High-performance environment-friendly hexagonal permanent magnetic ferrite material and preparation method thereof

A permanent magnet ferrite, environment-friendly technology, applied in magnetic circuits characterized by magnetic materials, inductance/transformer/magnet manufacturing, inorganic material magnetism, etc., can solve the problem that hexagonal permanent magnet ferrite materials cannot meet the requirements of high performance and Environmental protection and other issues, to achieve the effect of reducing development and utilization, reducing quantity and high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

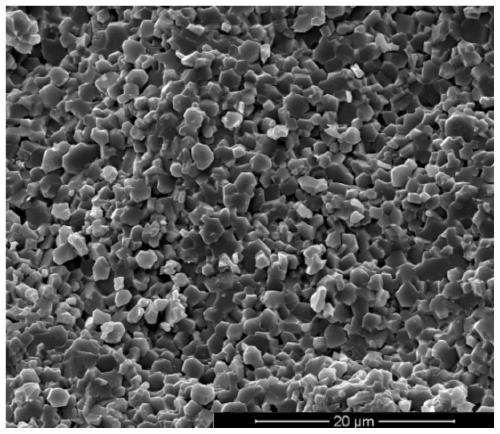

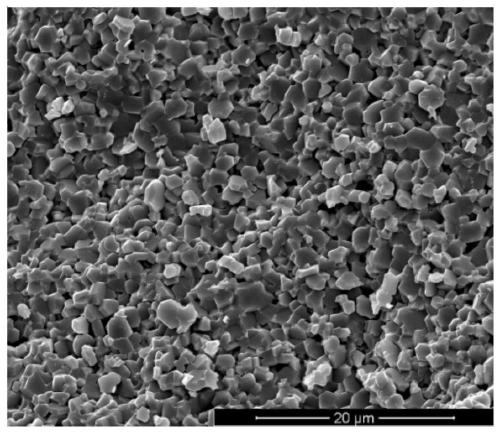

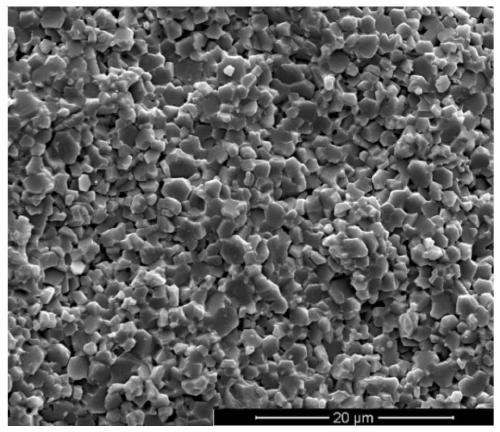

Image

Examples

preparation example Construction

[0034] The main component of the high-performance environment-friendly hexagonal permanent magnet ferrite material of the present invention is calculated as an oxide by mole percentage, and the dopant component is calculated by weight percentage as an oxide. Its preparation method specifically comprises the following steps:

[0035] Step 1. Ingredients:

[0036] with BaCO 3 , Fe 2 o 3 , CaCO 3 、La 2 o 3 , ZnO, MnO and Co 2 o 3 As a raw material, according to "1.3 ~ 6.3mol% BaCO 3 , 78.3~87.2mol% Fe 2 o 3 , 1.2~6.2mol%CaCO 3 , 0.8~6.2mol% La 2 o 3 , 0.3~1.1mol% ZnO, 0.4~1.2mol% MnO, 0.8~7.2mol% Co 2 o 3 "The ratio of weighing, mixing, preparation to obtain the initial powder;

[0037] Step 2, a ball mill:

[0038] Mix the initial powder obtained in step 1 evenly in a ball mill for 12 to 21 hours;

[0039] Step 3, pre-burning:

[0040] Dry the ball abrasive obtained in step 2, and pre-fire it in a sintering furnace. The pre-fired temperature is 1200-1350°C, an...

Embodiment

[0055] A method for preparing a high-performance environment-friendly hexagonal permanent magnet ferrite material, comprising the following steps:

[0056] Step 1. Ingredients:

[0057] with BaCO 3 , Fe 2 o 3 , CaCO 3 , La 2 o 3 , ZnO, MnO and Co 2 o 3 As a raw material, weigh and mix according to the ratio in the table below to prepare the initial powder;

[0058] Embodiment 1~4 master formula sees the following table:

[0059]

[0060] Step 2, a ball mill:

[0061] Mix the initial powder obtained in step 1 evenly in a ball mill for 16 hours;

[0062] Step 3, pre-burning:

[0063] Dry the ball abrasive obtained in step 2, and pre-fire it in a sintering furnace. The pre-fired temperature is 1300°C, and the pre-fired time is 3 hours. After completion, the temperature is naturally lowered to room temperature with the furnace to obtain a pre-fired powder;

[0064] Step 4, doping:

[0065] Add a dopant to the calcined powder obtained in step 3, and the content of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com