A boron-containing alumina carrier and its preparation method

A technology of alumina carrier and aluminum hydroxide, which is applied in the direction of catalyst carrier, chemical instruments and methods, chemical/physical processes, etc., can solve the problem of small increase in alumina pore volume and specific surface area, poor boron dispersion, and operating process Complicated problems, to achieve the effect of improving anti-coking or anti-coking performance, suitable pore structure and acidity, and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

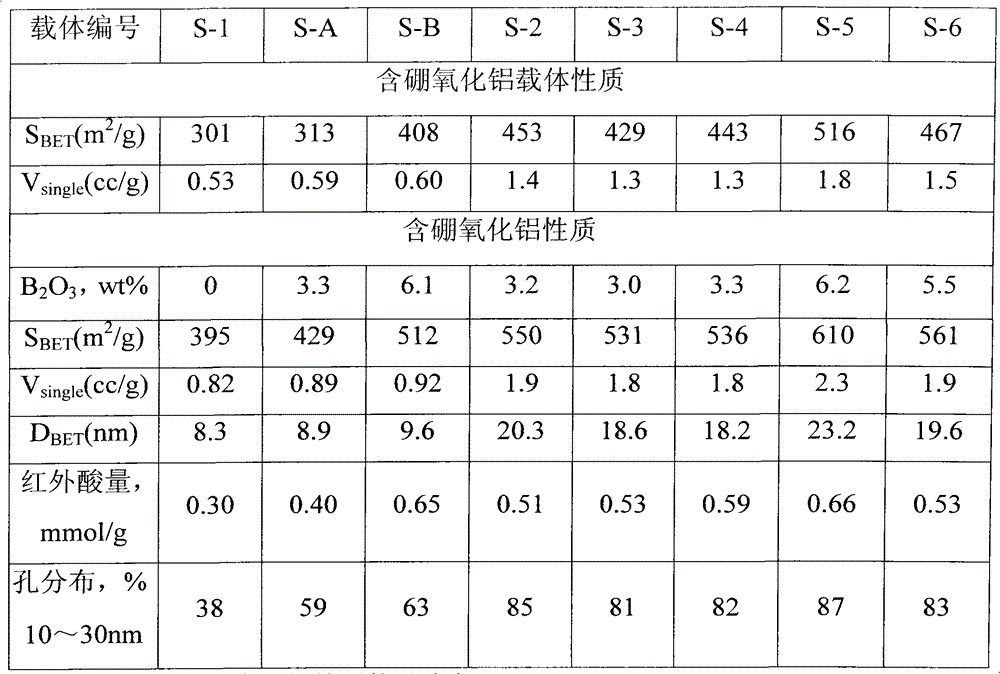

Examples

Embodiment 1

[0028] will contain Al 2 o 3 5g / 100mL AlCl 3 Solution 2000mL with NH 3 10g / 100mL of ammonia water was added dropwise into the gelling reaction tank stirred at a temperature of 60°C, and the pH value was maintained at 7.6, and the reaction contact time was 40min. Aging was performed at a temperature of 70°C and a pH of 8.0. The aging time is 1h. The product was filtered, and then washed with deionized water with a solid-to-liquid volume ratio of 1:20 at a washing temperature of 80° C. for three times. The obtained filter cake was dried at 120° C. for 3 hours to obtain aluminum hydroxide dry gel.

[0029] Take 100g of the above aluminum hydroxide dry glue, mix it with 110g of adhesive prepared by peptizing SB alumina powder with nitric acid, knead for 20min, make a plastic paste, and extrude it through a clover orifice plate with a diameter of 1.4mm. After the wet strip was dried at 130°C for 8h, it was calcined at 520°C for 4h to obtain alumina carrier S-1.

Embodiment 2

[0031] After the gelling reaction of Example 1, add the 2 o 3 3g / 100mL organic compound solution 100mL. The boron-containing organic compound solution is prepared by dissolving boric acid in water, and then the molar ratio of boric acid to mannitol is 1:1. The preparation of other aluminum hydroxide dry glue is the same as in Example 1 to obtain boron-containing aluminum hydroxide.

[0032] Take 120g of the above-mentioned boron-containing aluminum hydroxide, mix it with 126g of binder prepared by peptizing SB alumina powder with nitric acid, knead for 20min, make a plastic paste, and extrude it through a clover orifice plate with a diameter of 1.4mm. After the wet strip was dried at 130°C for 8h, it was calcined at 520°C for 4h to obtain carrier S-2.

Embodiment 3

[0034] The boron-containing organic compound solution in Example 2 was replaced by the boric acid to ethylene glycol molar ratio of 1.0:1.5, and other aluminum hydroxide dry glue was prepared in the same way as in Example 2 to obtain boron-containing aluminum hydroxide.

[0035]Take 110g of the above-mentioned boron-containing aluminum hydroxide, mix it with 118g of binder prepared by peptizing SB alumina powder with nitric acid, knead for 20min, make a plastic paste, and extrude it through a clover orifice plate with a diameter of 1.4mm. After the wet strip was dried at 130°C for 8h, it was calcined at 520°C for 4h to obtain carrier S-3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com