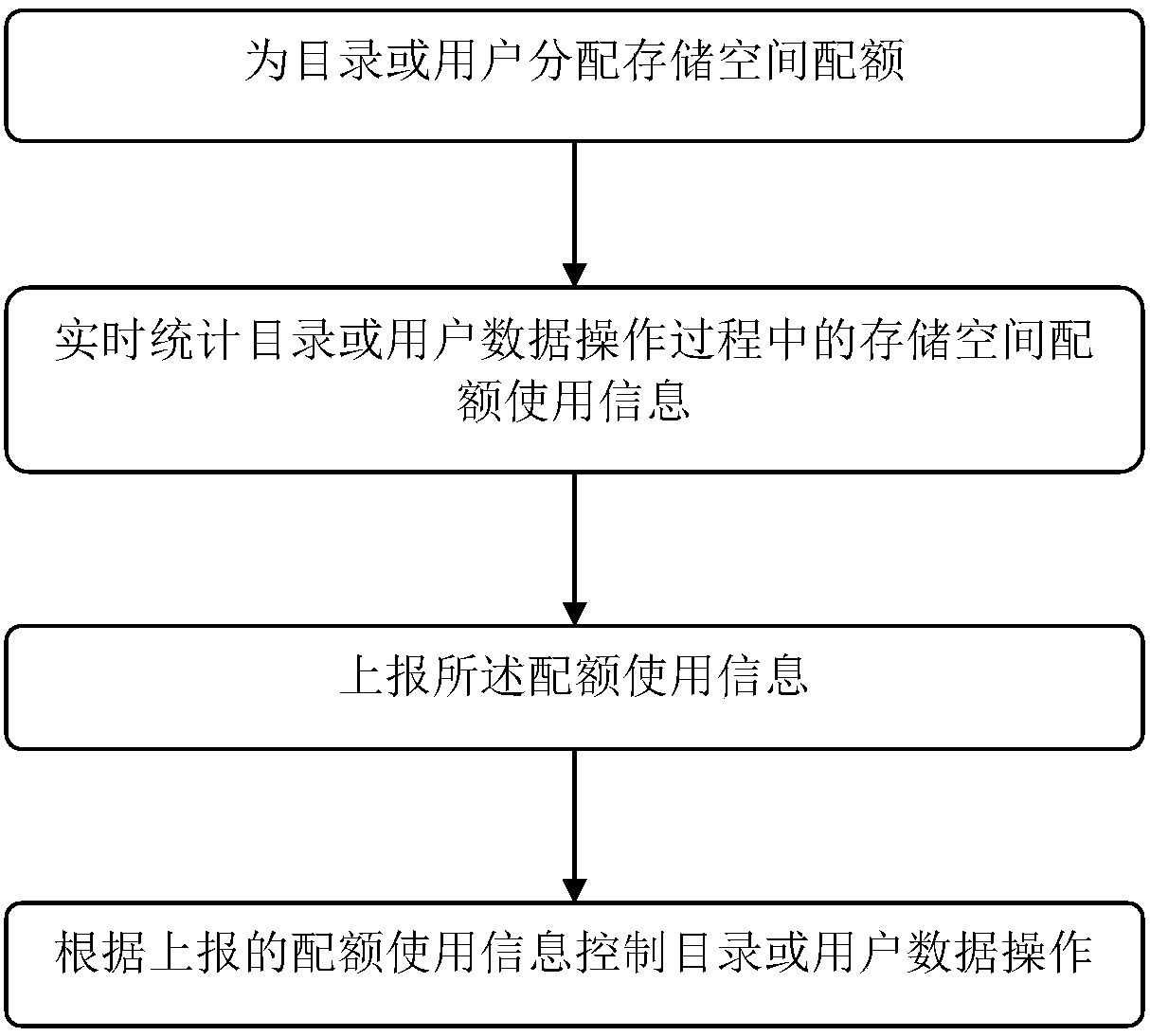

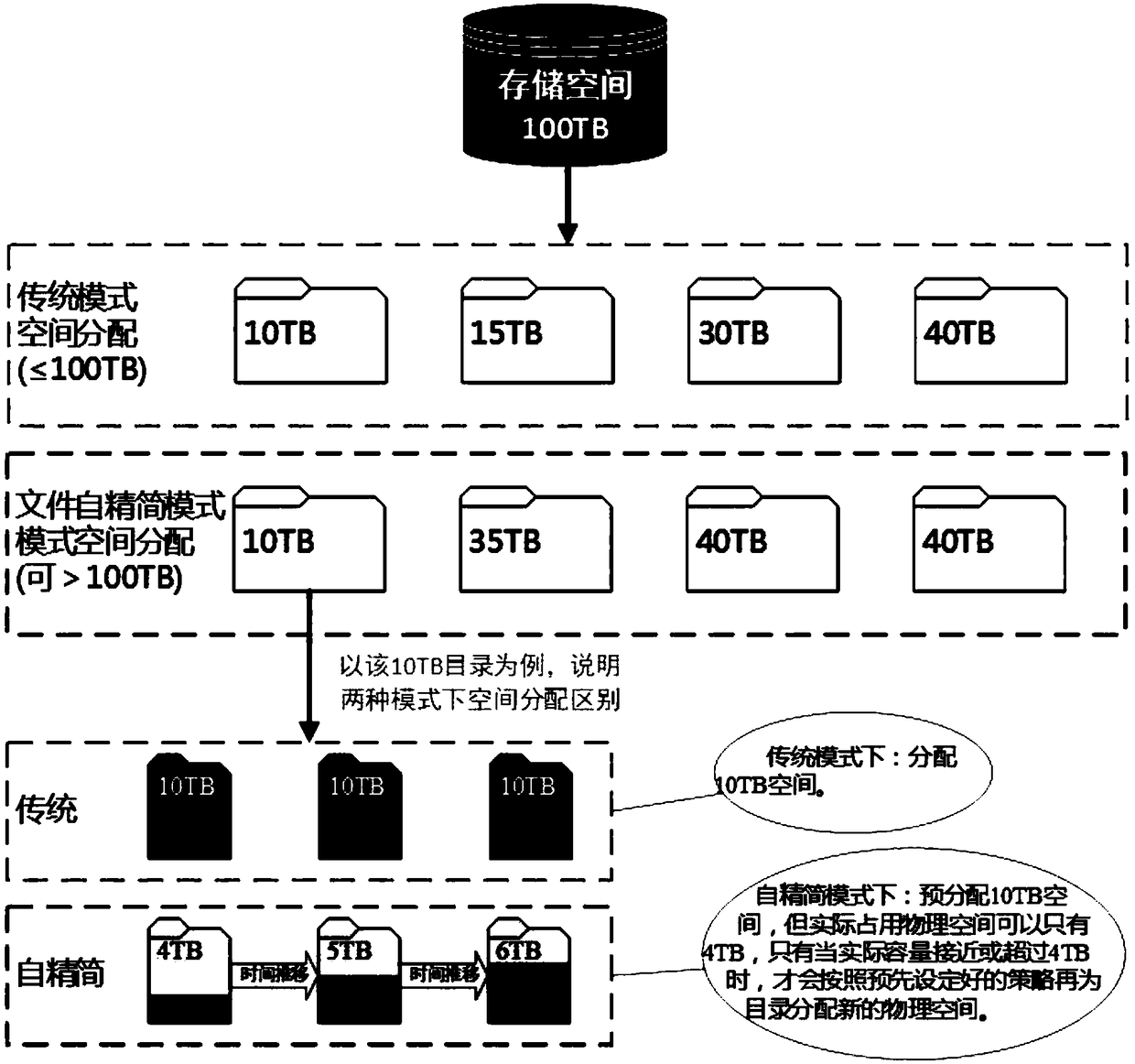

File self-reduction method and device for distributed cluster storage

The invention provides a file self-reduction method and device for distributed cluster storage. The method includes allocating storage space quotas for a directory or a user; counting storage space quota usage information during directory or user data operations in real time; reporting the quota usage information; and controlling directory or user data operations based on the reported quota usageinformation. By the method, a certain amount of space can be automatically pre-allocated for a target user, and when the pre-allocated space is reached, any operation that causes the directory to become large is prohibited.

Owner:ZHENGZHOU YUNHAI INFORMATION TECH CO LTD

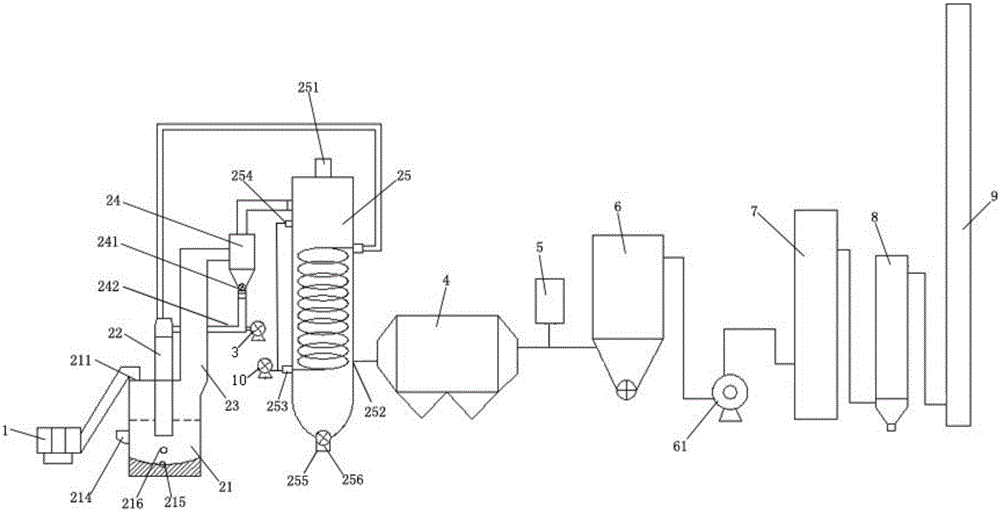

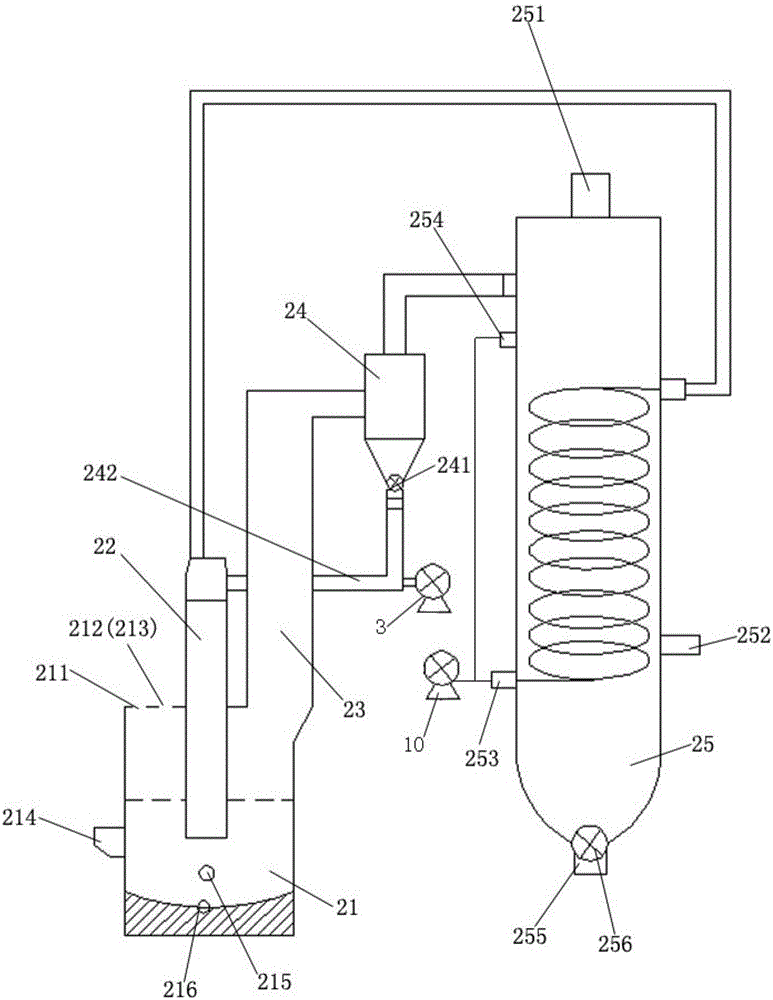

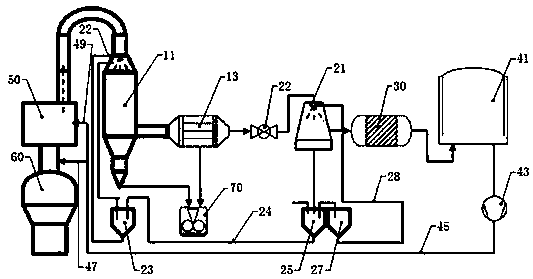

Recycling treatment device and method of waste circuit boards

ActiveCN106591585AHigh recovery rateEliminates the possibility of synthesisProcess efficiency improvementPrinted circuit boardCarbon particle

The invention provides a recycling treatment device and method of waste circuit boards. The recycling treatment device of waste circuit boards mainly comprises a crushing machine, a self-reduction smelting furnace, a Roots blower and an exhaust gas treatment device. The self-reduction smelting furnace is mainly composed of a smelting furnace body, a smelting spray gun, a vertically lifting flue, a cyclone separator and a combustion heat exchange tower, wherein the top of the smelting furnace body is provided with a charging port, a heat preservation gun port and a sampling port; the vertically lifting flue is connected with an inlet of the cyclone separator; an outlet of the cyclone separator is connected with the combustion heat exchange tower; an air heat exchanger is arranged inside the combustion heat exchange tower; and a hot air outlet is formed in the upper portion of the combustion heat exchange tower and connected with a smelting spray gun entering the smelting furnace through a pipeline. Through equipment transformation, process optimization and combination of recycled carbon particles as a reduction agent and recycled high-temperature process gas as heat, the recycling rate of valuable metal is effectively increased, the smoke volume of a system is reduced, energy is saved, and pollution is reduced.

Owner:中节能工程技术研究院有限公司

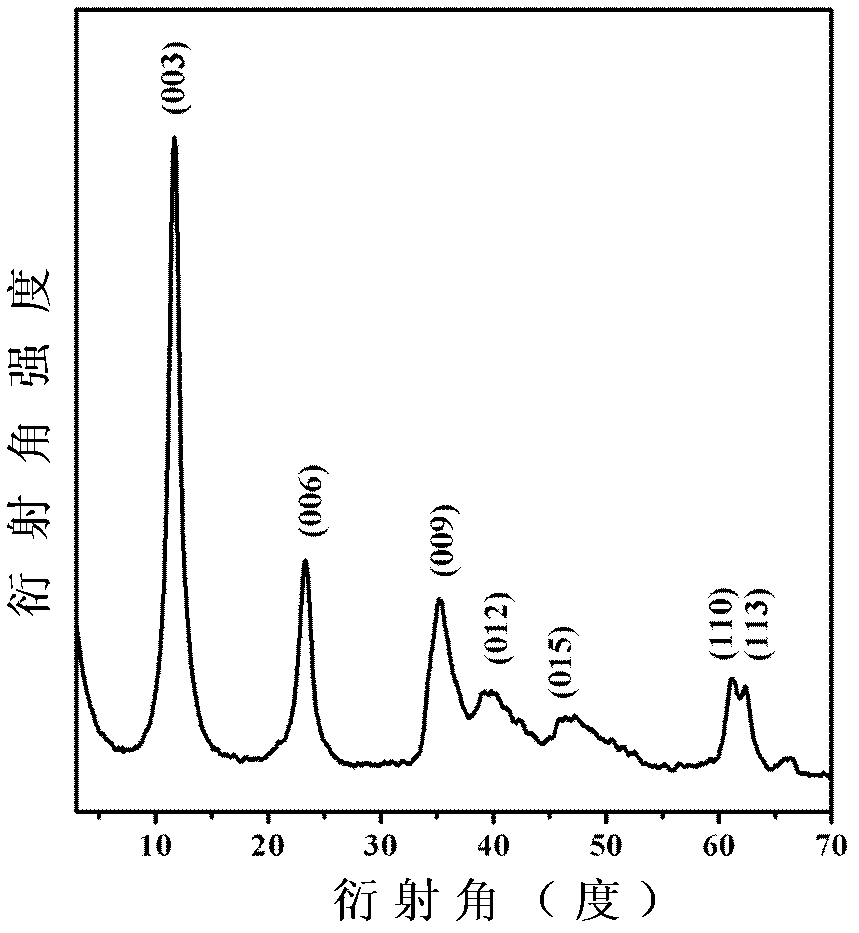

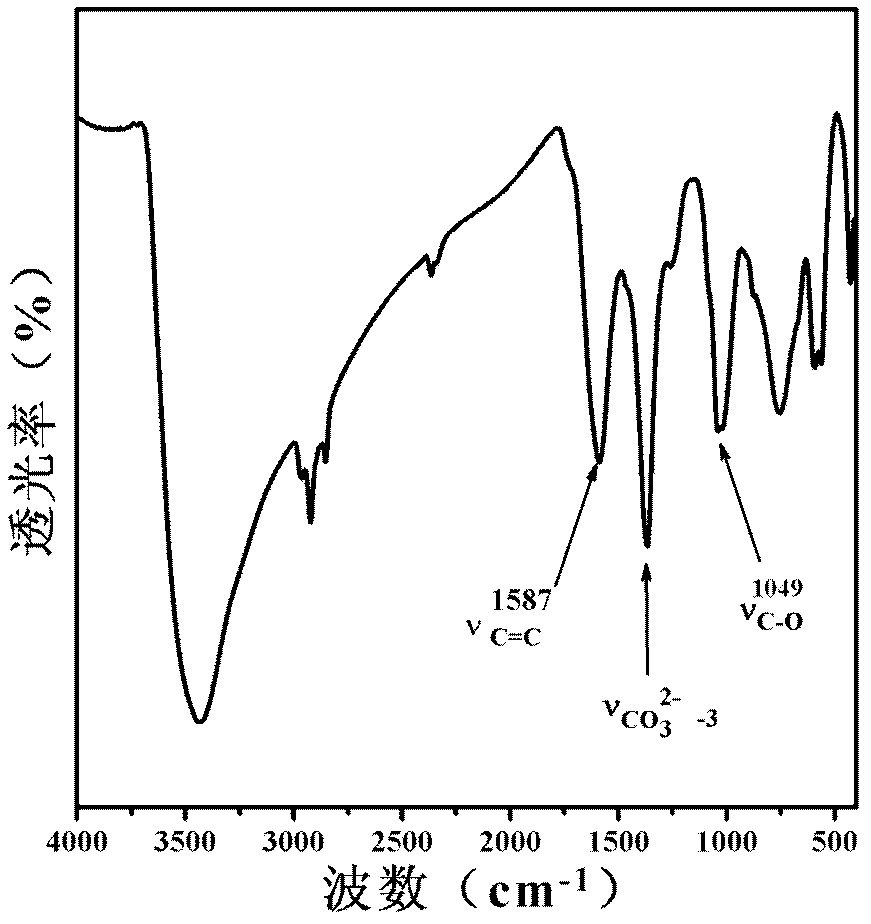

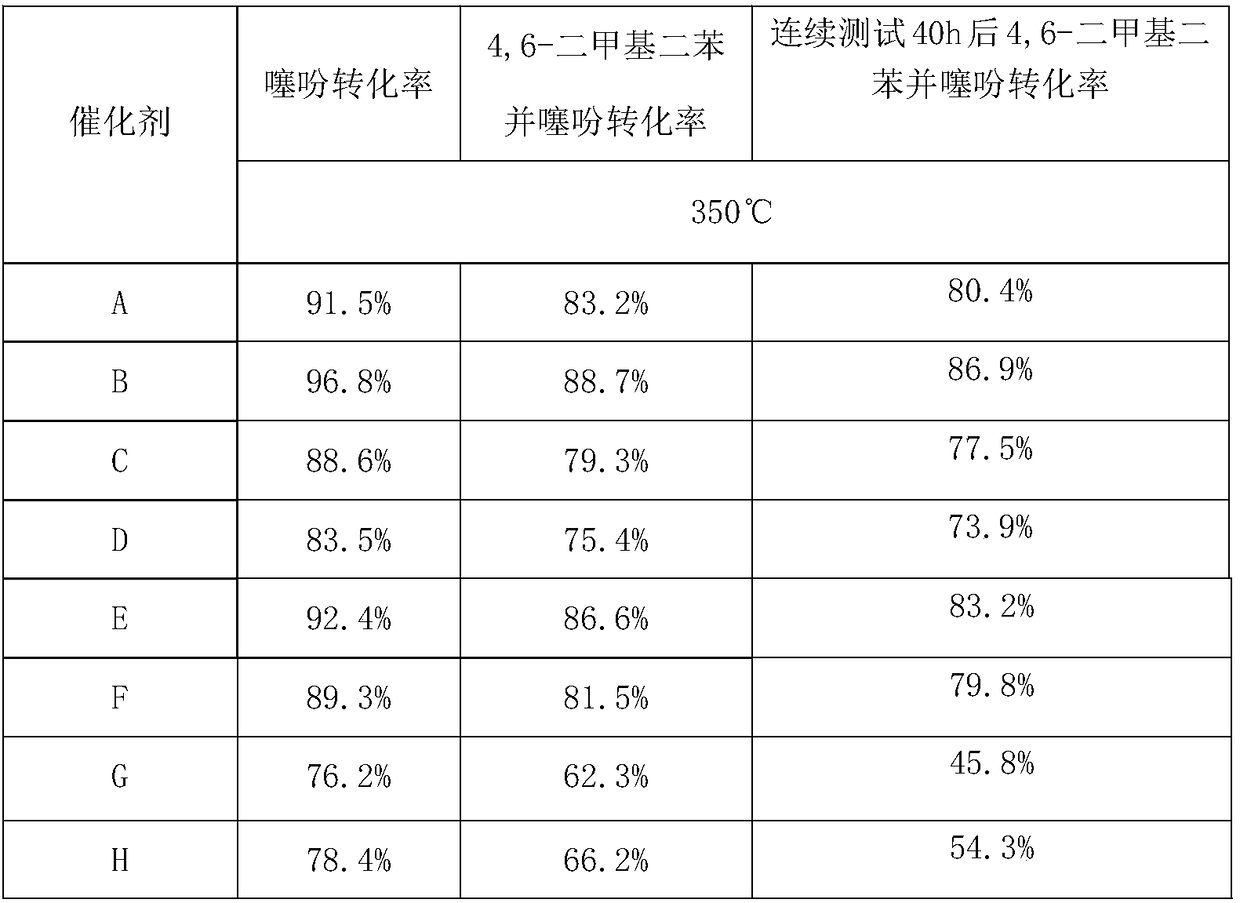

Precious metal hydrodesulfurization catalyst as well as preparation method and application thereof

InactiveCN108067252AGood dispersionImprove anti-sintering performanceCatalyst activation/preparationHydrocarbon oils refiningHydrodesulfurizationActive component

The invention belongs to the technical field of hydrodesulfurization catalysts and particularly relates to a precious metal hydrodesulfurization catalyst as well as a preparation method and application thereof. The catalyst comprises a carrier and precious metal active components; a precursor of the carrier is cobalt-containing hydrotalcite; the precious metal active components are distributed onthe surface of the cobalt-containing hydrotalcite. In the preparation process of the catalyst, precious metal simple substances are reduced and immobilized by adopting a self-reduction mode during theloading process of the precious metal active components, i.e., the aim of reducing precious metal is achieved by using the reducibility of Co<2+> in like hydrotalcite and the oxidbillity of preciousmetal salt (PtCl4<2-> and PdCl4<2->). Compared with a traditional impregnation method, the preparation method has a better dispersion effect; in addition, the precious metal hydrodesulfurization catalyst is better immobilized on the surface of the carrier; oxidative active sites are uniformly distributed on the surface of the catalyst by high-temperature roasting.

Owner:FUZHOU UNIV

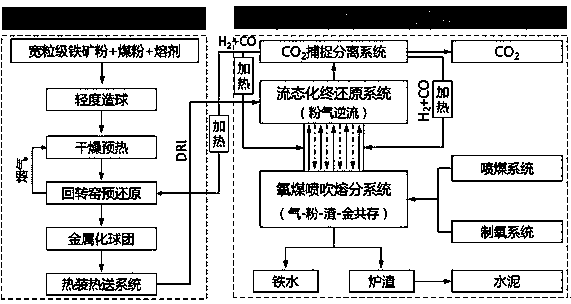

High density total oxygen short process high-efficiency cleaning iron-making process

InactiveCN108754056ASave the coking processSave grinding costRotary drum furnacesGas emission reductionCo2 removalSlag

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

Biochar-containing iron ore pellets and preparation method thereof

ActiveCN107868871AImprove mechanical propertiesImprove densification performanceSelf reductionMixed materials

The invention relates to biochar-containing iron ore pellets and a preparation method thereof. The preparation method comprises the following steps of: uniformly mixing iron ore powder, biochar, a binder and water to form a mixed material A; uniformly mixing iron ore powder, a binder and water to form a mixed material B; firstly putting the mixed material A in a pelletizer to prepare inner spheres, and then putting the mixed material B to form outer layers for coating the inner spheres, namely obtaining the biochar-containing iron ore pellets containing double-layer sphere structures; and controlling the diameter of the inner spheres to be D1 which is 8-10mm and the diameter of the pellets to be D2, wherein D2-D1 is 1-4mm and D2 is less than or equal to 12mm, the mass ratio of carbon of the biochar in in the inner spheres to oxygen of the iron ore powder is (0.95-1.3): 1, and the mass ratio of carbon of the biochar in the pellets to oxygen of the iron ore powder is (0.63-0.85): 1. Thetesting proves that the compression strength, drop strength and detonative temperature of the biochar-containing iron ore pellets prepared by the method can meet self-reduction pellets production verywell. The biochar-containing iron ore pellets are simple in technology, low in production cost and environmentally-friendly and have good industry foreground.

Owner:CENT SOUTH UNIV

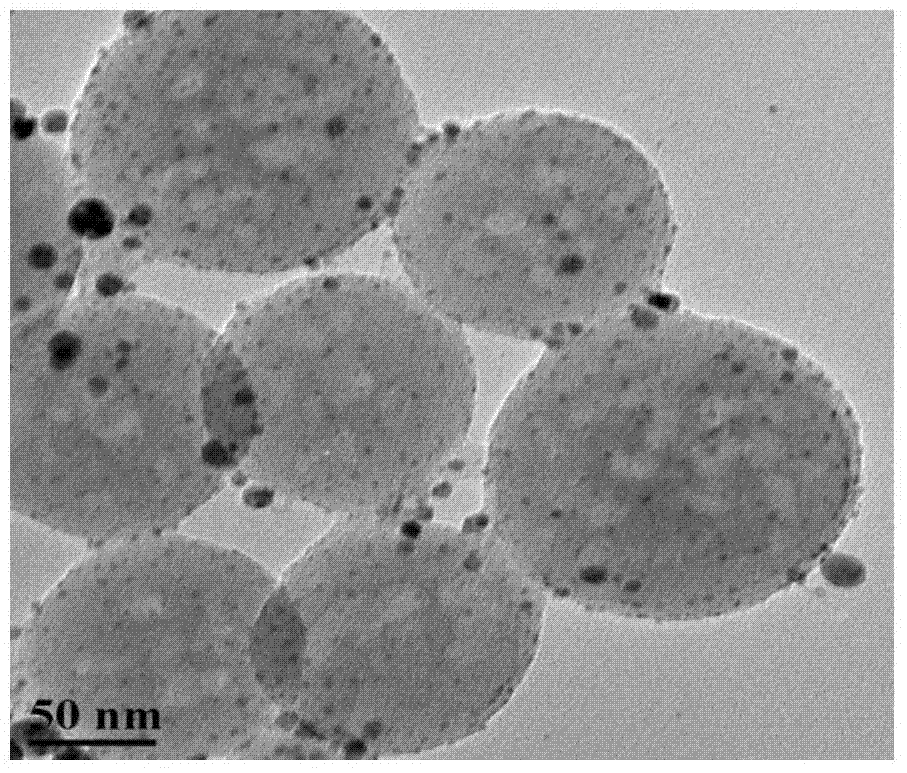

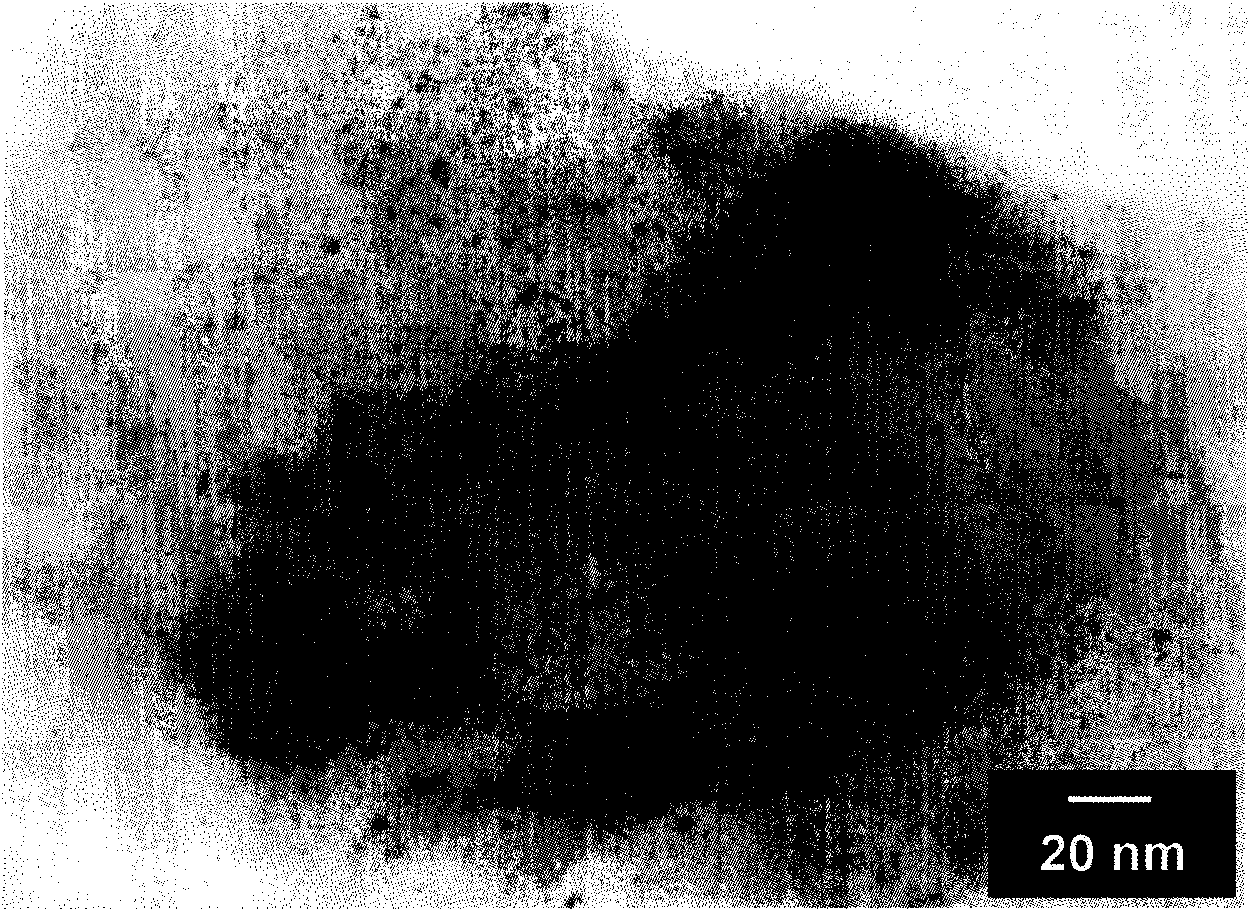

Amphiphilic polymer/ Ag nano composite microsphere preparation method

The invention belongs to the preparation field of organic inorganic nano composite materials, and mainly relates to an amphiphilic polymer / Ag nano composite microsphere preparation method. According to the method, polymer microspheres with surface silicon hydroxyl can be prepared by copolymerization of vinyl monomer and organic siloxane by miniemulsion polymerization, a silver salt compound is added for in situ production of nano Ag on the surface of polysiloxane microspheres by virtue of self reduction of polysiloxane to realize polymer / Ag nano composite microsphere preparation. The prepared polymer / Ag nano composite microsphere overcomes the problems that nano Ag is easy to agglomerate and difficult to disperse, and polymer is poor in compatibility and the like, and can be widely used in the fields of antibacterial materials, photocatalytic materials and the like.

Owner:RUNTAI CHEM TAIXING CO LTD

Carbon-supported metal catalyst and preparation method thereof

InactiveCN101618324AGood dispersionAchieve metallizationCell electrodesCatalyst activation/preparationFiltrationIon exchange

The invention discloses a carbon-supported metal catalyst and a preparation method thereof. The metal catalyst takes a transition metal element as an active metal, and the content of the metal component is accurate and adjustable within the range of 1-50wt%. The preparation method mainly comprises the following steps: (1) preparing salt precursor solution and placing in a reactor with continuously stirring; (2) adding negative resin which forms a certain proportion with metal content in the salt precursor or positive resin with the same proportion in the reactor for carrying out ion exchange reaction and controlling the temperature not to exceed 40 DEG C; (3) carrying out filtration on the solution of ion exchange reaction at room temperature, collecting filtered materials and drying at 80 DEG C; and (4) placing the dried filter materials in a tube furnace, increasing the temperature to 500 DEG C for baking under the protection of helium and nitrogen inert gas flow, keeping the temperature for a certain period of time and cooling to room temperature. The method removes impurities by synthesis process and self-reduction process of the catalyst and realizes metallization of the active component and high dispersion.

Owner:DALIAN JIAOTONG UNIVERSITY

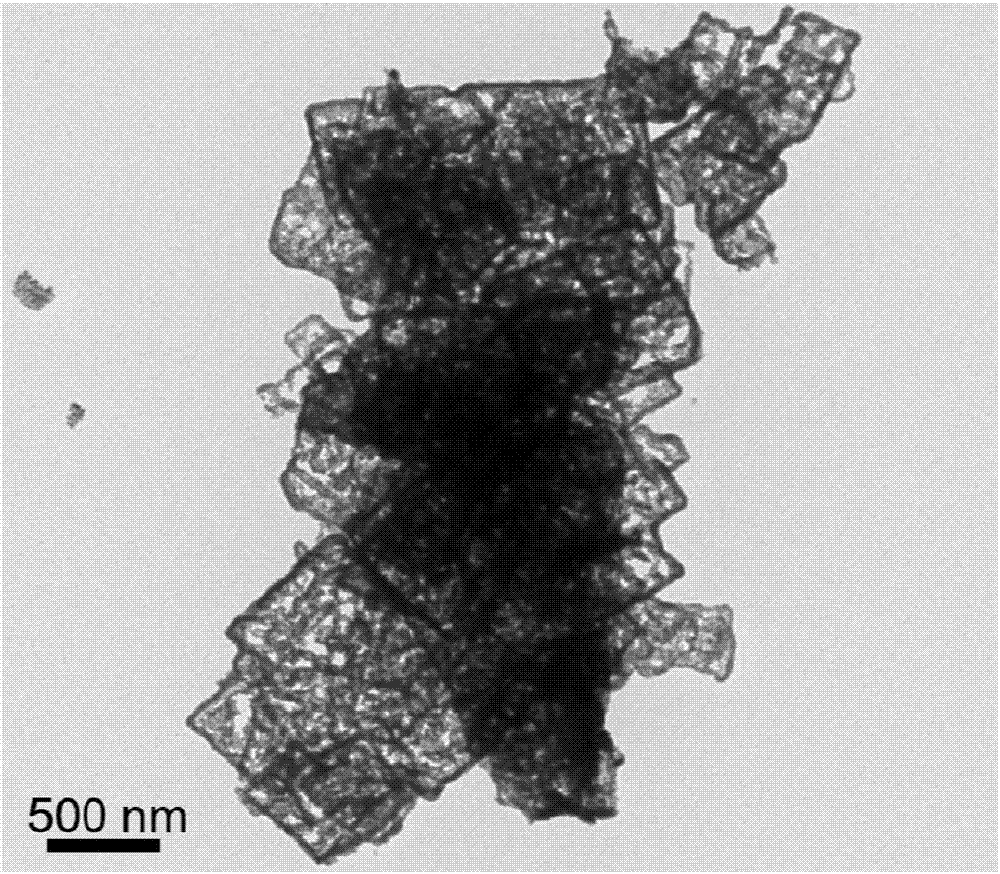

Preparing method of embedded porous Pd/C nano frame and obtained material and application thereof

ActiveCN107335431AExcellent formic acid oxidationExcellent electrocatalytic performance for oxygen reductionMaterial nanotechnologyCell electrodesHeat stabilityNitrogen gas

The invention discloses a preparing method of an embedded porous Pd / C nano frame. The preparing method includes the steps that naphthylamine (C10H9N) serving as a coordinated molecule forms yellow complex precipitate with PdCl2, the precipitate is dried to obtain flaky Pd(II) naphthylamine powder, under inert atmosphere (nitrogen, or argon or carbon dioxide), the temperature is raised to 200-1000 DEG C, then high-temperature self-reduction is carried out to obtain the embedded porous Pd / C nano frame. The method is simple and easy to implement, the raw materials are low in cost, and large-scale production can be achieved. The embedded porous Pd / C nano frame prepared through the method has the advantages of being superfine in particle size (-5.0 nm), high in electrical conductivity and electrochemical activity and good in electrochemical stability and heat stability, and presents high catalytic activity and stability serving as a formic acid oxidation anode catalyst and an oxygen reduction cathode catalyst.

Owner:NANJING NORMAL UNIVERSITY

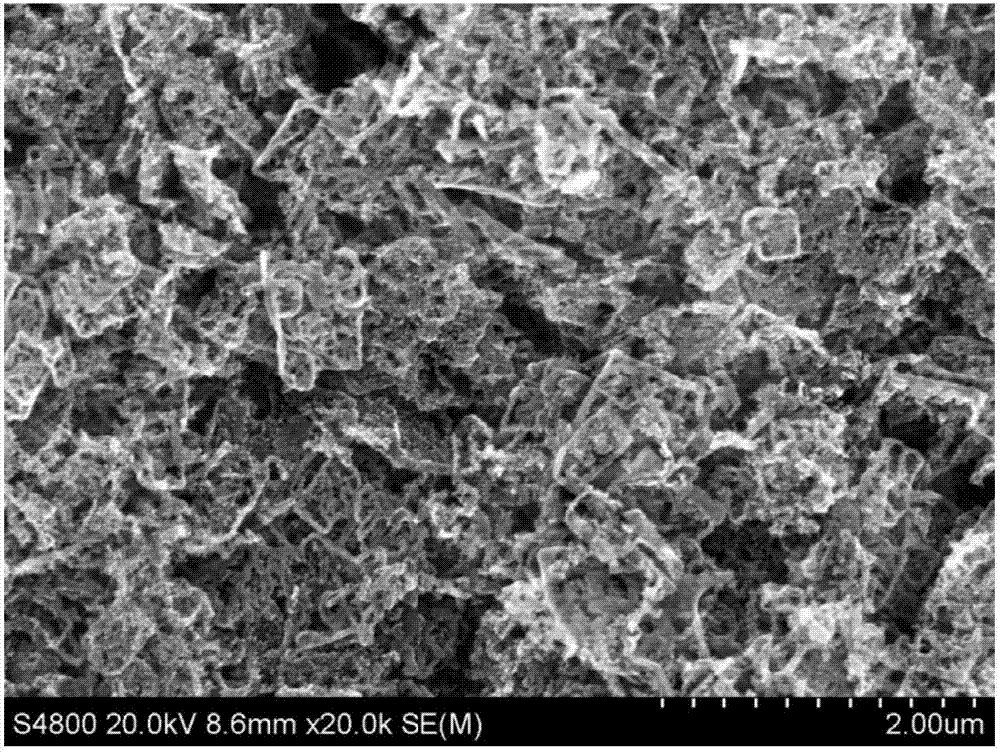

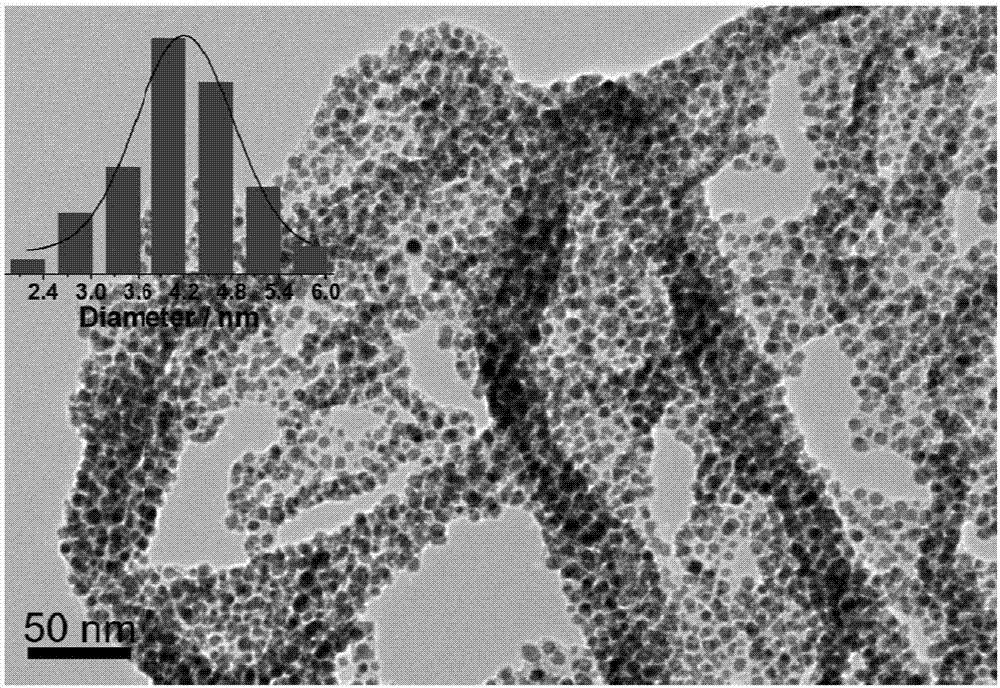

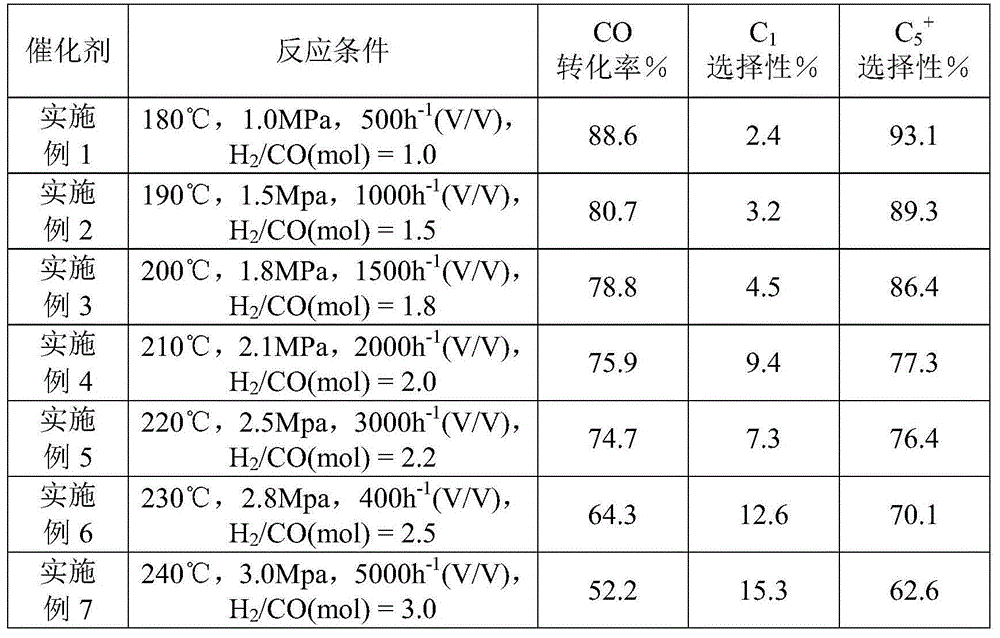

Cobalt-based catalyst for Fischer-Tropsch synthesis and application of cobalt-based catalyst

ActiveCN104162429APlay the role of hole expansionSimultaneous roastingLiquid hydrocarbon mixture productionMetal/metal-oxides/metal-hydroxide catalystsSelf reductionCarbon source

The invention relates to a cobalt-based catalyst for Fischer-Tropsch synthesis. The cobalt-based catalyst comprises cobalt oxide, an oxide support and surface passivated cobalt oxide, wherein the cobalt oxide comprises the following components metered by the weight of metal: 10wt%-30wt% of cobalt and the balance being the oxide support. According to the cobalt-based catalyst for Fischer-Tropsch synthesis, an organic carbon source, which has the characteristic of being decomposed in an inert atmosphere to generate a weak reduction component, namely simple substance carbon, is introduced into a process for preparing the catalyst support by virtue of a sol-gel method, and the carbon-containing support is dipped into cobalt and then is roasted, thereby obtaining a surface passivated self-reduction catalyst, wherein the roasting and the self reduction of the cobalt-based catalyst are carried out synchronously, and the online reduction temperature of the cobalt-based catalyst is greatly decreased.

Owner:中科潞安能源技术有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com