Die-casting aluminum alloy and preparation method and application thereof

A technology for casting aluminum alloys and aluminum alloys, which is applied in the field of aluminum alloys and can solve problems such as difficulty in obtaining thermal conductivity of die-casting aluminum alloys.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] The present invention also provides a method for preparing the above-mentioned die-casting aluminum alloy, wherein the method includes: smelting the aluminum alloy raw material and performing die-casting treatment to obtain a die-casting aluminum alloy; the composition of the aluminum alloy raw material is such that the obtained die-casting aluminum alloy is the The die-casting aluminum alloy described in the first aspect.

[0026] According to the method for preparing a die-casting aluminum alloy of the present invention, the aluminum alloy raw material may be a pure metal or a metal alloy, as long as the composition of the aluminum alloy obtained after smelting the added aluminum alloy raw material is within the above range. In a preferred case, the aluminum alloy raw material may include pure Al or Al alloy, pure Si or Si alloy, pure Fe or Fe alloy, pure Zn or Zn alloy, pure Sr or Sr alloy, pure Ni or Ni alloy and pure Ga or Ga alloy. In a more preferred situation, ...

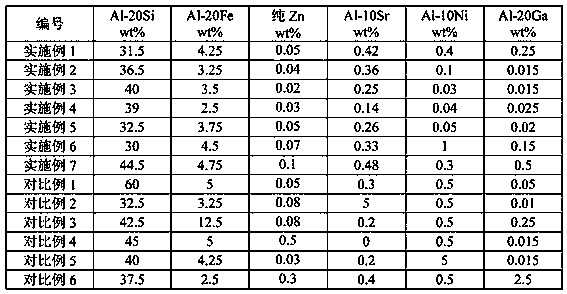

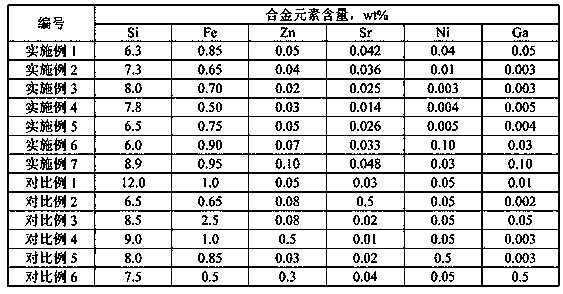

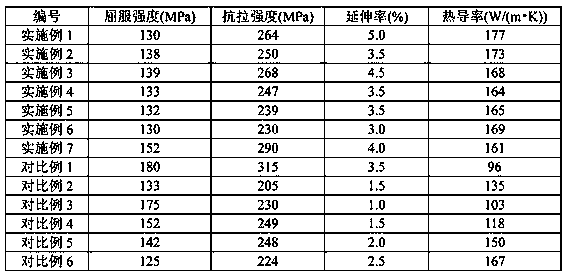

Embodiment 1

[0031] After calculating the ingredients, weigh each metal alloy and pure metal by weight, and then prepare die-cast aluminum alloy A1 according to the aluminum alloy smelting and die-casting sample preparation process provided above. The weight ratio of metal alloy and pure metal is shown in Table 1.

Embodiment 2

[0033] Die-casting aluminum alloy A2 was prepared according to the method of Example 1, the difference is that the weight ratio of the metal alloy and pure metal weighed is shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com