Fuse reducing iron-smelting process for rotating furnace

A technology of rotary hearth furnace and process, which is applied in the field of smelting reduction ironmaking process and related equipment, and can solve problems such as difficulty in popularization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

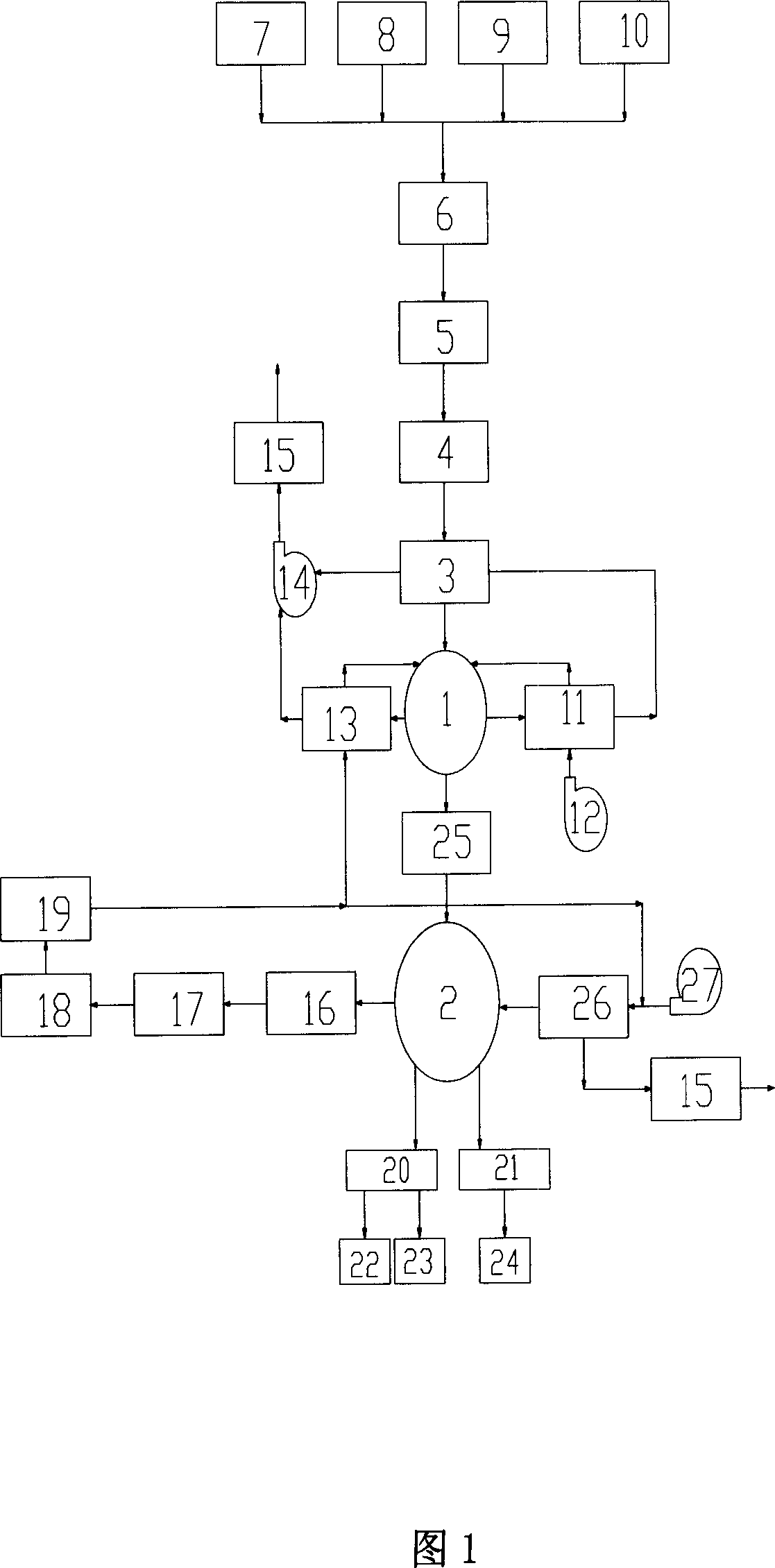

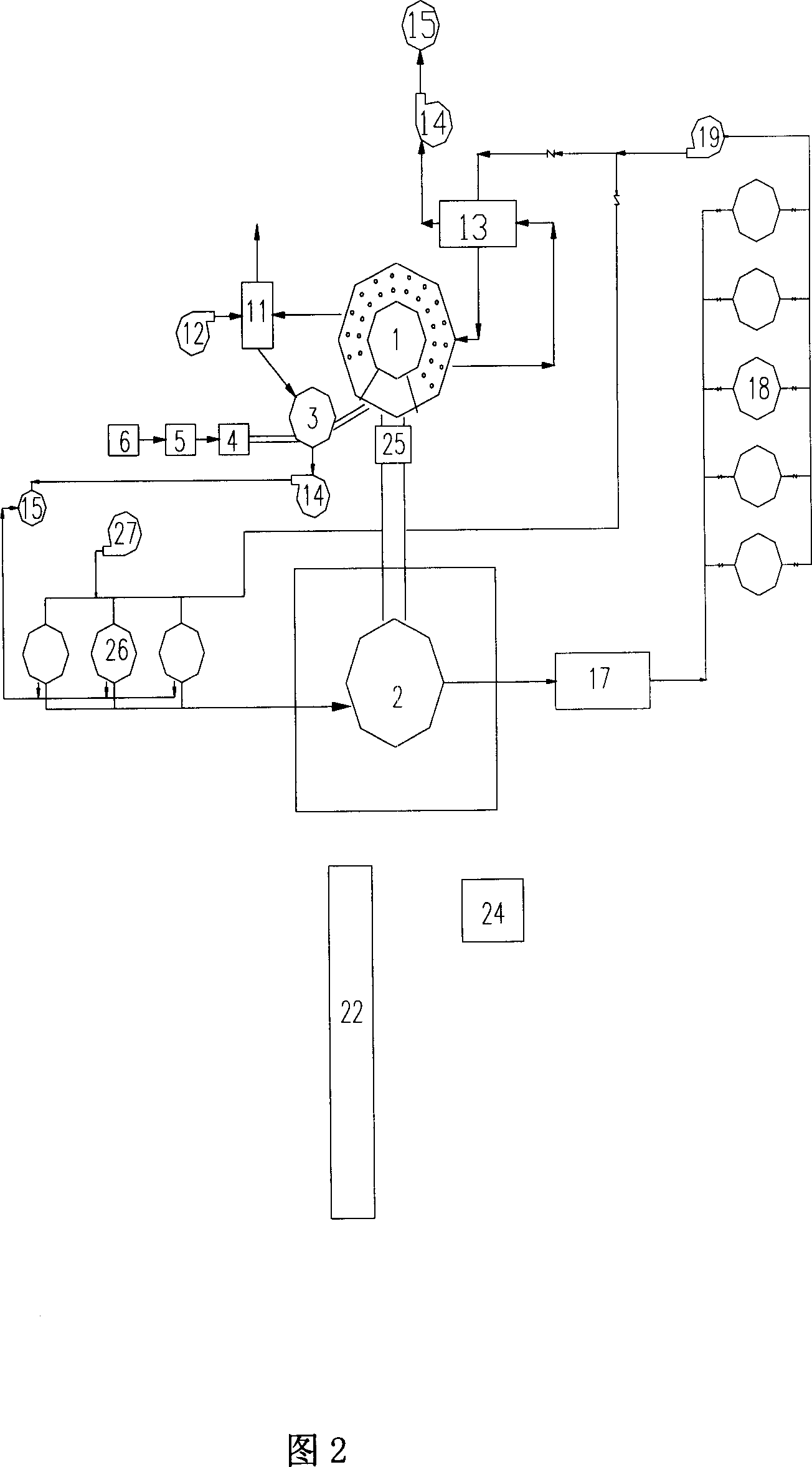

Method used

Image

Examples

Embodiment 1

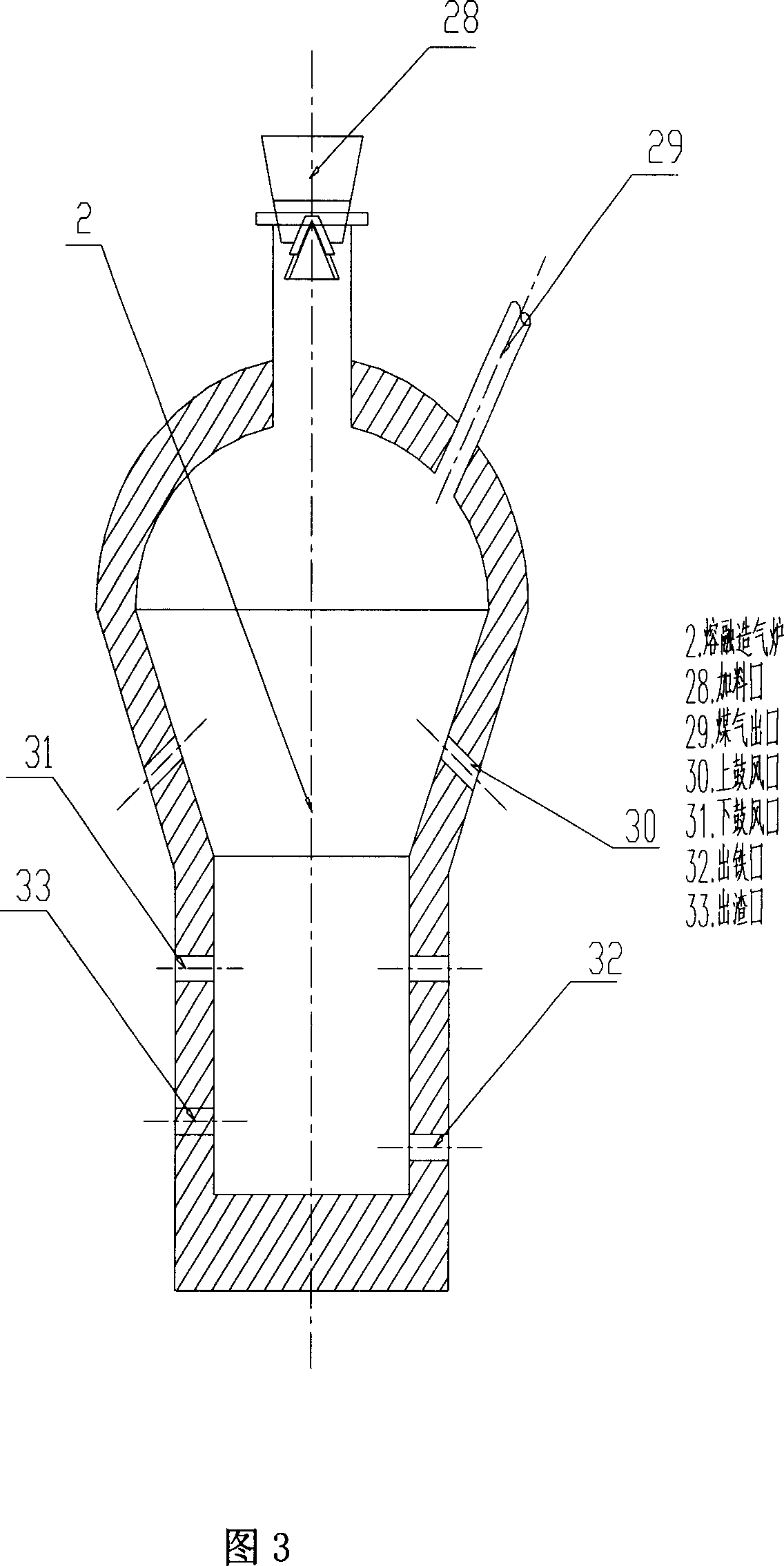

[0018] 78 parts (by weight, the same below) of fine iron powder (containing 65% iron), 19 parts of coal dust (13% of ash, 0.65% of sulfur), and 3 parts of binder were mixed and pelletized.

[0019] Dry the resulting balls and put them into a rotary hearth furnace for reduction. The reduction temperature is 1350°C, the treatment time is 15, 20, and 30 minutes, and the achieved metallization rates are 80%, 85%, and 88%, respectively.

[0020] The metallized pellets from the rotary hearth furnace are put into the melting gas-making furnace, and the briquettes are used as fuel to obtain molten iron with Fe 95.6%, C 3.8%, S 0.03%, P 0.07%, and Si 0.5%.

Embodiment 2

[0022] Mix 81 parts (weight, the same below) of fine iron powder (containing 68% iron), 17 parts of coal powder (12% of ash, 0.5% of sulfur), and 2 parts of binder, and make pellets after mixing. The dried balls were added to a rotary hearth furnace for reduction, the reduction temperature was 1300°C, the treatment time was 10, 15, 20, and 30 minutes respectively, and the metallization rates of the obtained metallized pellets were 78%, 81%, and 85% respectively. , 87%.

[0023] The metallized pellets from the rotary hearth furnace are put into the melting gas-making furnace, and the briquettes are used as fuel to obtain the molten iron composition: Fe 95.51%, C 4%, S 0.025%, P 0.065%, Si 0.4%.

[0024] In terms of environmental protection, the present invention has no solid waste discharge in the process, and the dust discharge is less than 100mg / m 3 , can be reduced to 50mg / m after passing through the dust collector 3 (The national standard is 100mg / m 3 ). Since there is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com