Cobalt-based catalyst for Fischer-Tropsch synthesis and application of cobalt-based catalyst

A technology of cobalt-based catalyst and Fischer-Tropsch synthesis, applied in the direction of physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, etc., can solve problems such as reducing the difficulty of manufacturing reactors, and achieve Reduce requirements, reduce reduction temperature, and expand the effect of application fields

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

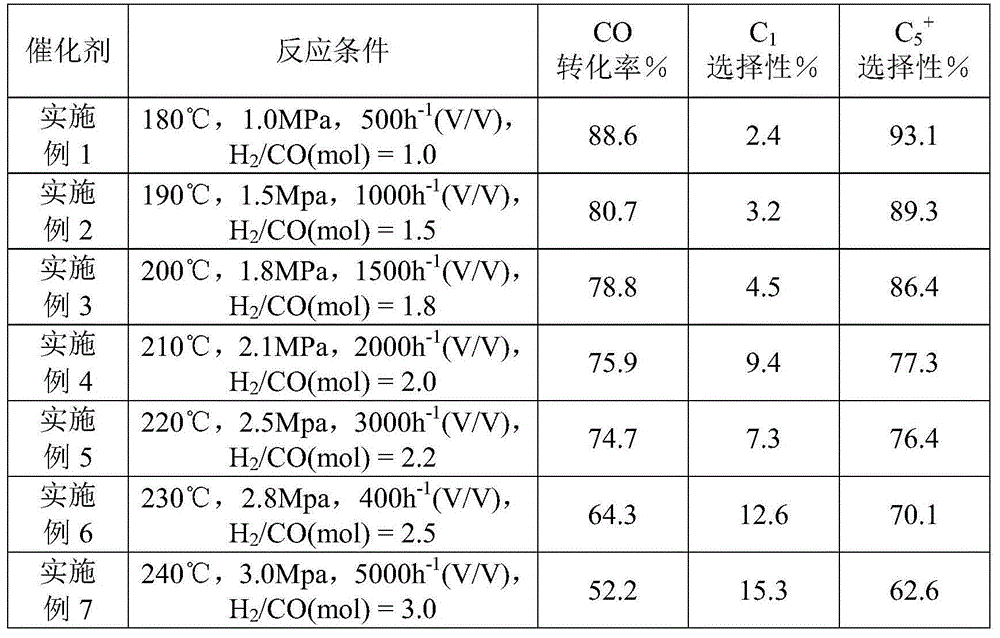

Examples

Embodiment 1

[0027] Press ZrO 2 Accounting for 70 (wt)% of the final catalyst composition, called zirconium n-propoxide, prepared into a 2.0mol / L aqueous solution, adding 0.01 (mol)% hydrolyzing agent sulfuric acid to the solution under stirring, keeping the temperature at 50°C for 6h, Make zirconium sol; Account for 30 (wt)% of final catalyst by Co, weigh Co(NO 3 ) 2 ·6H 2 O, add deionized water to prepare a solution; according to the need for cobalt reduction in the final catalyst, take the scallop powder and dissolve it in distilled water, wherein the safflower powder:cobalt nitrate (w / w)=0.5:1, stir to form a suspension The turbid liquid is gelatinized at 90°C for 0.4h, and the gelatinization temperature is maintained, and the zirconium sol is slowly added to the gelatinized scallop powder, kept for 1h, stopped stirring, and aged at room temperature for 12h to obtain a gel; The gel was dried in a drying oven at 60°C for 24 hours to obtain a xerogel; the obtained xerogel was placed i...

Embodiment 2

[0031] Press Al 2 o 3 75 (wt)% of final catalyst composition, take a certain amount of aluminum isopropoxide, be mixed with the aqueous solution of 1.8mol / L, add 0.05 (mol)% hydrolysis agent nitric acid to this solution under stirring, keep temperature 60 ℃, keep Time 5h, made aluminum sol; Account for 25 (wt)% of final catalyst by Co, take a certain amount of Co (CH 3 COO) 2 4H 2 O, add deionized water to prepare a solution; according to the need to reduce the cobalt in the final catalyst, weigh a certain amount of methylcellulose and dissolve it in distilled water, wherein methylcellulose:cobalt acetate (w / w)=0.2:1 , stirred to form a suspension, gelatinized at 80°C for 1h, and kept at the gelatinization temperature, slowly added aluminum sol to the gelatinized methylcellulose powder, kept for 2h, stopped stirring, aged at room temperature for 24h, and obtained Gel; put the obtained gel in a drying oven and dry at 70°C for 18 hours to obtain a xerogel; place the obtained...

Embodiment 3

[0035] by SiO 2 Accounting for 80 (wt)% of the final catalyst composition, weigh a certain amount of tetraethyl orthosilicate, and prepare it into a 1.5mol / L aqueous solution, add 0.1 (mol)% hydrolyzing agent nitric acid to the solution under stirring, and keep the temperature at 70°C , hold time 4h, make silica sol; Account for 20 (wt)% of final catalyst according to Co, take a certain amount of CoSO 4 ·7H 2 O, add deionized water to prepare a solution; according to the needs of reducing cobalt in the final catalyst, take a certain amount of methylcellulose powder and dissolve it in distilled water, wherein methylcellulose: cobalt sulfate (w / w)=0.75 : 1. Stir to form a suspension, gelatinize at 70°C for 2h, keep the gelatinization temperature, slowly add silica sol to the gelatinized methylcellulose, keep for 3h, stop stirring, and age at room temperature for 36h to obtain Gel; the obtained gel was dried in a drying oven at 80°C for 14 hours to obtain a xerogel; the obtaine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com