Brake pad with three grades of adjusting mechanisms

A technology for adjusting mechanisms and brake pads, applied in the direction of brake parts, brake types, brake components, etc., can solve the problem that the friction area between the brake pad and the brake disc cannot obtain the maximum effective fit, and does not have self- Adapt to the problems of performance, friction block drop and corner drop, etc., to achieve the effect of dissipating heat, reducing maintenance costs, and easy to disassemble

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

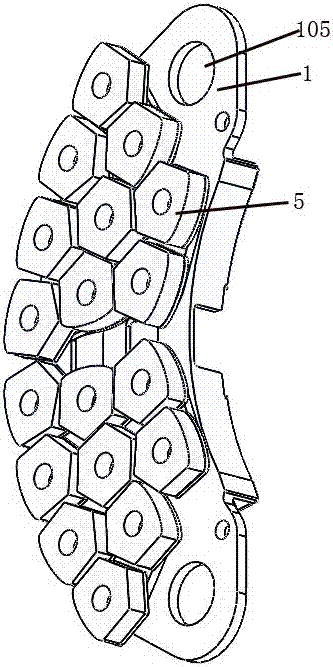

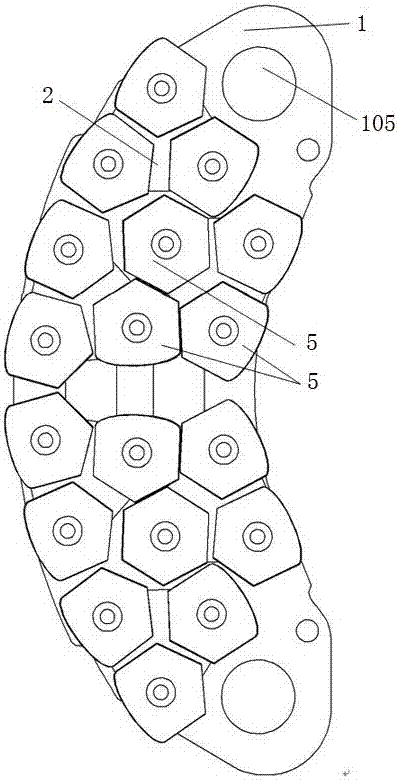

[0039] Example: see figure 1 ——14.

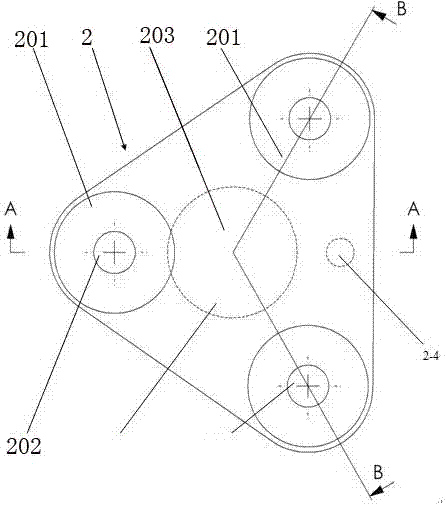

[0040] The invention discloses a brake pad with a three-stage adjustment mechanism, comprising a rigid plate 1 connected with a brake caliper, the rigid plate 1 is provided with a first-stage adjustment mechanism 2, a second-stage adjustment mechanism Mechanism 3, the third-level adjustment mechanism 4, the rigid plate 1 is provided with a recessed part 101 that does not pass through, and a connection hole 102 for connecting several friction blocks 5 is provided on the outside of the recessed part 101; the first The primary adjustment mechanism 2 is a connecting block, and the connecting block is provided with a smooth raised part 201, which is preferably a hemispherical surface, and the center of the raised part 201 is provided with a cylindrical through hole 202, and the lower part of the connecting block The surface is provided with an upwardly recessed smooth concave surface 203, the smooth curved surface is preferably a hemispherical ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com