A kind of preparation method of tin oxide film

A tin oxide and thin film technology, applied in tin oxide and other directions, can solve the problems of incomplete reaction, turbulent airflow, affecting the quality of the film layer, etc., and achieve the effects of good thickness consistency, smooth aerosol movement, and superior electrical conductivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

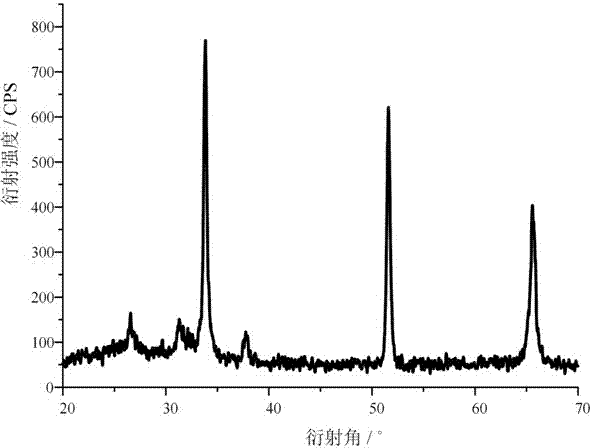

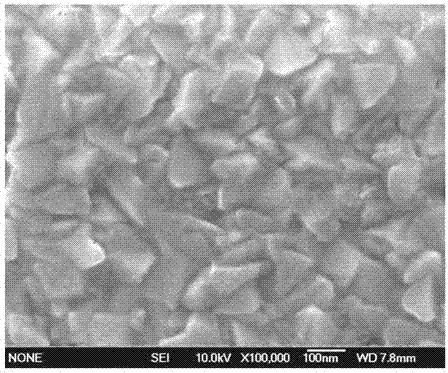

[0028] 1. Under room temperature, normal pressure, and dry environment, use antimony trifluoride as raw material and deionized water as solvent, and mix and stir to form a doping solution. Using tin tetrachloride (SnCl 4 ) as the raw material and deionized water as the solvent, mixed and stirred to form a tin salt solution. Then the doping solution is added dropwise to the tin salt solution under stirring conditions to form a mixed solution. The doping ratio in the mixed solution is: fluorine is 18 mol%, antimony is 6 mol%, and the molar concentration of tin is 3.5 mol / L , and then use hydrochloric acid to adjust the pH of the solution to about 2-3, and after airtight aging for 6 hours, a precursor coating solution is obtained.

[0029] The precursor coating solution is then added to the gas compression atomizer.

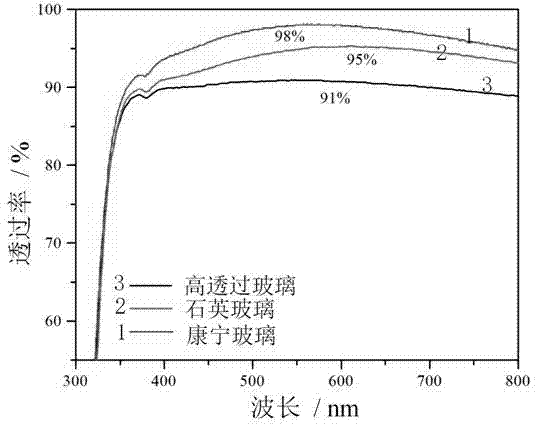

[0030] 2. Select one of the high-temperature-resistant materials such as high-transmission glass (low-Fe glass), quartz glass, Corning glass, and high-alumina til...

Embodiment 2

[0037] 1. Under room temperature, normal pressure, and dry environment, use antimony trifluoride as raw material and deionized water as solvent, and mix and stir to form a doping solution. Using tin tetrachloride (SnCl 4 ) as the raw material and deionized water as the solvent, mixed and stirred to form a tin salt solution. Then the doping solution is added dropwise to the tin salt solution under stirring conditions to form a mixed solution, and the doping ratio in the mixed solution is controlled: the fluorine is 24 mol%, the antimony is 8 mol%, and the tin molar concentration is 3.5 mol / L. The pH value of the mixed solution is adjusted to 2-3 with trifluoroacetic acid, and sealed and aged for 10 hours to obtain a precursor coating solution.

[0038] The precursor coating solution is then added to the gas compression atomizer.

[0039] 2. Select one of the high-temperature-resistant materials such as high-transmission glass (low-Fe glass), quartz glass, Corning glass, and h...

Embodiment 3

[0046] 1. Under room temperature, normal pressure, and dry environment, use antimony pentafluoride as raw material and deionized water as solvent, and mix and stir to form a doping solution. Using tin tetrachloride (SnCl 4 ·5H 2 O) as the raw material and deionized water as the solvent, mixed and stirred to form a tin salt solution. Then the doping solution is added dropwise to the tin salt solution under stirring conditions to form a mixed solution, and the doping ratio in the mixed solution is controlled: fluorine is 24 mol%, antimony is 4.8 mol%, tin is 2.5 mol / L, and hydrochloric acid is used adjust the mixed solution p The H value reaches 2-3, and after airtight aging for 10 hours, a precursor coating solution is obtained.

[0047] The precursor coating solution is then added to the gas compression atomizer.

[0048] 2. Select one of the high-temperature-resistant materials such as high-transmission glass (low-Fe glass), quartz glass, Corning glass, and high-alumina t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com