Method and device for smelting jamesonite by bottom-blowing pool

A technology for brittle sulphur, lead and antimony ore and molten pool smelting is applied in the field of bottom blowing molten pool smelting method and device for brittle sulphur, lead and antimony ore, and can solve the problems of low concentration, many intermediate products, waste of sulfur resources and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

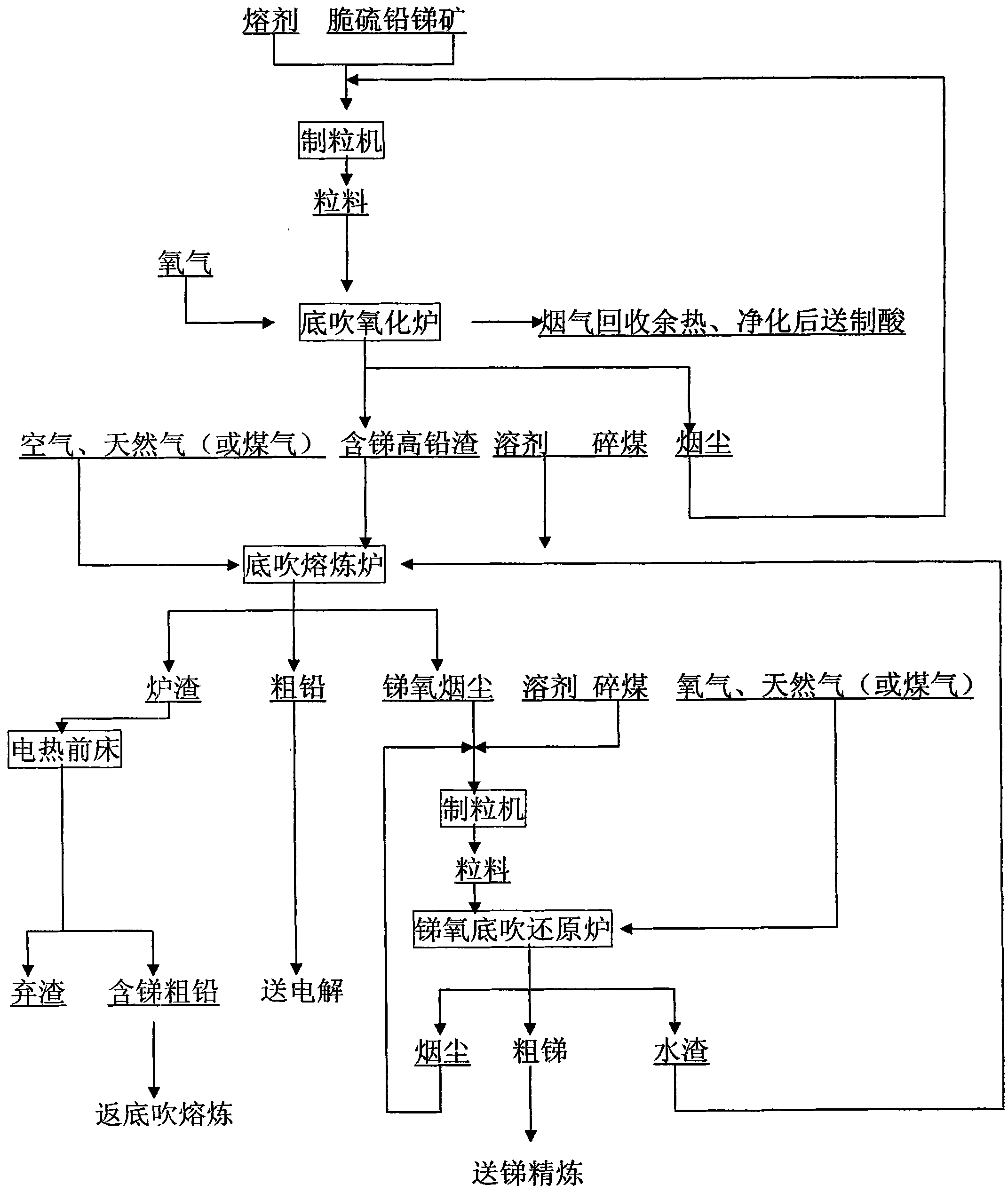

Method used

Image

Examples

Embodiment 1

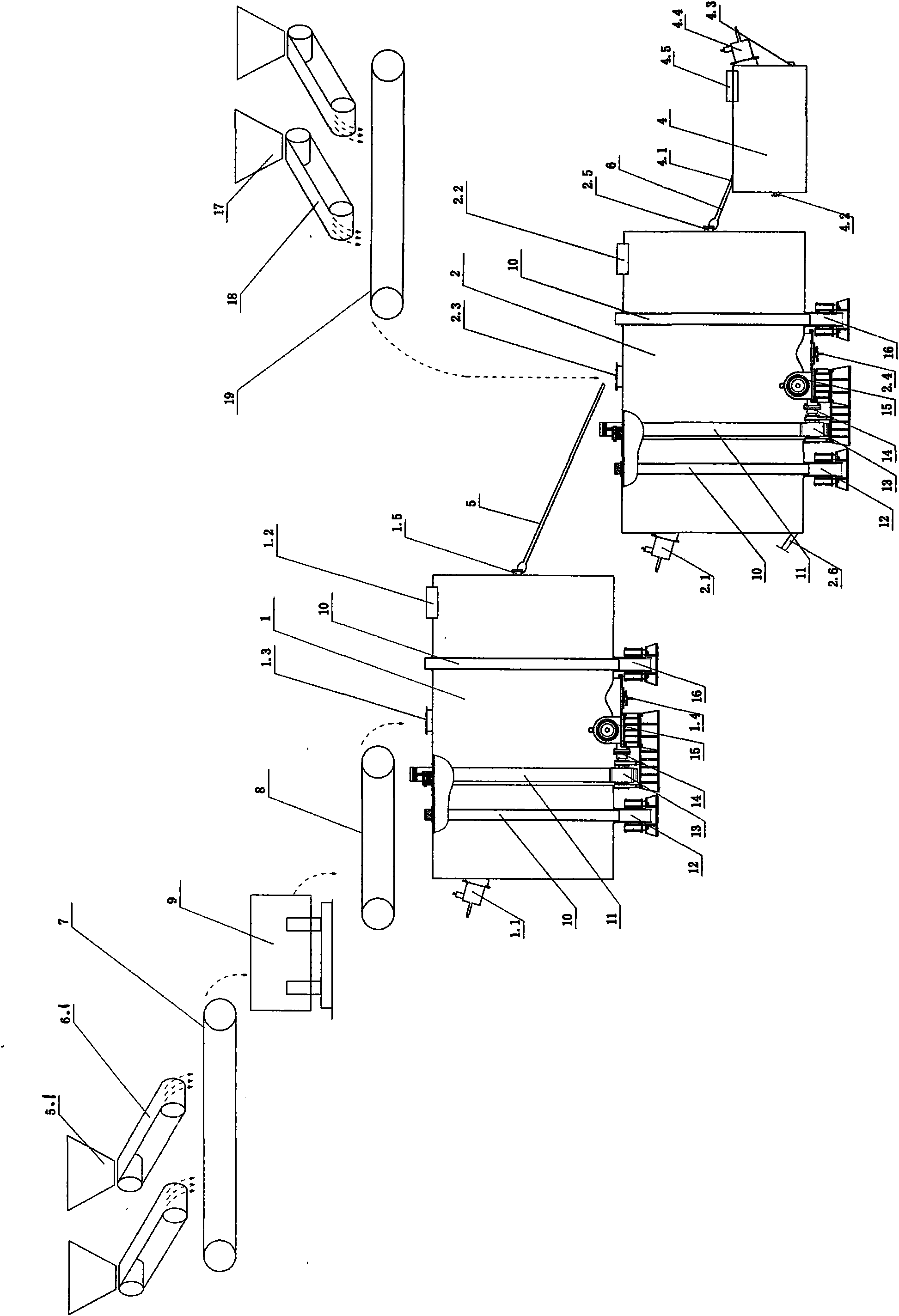

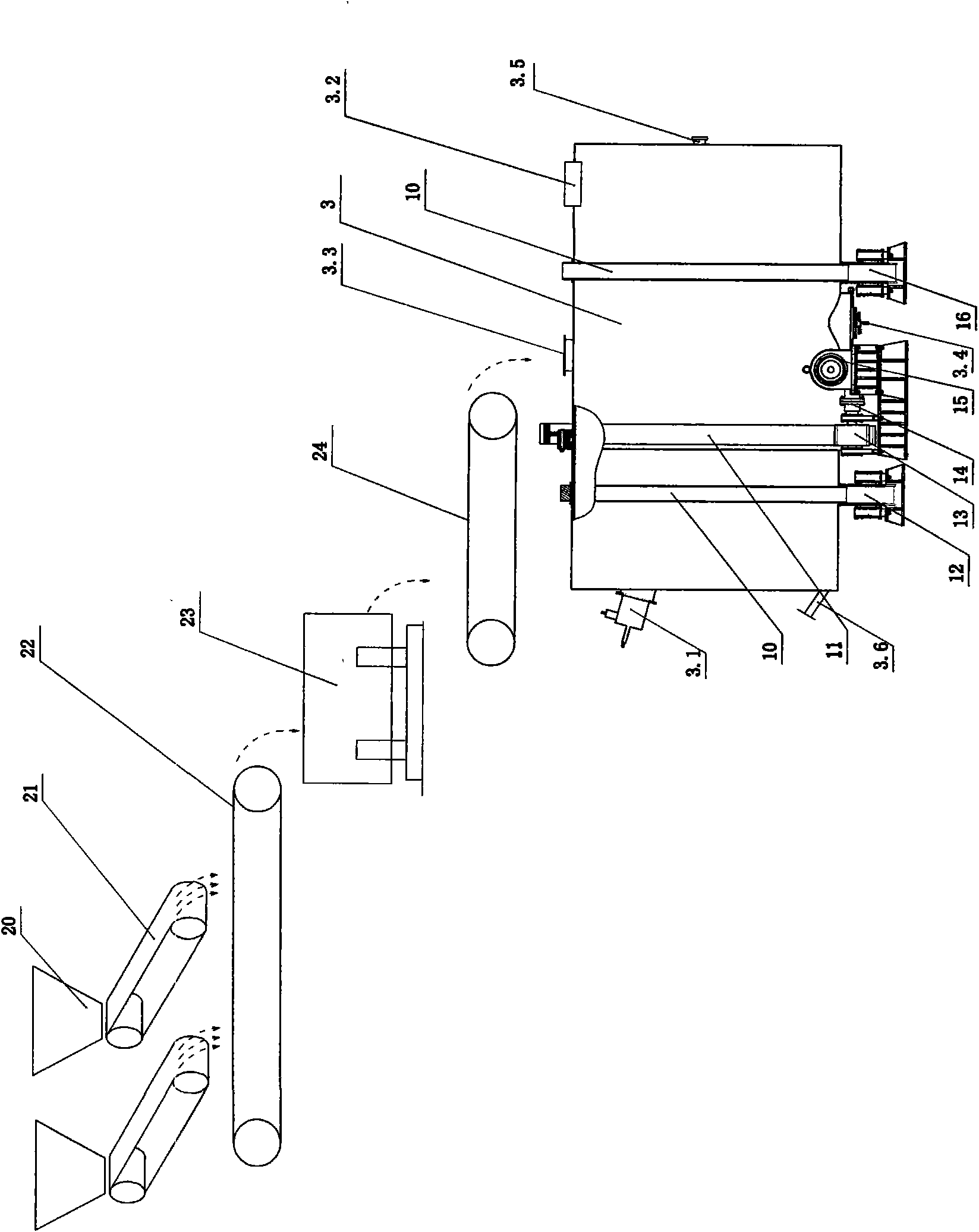

[0070] Embodiment 1 A kind of bottom-blown molten pool smelting device of brittle sulfur-lead-antimony ore, see figure 2 , image 3 , including a bottom-blown oxidation furnace 1, a bottom-blown smelting furnace 2, a bottom-blown reduction furnace 3 and an electric front bed 4, and the bottom-blown oxidation furnace 1, bottom-blown smelting furnace 2 and bottom-blown reduction furnace 3 are all cylindrical horizontal type converter, the bottom of the furnace body is provided with gas spray gun ports 1.4, 2.4, 3.4 respectively, the top of the furnace body is respectively provided with exhaust ports 1.2, 2.2, 3.2 and feeding ports 1.3, 2.3, 3.3, and the end is provided with burner ports 1.1, 2.1, 3.1, slag outlets 2.5, 3.5, 4.2 are provided at the end or cylinder, siphon lead outlet 2.6 is provided at the end of bottom-blowing smelting furnace 2, and antimony outlet is provided at the side of bottom-blown reduction furnace 3 cylinder Port 3.6, which can be rotated when the fur...

Embodiment 2

[0077] Embodiment 2 A bottom-blown molten pool smelting method for brittle sulfur-lead-antimony ore. The gas lance installed at the bottom lance port 2.4 of the bottom-blown smelting furnace 2 is continuously injected with gas and oxygen-enriched air, and the pressure of the gas is not lower than 0.4MPa, the gas is producer gas or coke oven gas, and the volume ratio of gas to oxygen is 2.5 to 6;

[0078] Coal gas and oxygen are continuously sprayed into the gas lance installed at the bottom gas lance mouth 3.4 of the bottom blowing reduction furnace 3, the pressure of the gas is not lower than 0.4MPa, the gas is producer gas or coke oven gas, and the volume of oxygen is The ratio is 3 to 7;

[0079] The rest are the same as Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com