Method for separating heating element Sr and metal element Ba from high-level waste

A technology of metal elements and elements, which is applied in the field of post-treatment of high-level radioactive waste in the nuclear industry, can solve the problems of slow adsorption rate, processing cost, increase of secondary waste, difficulty in achieving effective separation of Cs, etc., and achieve good separation effect and selective adsorption strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

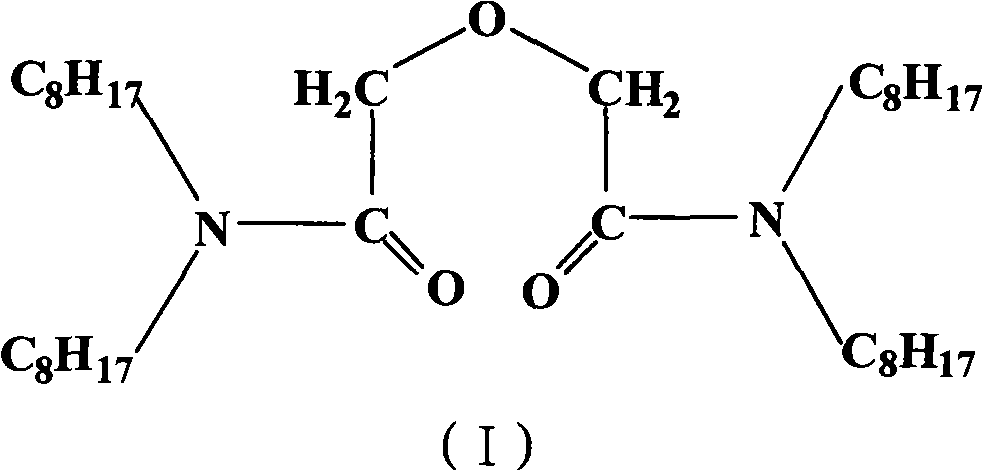

[0033] The preparation of embodiment 1 adsorbent

[0034] Dissolve 100 grams of TOOD in 500 mL of dichloromethane and mix well; add 200 grams of polymer-coated macroporous SiO 2 (SiO 2 -P) Stir evenly to volatilize most of the dichloromethane until the material is in a nearly dry state, and then vacuum-dry the nearly dry material at 45° C. for 24 hours.

Embodiment 2

[0035] The preparation of embodiment 2 adsorbents

[0036] Dissolve 100 grams of TOOD in 2000 mL of dichloromethane and mix well; add 1000 grams of polymer-coated macroporous SiO 2 (SiO 2 -P) Stir evenly to volatilize most of the dichloromethane until the material is in a nearly dry state, and then vacuum-dry the nearly dry material at 45° C. for 24 hours.

Embodiment 3

[0037] The preparation of embodiment 3 adsorbent

[0038] Dissolve 100 grams of TOOD in 3000 mL of dichloromethane and mix well; add 1500 grams of polymer-coated macroporous SiO 2 (SiO 2 -P) Stir evenly to volatilize most of the dichloromethane until the material is in a nearly dry state, and then vacuum-dry the nearly dry material at 45° C. for 24 hours.

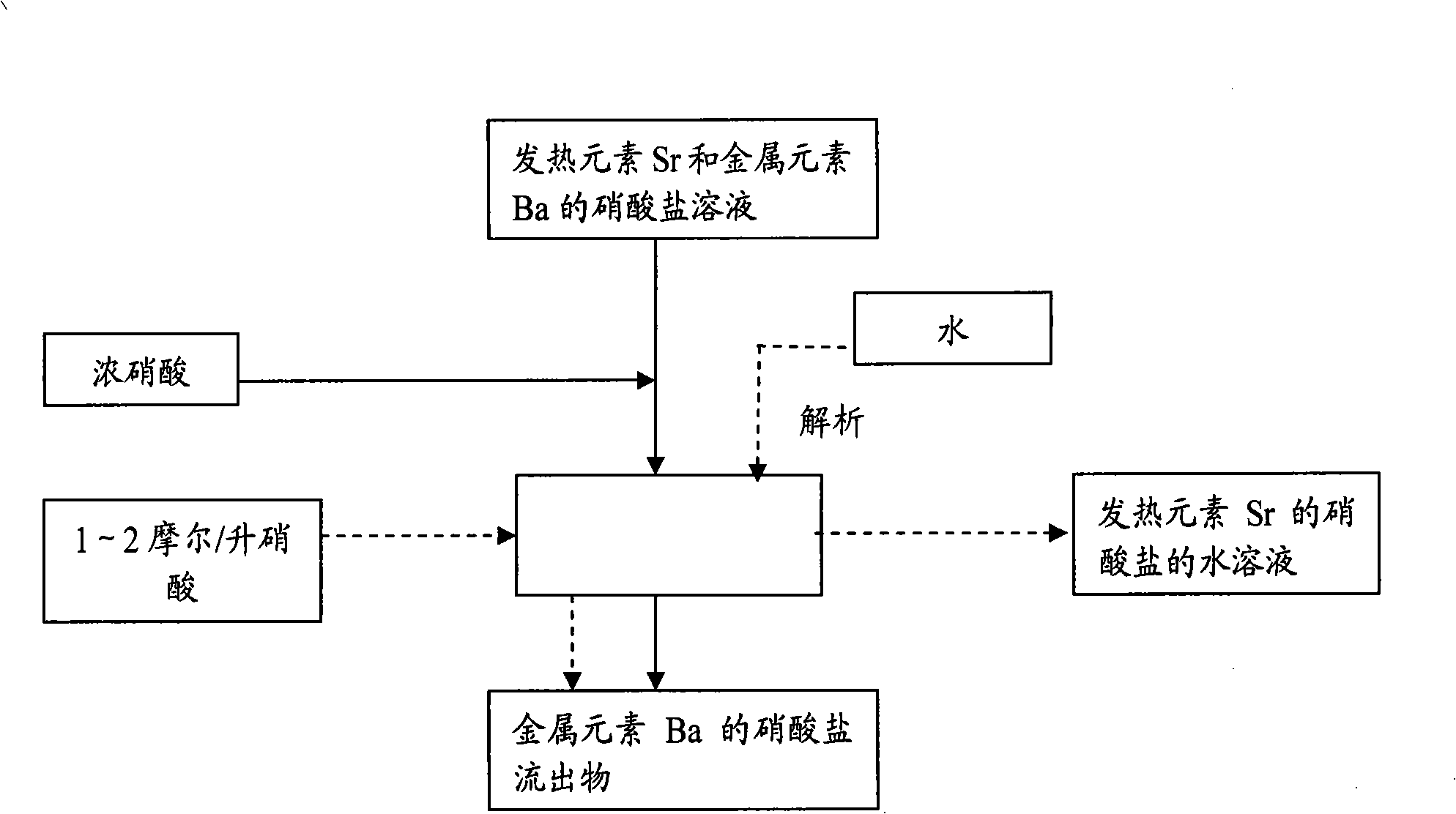

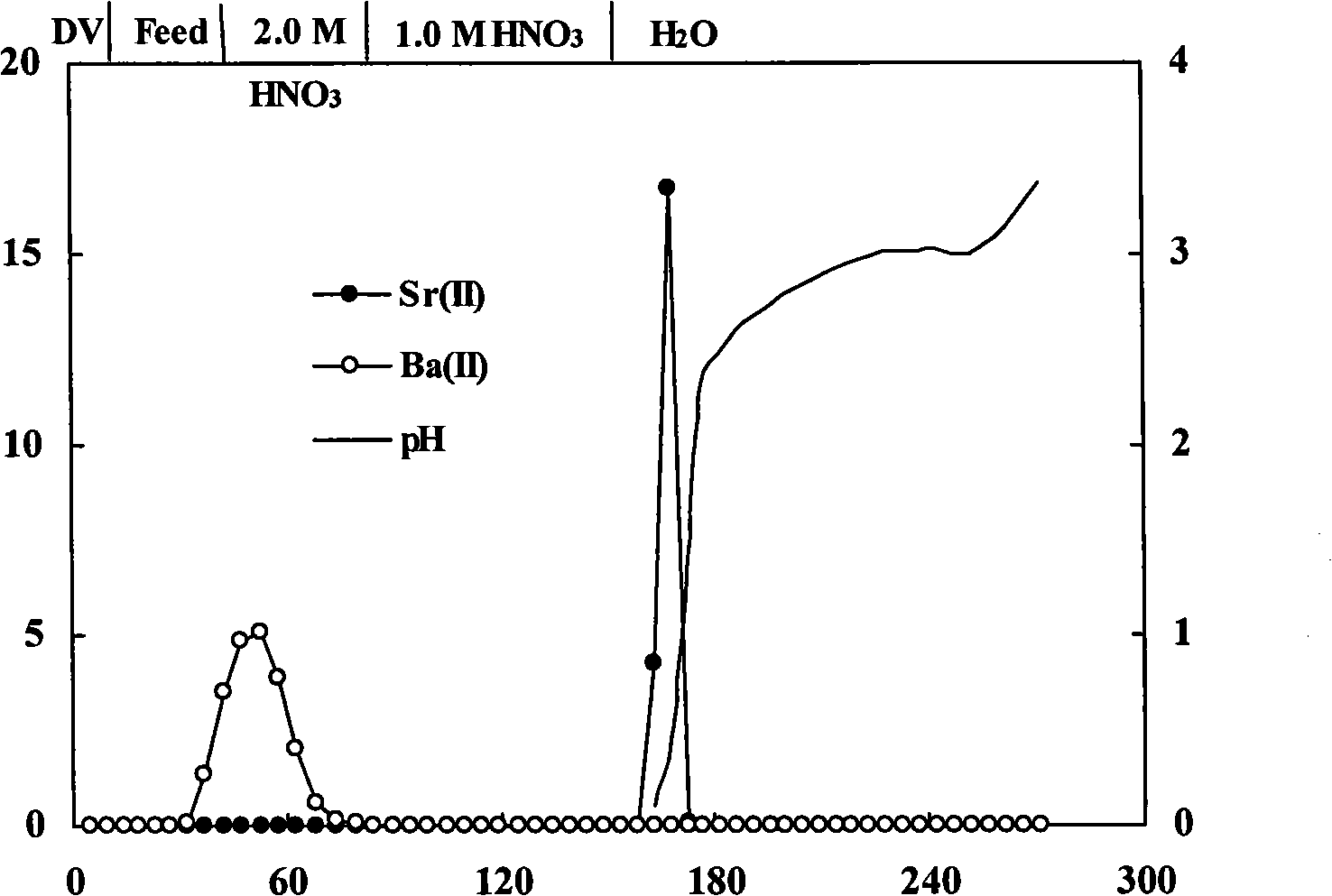

[0039] Separation of heating element Sr and black metal element Ba in high-level radioactive waste

[0040] The adsorbent prepared in Example 1 was filled into a chromatographic column, and the chromatographic column was a glass tube with an inner diameter of 1 cm, an outer diameter of 1.2 cm, and a height of 30 cm.

[0041] The mobile phase flow rate is typically 1.0 mL / min.

[0042] (1) According to the flow process disclosed by the Chinese invention patent application whose document number is CN101143273, the high-level waste is made into a nitrate solution to separate the exothermic elements Cs and Sr, and the chroma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com