Soil pollution repairing agent and repairing method thereof

A technology for soil pollution and remediation agent, applied in the field of soil pollution remediation agent and its remediation, can solve the problems of low removal rate and long curing period, and achieve the effect of increasing adsorption capacity, improving mutual synergy, and being beneficial to adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

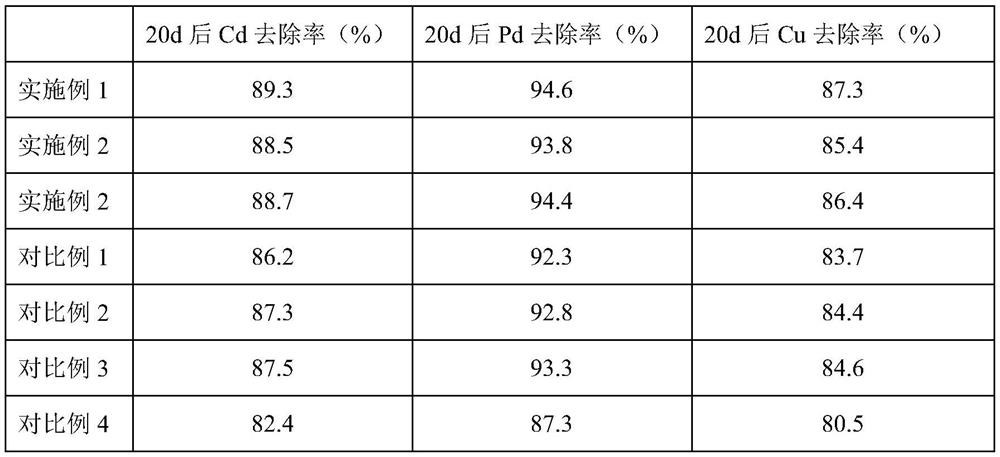

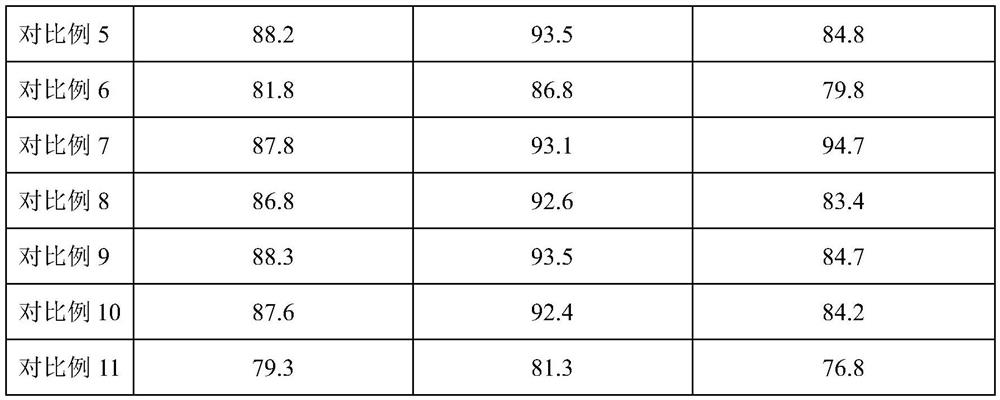

Examples

Embodiment 1

[0032] A soil pollution remediation agent, the preparation method of the remediation agent is as follows:

[0033] (1) Mix 2g of sepiolite powder, 0.6g of magnesite powder and 9g of corn stalk to obtain mixture A;

[0034] (2) Potassium permanganate, lanthanum nitrate and samarium nitrate are dissolved in deionized water of 100mL to obtain mixed solution B, wherein the concentration of potassium permanganate is 0.1mol / L, the concentration of lanthanum nitrate is 0.13mol / L, The concentration of samarium nitrate is 0.13mol / L;

[0035] (3) Add the mixture A obtained in step (1) to the mixed solution B, ultrasonically disperse for 3 hours, evaporate to dryness in a constant temperature water bath at 90°C, and then keep warm at 380°C for 3h under a nitrogen atmosphere with an oxygen content of 0.1% by volume , and then heat preservation treatment at 600° C. for 3 hours, and cool to room temperature to obtain a soil pollution remediation agent.

Embodiment 2

[0037] A soil pollution remediation agent, the preparation method of the remediation agent is as follows:

[0038] (1) 2g of sepiolite powder, 0.8g of magnesite powder and 6g of rice straw were uniformly mixed to obtain mixture A;

[0039](2) Potassium permanganate, lanthanum nitrate and samarium nitrate are dissolved in 100mL of deionized water to obtain mixed solution B, wherein the concentration of potassium permanganate is 0.1mol / L, the concentration of lanthanum nitrate is 0.14mol / L, The concentration of samarium nitrate is 0.12mol / L;

[0040] (3) Add the mixture A obtained in step (1) to the mixed solution B, ultrasonically disperse for 4 hours, evaporate to dryness in a constant temperature water bath at 100°C, and then keep the temperature at 400°C under a helium atmosphere with an oxygen content of 0.2% by volume 2h, then heat preservation treatment at 650°C for 2h, and cool to room temperature to obtain a soil pollution remediation agent.

Embodiment 3

[0042] A soil pollution remediation agent, the preparation method of the remediation agent is as follows:

[0043] (1) Mix 2g sepiolite powder, 0.4g magnesite powder and 12g wheat straw to obtain mixture A;

[0044] (2) configure potassium permanganate, lanthanum nitrate and samarium nitrate to be dissolved in 100mL of deionized water to obtain mixed solution B, wherein the concentration of potassium permanganate is 0.1mol / L, the concentration of lanthanum nitrate is 0.12mol / L, The concentration of samarium nitrate is 0.14mol / L;

[0045] (3) Add the mixture A obtained in step (1) to the mixed solution B, ultrasonically disperse for 2 hours, evaporate to dryness in a constant temperature water bath at 80°C, and then keep the temperature at 350°C under a neon atmosphere with an oxygen content of 0.05% by volume 4h, then heat preservation treatment at 550°C for 4h, and cool to room temperature to obtain a soil pollution remediation agent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com