Preparation method of Co-base porous ceramic with adjustable and controllable pore structure

A technology of porous ceramics and pore structure, applied in the field of porous ceramic materials, can solve the problems of difficult control of density, high requirements for raw materials, uncontrollable pore structure, etc., and achieves the effect of simple and easy method and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

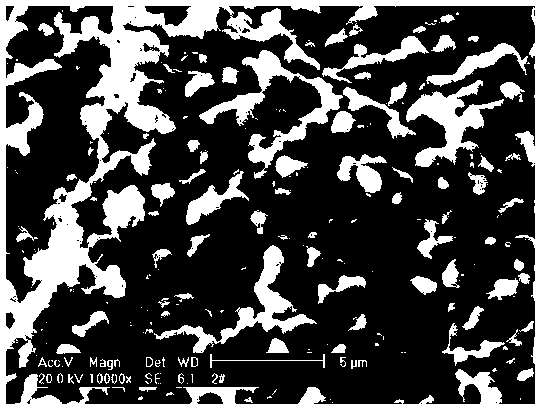

Embodiment 1

[0022] (1) with La 2 o 3 、Co 3 o 4 and SrCO 3 As the raw material, the molar ratio of La:Sr:Co is 0.8:0.2:1 to calculate the required raw materials, weigh and mix the raw materials, and then grind for 1.5h to obtain the mixed powder, and then press the mixed powder into a cylindrical shape , where the diameter is 2cm, the thickness is 4mm, the final pressure used is 24MPa, and the pressure is kept for 3min for every increase of 2MPa;

[0023] (2) Pre-fire the compressed tablet obtained in step (1) at a temperature of 880°C, a holding time of 15 hours, and a pre-fire atmosphere of air to obtain pre-fired ceramics;

[0024] (3) After the pre-fired ceramic obtained in step (2) drops to room temperature, grind for 1 hour, and then press into a cylindrical shape with a diameter of 2cm and a thickness of 5mm. The final pressure used is 30MPa, and the pressure is kept for every 3MPa increase. 5min, and then carry out secondary sintering at a temperature of 1100°C, a holding time...

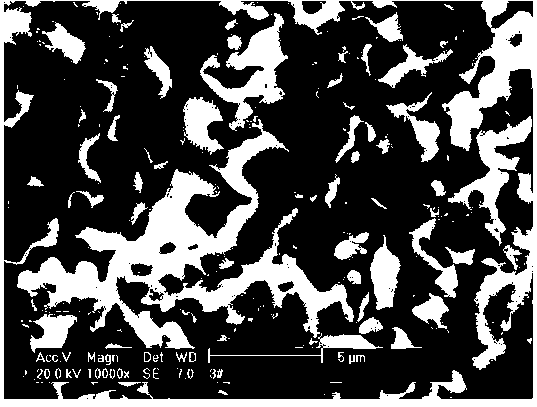

Embodiment 2

[0026] (1) with La 2 o 3 、Co 3 o 4 and SrCO 3 As the raw material, the molar ratio of La:Sr:Co is 0.5:0.5:1 to calculate the required raw materials, weigh and mix the raw materials, and then grind for 2 hours to obtain the mixed powder, and then press the mixed powder into a cylindrical shape, The diameter is 2cm, the thickness is 2mm, the final pressure used is 20MPa, and the pressure is kept for 1min for every increase of 4MPa;

[0027] (2) Pre-fire the compressed tablet obtained in step (1) at a temperature of 1050°C, a holding time of 10 hours, and a pre-fire atmosphere of air to obtain pre-fired ceramics;

[0028] (3) After the pre-fired ceramic obtained in step (2) drops to room temperature, grind for 1.5 hours, and then press into a cylindrical shape with a diameter of 2cm and a thickness of 4mm. The final pressure used is 20MPa, and every increase of 4MPa will keep the Pressing for 1min, and then performing secondary sintering at a temperature of 1200°C, a holding...

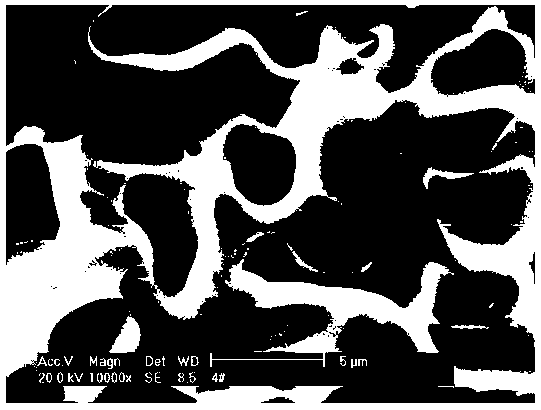

Embodiment 3

[0030] (1) with La 2 o 3 、Co 3 o 4 and SrCO 3 As a raw material, calculate the required raw materials with a molar ratio of La:Sr:Co of 0.1:0.9:1, weigh and mix the raw materials, and then grind for 1 hour to obtain a mixed powder, and then press the mixed powder into a cylindrical shape, The diameter is 2.5cm, the thickness is 5mm, the final pressure used is 30MPa, and the pressure is kept for 5min for every increase of 3MPa;

[0031](2) Pre-fire the compressed tablet obtained in step (1) at a temperature of 850°C, a holding time of 20 hours, and a pre-fire atmosphere of air to obtain pre-fired ceramics;

[0032] (3) After the pre-fired ceramic obtained in step (2) drops to room temperature, grind for 2 hours, and then press into a cylindrical shape with a diameter of 2.5cm and a thickness of 2mm. The pressure used is 6MPa, and the pressure is kept for every increase of 2MPa 4min, and then carry out secondary sintering at a temperature of 1250°C, a holding time of 20h, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com