Patents

Literature

448 results about "Electrostriction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Electrostriction (cf. magnetostriction) is a property of all electrical non-conductors, or dielectrics, that causes them to change their shape under the application of an electric field.

Three dimensionally periodic structural assemblies on nanometer and longer scales

InactiveUS6261469B1Low melting pointEasily de-infiltrateSilicaPaper/cardboard articlesChromatographic separationThermoelectric materials

This invention relates to processes for the assembly of three-dimensional structures having periodicities on the scale of optical wavelengths, and at both smaller and larger dimensions, as well as compositions and applications therefore. Invention embodiments involve the self assembly of three-dimensionally periodic arrays of spherical particles, the processing of these arrays so that both infiltration and extraction processes can occur, one or more infiltration steps for these periodic arrays, and, in some instances, extraction steps. The product articles are three-dimensionally periodic on a scale where conventional processing methods cannot be used. Articles and materials made by these processes are useful as thermoelectrics and thermionics, electrochromic display elements, low dielectric constant electronic substrate materials, electron emitters (particularly for displays), piezoelectric sensors and actuators, electrostrictive actuators, piezochromic rubbers, gas storage materials, chromatographic separation materials, catalyst support materials, photonic bandgap materials for optical circuitry, and opalescent colorants for the ultraviolet, visible, and infrared regions.

Owner:ALLIEDSIGNAL INC

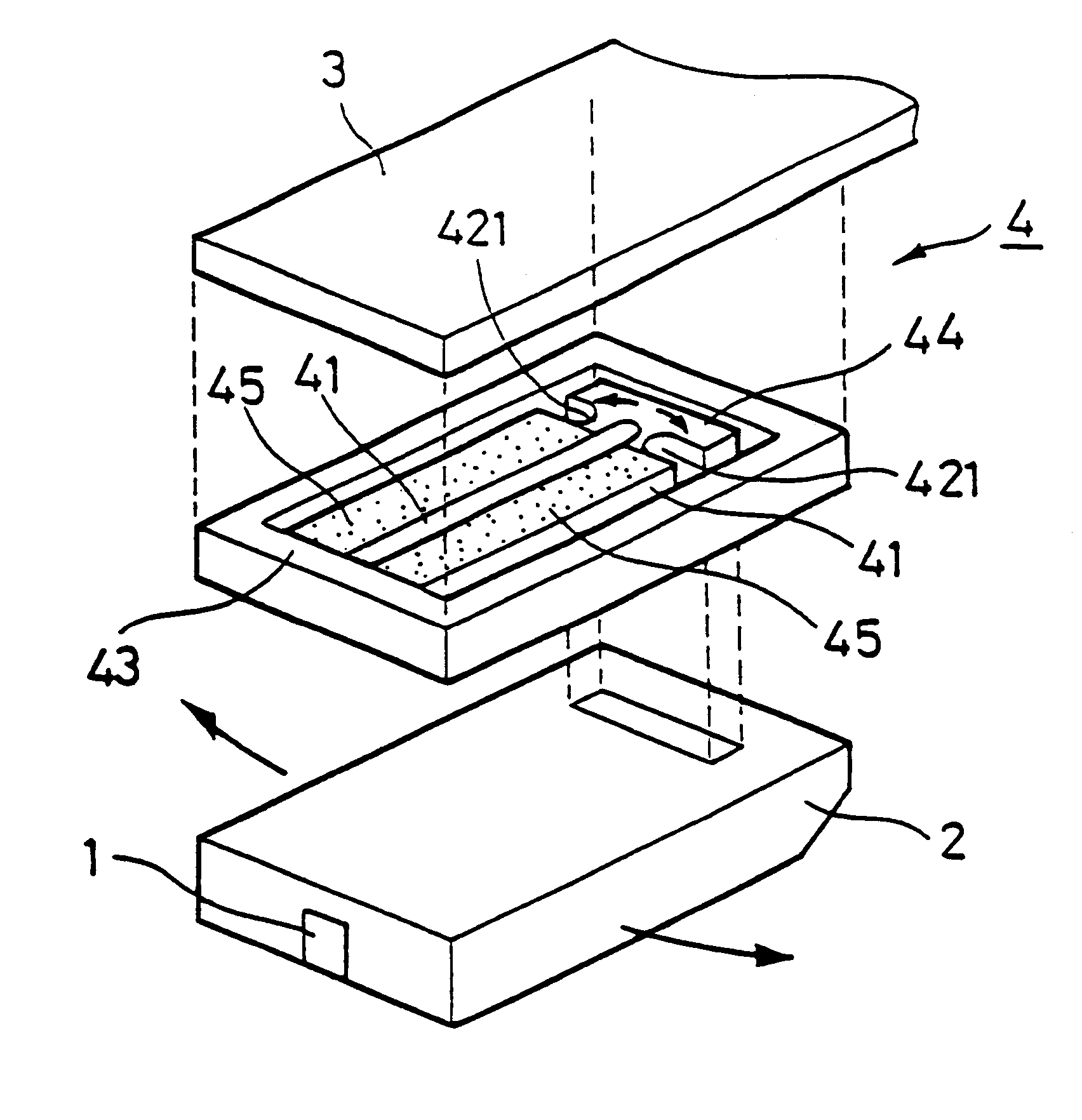

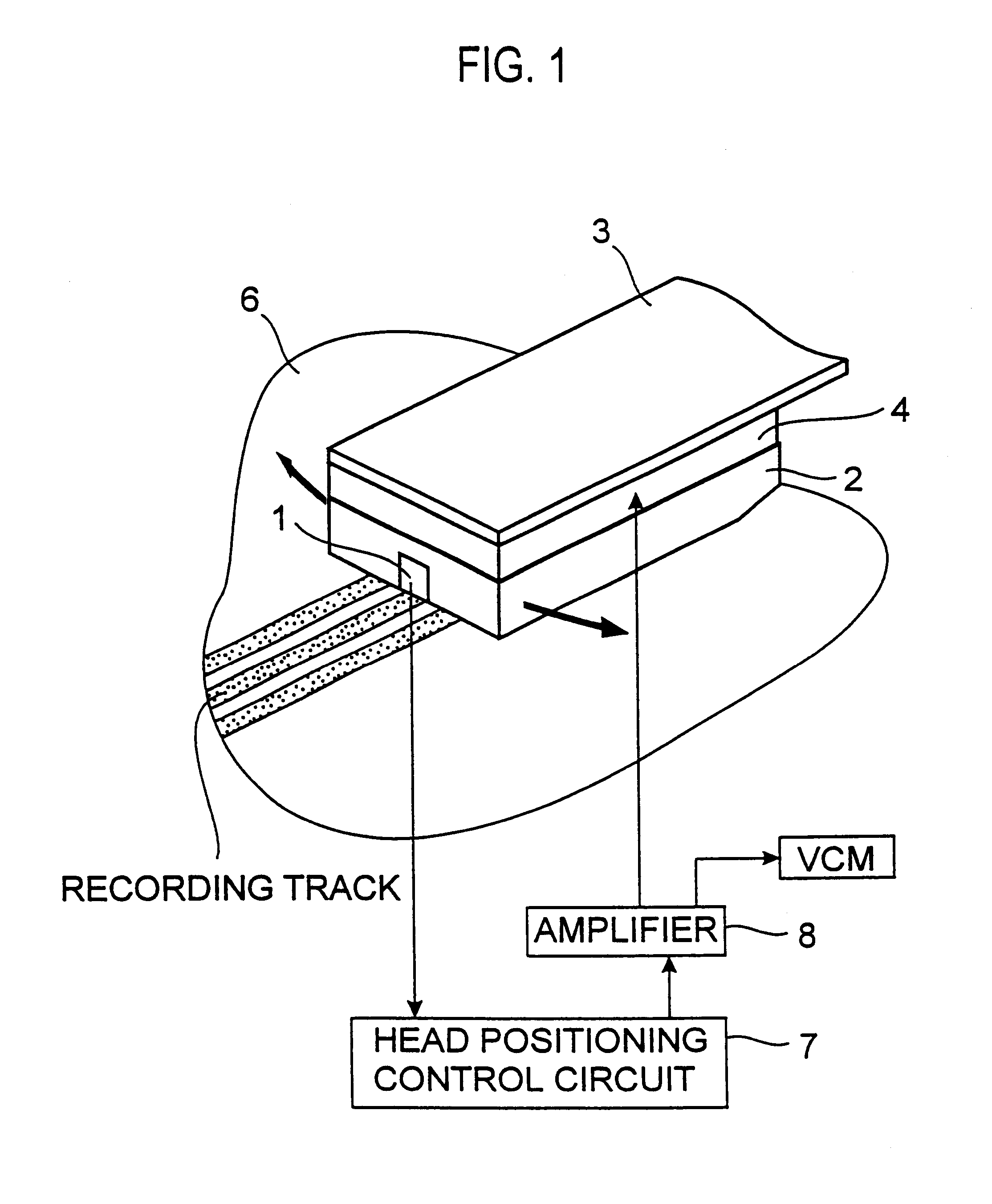

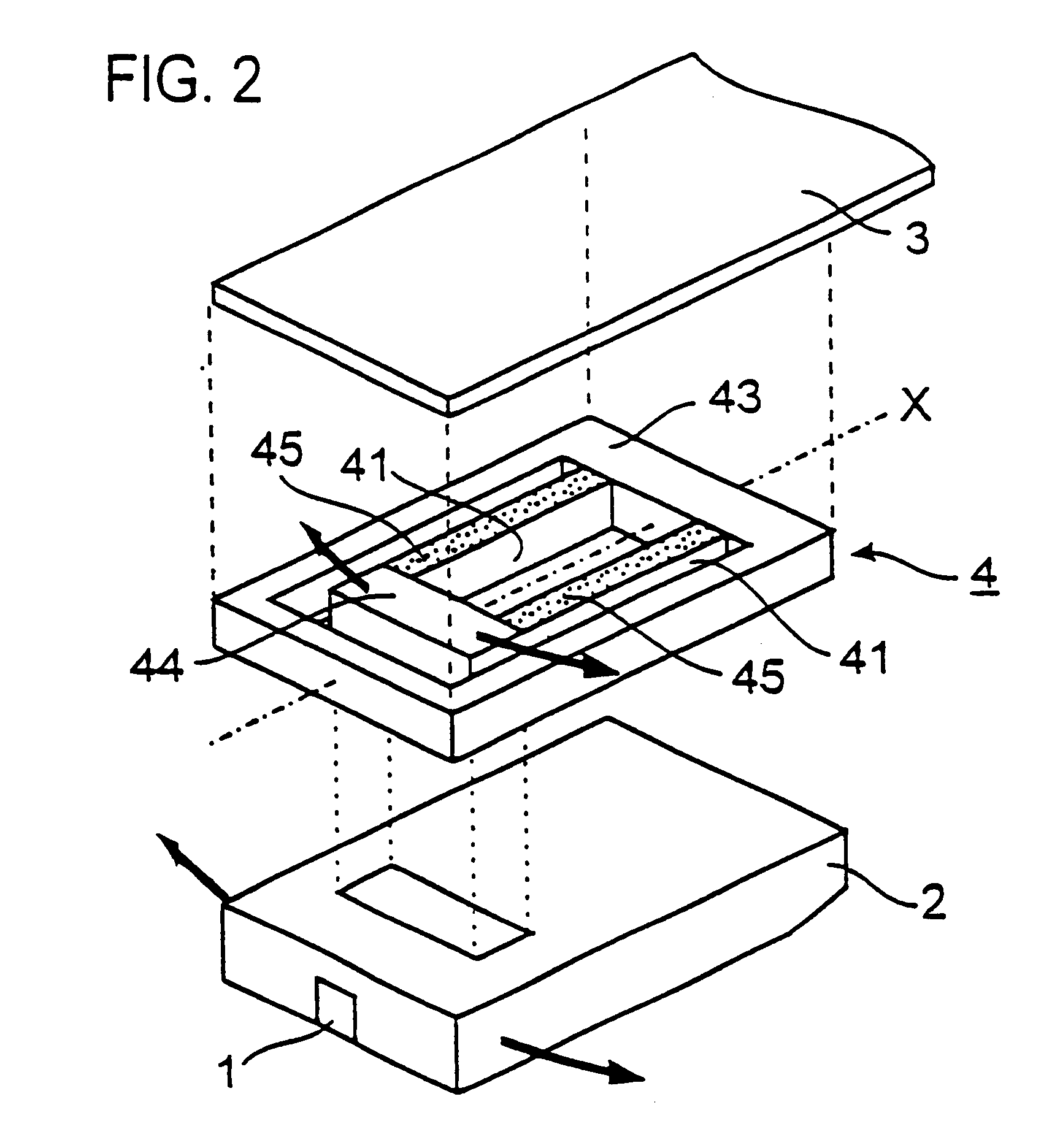

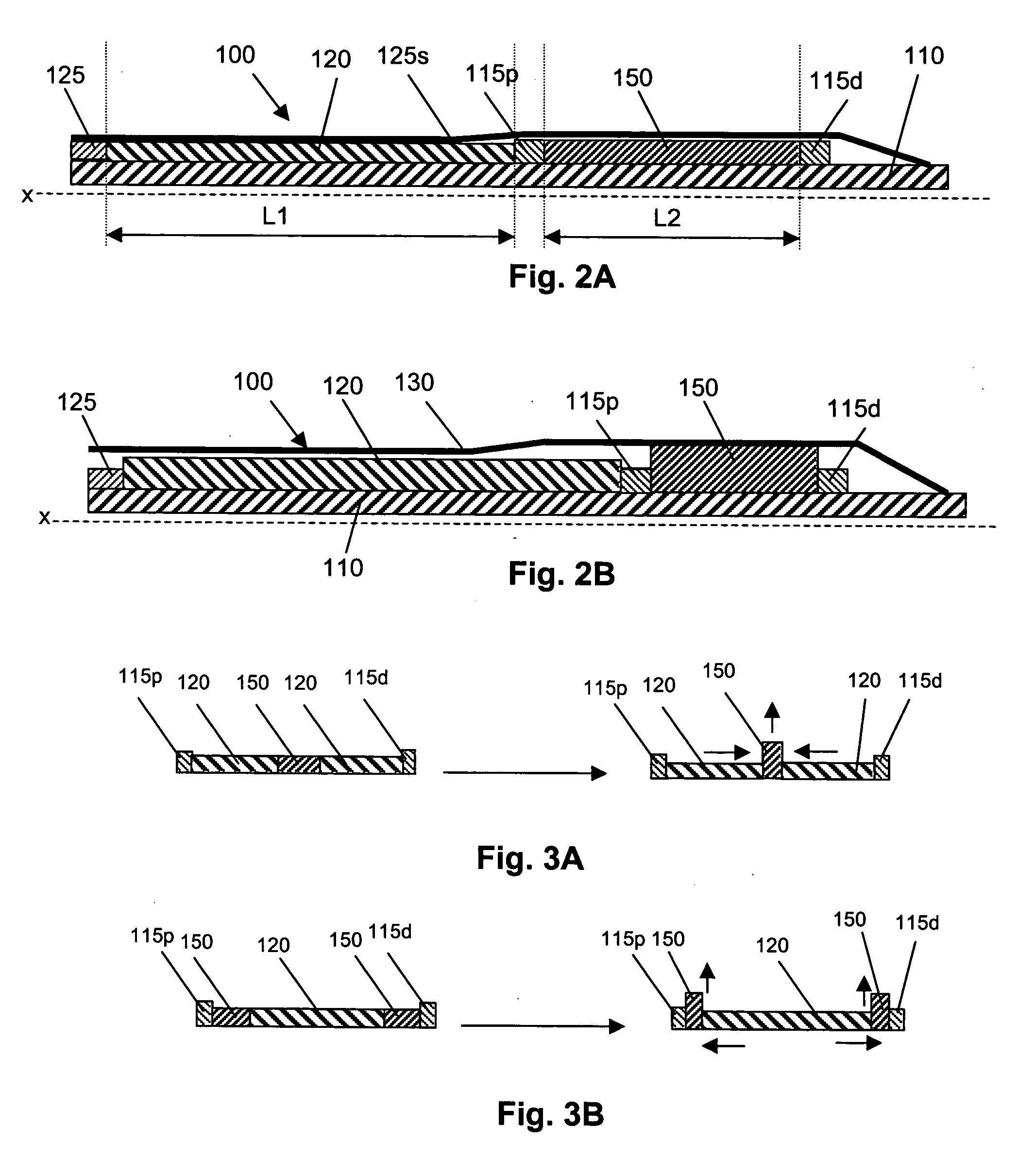

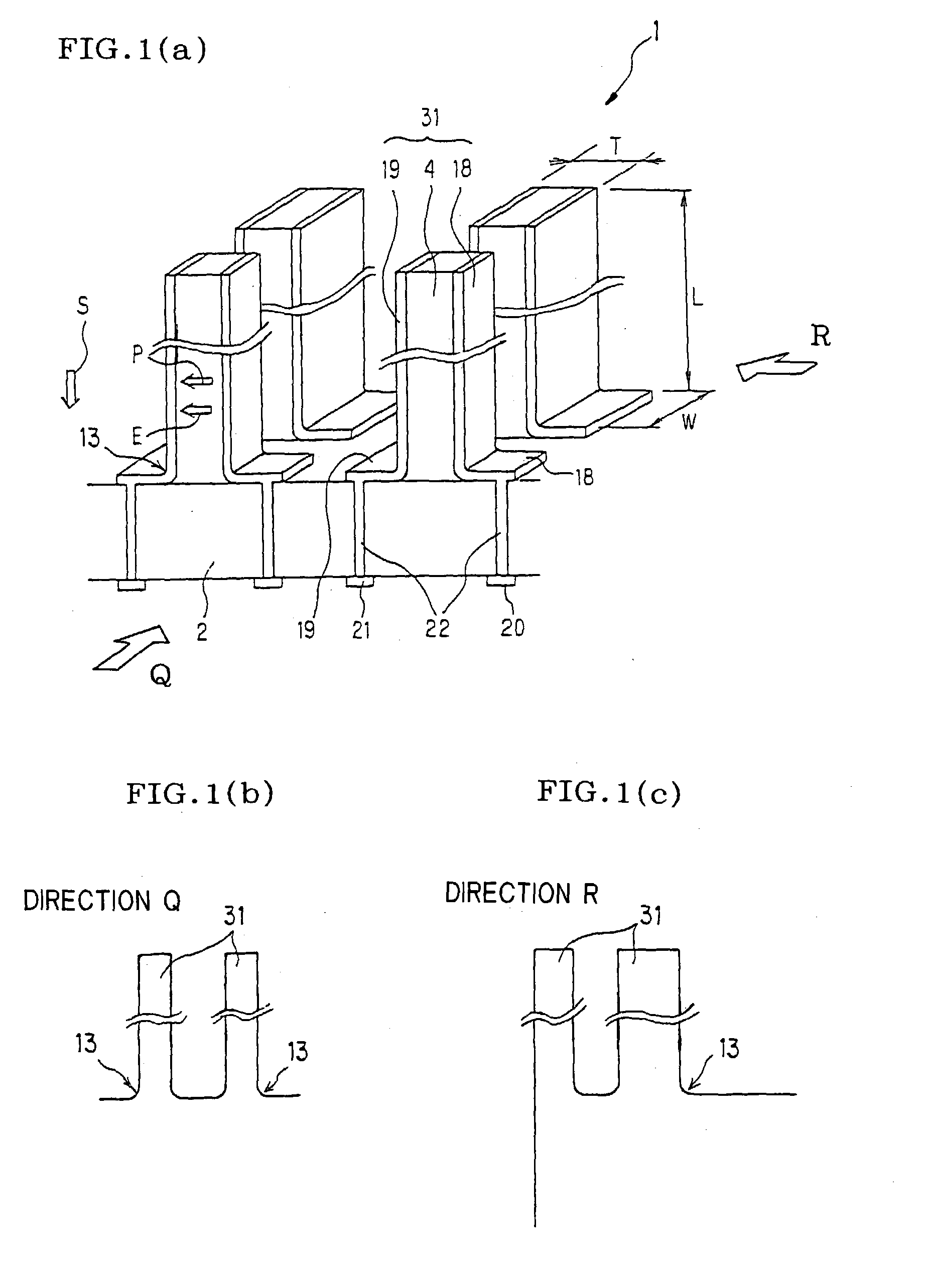

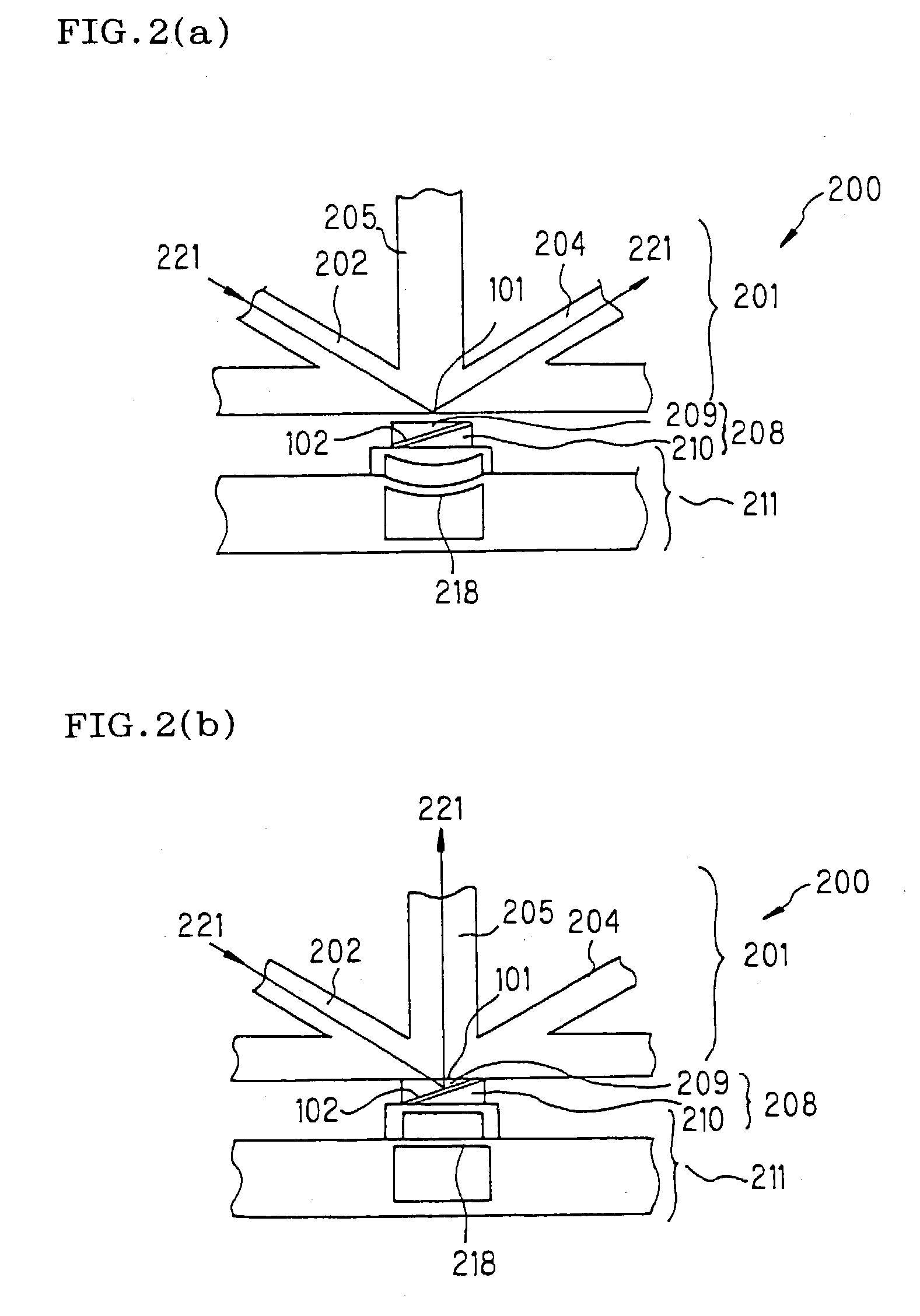

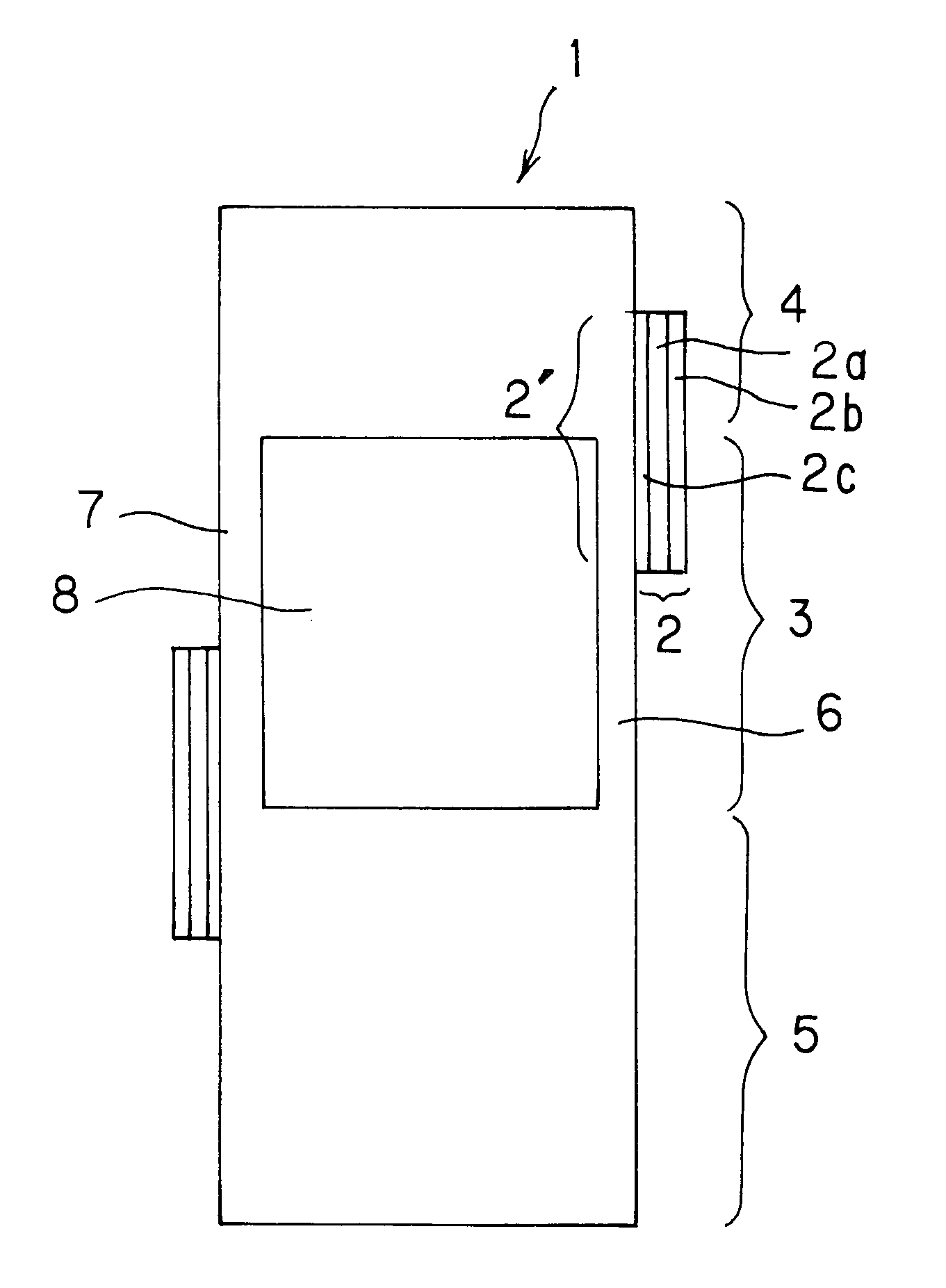

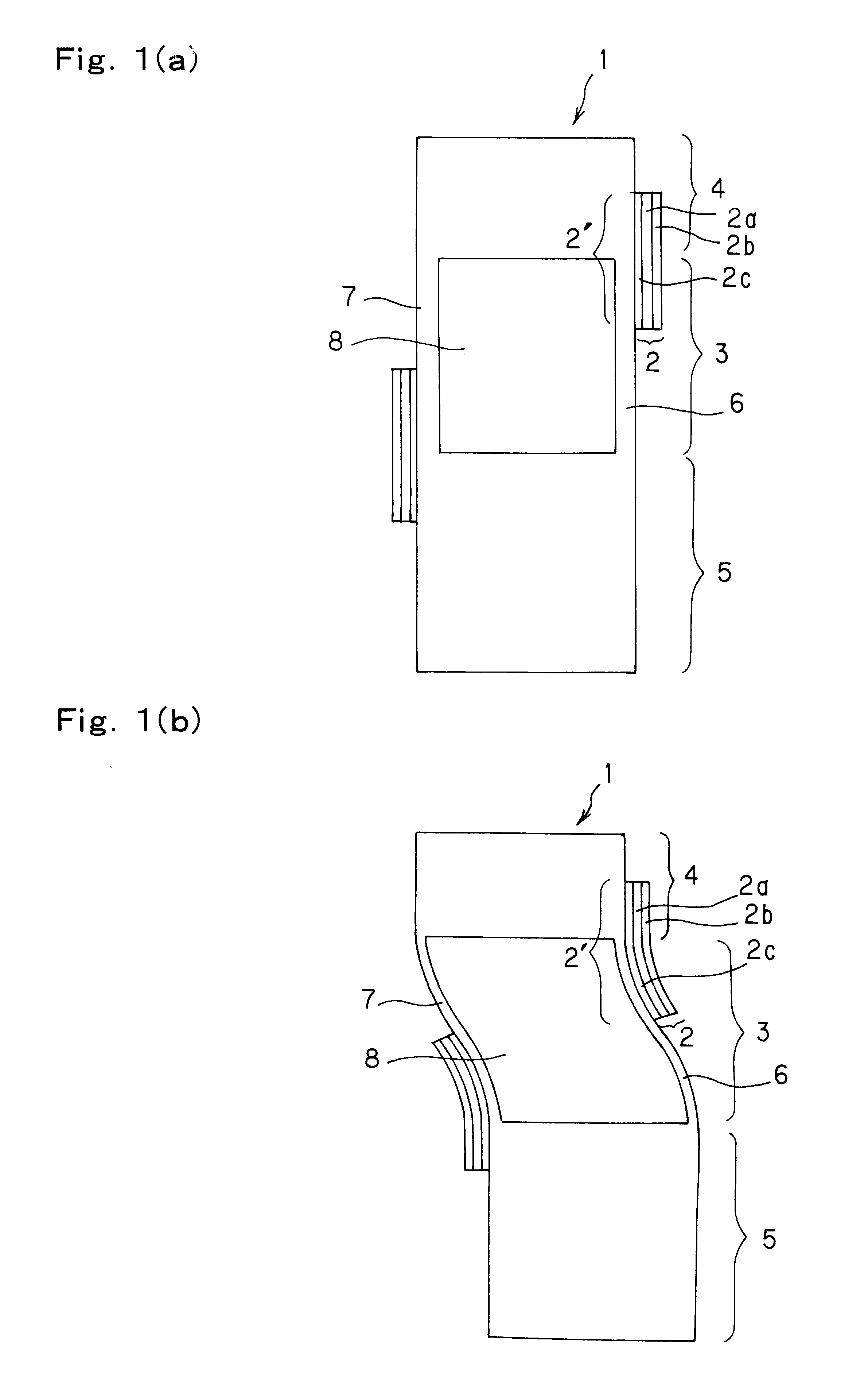

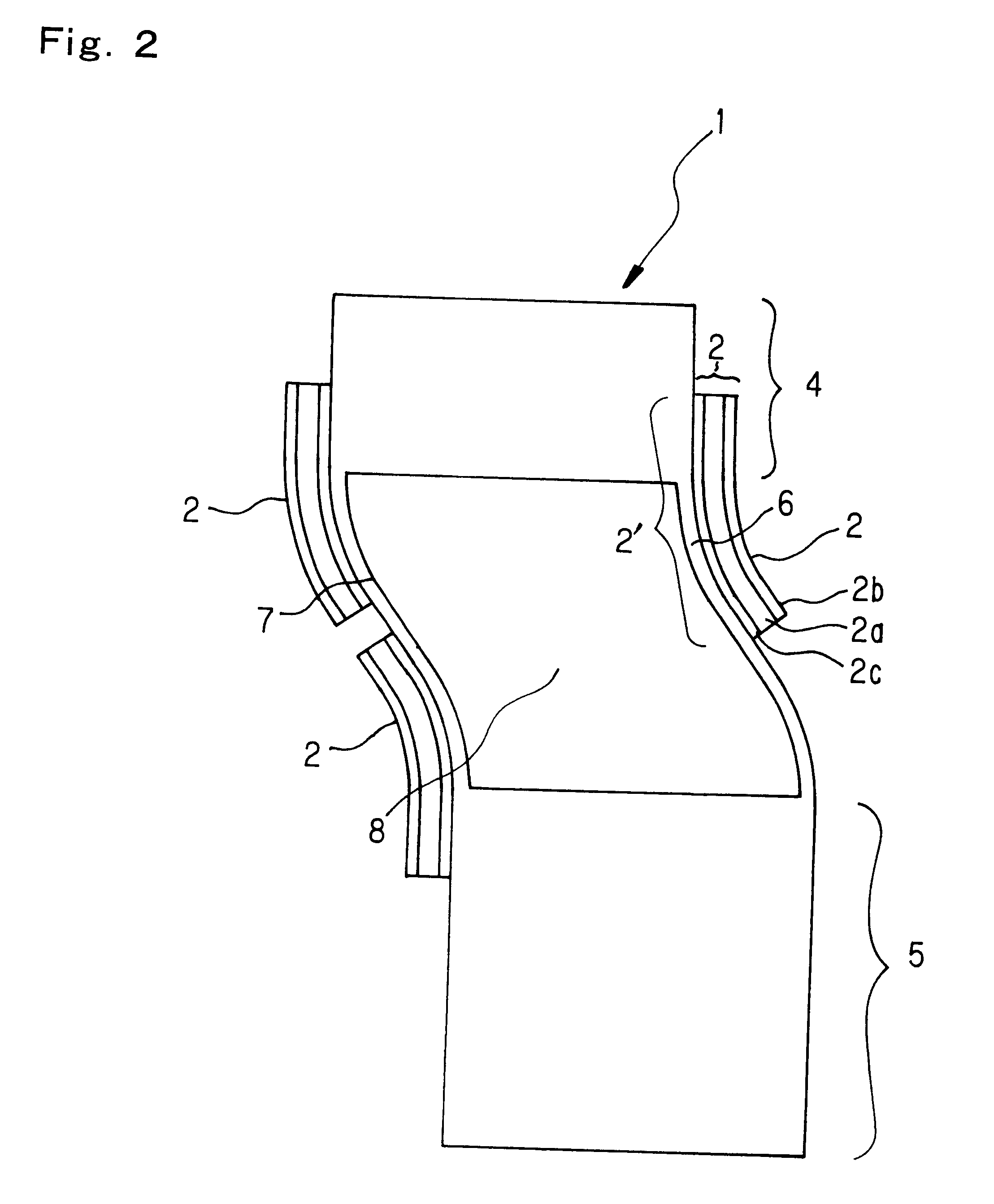

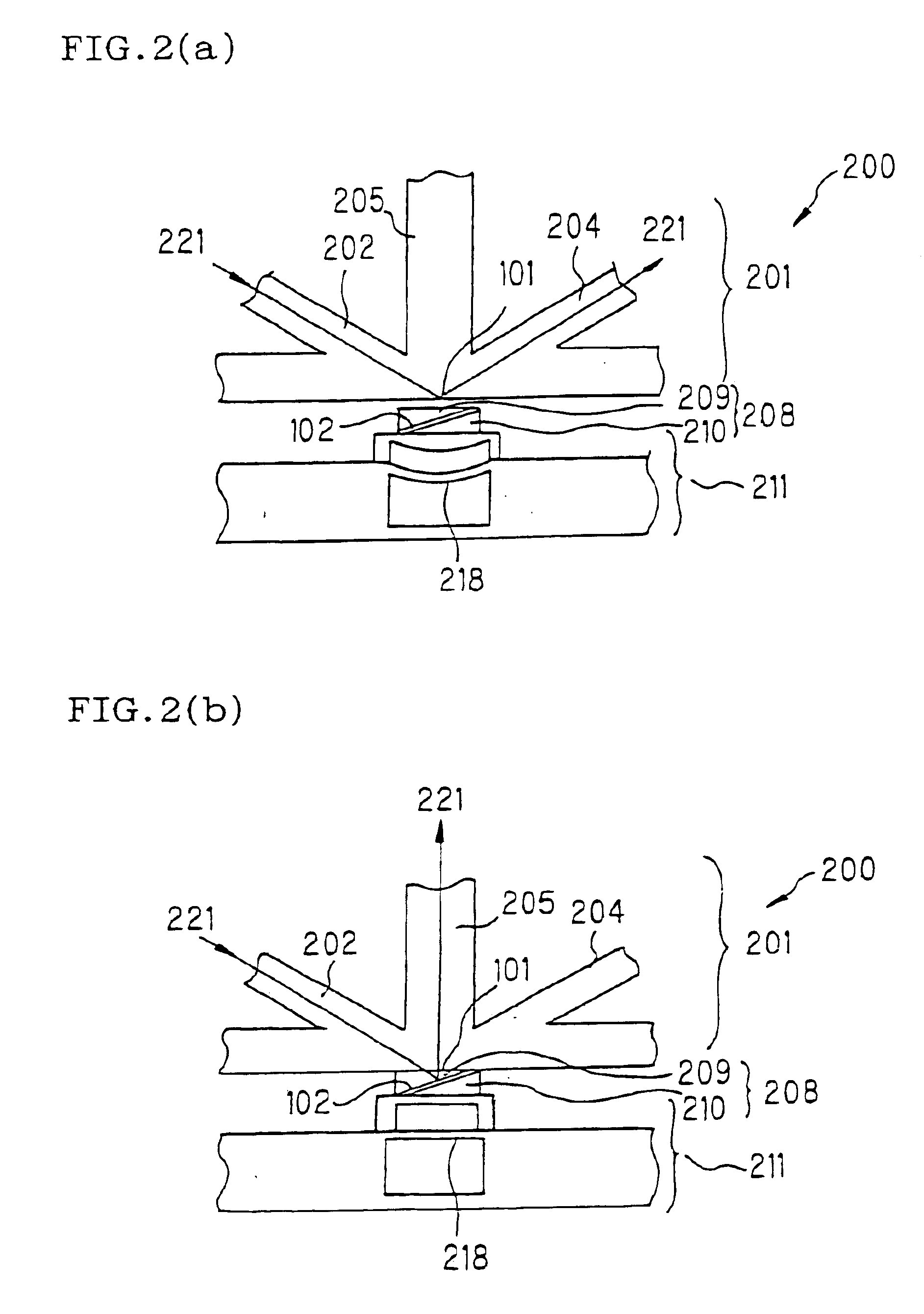

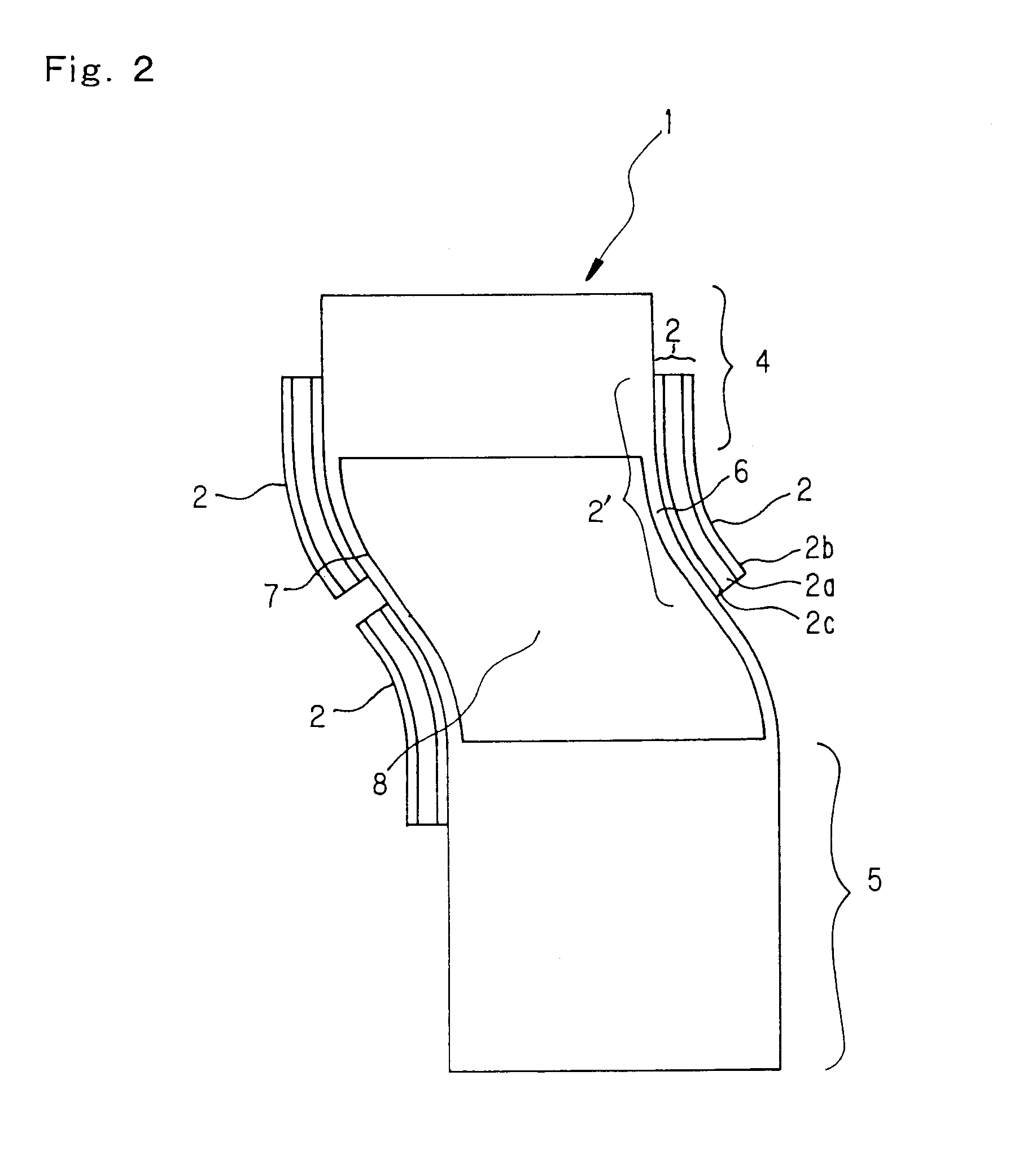

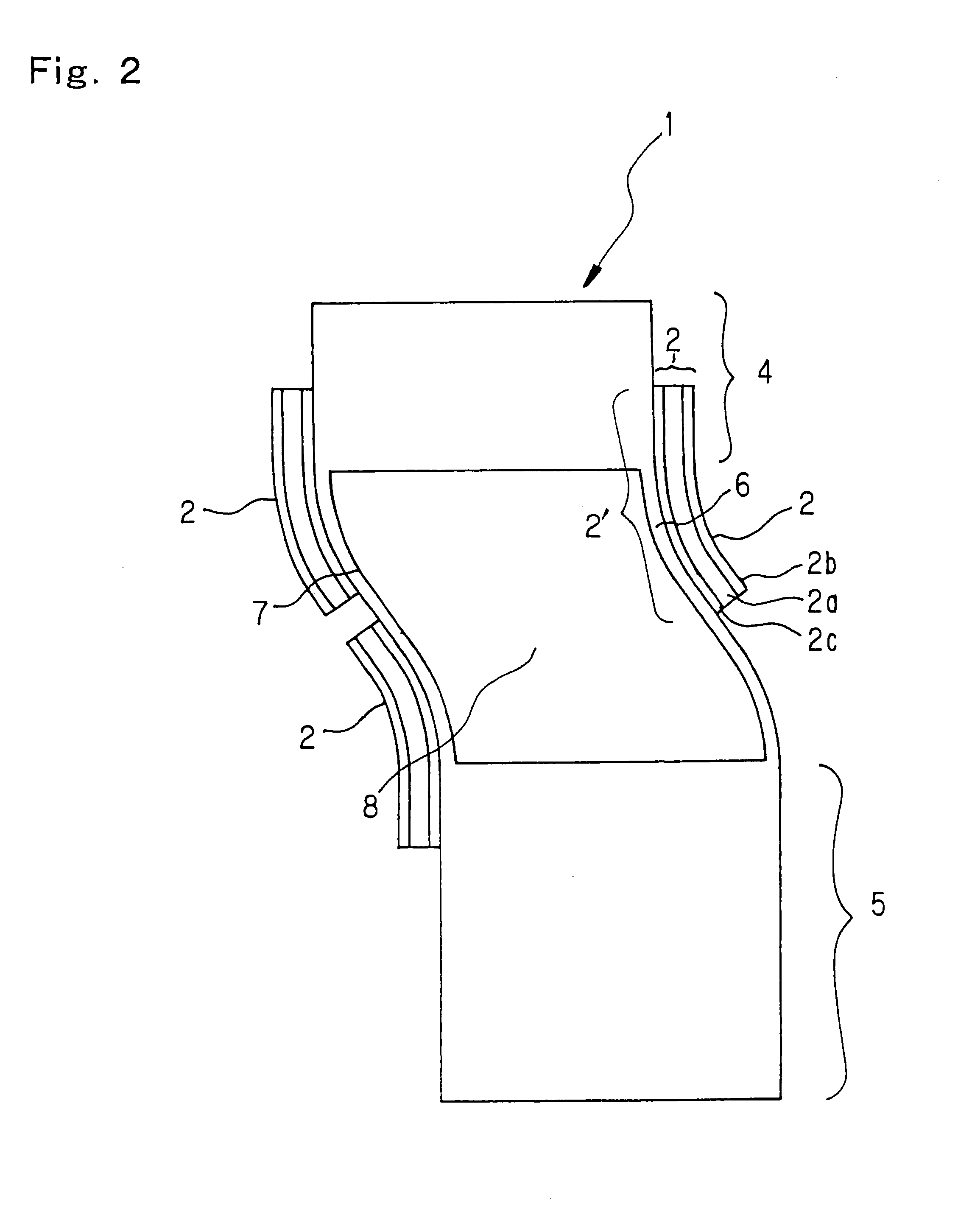

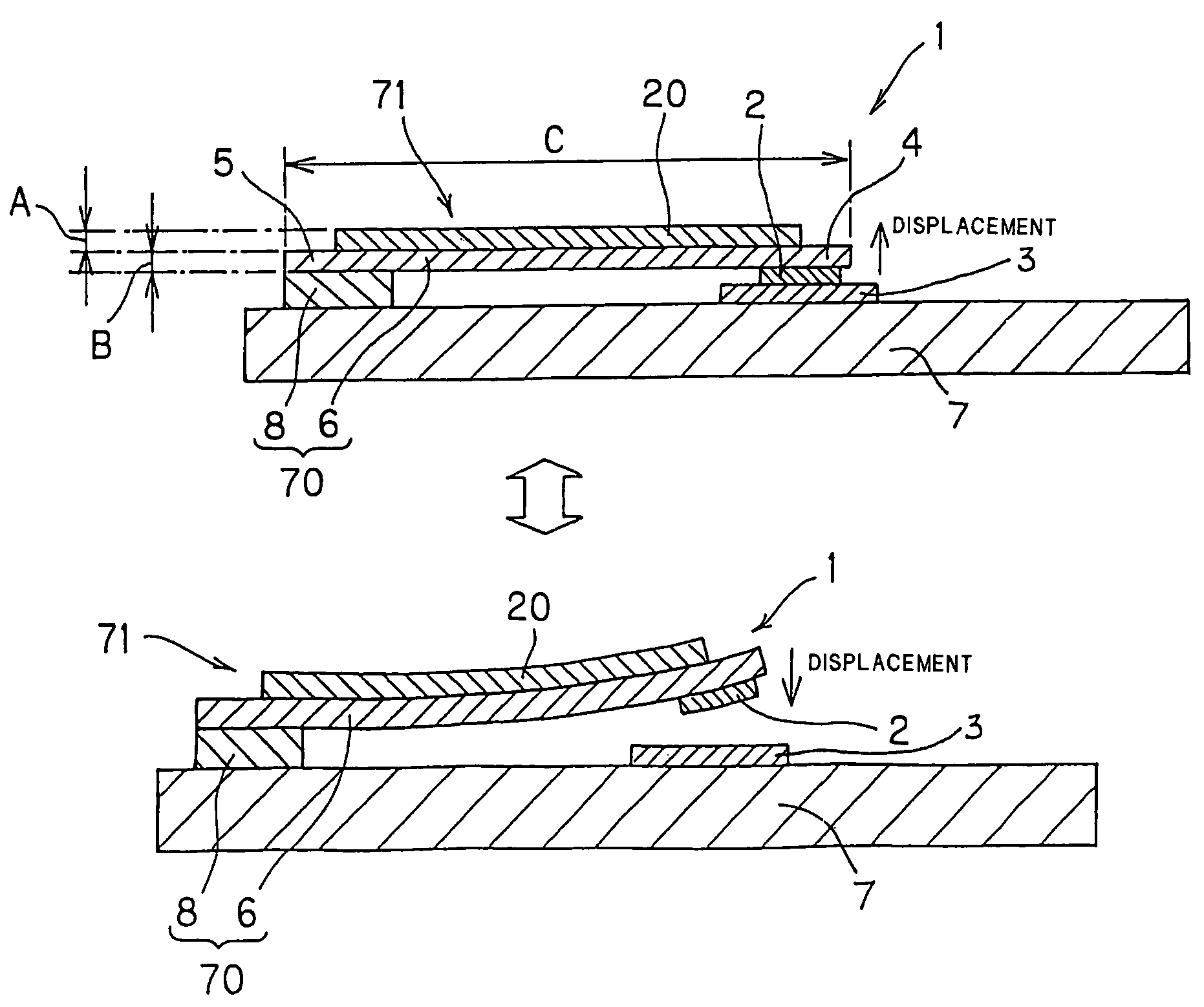

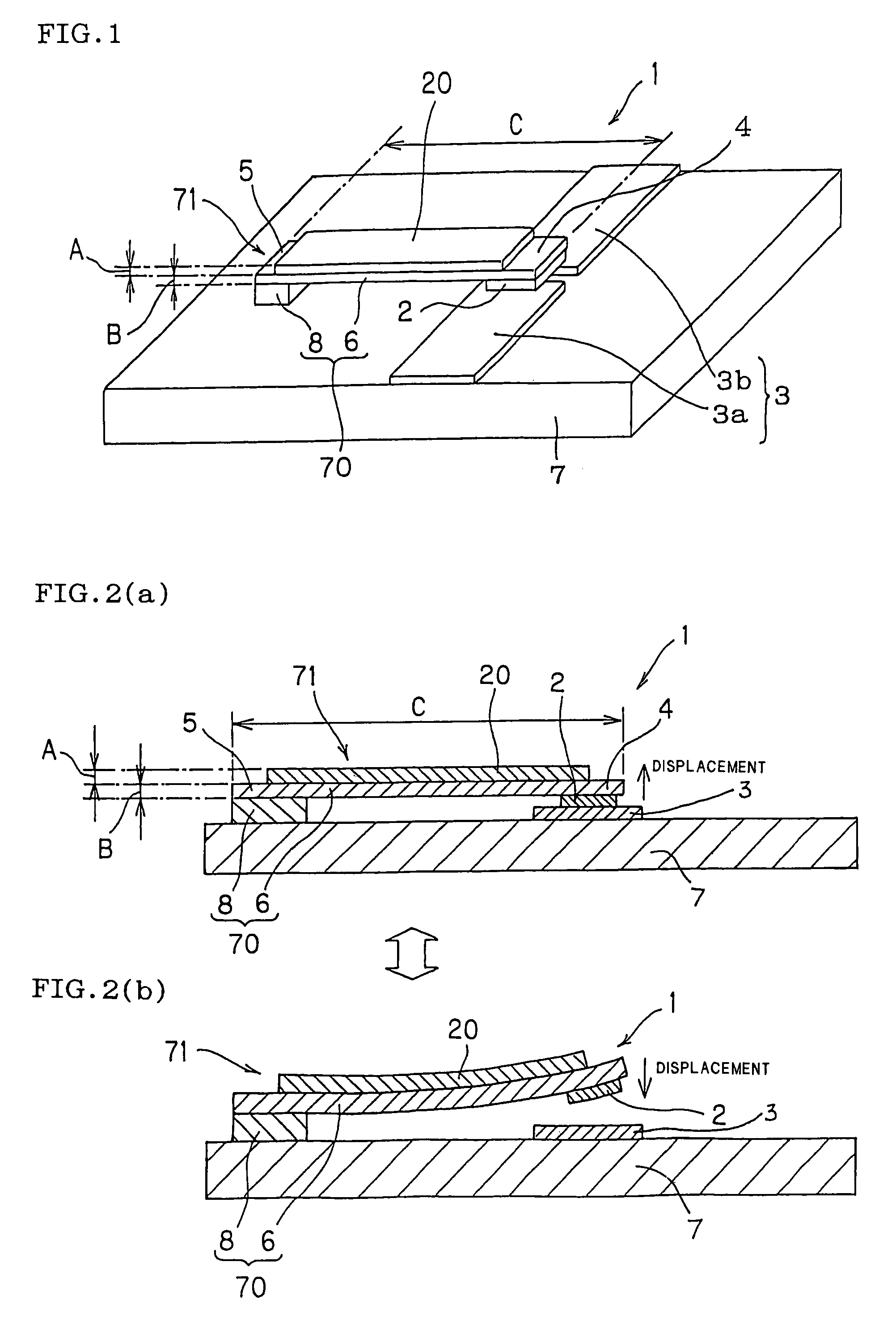

Read/write head including displacement generating means that elongates and contracts by inverse piezoelectric effect of electrostrictive effect

A read / write head includes a slider provided with an electromagnetic transducer element (or an optical module), an actuator, and a suspension. The actuator includes a fixed part, a movable part, and at least two beam members for coupling them together. The beam members have a displacement generating means that elongates and contracts by inverse piezoelectric effect or electrostrictive effect. The fixed part is fixed to the suspension, and the movable part is fixed to the slider. Upon the elongation and contraction of the displacement generator, the displacement generator deflects and the movable part displaces linearly, circularly or rotationally with respect to the fixed part, and the electromagnetic transducer element displaces in a linear or circular orbit, so that the electromagnetic transducer element intersects recording tracks. In the actuator, the fixed part, movable part and beam members are formed as an integrated single piece by providing a hole and / or a cutout in a sheet-like member constructed of a piezoelectric or electrostrictive material. The actuator of the structure illustrated is used for the positioning of a direction intersecting recording tracks. In this case, the total sum of voltages applied on the displacement generating means is controlled in such a manner that it is constant at any time, thereby controlling position fluctuations of the electromagnetic transducer element in the direction vertical to the recording medium surface.

Owner:TDK CORPARATION

Electrically actuated medical devices

The present invention relates to medical devices for implantation or insertion into body lumens, for example, catheters, guidewires, stents and aneurysm coils. The devices of the present invention comprise electrically actuated materials, such as electroactive polymers and piezoelectric and electrostrictive materials, which enhance or expand their functionality.

Owner:BOSTON SCI SCIMED INC

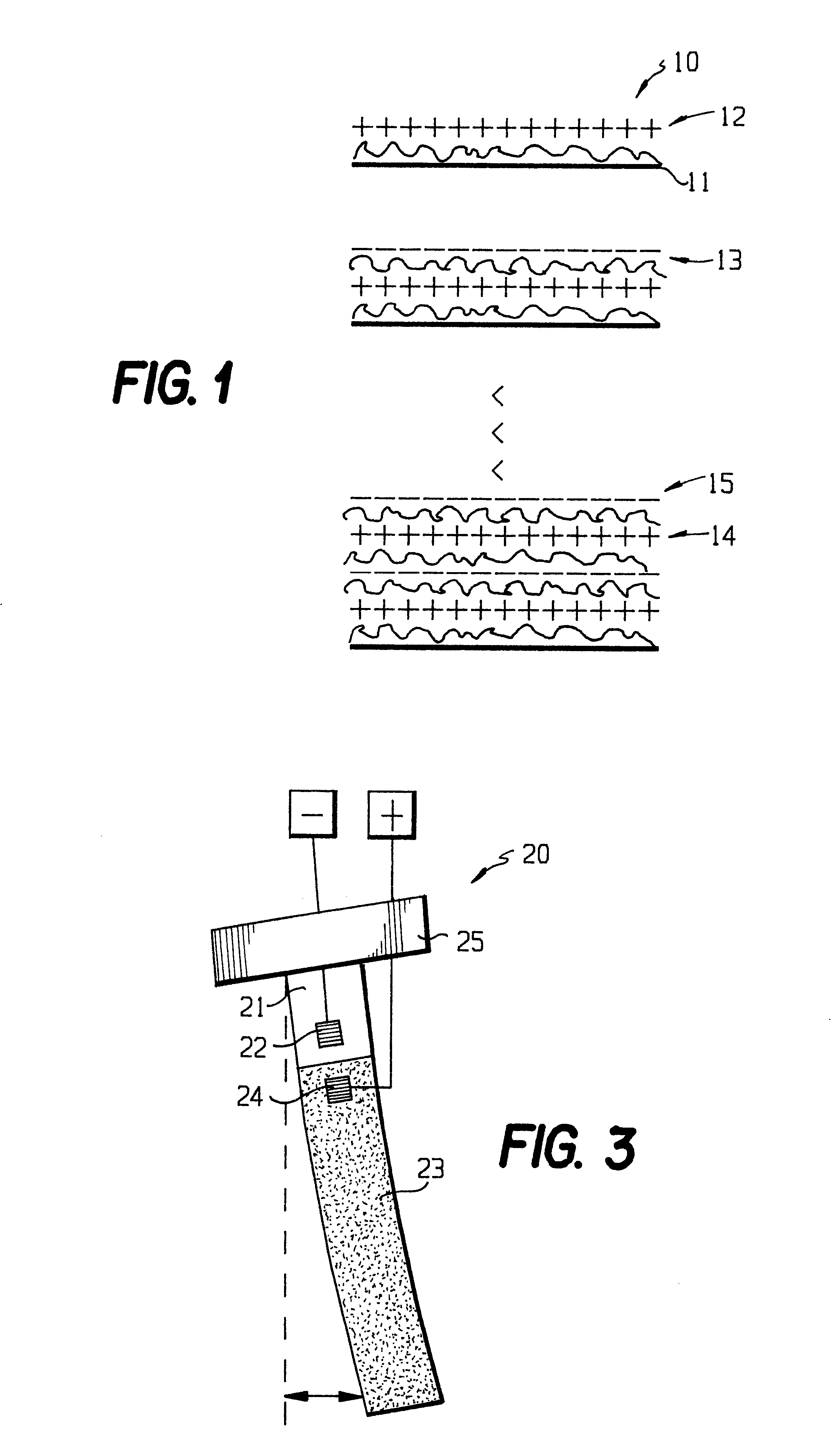

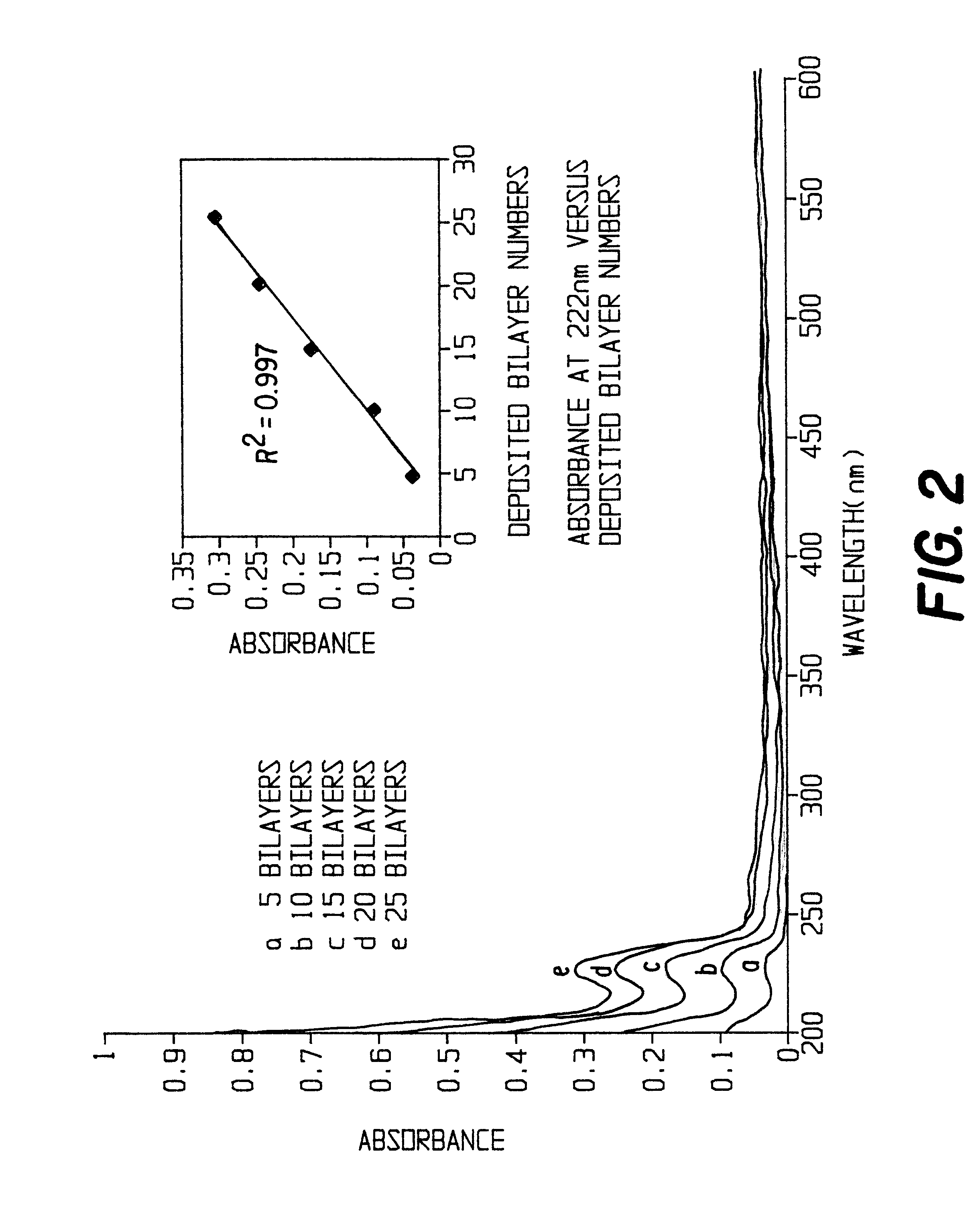

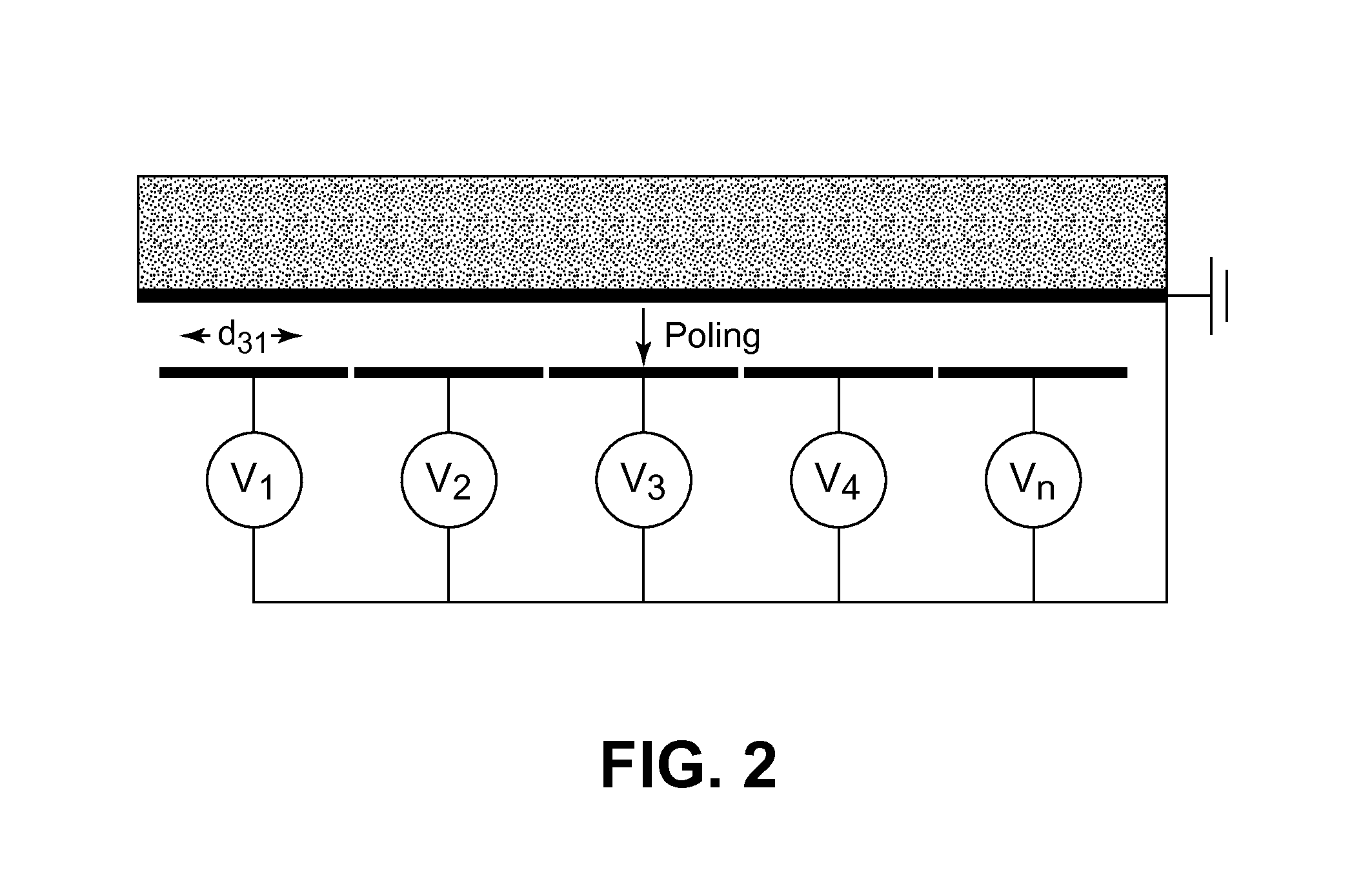

Electrostrictive and piezoelectric thin film assemblies and method of fabrication therefor

InactiveUS6447887B1Avoid misalignmentUniform propertyAnodisationMaterial nanotechnologyMolecular levelEngineering

An electrostatic self-assembly method of fabricating electrostrictive and piezoelectric thin film assemblies not only provides a thinner film than is attainable by conventional methods, but provides excellent molecular-level uniformity and precise structural control, and thus large, effective piezoelectric coefficients. The method produces a thin film assembly including (a) a substrate, and (b) a film having one or a plurality of layers disposed upon the substrate, wherein at least one of the layers includes a dipolar material, and this layer of dipolar material has a uniform thickness of at most 500 nm.

Owner:VIRGINIA TECH INTPROP INC

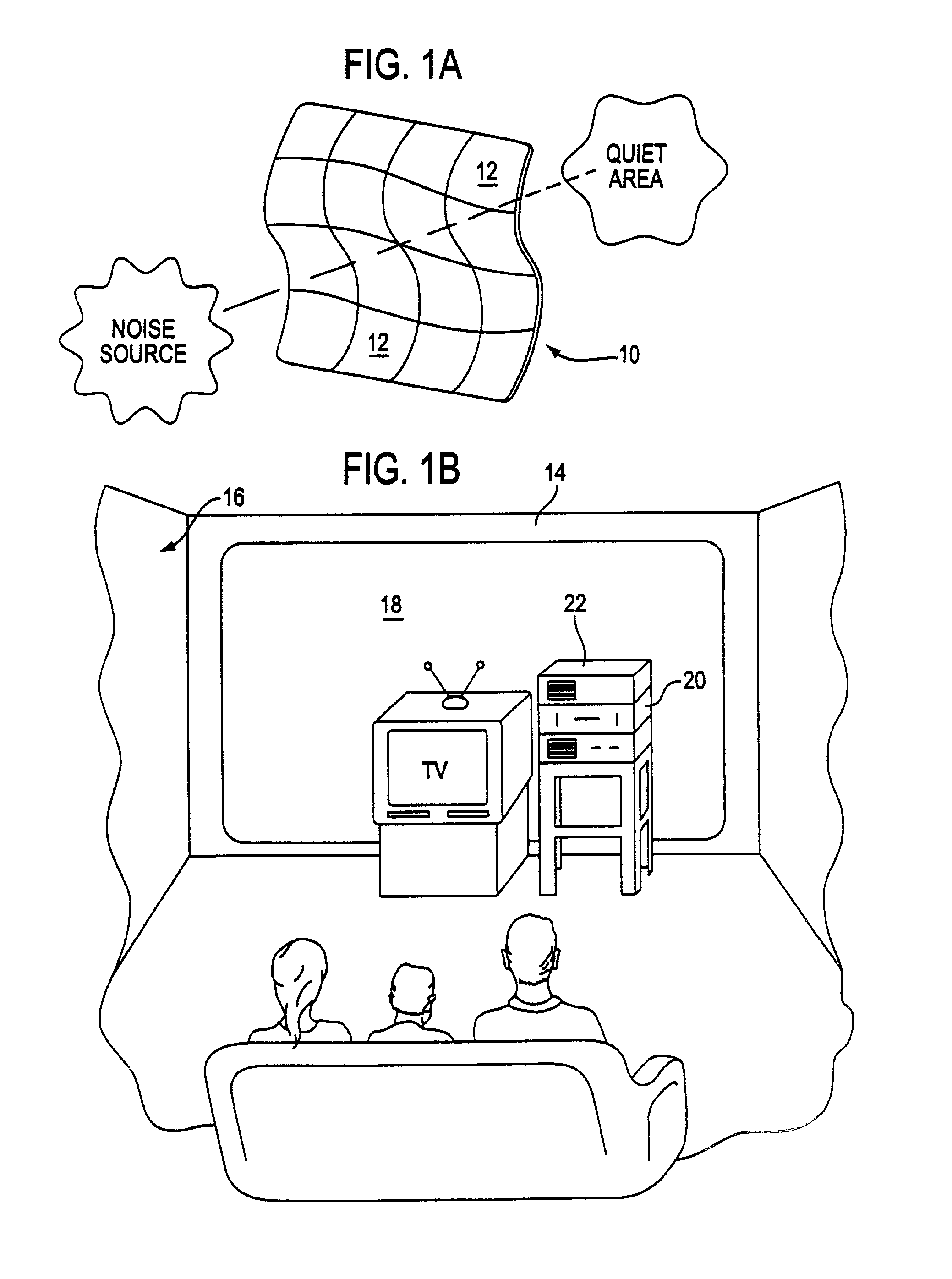

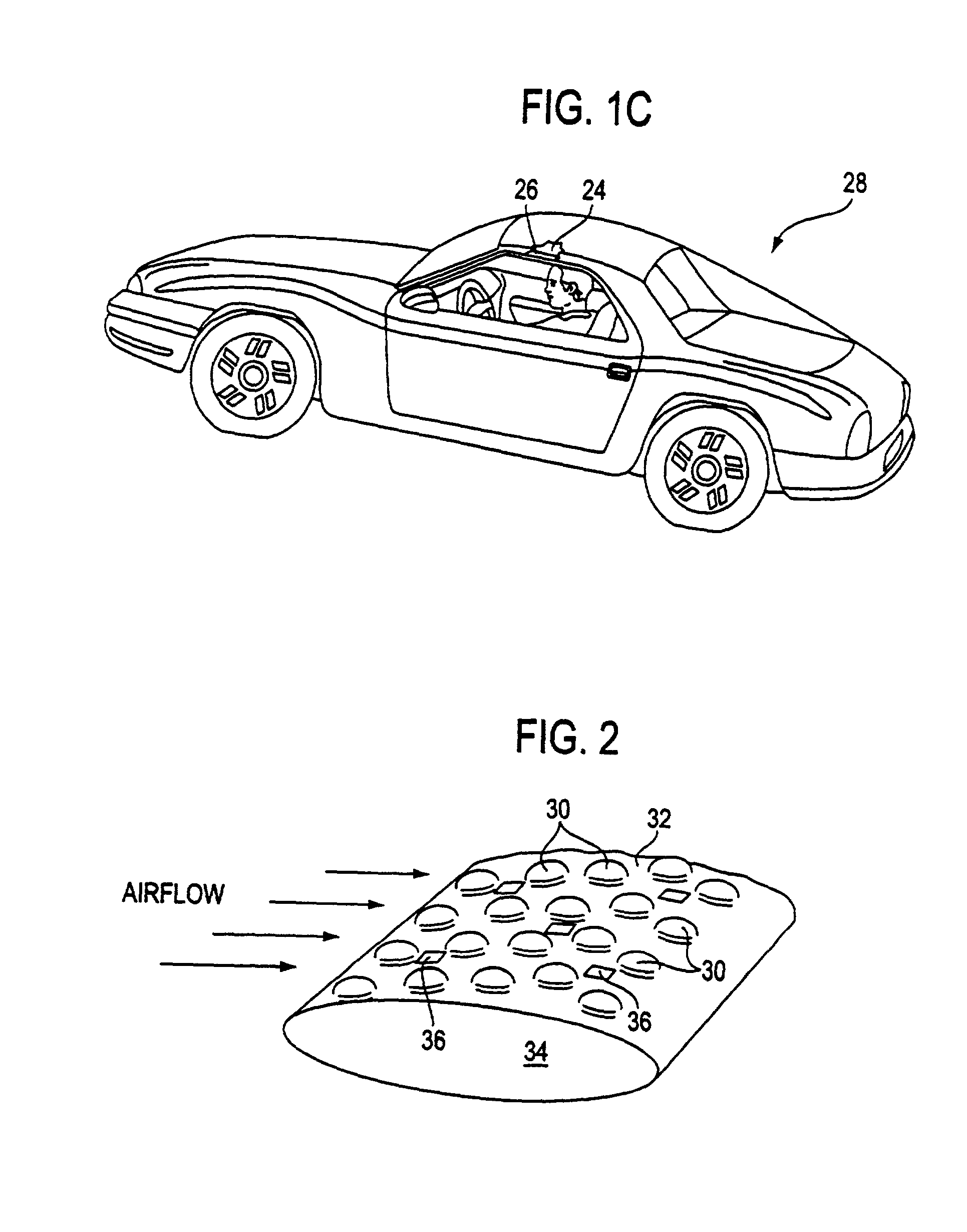

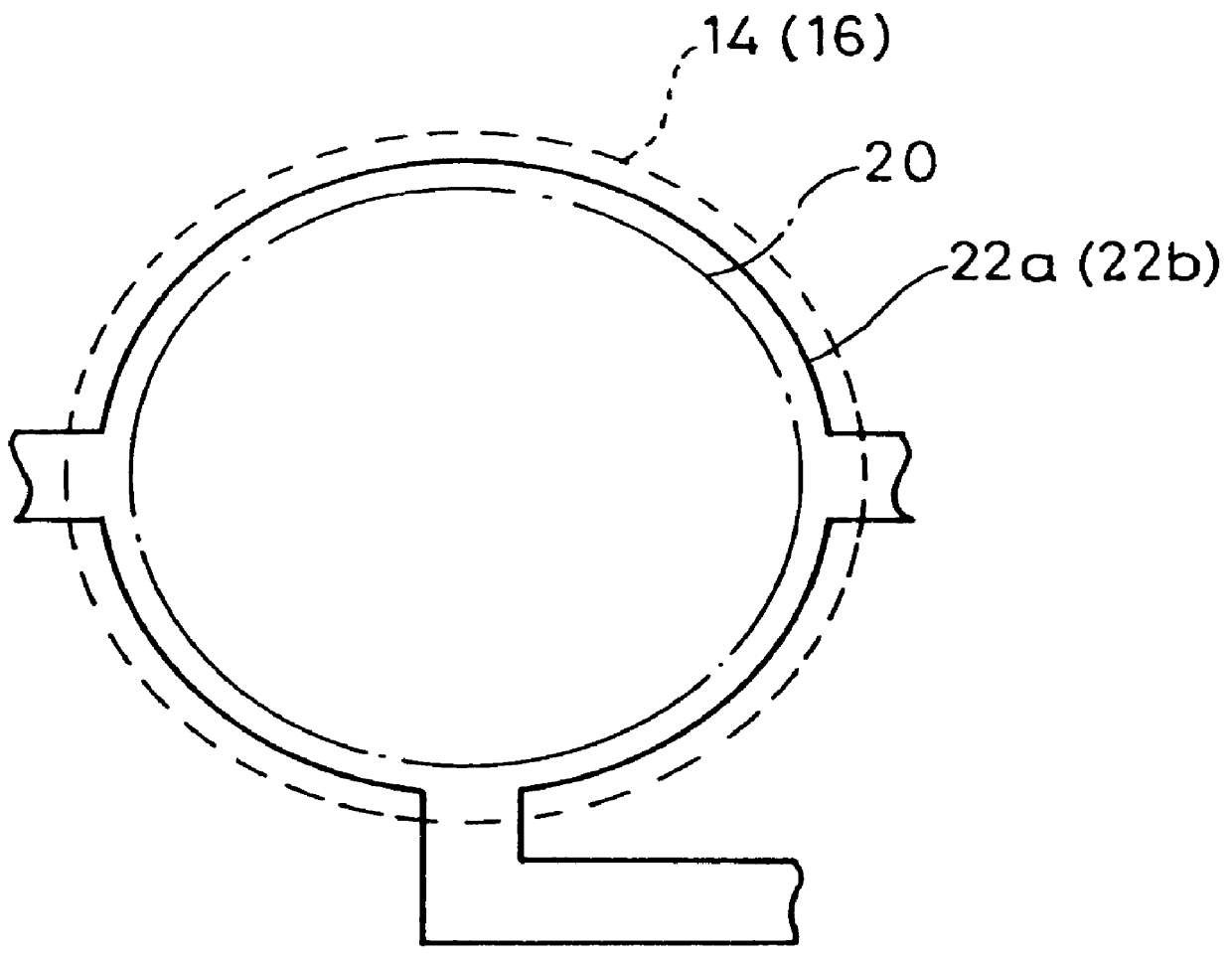

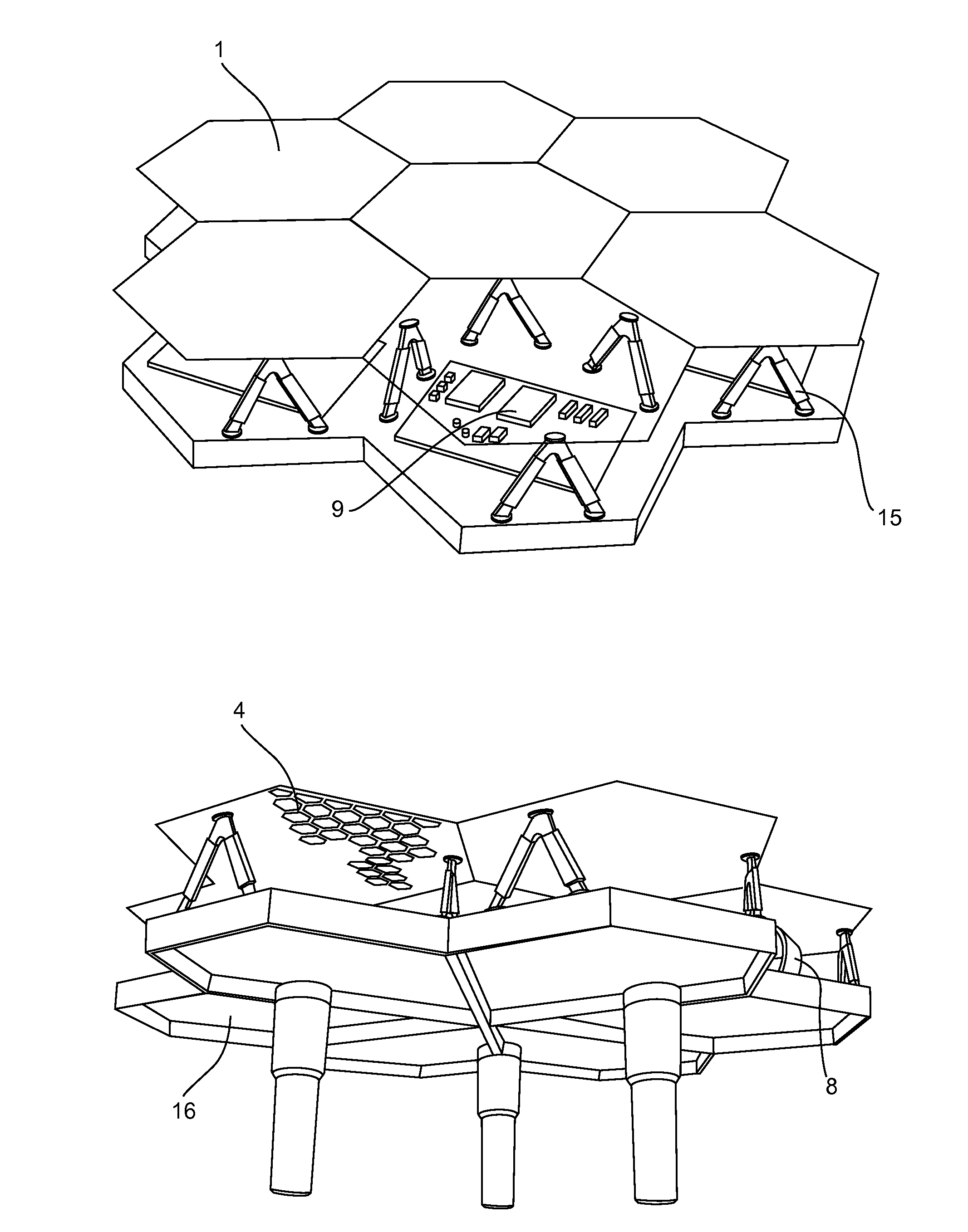

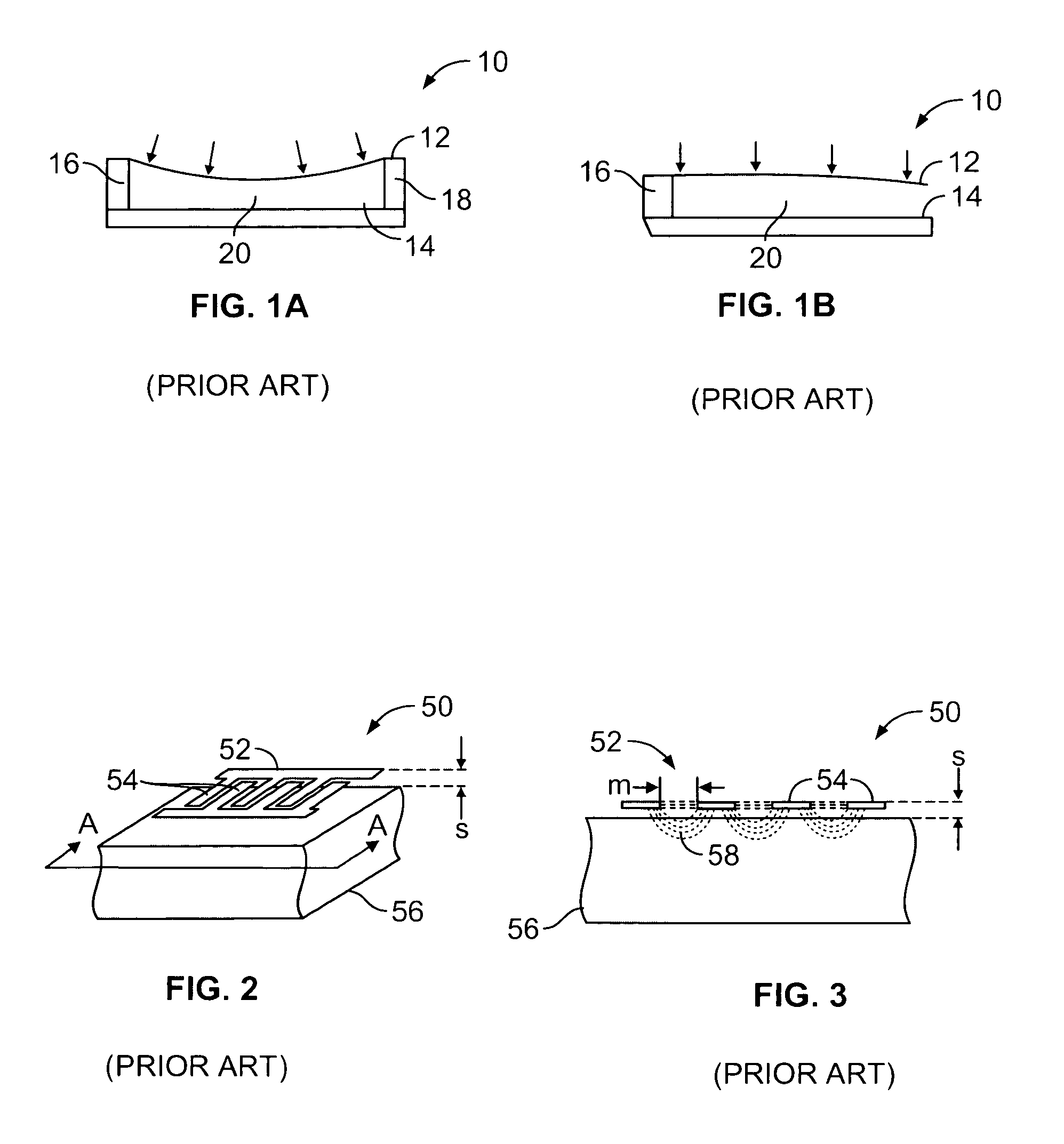

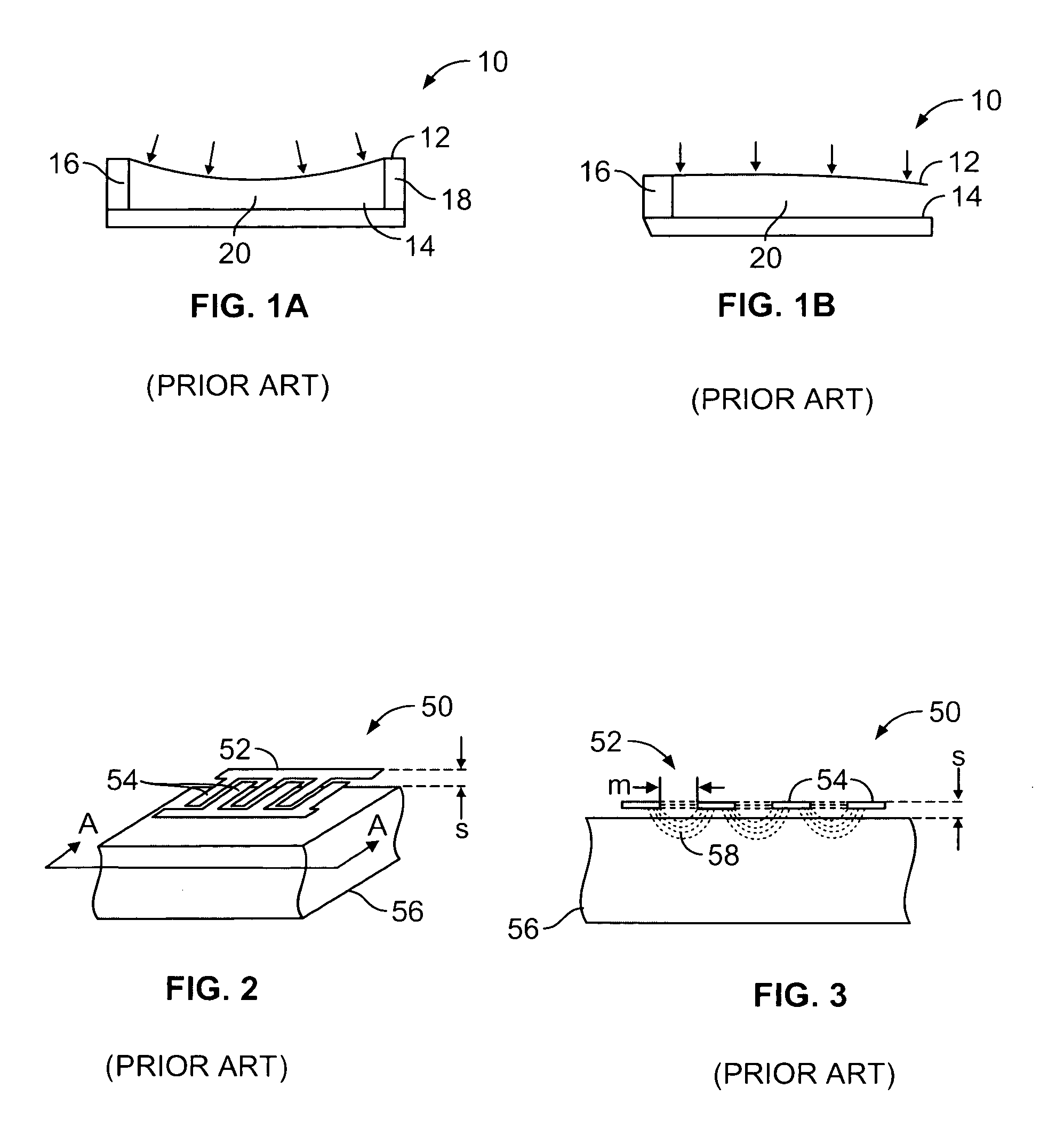

Elastomeric dielectric polymer film sonic actuator

InactiveUS7062055B2Optimize power outputLow working voltagePiezoelectric/electrostrictive gramophone pickupsStirling type enginesDielectricConductive polymer

A sonic actuator including a multi-layer membrane having a non-metallic elastomeric dielectric polymer layer with a first surface and a second surface, a first compliant electrode layer contacting the first surface of the polymer layer, and a second compliant electrode layer contacting the second surface of the polymer layer. The actuator further includes a support structure in contact with the sonic actuator film. Preferably, the non-metallic dielectric polymer is selected from the group consisting essentially of silicone, fluorosilicone, fluoroelastomer, natural rubber, polybutadiene, nitrile rubber, isoprene, and ethylene propylene diene. Also preferably, the compliant electrode layer is made from the group consisting essentially of graphite, carbon, and conductive polymers. The support structure can take the form of grid having a number of circular apertures. When a voltage is applied to the electrodes, portions of the film held at the aperture of the support structure can bulge due to the electrostriction phenomenon. The resultant “bubbles” can be modulated to generate sonic vibrations, or can be used to create a variable surface for airflow control.

Owner:SRI INTERNATIONAL

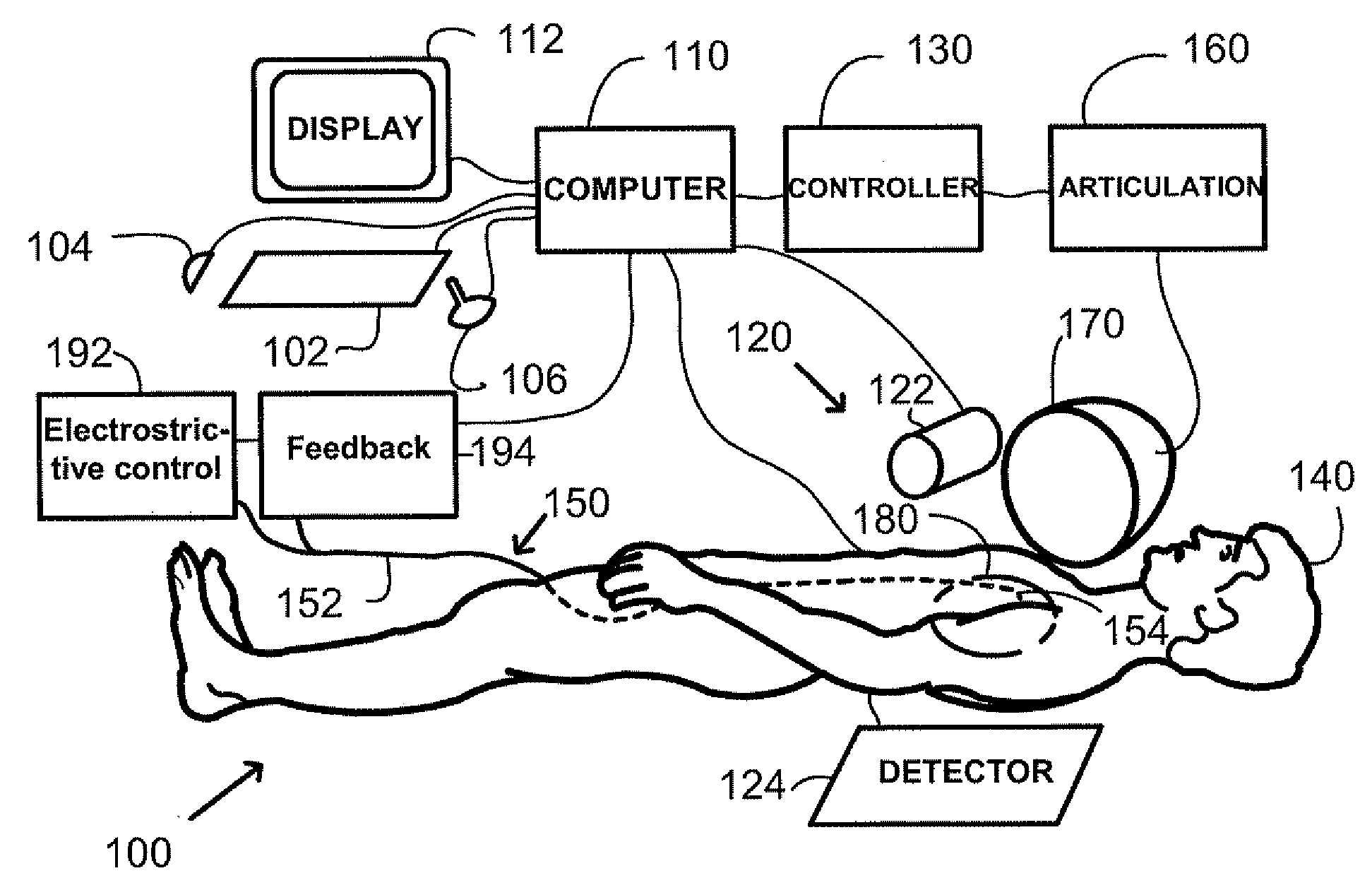

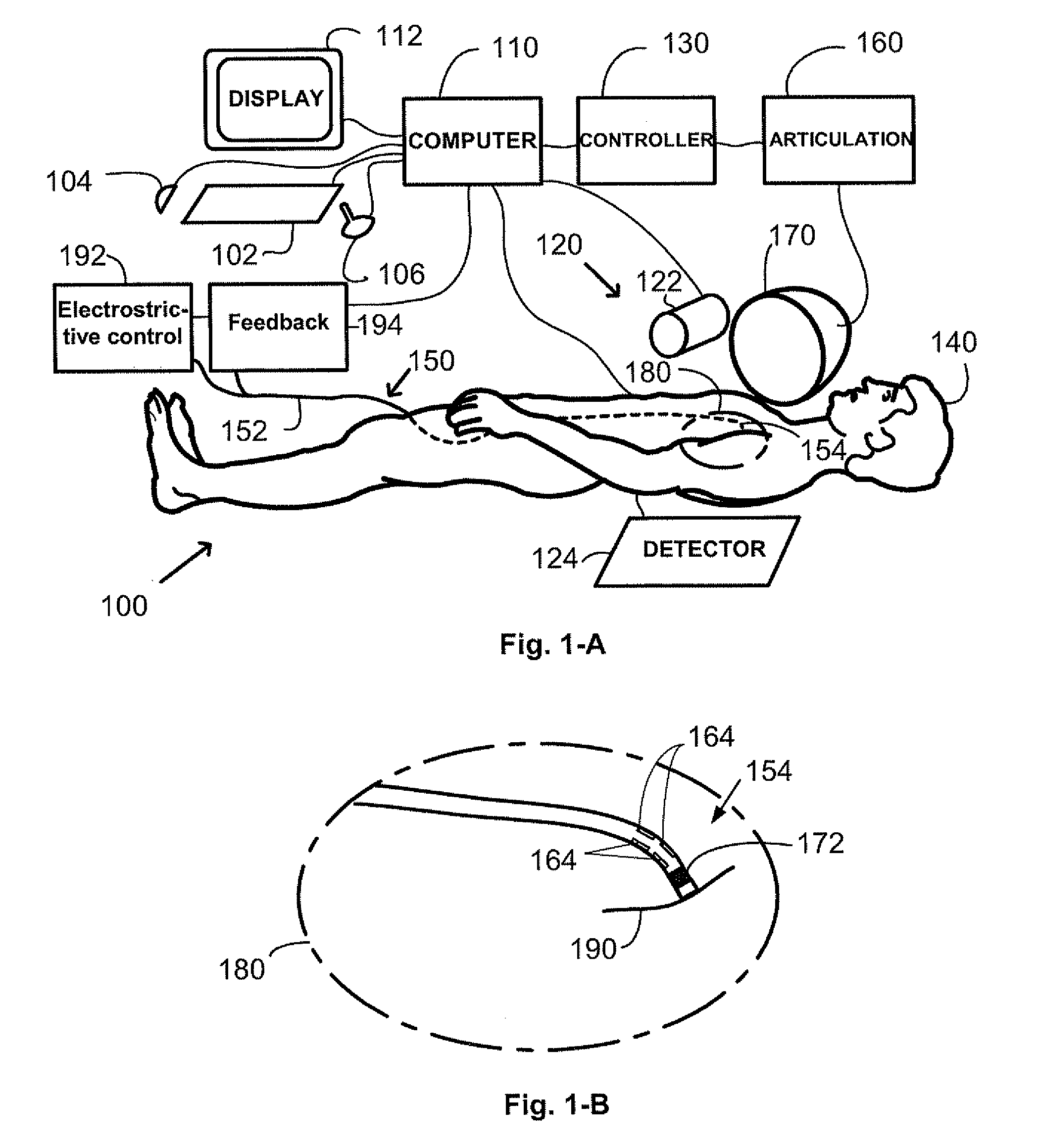

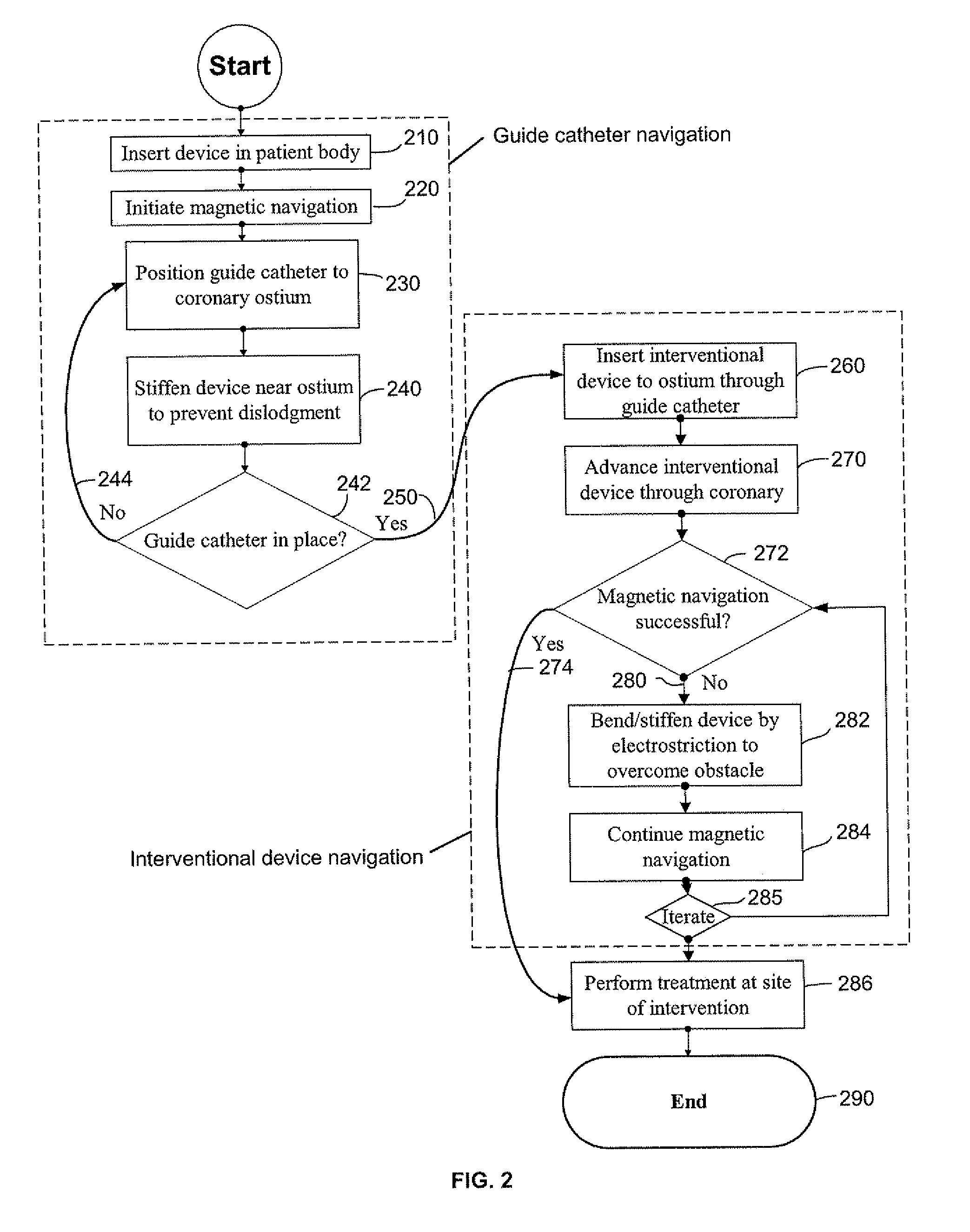

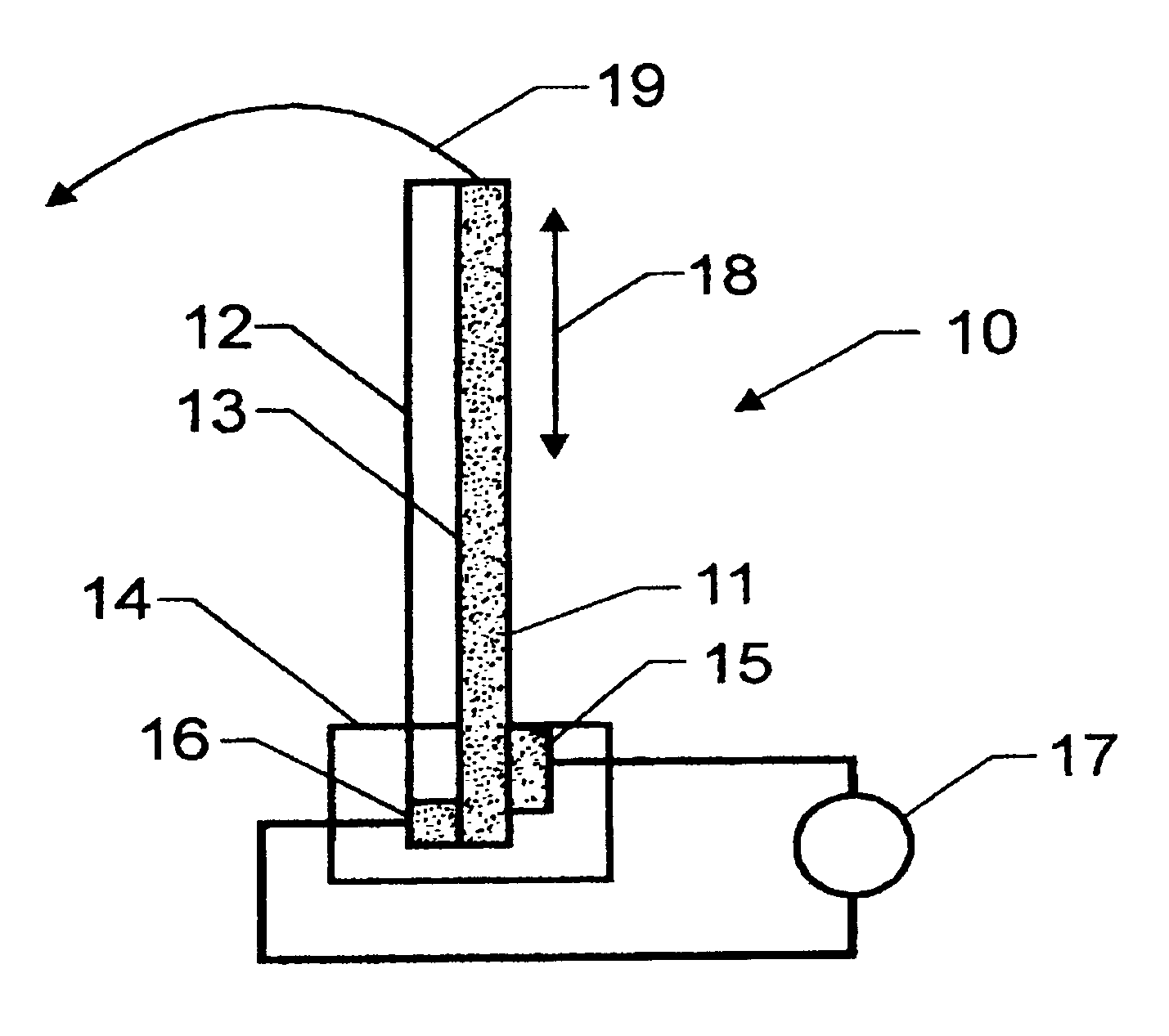

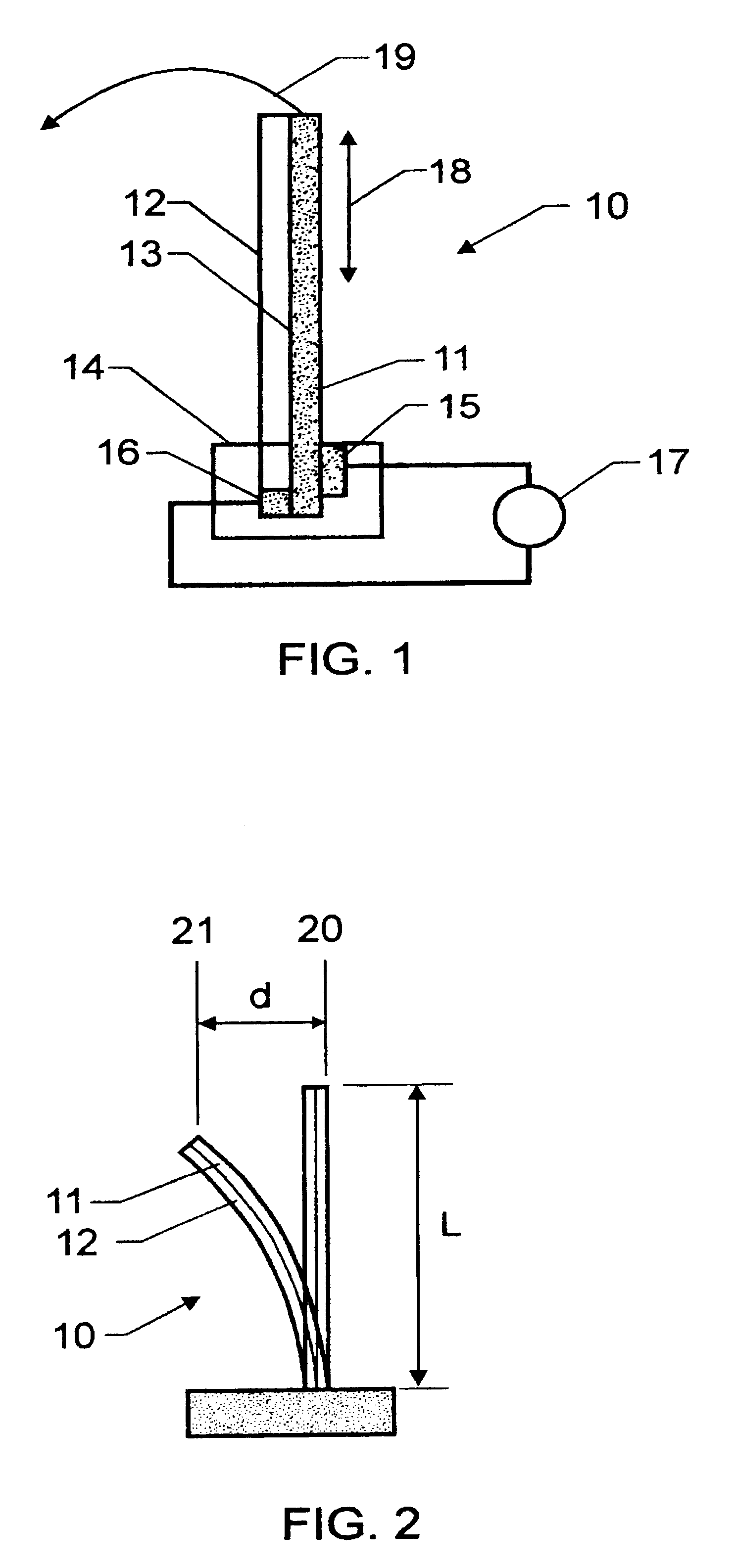

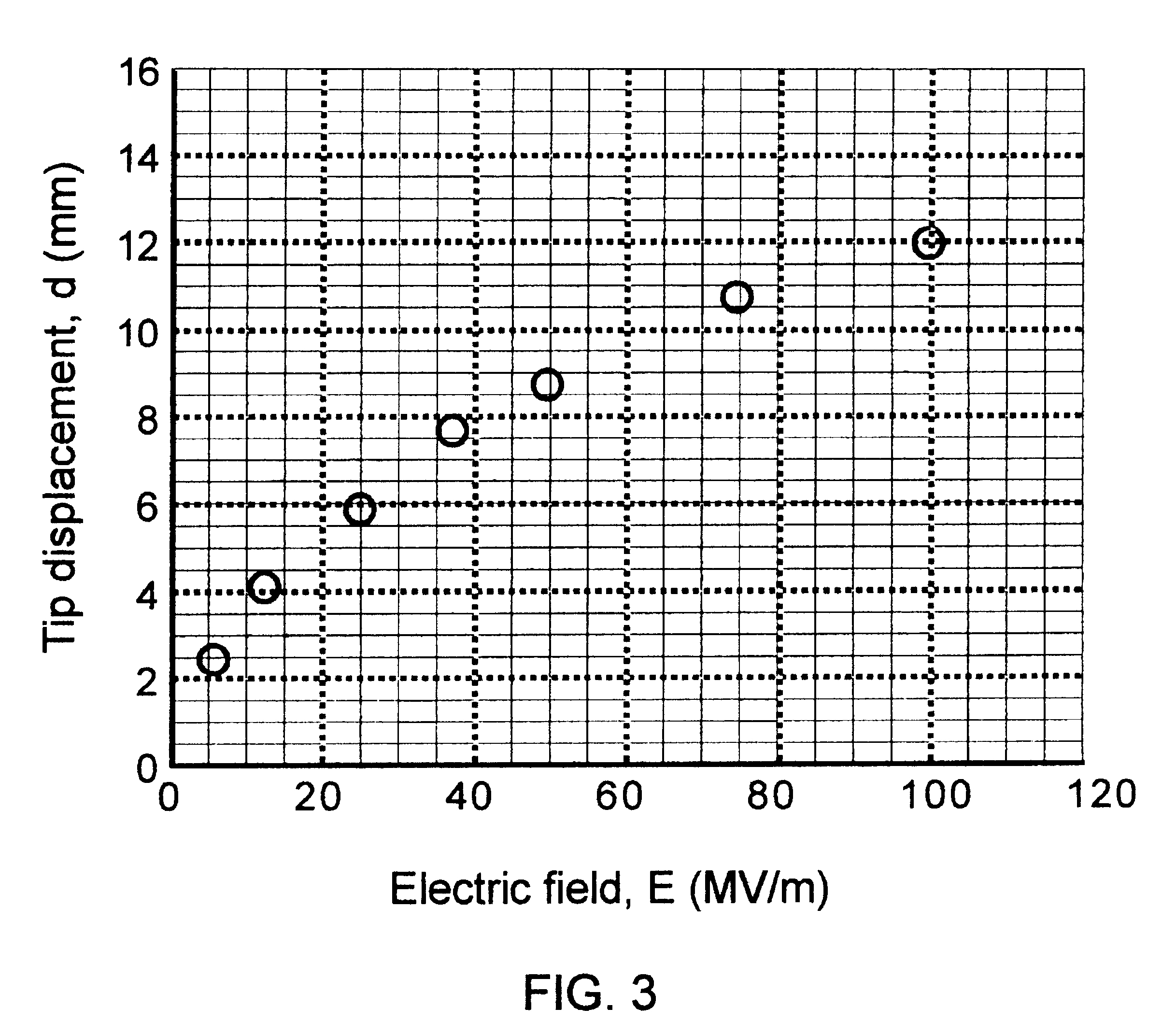

Electrostriction Devices and Methods for Assisted Magnetic Navigation

ActiveUS20080004595A1Increase deflectionImprove other aspectEar treatmentDiagnosticsElectricityDistal portion

An apparatus and method for interventional navigation within a subject's body is provided in which a medical device having at least one electrostrictive element is adapted to cause the distal end of the medical device to bend in a given direction for improving navigation. The medical device may further comprise at least one magnetically responsive element on the distal end, which may be oriented in the approximate direction of a magnetic field that is applied to the subjects body. At least one method for navigating a medical device though a subject's body is provided, by changing the direction of an applied magnetic field to align a magnetically responsive element on the distal end for orienting the distal end, and by applying a voltage to at least one electrostrictive element disposed in the distal portion of the device for causing the distal end to change orientation from that achieved by application of the magnetic field alone.

Owner:STEREOTAXIS

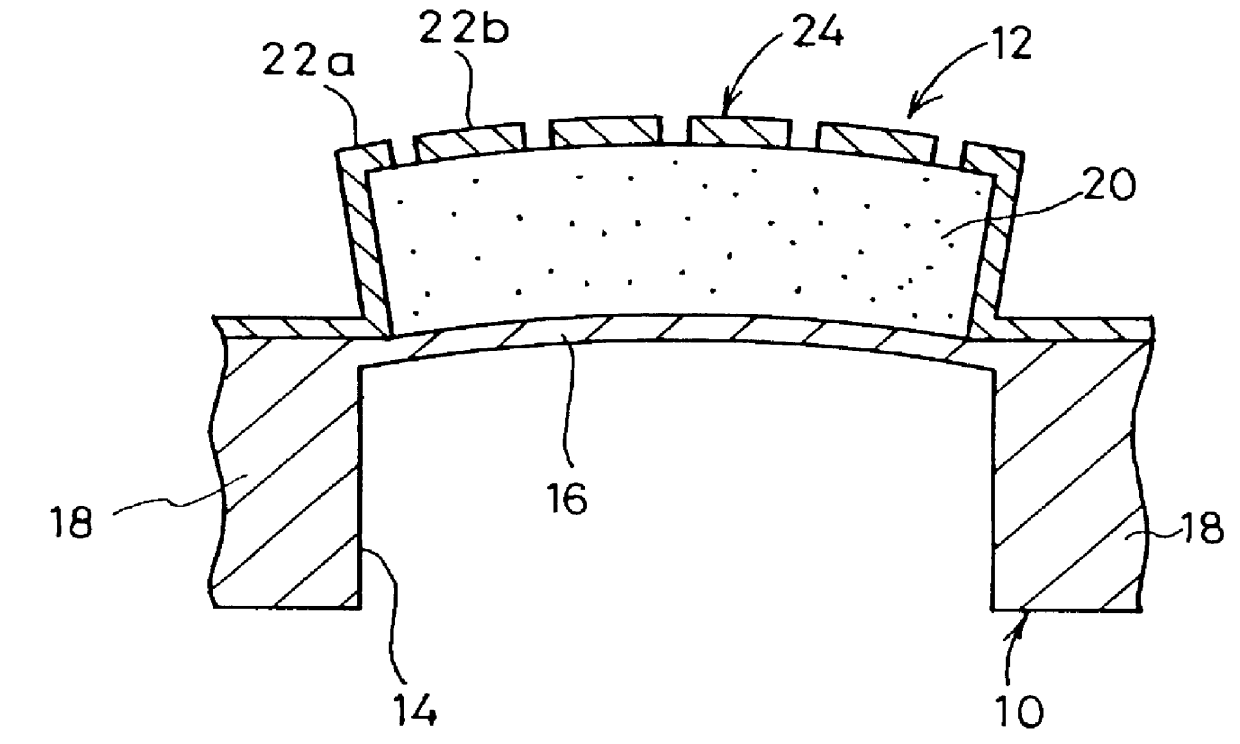

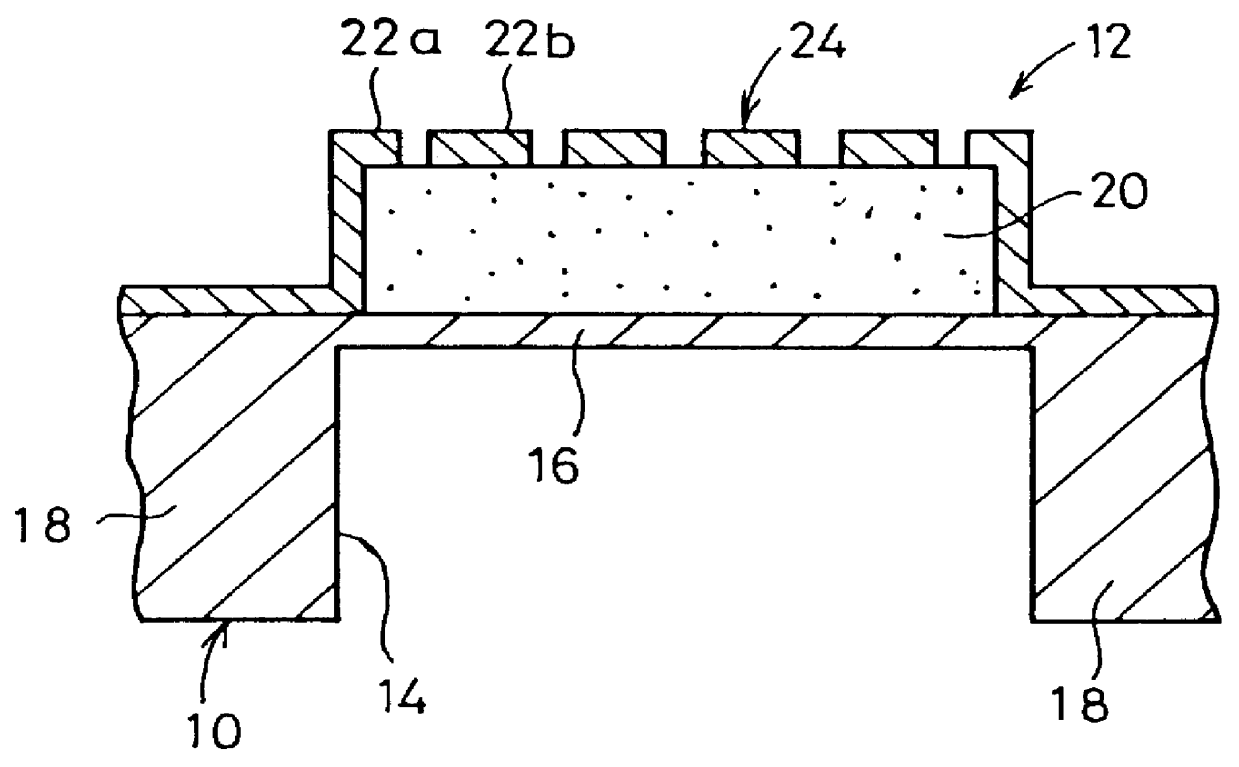

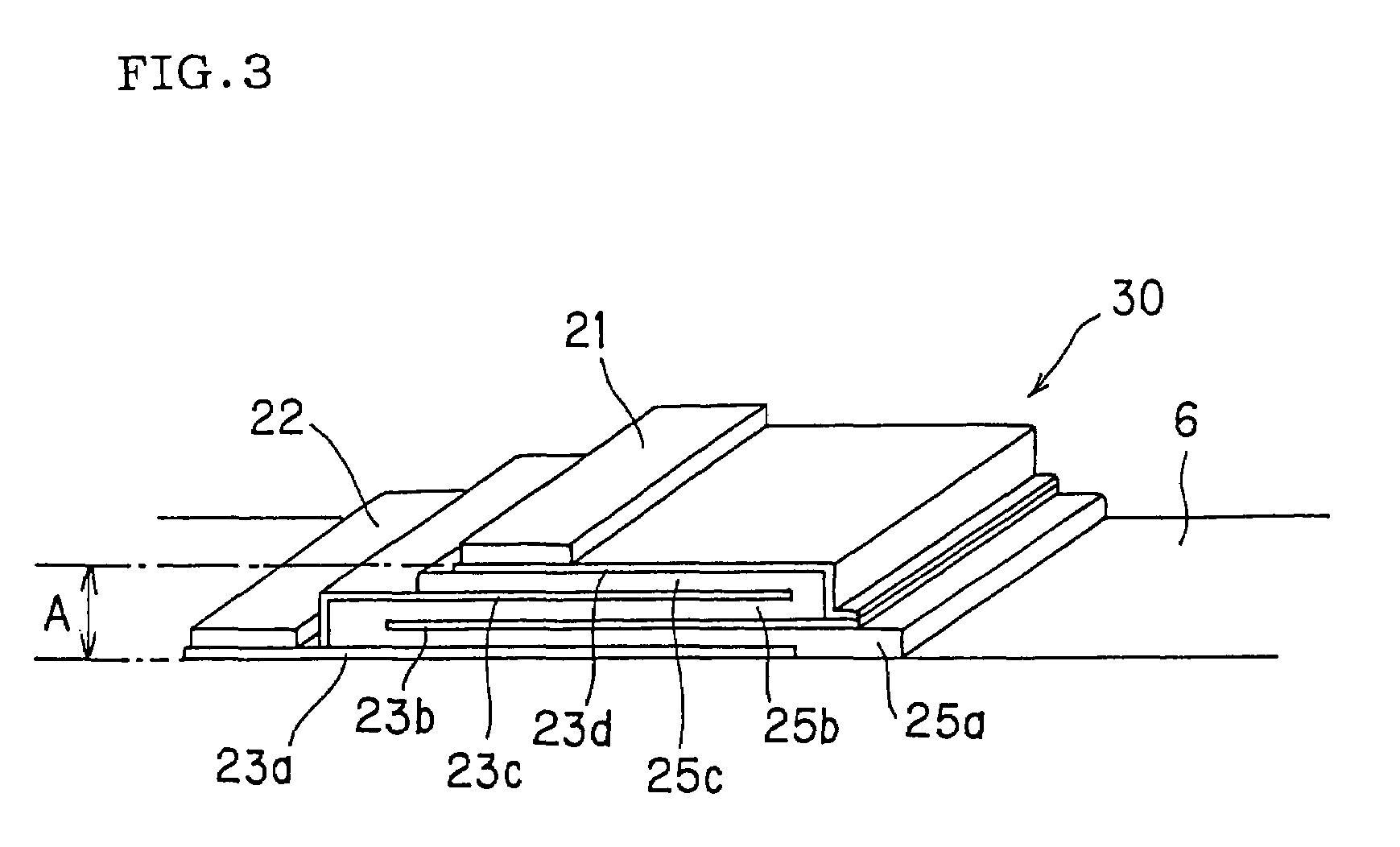

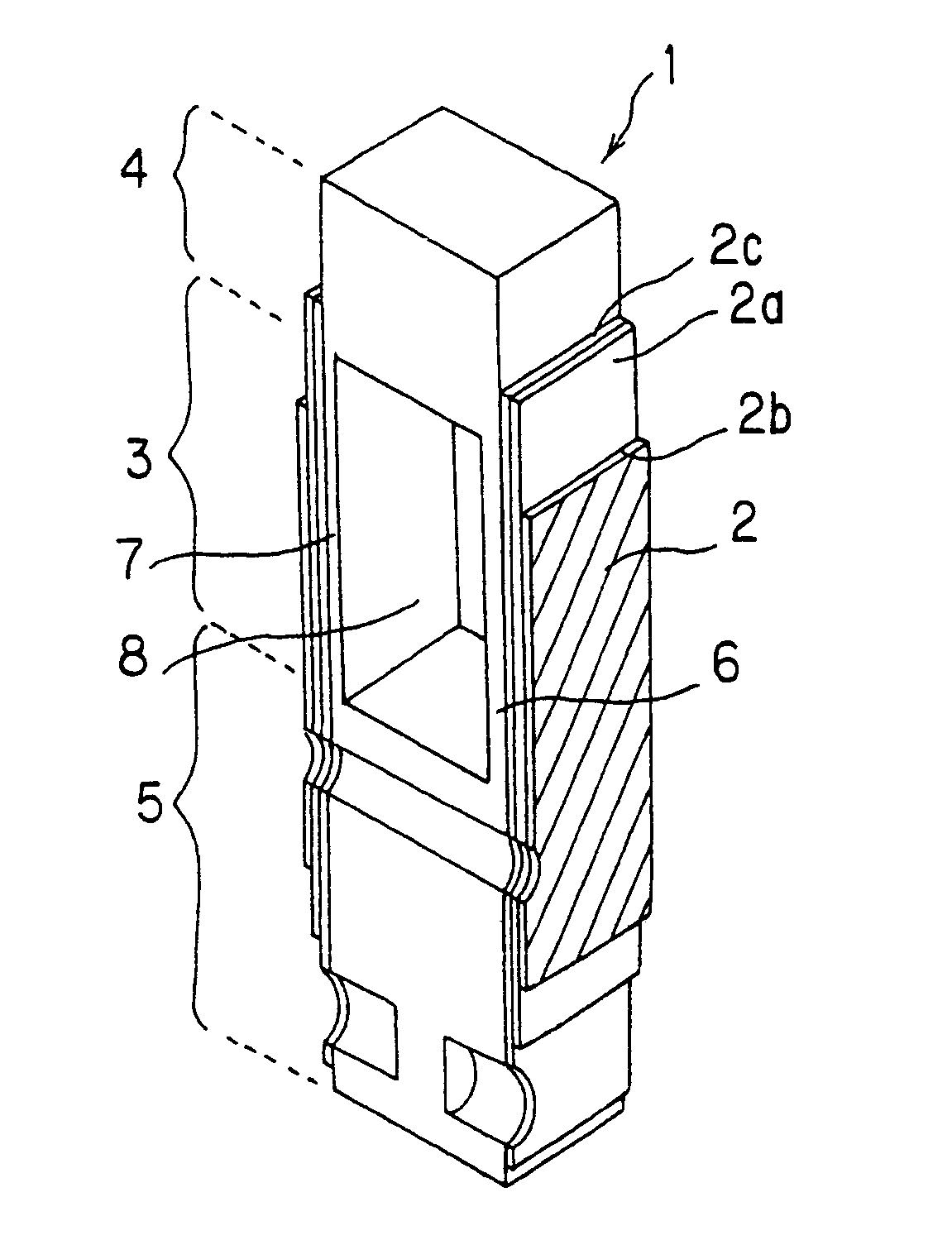

Piezoelectric/electrostrictive element

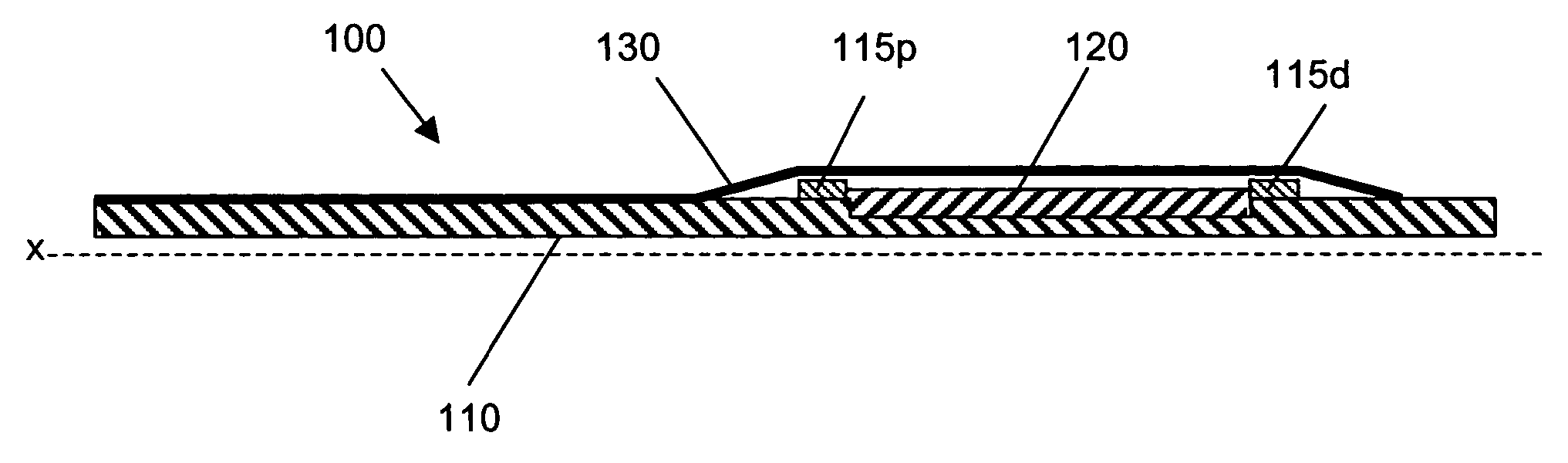

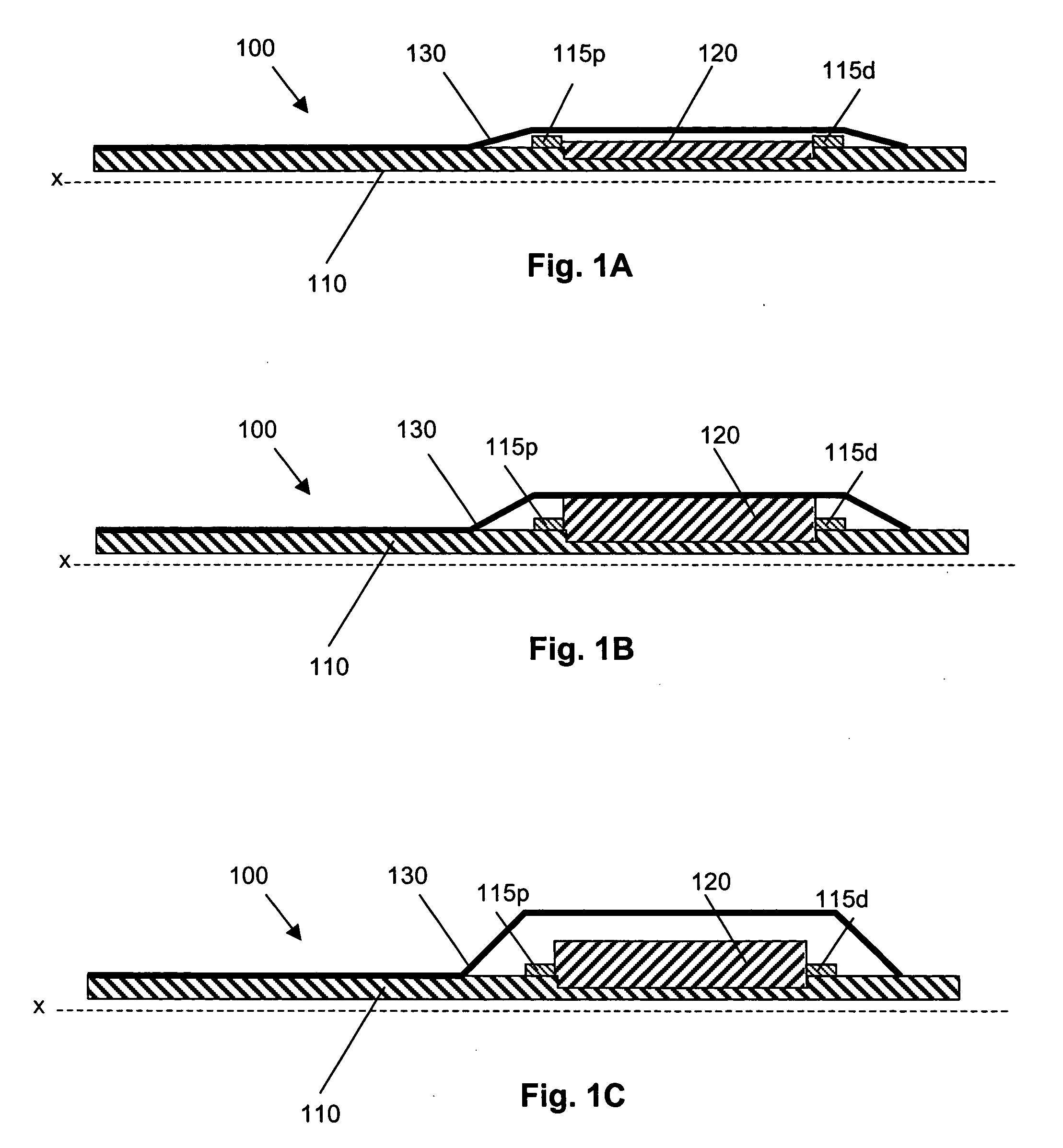

InactiveUS6091182APiezoelectric/electrostriction/magnetostriction machinesStatic indicating devicesElectricityRelative displacement

Disclosed is a piezoelectric / electrostrictive element composed of an actuator section of a uni-morph type comprising a main actuator element including a piezoelectric / electrostrictive layer and a pair of electrodes formed on a first principal surface of the piezoelectric / electrostrictive layer; a vibrating section which contacts with a second principal surface of the piezoelectric / electrostrictive layer for supporting the main actuator element; and a fixed section for supporting the vibrating section in a vibrative manner; wherein a relationship of y=ax is satisfied, and an expression of +E,fra 1 / 10+EE < / =a< / =100 is satisfied provided that x represents a distance between the pair of electrodes (1 mu m< / =x< / =200 mu m), and y represents a thickness of the piezoelectric / electrostrictive layer (1 mu m< / =y< / =100 mu m). Accordingly, it is possible to greatly increase the relative displacement amount between the no-voltage-loaded state and the voltage-applied state and the relative displacement amount between the states in which mutually opposite electric fields are applied, making it possible to realize easy control when the element is utilized for actuators and improvement in sensitivity when the element is utilized for sensors.

Owner:NGK INSULATORS LTD

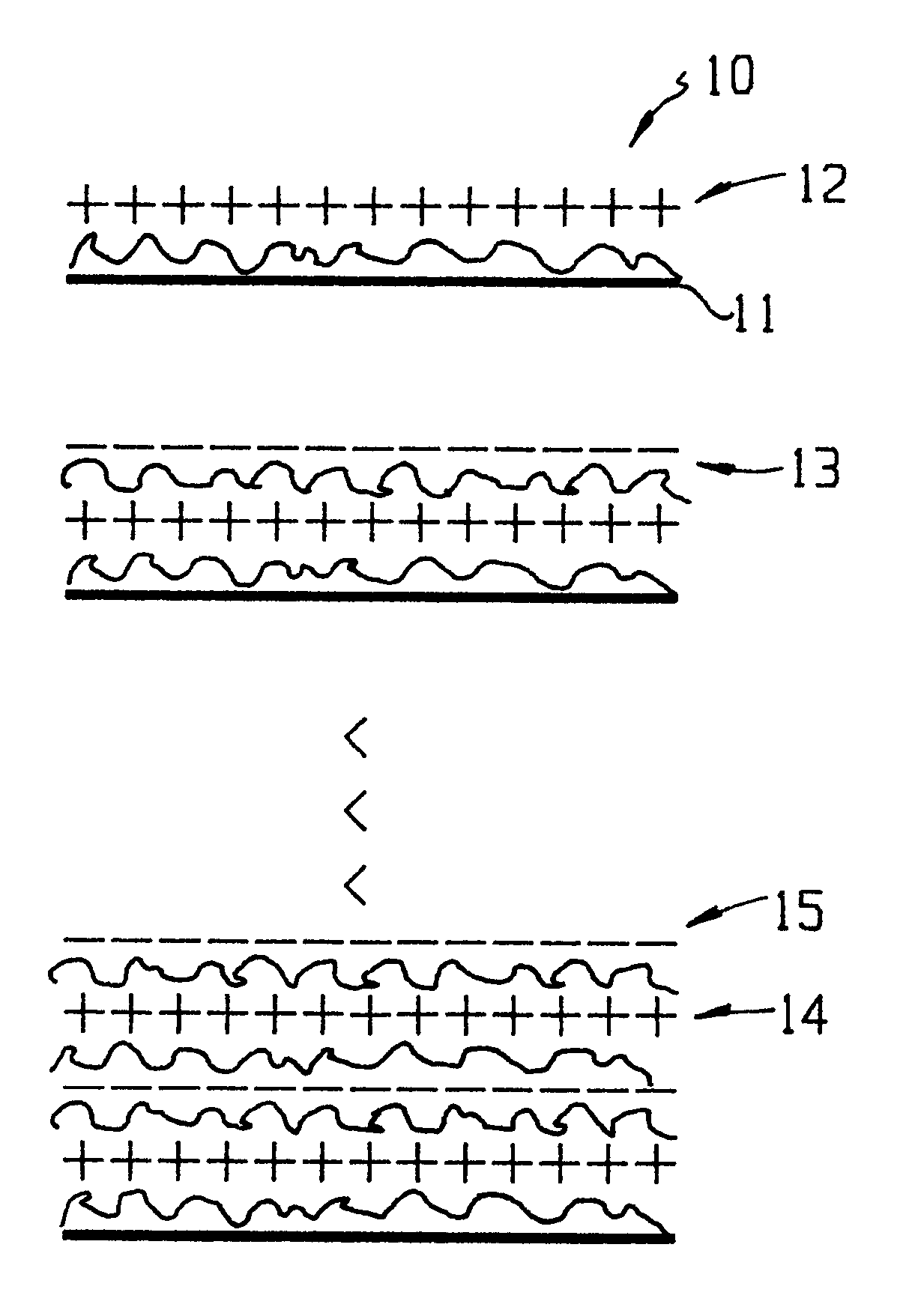

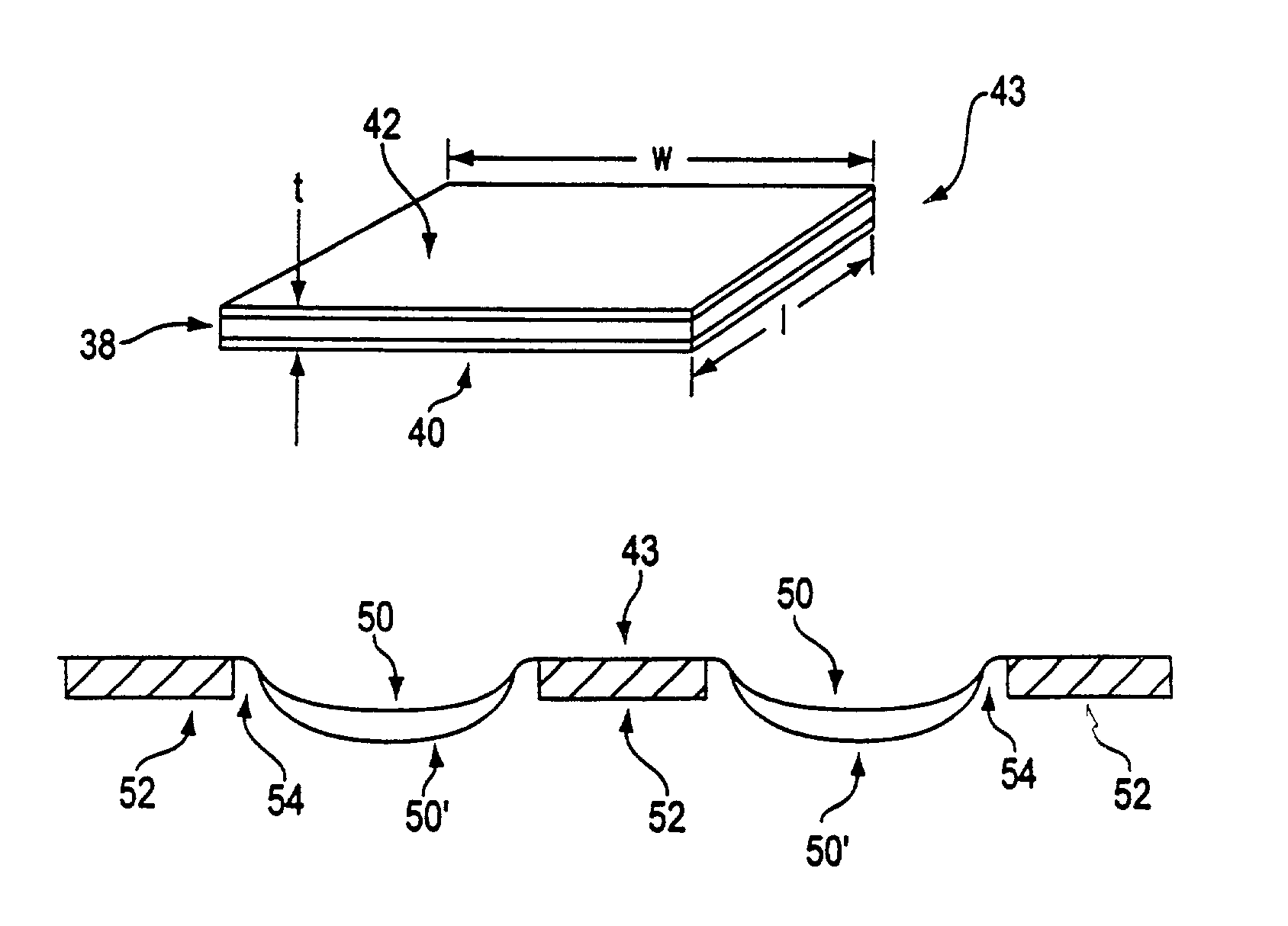

Polymer-polymer bilayer actuator

InactiveUS6545391B1Piezoelectric/electrostriction/magnetostriction machinesPiezoelectric/electrostrictive device material selectionElectrical polarityEngineering

A device for providing an electromechanical response includes two polymeric webs bonded to each other along their lengths. At least one polymeric web is activated upon application thereto of an electric field and exhibits electrostriction by rotation of polar graft moieties within the polymeric web. In one embodiment, one of the two polymeric webs in an active web upon application thereto of the electric field, and the other polymeric web is a non-active web upon application thereto of the electric field. In another embodiment, both of the two polymeric webs are capable of being active webs upon application thereto of the electric field. However, these two polymeric webs are alternately activated and non-activated by the electric field.

Owner:NASA

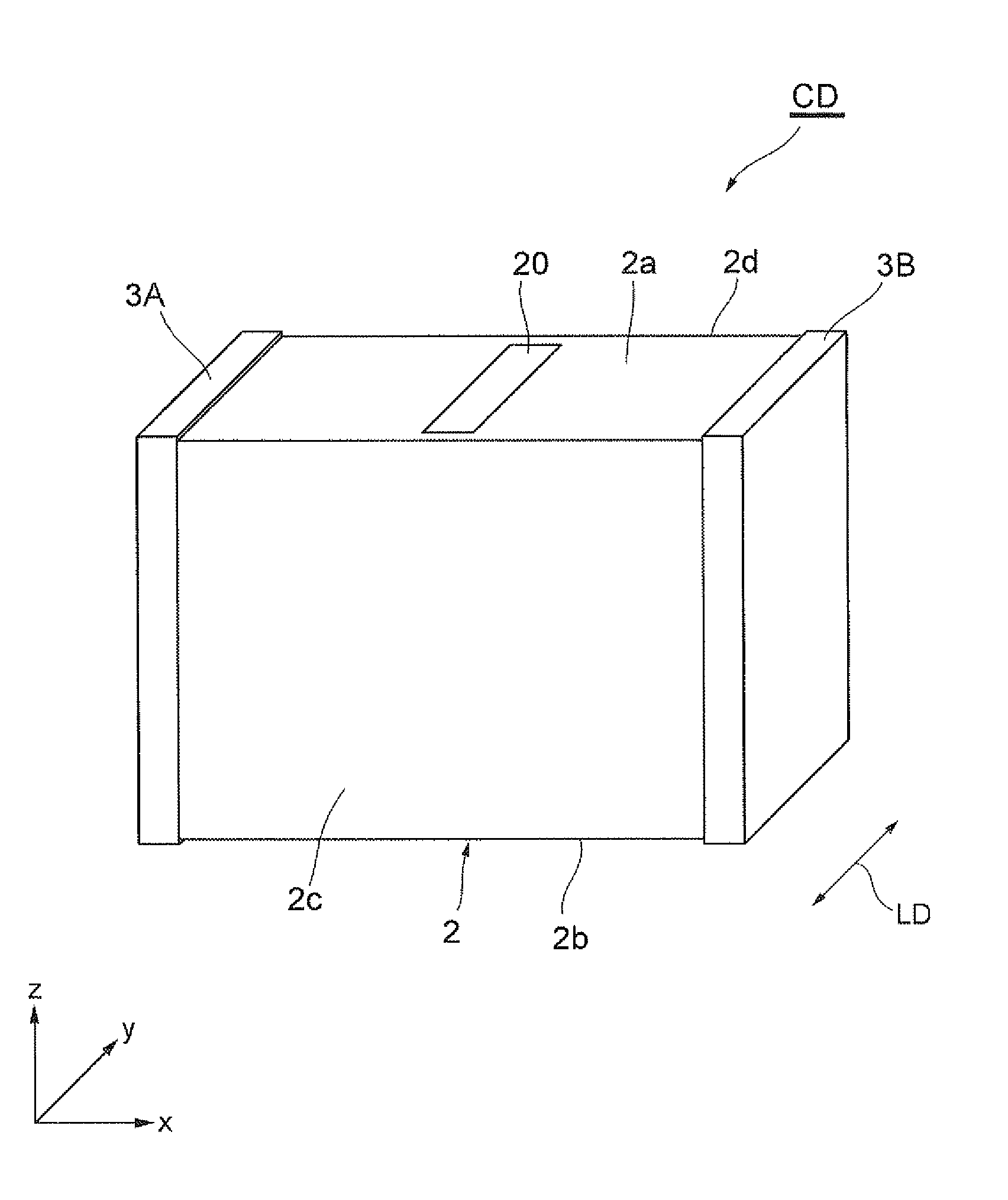

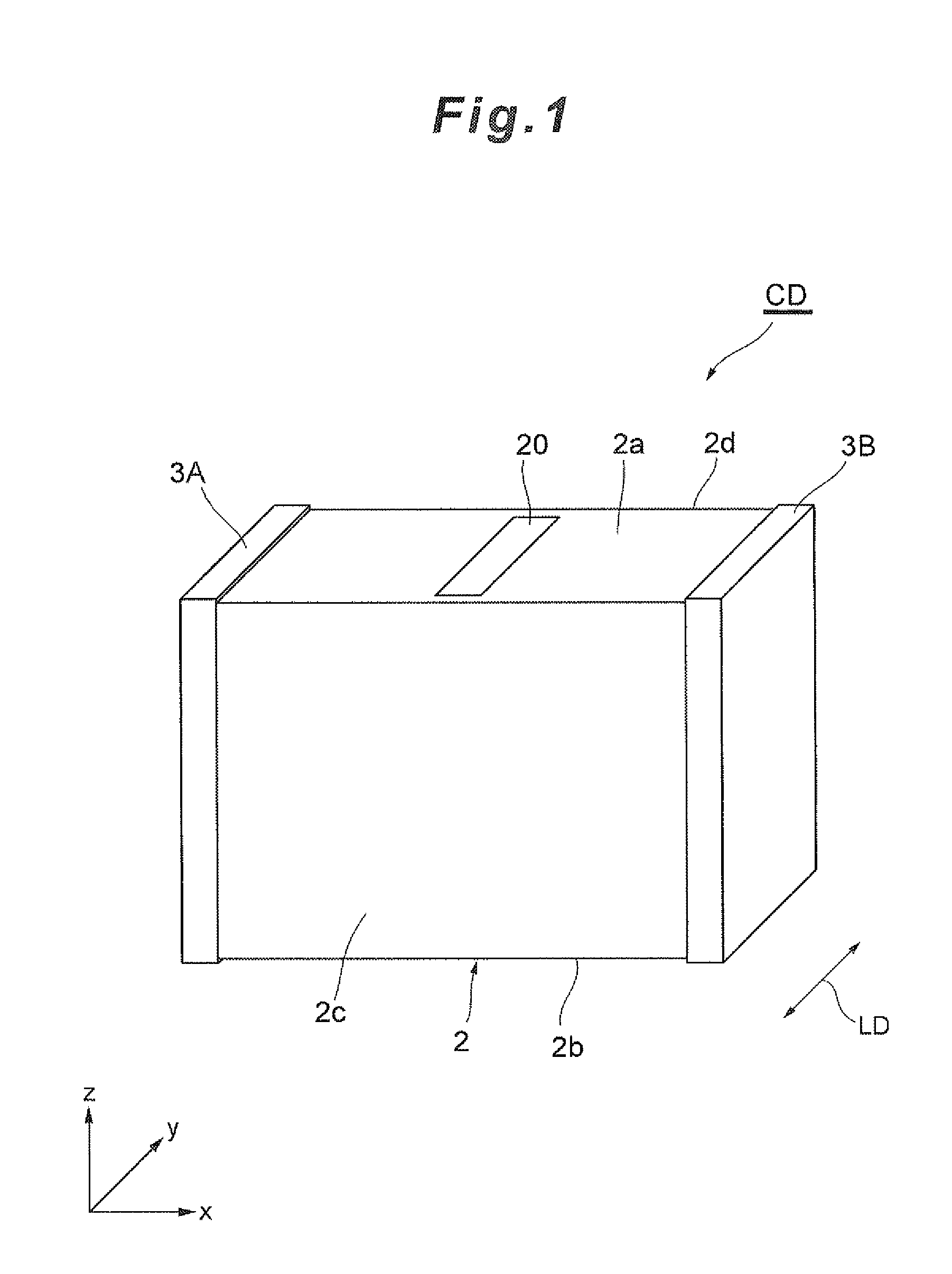

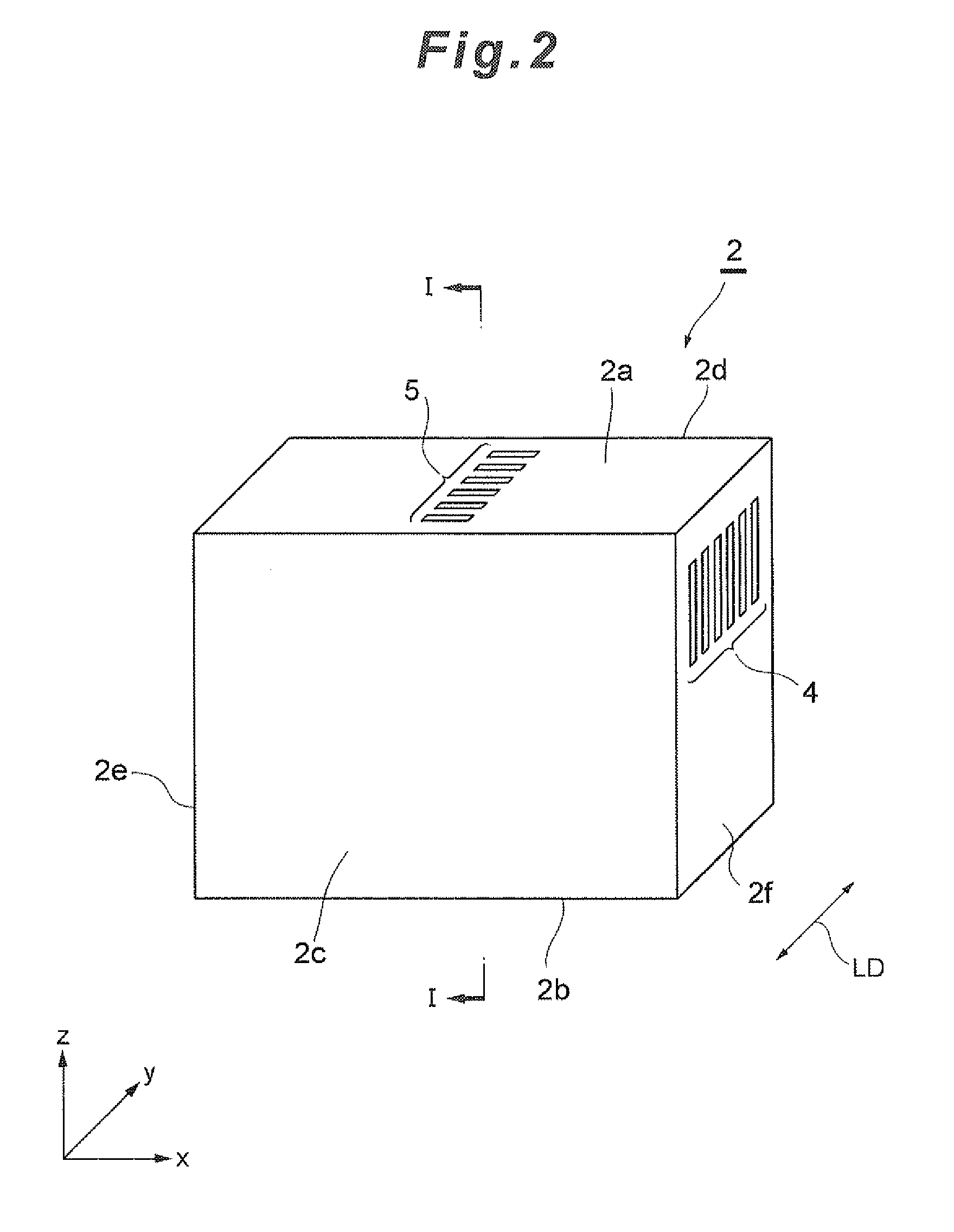

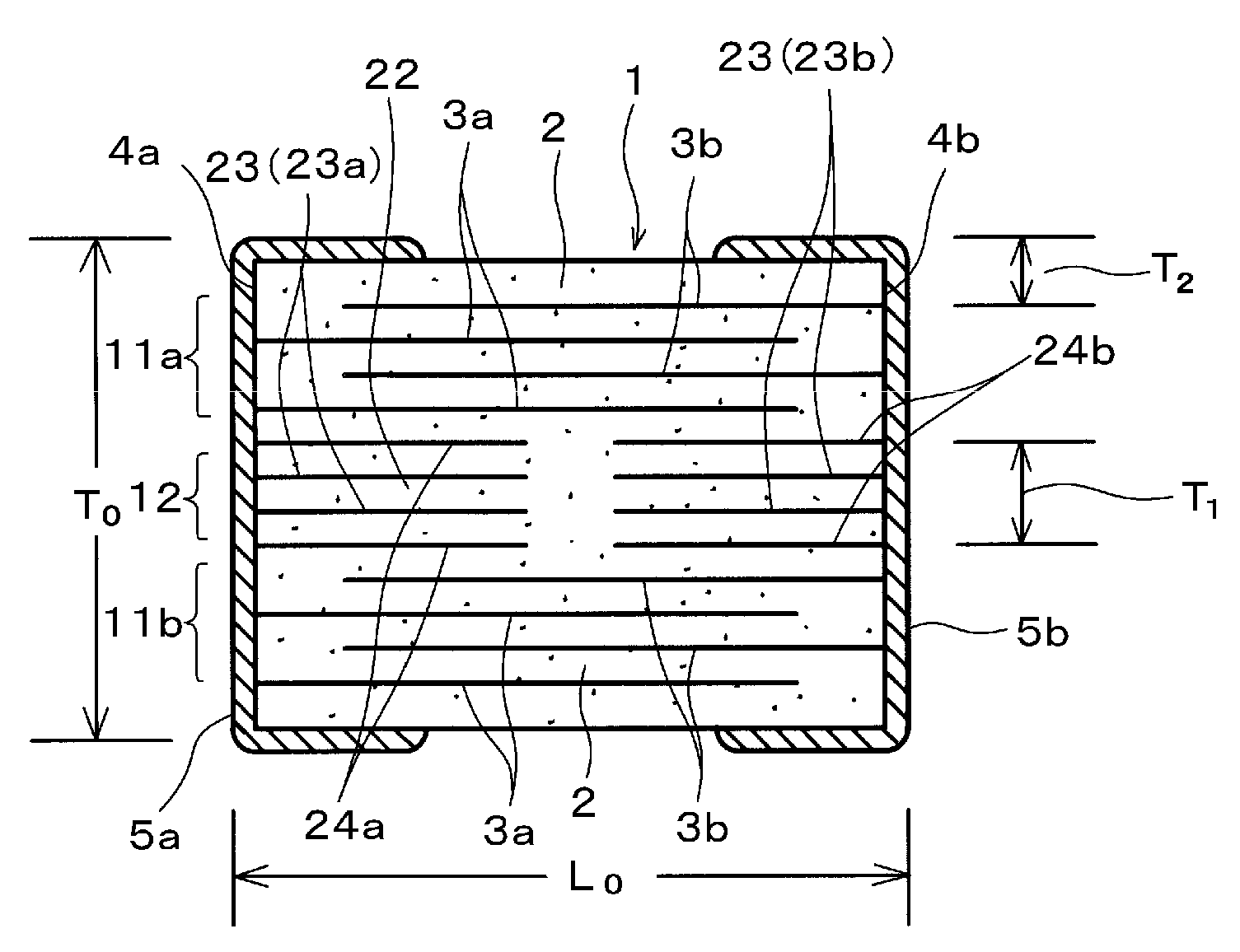

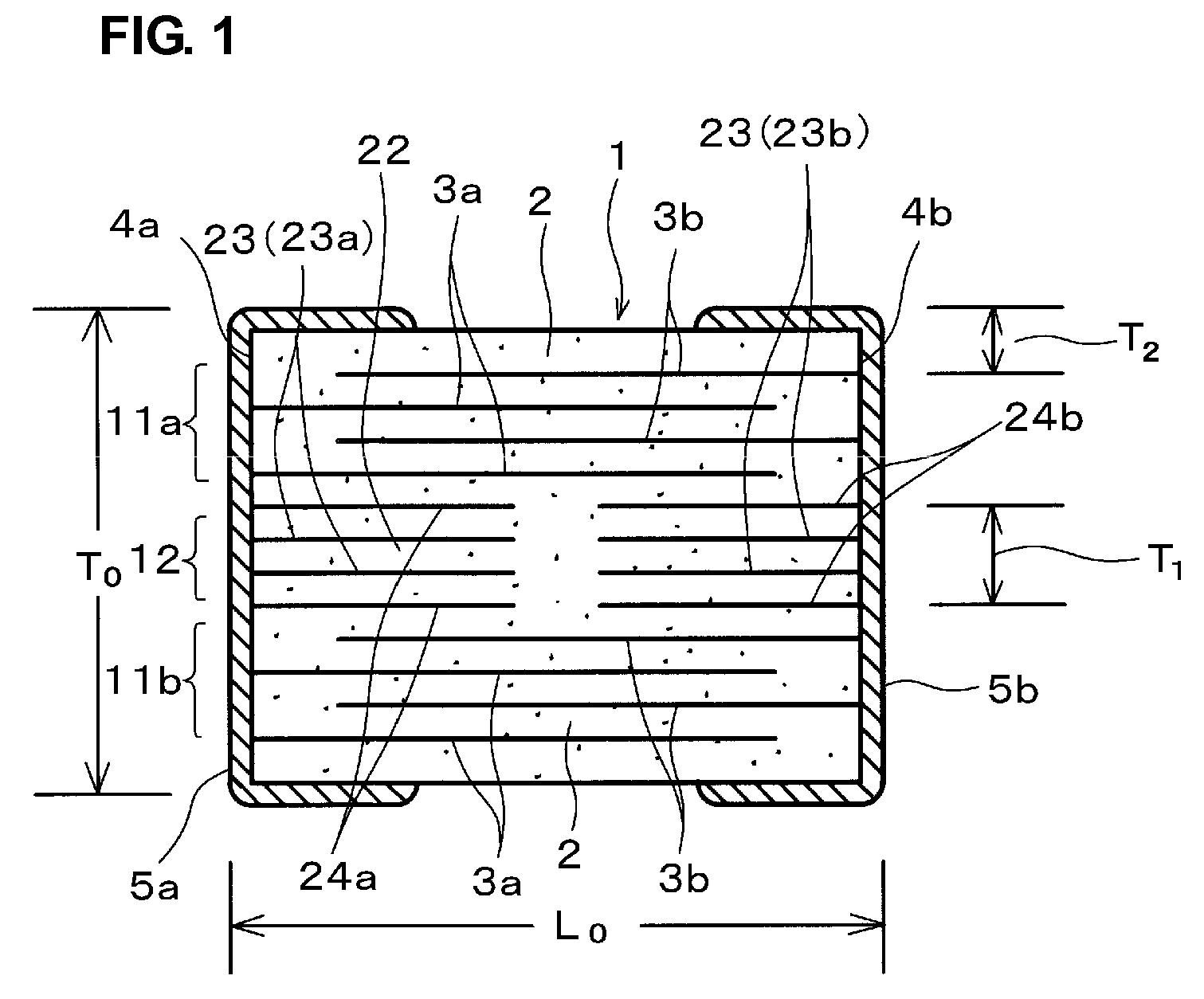

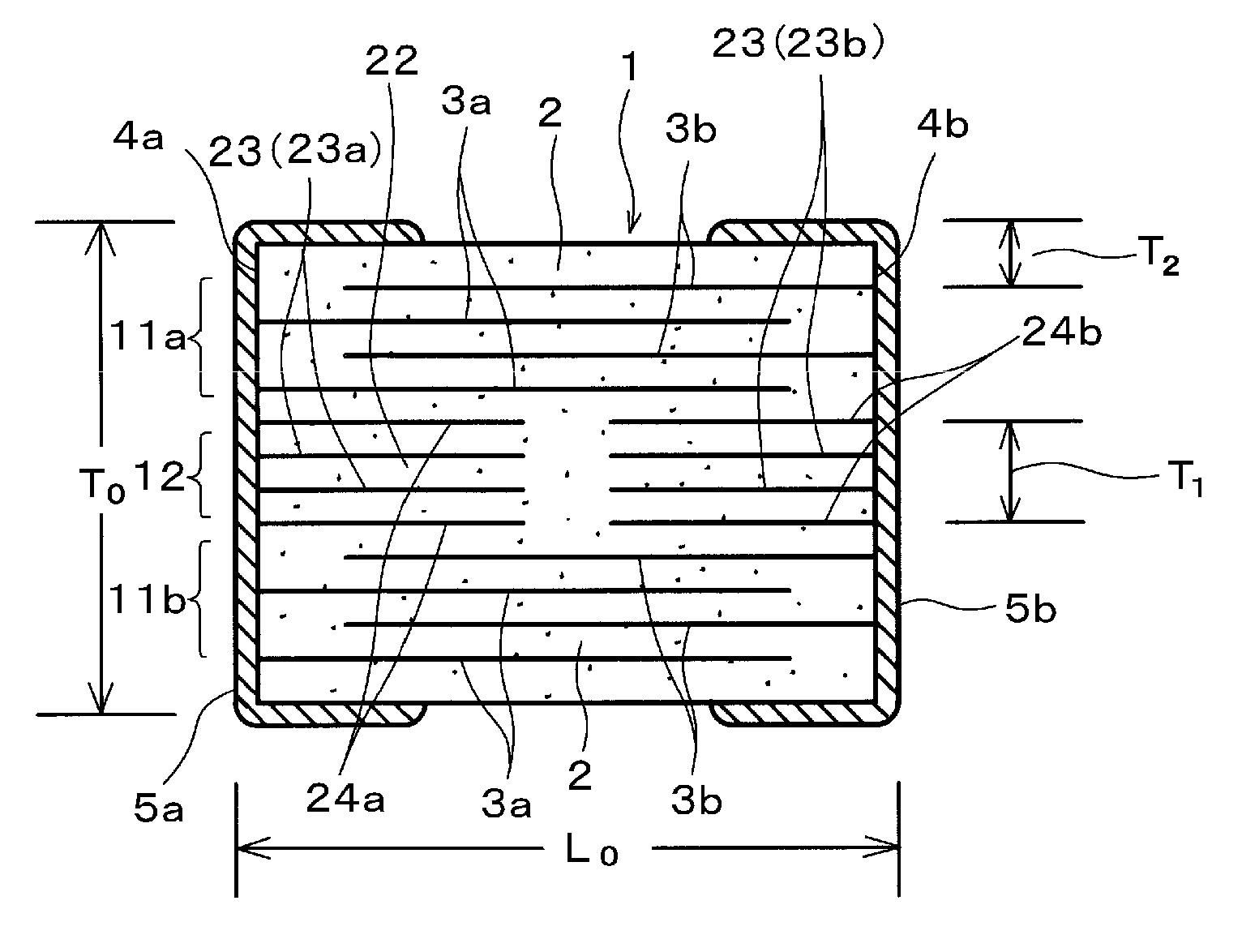

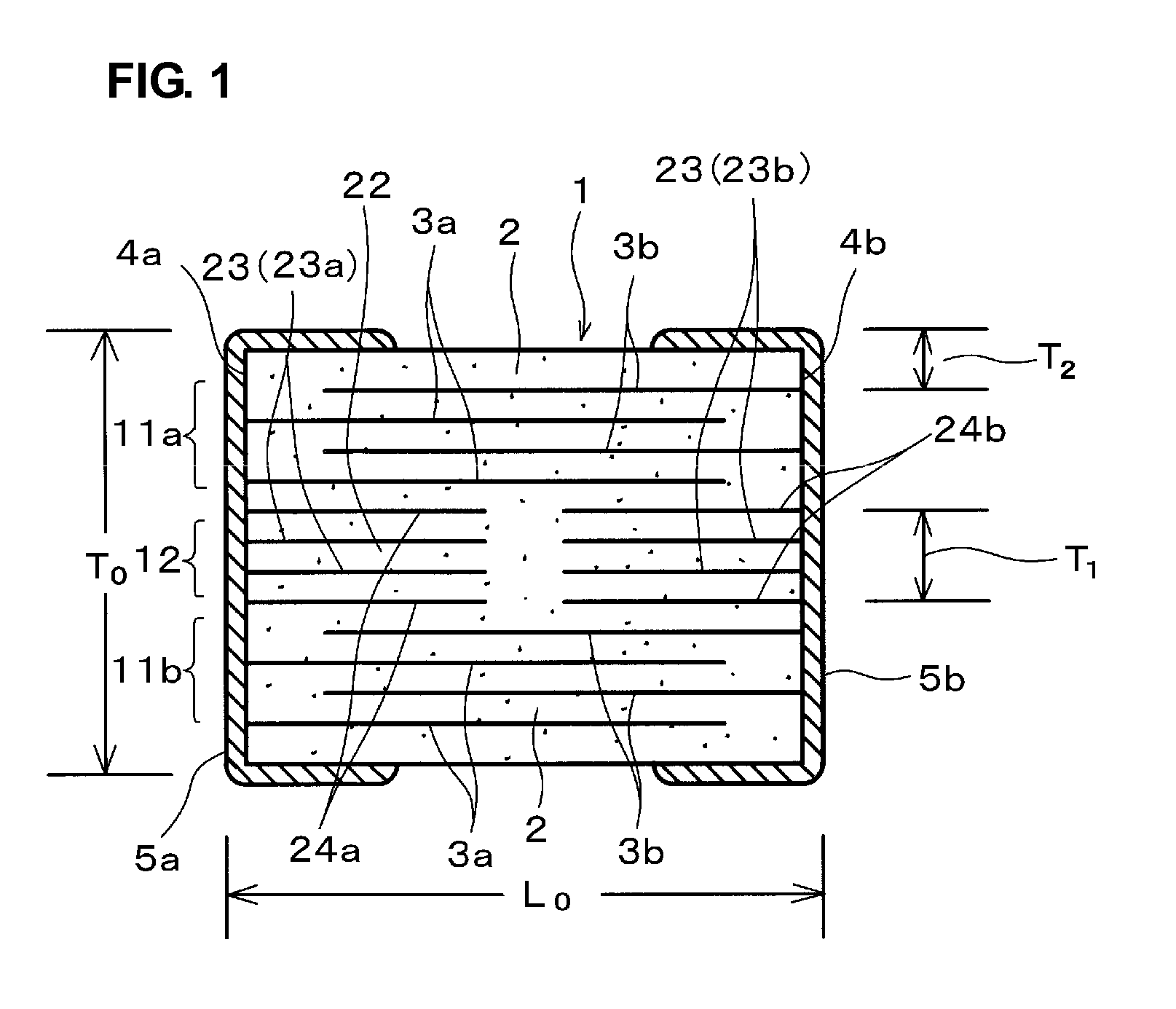

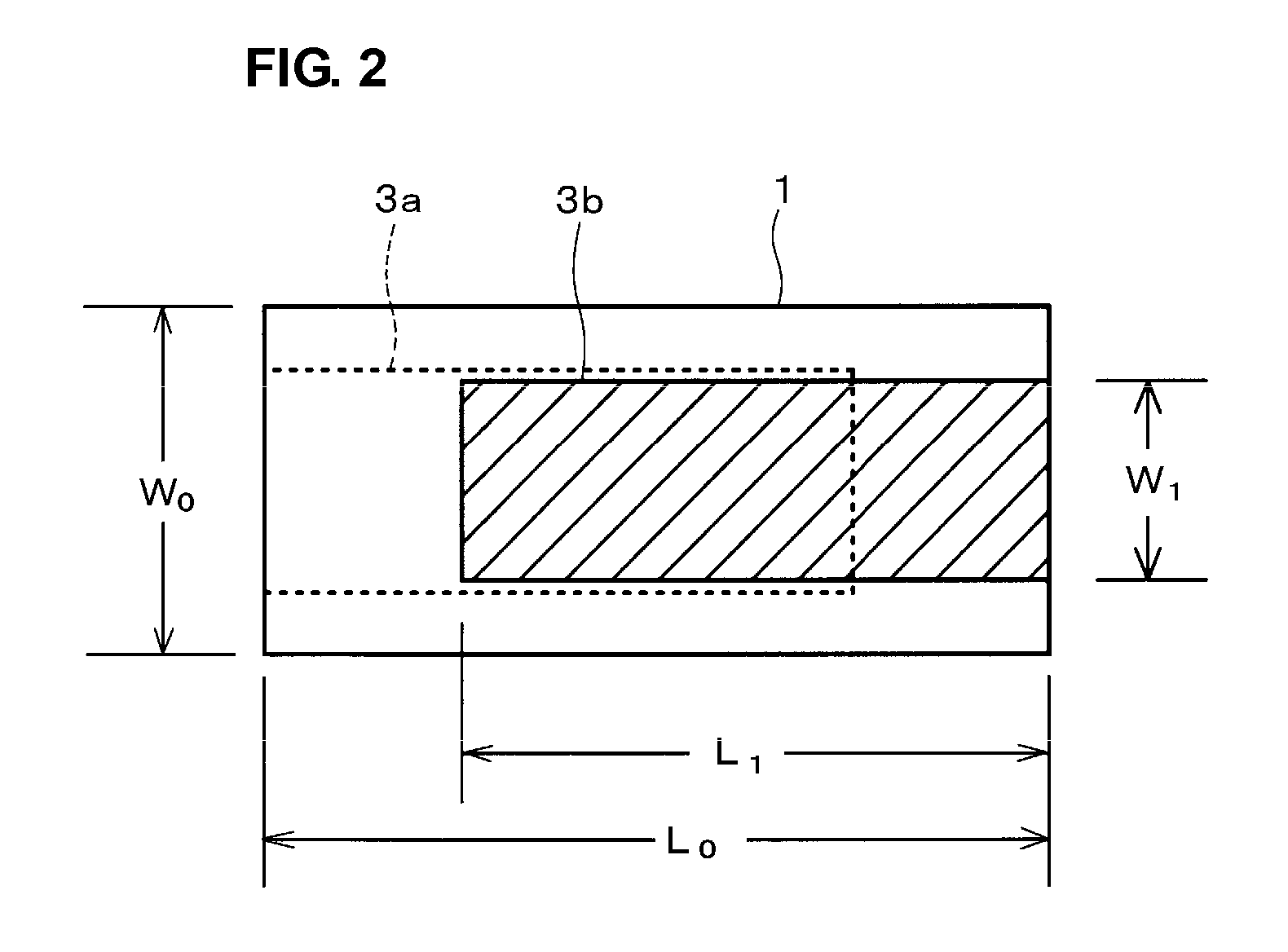

Multilayer capacitor

ActiveUS20130038979A1Reduce vibrationSuppress electrostrictive vibrationFixed capacitor electrodesStacked capacitorsGeneral purposeCapacitor

A multilayer capacitor that can suppress electrostrictive vibration without material constraint and with applicability to various structures, including general-purpose structures. A multilayer capacitor has: an element body formed of dielectric ceramic; and a plurality of internal electrodes disposed inside the element body such that the internal electrodes are stacked with ceramic layers sandwiched therebetween. The multilayer capacitor is provided with a capacitor area which includes the plurality of internal electrodes and a first suppression area and a second suppression area for reducing electrostriction caused by the plurality of internal electrodes so as to suppress noise. The first suppression area is adjacent to the capacitor area and the thickness of the second suppression area is determined according to the arrangement of the plurality of internal electrodes.

Owner:TDK CORPARATION

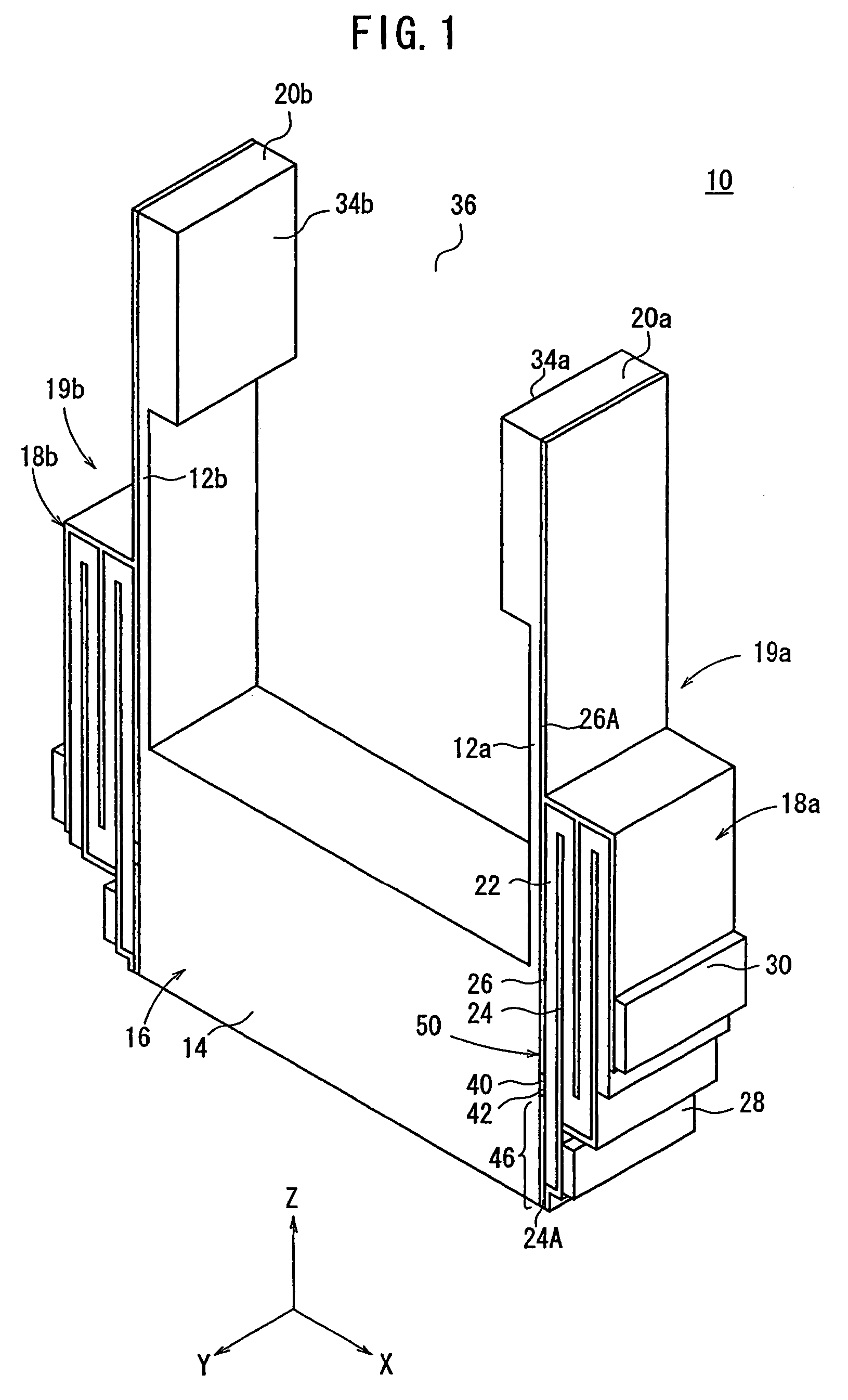

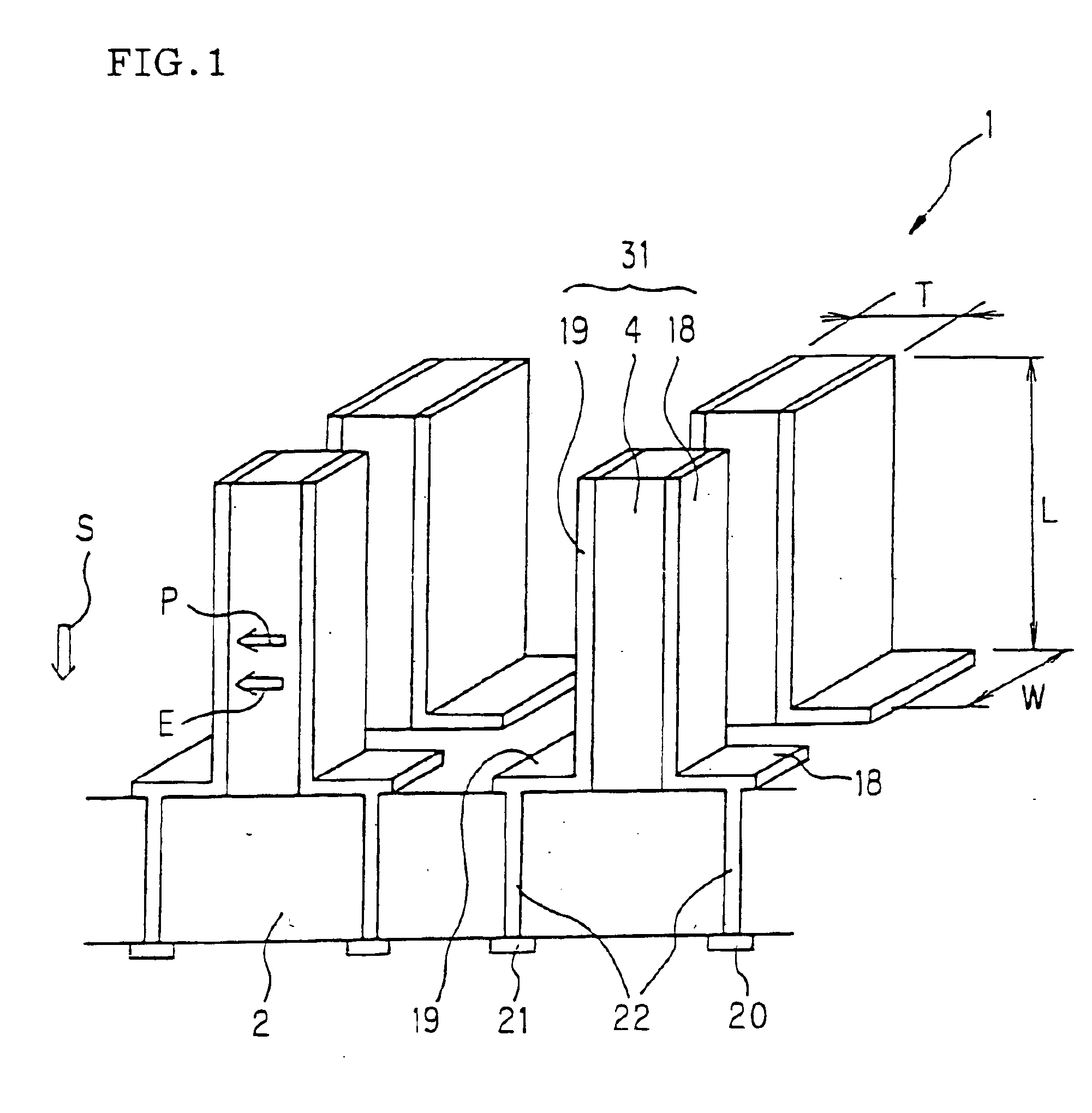

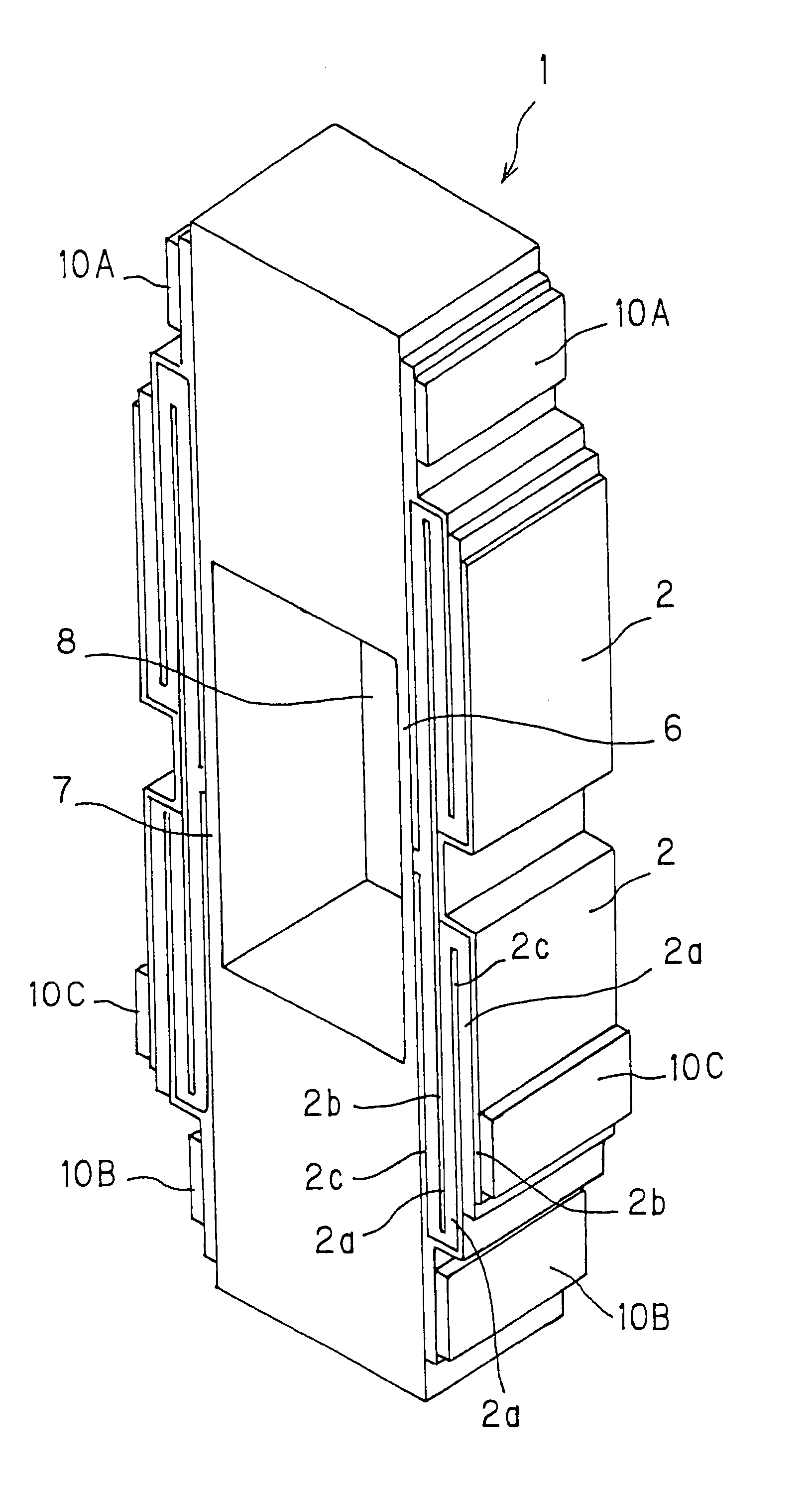

Matrix type piezoelectric/electrostrictive device and manufacturing method thereof

InactiveUS20030098632A1Piezoelectric/electrostriction/magnetostriction machinesSolid-state devicesForce generationLow voltage

A matrix type piezoelectric / electrostrictive device in which a plurality of piezoelectric / electrostrictive elements almost in a pillar shape, each having a piezoelectric / electrostrictive substance and at least a pair of electrodes, are vertically provided on a thick ceramic substrate, and which is driven by displacement of the piezoelectric / electrostrictive substance. In this matrix type piezoelectric / electrostrictive device, a plurality of piezoelectric / electrostrictive elements are integrally bonded to the ceramic substrate and independently arranged in two dimensions. The pair of electrodes is formed on the sides of the piezoelectric / electrostrictive substance. The percentage of transgranularly fractured crystal grains on at least the sides of the piezoelectric / electrostrictive substance on which the electrodes are formed is 10% or less. The piezoelectric / electrostrictive substance forms a curved surface near a joined section between the piezoelectric / electrostrictive substance and the ceramic substrate. According to this piezoelectric / electrostrictive device, large displacement is obtained at a low voltage, with achievement of a high speed response, a large force generation, excellent mounting capability, a higher degree of integration. The action such as pushing, distorting, moving, striking (impacting), or mixing can be applied to an object of action, or the device operates when such action is applied.

Owner:NGK INSULATORS LTD

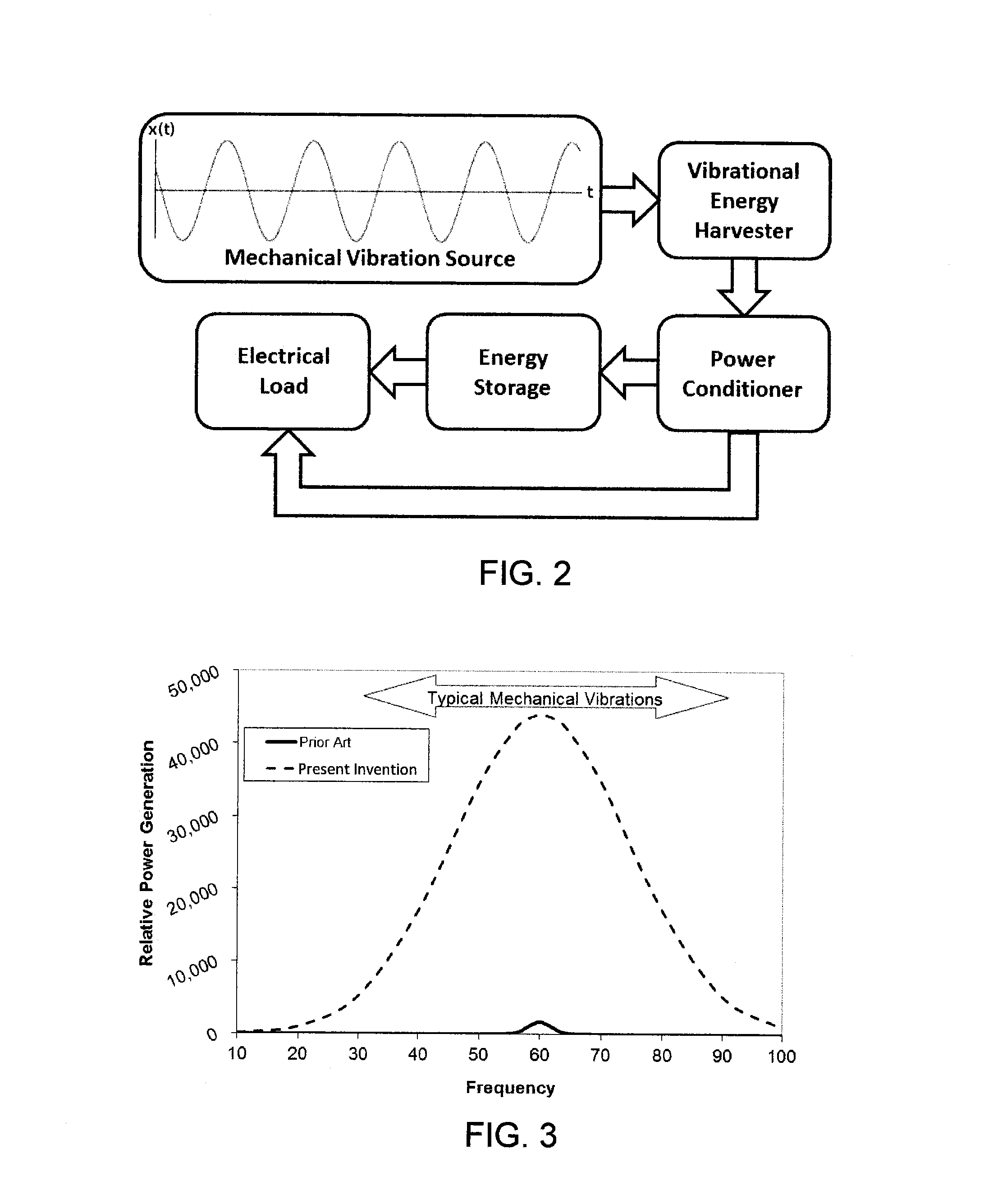

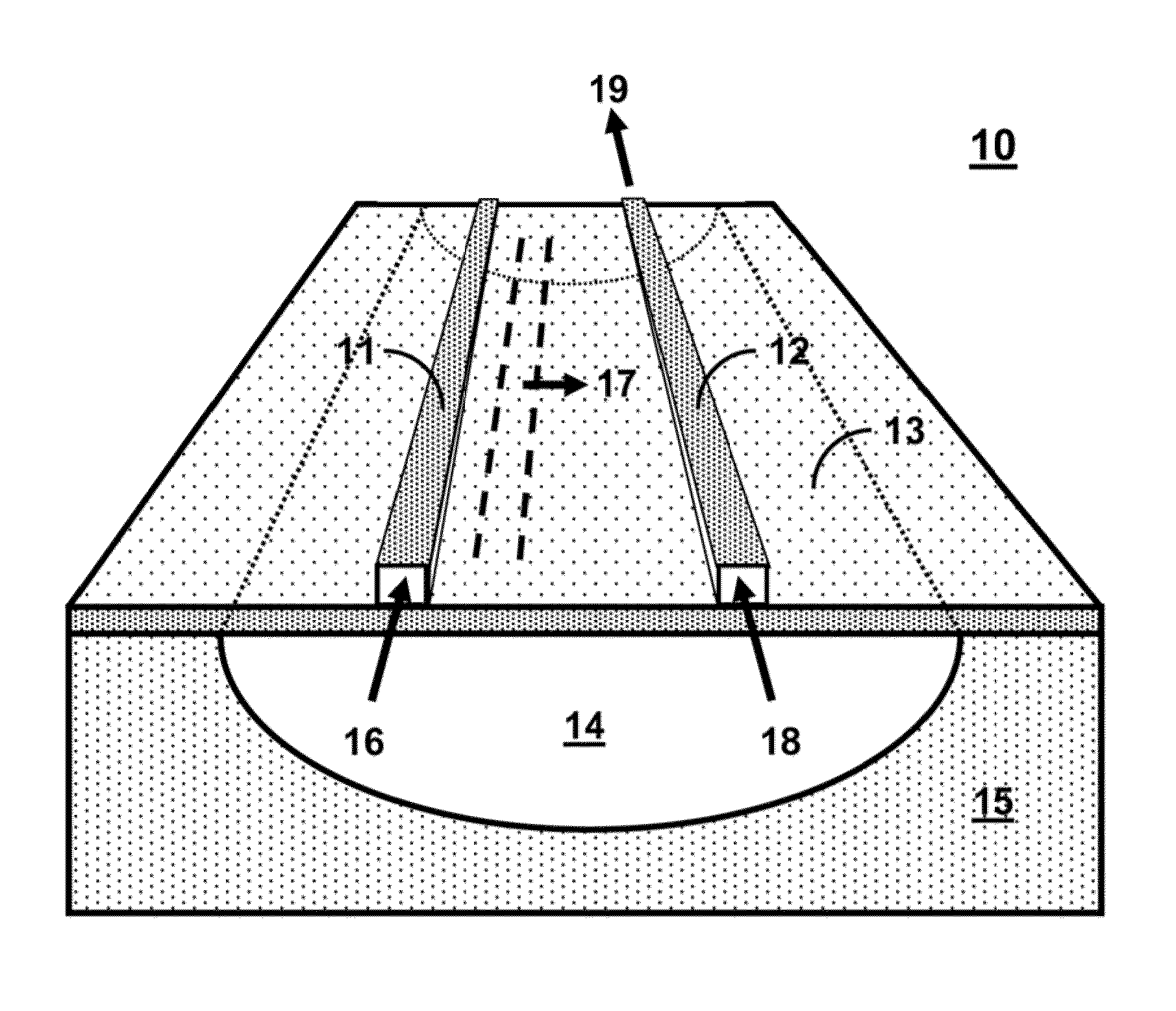

Power generator

InactiveUS20130207520A1Low costNegatively impact reliabilityPiezoelectric/electrostriction/magnetostriction machinesPiezoelectric/electrostrictive/magnetostrictive devicesEngineering physicsEnergy storage

An electrical power generator has one or more serpentine elements that are made of a poled piezoelectric or electrostrictive ceramic, one or more electrically conductive shims or foils and at least two electrically conductive electrode coatings on the serpentine element. The conductive electrodes are further electrically connected to an electrical load or energy storage device or both, and the serpentine element is mechanically affixed to a source of compression or vibration or both.

Owner:GENZIKO

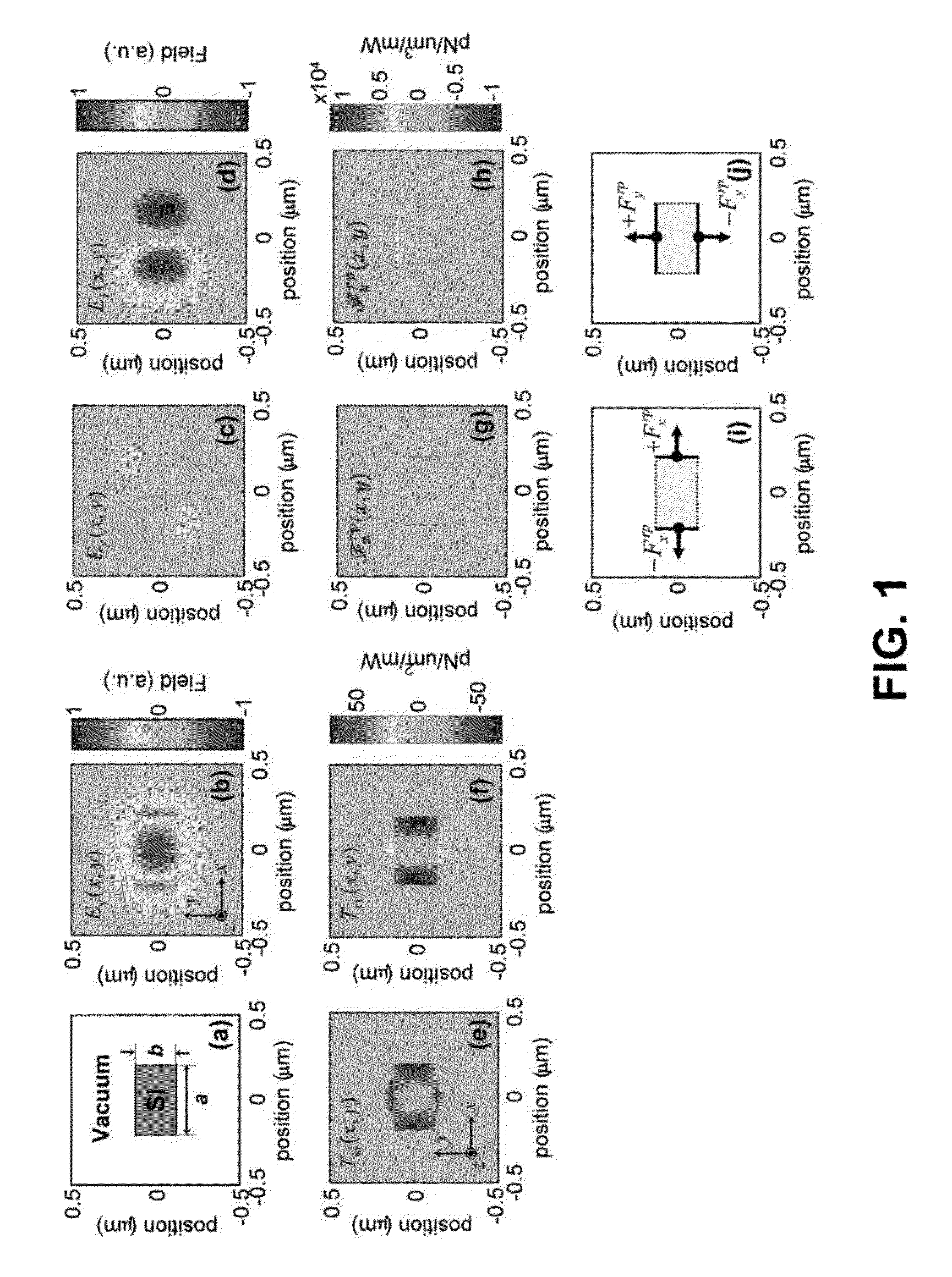

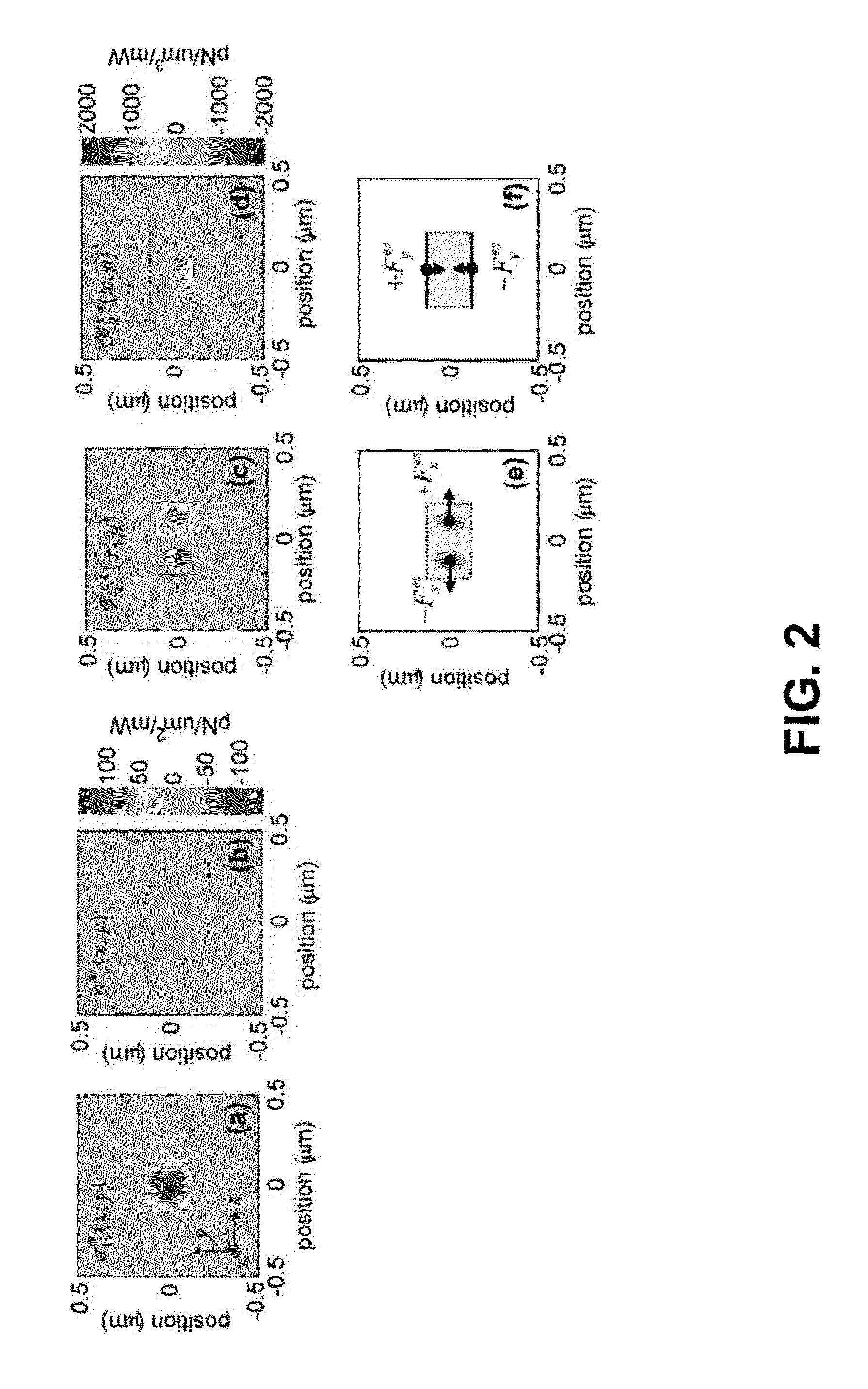

Nano-optomechanical transducer

A nano-optomechanical transducer provides ultrabroadband coherent optomechanical transduction based on Mach-wave emission that uses enhanced photon-phonon coupling efficiencies by low impedance effective phononic medium, both electrostriction and radiation pressure to boost and tailor optomechanical forces, and highly dispersive electromagnetic modes that amplify both electrostriction and radiation pressure. The optomechanical transducer provides a large operating bandwidth and high efficiency while simultaneously having a small size and minimal power consumption, enabling a host of transformative phonon and signal processing capabilities. These capabilities include optomechanical transduction via pulsed phonon emission and up-conversion, broadband stimulated phonon emission and amplification, picosecond pulsed phonon lasers, broadband phononic modulators, and ultrahigh bandwidth true time delay and signal processing technologies.

Owner:NAT TECH & ENG SOLUTIONS OF SANDIA LLC

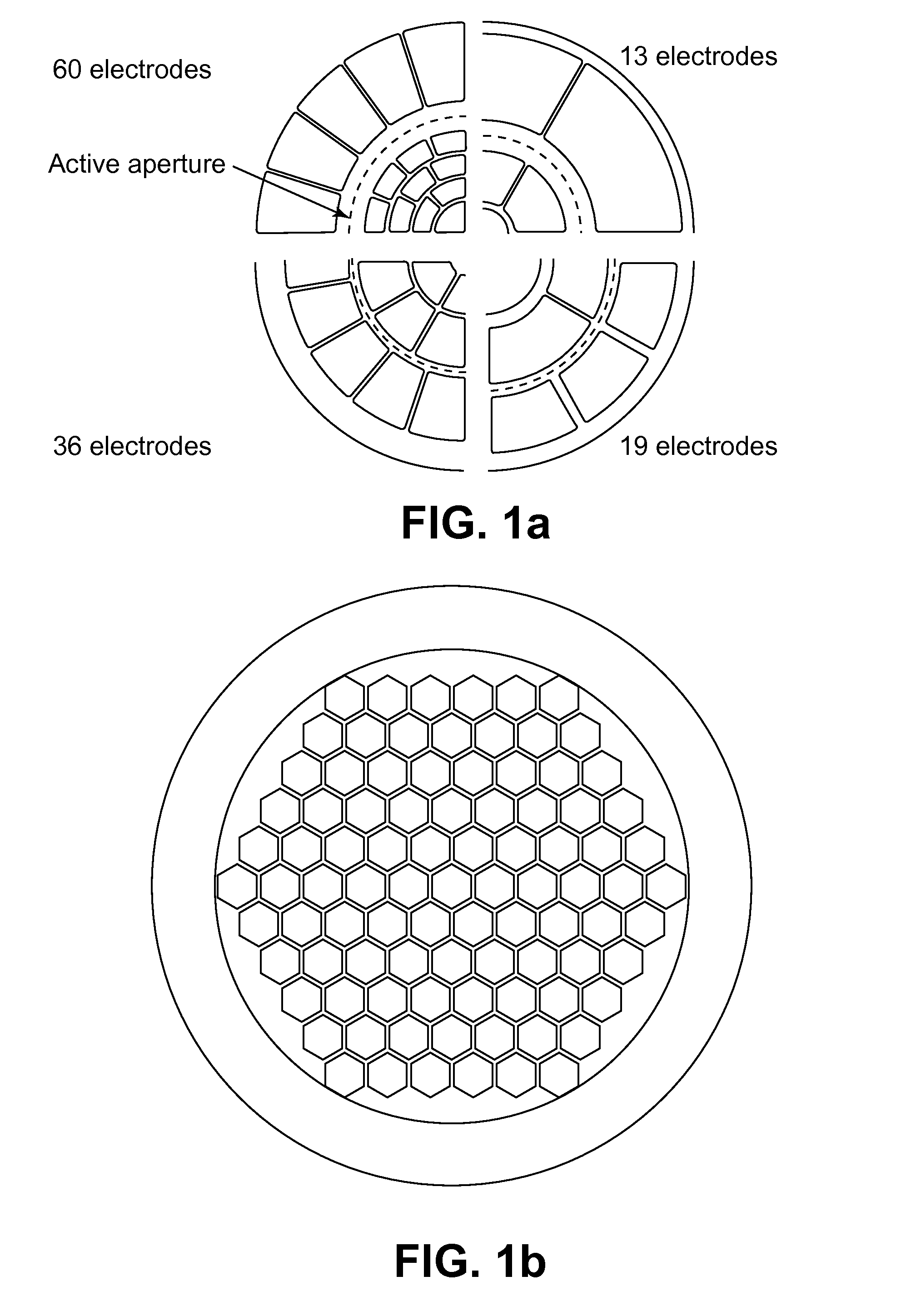

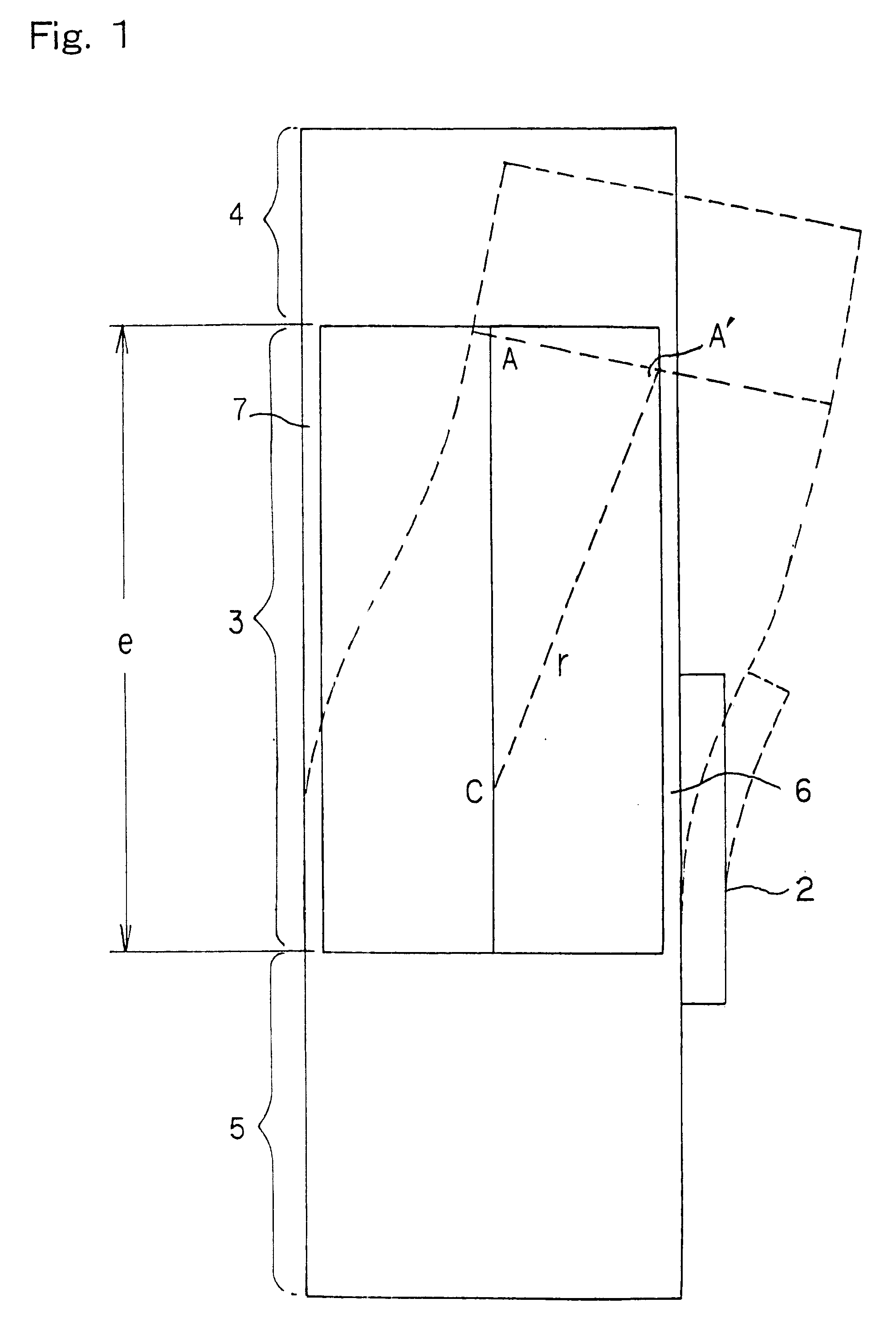

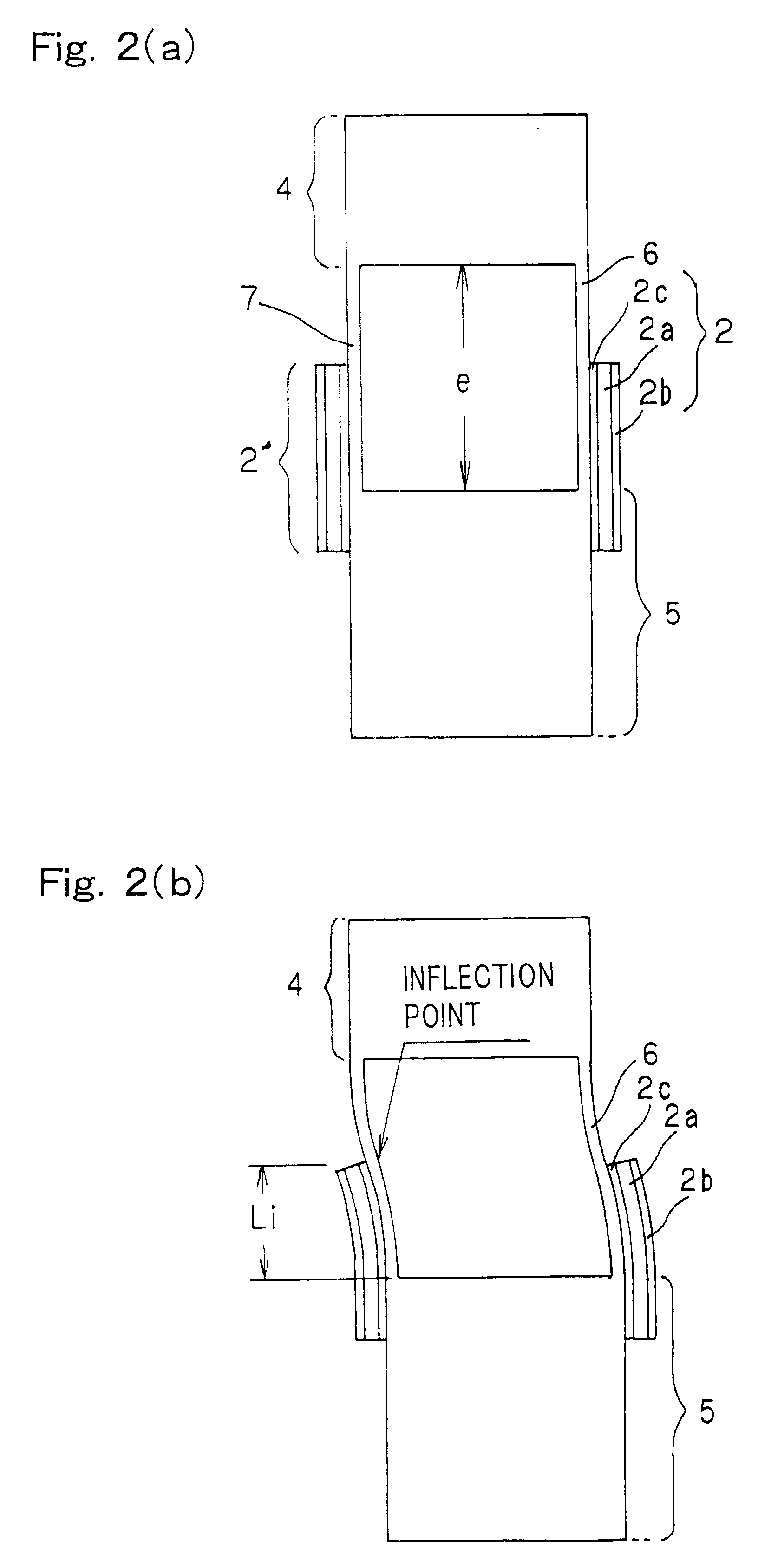

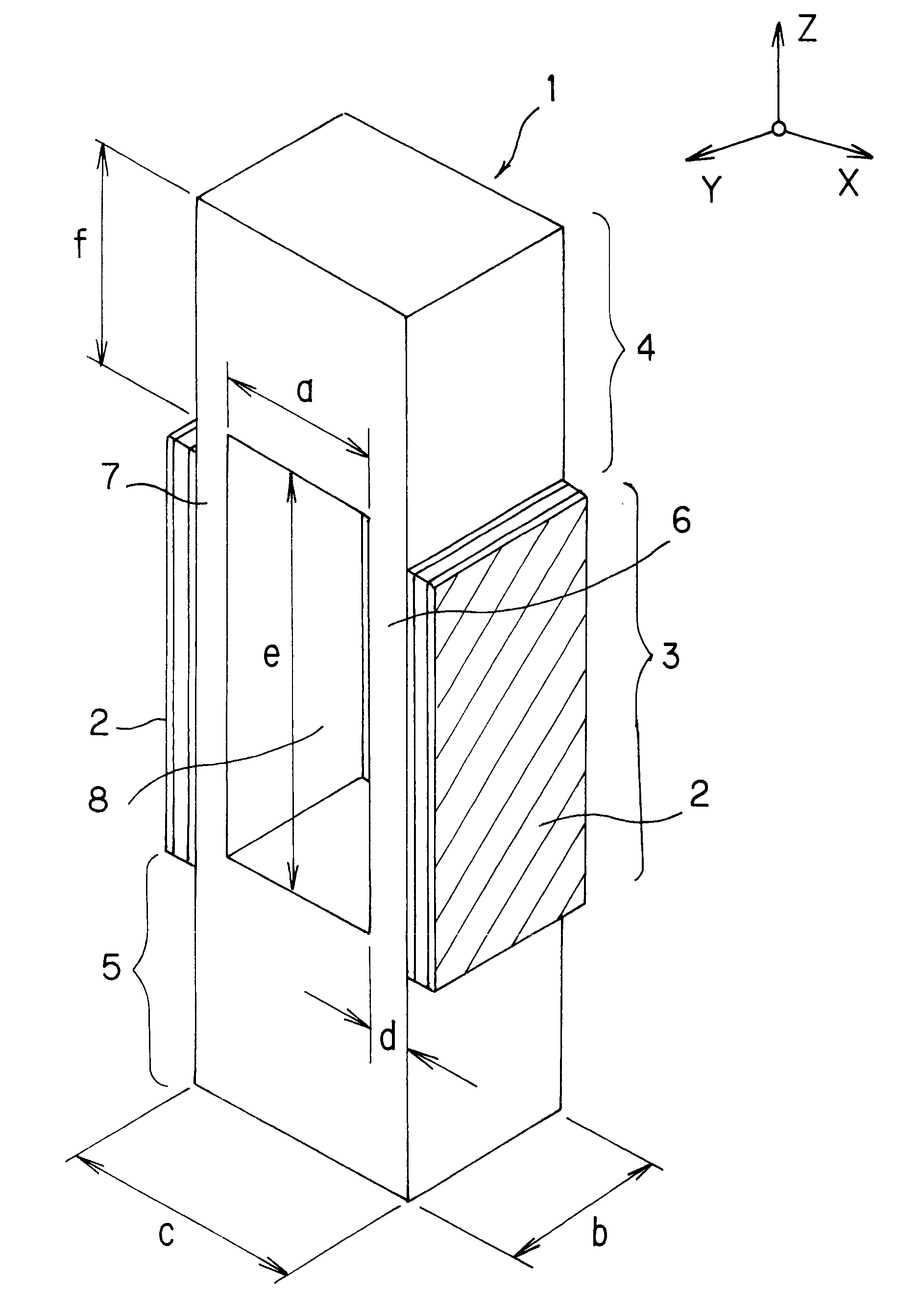

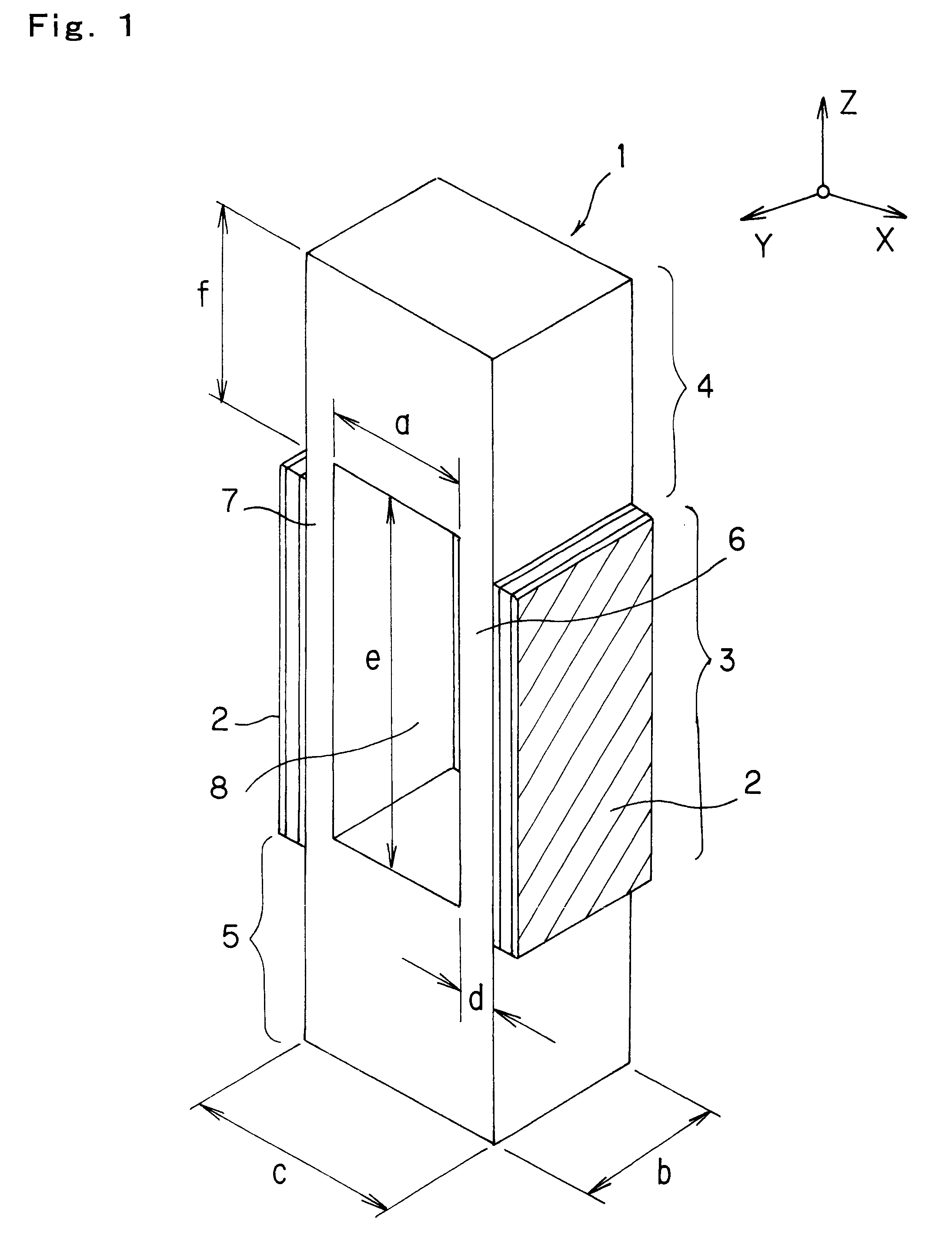

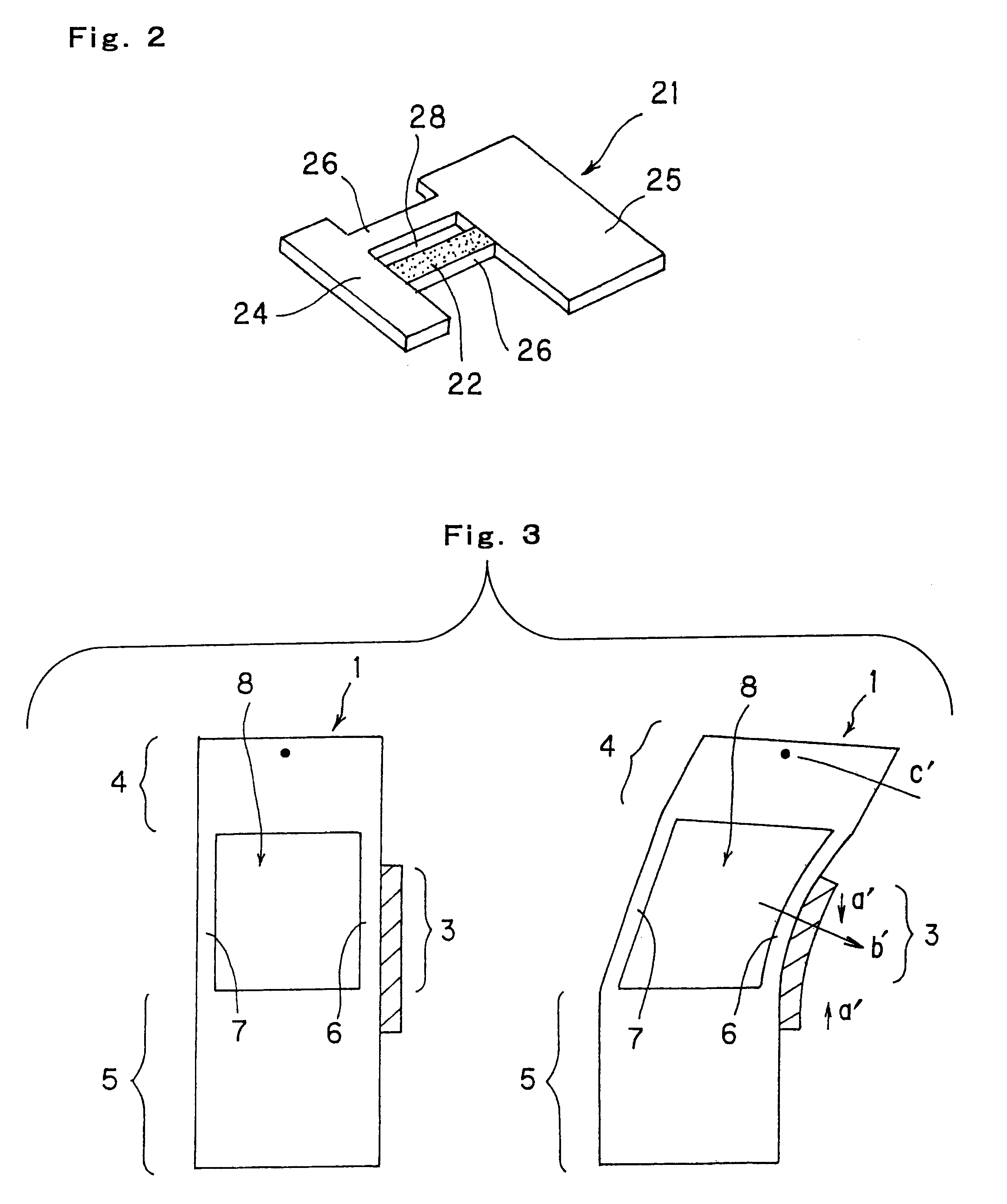

Deformable mirror

The present invention is related to a deformable mirror comprising individual units (1), each unit including a continuous reflective substrate (2) having a front and back surface, on the back surface of the substrate: a continuous mass electrode (3) and a plurality of in-plane actuators (4) of electrostrictive or piezo-electric material, arranged between the mass electrode (3) and individual addressing electrodes (5).

Owner:UNIV LIBRE DE BRUXELIES

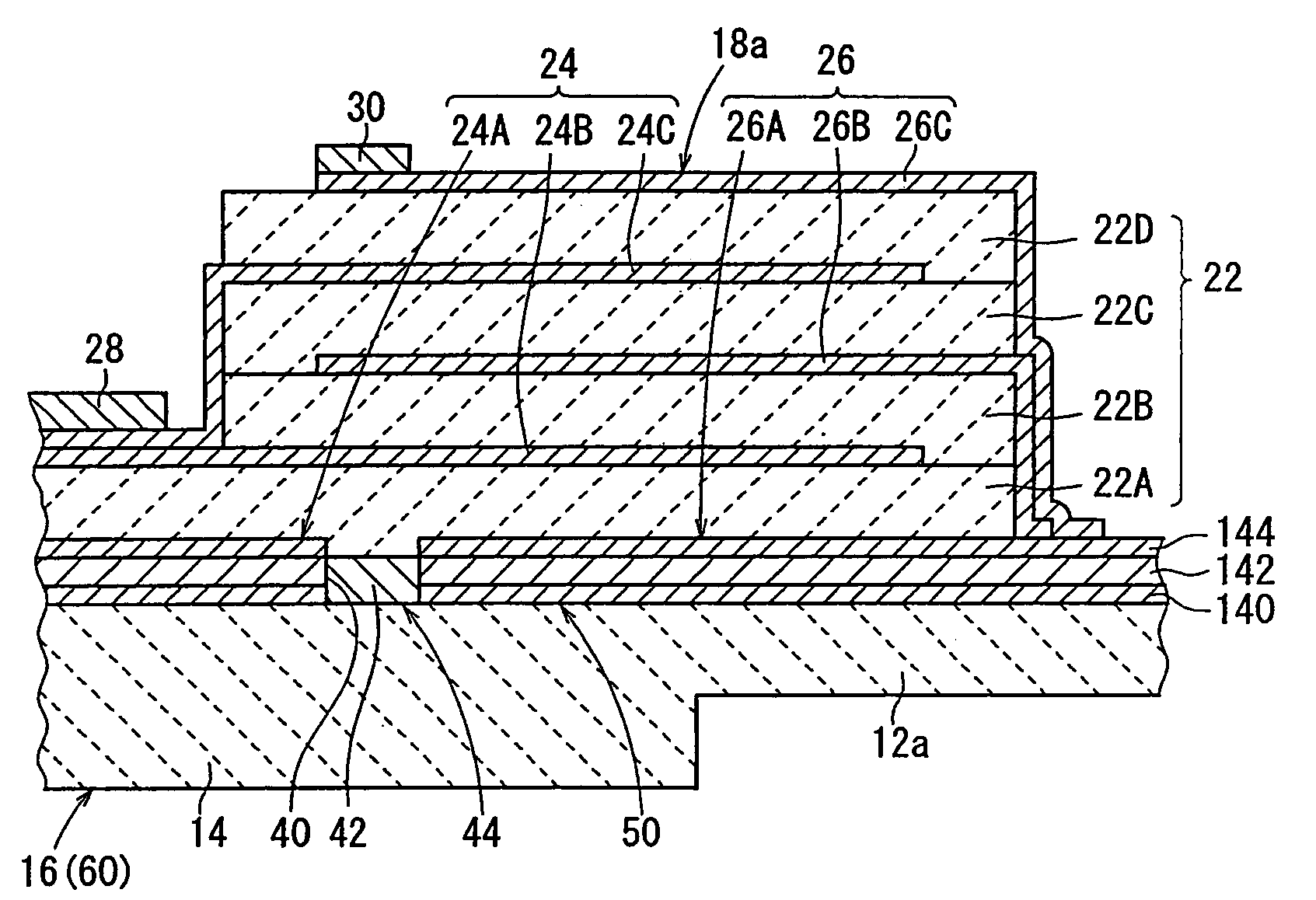

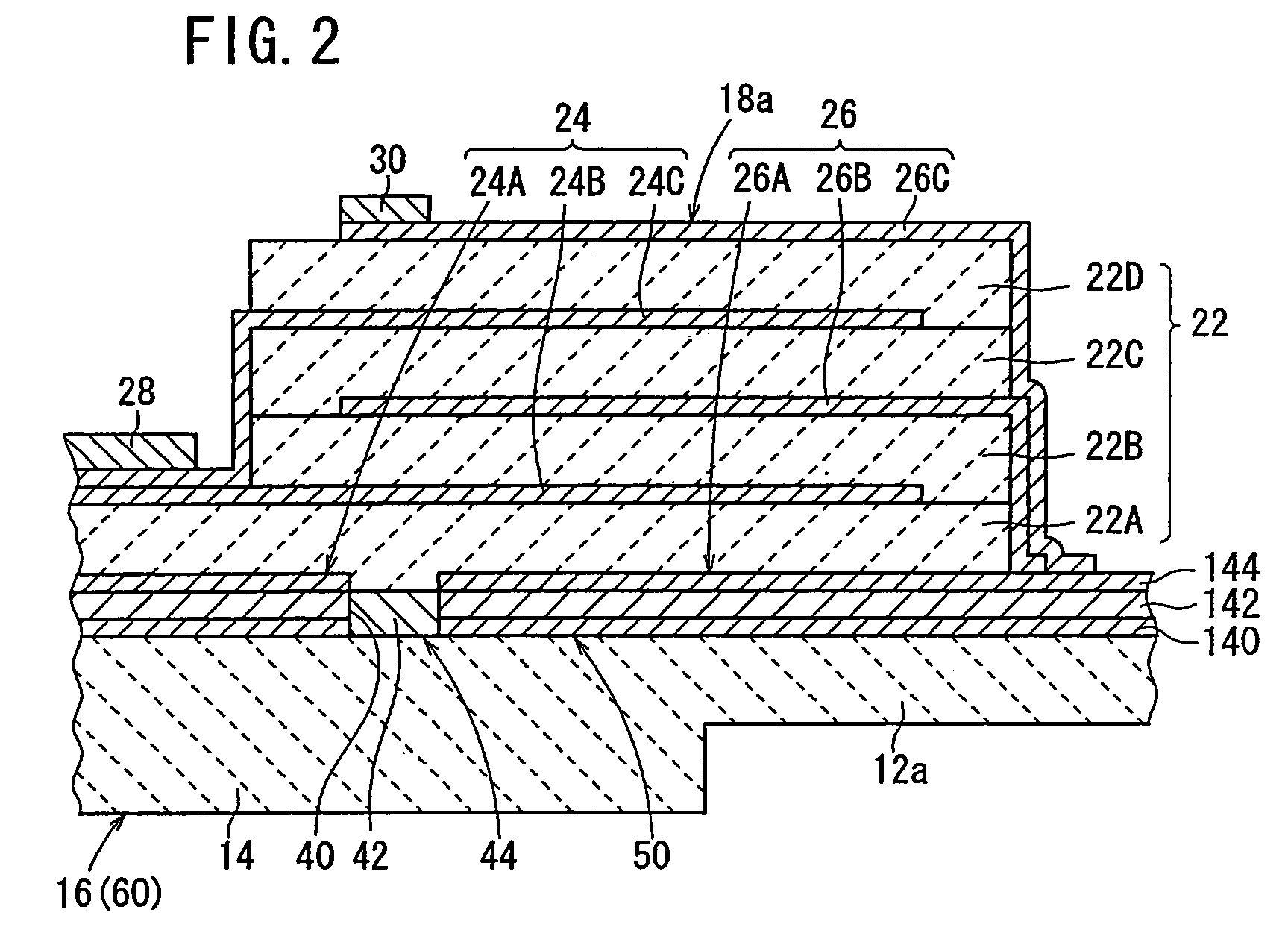

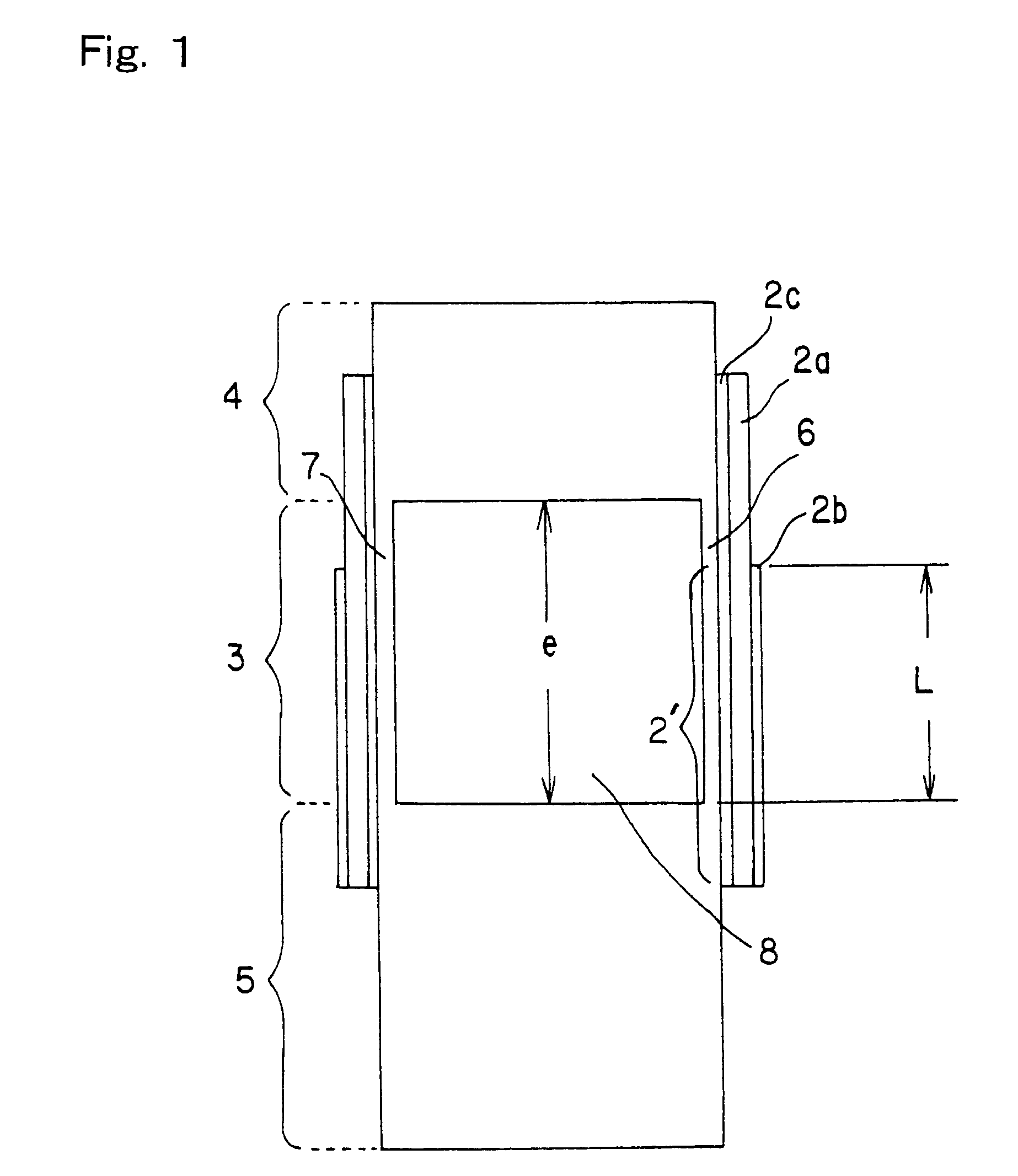

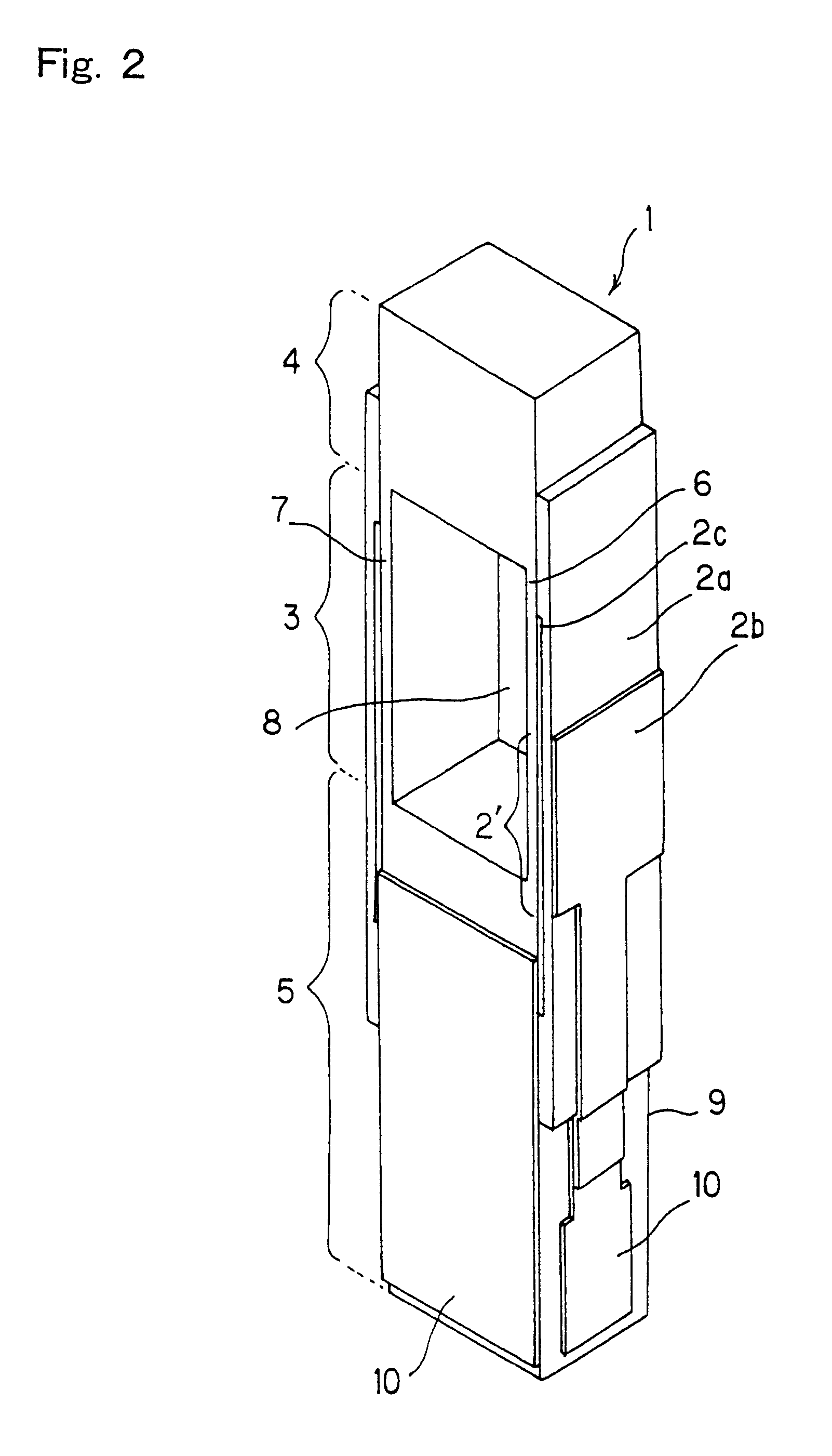

Piezoelectric/electrostrictive device and method of manufacturing same

InactiveUS6992421B2Increase the conductive areaIncrease productionPiezoelectric/electrostriction/magnetostriction machinesPiezoelectric/electrostrictive device detailsConductive materialsMaterials science

A pair of opposing thin plate sections, movable sections, and fixed sections for supporting the thin plate sections and the movable sections are provided on a ceramic substrate. After a wiring pattern and a gap or an insulating layer of cermet layer for filling the gap are formed on a ceramic substrate, these are sintered. After that, piezoelectric / electrostrictive layers and cermet electrode layers including a piezoelectric / electrostrictive material and a conductive material are alternately stacked in a comb like structure on the ceramic substrate. Accordingly, a piezoelectric / electrostrictive device having the piezoelectric / electrostrictive element in multilayer structure is obtained.

Owner:NGK INSULATORS LTD

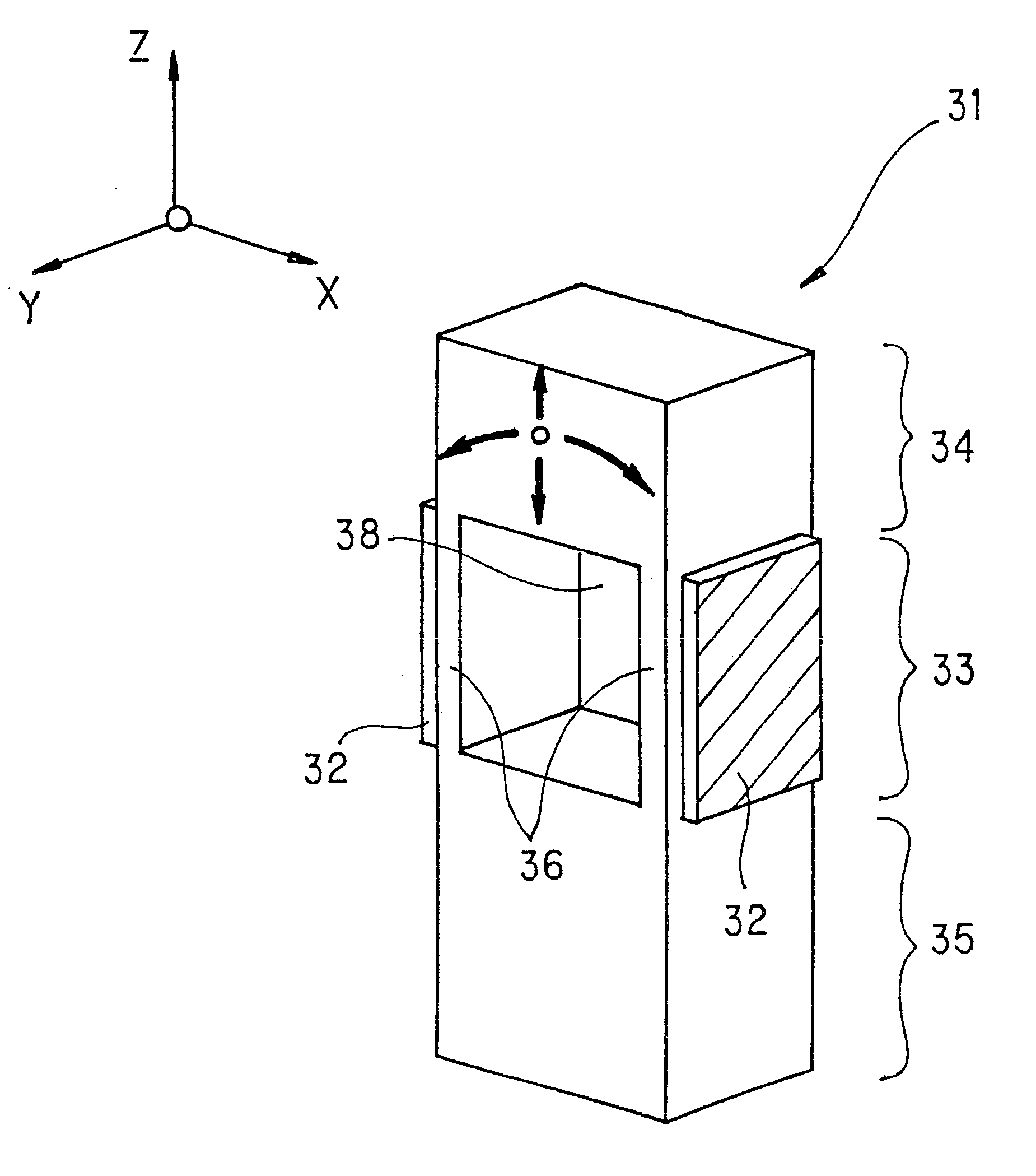

Piezoelectric/Electrostrictive device

InactiveUS6323582B1Piezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostriction/magnetostriction machinesEngineeringMechanical engineering

Owner:NGK INSULATORS LTD

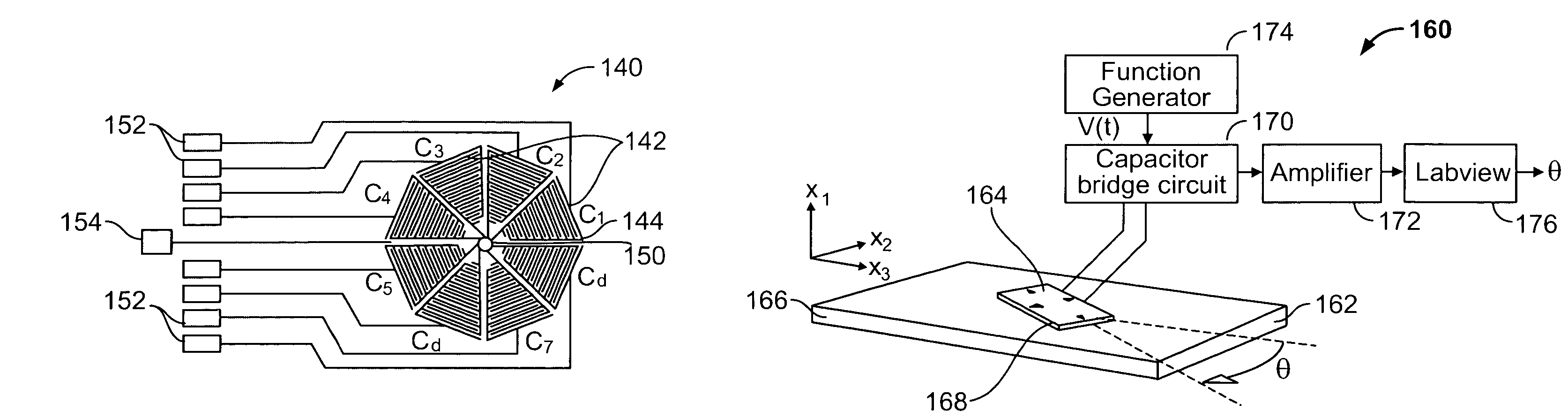

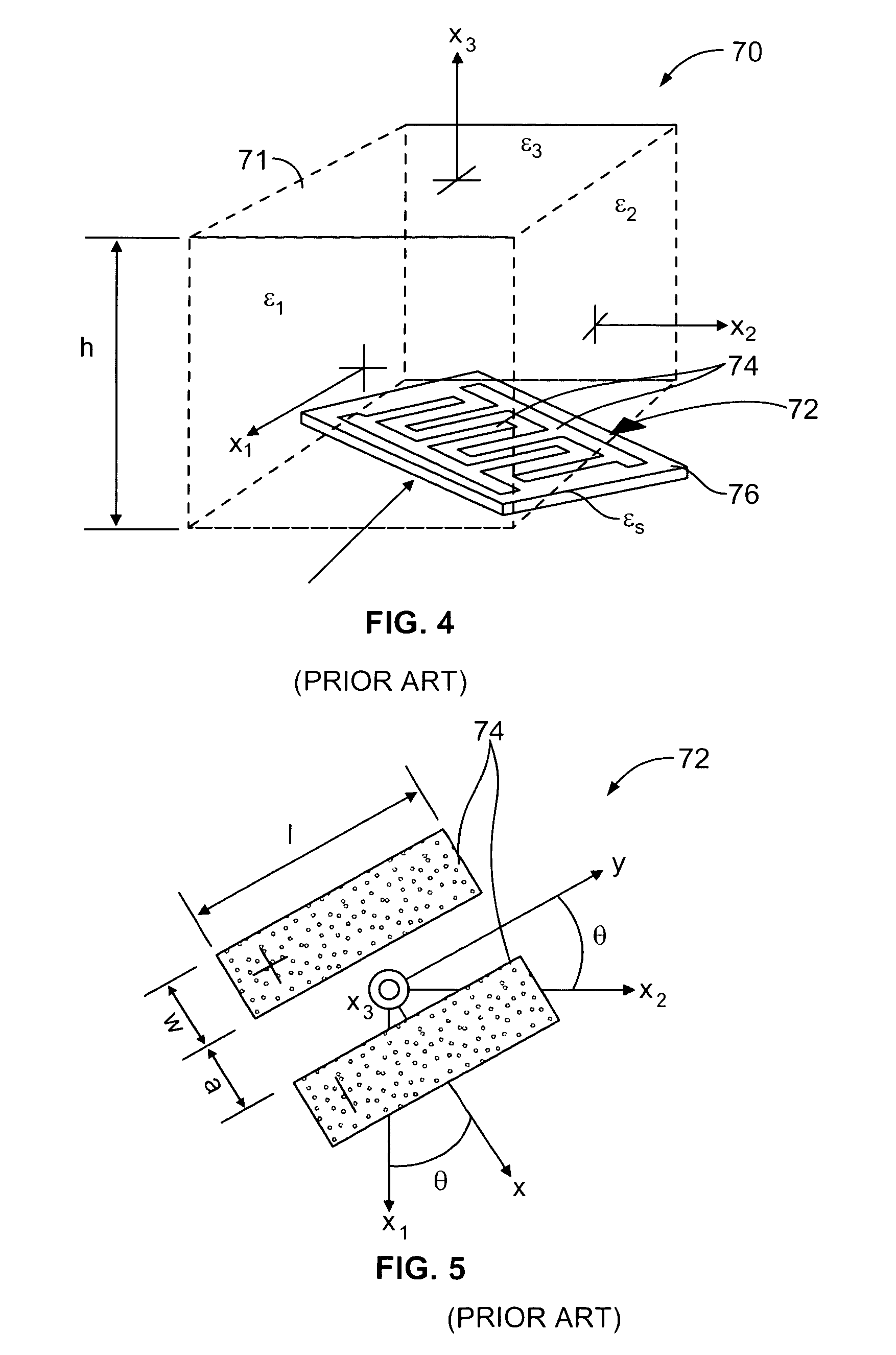

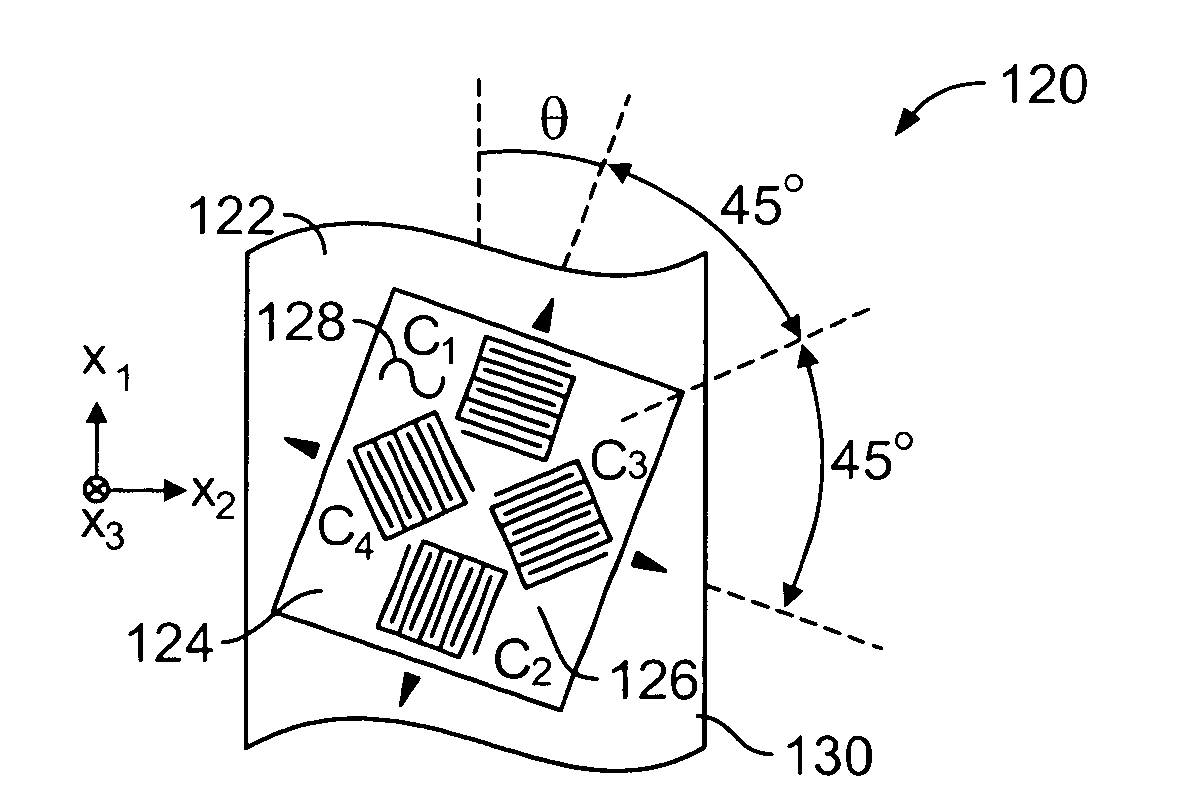

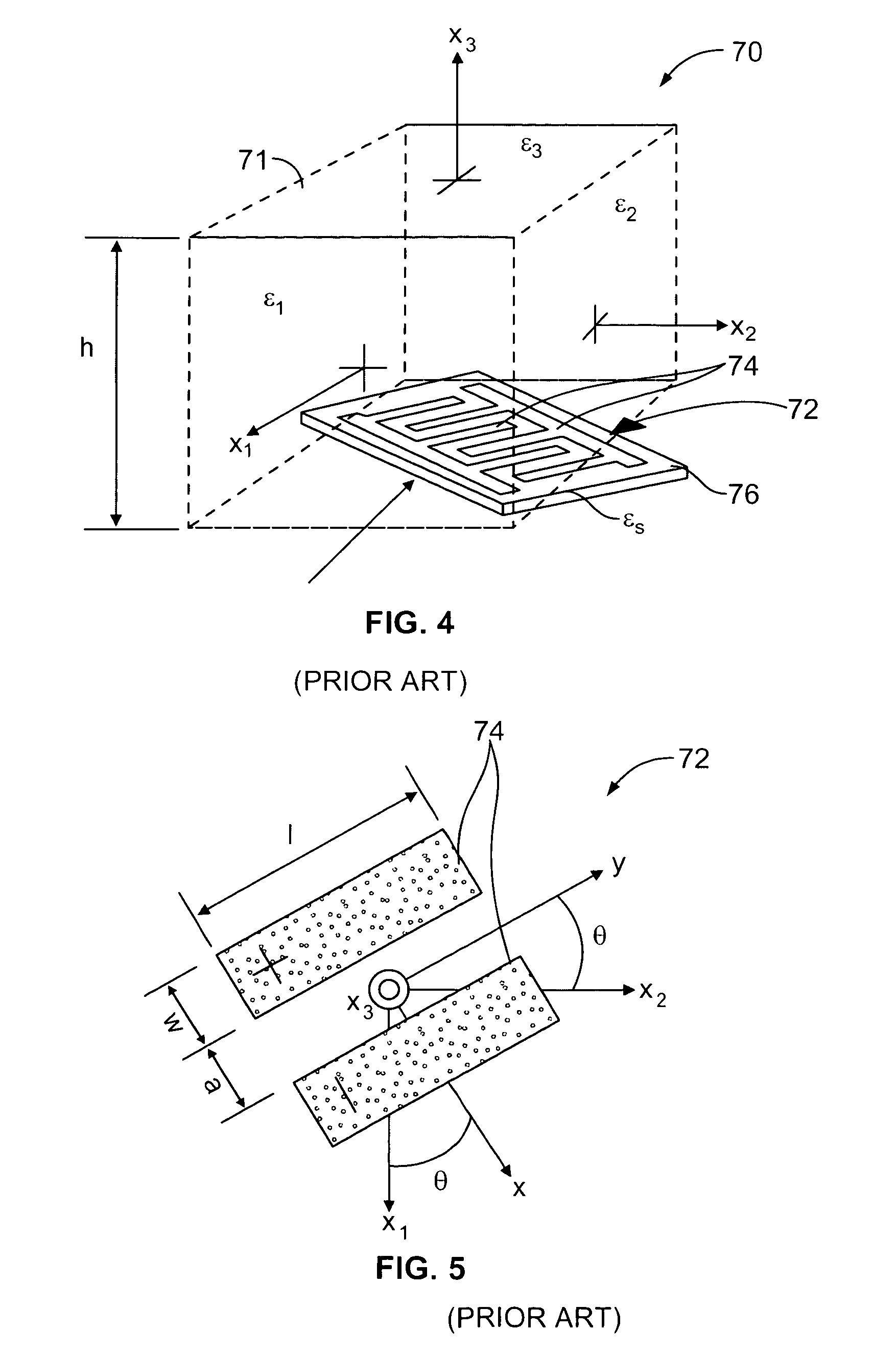

Dielectrostrictive sensor for measuring deformation

An apparatus and method directed to a solid-state capacitance sensor for measuring a strain force on a dielectric including at least one pair of electrostriction sensors each sensor having at least two electrodes and each having a central axis. The central axes are disposed in a common plane and are oriented substantially mutually perpendicularly to one another. Preferably, at least two pairs of sensors, forming a rosette, are provided to facilitate multi-component analysis of a sample having dielectric properties under stress / strain.

Owner:WISCONSIN ALUMNI RES FOUND

High power-to-mass ratio actuator

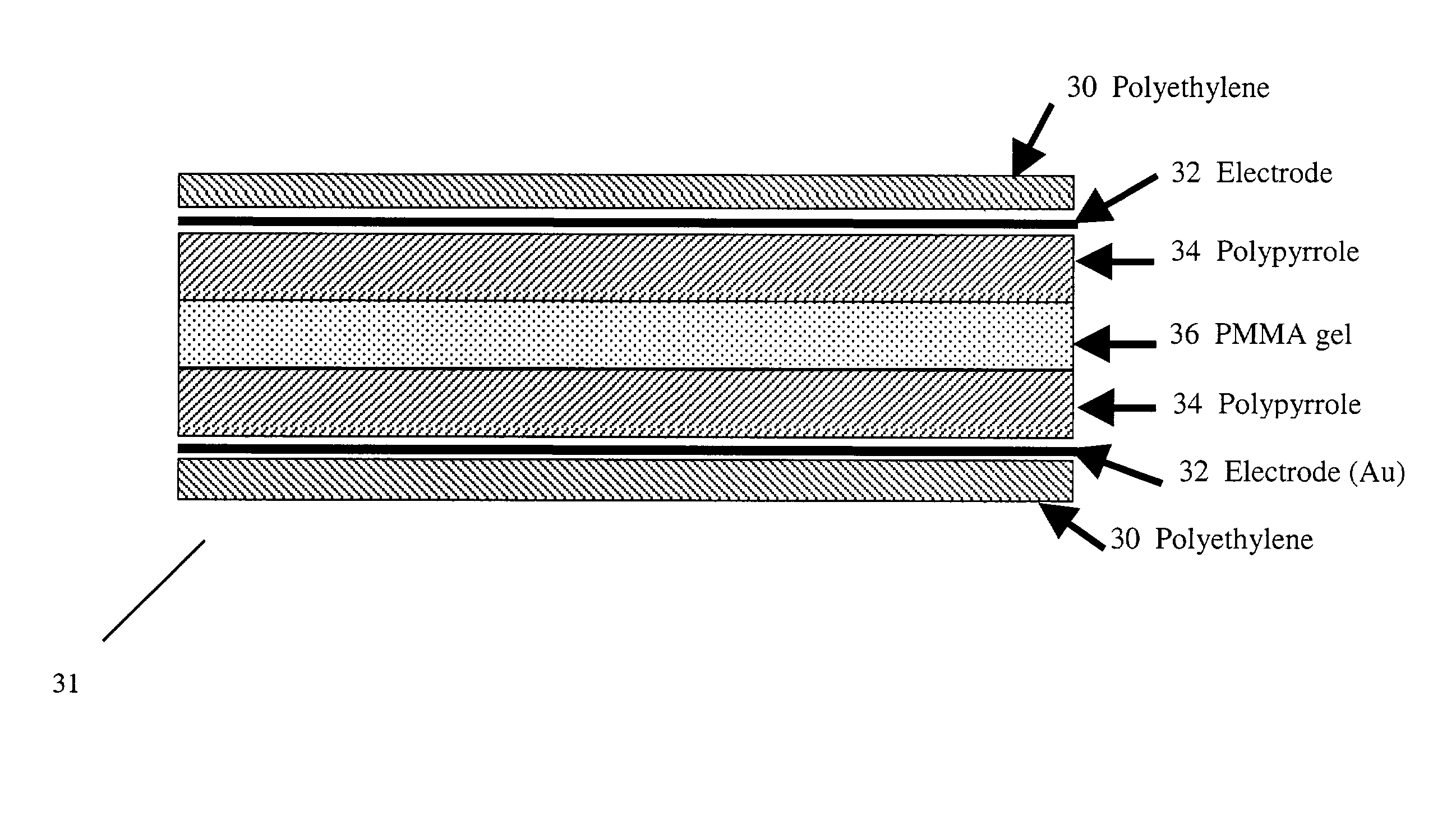

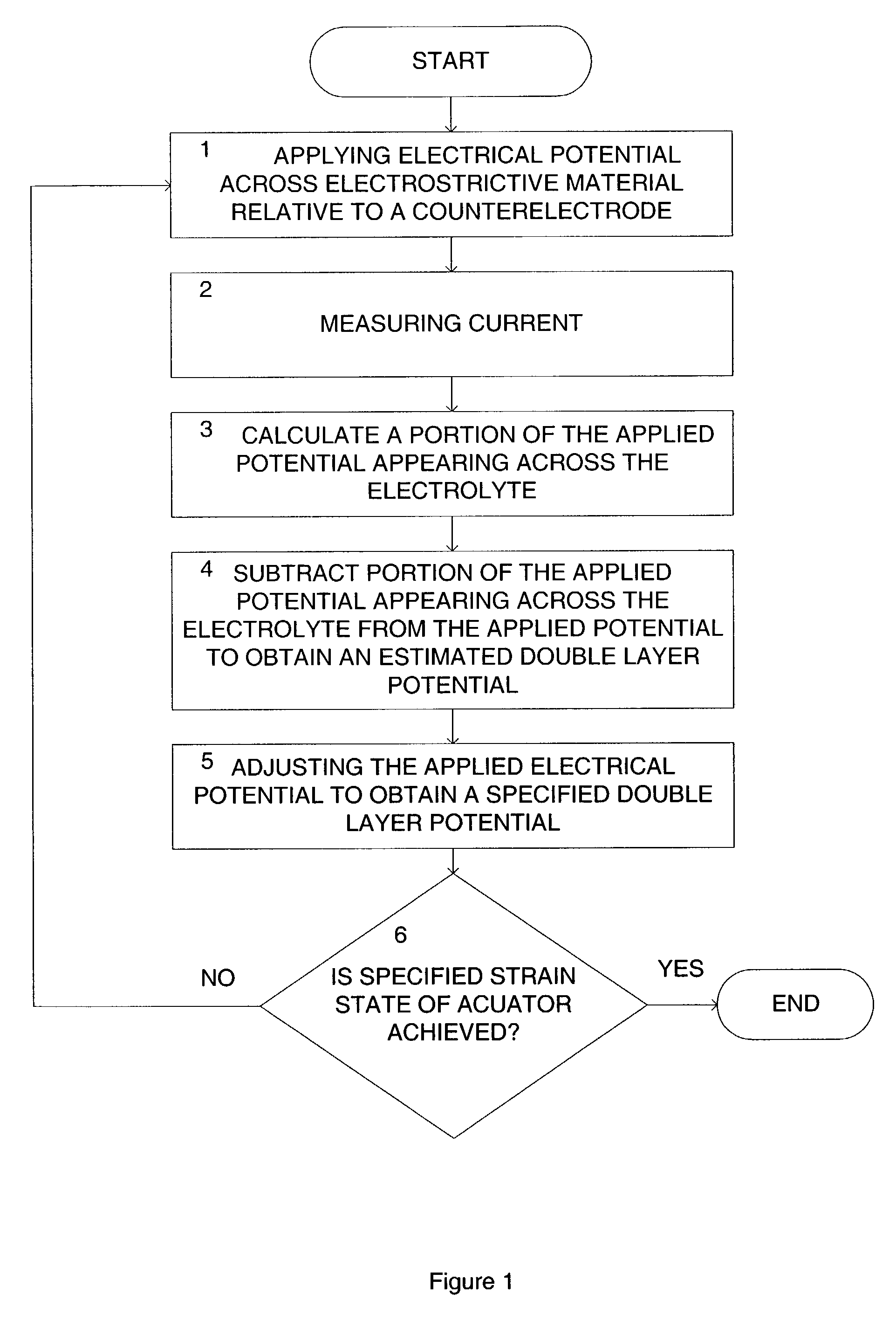

InactiveUS20020195326A1Piezoelectric/electrostrictive device material selectionMachines/enginesElectrolytic agentEngineering

A method for driving an actuator. The method includes applying an electrical potential across an electrostrictive material relative to a counterelectrode disposed within an electrolyte, thereby creating a double layer potential across a region of enhanced ionic concentration. A current flowing between the electorostrictive material and the counterelectrode is measured. A portion of the applied potential appearing across the electrolyte and counterelectrode is calculated and subtracted from the applied potential to obtain an estimated double layer potential. The applied electrical potential is adjusted to obtain a specified double layer potential.

Owner:MASSACHUSETTS INST OF TECH

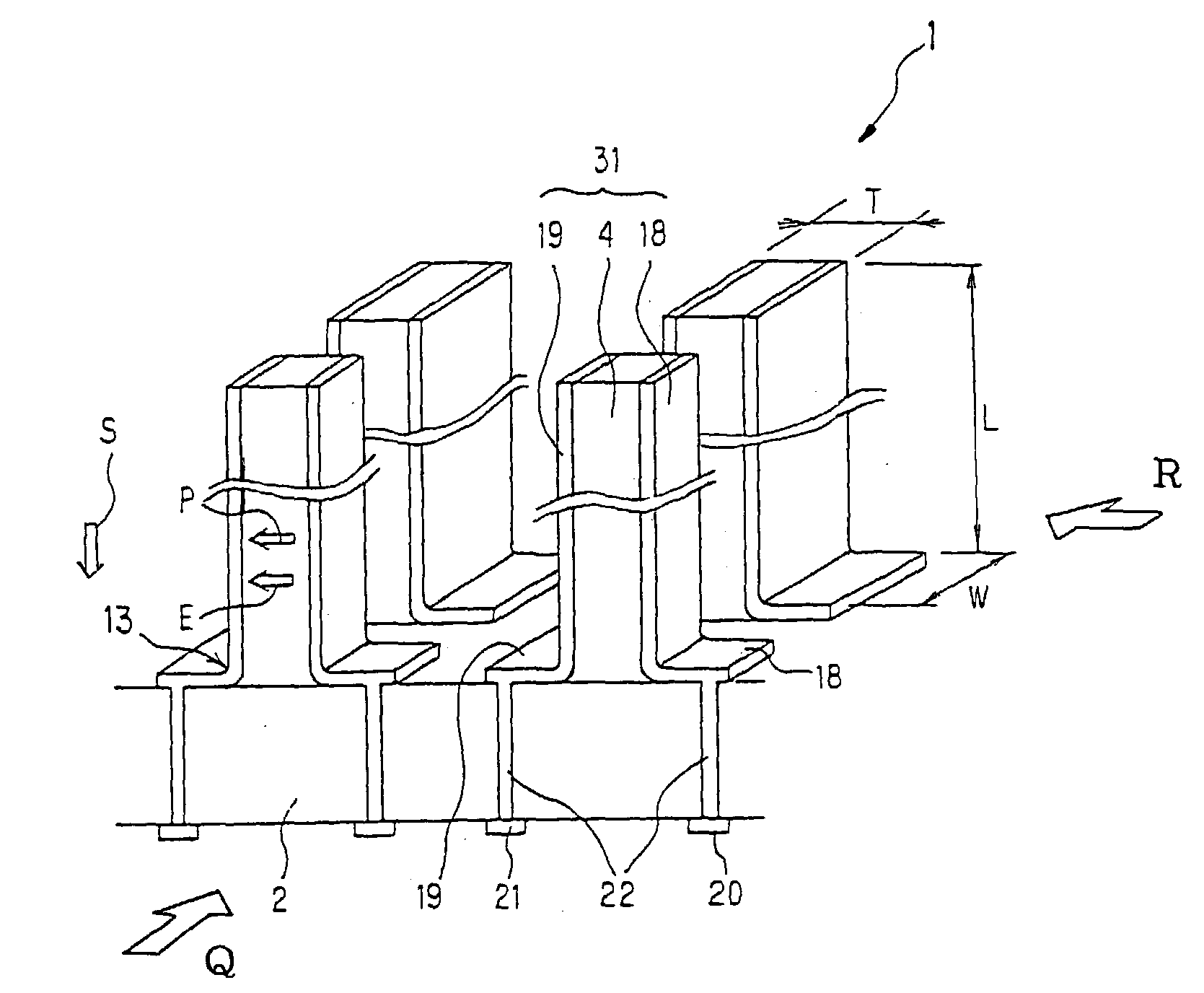

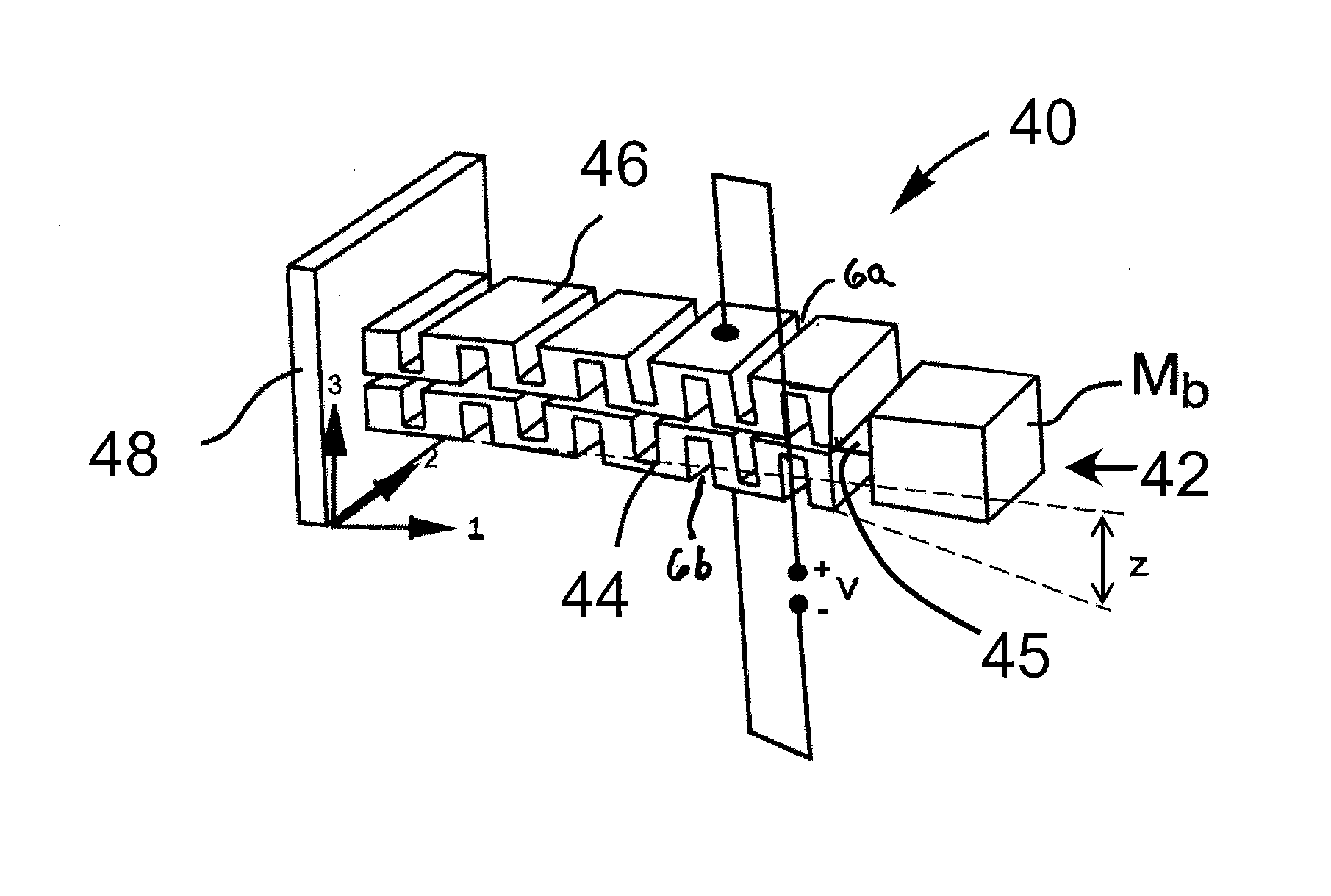

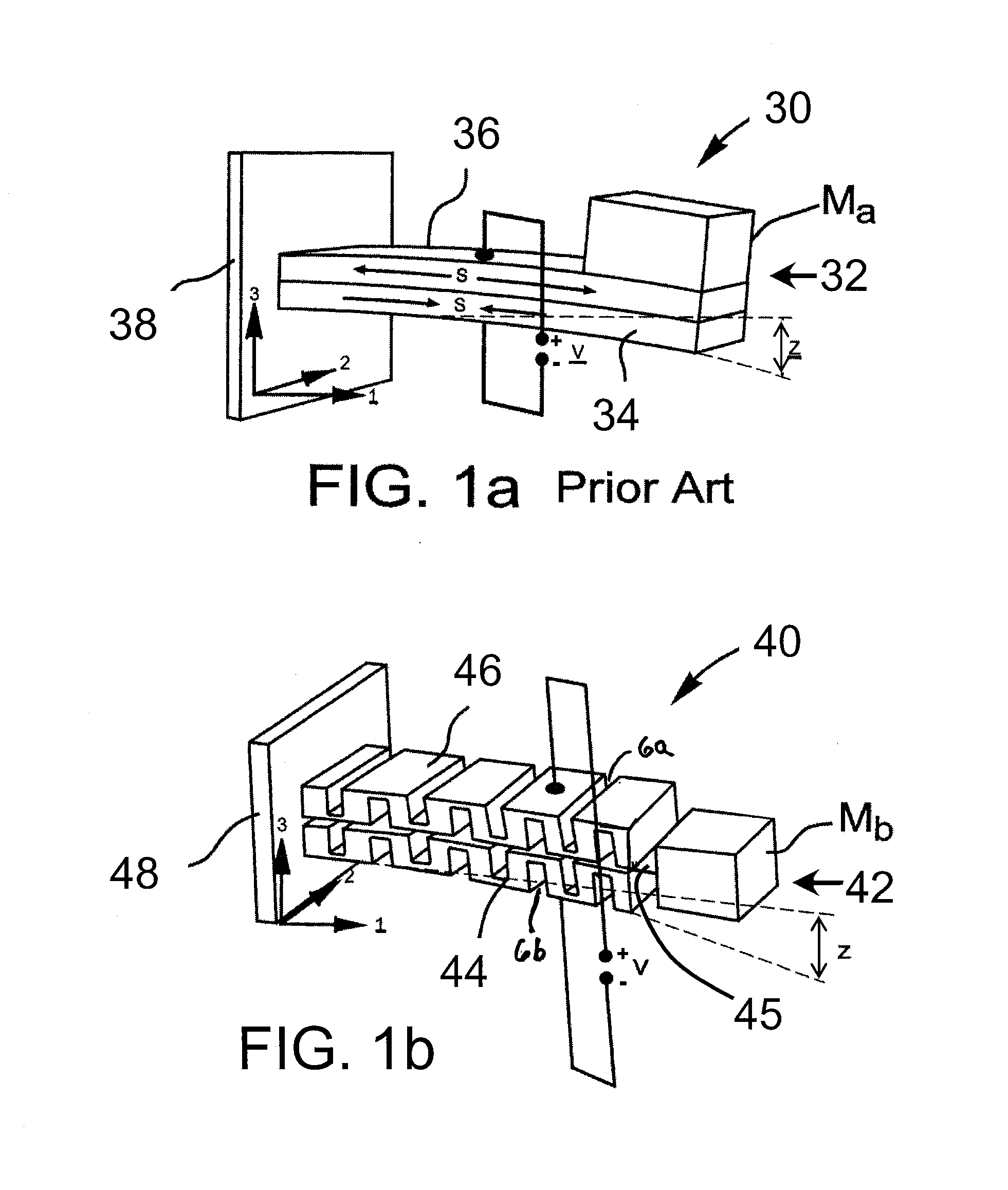

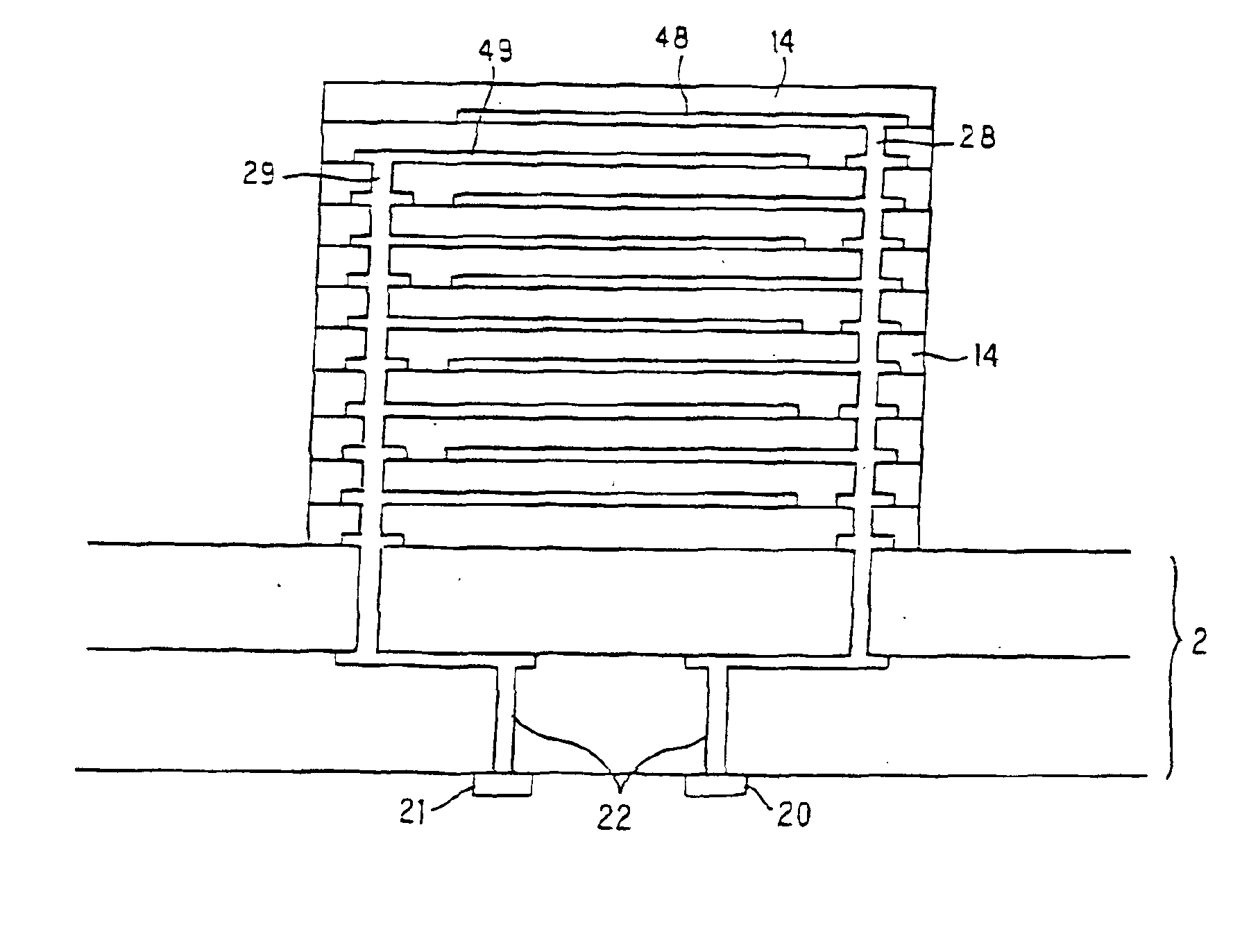

Matrix type actuator

InactiveUS6864620B2Printed circuit assemblingPiezoelectric/electrostriction/magnetostriction machinesLow voltageActuator

A matrix type piezoelectric / electrostrictive (PIE) actuator includes a plurality of piezoelectric / electrostrictive elements, each including a piezoelectric / electrostrictive body and at least one pair of electrodes formed on a ceramic substrate. The matrix type P / E actuator is activated by displacement of the piezoelectric / electrostrictive bodies. The piezoelectric / electrostrictive elements are joined to the ceramic substrate as respective unified bodies, and are two-dimensionally arranged independently from each other. The piezoelectric / electrostrictive actuator provides a greater displacement with a lower voltage, a high responsive speed, and a greater generating force, as well as enhancing the mounting ability and the integration. A method for manufacturing such a matrix type P / E actuator is also disclosed.

Owner:NGK INSULATORS LTD

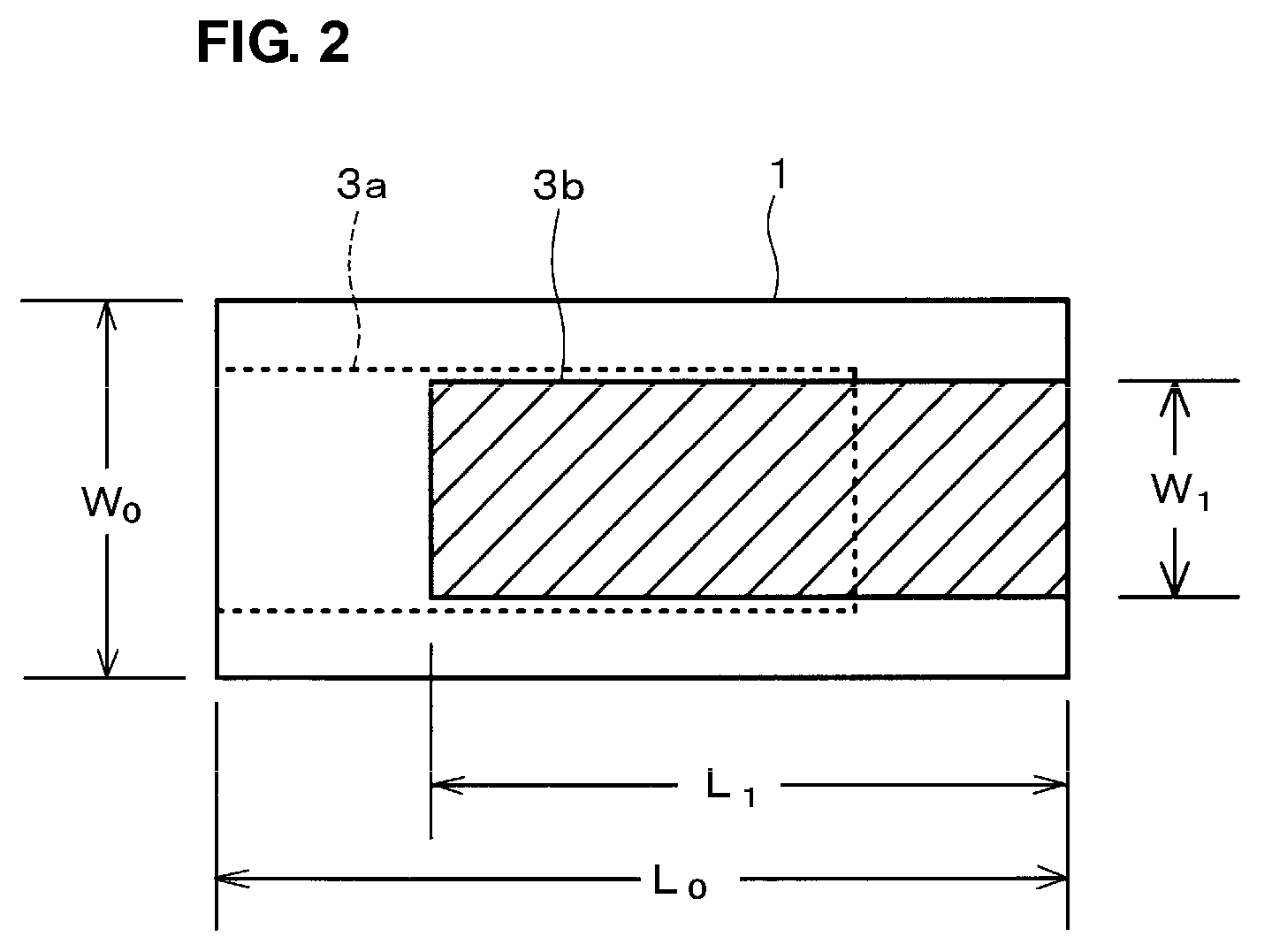

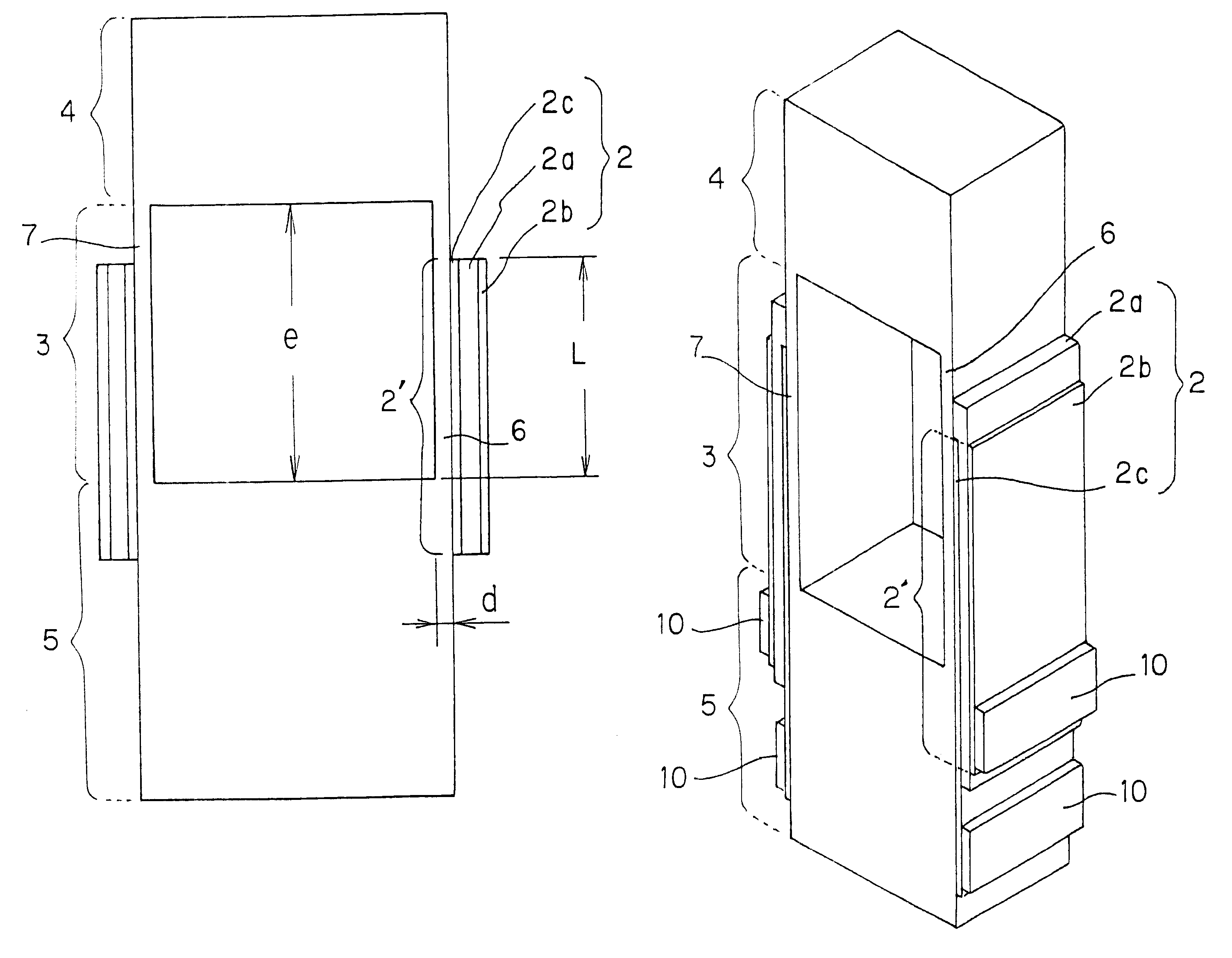

Piezoelectric/electrostrictive device

InactiveUS6476539B1Piezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostriction/magnetostriction machinesMechanical engineeringElectrostriction

Owner:NGK INSULATORS LTD

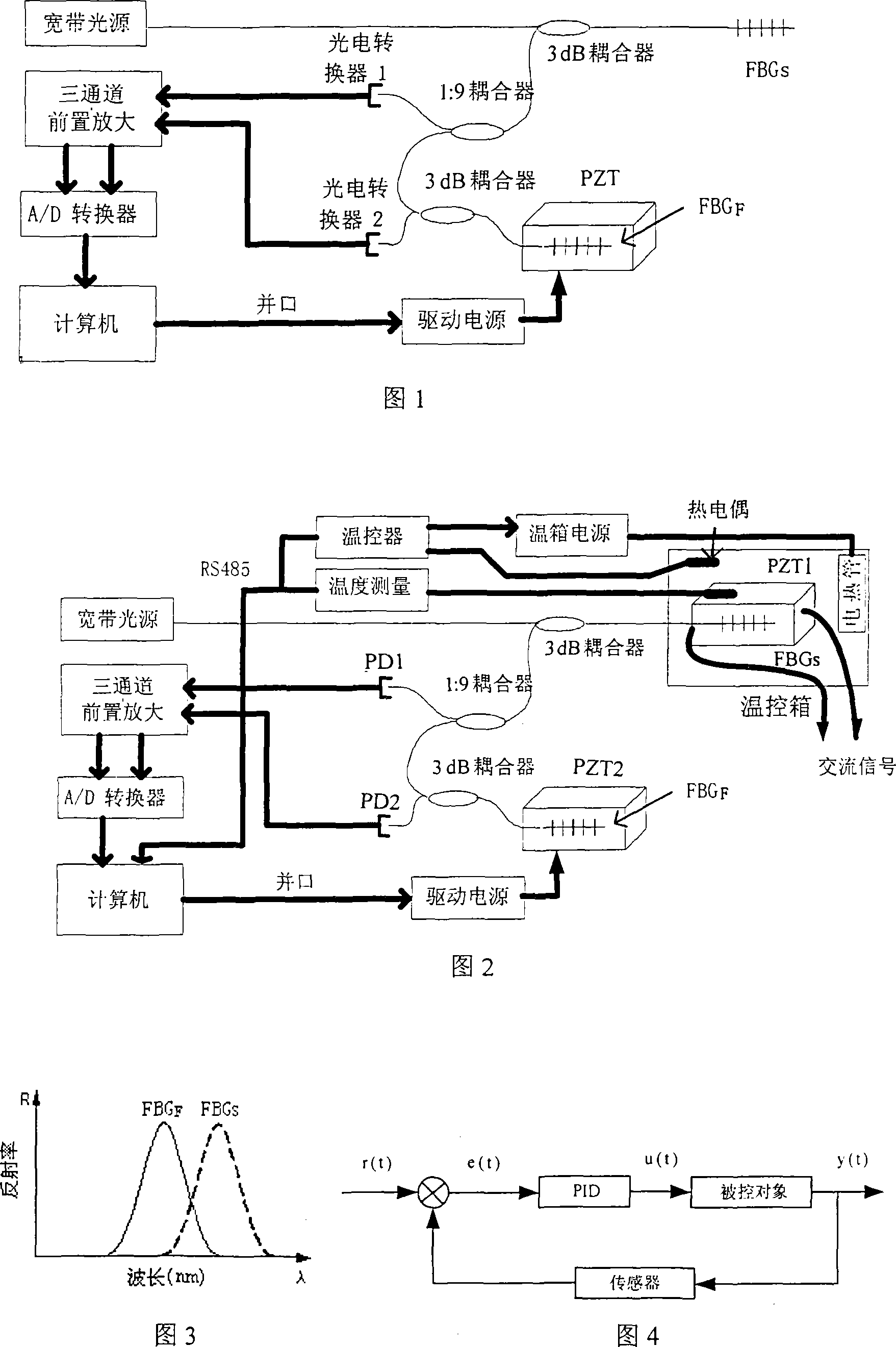

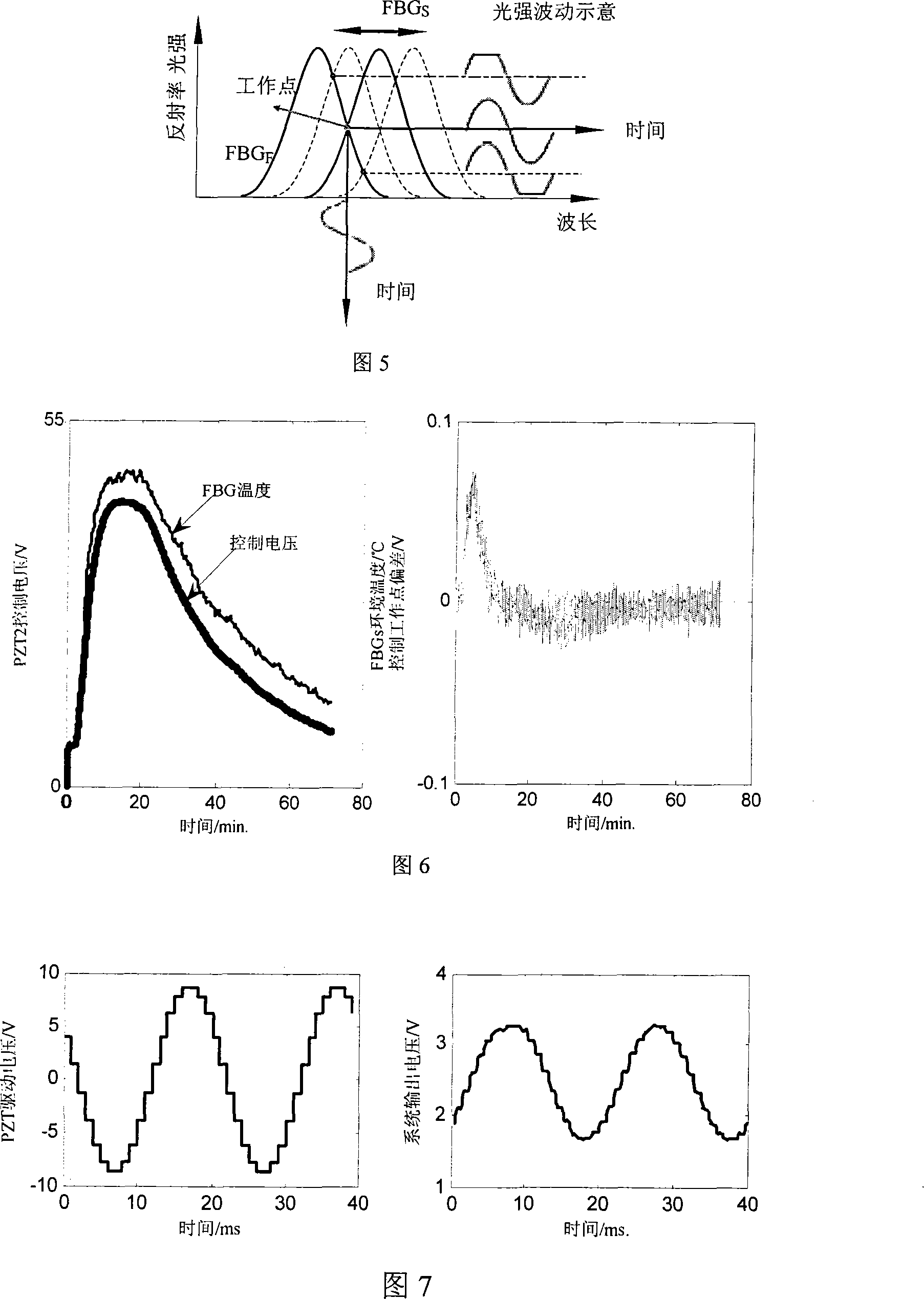

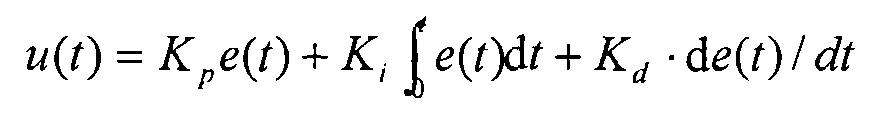

Temperature self-compensation optical fiber/optical grating dynamic strain measurement method and system

InactiveCN101226051AHigh sensitivityHigh acceleration valueThermometers using physical/chemical changesUsing optical meansGratingMeasurement point

The invention relates to an automatic temperature compensated FBG dynamic strain measurement method and the system. The invention comprises a plurality of steps: adopt sensing Prague-FBG and filtering Prague-FBG as the match grating; control the central wavelength of the filtering Prague-FBG through the PID closed-loop control structure; when the FBGs central wavelength varies with the temperature, let the central wavelength of the filtering Prague-FBG vary with the central wavelength of the sensing Prague-FBG and keep a constant difference of the central wavelength of two FBGs; thus stabilize the static state of the measurement system which becomes self-adaptive to the environment temperature. The system comprises a broadband light source, a coupler, a sensing Prague-FBG, a filtering Prague-FBG, an electricity diode, a preamplifier, an A / D data converter, a computer, a plurality of electrostriction materials and a driving power for the electrostriction materials. The automatic temperature compensated FBG dynamic strain measurement method and the system has the advantages that reducing the technical requirements for making matching FBG and improving the temperature stability of the system; the automatic temperature compensated FBG dynamic strain measurement method can achieve the measurement of dynamic strain and temperature measurement points at the same time and can demodulate the high resonant frequency.

Owner:HARBIN NORMAL UNIVERSITY

Laminated ceramic capacitor

ActiveUS7436650B2Improve breakdown voltageImprove pressure resistanceFixed capacitor electrodesFixed capacitor dielectricCapacitanceStress relieving

A laminated ceramic capacitor has a high breakdown voltage and excellent withstand-voltage performance, and prevents cracks generated during firing even when the number of lamination layers constituted by ceramic layers and inner electrode layers is increased. The laminated ceramic capacitor includes capacitance forming layers in which ceramic dielectric layers and capacitance-forming inner electrode layers are laminated, and a stress relieving layer. The stress relieving layer is disposed between the capacitance forming layers. In the stress relieving layer, ceramic dielectric layers, dummy inner electrode layers (split electrodes) that do not contribute to the formation of electrostatic capacitance, and capacitance-formation-preventing inner electrode layers that prevent capacitance from being formed between the capacitance-forming inner electrode layers and the dummy inner electrode layers are laminated. The thickness of the stress relieving layer is in the range of about 100 μm to about 300 μm inclusive. The plane area of the dummy inner electrode layers is about 60% or more of that of the capacitance-forming inner electrode layers. The dummy inner electrode layers are undivided or are divided into two or three parts in a single layer. With this structure, stress caused by electrostriction is relieved.

Owner:MURATA MFG CO LTD

Piezoelectric/electrostrictive device having mutually opposing thin plate portions

InactiveUS6396193B1Superior in handling property and impact resistanceLarge displacementPiezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostriction/magnetostriction machinesEngineeringMechanical engineering

Owner:NGK INSULATORS LTD

Dielectrostrictive sensor for measuring deformation

An apparatus and method directed to a solid-state capacitance sensor for measuring a strain force on a dielectric including at least one pair of electrostriction sensors each sensor having at least two electrodes and each having a central axis. The central axes are disposed in a common plane and are oriented substantially mutually perpendicularly to one another. Preferably, at least two pairs of sensors, forming a rosette, are provided to facilitate multi-component analysis of a sample having dielectric properties under stress / strain.

Owner:WISCONSIN ALUMNI RES FOUND

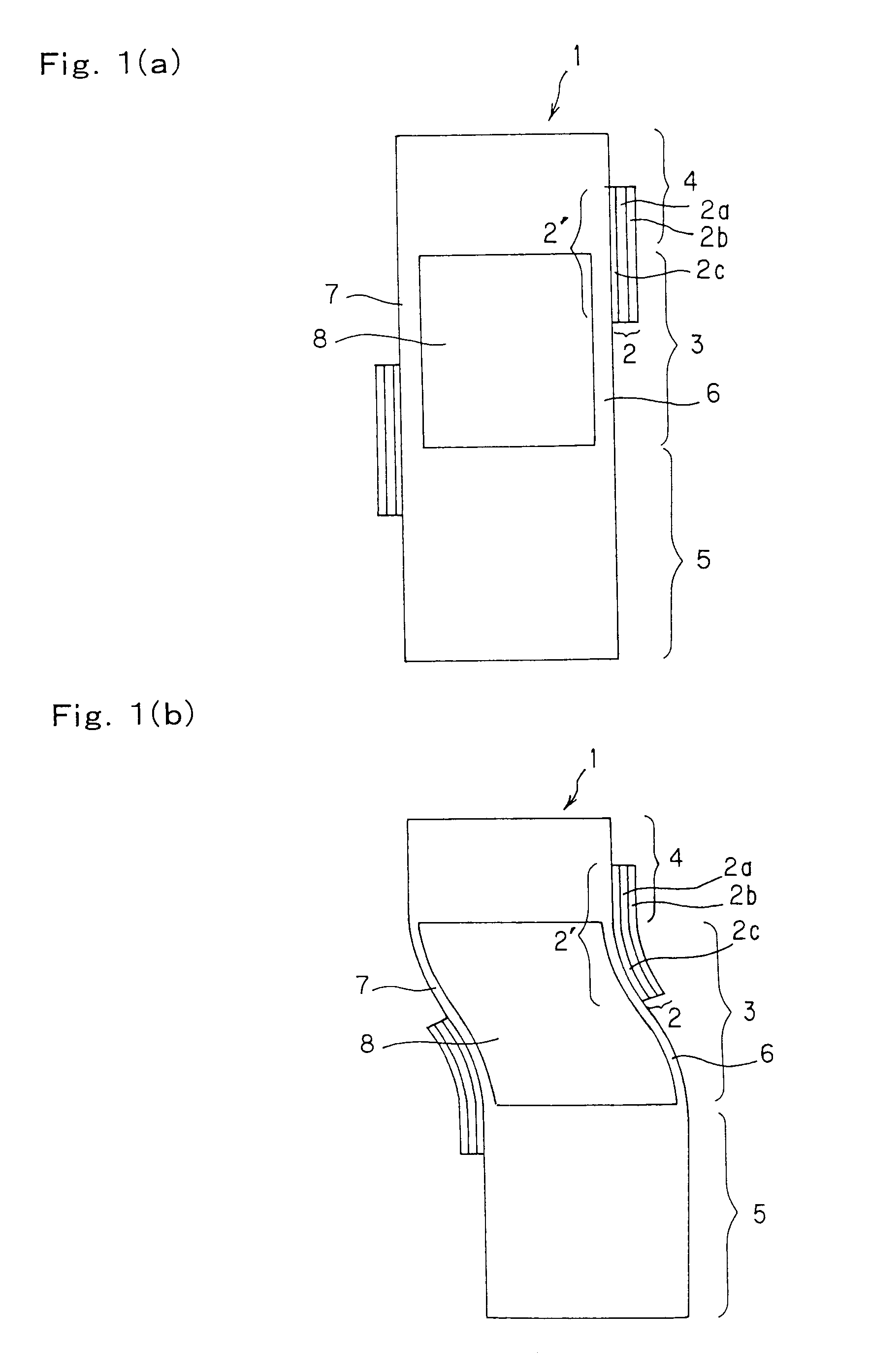

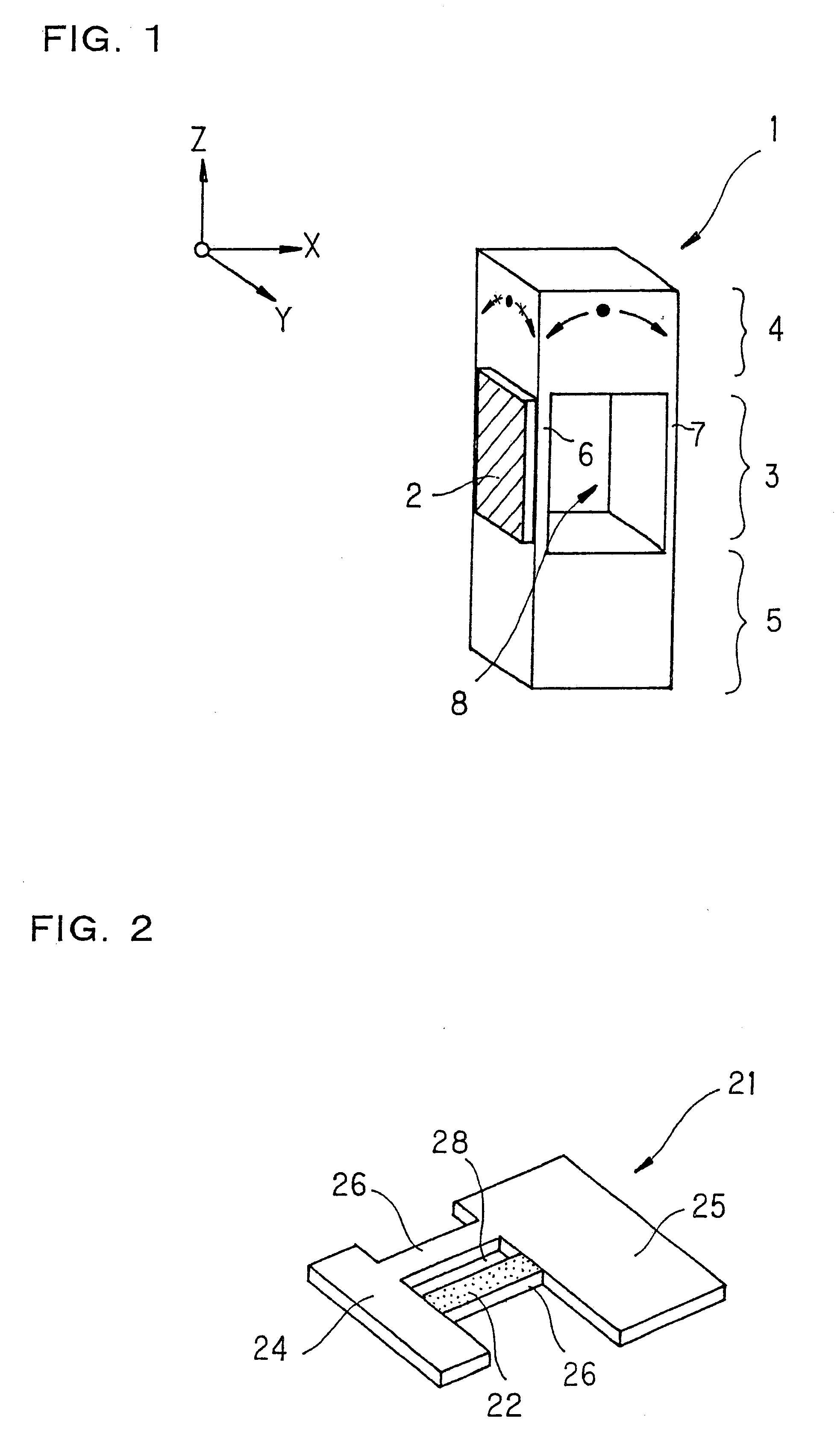

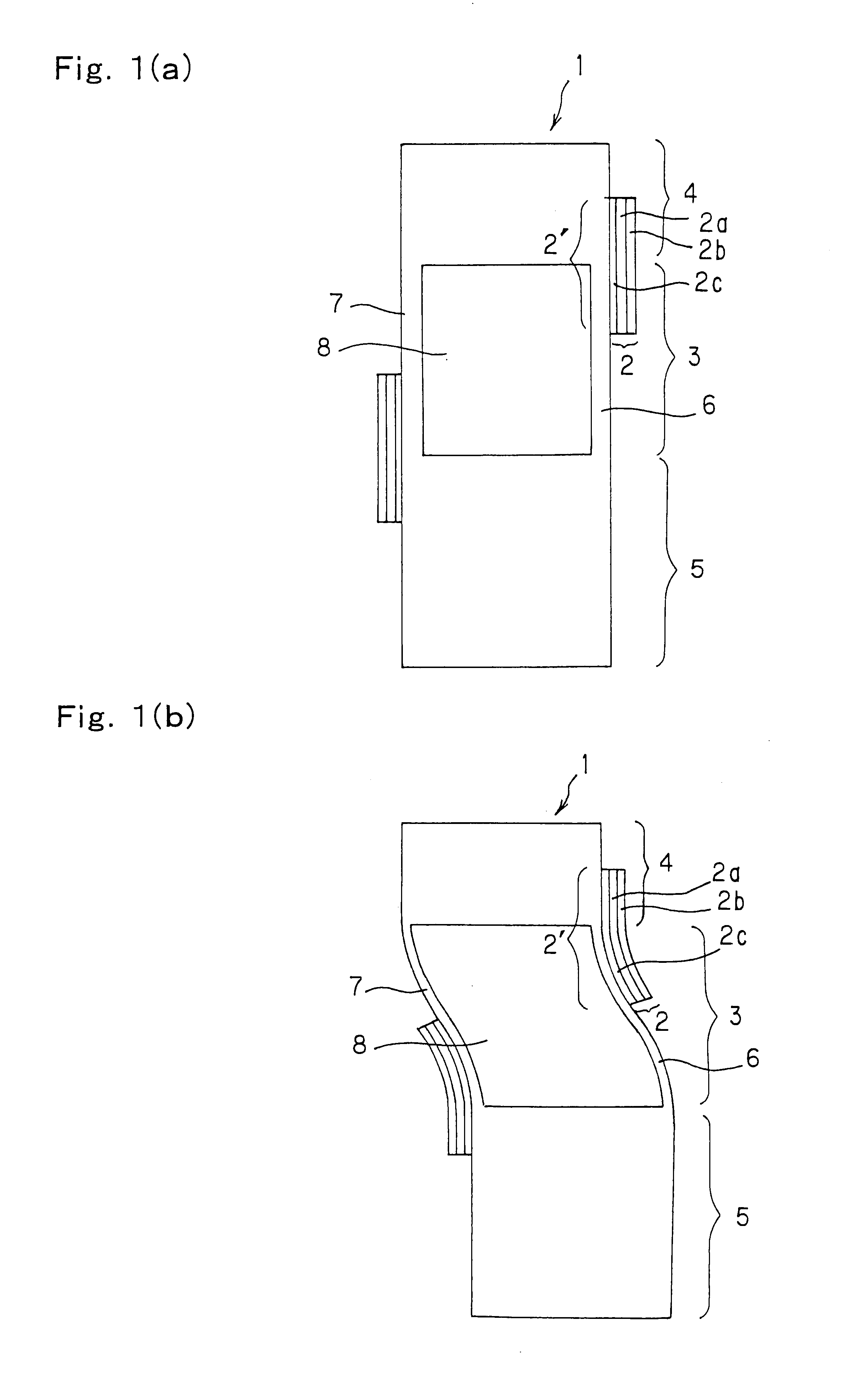

Piezoelectric/electrostrictive device and production method thereof

InactiveUS6329740B1Piezoelectric/electrostriction/magnetostriction machinesPiezoelectric/electrostrictive devicesPiezo electricMoisture resistance

A piezoelectric / electrostrictive device includes: a driving portion which is driven by displacement of a piezo-electric / electrostrictive element, a movable portion which operates on the basis of a drive of the driving portion, and a fixed portion for supporting the above driving portion and movable portion. It has a driving portion including thin plates facing each other and a thin film piezoelectric / electrostrictive element formed on the surface of at least one of the thin plates, and the above fixed portion and the above movable portion are joined by the driving portion. In this piezoelectric / electrostrictive element, the movable portion can largely be displaced, and it is not easily affected by a harmful vibration in operation, and it is excellent in mechanical strength, handling efficiency, impact resistance, and moisture resistance.

Owner:NGK INSULATORS LTD

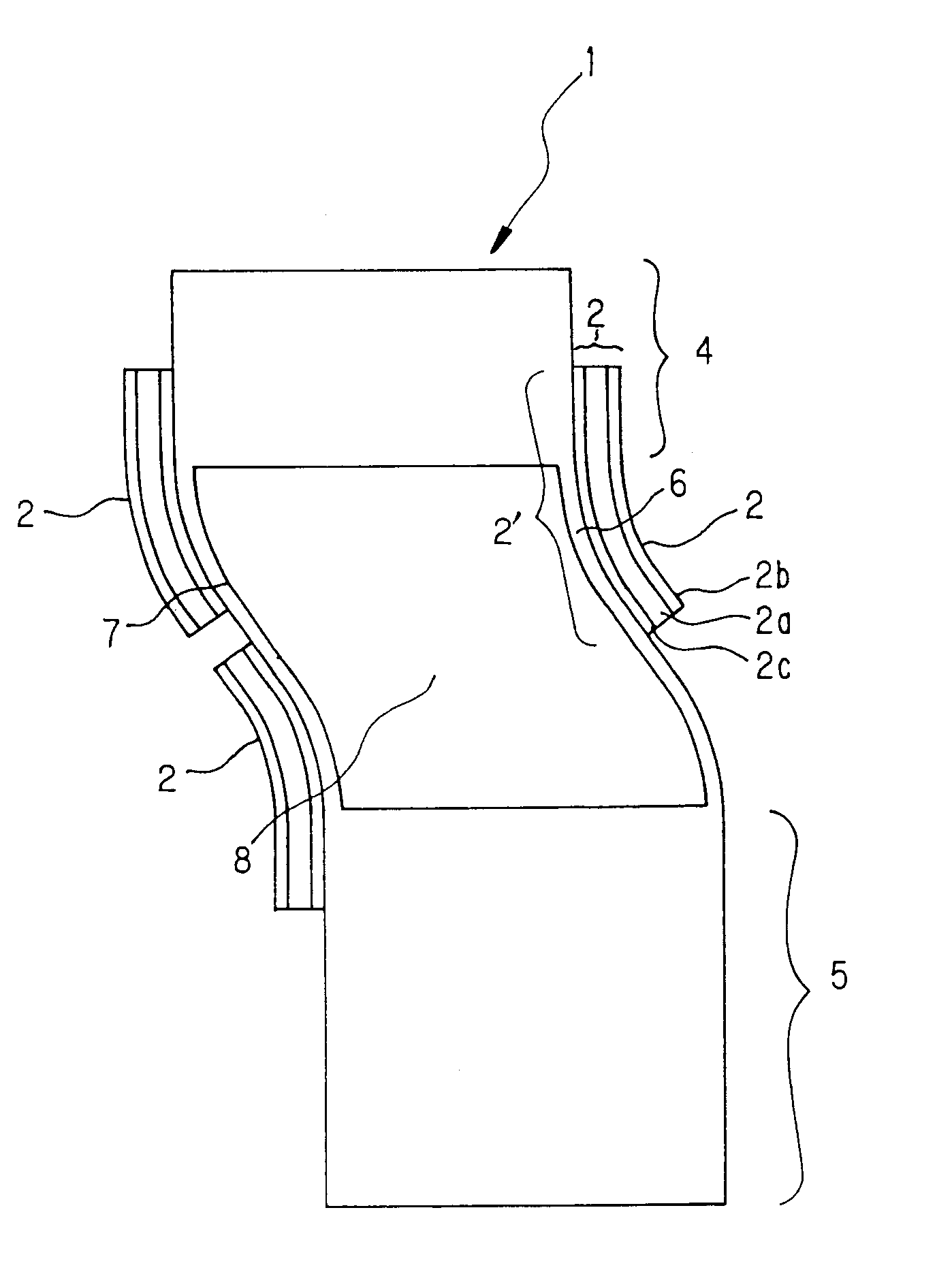

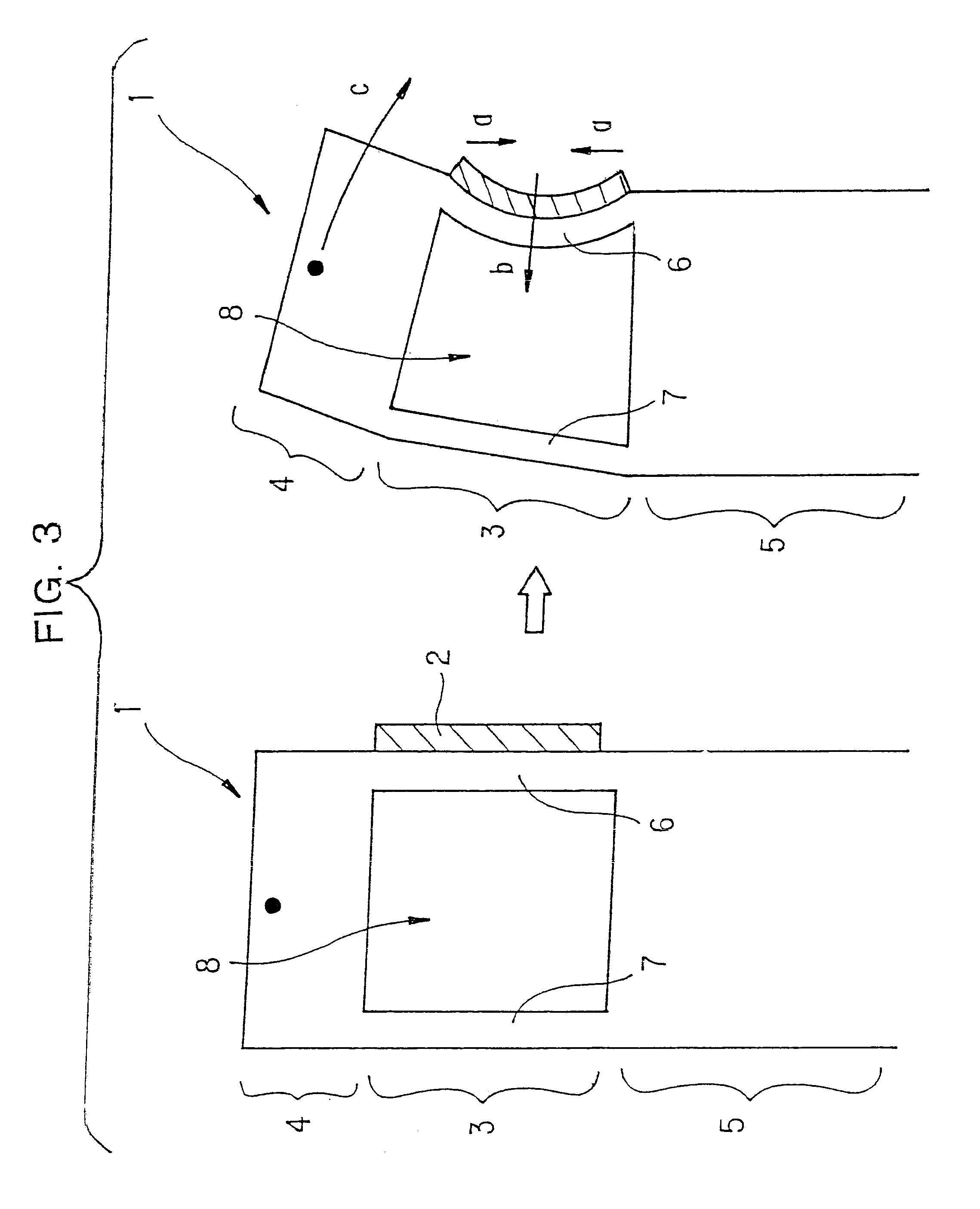

Piezoelectric/electrostrictive device and production method thereof

InactiveUS6335586B1Piezoelectric/electrostriction/magnetostriction machinesPiezoelectric/electrostrictive devicesMechanical engineeringThin sheet

A piezoelectric / elecrostrictive device comprising a driving portion to be driven by a displacement of a piezoelectric / electrostrictive element, a movable portion to be operated based on a drive of the driving portion, and a fixing portion for holding the driving portion and the movable portion. The driving portion comprises a pair of thin plate portions facing each other, and a film-like piezoelectric / electrostrictive element including at least a pair of electrode films and a piezoelectric / electrostrictive film formed at least on the outer surface of at least one thin plate portion of the thin plate portions. The fixing portion is coupled with the movable portion via the driving portion, a hole is defined by an inner wall of the driving portion, an inner wall of the movable portion, and an inner wall of the fixing portion, and at least one side of a piezoelectric operating portion of said piezoelectric / electrostrictive element in a direction in which said thin plate portion connects with said fixing portion with the movable portion is structured to exist on the fixing portion or the movable portion. A ratio a / b of the thickness a of said hole and the width b of said thin plate portion is 0.5 to 20. Since the movable portion can be largely operated, the device can be used as a displacement element which is hardly affected by a harmful vibration in operation, and superior in mechanical strength, handling property, impact resistance, and humidity resistance, and a sensor element capable of detecting a vibration of the movable portion with fine precision.

Owner:NGK INSULATORS LTD

Laminated ceramic capacitor

ActiveUS20080084651A1Improve breakdown voltageImprove pressure resistanceFixed capacitor electrodesFixed capacitor dielectricCapacitanceCrazing

A laminated ceramic capacitor has a high breakdown voltage and excellent withstand-voltage performance, and prevents cracks generated during firing even when the number of lamination layers constituted by ceramic layers and inner electrode layers is increased. The laminated ceramic capacitor includes capacitance forming layers in which ceramic dielectric layers and capacitance-forming inner electrode layers are laminated, and a stress relieving layer. The stress relieving layer is disposed between the capacitance forming layers. In the stress relieving layer, ceramic dielectric layers, dummy inner electrode layers (split electrodes) that do not contribute to the formation of electrostatic capacitance, and capacitance-formation-preventing inner electrode layers that prevent capacitance from being formed between the capacitance-forming inner electrode layers and the dummy inner electrode layers are laminated. The thickness of the stress relieving layer is in the range of about 100 μm to about 300 μm inclusive. The plane area of the dummy inner electrode layers is about 60% or more of that of the capacitance-forming inner electrode layers. The dummy inner electrode layers are undivided or are divided into two or three parts in a single layer. With this structure, stress caused by electrostriction is relieved.

Owner:MURATA MFG CO LTD

Piezoelectric/electrostrictive device

InactiveUS6570297B1Piezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostriction/magnetostriction machinesEngineeringThin sheet

Owner:NGK INSULATORS LTD

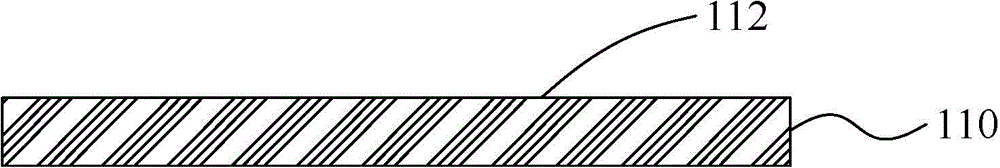

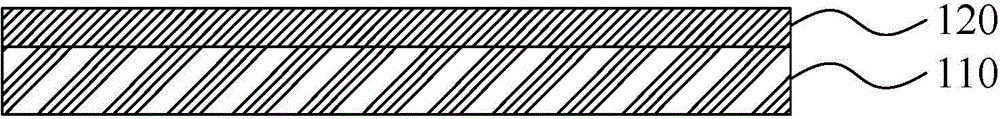

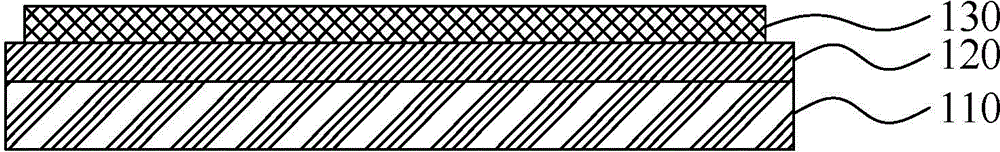

Method for manufacturing flexible display device and flexible display device

ActiveCN104465475AReduce manufacturing costIncrease productivityFinal product manufactureSolid-state devicesEngineeringFlexible display

The invention discloses a method for manufacturing a flexible display device and the flexible display device obtained through the manufacturing method. The method comprises the steps that a conductive layer is formed on the surface of a hard substrate; an inverse electrostriction thin film layer is formed on the conductive layer; a flexible base material is attached to the surface of the inverse electrostriction thin film layer; a display element layer is manufactured on the flexible base material; after the display element layer is manufactured, alternating currents are applied to the conductive layer, and the hard substrate and the flexible base material are separated through the micromechanical vibration of an inverse electrostriction thin film. The inverse electrostriction thin film layer on the hard substrate is adopted as a release layer, after the alternating currents are applied, mechanical stress between the inverse electrostriction thin film and the flexible base material is far smaller than binding force between the inverse electrostriction thin film and the lower hard substrate, the flexible base material and the hard substrate can be separated, the hard substrate can be used repeatedly, manufacturing cost is greatly saved, production efficiency is improved, and the product yield is improved.

Owner:CHENGDU VISTAR OPTEOLECTRONICS CO LTD

Microswitch and method for manufacturing the same

InactiveUS7372191B2Efficient switchingReduce power consumptionPiezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostriction/magnetostriction machinesElectrode ContactThin sheet

Owner:NGK INSULATORS LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com