Patents

Literature

57 results about "Sr element" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

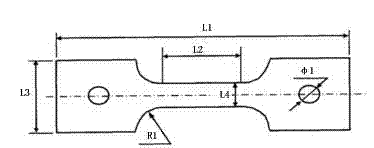

High-performance semi-solid die cast aluminum alloy and preparation method thereof

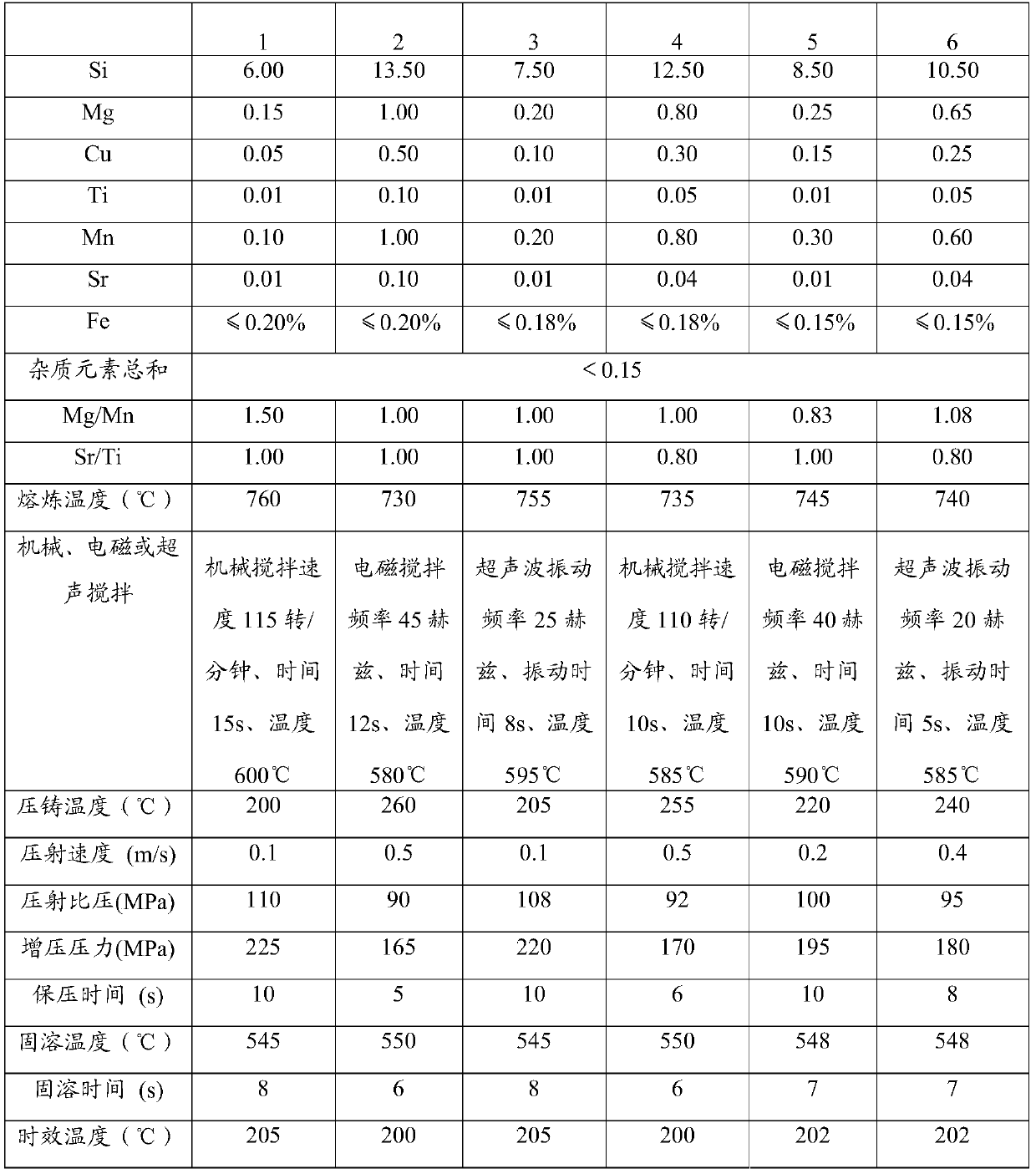

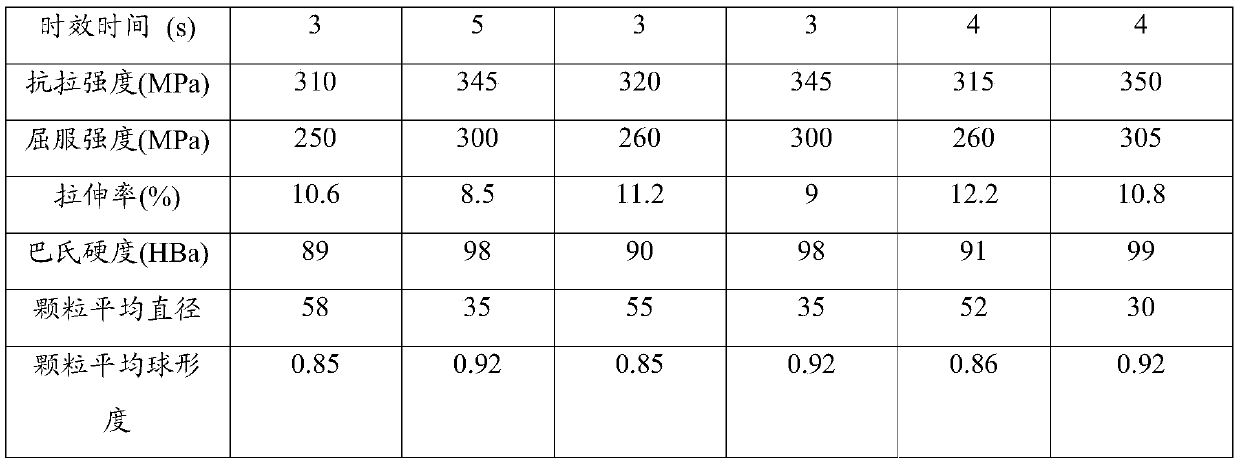

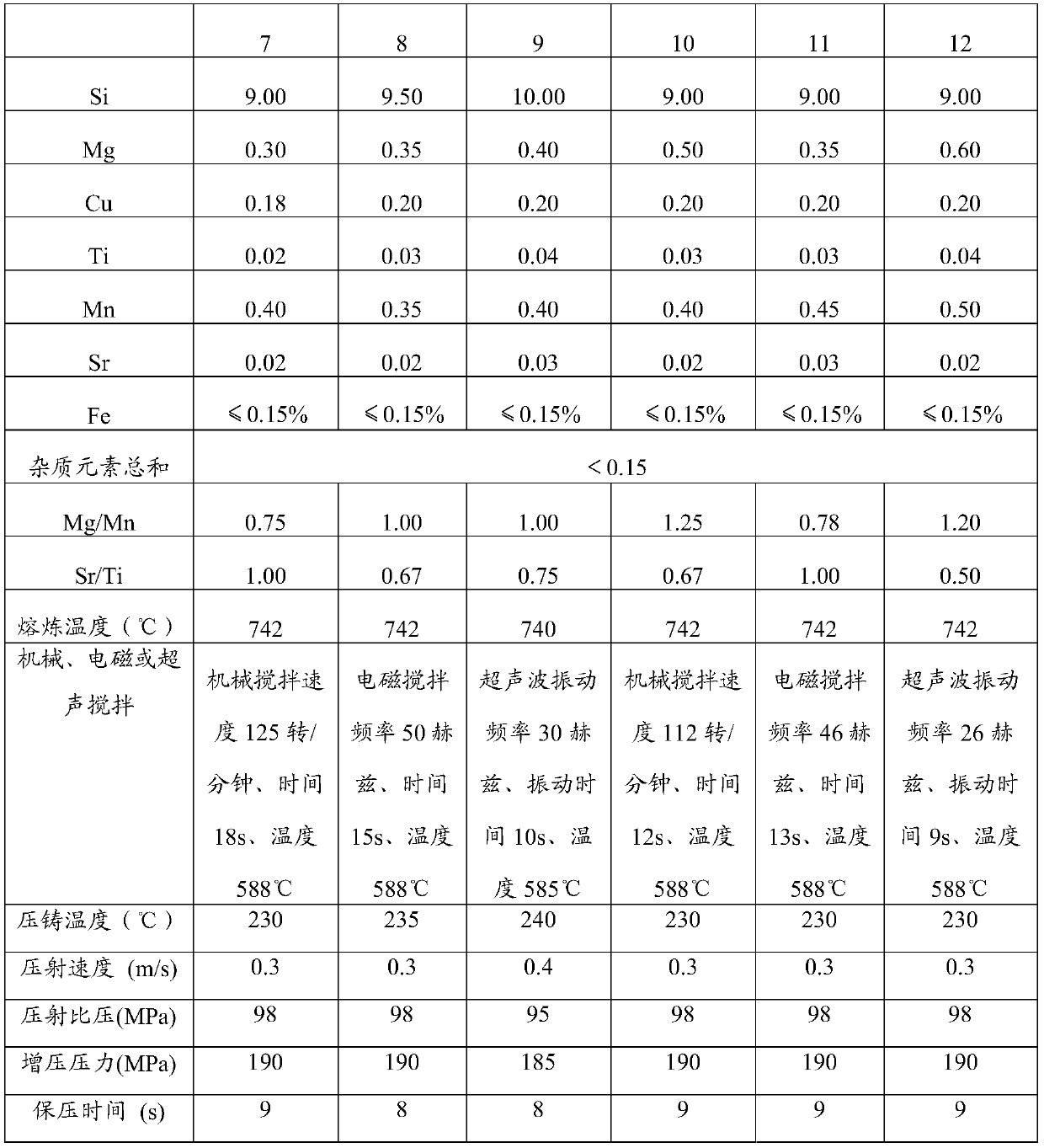

The invention relates to the technical field of aluminum alloy processing, in particular to a high-performance semi-solid die cast aluminum alloy and a preparation method of the high-performance semi-solid die cast aluminum alloy. The aluminum alloy comprises the following components of, by weight percentage, 6.00-13.50% of Si, 0.15-1.00% of Mg, 0.05-0.50% of Cu, 0.01-0.10% of Ti, 0.10-1.00% of Mn, 0.01-0.10% of Sr, not larger than 0.20% of Fe, impurity elements and the balance aluminum, wherein the sum of the impurity elements is less than 0.15, and the ratio of weight percent C 1 is equal toMg / Mn and is in the range of 0.75-1.50. According to the high-performance semi-solid aluminum alloy, on the basis of optimizing the Si, Mg and Mn main alloy elements, the Ti element is added to refine the alpha-Al crystal grains, the Sr element is added to refine the metamorphic eutectic Si phase, and the content of the elements and the impurity elements is controlled so that the elements can cooperate mutually, so that the aluminum alloy has high strength, good plasticity and excellent semi-solid state die casting process performance.

Owner:ZHUHAI RUNXINGTAI ELECTRICAL

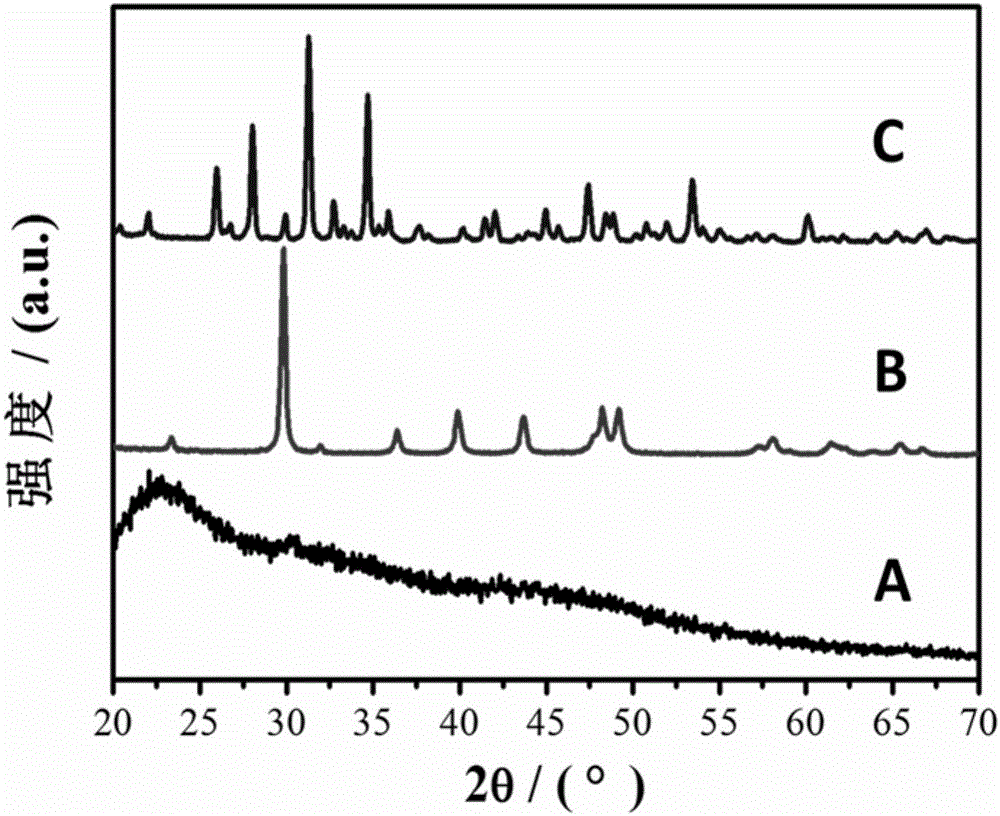

Secondary aluminum prepared by using Al-Ti-C-Sr alloy refiner and preparation thereof

The invention discloses a secondary aluminum produced by using Al-Ti-C-Sr alloy refining agent and the preparation method thereof. The compositions of the prepared secondary aluminum by weight percent are: Sr of 0.02 to 0.03 percent, Si of 6.5 to 7.5 percent, Mg of 0.25 to 0.4 percent; the content of the impurities meets the ZL101A standard; Fe of less than or equal to 0.2 percent, Cu of less than or equal to 0.1percent, Zn of less than or equal to 0.1 percent, Mn of less than or equal to 0.1 percent, the total of the impurities of less than 0.7 percent, and the remainder is aluminum. The compositions of the Al-Ti-C-Sr alloy refining agent by weight percentage are: Al of 81.5 to 86.5 percent, Ti of 4 to 7 percent, C of 0.3 to 0.5, and Sr of 10 to 11 percent. With the alloy refining agent in the invention for production of the secondary aluminum, the invention has a simple method and no pollution to the environment; the excellent fining function and deterioration function of the fining agent are fully played through the rational proportion of Sr element in the fining agent; the obtained secondary aluminum has high yield and excellent performance.

Owner:ZHEJIANG JINFEI KAIDA WHEEL

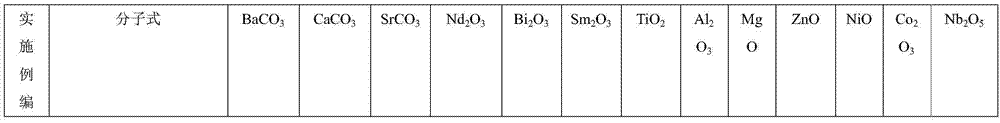

A-B site simultaneously substituting microwave dielectric ceramic material and preparation method thereof

The invention provides an A-B site simultaneously substituting microwave dielectric ceramic material and a preparation method thereof. The general chemical formula of the material is (Ba1-aAa)6-3x(Nd1-bBb)8+2x(Ti1-cCc)18O54, C=MN, wherein x=3 / 4, a is greater than or equal to 0.05 and smaller than or equal to 0.2, b is greater than or equal to 0.05 and smaller than or equal to 0.15, c is greater than or equal to 0.02 and smaller than or equal to 0.08, A represents divalent Ca and Sr elements substituting A1 sites, B represents trivalent Sm and Bi elements substituting A2 sites, M represents Nb with the valence state higher than tetravalency, N represents other one or more elements with a valence state lower than tetravalency and an ionic radius similar to Ti, and M and N substitute simultaneously or individually. The preparation method includes: determining the respective mass percentage content according to the general chemical formula, conducting ball mill mixing, performing presintering under 1000-1150DEG C, and then conducting sintering at 1250-1450DEG C. The prepared material has adjustable dielectric constant and frequency-temperature coefficient and at the same time maintains a high Q*f value. The formula does not contain Pb, Cd and other volatile or heavy metals, the performance is greatly enhanced, the raw materials are in abundant supply, and the price is low, so that low cost of high performance microwave ceramics becomes possible.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

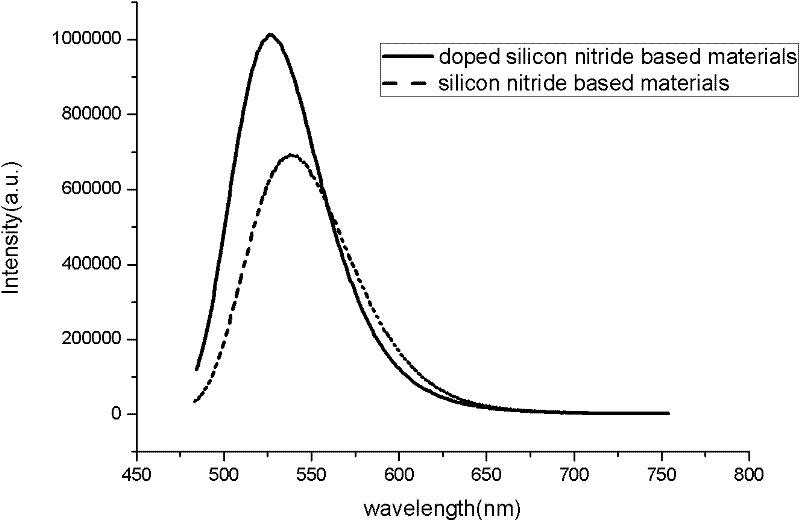

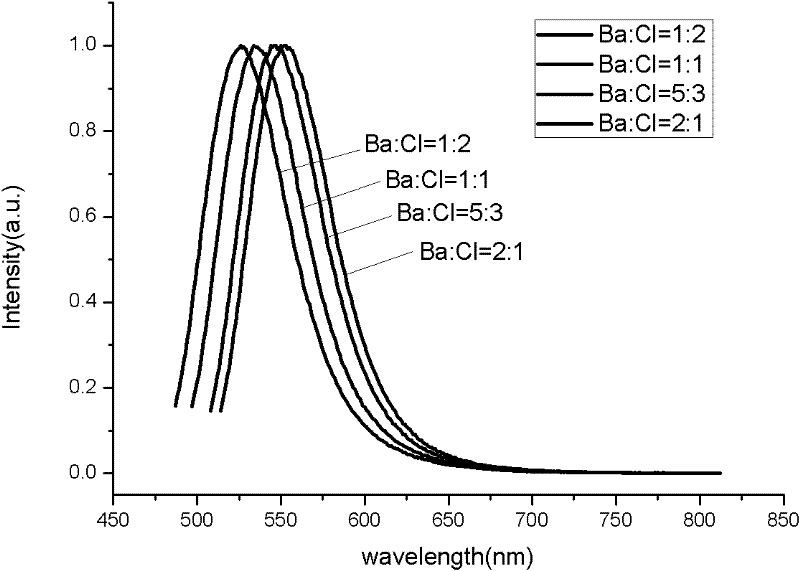

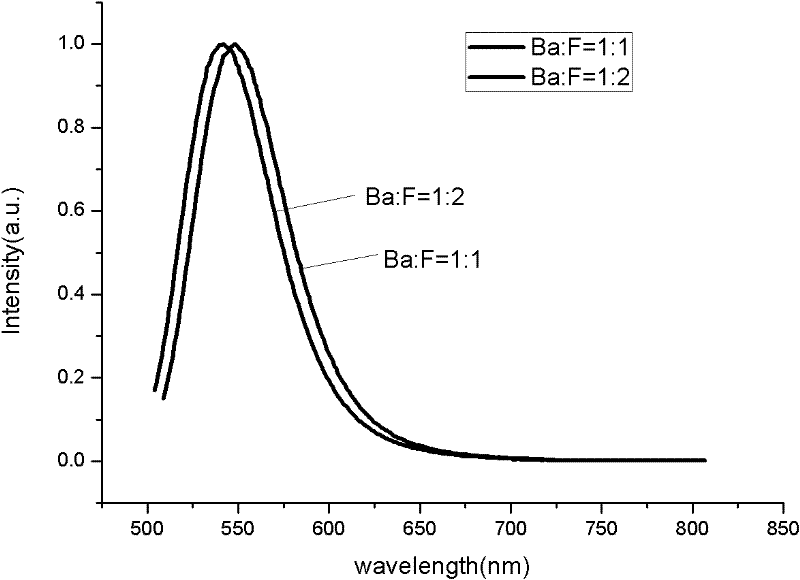

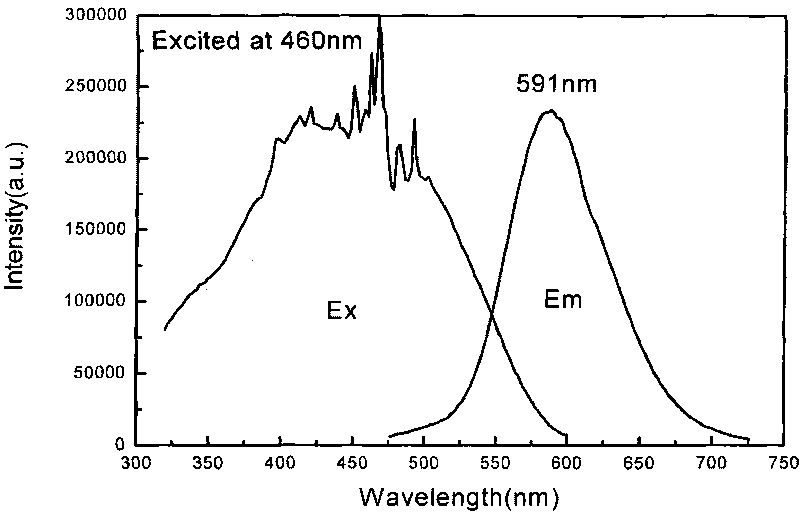

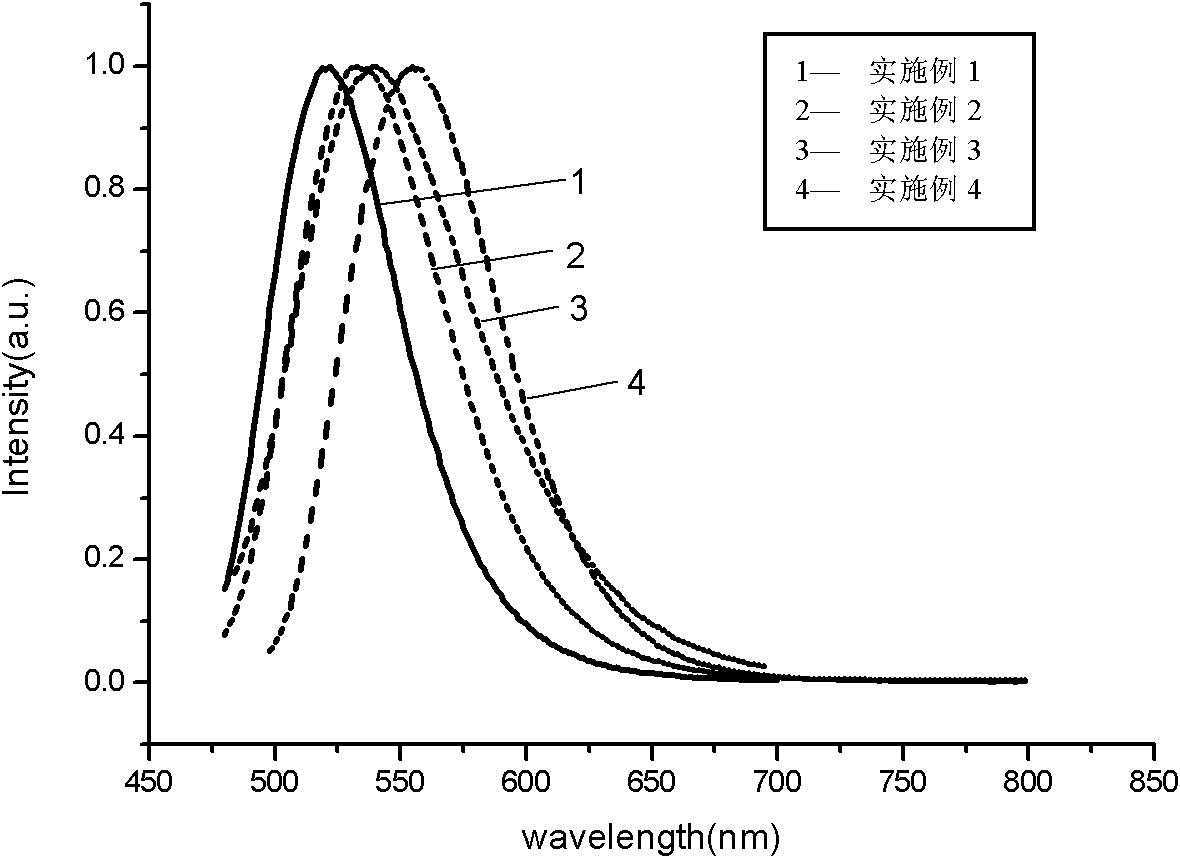

Preparation method of nitrogen oxide green fluorescent powder material

InactiveCN102191045AIncrease brightnessModulation of emission wavelengthGas discharge lamp usageLuminescent compositionsSr elementNitrogen oxides

The invention discloses a nitrogen oxide green fluorescent powder material; and the chemical general formula of the nitrogen oxide green fluorescent powder material is (Ba,A)(2-x)Siy(O,B)zN2+4y-2z:xEu, wherein 0<=x<1.0, 0<y<=1, 1<z<=2.0, A is Ca or Sr element, and B is F or Cl element. In the preparation method, two-step synthesis is adopted to prepare the nitrogen oxide green fluorescent powder and the method comprises the following steps: 1) synthesizing A2SiO4 which is the precursor of the nitrogen oxide green fluorescent powder; and 2) doping elements in the matrix structure provided by the precursor A2SiO4 to synthesize the nitrogen oxide green fluorescent powder material (Ba,A)(2-x)Siy(O,B)zN(2+4y-2z):xEu. By adopting the method, the brightness of the nitrogen oxide green fluorescent powder can be increased and the emission wavelength of the nitrogen oxide green fluorescent powder can be modulated; by adjusting the doping amount of each element, the color gamut of the nitrogen oxide green fluorescent powder can be broadened effectively; and the fluorescent powder can be used to satisfy the lighting demand and used in the white LED backlight with high color rendering index. The method is simple and practical, and is suitable for the large-scale industrial production.

Owner:IRICO

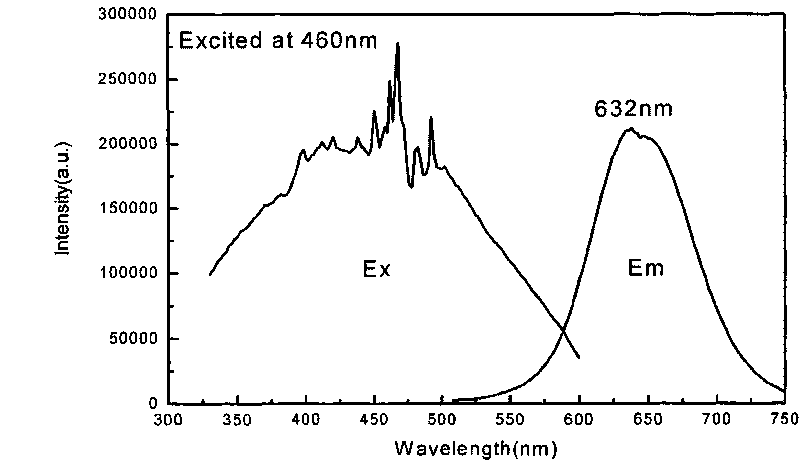

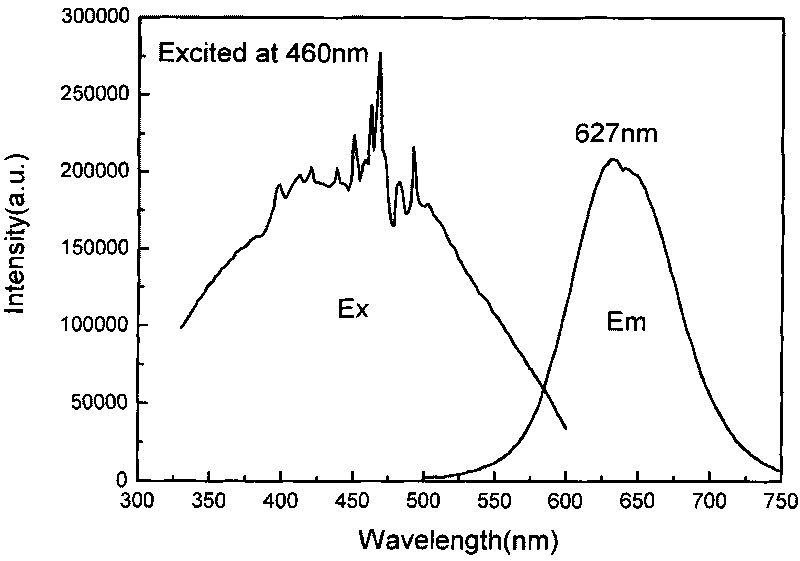

Red luminous silicon-oxygen nitride fluorescent material, preparation method and light emitting device using same

InactiveCN101724401AAdjust emission wavelengthEnhanced emission wavelengthGas discharge lamp usageLuminescent compositionsSr elementSynthesis methods

The invention relates to red luminous silicon-oxygen nitride fluorescent material, preparation method and light emitting device using same. The general formula of the fluorescent material is MIuMIIv(Sil-alphaAalpha)wO deltaN(2 / 3(u+v)+4 / 3w-2 / 3delta): Eux, Ry, Dz, wherein MI is a Ca or Sr element; MII is selected from at least one element of Sr or Ca, Ba and Zn; A is selected from at least one element of Ge, Al, Ca and In; R is selected from at least one element of Nd, Dy, Ho, Tm, Ce, Er, Pr, Bi, Sm, Yb, Lu, Gd, Tb and Mn; D is selected from at least one ion of F-, Cl-, Br- and I-; and u, v, w, alpha, delta, x, y and z are molar coefficients. The fluorescent material capable of being excited by ultraviolet-blue-green light and emitting red light is prepared by adopting a normal pressure self-reduction synthesis method and applied to manufacture LED devices.

Owner:DALIAN LUMINGLIGHT SCIENCE & TECHNOLOGY CO LTD

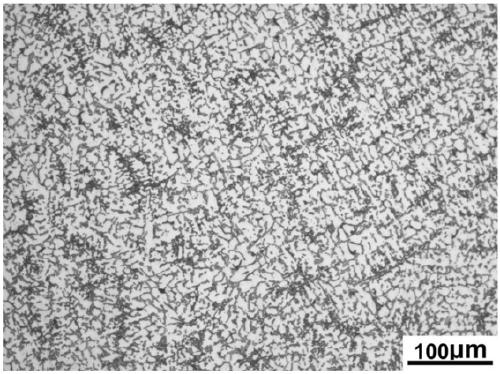

Compound processing method for simultaneously improving heat-conducting and mechanical properties of die casting aluminum alloy

The invention discloses a compound processing method for simultaneously improving heat-conducting and mechanical properties of die casting aluminum alloy. The method comprises the steps of preparing and melting aluminum alloy first, adding Al-B intermediate alloy for B treatment, controlling the processing temperature between 700 and 730 DEG C, mixing until alloy components are uniform, standing and insulating, and controlling the weight percent of the B element to be 0.03 to 0.15% of the total weight of the alloy; adding Al-Sr and Al-Re intermediate alloy to melt for compound modification treatment, controlling the processing temperature between 680 and 720 DEG C, mixing until the alloy components are uniform, standing and insulating, and controlling the weight percent of the Sr element to be 0.03 to 0.2% of the total weight of the alloy; and performing refining and deslagging treatment, and discharging for cast forming after slagging off so as to obtain the compound aluminum alloy melt. The compound processing method has the advantages of simple and convenient process, easiness in implementation, easiness in control over the addition and obvious effect, and the heat-conducting and mechanical properties of the die casting aluminum alloy can be simultaneously improved and increased.

Owner:SOUTH CHINA UNIV OF TECH +1

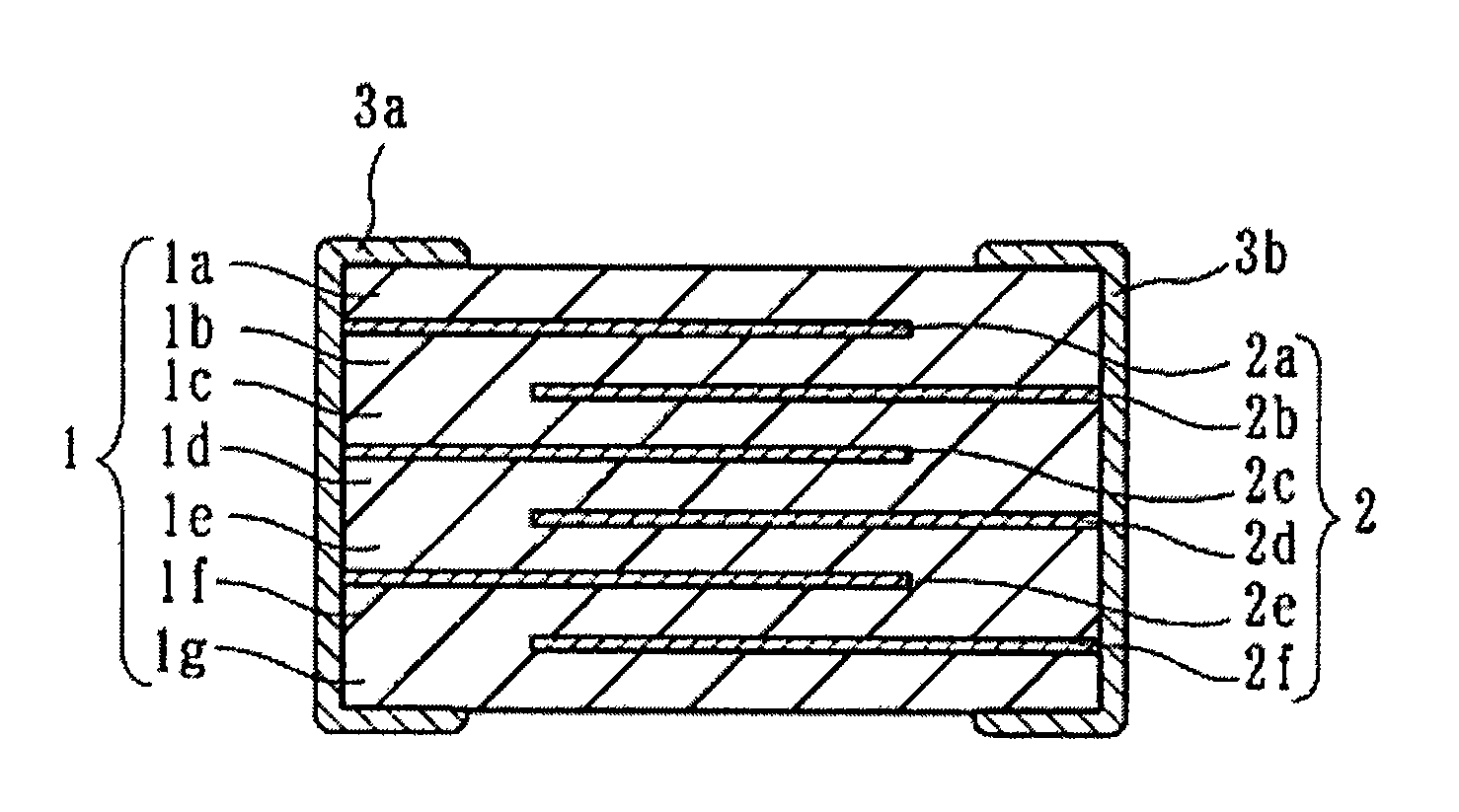

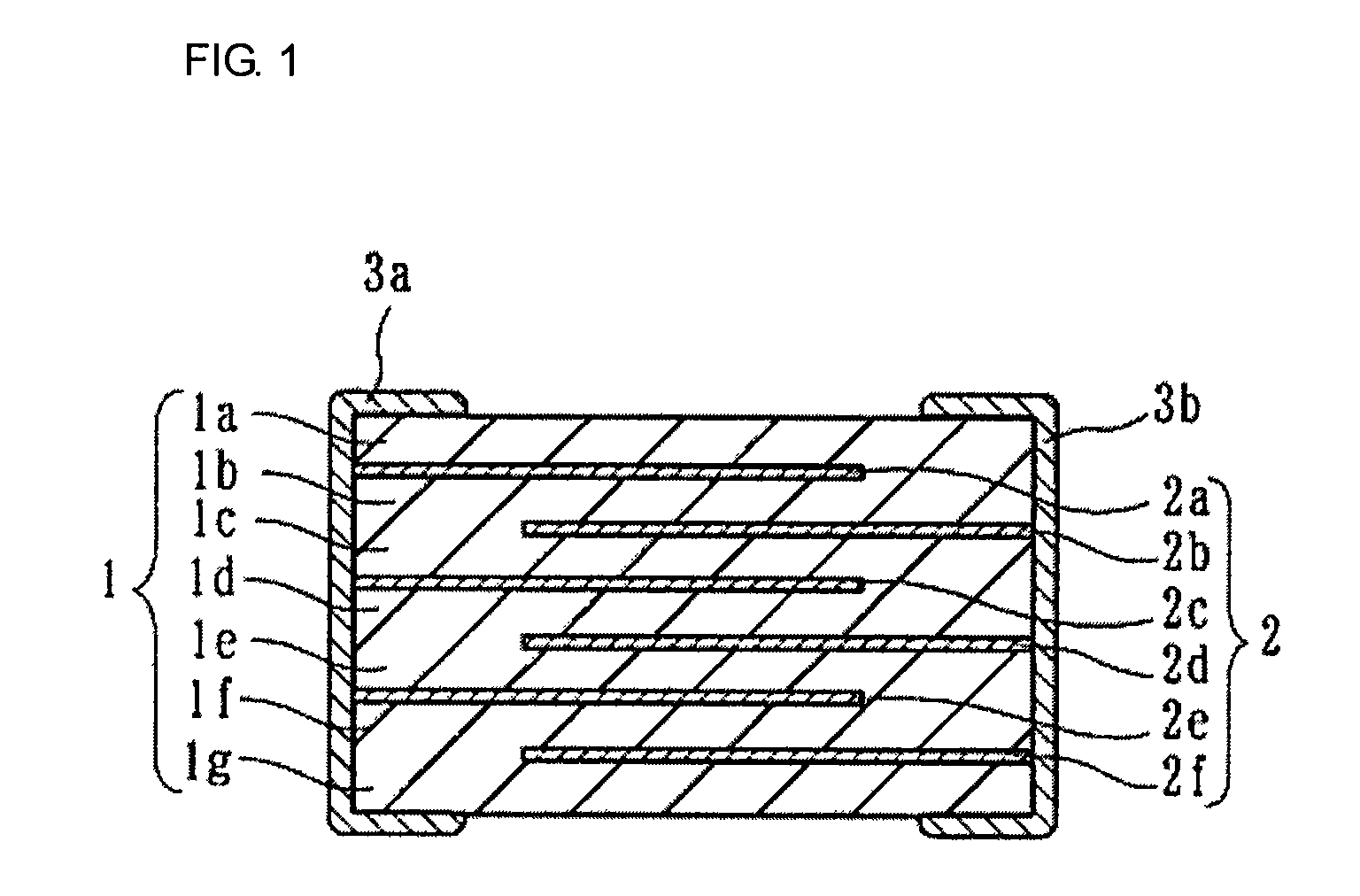

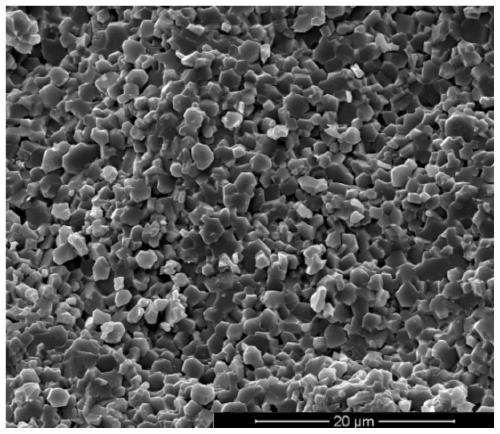

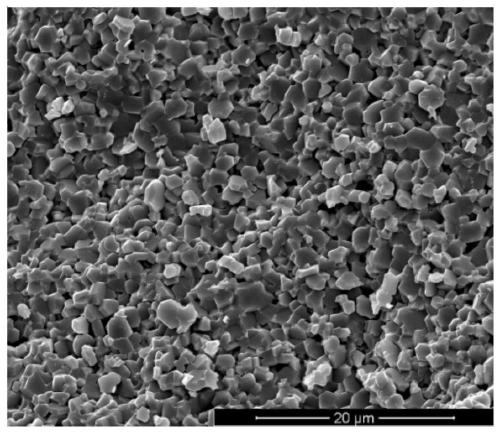

Semiconductor ceramic and multilayered-type semiconductor ceramic capacitor

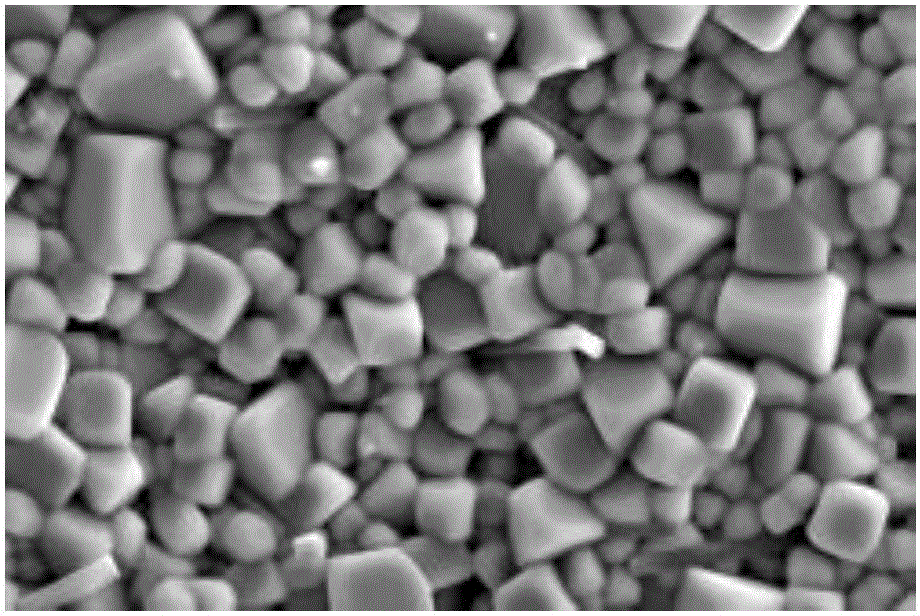

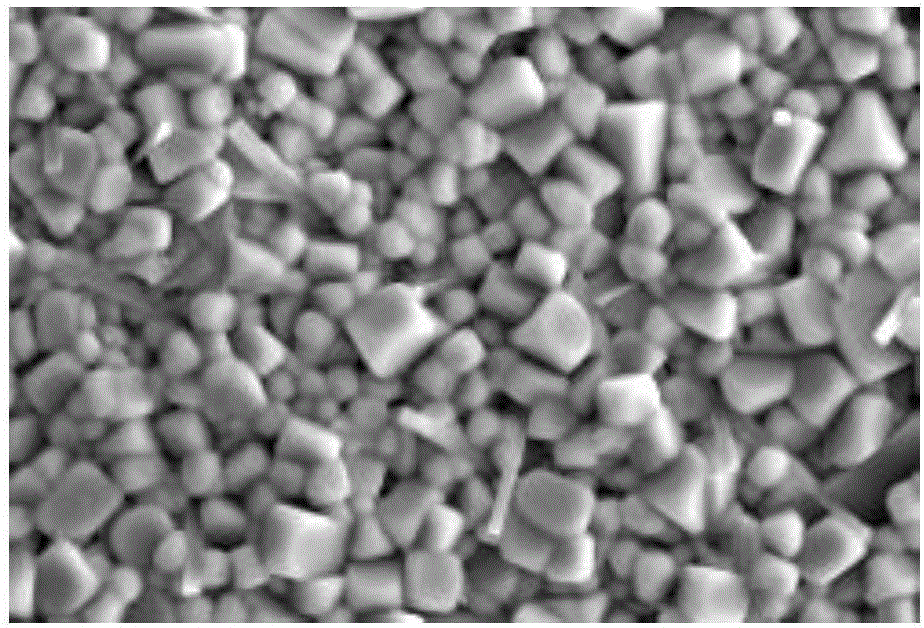

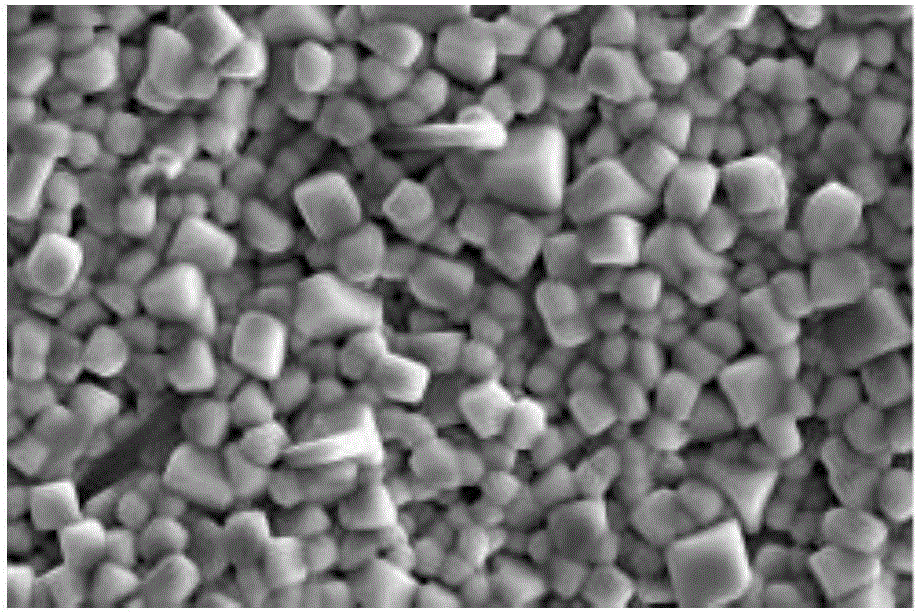

A semiconductor ceramic has a mixing molar ratio m between the Sr site and the Ti site satisfying the relationship 1.000≦m<1.020, a donor element in an amount of 0.8 to 2.0 moles relative to 100 moles of the Ti element dissolved in the Sr site to form a solid solution, the donor element having a higher valency than the Sr element, a transition metal element, such as Mn, incorporated in an amount of 0.3 to 1.0 mole relative to 100 moles of the Ti element so as to be segregated in grain boundaries, and an average grain size of crystal grains is 1.0 μm or less. A component body in which semiconductor ceramic layers are stacked and internal electrodes 2 are embedded provides a SrTiO3-based grain boundary insulation type semiconductor ceramic having a high apparent relative dielectric constant of 5,000 or more even if the average grain size of crystal grains is decreased to 1 μm or less, and a semiconductor ceramic capacitor in which it is possible to achieve both a reduction in layer thickness and improvement in dielectric characteristics by using the SrTiO3-based grain boundary insulation type semiconductor ceramic.

Owner:MURATA MFG CO LTD

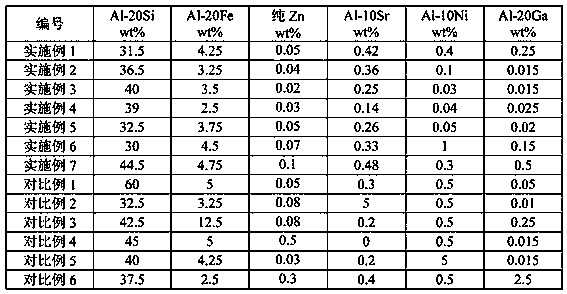

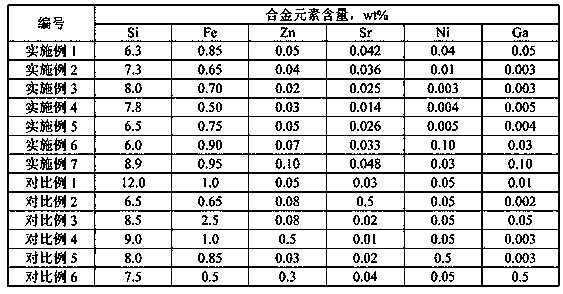

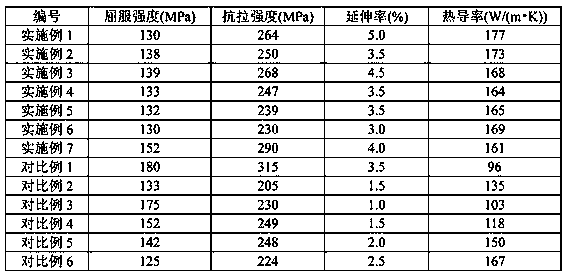

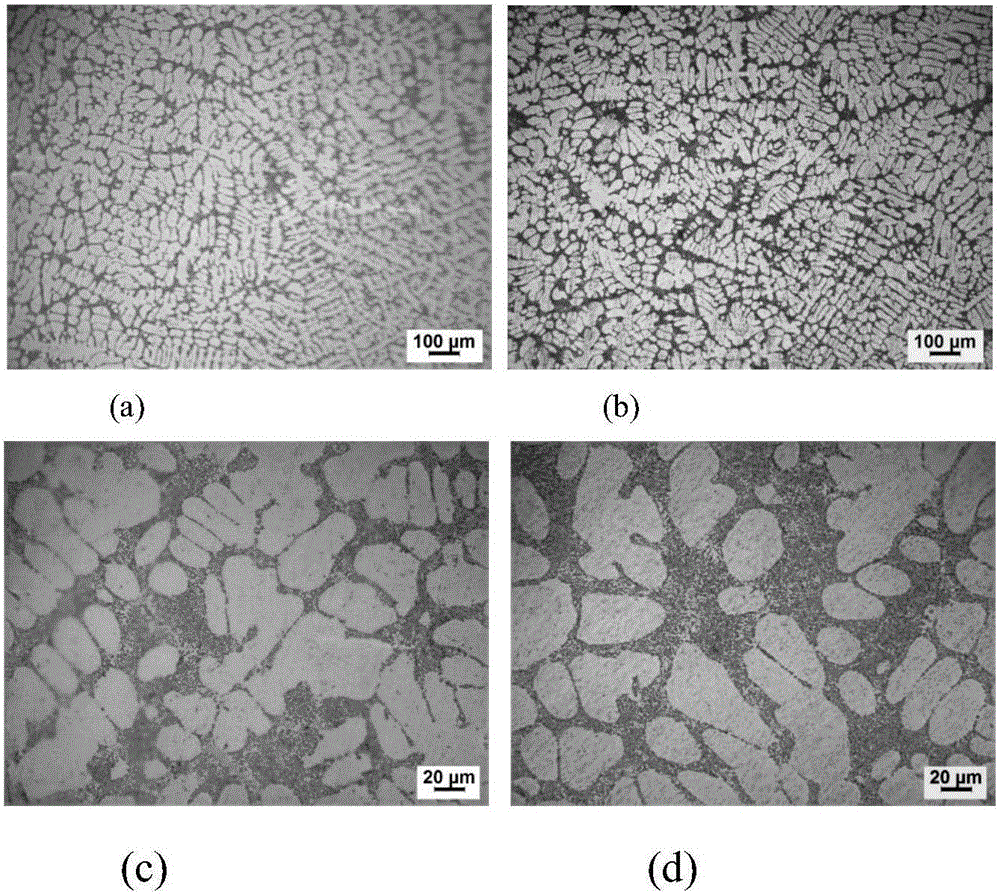

Die-casting aluminum alloy and preparation method and application thereof

ActiveCN110527871AImprove mechanical propertiesImprove thermal conductivitySr elementHeat conducting

The invention discloses a die-casting aluminum alloy. The die-casting aluminum alloy comprises, by weight percentage composition, 6.0%-9.0% of Si, 0.5%-1.0% of Fe, 0.01%-0.1% of Zn, 0.01%-0.05% of Sr,0.001%-0.1% of Ni, 0.001%-0.1% of Ga and the balance Al and inevitable impurity elements. According to the die-casting aluminum alloy and the preparation method thereof, the content of Si is reasonably adjusted, Zn and Sr elements are added according to a certain proportion on the basis, and the content of Fe, Ni and Ga elements is controlled, so that the prepared die-casting aluminum alloy has the good mechanical property, heat-conducting property and relatively higher elongation.

Owner:BYD CO LTD

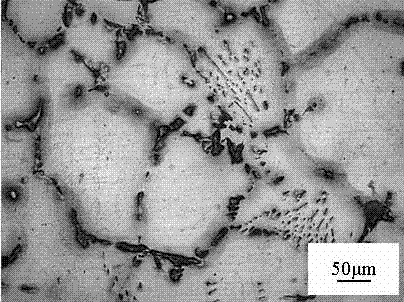

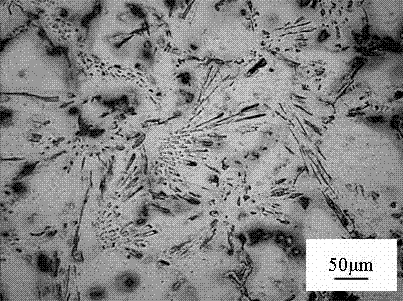

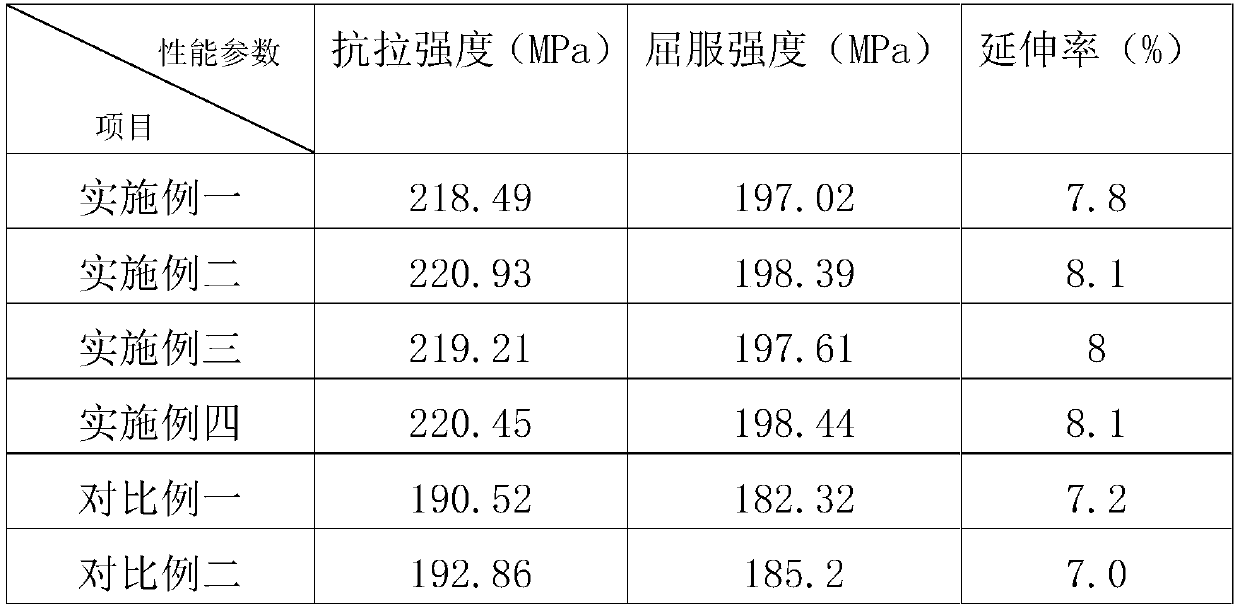

Composite refinement and modification method for improving mechanical performance of aluminium alloy

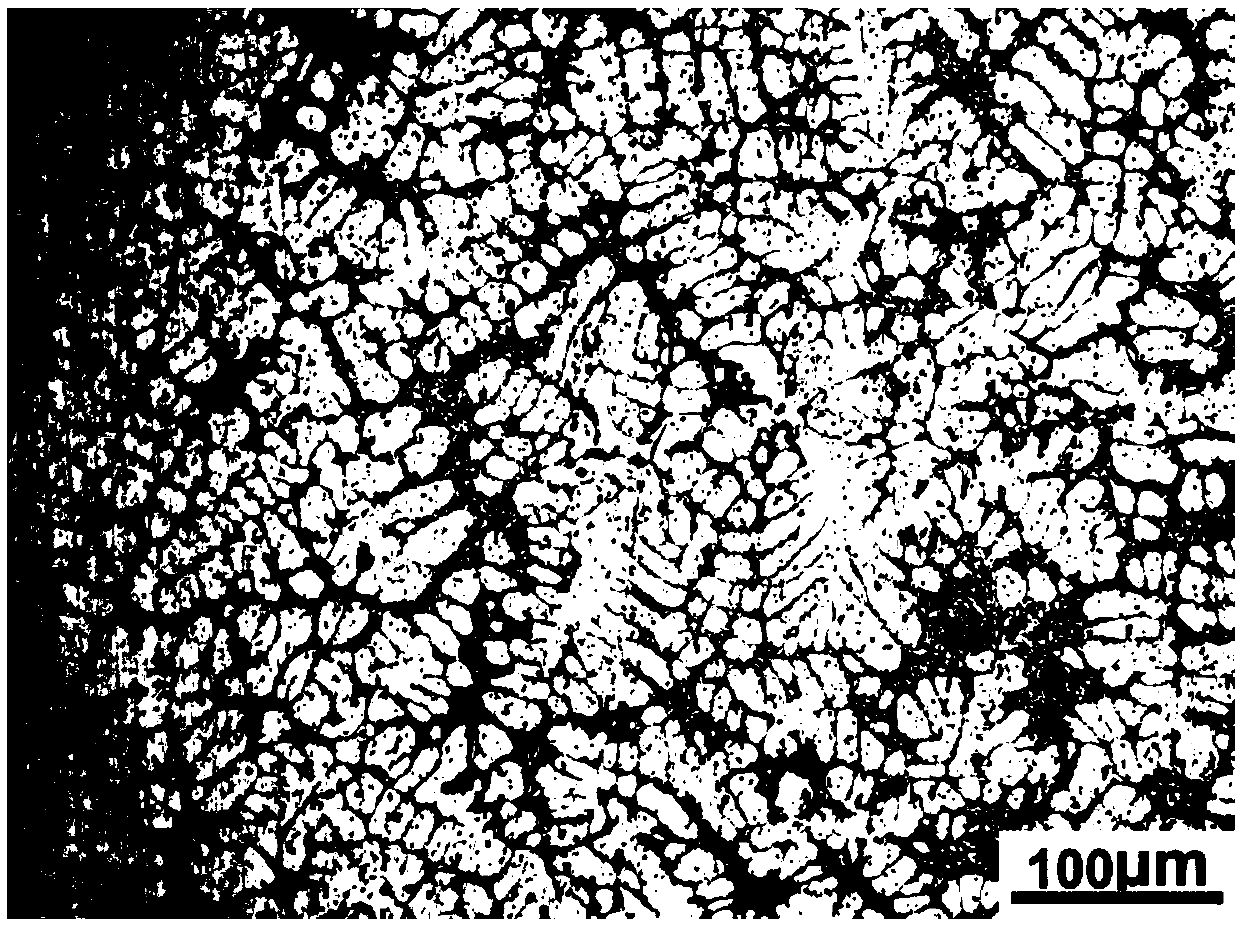

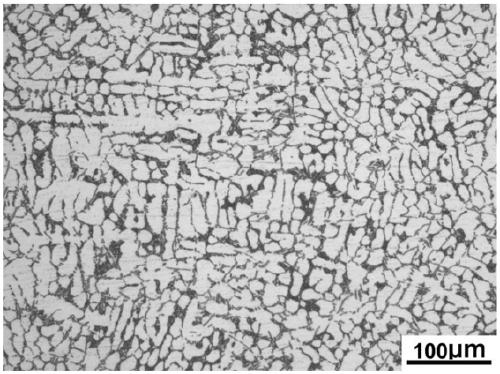

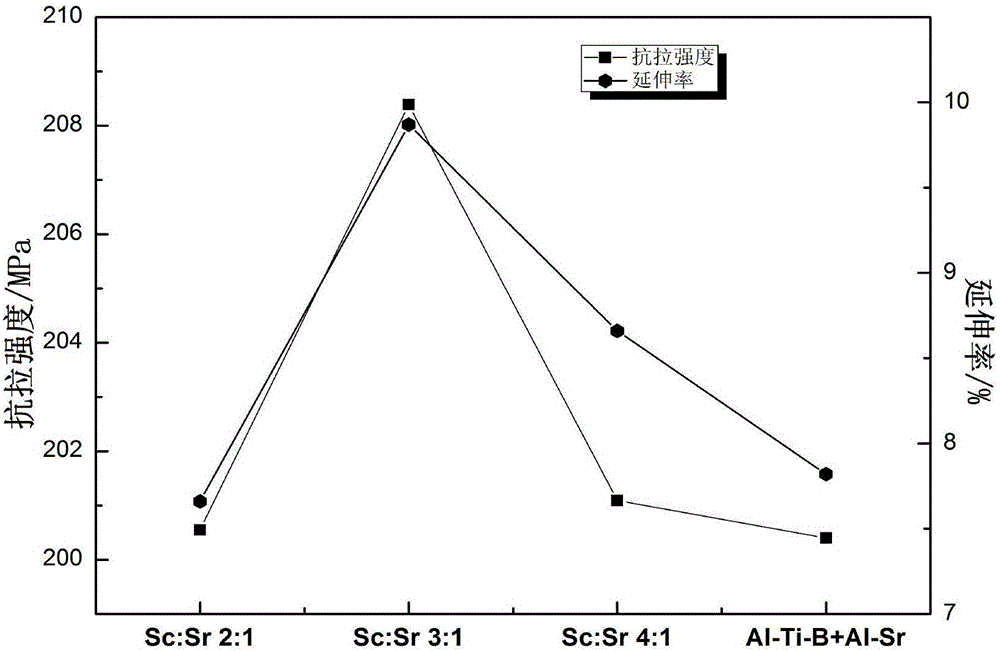

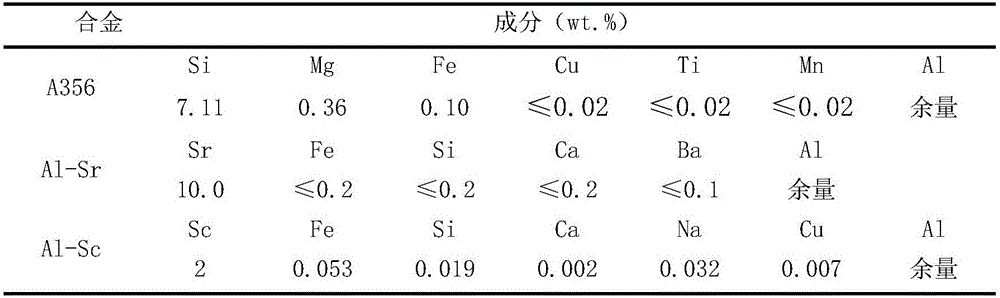

The invention discloses a composite refinement and modification method for improving mechanical performance of an aluminium alloy. The method comprises steps as follows: an alloy A356.2 is smelted and refined for 3-5 min; then an Al-2Sc intermediate alloy and an Al-10Sr intermediate alloy are sequentially added to an alloy liquid, wherein the mass percentage of Sc ranges from 0.02%-0.08%, the mass percentage of Sr ranges from 0.02%-0.03%, and the mass ratio of Sc to Sr ranges from 2:1 to 4:1; after the temperature is kept for 8-12 min, argon is introduced for refinement again for 3-5 min; and after the mixture is left to stand for 5-10 min, the refined and modified aluminium alloy A356.2 is obtained. With the method, traces of rare earth Sc and Sr elements are added to the aluminium alloy A356.2, and the ratio of Sc to Sr is reasonably designed, so that grains in the aluminium alloy A356.2 are remarkably reduced, and the relatively good refinement effect is realized. The tensile strength is up to 208.39 MPa and is 4% higher than that of an alloy treated with a traditional refinement and modification agent, and the ductility is up to 9.87% and is 26.2% higher than that of the alloy treated with the traditional refinement and modification agent.

Owner:HEBEI UNIV OF TECH

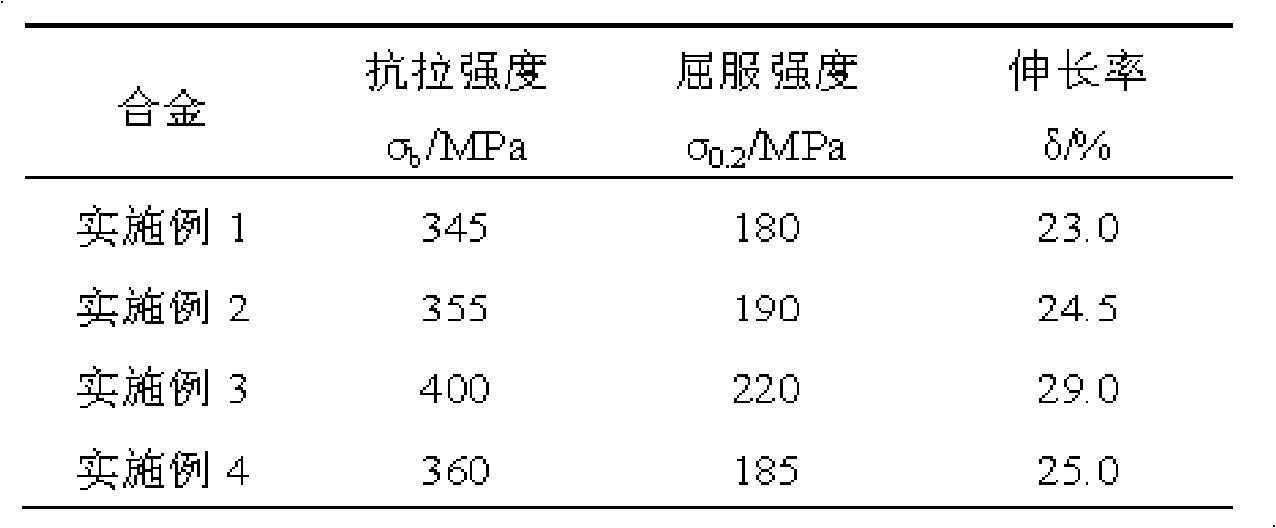

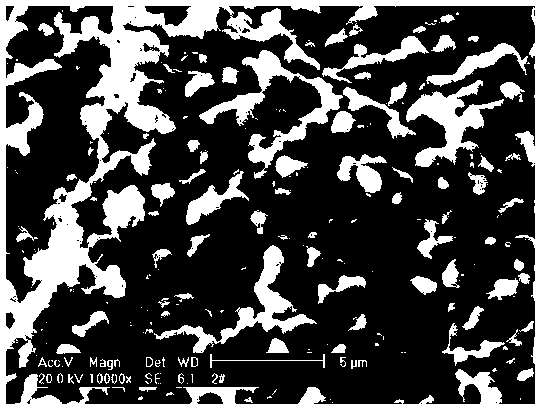

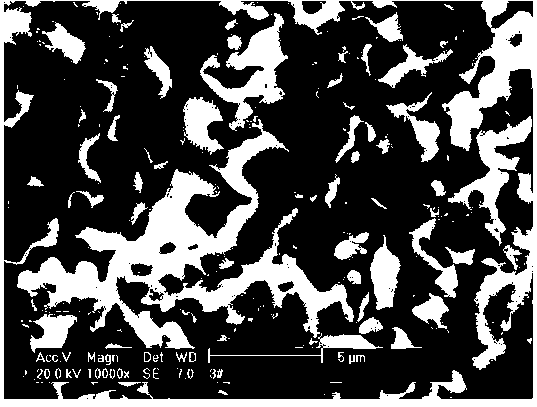

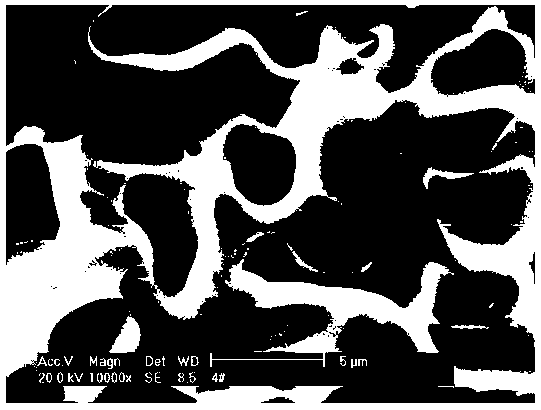

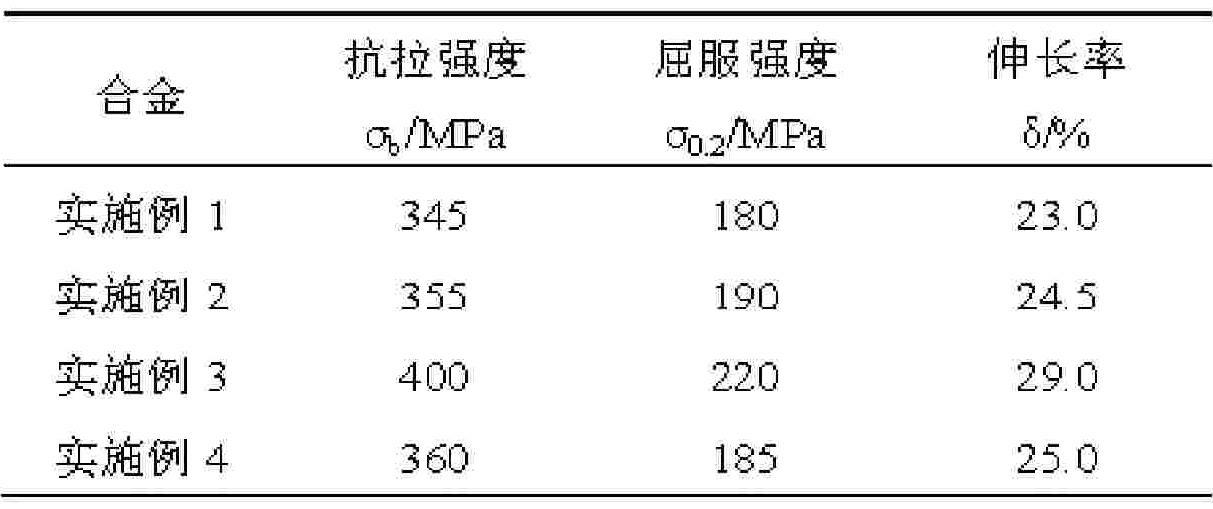

Al-Mg-Mn-Zr-Sr alloy and preparation method thereof

The invention relates to a medium- and high-strength, high-toughness and weldable Al-Mg-Mn-Zr-Sr alloy containing strontium, which consists of the components of Al, MG, Mn, Zr and Sr. A preparation method thereof comprises the following steps: preparing raw materials according to the weight percentage of each component; then heating the components to 820 DEG C to 850 DEG C, totally melting, reducing temperature, standing, refining with C2Cl6, pouring into a preheat mould; after homogenizing cast ingot, heating, and extruding to deform with the extruding ratio of 12. The invention is reasonablein component proportion, easy to process and manufacture, simple in operation process and uses Sr element for alloying, thereby effectively improving the organizational structure of aluminum alloy, the comprehensive mechanical property of aluminum alloy and is adapted for industrialized application. The invention provides an achievable way to improve the comprehensive mechanical property of the medium- and high-strength and weldable aluminum alloy in the Al-Mg-Mn-Zr-Sr system.

Owner:CENT SOUTH UNIV

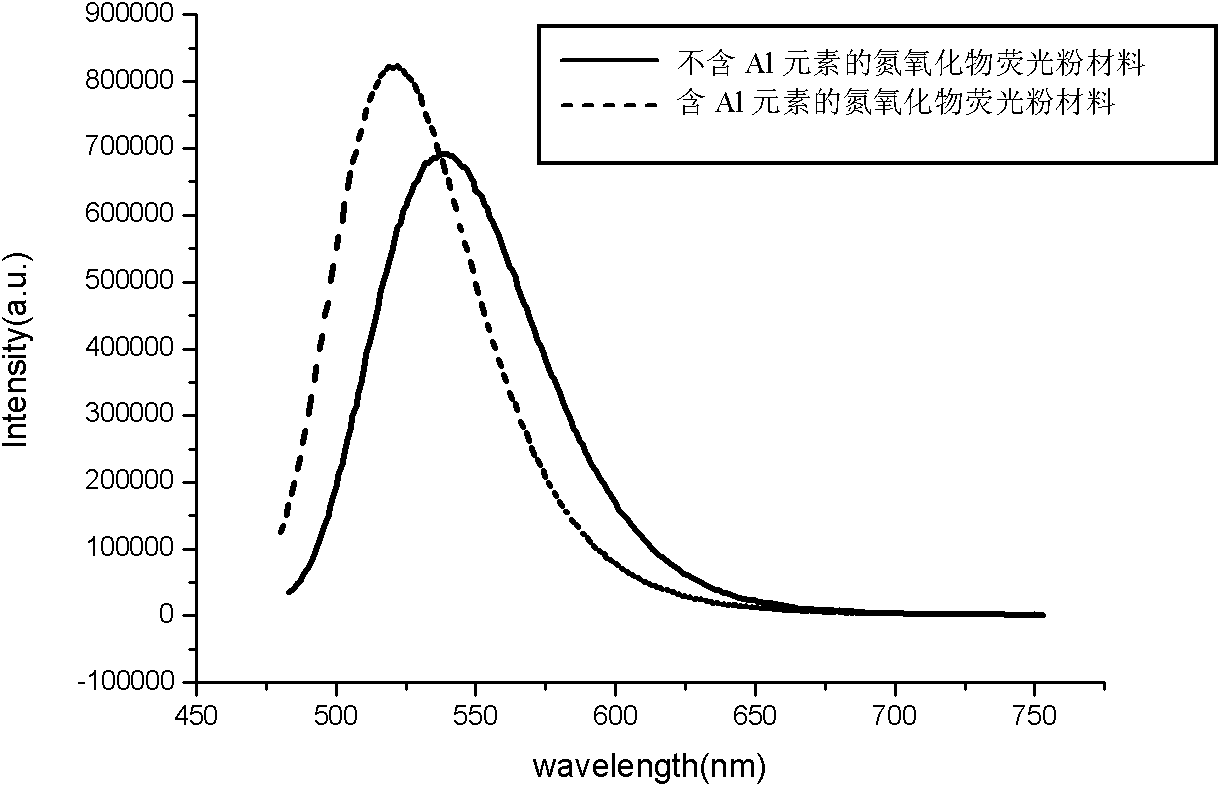

Oxynitride green emitting phosphor material containing AL element and preparation method thereof

InactiveCN101948689ADoping effectiveStable crystal structureLuminescent compositionsSr elementPhosphor

The invention relates to an oxynitride green emitting phosphor material containing AL element and a preparation method thereof. The preparation method adopts two steps to synthesize oxynitride green emitting phosphor, wherein in the first step, a precursor A2SiO4 of the oxynitride green emitting phosphor containing the AL element is synthesized, wherein A is one of Ca, Ba or Sr element; and in the second step, the AL element is doped in a substrate structure provided by the precursor, and the emission wavelength of the oxynitride green emitting phosphor as shown in Al-x(Si, Al) yOzN2 / 3+4 / 3y-2 / 3z: xEu is modulated by adjusting the proportion of Si and Al elements so that the emission peak of the product is between 520nm and 540nm. In the method, an Al element-doping mode is used to reduce the synthesis temperature of the oxynitride green emitting phosphor. The invention particularly relates to a method for modulating the emission wavelength of the oxynitride green emitting phosphor, and the method is simple and practicable, and is applicable to large-scale industrial production.

Owner:IRICO

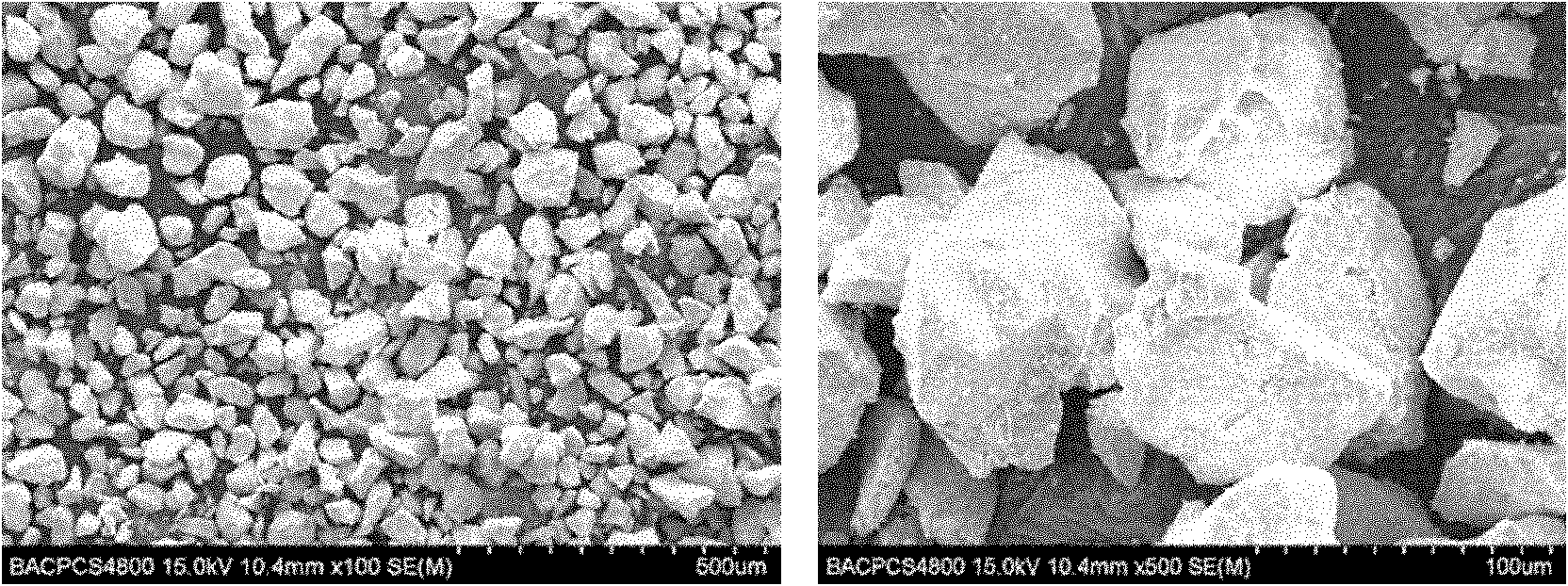

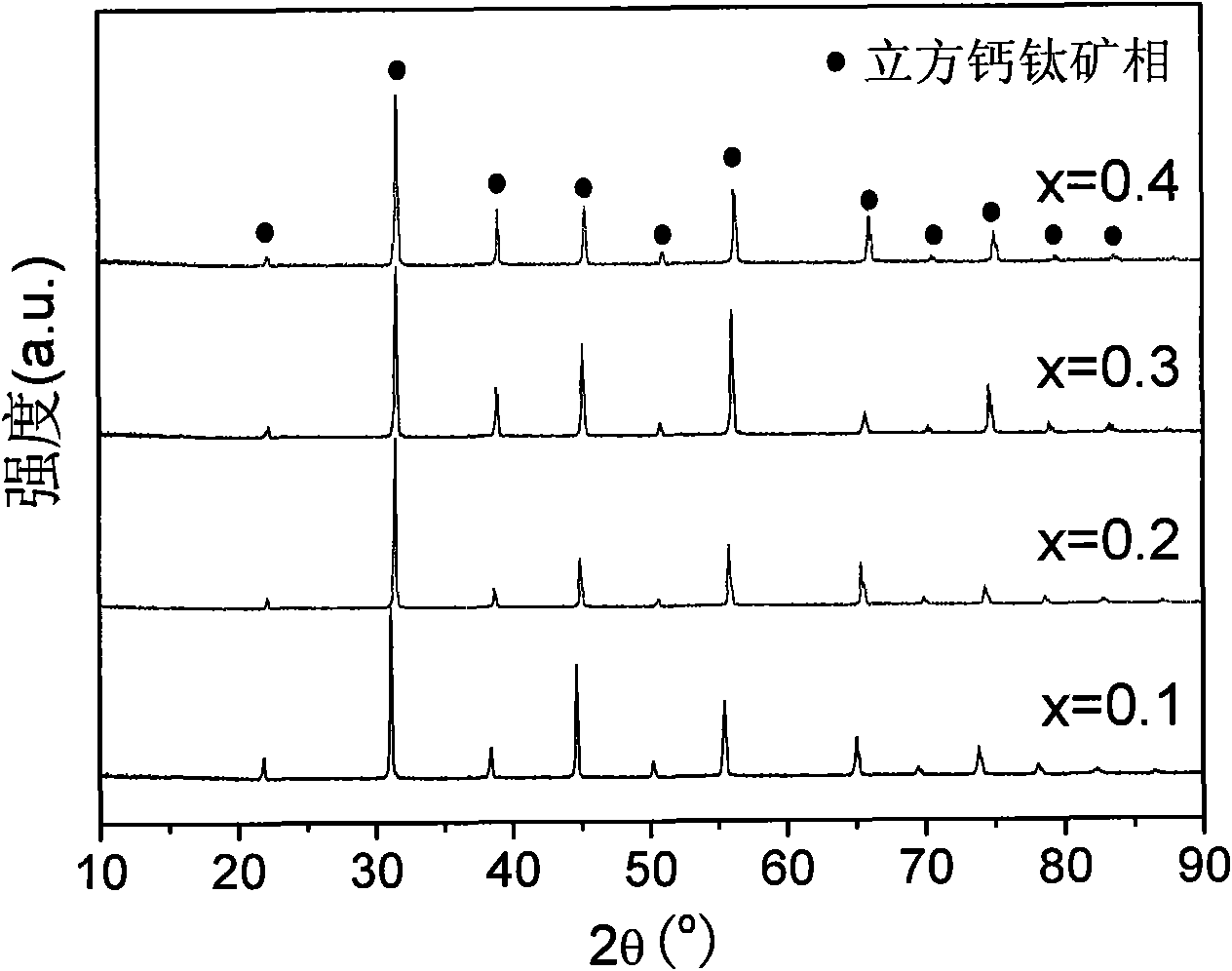

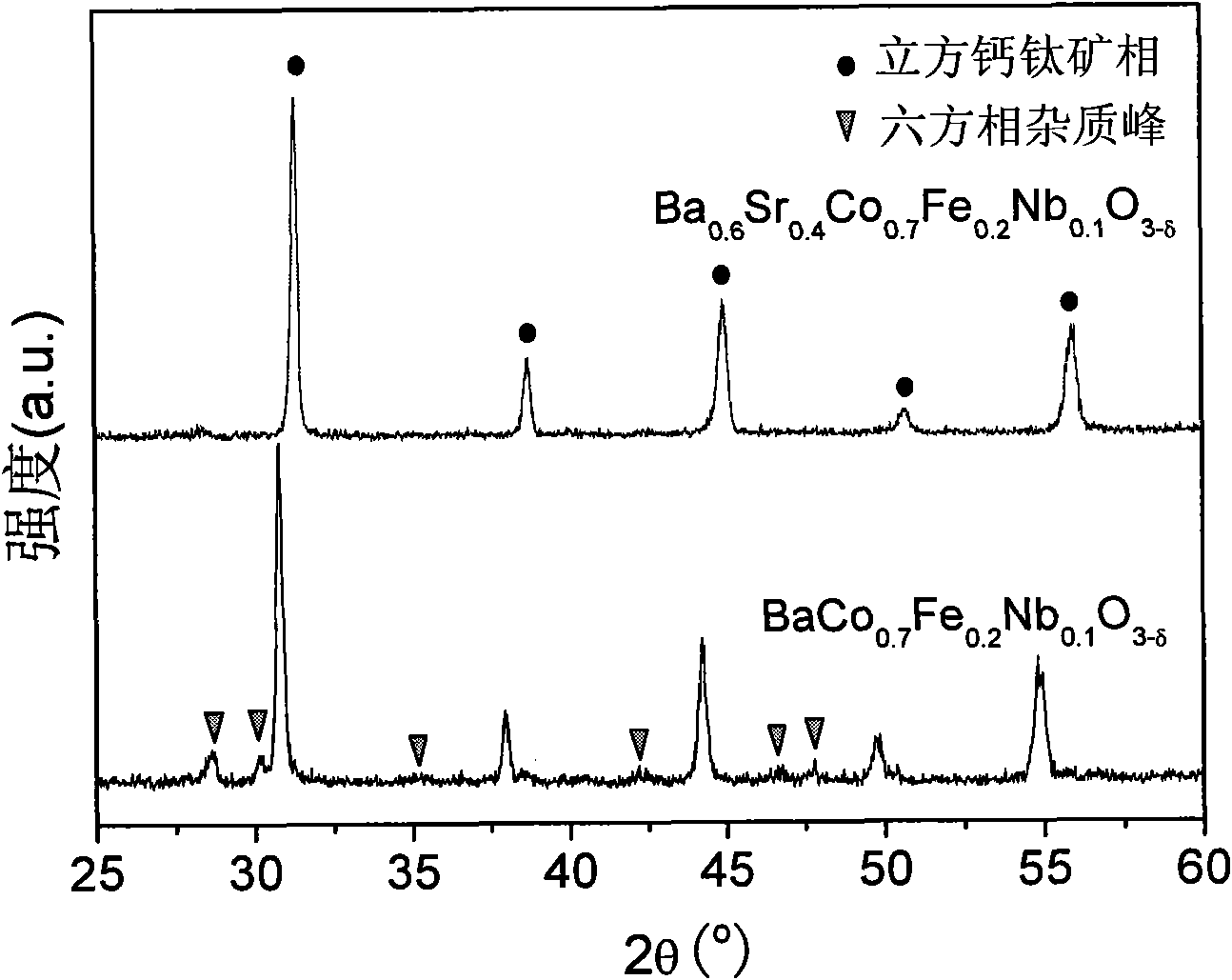

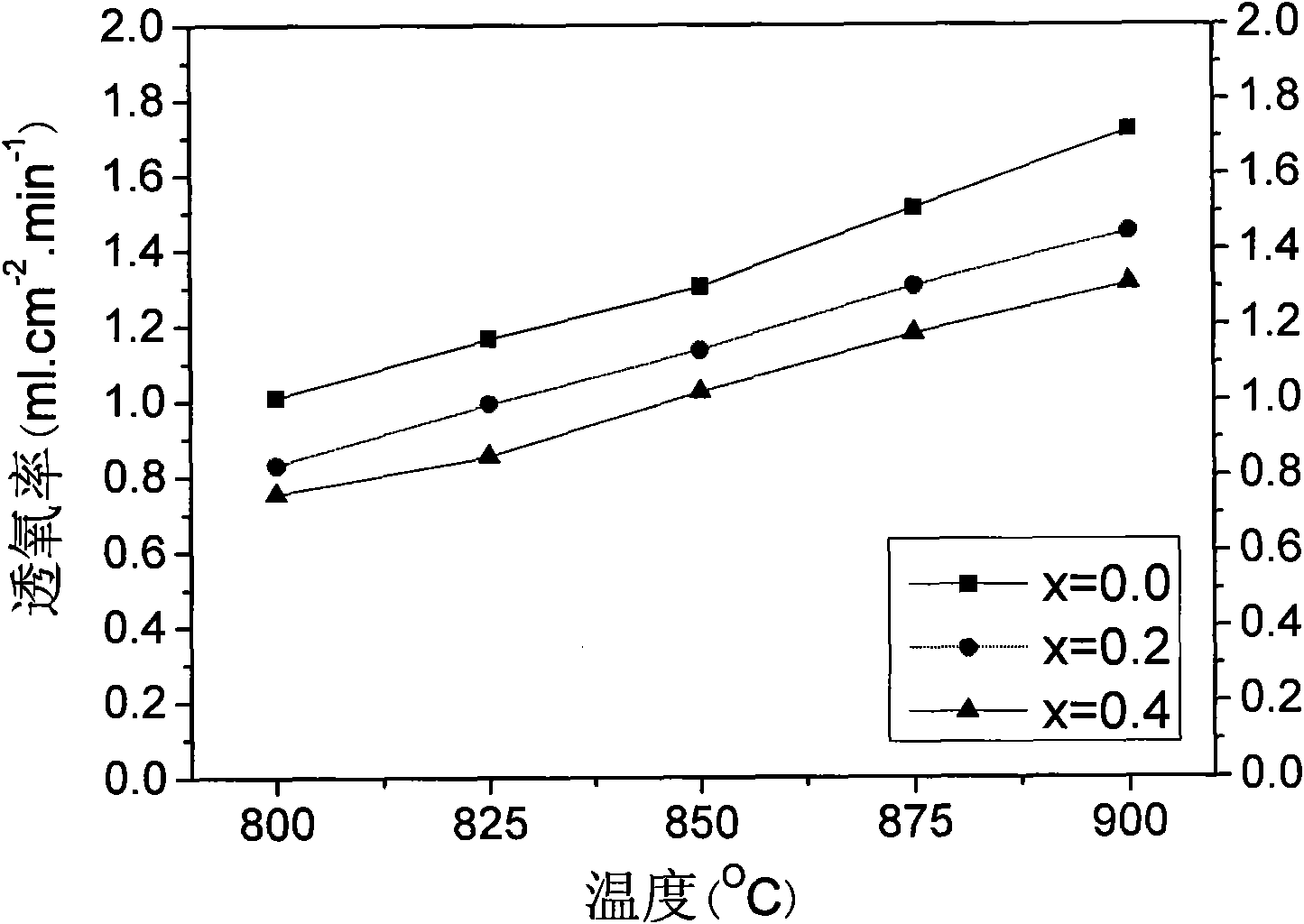

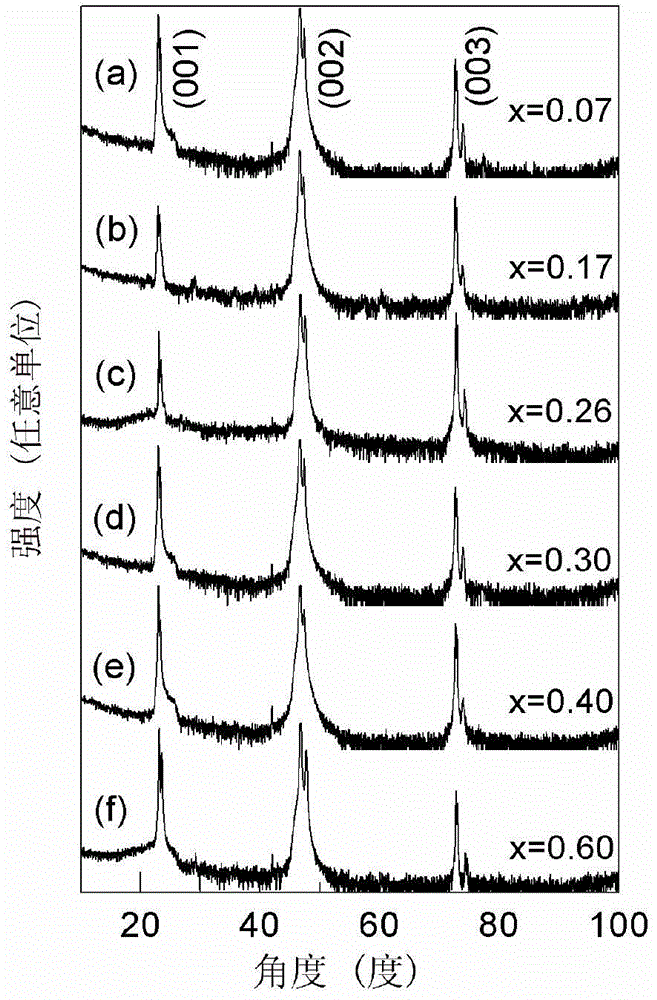

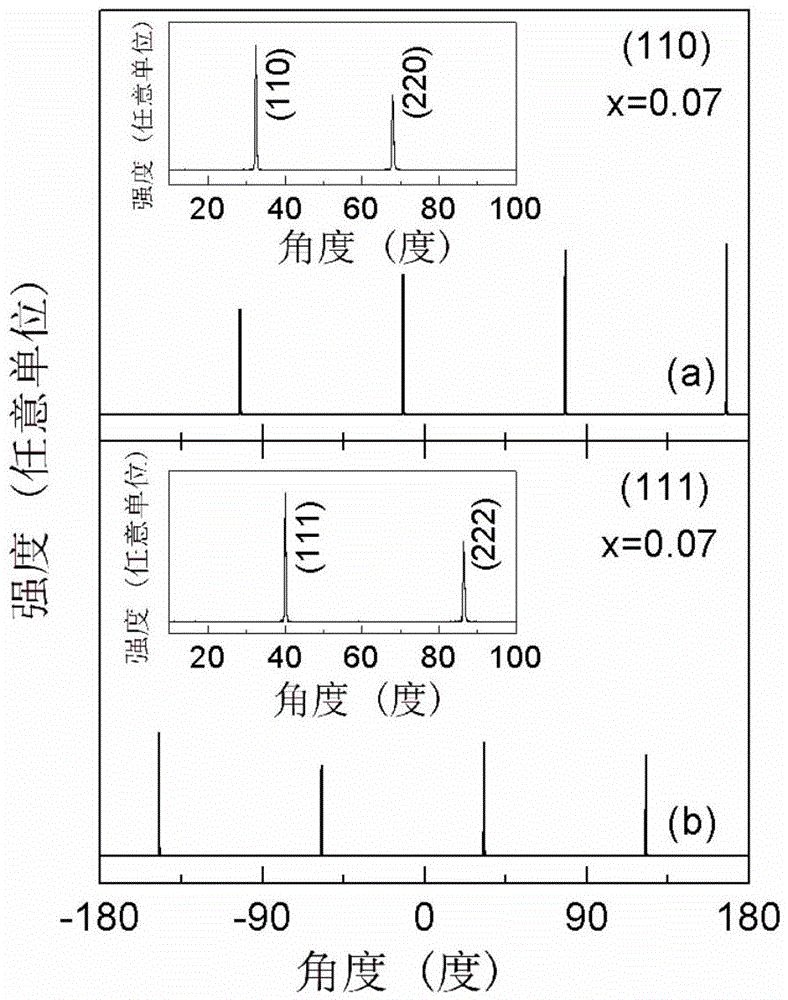

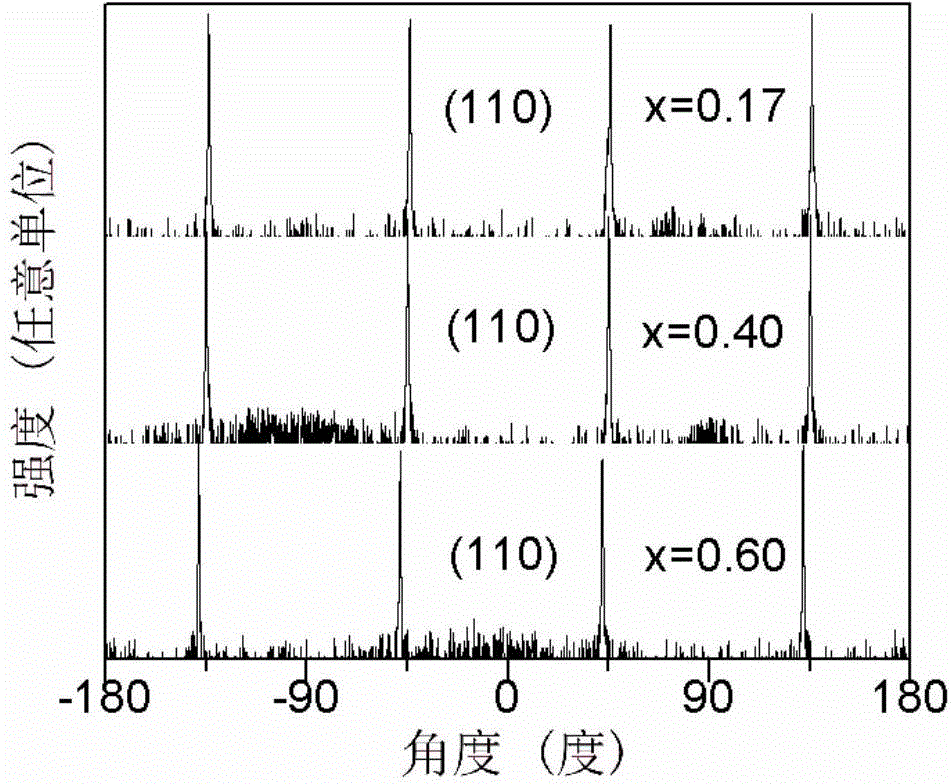

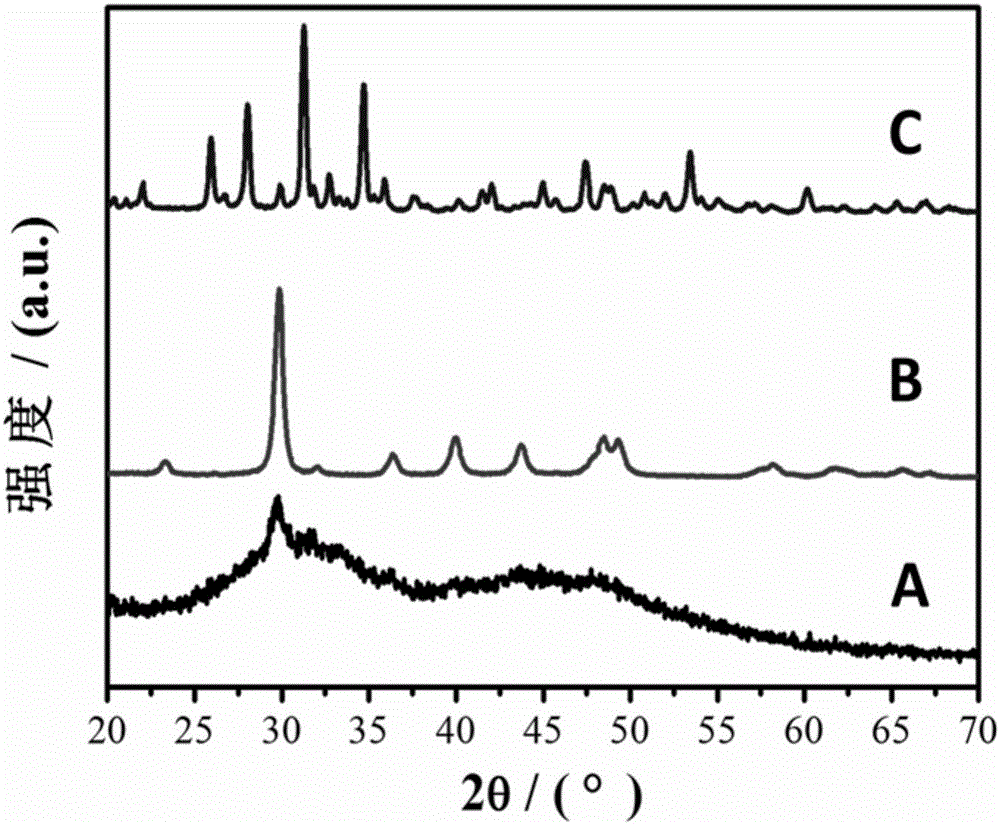

Method for improving structural stability of BaCo0.7Fe0.2Nb0.1O3-Delta oxygen permeation membrane material

InactiveCN101575210AImprove resistance to reductionGood solid solution effectSemi-permeable membranesHydrogenSr elementConcentration gradient

The invention relates to a method for improving the structural stability of a BaCo0.7Fe0.2Nb0.1O3-Delta oxygen permeation membrane material, which belongs to the technical field of oxygen permeation membranes. The method is characterized in that Sr element is doped into the BaCo0.7Fe0.2Nb0.1O3-Delta base material with a perovskite structure, and the obtained oxygen permeation membrane material has a chemical formula of Ba1-xSrxCo0.7Fe0.2Nb0.1O3-Delta, wherein x is equal to 0.05-0.4. The oxygen permeation membrane material provided by the method remarkably improves the phase structure stability of the BaCo0.7Fe0.2Nb0.1O3-Delta base material under the condition of high temperature and low oxygen partial pressure, and the improved oxygen permeation membrane material can be applied within wider oxygen partial pressure range and under larger oxygen concentration gradient.

Owner:UNIV OF SCI & TECH BEIJING

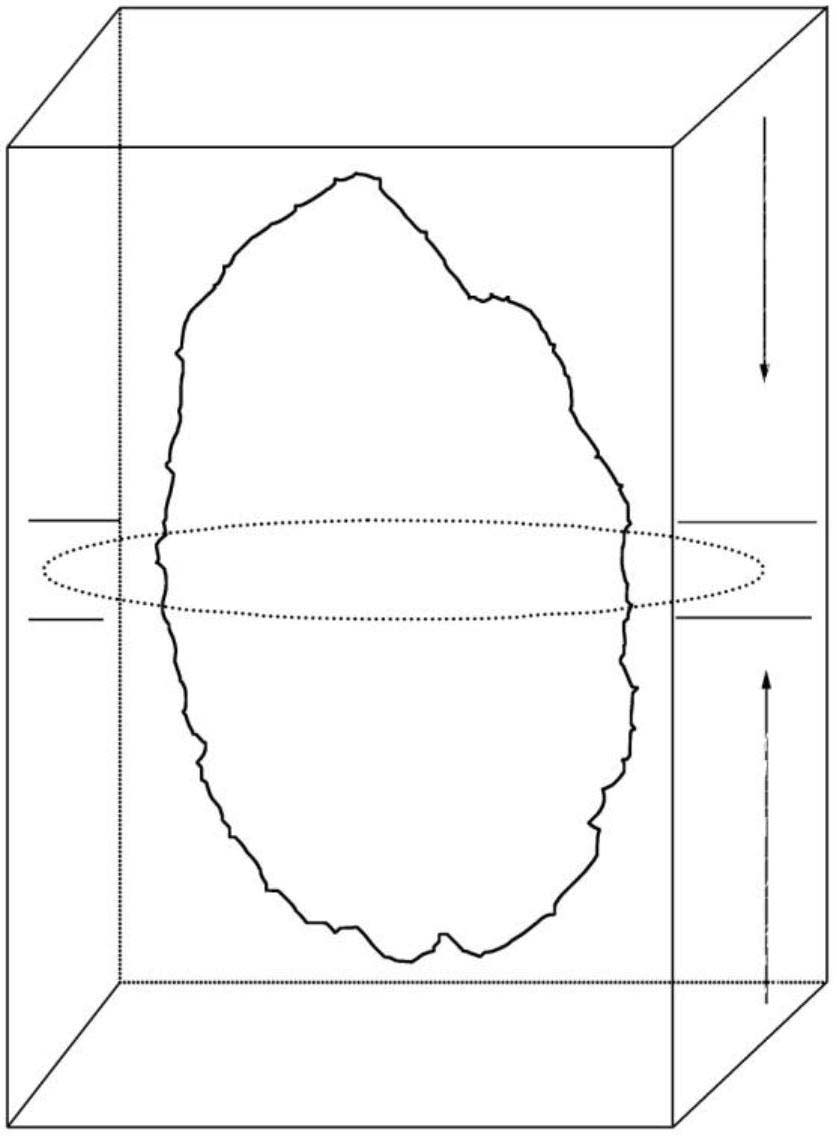

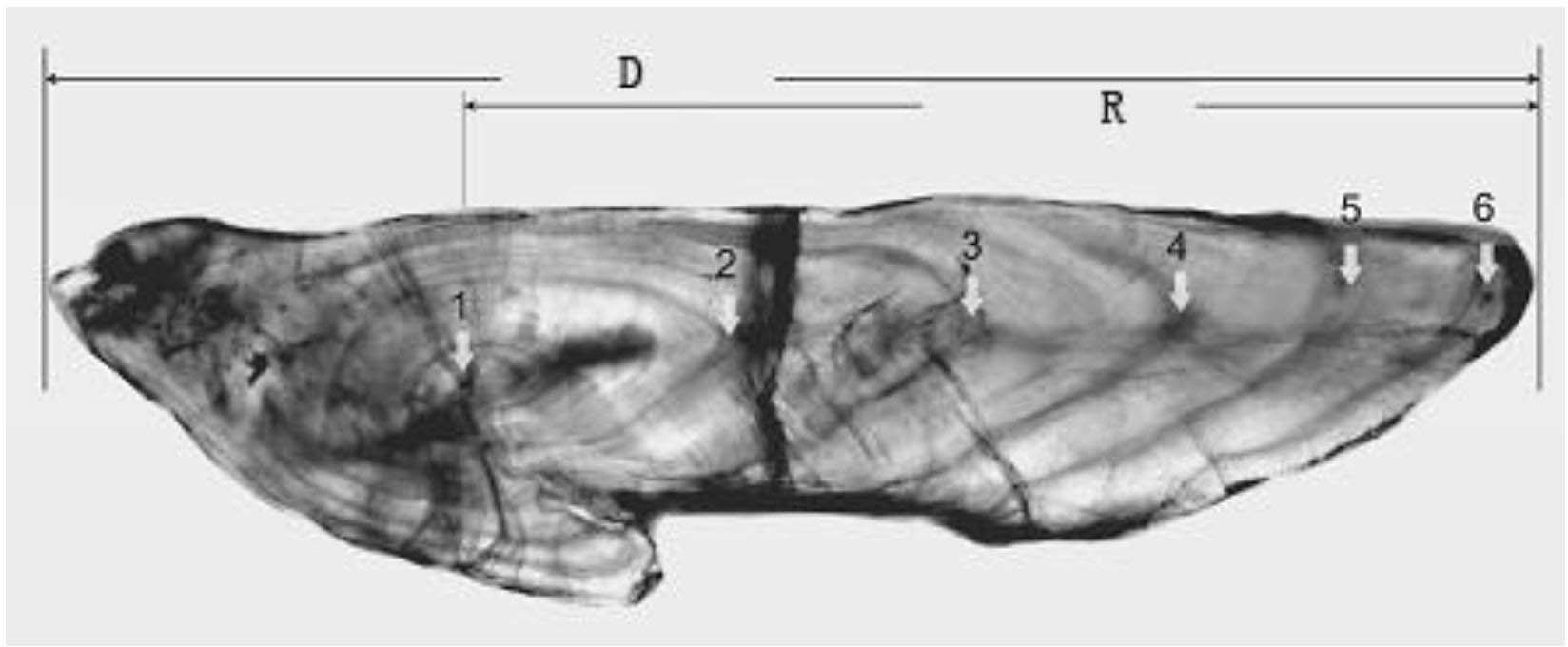

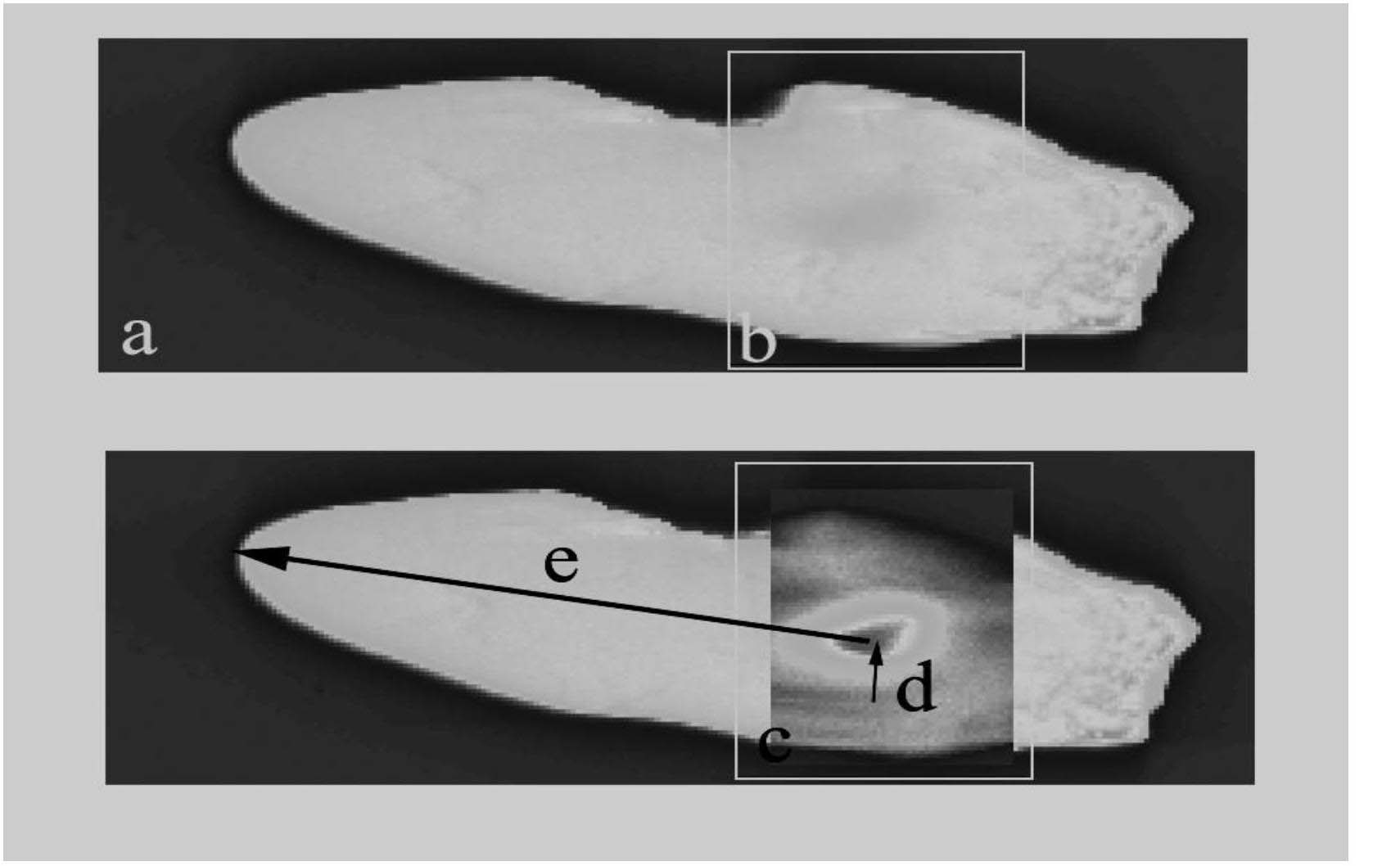

Method for researching migratory behaviour of anguilla japonica by employing otolith microchemistry

InactiveCN102687693AReduce measurement errorHigh detection sensitivityClimate change adaptationPisciculture and aquariaRiver mouthSr element

The invention discloses a method for researching migratory behaviour of anguilla japonica by employing otolith microchemistry, wherein the migratory behaviour of anguilla japonica is determined by analyzing the microchemical constitution of the cross section of otolith life history of anguilla japonica by using a proton scanning microprobe technique, and the process comprises otolith excavating, embedding, flaking, film bonding, otolith centering, life history cross section scanning, guide sample correction and life history analysis. The invention provides a method which is capable of accurately positioning the center of otolith, sensitive in detection and quick in analyzing Sr / Ca ratio change in the cross section of the otolith life history, so that the following problems are solved: low Sr element content in otolith, long detection time, big errors, difficulty in accurate positioning because the center of an otolith ground slice of anguilla japonica is not at the geometric center, easiness in loss of information of partial stages of the life history caused by the use of a quick line scanning manner, and the like; and in combination with the annual ring marks of the otolith, the migratory behaviour of anguilla japonica at habitats such as fresh water, river mouths, oceans and the like can be effectively analyzed.

Owner:SHANGHAI OCEAN UNIV

Preparation method of epitaxial lanthanum strontium cobalt oxide film based on radio-frequency reactive sputtering

InactiveCN104404464AChoose simpleIncrease usageVacuum evaporation coatingSputtering coatingSr elementOxygen vacancy

The invention relates to a preparation method of an epitaxial lanthanum strontium cobalt oxide film based on radio-frequency reactive sputtering. A radio-frequency reactive magnetron sputtering technology is adopted, and factors such as sputtering power, sputtering air pressure, the flow ratio of argon to oxygen and the temperature of a substrate are taken into comprehensive consideration in the sputtering process. According to the method, the importance of post-annealing is specially emphasized, sufficient oxygen is needed in the preparation process of La(1-x)SrxCoO3 film to avoid influence on the related physical characteristics of the film caused by forming of an oxygen vacancy, the defects such as the oxygen vacancy can be overcome by the post-annealing, and the surface of the film can be smoother. The preparation method of the epitaxial La(1-x)SrxCoO3 film has the advantages of compatibility with conventional industrial production, convenience in doping, simplicity in regulation of the concentration of a doped Sr element, simplicity in selection of a target material, higher utilization rate of the target material and the like, and is widely applicable to the preparation of related spintronics devices.

Owner:TIANJIN UNIV

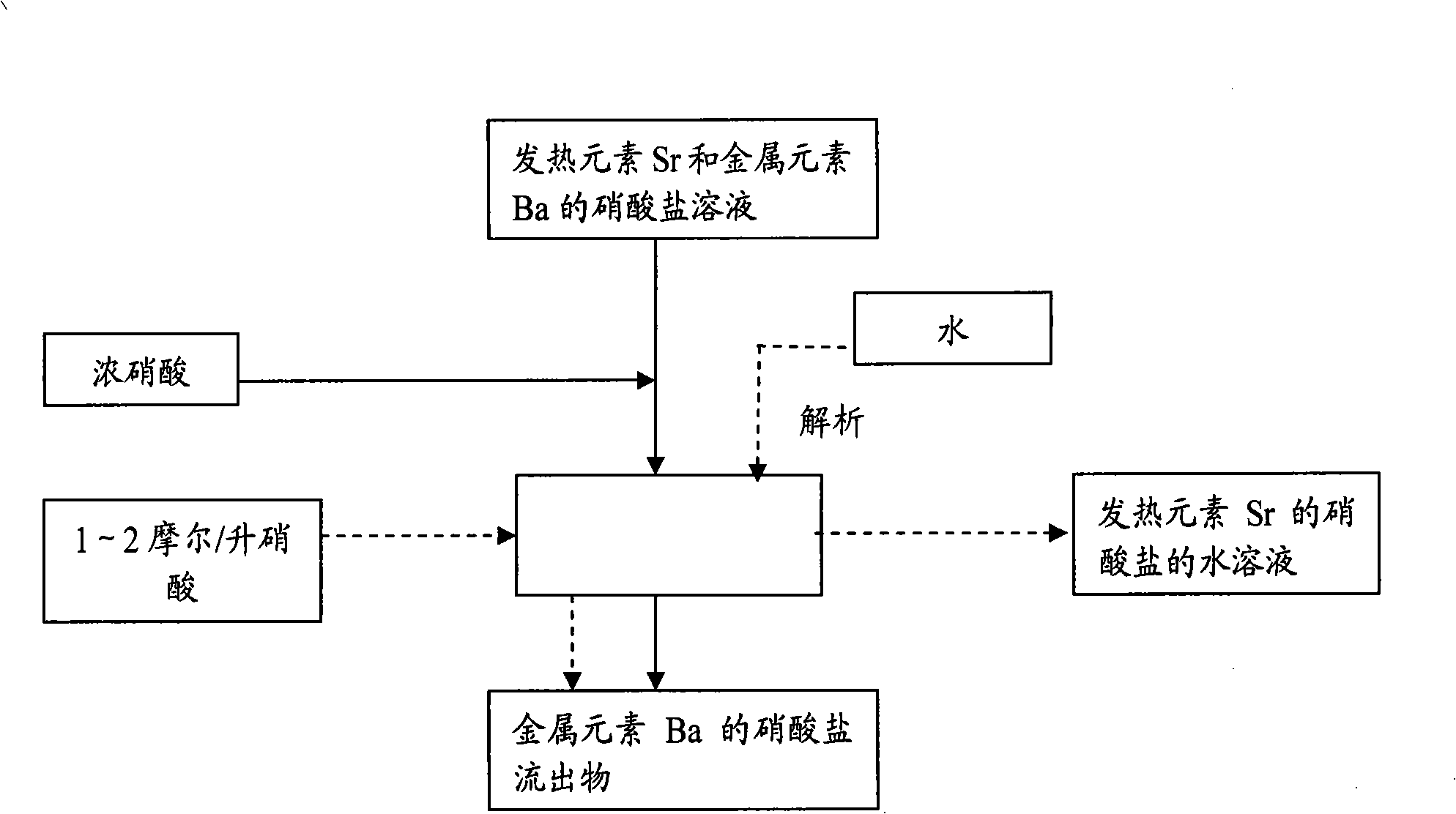

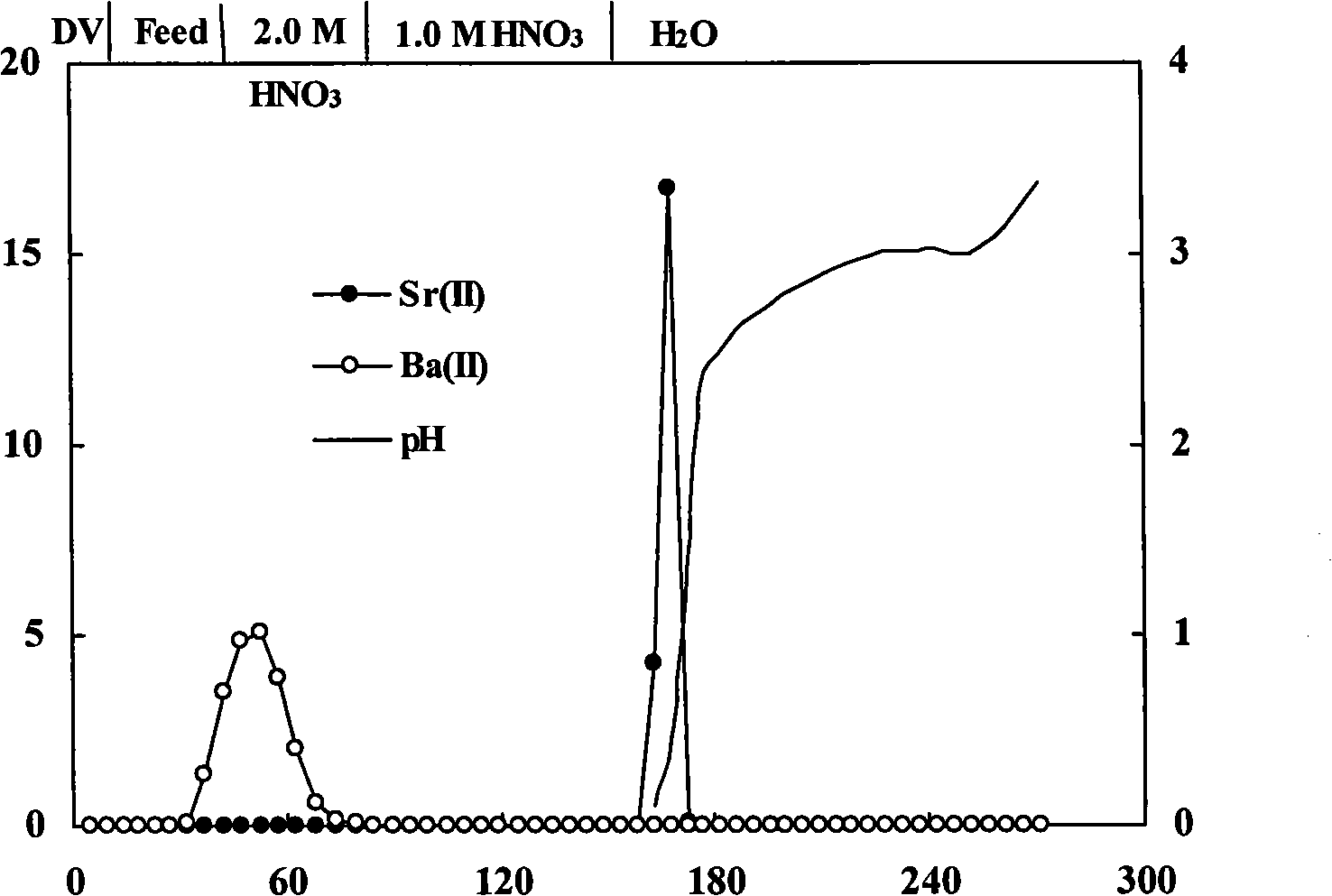

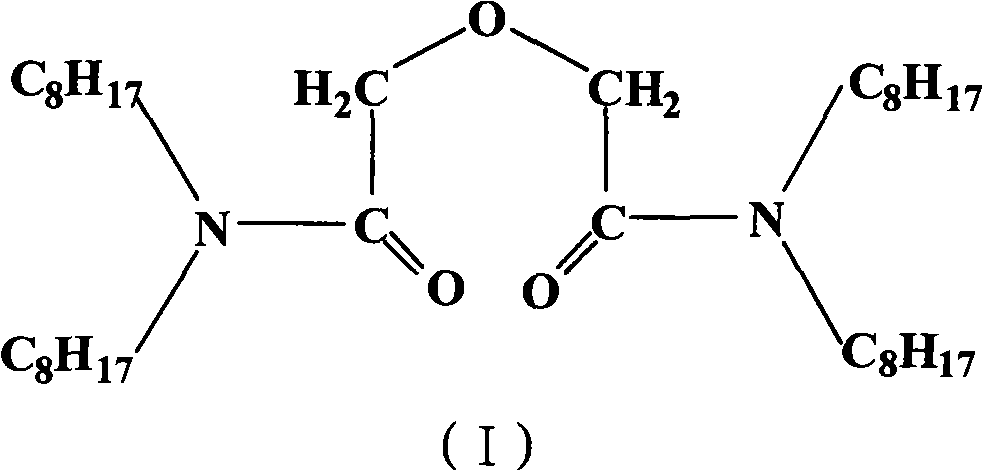

Method for separating heating element Sr and metal element Ba from high-level waste

InactiveCN101323906AImprove adsorption capacityEasy to separateProcess efficiency improvementSr elementNitrate

The invention discloses a method for separating a heating element of Sr and a metallic element of Ba from high-level wastes, comprising the following steps: (1) the concentration of nitric acid in a nitrate solution containing the heating element of Sr and the metallic element of Ba is adjusted to 0.5 to 4 mol / L; (2) after adjusting the concentration of nitric acid, the nitrate solution flows through a chromatographic column filled with a sorbent; the heating element of Sr is adsorbed by the filled sorbent while the metallic element of Ba flows out; (3) chromatographic column adsorbing the heating element of Sr is washed by deionized water and the heating element of Sr is washed out in a form of nitrate. The method of the invention has the advantages of good separation effect, strong preferential adsorption of the sorbent and being capable of separating the heating element of Sr and the metallic element of Ba from the high-level wastes thoroughly.

Owner:ZHEJIANG UNIV

High-performance environment-friendly hexagonal permanent magnetic ferrite material and preparation method thereof

ActiveCN109851349AImprove stabilityReduce exploitationInorganic material magnetismInductances/transformers/magnets manufactureMaterials preparationDopant

The invention discloses a high-performance environment-friendly hexagonal permanent magnetic ferrite material, and belongs to the technical field of material preparation. A main formula of the permanent magnetic ferrite material is as the follows: 1.3-6.3 mol% of BaCO3, 78.3-87.2 mol% of Fe2O3, 1.2-6.2 mol% of CaCO3, 0.8-6.2 mol% of La2O3, 0.3-1.1 mol% of ZnO, 0.4-1.2 mol% of MnO and 0.8-7.2 mol%of Co2O3. Based on 100 wt% of the main formula, a dopant consists of the following components based on oxides: 0.2-0.6 wt% of SiO2, 0.5-1.5 wt% of CaCO3, 0.2-0.5 wt% of H3BO3, 0.2-1.2 wt% of Bi2O3, 0.1-1.0 wt% of La2O3 and 0.1-0.5 wt% of an isobutene-maleic anhydride copolymer (ISOBAM). According to the permanent magnetic ferrite material disclosed by the invention, Sr element in the main formulais completely replaced, and meanwhile, high B<r>, high H<cj> content and high (BH)<max> are achieved.

Owner:SICHUAN MAGUNION TECH CO LTD

Method for preparing ferrite epitaxial thin film with indoor temperature broadband big magnetocapacitance effect

ActiveCN106431382ASignificant magnetocapacitive effectWith room temperature broadband magnetocapacitive effectVacuum evaporation coatingSputtering coatingCapacitanceSr element

The invention relates to a method for preparing a ferrite epitaxial thin film with an indoor temperature broadband big magnetocapacitance effect. The method comprises the first step of preparing the ferrite, wherein the component of the ferrite is represented by AFe12-xMxO19, A is one or more of Ba element or Sr element, M is one or more of Sc element, Mg element or Cr element, x is content of the M, and the range of the x is : 0<x<=4; the second step of conducting bombardment on the ferrite using pulse laser in a vacuum background, conducting precipitation of the bombarded ferrite material on a substrate, and growing the ferrite epitaxial thin film on the substrate, wherein the substrate is one of monocrystal Si substrate, Si / Pt substrate, monocrystal Al2O3 substrate and monocrystal SrTiO3 substrate; the third step of conducting cooling treatment on the ferrite epitaxial thin film after the film finishes growing and the fourth step of conducting post annealing treatment on the ferrite epitaxial thin film. The prepared ferrite epitaxial thin film has the indoor temperature broadband big magnetocapacitance effect, and makes up insufficiency of current single-phase magnetocapacitance film materials which have weak indoor temperature magnetocapacitance effect and a narrow frequency domain.

Owner:SUZHOU UNIV

Sr-containing heat-resisting casting magnesium alloy

The invention discloses a Sr-containing heat-resisting casting magnesium alloy. The magnesium alloy is characterized by comprising the following components in percentage by mass: 3.5 to 5.5 percent of Sn, 1 to 3 percent of Si, 0.5 to 3 percent of Sr and the balance of Mg and impurities. Sn and Si elements are added in a combination manner to generate Mg2Sn and Mg2Si high-temperature strengthening phases; a Sr element is added to refine the Mg2Si phase; simultaneously, a thermal stabilization phase MgSnSr of which the heat resistance is higher than that of Mg2Sn is formed. Compared with the conventional heat-resisting casting magnesium alloy, the Sr-containing heat-resisting casting magnesium alloy has excellent room temperature and high-temperature performance and low production cost, and can be widely applied to production of automobiles, electronics and space flight and aviation parts.

Owner:SHENYANG POLYTECHNIC UNIV

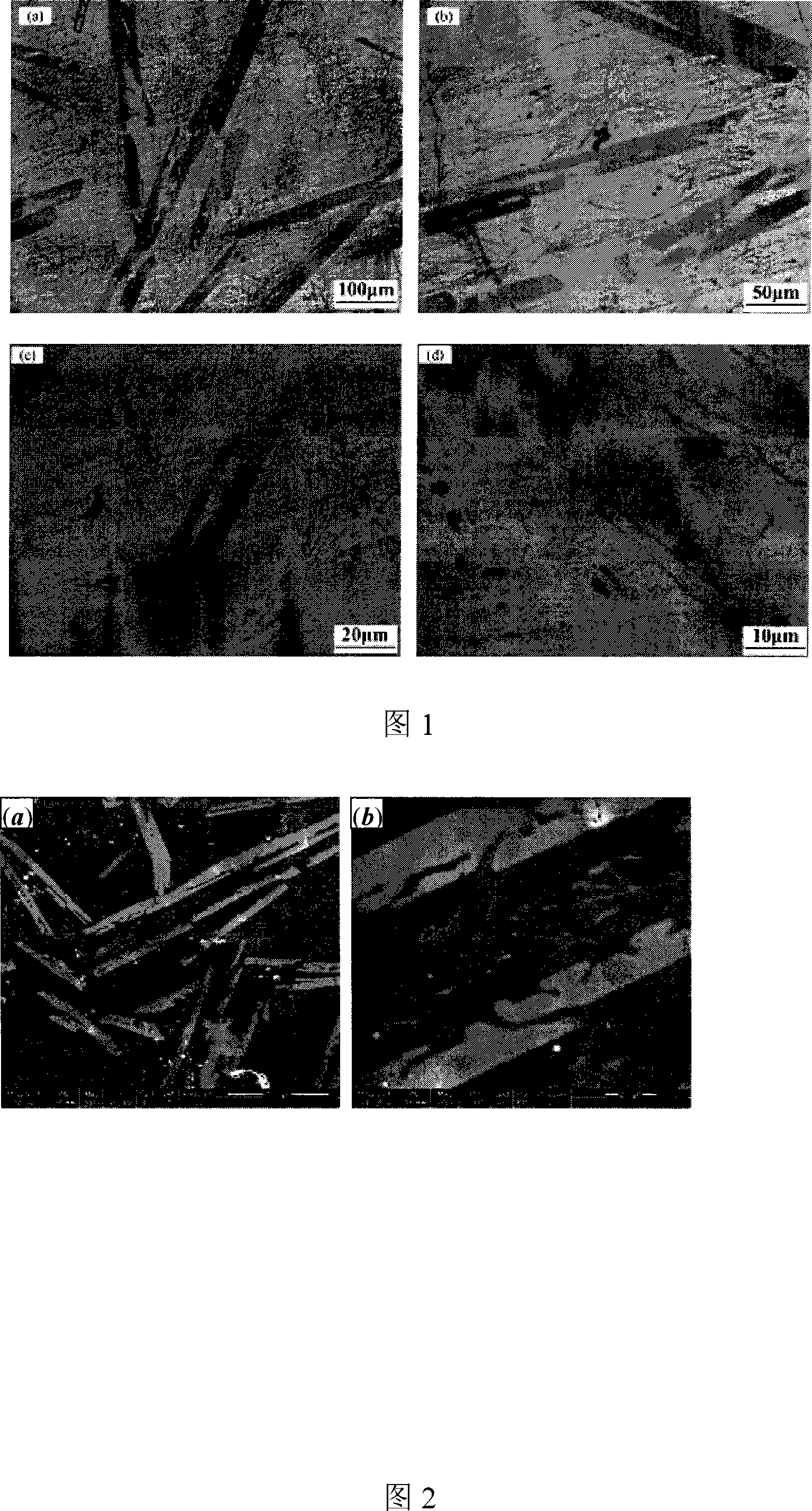

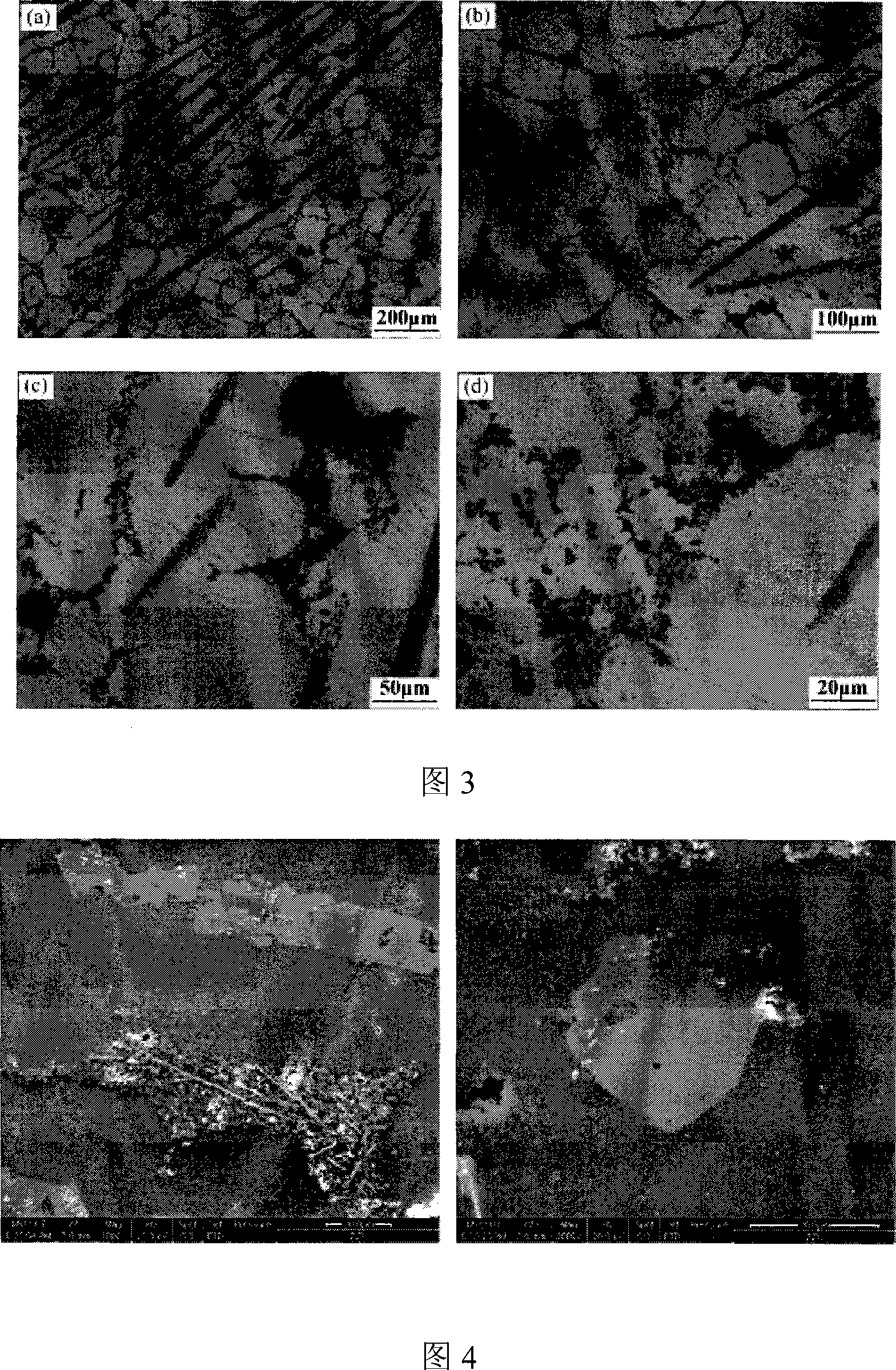

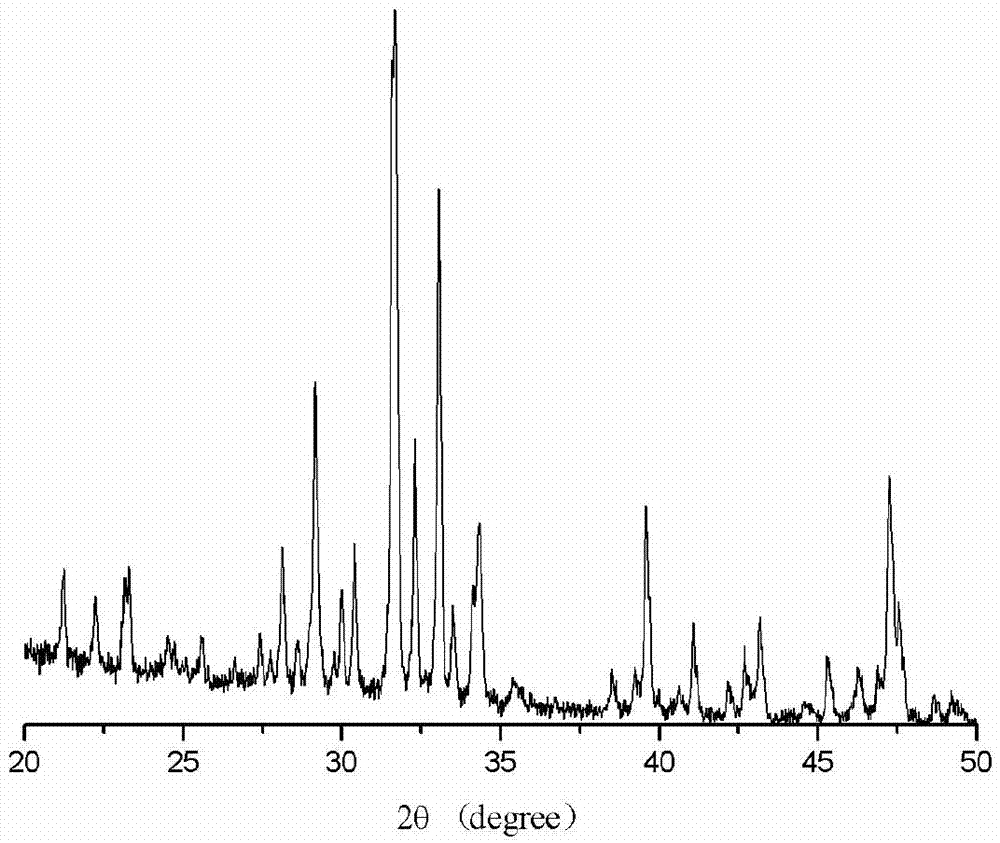

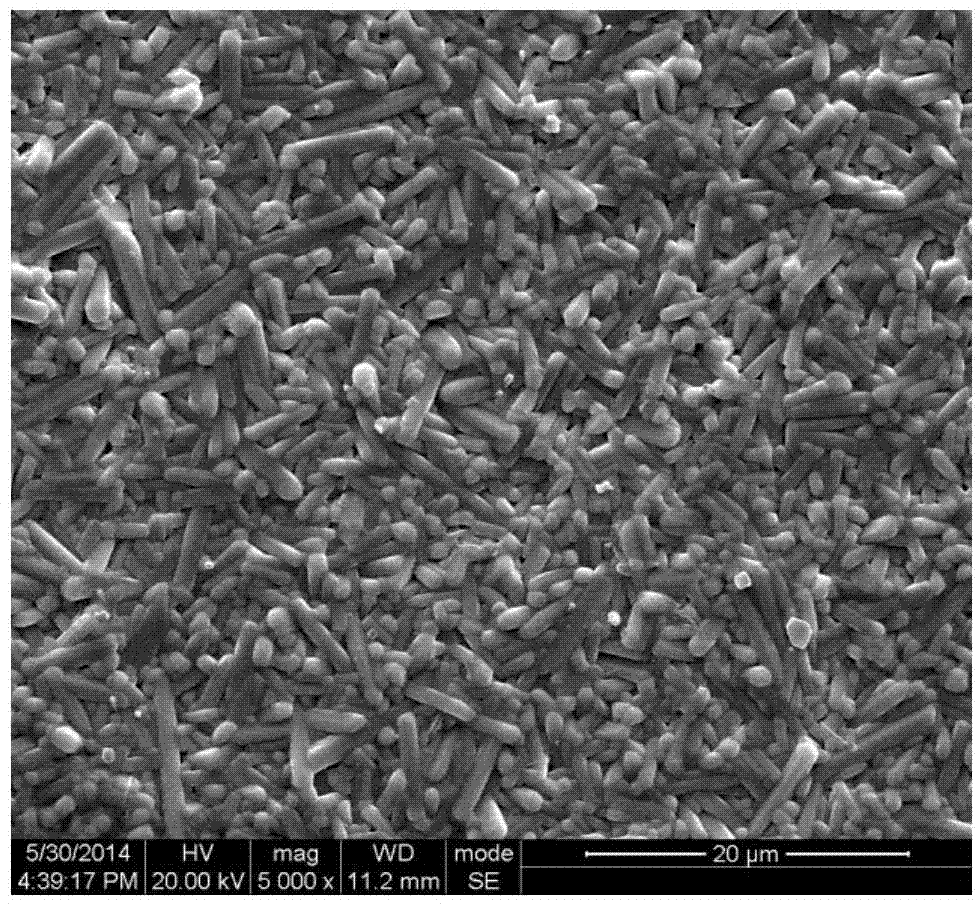

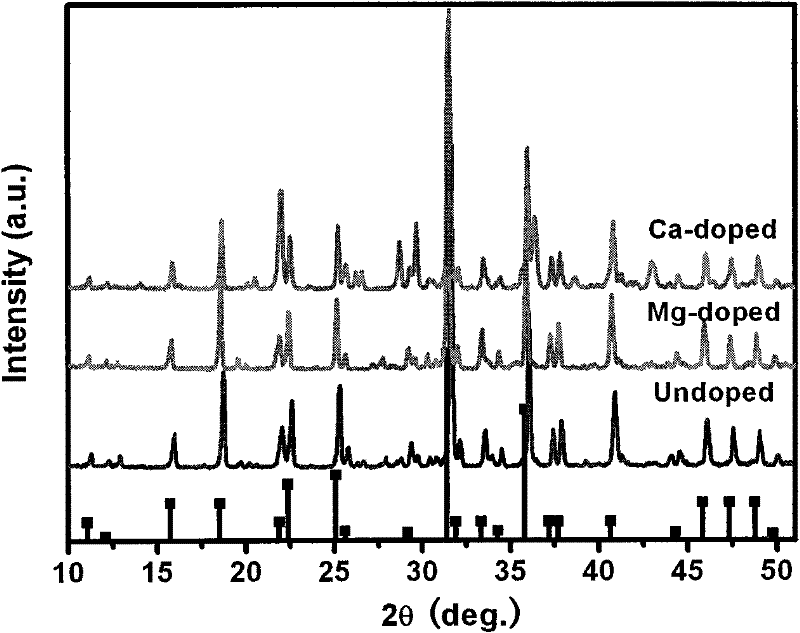

Method for preparing beta-tricalcium phosphate crystal material under low temperature condition

ActiveCN105948012ASolve the problem that it is difficult to prepare β-TCP nanomaterialsLow reaction temperatureTissue regenerationPhosphorus compoundsSr elementApatite

The invention discloses a method for preparing a beta-tricalcium phosphate crystal material under a low temperature condition, and belongs to the technical field of biomaterials. The method comprises the following steps: preparing amorphous calcium carbonate doped with different contents of Mg and amorphous apatite doped with different contents of Mg and Sr through a rapid precipitation technology, and converting the Mg-containing calcite and the amorphous apatite containing Mg and Sr into Mg-doped or Mg and Sr codoped beta-TCP crystal material through using a hydrothermal synthesis technology. Compared with present high temperature calcining or solid phase reaction methods for preparing the beta-TCP crystal material, the method disclosed in the invention has the advantages of low reaction temperature, production cost reduction, and solving of the problem of preparation of beta-TCP crystal nanomaterial through a high temperature reaction. Mg and Sr element doping also can improve the bioactivity of the beta-TCP material, is in favor of promoting bone restoration, and has great values in the fields of bone restoration and bone transplantation.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

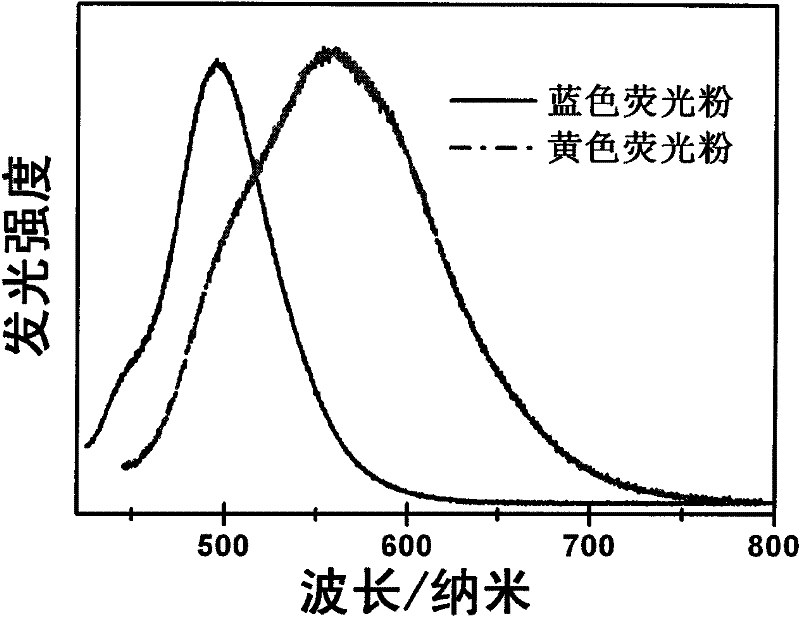

Rare earth double primary colour luminescent material for converting white light by utilizing violet light LED (light-emitting diode) and preparation method thereof

InactiveCN102229802ASimple processNo pollution in the processGas discharge lamp usageLuminescent compositionsSr elementRare earth

The invention belongs to the technical field of luminescence and display, relating to blue and yellow luminescent materials in a novel rare earth double primary colour luminescent material for converting white light by utilizing a violet light LED (light-emitting diode). The structural formulas of blue phosphor powder and yellow phosphor powder are MxN(4-x-y)Si3O8Cl4: Ry and WxS(4-x-y)Si3O8Cl4: Yy. Tz, wherein N is Sr element when M is Mg, and the phosphor powder is blue when R is Eu element. When W is Ca, S is Sr element and Y is Eu element, and the phosphor powder is yellow when T is Mn element. Materials are respectively weighed according to mass percent, after fully grinding and evenly mixing, calcining at a high temperature is carried out, a mixture is taken out after cooling is carried out, grinding is carried out, then high temperature calcining is carried out, and a sample is cooled and taken out to be ground, thus a power crystal emitting bright blue light or yellow light under the excitation of violet light is obtained. The blue phosphor powder and the yellow phosphor powder are mixed in a certain proportion to realize white light phosphor powder with different colour temperatures.

Owner:NORTHEAST NORMAL UNIVERSITY

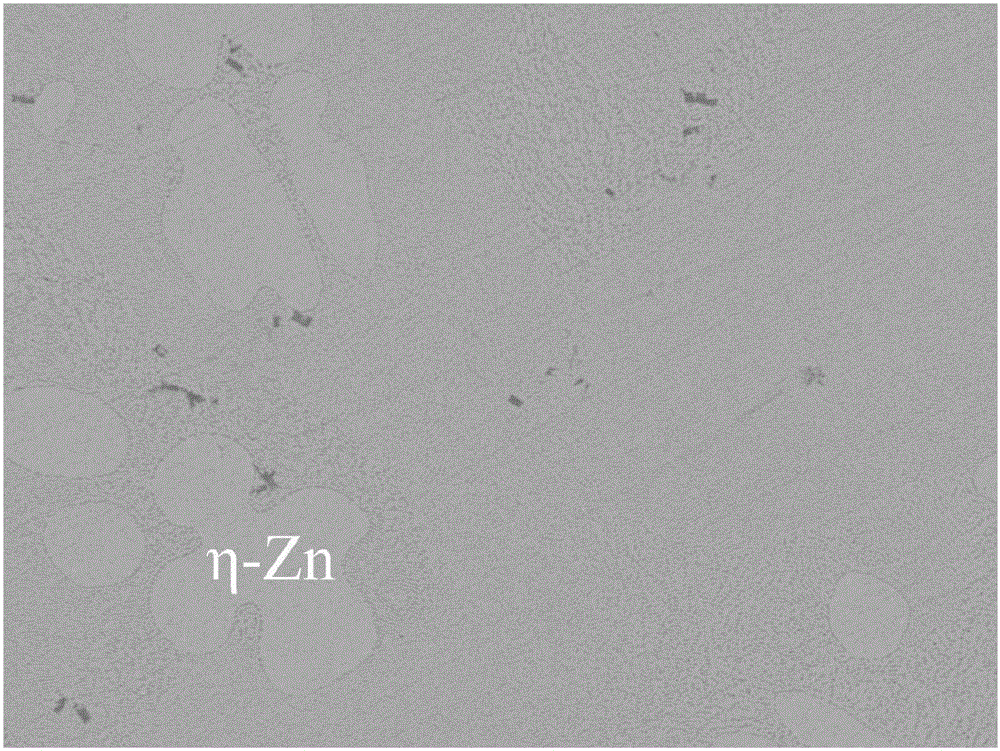

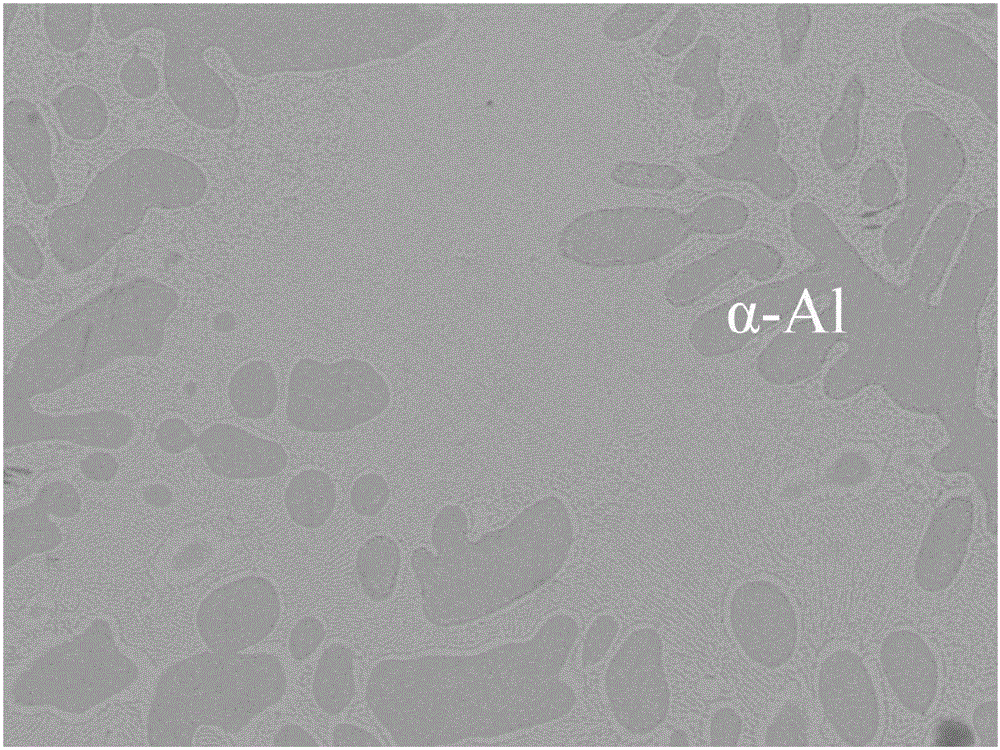

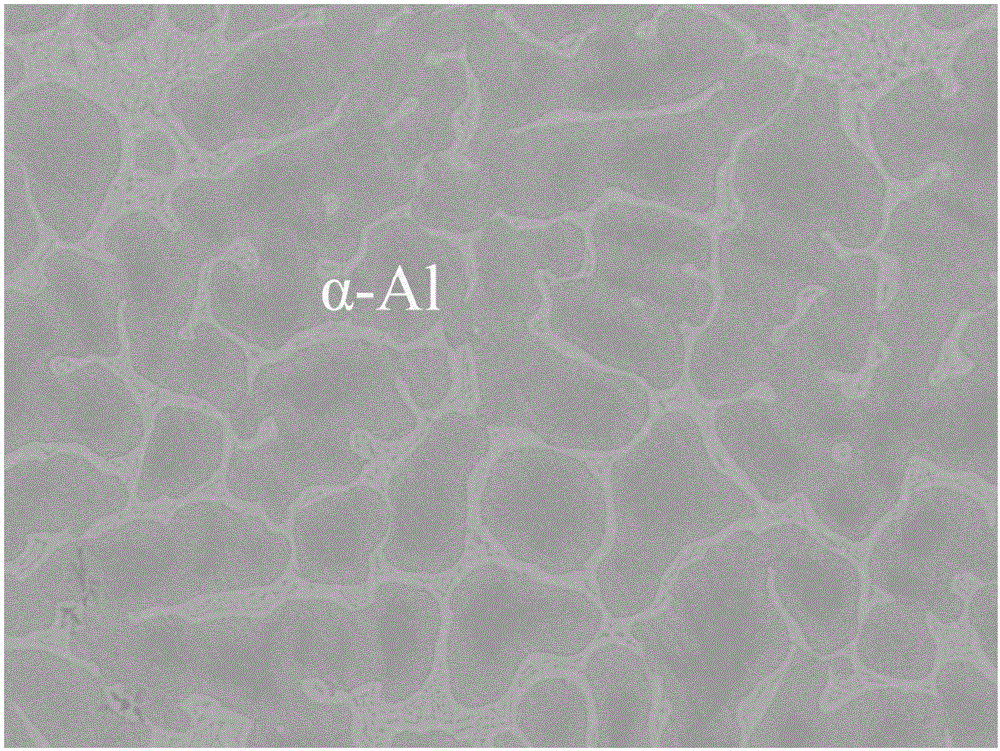

Zn-Al-Sr alloy and preparation method thereof

InactiveCN105714151ALow melting pointImprove microstructureHot-dipping/immersion processesSr elementStrontium

The invention relates to Zn-Al alloy materials and a preparation method thereof, in particular to Zn-Al-Sr alloy and a preparation method thereof, and the Zn-Al-Sr alloy serves as a modificator and a grain refiner. The Zn-Al-Sr alloy is prepared through the method that molten zinc and aluminum and SrCl2 are mechanically mixed and react. ZnCl2 and AlCl3 are formed by the Cl element with the Zn element and the Al element. During smelting, the ZnCl2 and the AlCl3 are evaporated in a gaseous state, and the Sr element is molten into the molten zinc and aluminum, so that the Zn-Al-Sr alloy is obtained. The Zn-Al-Sr alloy is prepared through the method that the molten zinc and aluminum and the SrCl2 are mechanically mixed and react, and the matrix structure of the alloy is composed of an eta-Zn phase, an alpha-Al phase and a ZnSr13 phase containing Al. The Zn-Al-Sr alloy can be used for improving the microstructure and mechanical performance of a hot-dipping galvanizing aluminum alloy clad layer. The Zn-Al-Sr alloy is low in melting point, not sticky to a pot, capable of being fast molten into a molten pool after being stirred, and capable of improving efficiency when applied to the hot-dipping galvanizing industry.

Owner:CHANGZHOU UNIV

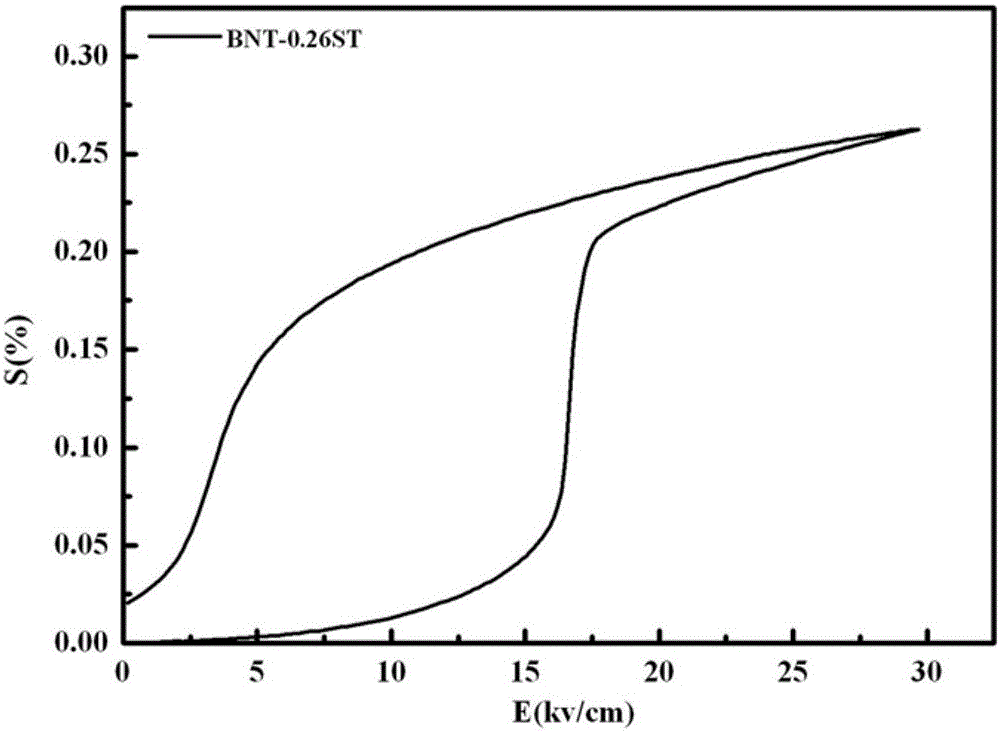

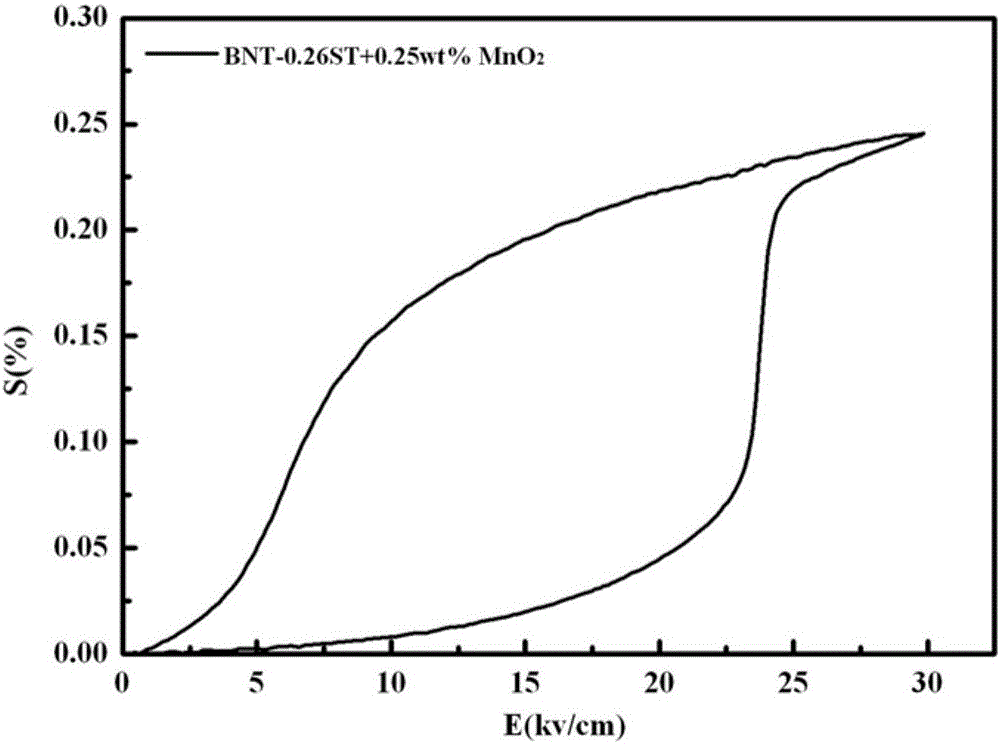

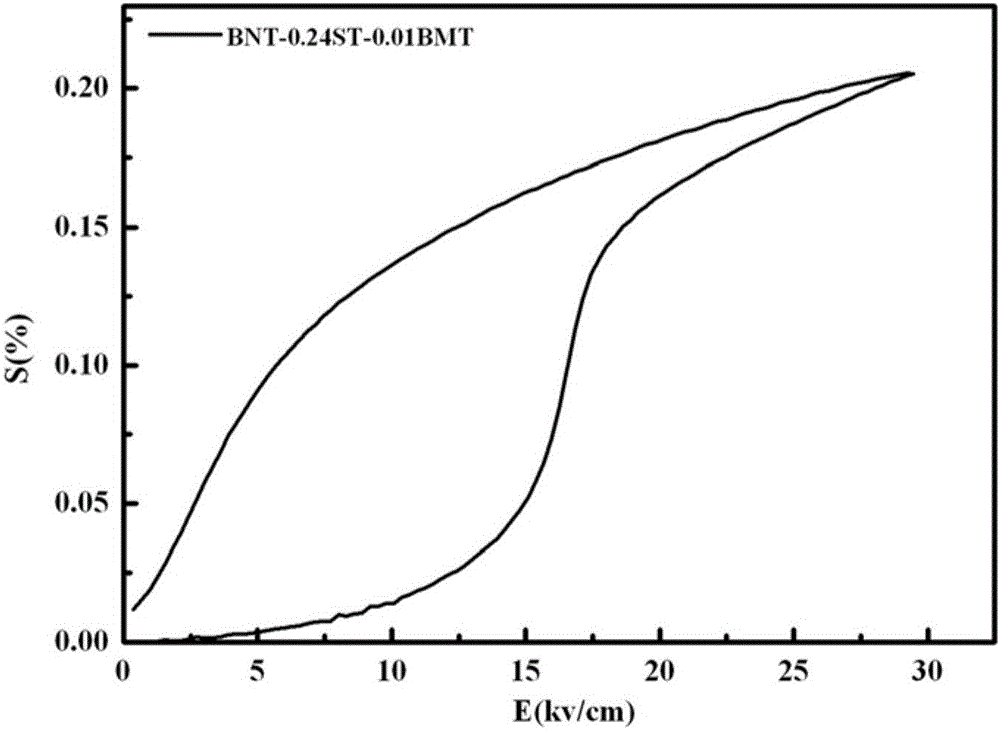

Bismuth-based leadless piezoelectric ceramic and piezoelectric actuator with application of material thereof

ActiveCN106064943AEnvironmentally friendlyEasy to drivePiezoelectric/electrostrictive/magnetostrictive devicesSr elementIndustrial area

The invention discloses bismuth-based leadless piezoelectric ceramic and a piezoelectric actuator with application of the material thereof, relates to the technical field of electronic ceramics and components, and specifically provides a new leadless piezoelectric ceramic material which can replace traditional lead-based piezoelectric ceramic and is used in related fields of piezoelectric actuator application. The material provided by the invention mainly contains Bi, Ti, Na and Sr elements and a small amount of other elements, and has more excellent field-induced strain performance than PZT ceramic in the applied electric field of a traditional driver. The piezoelectric actuator based on the material can be widely applied in industrial areas of piezoelectric oil atomizers, piezoelectric precision platforms and the like.

Owner:INST OF OPTICS & ELECTRONICS - CHINESE ACAD OF SCI

Rare earth aluminum alloy cable for railway and conductor preparation method

InactiveCN108281213AEffective control formEffective size controlApparatus for heat treatmentConductive materialRare-earth elementSr element

The invention belongs to the technical field of the aluminum alloy material preparation, the nonferrous metal conductor processing forming and the cable manufacturing, and particularly relates to a rare earth aluminum alloy cable for a railway and a conductor preparation method. In the rare earth aluminum alloy cable, the Fe element content is 0.5-1 wt%, the Cu element content is 0.3-0.5 wt%, theB element content is 0.01-0.05 wt%, the Sr element content is 0.01-0.03 wt%, the rare earth element content is 0.01-0.05 wt%, the Si element content is less than 0.05 wt%, and the balance is Al, wherein the rare earth is the mixed rare earth formed by lanthanum, cerium, neodymium and yttrium. The conductor is prepared by using a horizontal continuous casting + continuous extrusion + multi-die drawing technology. Through continuously extruding and shear-deforming, refining tissues and crushing a thick intermetallic compound, the comprehensive property of the alloy is further improved. A novel aluminum alloy cable with good electrical property and corrosion resisting property is provided for the railway. The conductor preparation technology is simple, the investment is small, the cost is low, and the production efficiency is high. The method is suitable for the industrial large-scale batch production, and has the remarkable economic benefit.

Owner:GENERAL RESEARCH INSTITUTE FOR NONFERROUS METALS BEIJNG +2

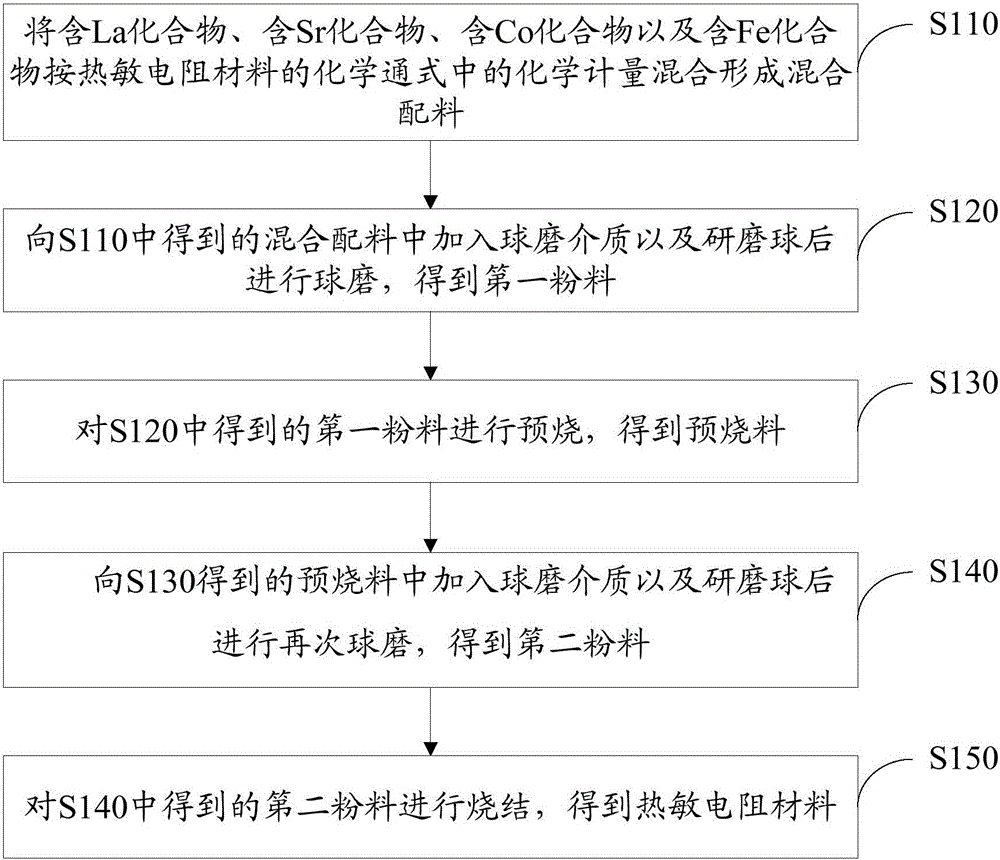

Thermistor material and preparation method and application thereof

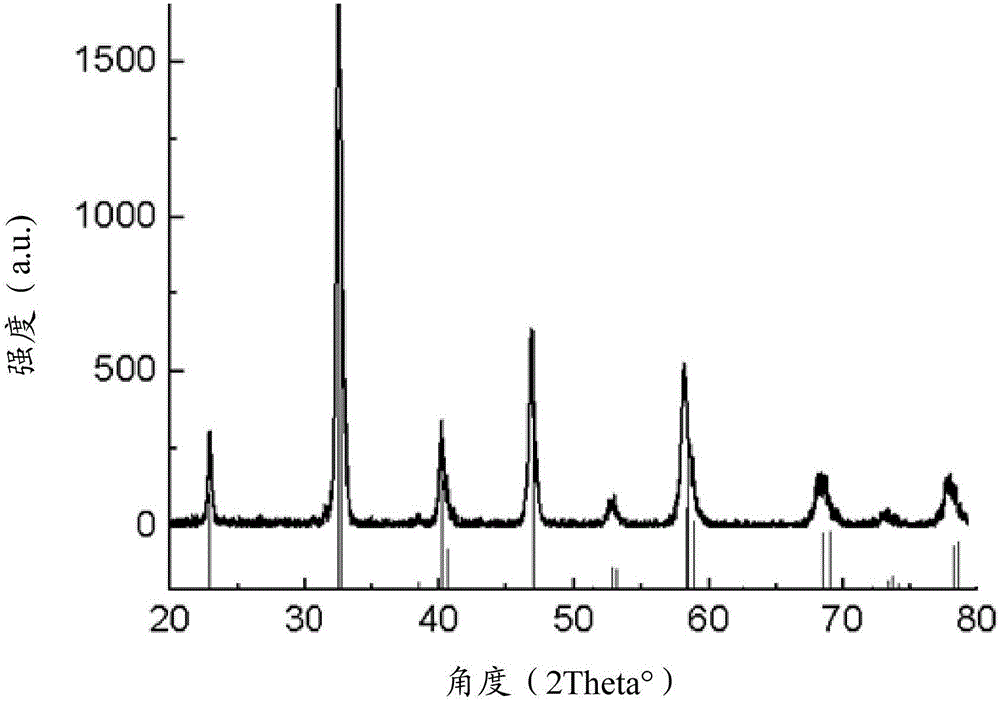

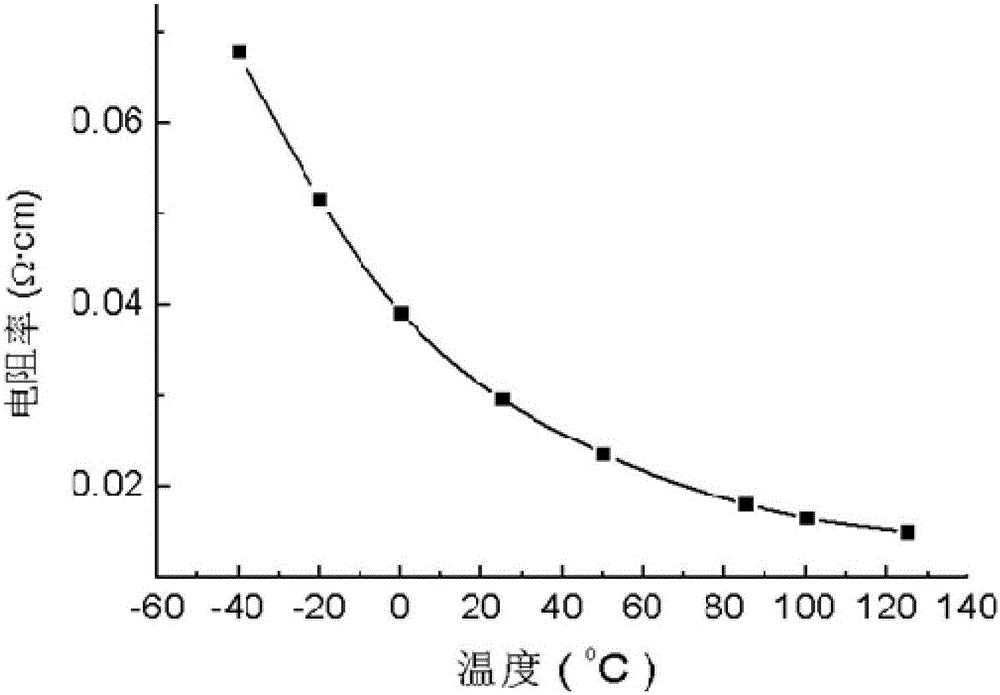

The invention discloses a thermistor material and a preparation method and application thereof. The chemical general formula of the thermistor material is LaxSr1-xCoyFe1-yO3, wherein 0.5 < x< 1, and 0 < y< 1. Four kinds of metal elements and O form a La-Sr-Co-Fe-O system. Theratio of the sum of the mole number of two elements La and Sr to the sum of the mole number of two elements Co and Fe is 1:1,0.5< x< 1, and the proportion of the element La in the thermistor material is higher than the proportion of the element Sr in the thermistor material. A test proves that the thermistor material has good crystallinity, a B value is low, and the resistivity is smaller. The thermistor material can be applied to the temperature attenuation compensation ofspecific occasions such as low temperature, high frequency and high power.

Owner:GUANGDONG FENGHUA ADVANCED TECH HLDG +1

Electrostriction material and preparation method thereof

InactiveCN101450860ALarge deformationLarge design spacePiezoelectric/electrostrictive/magnetostrictive devicesElectricitySr element

The invention provides an electrostriction material and a preparation method thereof. The invention provides the electrostriction material having the advantages of good pressure resistant performance, large deformation and low consumption by using Sr element or La element to partially replace Pb in PMN and simultaneously doping Sc2O3 and adding Cr2O3 or Bi2O3, and using a low-cost production line and optimized technological conditions. The electrostriction material can be widely applied in the fields of aerospace, precision optics, precision finishing and so on with large-deformation driving and positioning.

Owner:INST OF ACOUSTICS CHINESE ACAD OF SCI

BNT-BST-KNN anti-ferroelectric energy-storage ceramic and preparation method thereof

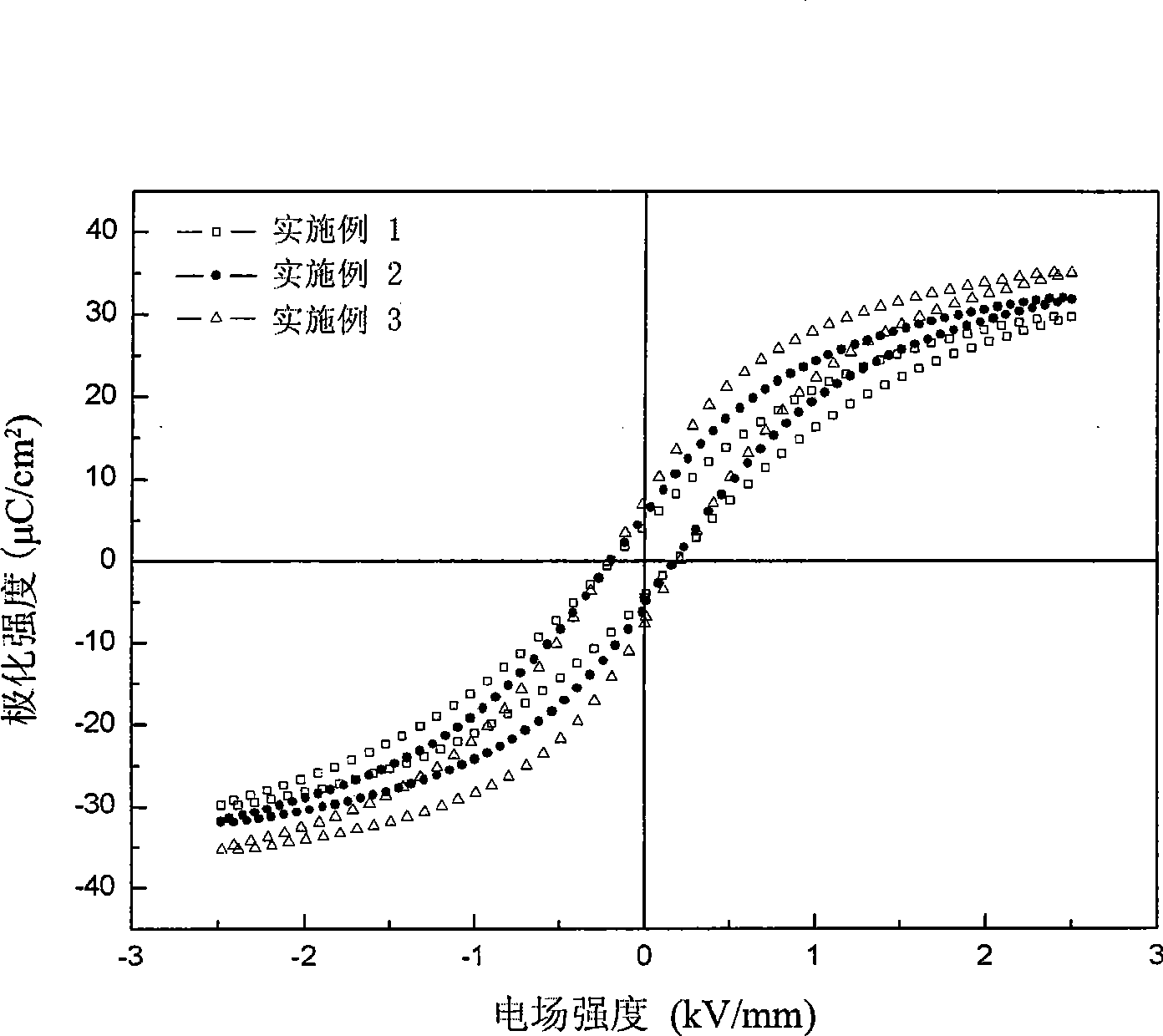

The invention discloses a BNT-BST-KNN anti-ferroelectric energy-storage ceramic and a preparation method thereof, which belong to the technical field of functional ceramic. A molecular formula is (1-x)Bi1 / 2Na1 / 2TiO3 xBa1 / 2Sr1 / 2TiO3-0.05KNaNbO3, wherein x is 0.01, 0.03, 0.05 or 0.07. The BNT-BST-KNN anti-ferroelectric energy-storage ceramic solves the problems that La<3+>-doped electroceramic reduces the electric field hysteresis and increases the phase-transition electric field of a material, and the anti-ferroelectric phase of B site Zr<2+> element-doped electroceramic is unstable; the added Sr element is helpful for enlarging a stable area of the tetragonal anti-ferroelectric phase, and the electricity performance of the BNT-BST-KNN anti-ferroelectric energy-storage ceramic can be changed by doping BaSrTiO3 and KNaNbO3.

Owner:XIAN AERONAUTICAL UNIV

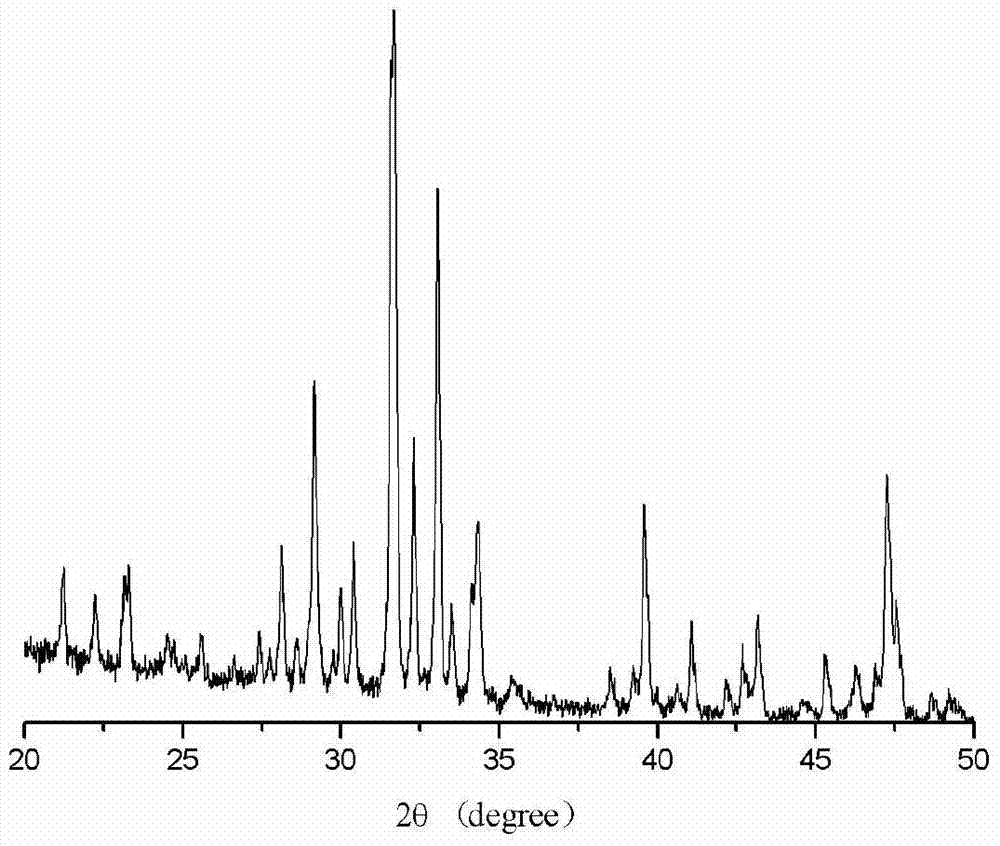

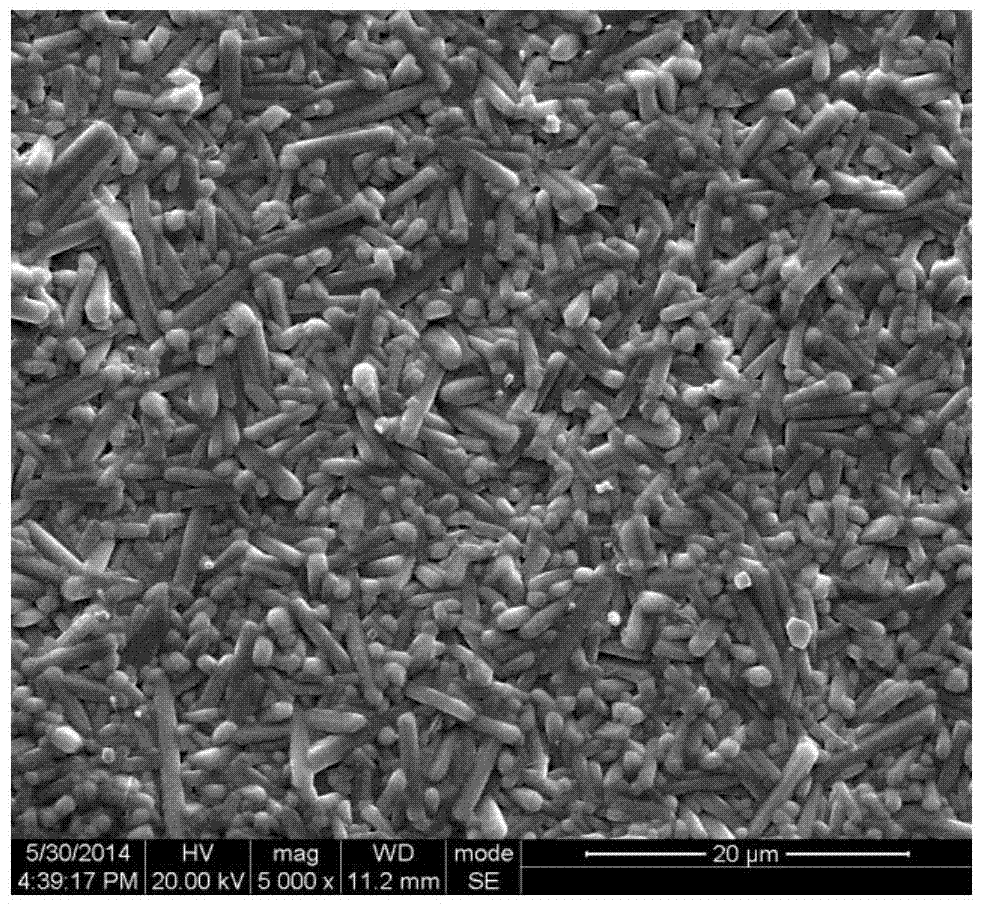

Microwave dielectric ceramic material with ab positions substituted simultaneously and preparation method thereof

The invention provides a microwave dielectric ceramic material with AB positions replaced simultaneously and a preparation method thereof. The general chemical formula of the material is (Ba1-aAa)6-3x(Nd1-bBb)8+2x(Ti1-cCc)18O54, C=MN , where x=3 / 4, 0.05≤a≤0.2, 0.05≤b≤0.15, 0.02≤c≤0.08, A represents the divalent Ca and Sr elements that replace the A1 position, B represents the trivalent Sm and Bi that replace the A2 position Elements, M represents Nb whose valence is higher than tetravalent, N represents one or several other elements whose valence is lower than tetravalent and the ionic radius is similar to Ti, M and N are substituted at the same time or alone, and the preparation method is according to chemical The general formula determines the respective mass percentages, which are mixed by ball milling, pre-fired at 1000-1150°C, and then sintered at 1250-1450°C; the dielectric constant and frequency temperature coefficient of the prepared material can be adjusted while maintaining high The Q×f value of the formula does not contain Pb, Cd and other volatile or heavy metals, and the performance has been greatly improved. The domestic supply of raw materials is sufficient and the price is low, making it possible to reduce the cost of high-performance microwave ceramics.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Formula and manufacturing method of high-performance A356 aluminum alloy

InactiveCN110592438AGuarantee that the components meet the standardsEffective monitoringSr elementToughness

The invention discloses a formula and manufacturing method of a high-performance A356 aluminum alloy, and relates to the technical field of aluminum alloy production. The formula includes the following components in percentage by mass: 6.8-7.4% of Si, 0.30-0.35% of Mg, 0.10-0.15% Ti, 0.02-0.030% of Sr, less than or equal to 0.10% of Fe, less than 0.003% of Ca, less than 0.03% of Zn, less than 0.05% of Mn, less than 0.008% of Ni, less than 0.002% of P, less than 0.05% of Cu, and the balance Al. According to the formula and the manufacturing method, Ti and Sr elements are added in a reasonable proportioning mode, and the elements of Fe, Ca, Zn, Mn, Ni, P and Cu are each controlled on a reasonable low content level, so that the formula of the A356 aluminum alloy and the formula of the manufacturing method have stable and reasonable component distribution ratio, the structure is uniform, the strength and the toughness are remarkably improved, and the market development needs are well met.

Owner:滨州联信新材料科技有限公司

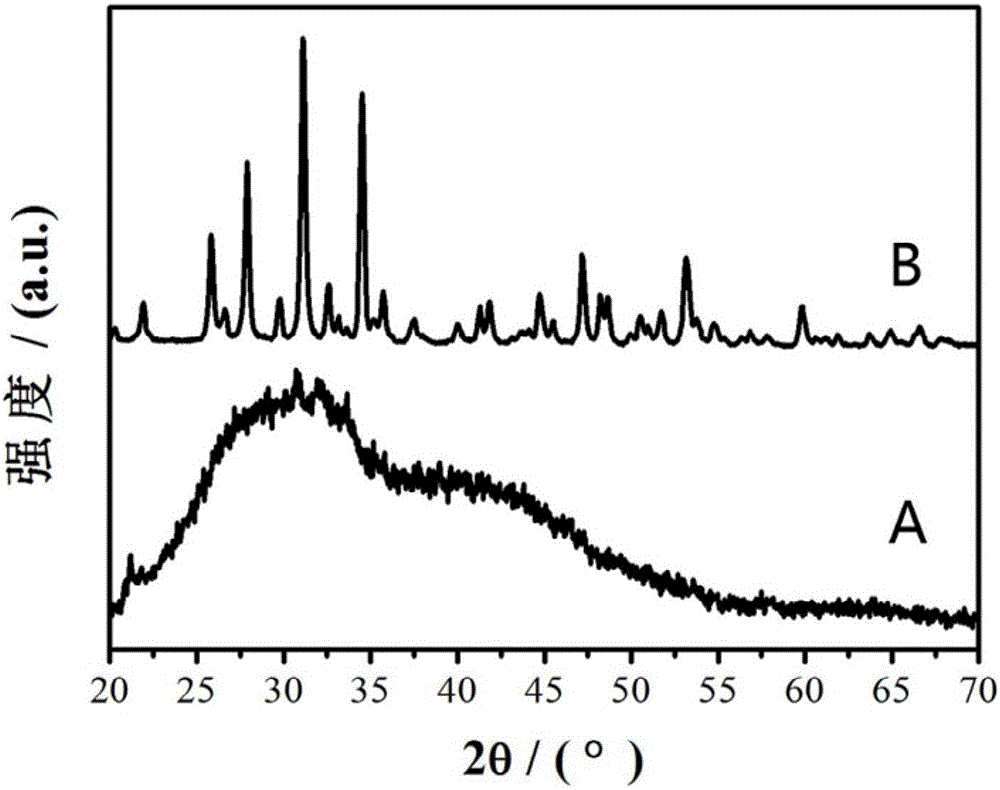

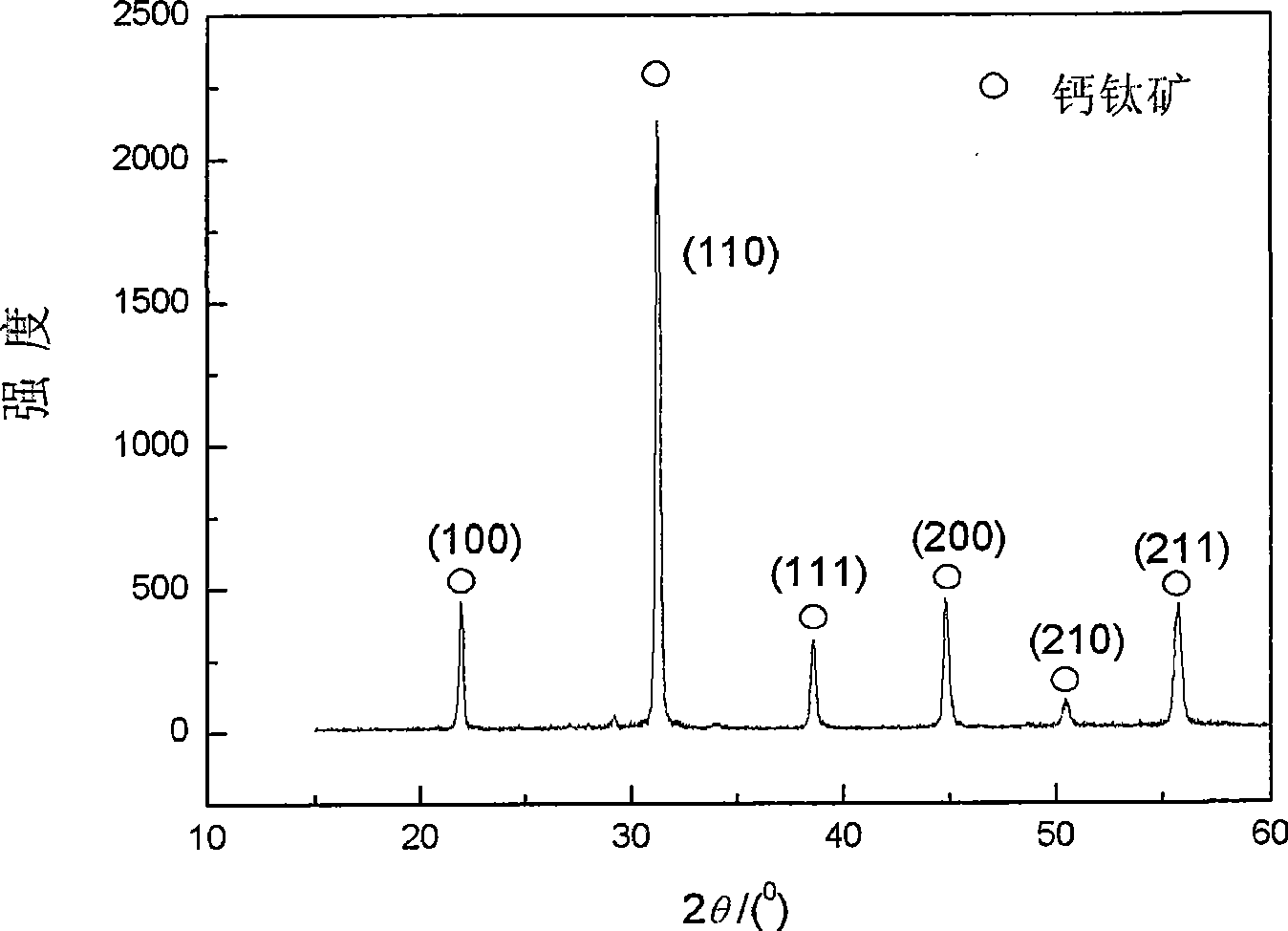

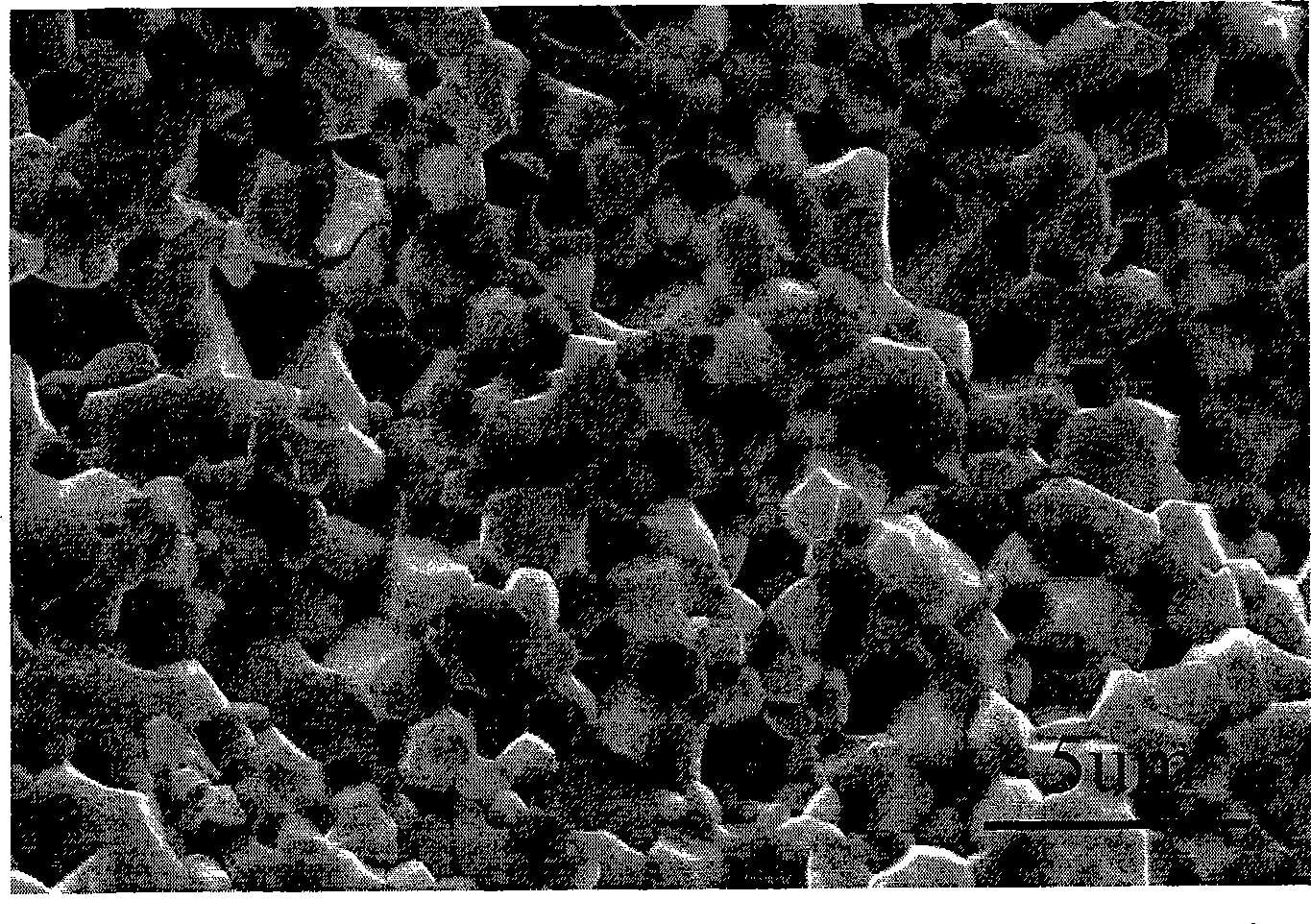

Preparation method of Co-base porous ceramic with adjustable and controllable pore structure

The invention discloses a preparation of Co-base porous ceramic with an adjustable and controllable pore structure. The Co-base porous ceramic is prepared from La2O3, Co3O4 and SrCO3, and is prepared by the following steps of: calculating required raw materials at a mol ratio of (1-x):x:1 of La:Sr:Co, wherein x ranges from 0 to 1; weighing and mixing the raw materials, grinding the raw materials to obtain mixed powder, and tableting the mixed powder; pre-sintering obtained tablets to obtain pre-sintered ceramic; cooling the pre-sintered ceramic to room temperature and grinding; and tableting the ceramic and sintering for the second time, so as to obtain the La(1-x)SrxCoO3 porous ceramic. The obtained La(1-x)SrxCoO3 porous ceramic material is 14-19% in porosity, 4.5-6.5g / cm<3> in density and 75-90% in relative density. The method is simple and easy to implement, and low in cost; and the preparation method of the perovskite type Co-base porous ceramic which is adjustable and controllable in pore structure and uniform in distribution, by changing the doping amount of a Sr element, can achieve control on the pore structure and the porosity.

Owner:KUNMING UNIV OF SCI & TECH

Al-Mg-Mn-Zr-Sr alloy and preparation method thereof

The invention relates to a medium- and high-strength, high-toughness and weldable Al-Mg-Mn-Zr-Sr alloy containing strontium, which consists of the components of Al, MG, Mn, Zr and Sr. A preparation method thereof comprises the following steps: preparing raw materials according to the weight percentage of each component; then heating the components to 820 DEG C to 850 DEG C, totally melting, reducing temperature, standing, refining with C2Cl6, pouring into a preheat mould; after homogenizing cast ingot, heating, and extruding to deform with the extruding ratio of 12. The invention is reasonable in component proportion, easy to process and manufacture, simple in operation process and uses Sr element for alloying, thereby effectively improving the organizational structure of aluminum alloy, the comprehensive mechanical property of aluminum alloy and is adapted for industrialized application. The invention provides an achievable way to improve the comprehensive mechanical property of the medium- and high-strength and weldable aluminum alloy in the Al-Mg-Mn-Zr system.

Owner:CENT SOUTH UNIV

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com