Electrostriction material and preparation method thereof

A technology of electrostrictive materials and raw materials, applied in the direction of piezoelectric/electrostrictive/magnetostrictive devices, circuits, electrical components, etc., can solve the problems of poor pressure resistance, high manufacturing cost, high loss, etc., and achieve voltage resistance The effect of high performance, low cost and low loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

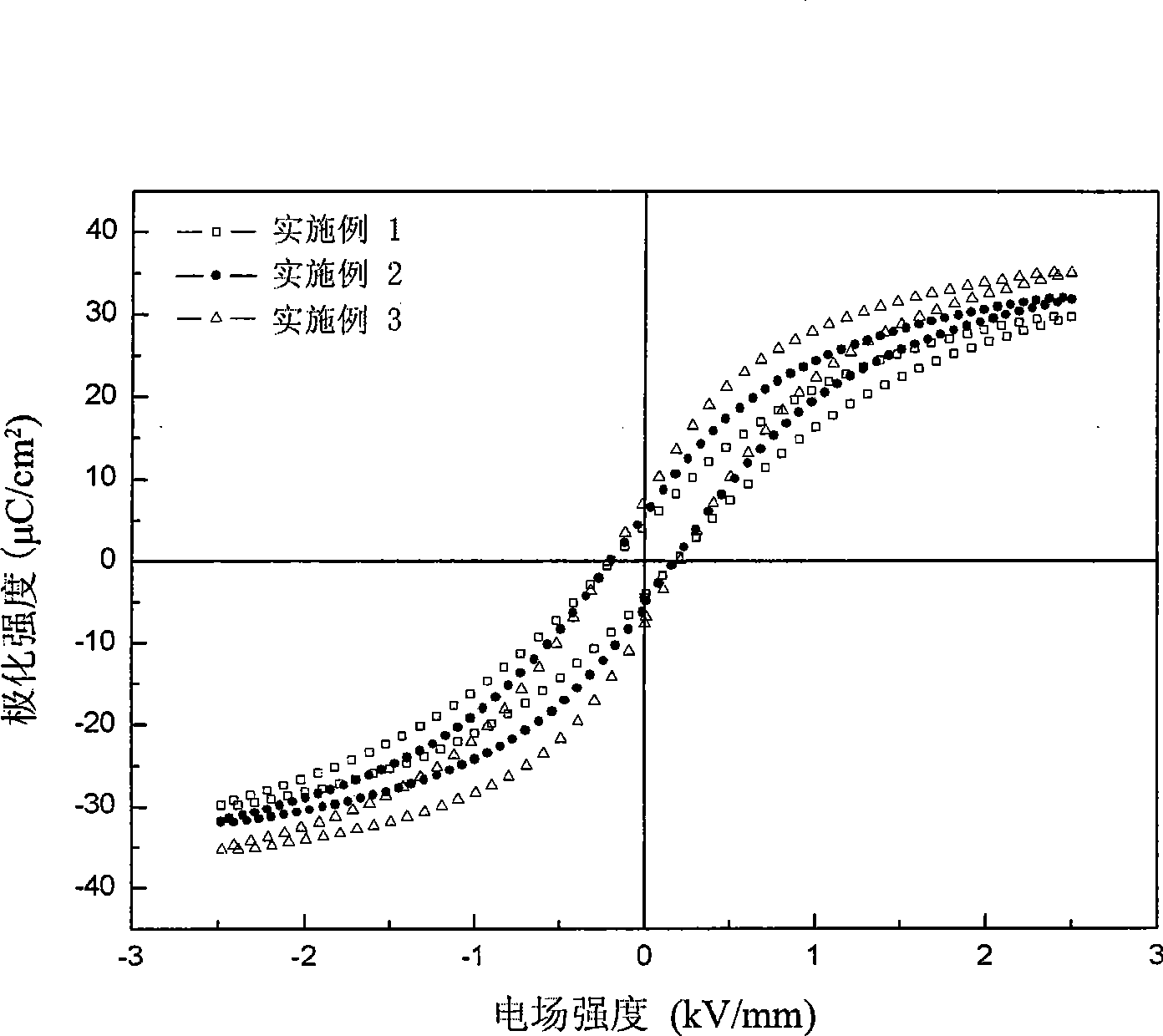

Embodiment 1

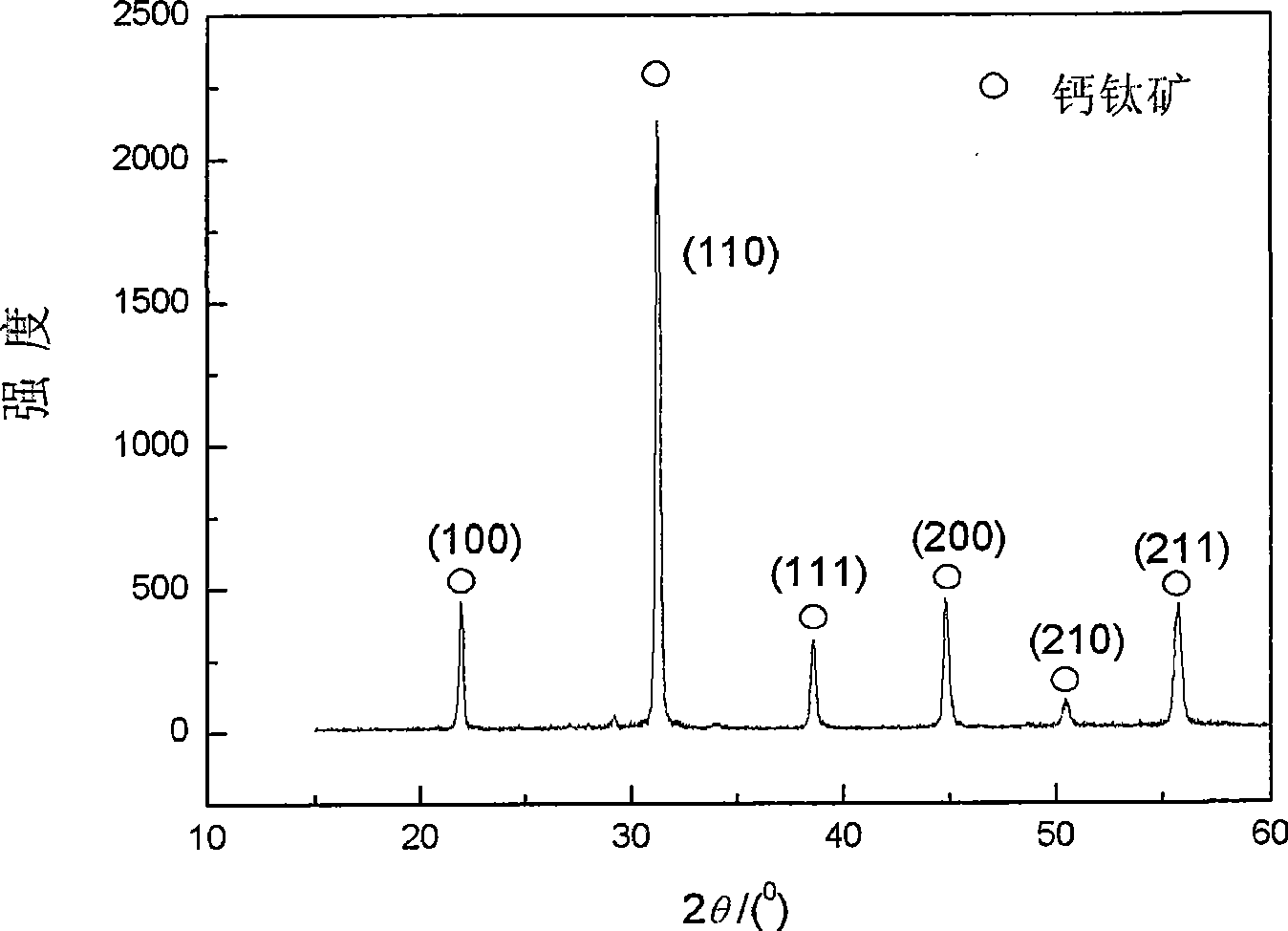

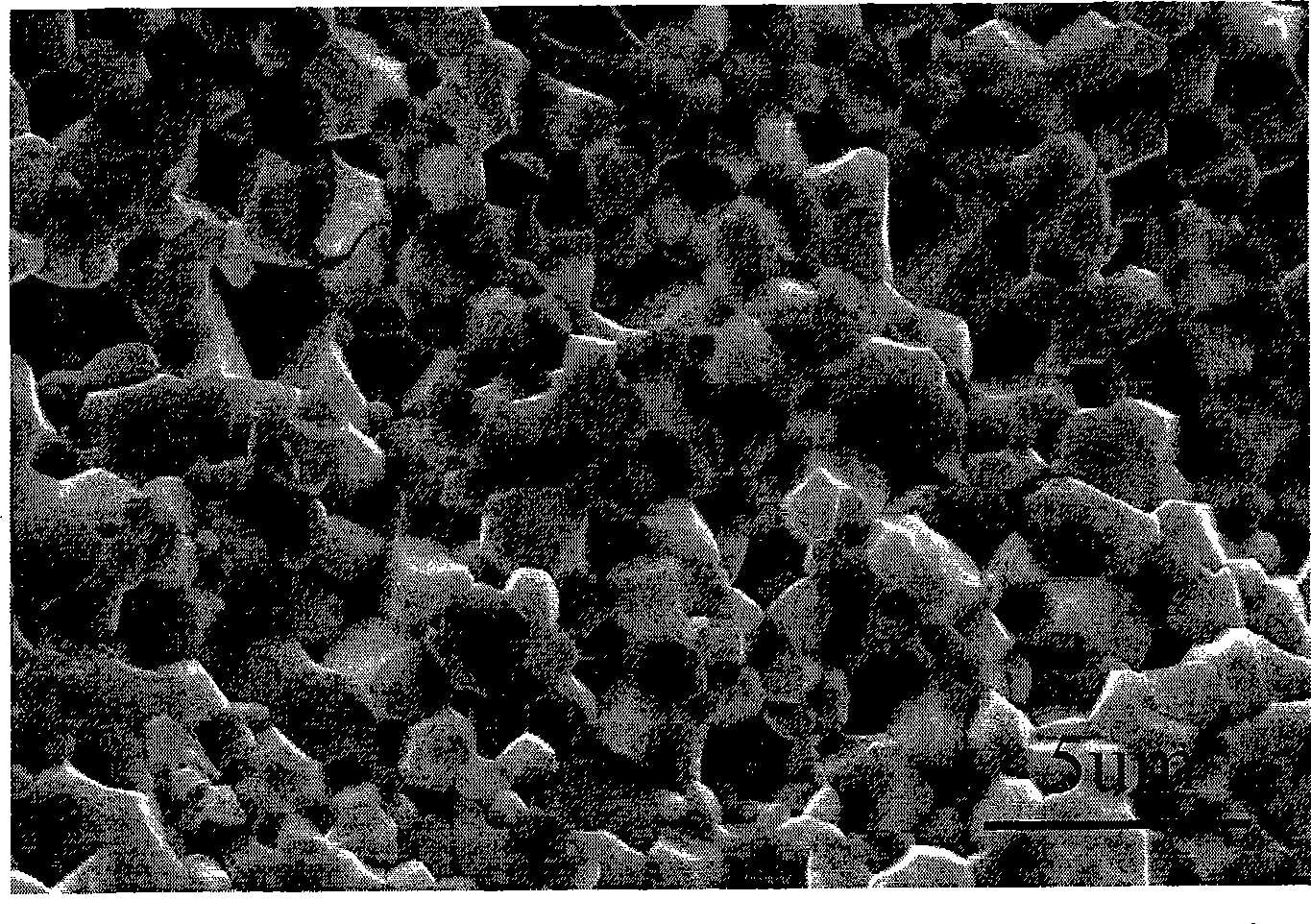

[0029] 1) With chemically pure PbO, TiO 2 , Mg(OH) 2 , Nb 2 o 5 , SrCO 3 、Sc 2 o 3 、Cr 2 o 3 As raw material, according to the composition formula Pb 0.95 Sr 0.05 (Mg 1 / 3 Nb 2 / 3 ) 0.1 Ti 0.9 o 3 +0.01mol%Sc 2 o 3 +0.02mol% Cr 2 o 3 The stoichiometric ratio is accurately weighed;

[0030] 2) First with Mg(OH) 2 and Nb 2 o 5 As a raw material, MgNb is first synthesized by incubating at 800-1000°C for 2.5 hours 2 o 6 , and then with PbO, TiO 2 , SrCO 3 、Sc 2 o 3 、Cr 2 o 3 Carry out mixing and ball milling according to the corresponding proportion, and heat preservation at 800-1000°C for 2.5 hours to synthesize lead magnesium niobate powder for the second time;

[0031] 3) After the secondary synthetic lead magnesium niobate powder obtained in step 2) is ball-milled into micron again, 0.5wt% polyvinyl alcohol is added as a binder to granulate and shape, and then keep warm at 1100-1250°C for 2 hours. Sintering to obtain electrostrictive materials.

[...

Embodiment 2

[0037] 1) With chemically pure PbO, TiO 2 , Mg(OH) 2 , Nb 2 o 5 , La 2 o 3 、Sc 2 o 3 、 Bi 2 o 3 As raw material, according to the composition formula Pb 0.98 La 0.02 (Mg 1 / 3 Nb2 / 3 ) 0.05 Ti 0.95 o 3 +0.3mol%Sc 2 o 3 +0.1mol% Bi 2 o 3 The stoichiometric ratio weighing;

[0038] 2) First with Mg(OH) 2 and Nb 2 o 5 As a raw material, MgNb was first synthesized by incubating at 850°C for 1.5 hours 2 o 6 , and then with PbO, TiO 2 , La 2 o 3 、Sc 2 o 3 、 Bi 2 o 3 Carry out mixing ball milling according to the corresponding proportion, and heat preservation at 850°C for 1.5 hours to synthesize lead magnesium niobate powder for the second time;

[0039] 3) After the secondary synthetic lead magnesium niobate powder obtained in step 2) is ball-milled into micron again, 0.5wt% polyvinyl alcohol is added as a binder to granulate, and then sintered at 1200° C. for 2 hours. Thus an electrostrictive material is obtained.

[0040] Then, the same processing tec...

Embodiment 3

[0042] 1) With chemically pure PbO, TiO 2 , Mg(OH) 2 , Nb 2 o 5 、Sc 2 o 3 、Cr 2 o 3 As raw material, according to the composition formula Pb(Mg 1 / 3 Nb 2 / 3 ) 0.15 Ti 0.85 o 3 +0.02mol% Sc 2 o 3 +0.48mol%Cr 2 o 3 The stoichiometric ratio weighing;

[0043] 2) First with Mg(OH) 2 and Nb 2 o 5 As a raw material, MgNb was first synthesized by incubating at 1000°C for 1 hour 2 o 6 , and then with PbO, TiO 2 、Sc 2 o 3 、Cr 2 o 3 Carry out mixing ball milling according to the corresponding proportion, and heat preservation at 1000°C for 1 hour to synthesize lead magnesium niobate powder for the second time;

[0044] 3) After the secondary synthetic lead magnesium niobate powder obtained in step 2) is ball-milled into micron again, 0.5wt% polyvinyl alcohol is added as a binder to granulate, and then sintered at 1250°C for 1 hour. Thus an electrostrictive material is obtained.

[0045] Then, the same processing technology as in Example 1 was adopted for the pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com