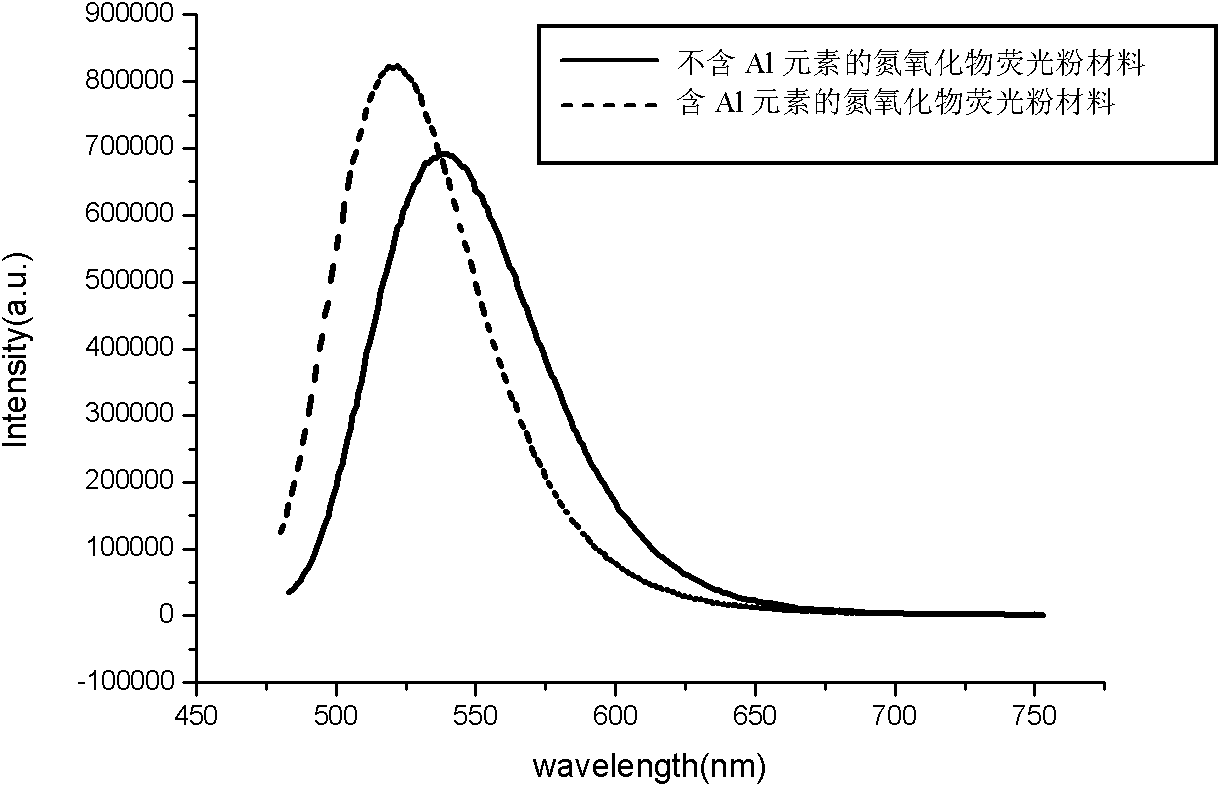

Oxynitride green emitting phosphor material containing AL element and preparation method thereof

A green fluorescent powder and nitrogen oxide technology, which is applied in the direction of luminescent materials, chemical instruments and methods, etc., can solve the problems of high equipment requirements and high synthesis temperature, and achieve the effects of wide process window, widened color gamut, and low raw material prices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

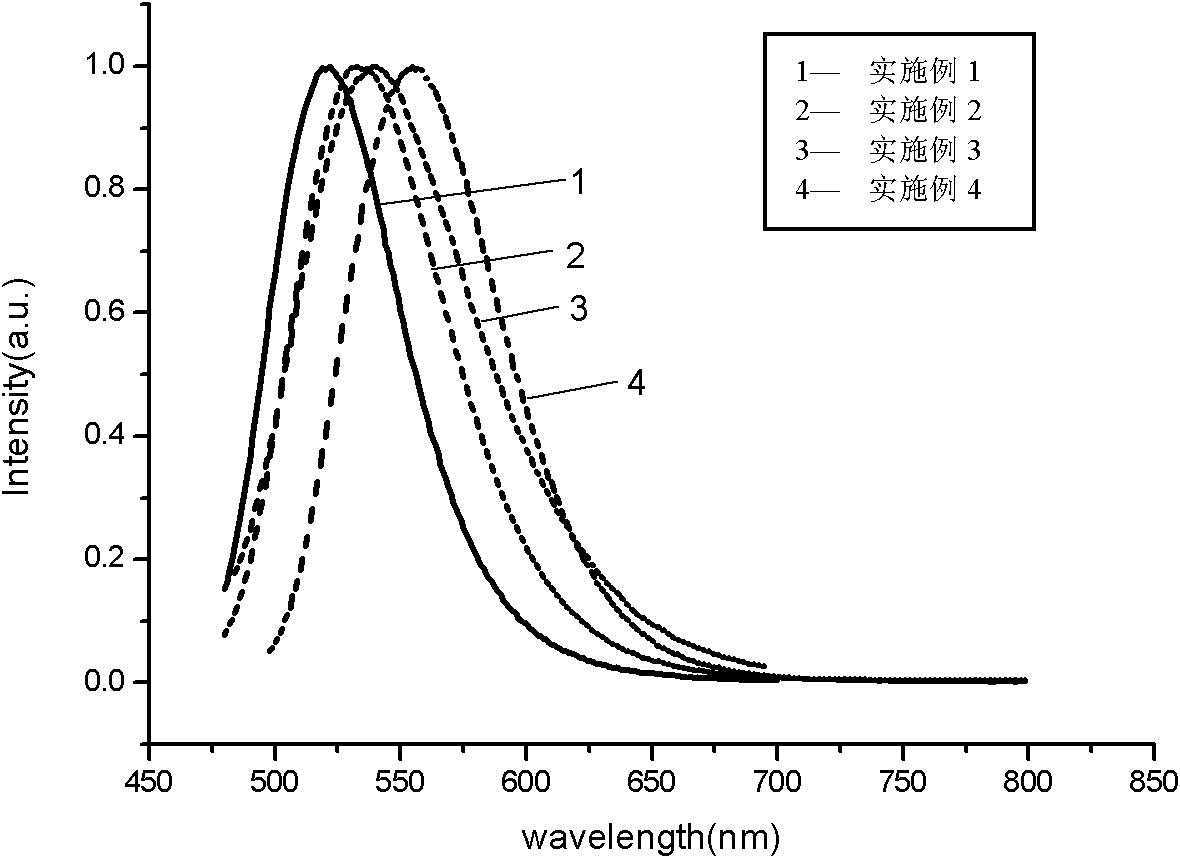

Embodiment 1

[0018] The first step to synthesize the precursor Sr of the green phosphor containing oxynitride of Al element 2 SiO 4 : Weigh SrCO according to the stoichiometric ratio 3 198.17g, SiO 2 60.1g, and accounted for SrCO 3 and SiO 2 3wt% of the total mass of catalyst SrF 2 , after mixing and fully grinding, put it in an alumina crucible, place the crucible in a tube furnace, sinter at 1300°C for 3 hours in a protective gas, and then cool to obtain Sr 2 SiO 4 . Shielding gas can be selected Shielding gas can be selected H 2 , N 2 / H 2 , NH 3 one or a combination of several. Wherein a certain amount of flux can be added, and the flux can be selected from SrF 2 or NH 4 Cl.

[0019] The second step is in the prebody Sr 2 SiO 4 The provided matrix structure is doped with Al element to synthesize the nitrogen oxide green phosphor Sr 0.98 Si 1.7 al 0.3 N 2 o 2 :0.02Eu: According to the stoichiometric ratio, the resulting Sr 2 SiO 4 After grinding and sieving, weigh...

Embodiment 2

[0021] The first step to synthesize the precursor Sr of the green phosphor containing oxynitride of Al element 2 SiO 4 : Weigh SrCO according to the stoichiometric ratio 3 198.17g, SiO 2 60.1g, and accounted for SrCO 3 and SiO 2 3wt% of the total mass of catalyst SrF 2 , after mixing and fully grinding, put it in an alumina crucible, put the crucible in a tube furnace, sinter at 1300°C for 3 hours in a protective atmosphere, and then cool to obtain Sr 2 SiO 4 .

[0022] The second step is in the prebody Sr 2 SiO 4 The provided matrix structure is doped with Al element to synthesize the nitrogen oxide green phosphor Sr 0.98 Si 1.5 al 0.5 N 2 o 2 : 0.02Eu, according to the stoichiometric ratio will be obtained from the first step Sr 2 SiO 4 After grinding and sieving, weigh 5g, and then weigh 0.782g of AlN, α-Si 3 N 4 1.804g and Eu 2 o 3 0.134g, post-adding SrF accounting for 3wt% of the total mass of the aforementioned substances 2 and BaF 2 The mixing aid,...

Embodiment 3

[0024] The first step to synthesize the precursor Sr of the green phosphor containing oxynitride of Al element 2 SiO 4 : Weigh SrCO according to the stoichiometric ratio 3 198.17g, SiO 2 60.1g, and accounted for SrCO 3 and SiO 2 3wt% of the total mass of catalyst SrF 2 , after mixing and fully grinding, put it in an alumina crucible, place the crucible in a tube furnace, sinter in air at 1300°C for 3 hours, and then cool to obtain Sr 2 SiO 4 .

[0025] The second step is in the prebody Sr 2 SiO 4 The provided matrix structure is doped with Al element to synthesize the nitrogen oxide green phosphor Sr 0.98 Si 1.3 al 0.7 N 2 o 2 :0.02Eu: According to the stoichiometric ratio, the Sr obtained in the first step 2 SiO 4 After grinding and sieving, weigh 5g, then weigh 1.095g of AlN, α-Si 3 N 4 1.447g and Eu 2 o 3 0.134g, post-adding SrF accounting for 3wt% of the total mass of the aforementioned substances 2 and BaF 2 The mixing aid, where SrF 2 :BaF 2 = 1:1,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com