Nitrogenous silicate yellow green luminescent material for white light LED (light-emitting diode) and preparation thereof

A technology of luminescent materials and silicates, applied in luminescent materials, chemical instruments and methods, etc., can solve problems such as inconvenience and insecurity, and achieve the effects of improved luminescent performance, simple preparation method and high luminous intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

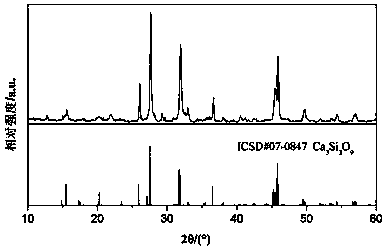

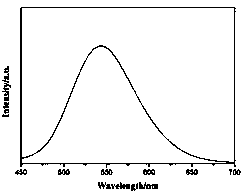

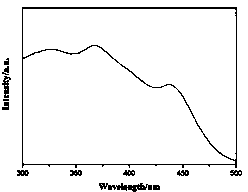

[0023] Example 1 Calcium nitrate (CaN) was weighed according to the molar ratio of Ca:Si:Eu of 1.96:2:0.4 2 O 6 ·4H 2 O), Ethyl orthosilicate (C 8 H 20 O 4 Si) and Europium Nitrate (EuN 3 O 9 ·6H 2 O). First, dissolve calcium nitrate and europium nitrate in a mixture of absolute ethanol and water with a volume ratio of 3:1, stir until the calcium nitrate and europium nitrate are uniformly dissolved, and then adjust the pH of the solution to 2. Add the weighed ethyl orthosilicate into the prepared solution, stir for 2 hours to obtain a clear sol, heat the sol in a water bath at 60°C for 4 hours to obtain a dry colloid, and put the dry gel in a drying box It was dried at 120°C for 12 hours to obtain a precursor. The precursor is ground and calcined in a resistance furnace at 1100°C for 2 hours to obtain Ca 2 SiO 4 :Eu 3+ product. In molar ratio Ca2SiO4: Eu 3+ :Si 3 N 4 Weigh Ca in a ratio of 1:1 2 SiO 4 :Eu 3+ And Si 3 N 4 , Will Ca 2 SiO 4 :Eu 3+ And Si 3 N 4 Mix evenly and put...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com