Preparation method of nitrogen oxide green fluorescent powder material

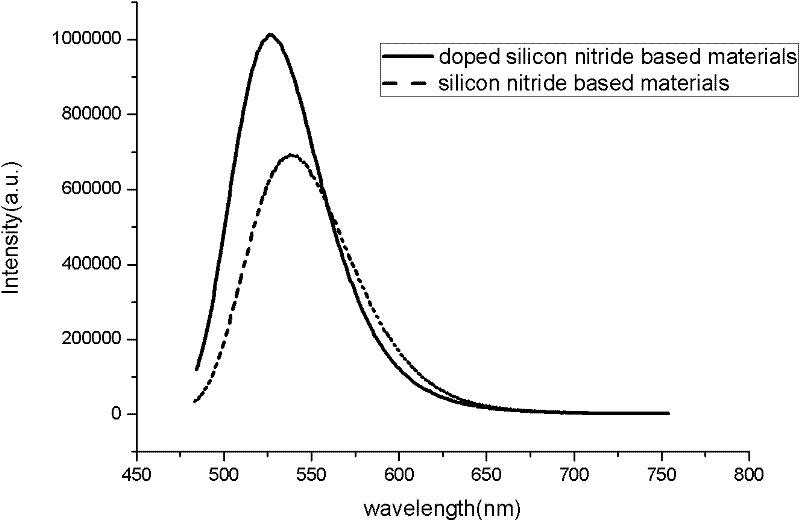

A technology of green fluorescent powder and nitrogen oxides, which is applied in the direction of luminescent materials, chemical instruments and methods, and the use of gas discharge lamps, etc., can solve the problems of low brightness, harsh synthesis conditions, and low purity of product crystal phases, and achieve broad color gamut, brightening effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The first step is to synthesize the precursor Sr of the nitrogen oxide green phosphor material 2 SiO 4 :

[0025] Weigh SrCO according to the stoichiometric ratio Sr:Si=2:1 3 147.61g, SiO 2 30.04g, and it is ground, mixes and obtains primary mixture, adds the fluxing agent SrF that accounts for primary mixture total amount 3wt% in primary mixture 2 , put in an alumina crucible after mixing and fully grinding, put the crucible in a tube furnace, in the protective gas N 2 / H 2 Sintered at 1250°C for 3 hours and then cooled to obtain Sr 2 SiO 4 .

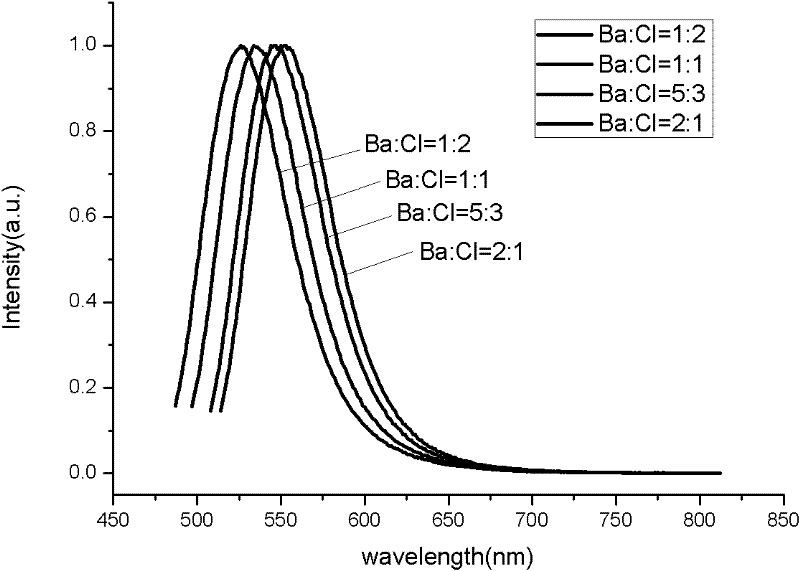

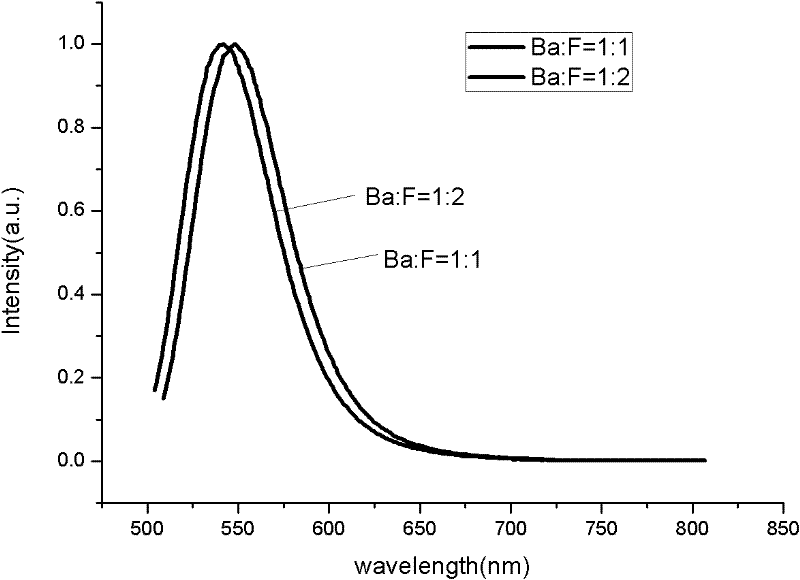

[0026] In the second step, in the prebody Sr 2 SiO 4 Doping elements in the provided matrix structure to synthesize the oxynitride green phosphor material BaSr 0.98 SiO 1.5 ClN:0.02Eu:

[0027] According to BaSr 0.98 SiO 1.5The stoichiometric ratio of ClN:0.02Eu (Sr, Ba):Si:(O,Cl):N:Eu=1.98:1:2.5:1:0.02, weigh BaCO 3 2.5g, BaCl 2 2.638g, α-Si 3 N 4 0.605g and Eu 2 o 3 0.089g; Then the gained Sr 2 SiO 4 Afte...

Embodiment 2

[0029] The first step is to synthesize the precursor Sr of the nitrogen oxide green phosphor material 2 SiO 4 :

[0030] Weigh SrCO according to the stoichiometric ratio Sr:Si=2:1 3 147.61g, SiO 2 30.04g, and it is ground, mixes and obtains primary mixture, adds the fluxing agent SrF that accounts for primary mixture total amount 2wt% in primary mixture 2 , put in an alumina crucible after mixing and fully grinding, put the crucible in a tube furnace, in the protective gas N 2 Sintered at 1250°C for 3 hours and then cooled to obtain Sr 2 SiO 4 .

[0031] In the second step, in the prebody Sr 2 SiO 4 Doping elements in the provided matrix structure to synthesize the oxynitride green phosphor material BaSr 0.98 SiOCl 2 N:0.02Eu:

[0032] According to BaSr 0.98 SiOCl 2 N:0.02Eu element stoichiometric ratio (Sr, Ba):Si:(O,Cl):N:Eu=1.98:1:3:1:0.02, weigh BaCl 2 5g, α-Si 3 N 4 0.605g and Eu 2 o 3 0.089g, then the resulting Sr 2 SiO 4 After grinding and sieving,...

Embodiment 3

[0034] The first step is to synthesize the precursor Sr of the nitrogen oxide green phosphor material 2 SiO 4 :

[0035] Weigh SrCO according to the stoichiometric ratio Sr:Si=2:1 3 147.61g, SiO 2 30.04g, SrF 2 , and it is ground and mixed to obtain a primary mixture, and the fluxing agent SrF that accounts for 4wt% of the total amount of the primary mixture is added in the primary mixture 2 , put in an alumina crucible after mixing and fully grinding, put the crucible in a tube furnace, in the protective gas NH 3 Sintered at 1250°C for 3 hours and then cooled to obtain Sr 2 SiO 4 .

[0036] In the second step, in the prebody Sr 2 SiO 4 Doping elements in the provided matrix structure to synthesize the oxynitride green phosphor material BaSr 0.98 SiO 1.7 Cl 0.6 N:0.02Eu:

[0037] According to BaSr 0.98 SiO 1.7 Cl 0.6 N:0.02Eu element stoichiometric ratio (Sr, Ba):Si:(O,Cl):N:Eu=1.98:1:2.3:1:0.02, weigh BaCO 3 3.499g, BaCl 2 1.583g, α-Si 3 N 4 0.605g and E...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com