Patents

Literature

64results about How to "Control pore structure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Nano-ceramic particle reinforced aluminum foam matrix composite material and preparation method thereof

A nano-ceramic particle reinforced aluminum foam matrix composite material and a preparation method thereof relates to an aluminum foam matrix composite material and a preparation method thereof. The invention solves the problem that in the preparation method of the ceramic particle reinforced aluminum foam matrix composite material, ceramic particles are micron-sized, the uniform distribution of nano-ceramic particles can not be realized, and the existing ceramic particle reinforced aluminum foam matrix composite material has wide aperture and low compressive yield strength. The aluminum foam matrix composite material of the invention is prepared from aluminum or aluminum alloy powder, CaCO3 and nano-ceramic particles. The preparation method comprises the following steps: using a ball mill to process raw material powder and stearic acid, mixing powder, then placing the mixture in a graphite mould to perform vacuum hot press sintering and obtain a perform, performing forward extruding to obtain a semi-finished product, heating and foaming to obtain the finished product. The aperture of the aluminum foam matrix composite material is less than 1mm, and the compressive yield strength is 50-98MPa which is 2-20 times of that of the existing aluminum foam matrix composite material. By using the method of the invention, the nano-ceramic particles can be uniformly distributed in the aluminum foam matrix composite material.

Owner:HARBIN INST OF TECH

Method for performing three-dimensional printing on biological ceramic bracket based on light-cured molding, and application

ActiveCN107296985AIncreased intensityHigh precisionAdditive manufacturing apparatusTissue regenerationThree Dimensional SizeRepair material

Owner:GUANGDONG UNIV OF TECH

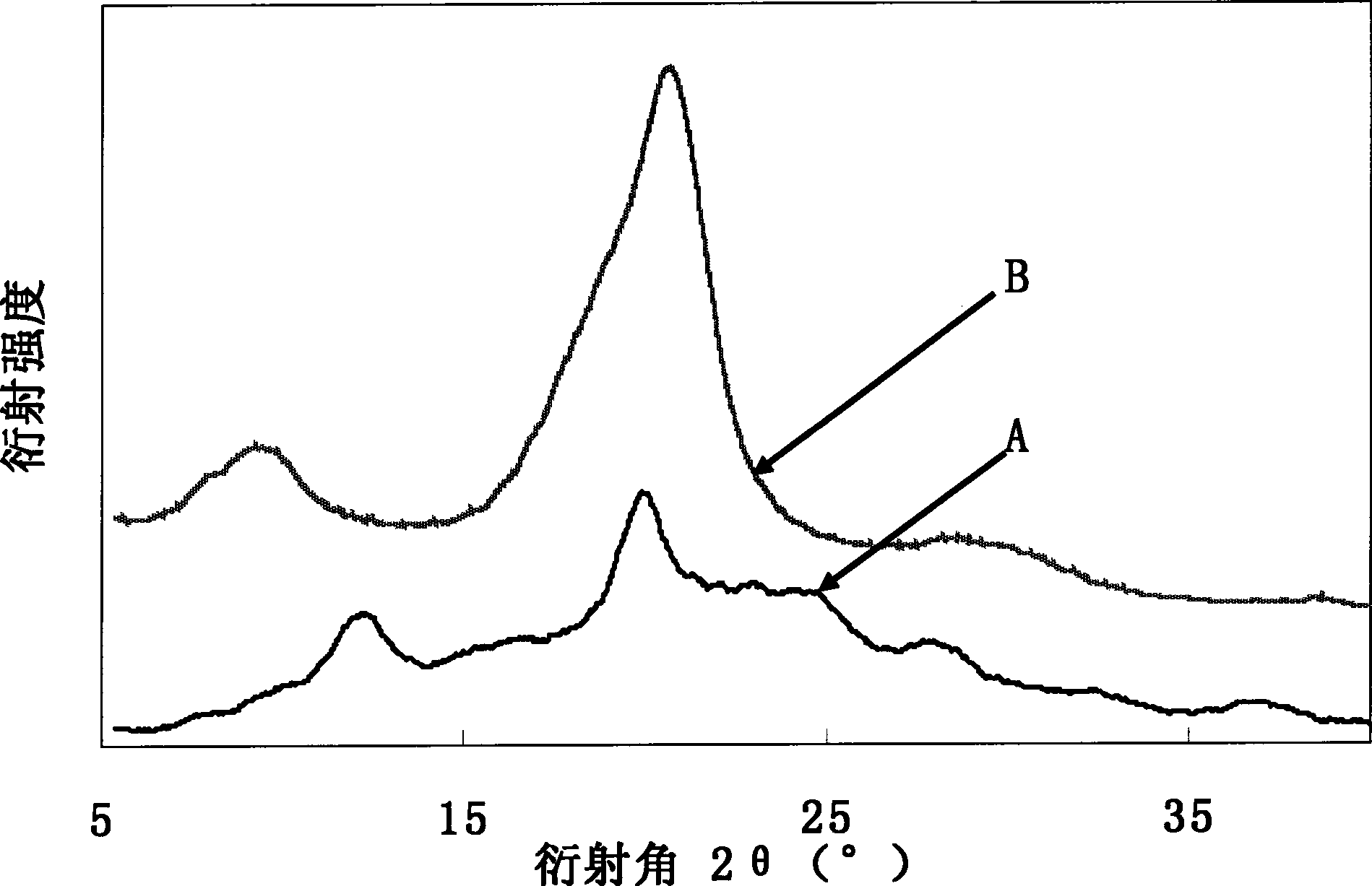

Silk fibroin porous three-dimensional material and preparation method thereof

The invention relates to a porous material and a preparation method thereof, in particular to a technology in which silk fibroin is taken as a raw material to prepare porous three-dimensional materials. In the method, silk fibroin solution is injected into a metal mould, 1-24 hours of quick freezing is carried out on the solution at the low temperature of minus 10-minus 80 DEG C, thus obtaining afrozen body; the frozen body is preserved at the temperature of minus 5-minus 25 DEG C for 2-60 days, thus obtaining frozen crystalline solid; then the frozen crystalline solid is thawed and dried, thus obtaining the silk fibroin porous three-dimensional material. The silk fibroin of the porous material is fibroin I type crystal structure, therefore, the silk fibroin is insoluble in water and canbe completely degraded in a while and is finally degraded into nonpoisonous amino acid; the material of the invention has mutual run-through pores with aperture of 10-500 microns; the pores and pore diameter are relatively large, thus being suitable for growth of cells; meanwhile, in the process of preparation, no chemical cross linking agent, foaming agent or denaturing agent are needed, thus retaining fine biocompatibility of the silk fibroin.

Owner:苏州盛泽科技创业园发展有限公司

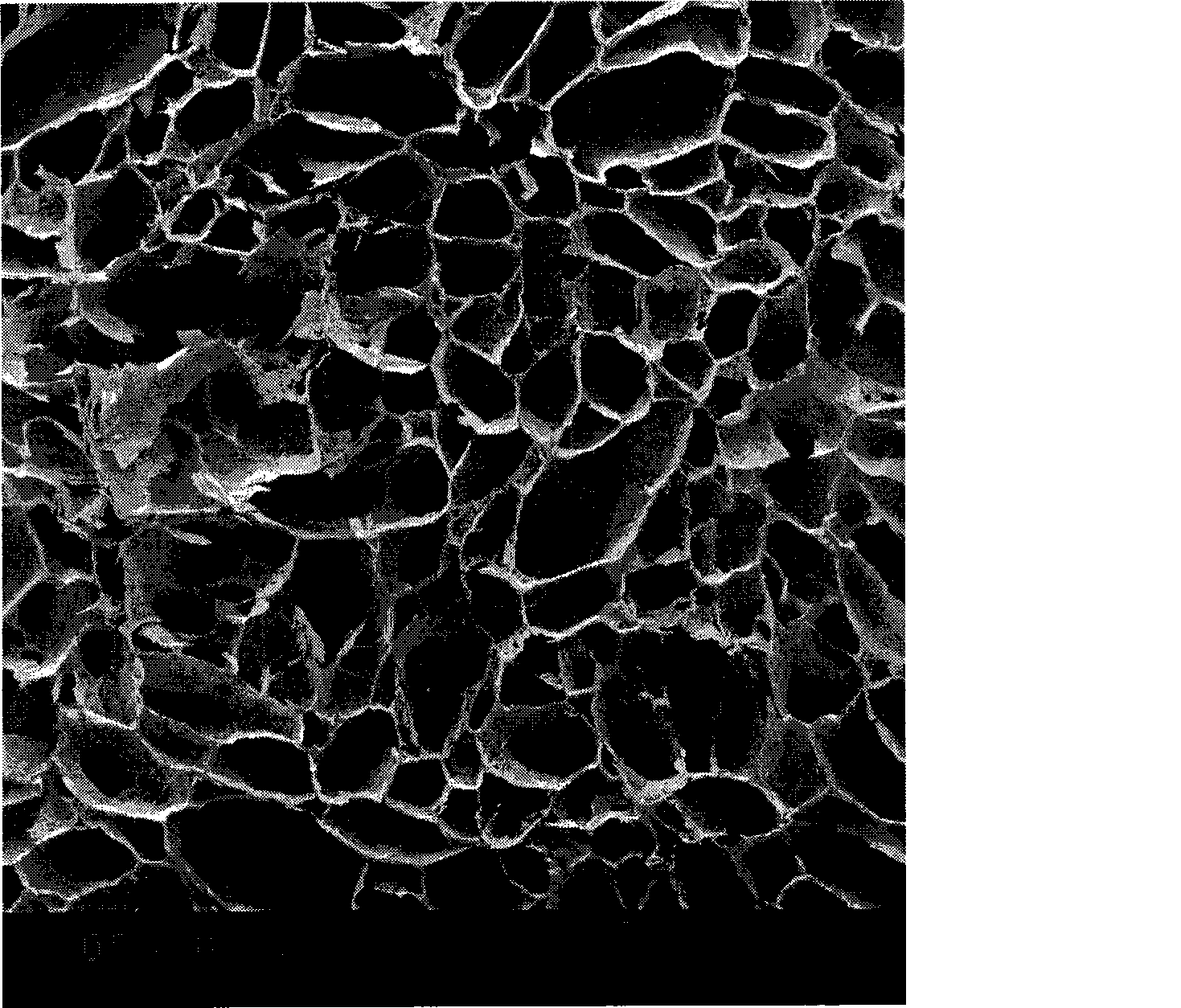

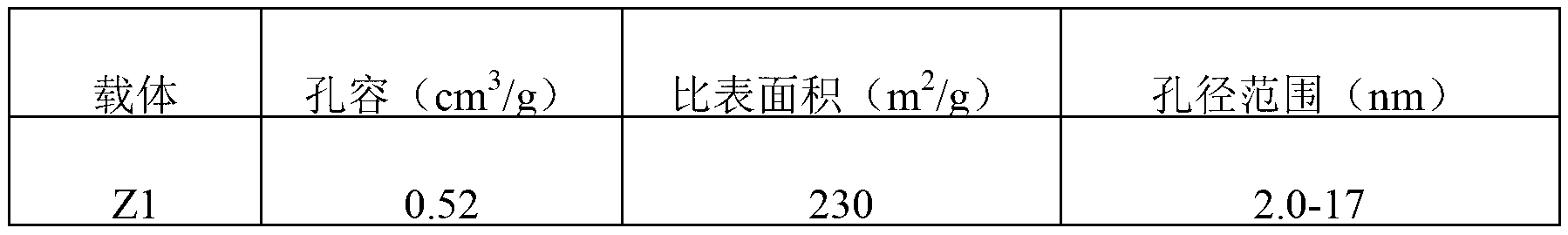

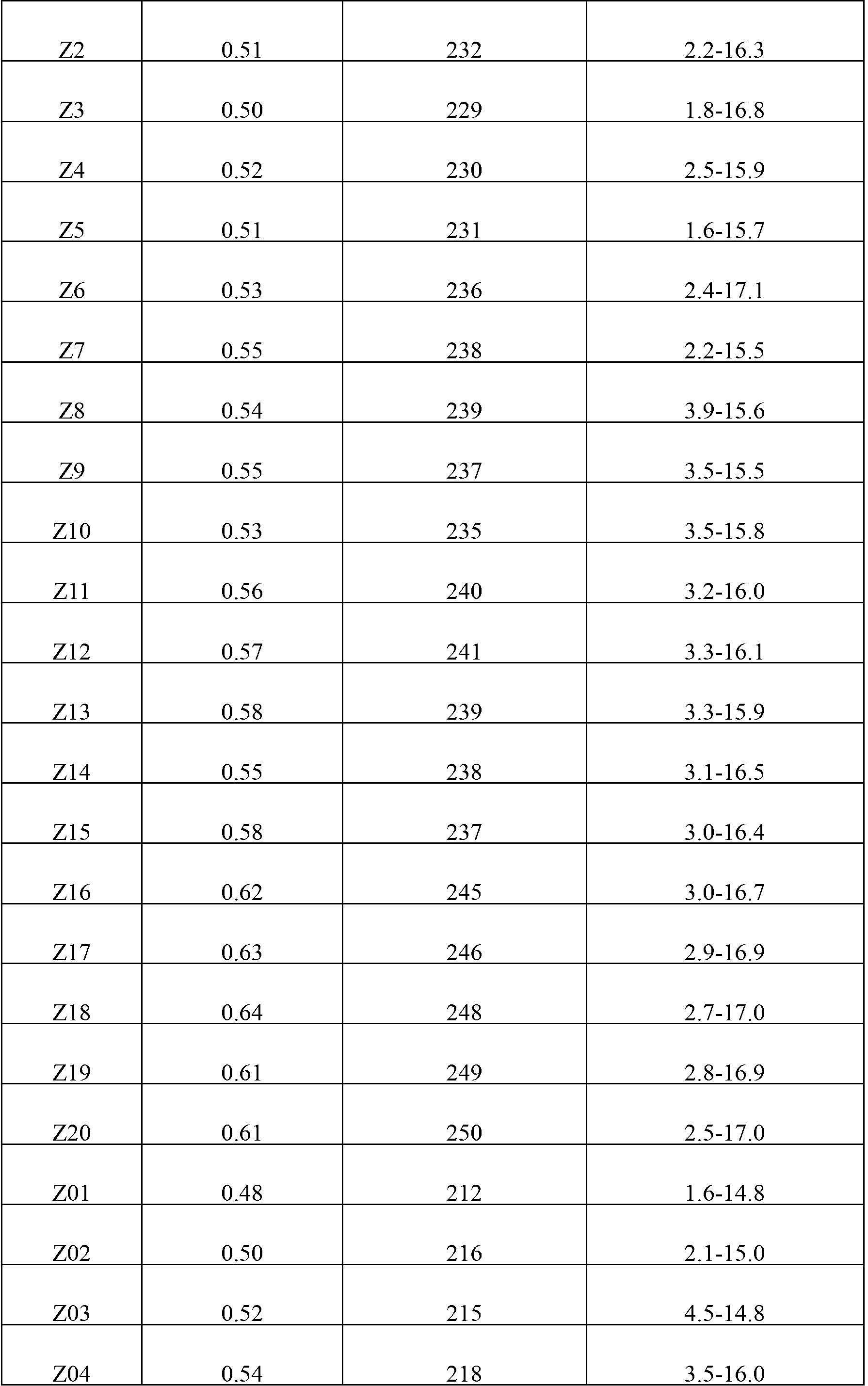

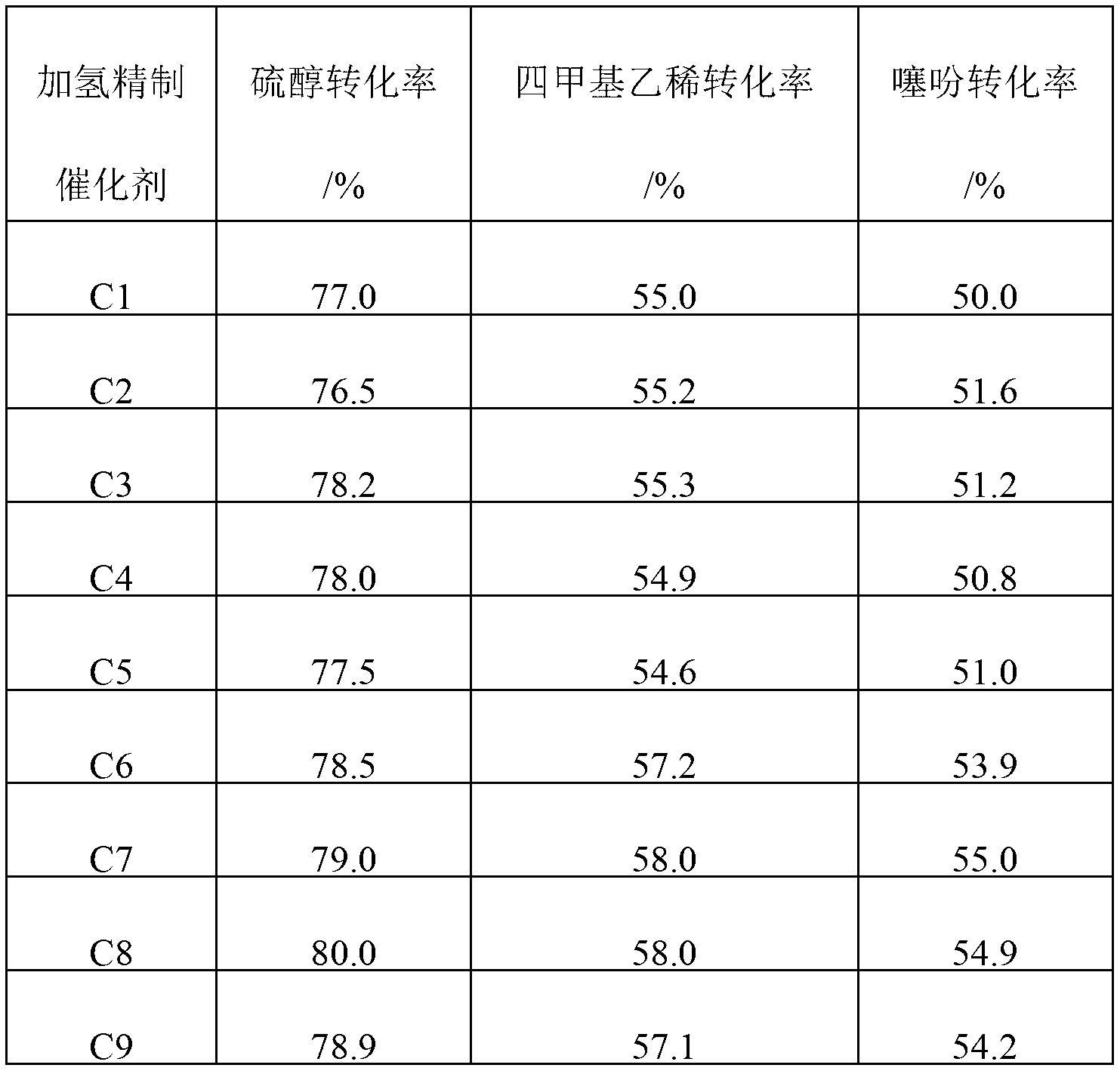

Hydrofining catalyst carrier and preparation method thereof as well as hydrofining catalyst using carrier and preparation method of hydrofining catalyst

ActiveCN103212449ALarge specific surface areaHigh porosityCatalyst carriersMetal/metal-oxides/metal-hydroxide catalystsOrganic sulfide compoundNaphtha

The invention belongs to the technical field of hydrofining catalysts, and particularly relates to a hydrofining catalyst carrier and a preparation method thereof as well as a hydrofining catalyst using the carrier and a preparation method of the hydrofining catalyst. The preparation method of the carrier comprises the steps of: mixing modified diatomite, alumina powder, a bonding agent and a pore-enlarging agent, then kneading and forming, drying and roasting to obtain the carrier, and is characterized in that the modified diatomite is prepared by steeping diatomite in alkali liquor and neutralizing in acid liquor and then carrying out water washing and filter pressing, wherein the amount of impurities on the surface and in pore spaces can be greatly reduced, thereby being beneficial to load of active ingredients; and the hydrofining catalyst prepared by using the carrier is applicable to removal of organic sulfides and unsaturated hydrocarbons in light naphtha, liquefied gas, natural gas and oil refining dry gas.

Owner:SHENYANG SANJUKAITE CATALYST

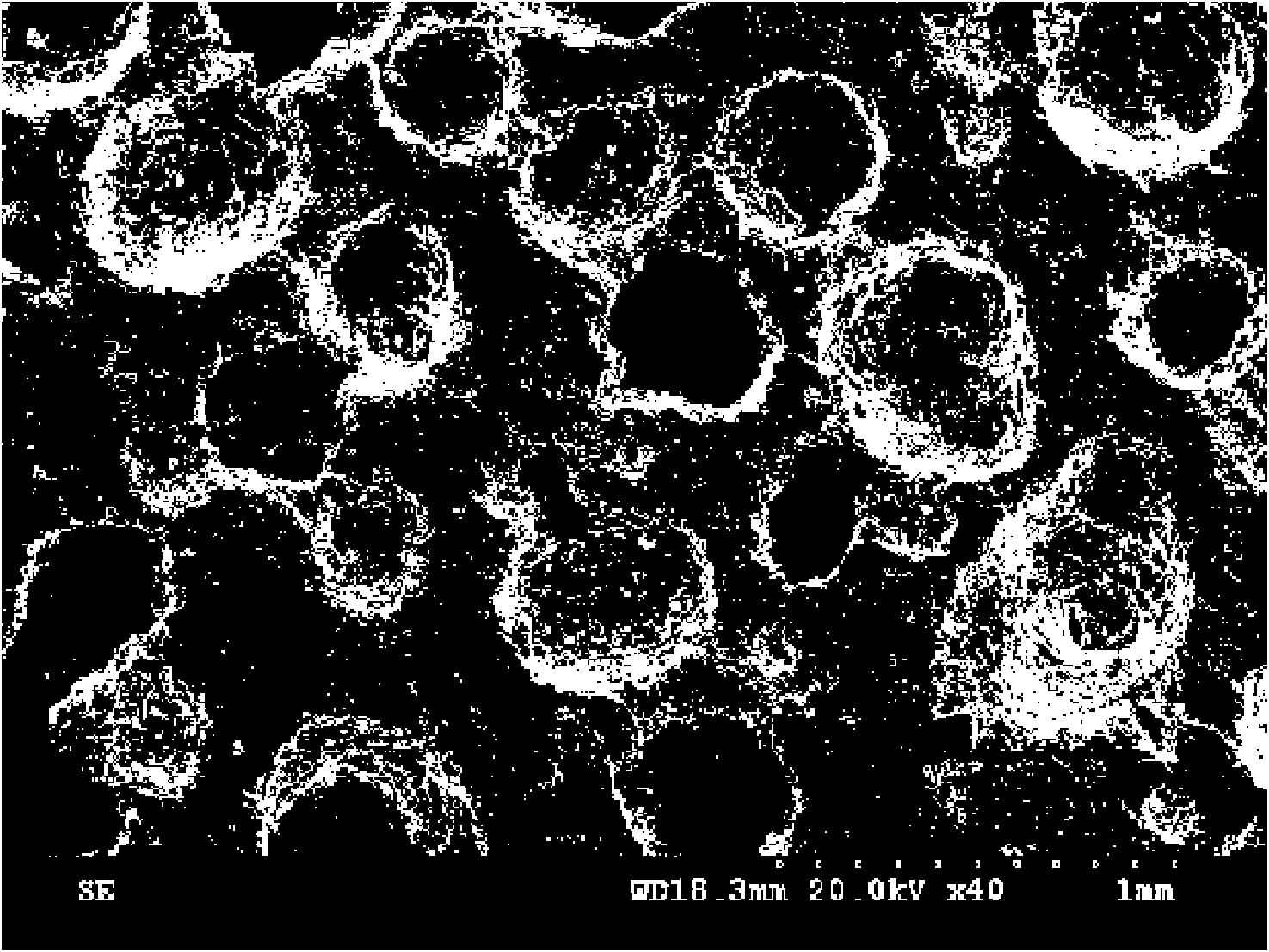

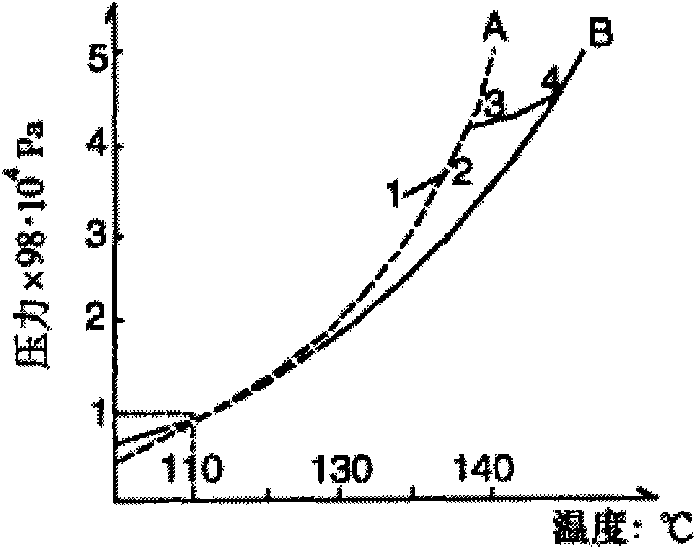

Method for preparing ceramic particle reinforced foamed aluminum-matrix composite material

The invention relates to a method for preparing a ceramic particle reinforced foamed aluminum-matrix composite material, which relates to a method for preparing a foamed aluminum-matrix composite material. The method solves the problems of high production cost and nonuniform pore distribution of the obtained foamed aluminum-matrix composite material due to a foaming agent TiH2 adopted in a conventional melt-foaming method which is expensive, needs pretreatment and has a difficultly controlled decomposition rate. The method comprises the following steps of: mixing aluminum alloy powder, ceramic particles and calcium carbonate (CaCO3) powder and placing a mixture into a graphite mould; placing the graphite mould into a vacuum hotpressing sintering furnace to prepare a prefabricated body; and performing forward extrusion, heating and foaming on the prefabricated body to obtain the ceramic particle reinforced foamed aluminum-matrix composite material. By using a powder metallurgic method and taking the CaCO3 powder as a foaming agent, the method has the advantages of low price, no pretreatment, simple process, stable decomposition rate, convenience for industrial production and uniform pore distribution of the obtained composite material which has a pore diameter of 0.5 to 2 mm, a porosity of 40 to 82 percent and a compressive yield strength of 36 to 70 MPa.

Owner:HARBIN INST OF TECH

Preparation method of porous film

ActiveCN106000123AControl pore structureHigh porosityMembranesSemi-permeable membranesChemical reactionAdditive ingredient

The invention discloses a preparation method of a porous film. The preparation method comprises the following steps: (1) acquiring a porous support body; (2) preparing a thick size containing raw material powder, a binder, a dispersant and a pore forming agent; (3) loading the size onto the porous support body, and drying to make a film billet; (4) sintering the film billet to make a porous film precursor; (5) removing the pore forming agent from the precursor to obtain a porous film with the thickness of 5-3,000 [mu]m, the average aperture of 0.05-100 [mu]m and the porosity of 40-90%. The preparation method has the following advantages: firstly, no chemical reaction occurs between the pore forming agent and the raw material powder, so that the ingredients of the porous film cannot be damaged; secondly, the pore forming agent is excellent in thermal stability and always occupies a certain space (place) in the sintering process; after sintering, the pore forming agent is removed, holes or pores are generated in situ; therefore, the whole technological process is simple, the hole structure of the porous film is easy to control, and the porosity is remarkably improved.

Owner:CHENGDU INTERMENT TECH

Method for directly preparing porous metal product by molten salt electrolysis

The invention discloses a method for directly preparing a porous metal product by molten salt electrolysis. The method comprises the following step of: performing molten salt electrolysis for 4 to 30 hours in the presence of argon shielding gas under such conditions that a metal blank is used as cathode, graphite as anode and CaCl2 is used as electrolyte, to obtain a porous metal product with a porosity of 15 to 78%. The temperature of electrolysis is 850 DEG C to 1200 DEG C, the voltage of electrolysis is 2.8 V to 3.8 V, and the metal blank is prepared from metal oxide powders as raw materials by the conventional method in which a pore-forming agent is added prior to pressing and sintering. The porous metal product is prepared by molten salt electrolysis of the metal blank. Since the deoxidation process is an exothermic process, the temperature is increased to produce a sintering effect during cathode reduction, as a result, the strength of the product is increased. Besides, the sintering effect as local sintering effect has a small impact on deformation of the product.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

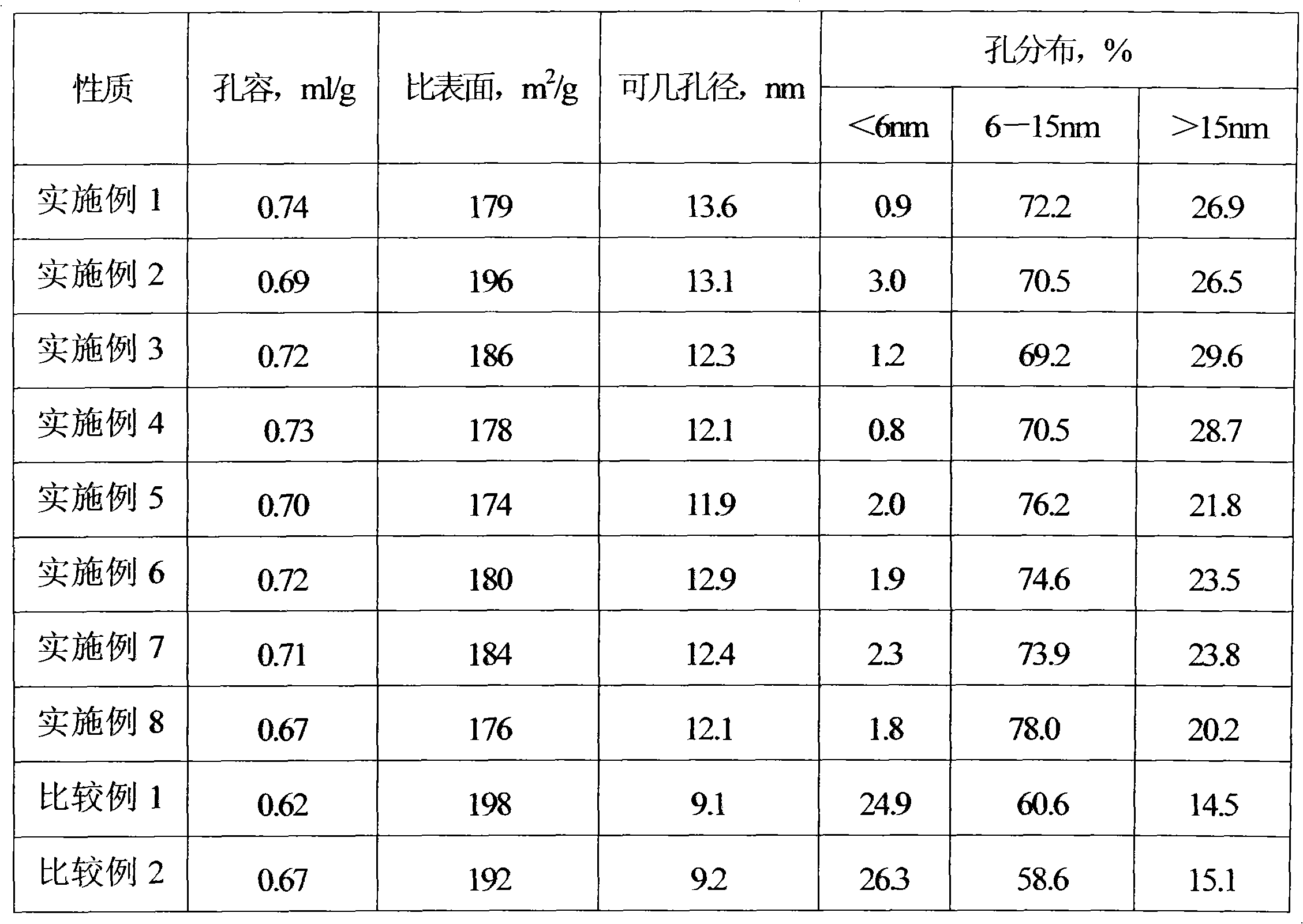

Preparation method of alumina carrier

ActiveCN102039195ALarge hole volumeLarge apertureCatalyst carriersCatalyst activation/preparationCarbonizationResidual oil

The invention discloses a preparation method of alumina carrier, wherein the alumina carrier is prepared by means of a carbonization method, and an organic pore-enlarging agent and a defoaming agent are added before infusing CO2, so that the size and the distribution of air bubble are controlled, the alumina carrier which is obtained by means the method has the advantages of large pore volume, large aperture, centralized hole distribution and even distribution of macropore, and the preparation method provided by the invention is particularly suitable for preparing the hydrotreating catalyst carrier of heavy oil or residual oil.

Owner:CHINA PETROLEUM & CHEM CORP +1

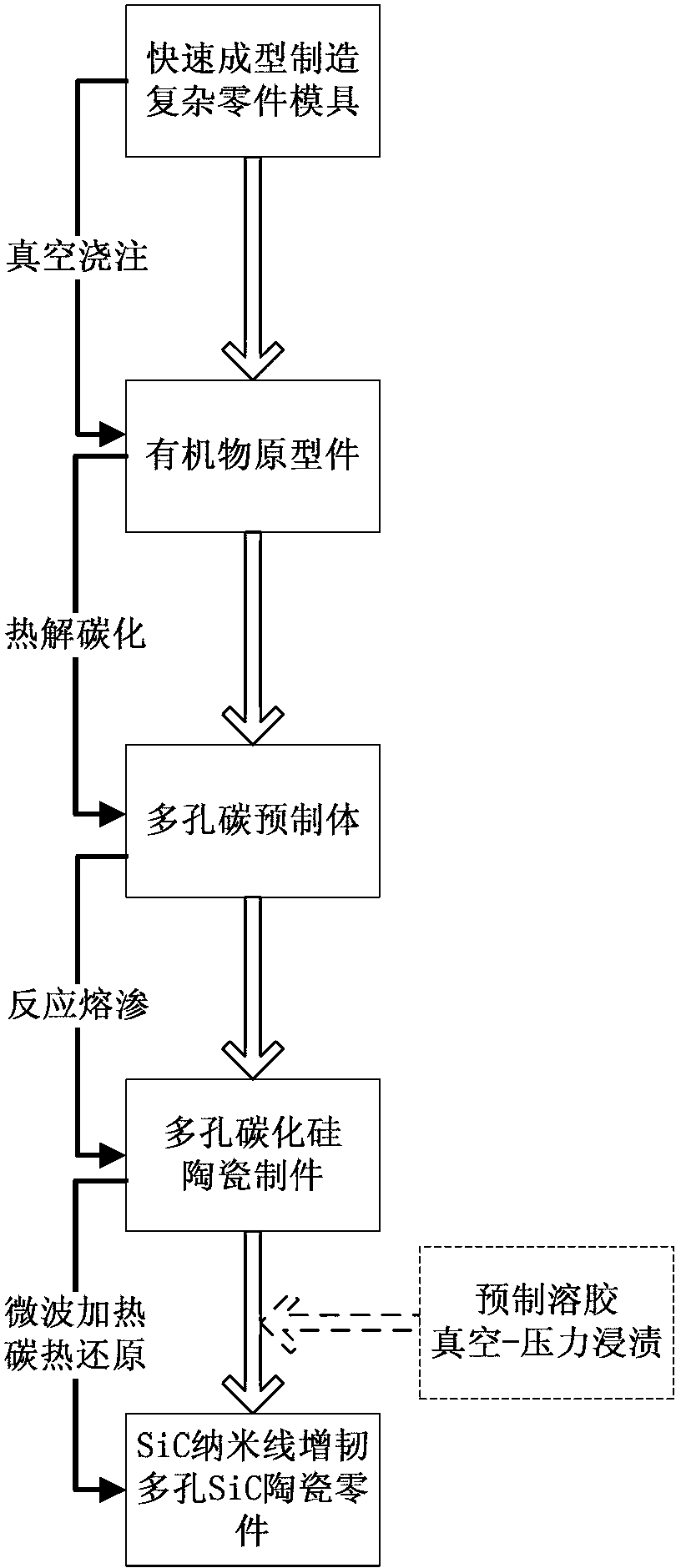

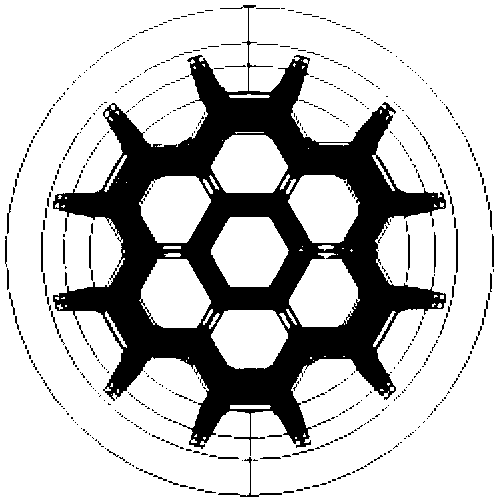

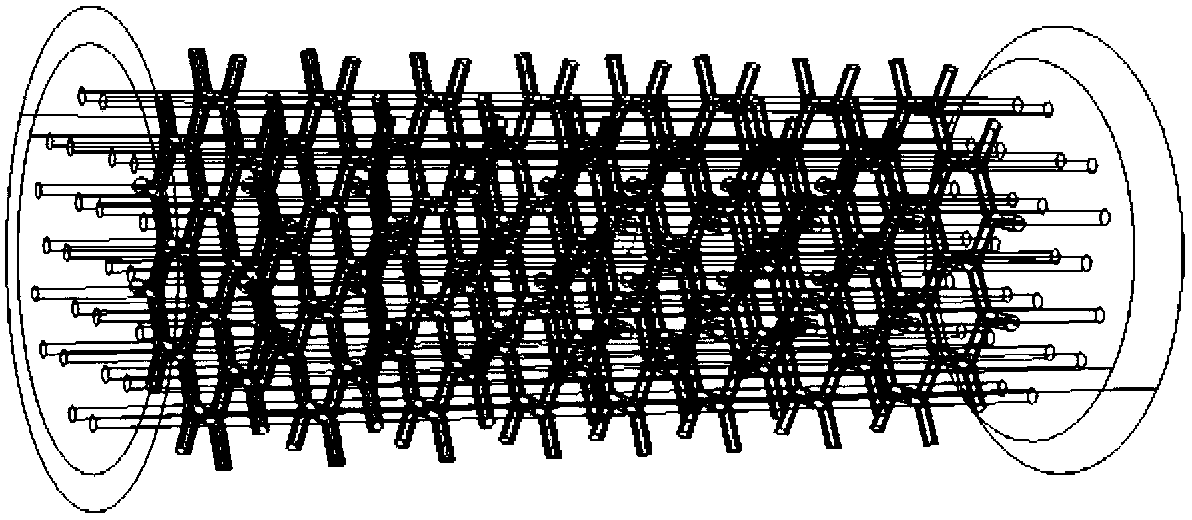

Making method of high-toughness porous SiC ceramic complex part

InactiveCN103130525AImprove part performanceExcellent flexural strengthCeramicwareTemperature resistanceOxidation resistant

The invention discloses a making method of a high-toughness porous SiC ceramic complex part. A light-cured rapid forming technology is adopted to make a resin die of the complex part, a high-residual carbon resin slurry is casted, cured and pyrolyzed to make a porous carbon perform, silicon-carbon reaction sintering and high-temperature vacuum silicon discharge technologies are adopted to make a porous SiC complex part, and matrix aperture internal SiC nanowires are made through a microwave heating process to realize the toughening purpose. The method has the advantages of free forming of the complex structure, uniform and controllable aperture, high specific surface area, high fracture toughness, high-temperature resistance, anti-oxidation and the like.

Owner:XI AN JIAOTONG UNIV

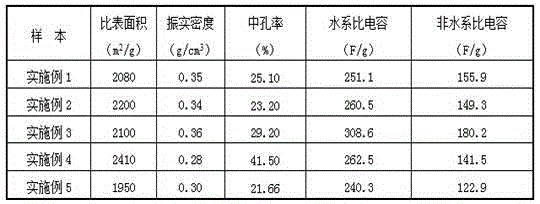

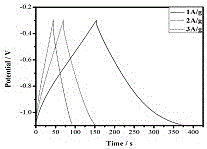

Preparation method of activated carbon for making supercapacitors

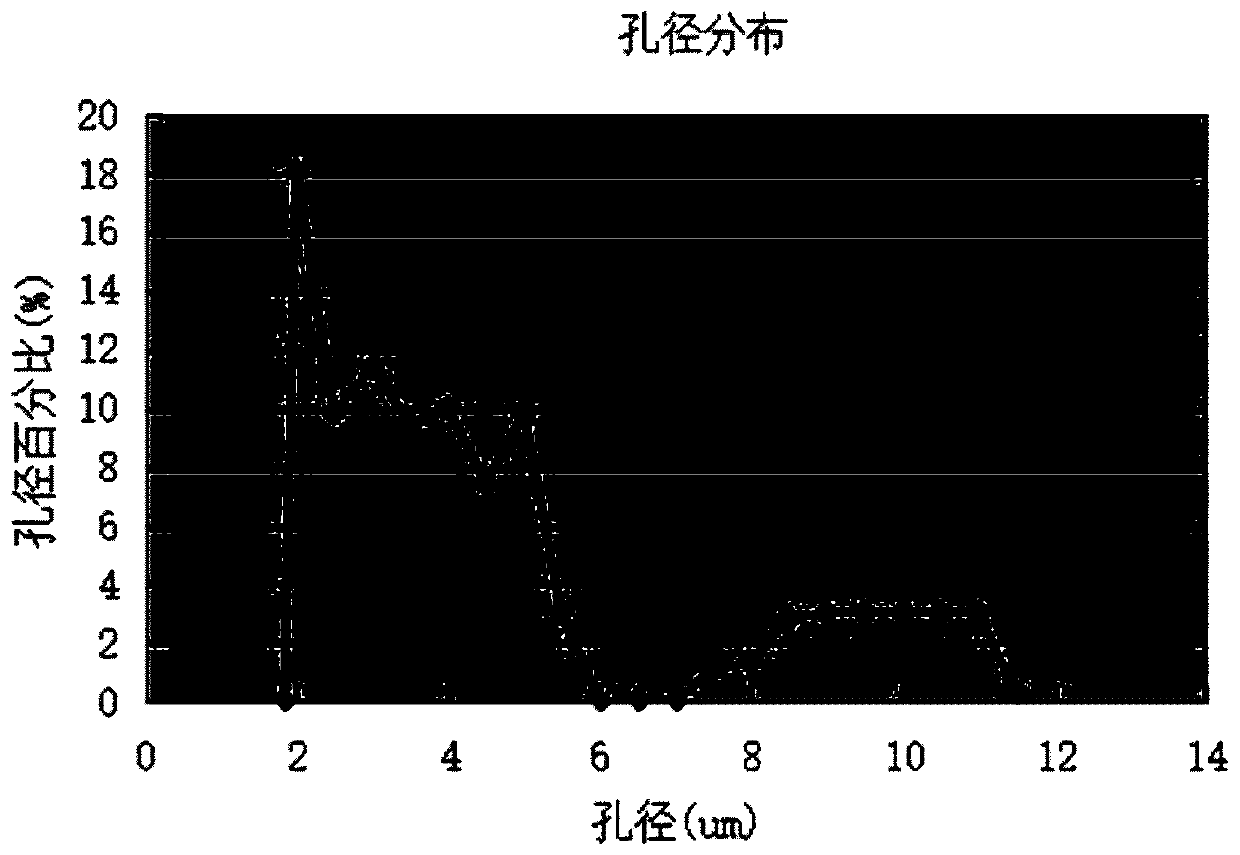

The invention relates to a preparation method of activated carbon for making supercapacitors, which comprises the following steps: by using pre-calcination petroleum coke and potassium hydroxide as raw materials, pulverizing, screening, carrying out impregnating pretreatment on the raw material, mechanically stirring, activating at high temperature, washing with water, washing with acid, and drying. The raw materials are subjected to pulverization, screening, impregnating pretreatment, mechanical stirring pre-activation, high-temperature activation and the like, so that the activation technique for preparing activated carbon from petroleum coke is effectively controlled. The ethanol-water mixed solvent impregnation technique is adopted to lower the carbon / alkali ratio to 3.5, thereby lowering the apparatus corrosion. The prepared activated carbon has centralized micropore distribution, the mesopore rate is controlled at 20-30%, and the pore size is centralized at 2nm or so, thereby being beneficial to the intercalation of the electrolyte in the pore canals. The pore structure of the product is effectively controlled, the tap density of the product is stabilized at 0.3 g / cm<3> above, and the specific capacity of the supercapacitor prepared from the activated carbon can reach 160 F / g above.

Owner:FANGDA CARBON NEW MATERIAL CO LTD

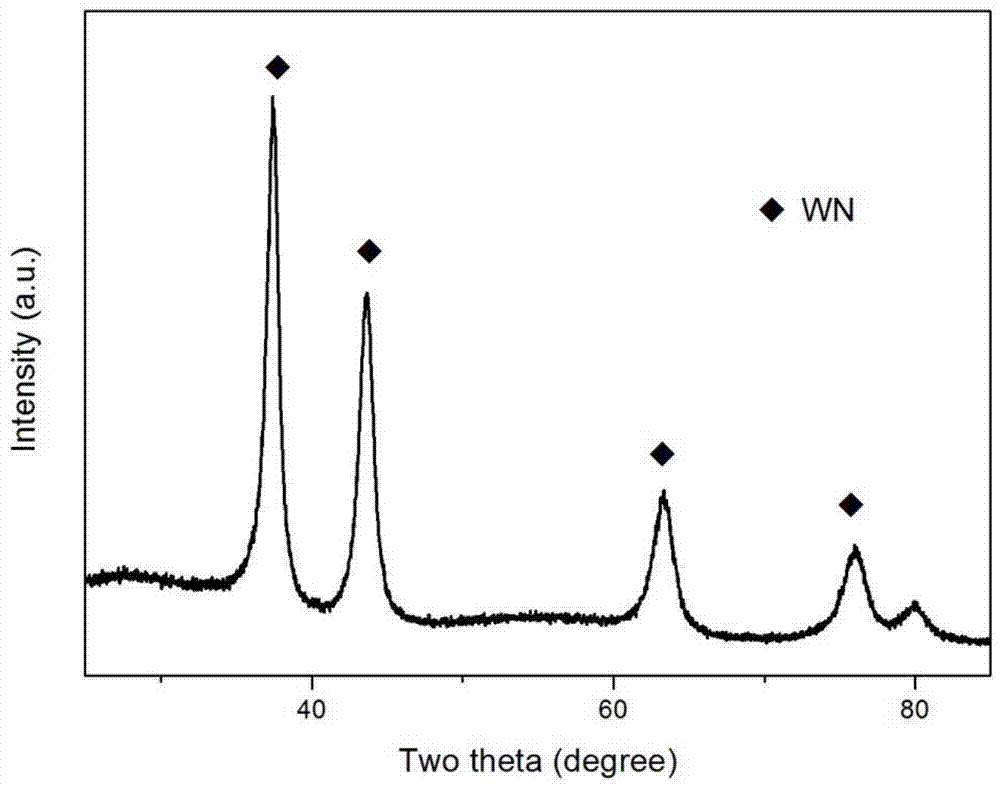

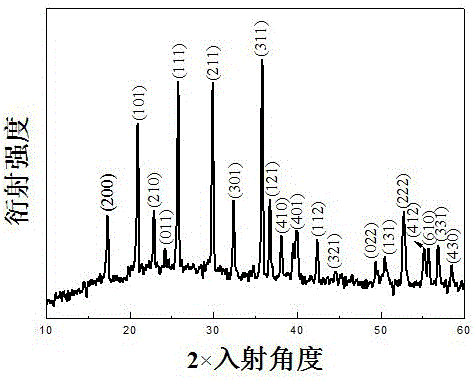

Synthesis method of tungsten nitride with high catalytic performance

ActiveCN104743529AShort processLow costMaterial nanotechnologyNitrogen-metal/silicon/boron binary compoundsSynthesis methodsTungsten nitride

The invention discloses a method for preparing nano tungsten nitride, belonging to the technical field of powder metallurgy preparation. The method comprises the following steps: synthesizing and preparing a tungsten oxide precursor through a solution method; and nitriding the tungsten oxide precursor in ammonia gas to obtain nanocrystalline tungsten nitride powder, wherein the particle size of the powder is 30-120nm. By virtue of the method disclosed by the invention, the problems that ultrafine nanocrystalline powder can be difficultly prepared by a traditional preparation method and the preparation time is long in the traditional preparation method can be solved. The tungsten nitride powder prepared by using the method disclosed by the invention is controllable in particle size, low in cost and high in utilization rate of raw material powder and has remarkable catalytic performance.

Owner:UNIV OF SCI & TECH BEIJING

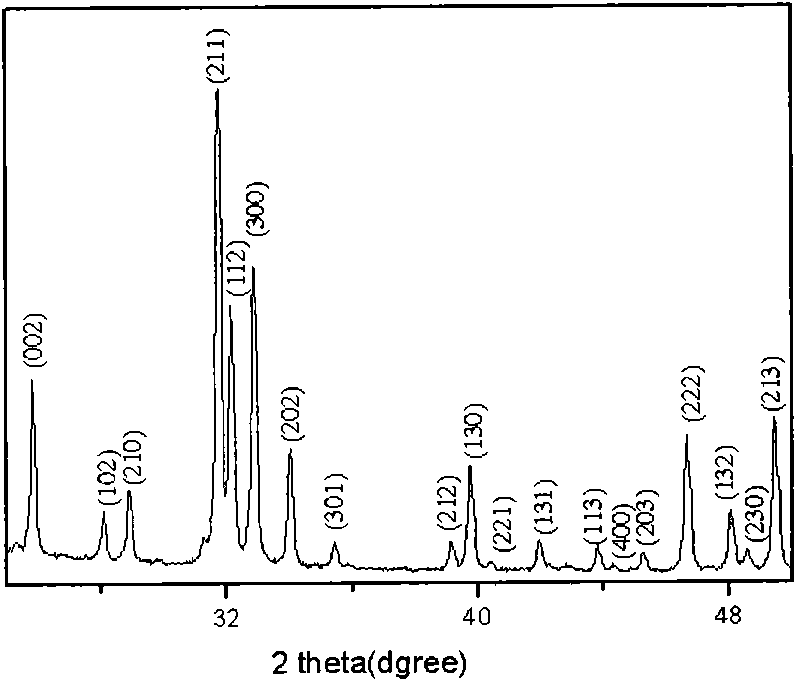

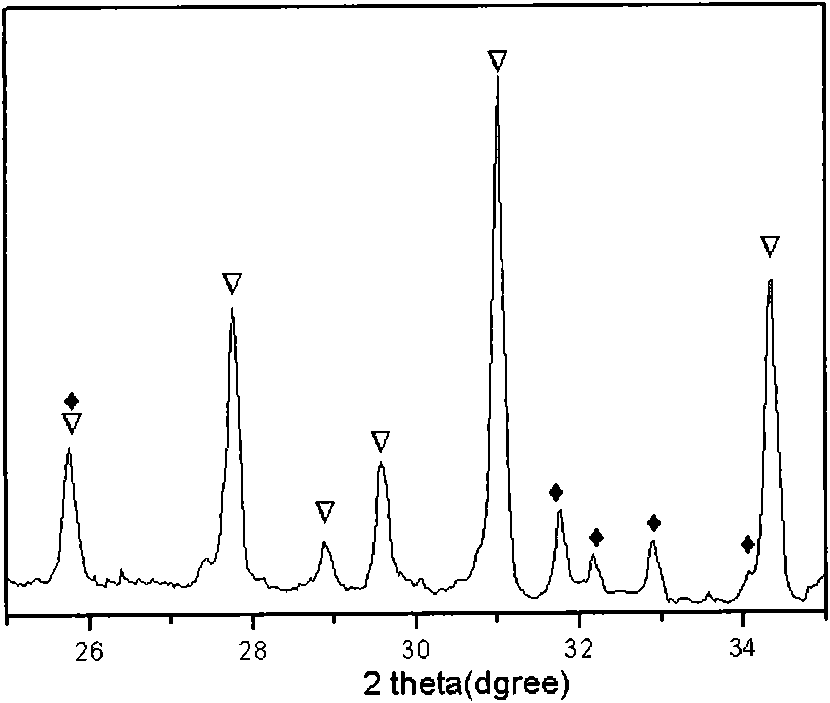

Alpha-calcium sulfate hemihydrates/beta-tertiary calcium phosphate porous granular-type composite artificial bones and preparation method thereof

The invention discloses a method for preparing alpha-calcium sulfate hemihydrates (alpha-CSH) / beta-tertiary calcium phosphate (beta-TCP) porous granular-type composite artificial bones, which is characterized in that the alpha-CSH is directly synthesized on the surface and / or in the pores of the beta-TCP granules synchronously by the hydrothermal synthesis process and finally the alpha-CSH / beta-TCP porous granular-type artificial bones is prepared. The invention has the advantages that the preparation process is simpler, the preparation period can be effectively reduced, and the preparation efficiency is improved; the proportion between alpha-CSH and beta-TCP phases of the granular-type composite artificial bones can be effectively controlled, thereby controlling the pore structure of the artificial bone granules; meanwhile, the invention guarantees the in-situ solidifying performance and degrading performance of the composite artificial bones, controls the evenness of the product and the porosity and pore diameter of the beta-TCP granules, improves the bone-formation performance and degrading performance of the composite artificial bones and further improves the quality of the product, thereby finally obtaining the composite artificial bones having self-solidifying performance and controllable degradation and having a certain biomechanical strength. The invention has good application and market prospect.

Owner:BEIJING ZHONGNUO HENGKANG BIOTECH

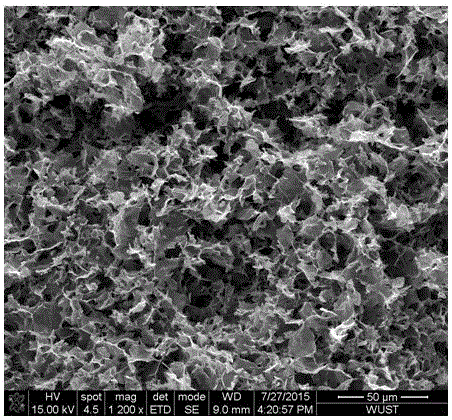

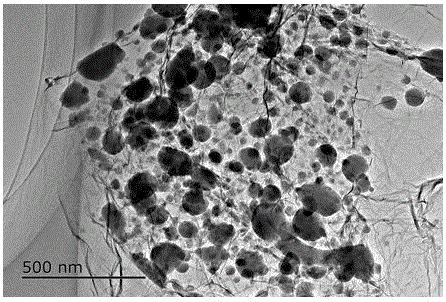

Graphene aerogel loaded lithium iron phosphate porous composite material and preparation method thereof

ActiveCN106025241AImprove structural stabilityImprove cycle performanceCell electrodesSecondary cellsHigh ratePhosphate

The invention relates to a graphene aerogel loaded lithium iron phosphate porous composite material and a preparation method thereof. The technical scheme of the invention is as follows: the preparation method comprises the steps: adding a graphene oxide into deionized water, and carrying out stirring so as to obtain a solution I with the concentration of 2kg / m<3> to 5kg / m<3>; adding a ferric salt into the solution I in accordance with that the mass ratio of the ferric salt to the graphene oxide is 1: (0.03 to 0.3), and carrying out stirring so as to obtain a solution II; adding phosphate and a lithium salt into the solution II in accordance with that the mass ratio of the ferric salt to the phosphate to the lithium salt is 1: 1: 2, carrying out stirring, carrying out a hydrothermal reaction in a reactor, carrying out washing, carrying out freezing, and carrying out drying in a vacuum freeze drier; carrying out heat preservation for 4 to 10 hours in a tube type furnace in a protective atmosphere at the temperature of 550 DEG C to 850 DEG C, and carrying out furnace cooling, thereby preparing the graphene aerogel loaded lithium iron phosphate porous composite material. According to the graphene aerogel loaded lithium iron phosphate porous composite material and the preparation method thereof, the operation is convenient, industrial production is facilitated, the prepared product is adjustable in pore structure and particle size of lithium iron phosphate loaded on the surface of graphene, and the structural stability, cycle performance and high rate capability are excellent.

Owner:WUHAN UNIV OF SCI & TECH

Vacuum concrete mixing process

The invention provides a vacuum concrete mixing process. The vacuum concrete mixing process is characterized in that via simple structural modification, after a mixing drum of a mixer is sealed, the interior of the mixing drum is vacuumized, that is, before mixing, a certain vacuum degree is formed in the mixing drum, so that contact between freshly mixed concrete slurry and air in the mechanical mixing process is greatly reduced, formation of bubbles in concrete is reduced, and accordingly, the porosity is greatly reduced. Furthermore, the minimum pressure in the mixing drum is controlled, so that the ambient temperature is lower than the boiling point of moisture in the mixing drum, accordingly, moisture evaporation is avoided, the phenomenon that pores are formed by moisture evaporation is prevented, and the porosity is further reduced. The vacuum concrete mixing process is simple, is convenient to operate, and can efficiently improve the concrete compactness, strength and durability.

Owner:HUNAN UNIV OF TECH

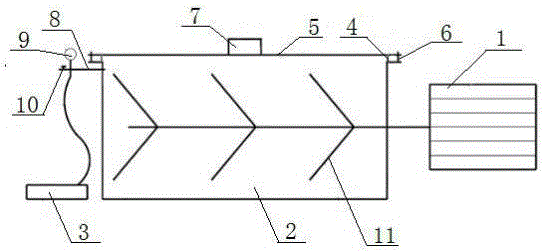

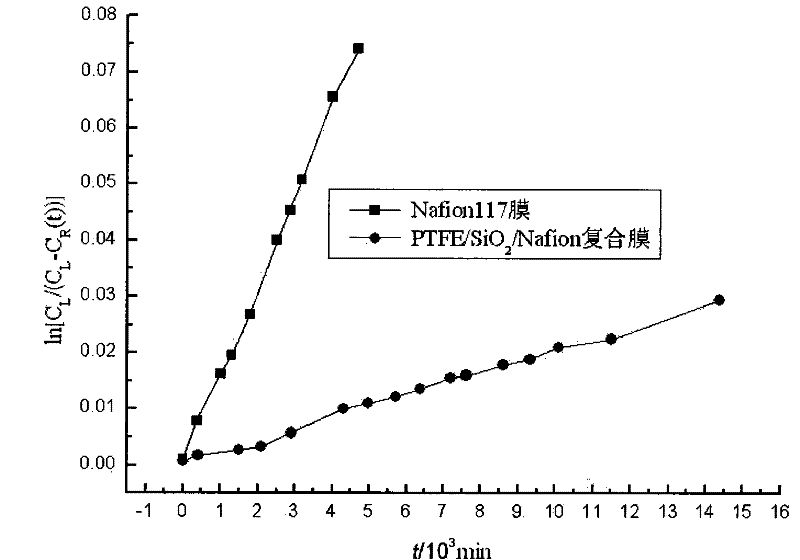

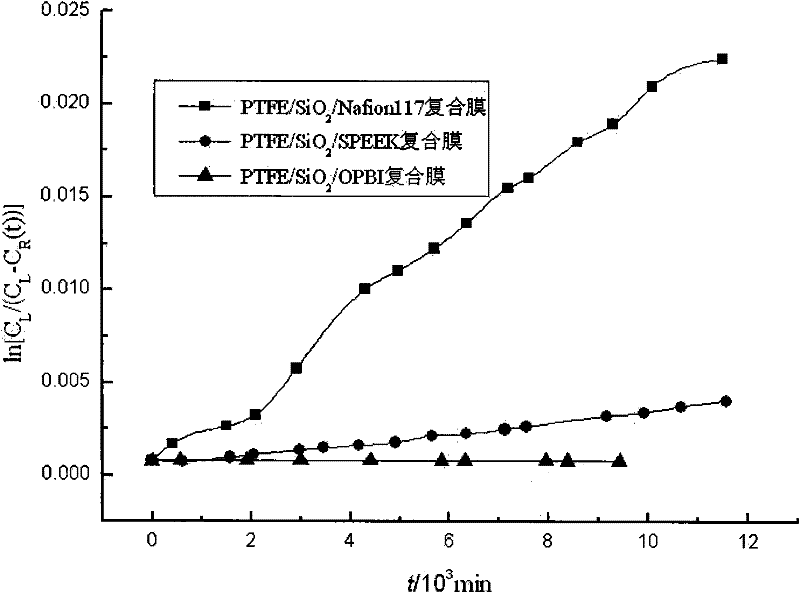

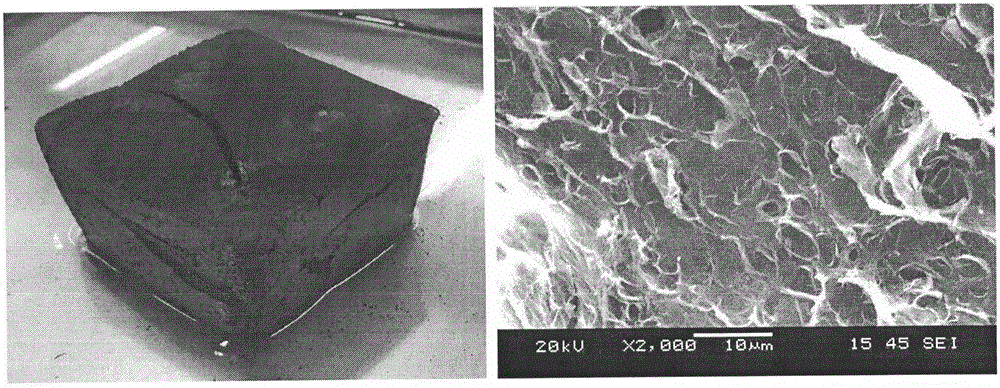

Electrolyte diaphragm for vanadium cell and preparation method thereof

InactiveCN102453262AImprove pore structureImprove mechanical propertiesFinal product manufactureCell component detailsTetrafluoroethyleneConductive polymer

The invention discloses an electrolyte diaphragm for a vanadium cell and a preparation method thereof. The method comprises the following steps of: (1) soaking a porous polyfluortetraethylene film in a mixed liquid consisting of methanol and water to obtain a mixed liquid I; and (2) uniformly mixing the mixed liquid consisting of methanol and ethyl orthosilicate with the mixed liquid I obtained in the step (1), reacting, taking an obtained porous polyfluortetraethylene film out after reacting, drying in vacuum, and soaking into a proton conductive polymer solution to obtain the electrolyte diaphragm for the vanadium cell. In the electrolyte diaphragm for the vanadium cell provided by the invention, the using amount of the proton conductive polymer with high price is reduced on the whole, and the cost of the electrolyte diaphragm is lowered; and nano-silicon dioxide is added, so that the pore diameter structure of an ion film can be effectively controlled, the permeation of vanadium ions is reduced, and the conservation of cell capacity is facilitated.

Owner:CHINA NAT OFFSHORE OIL CORP +2

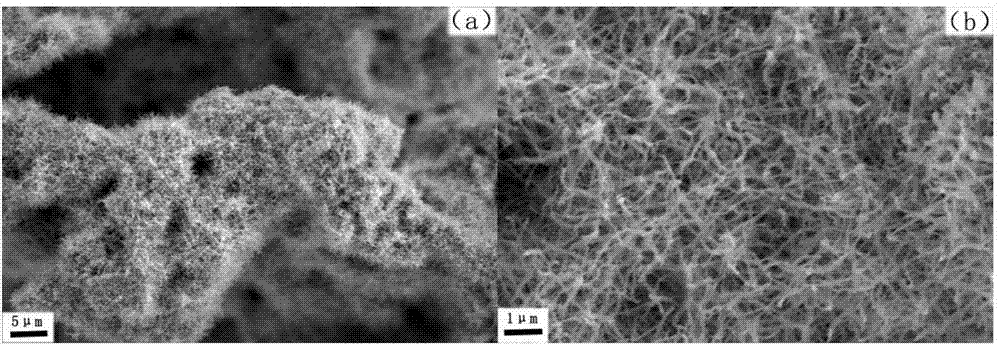

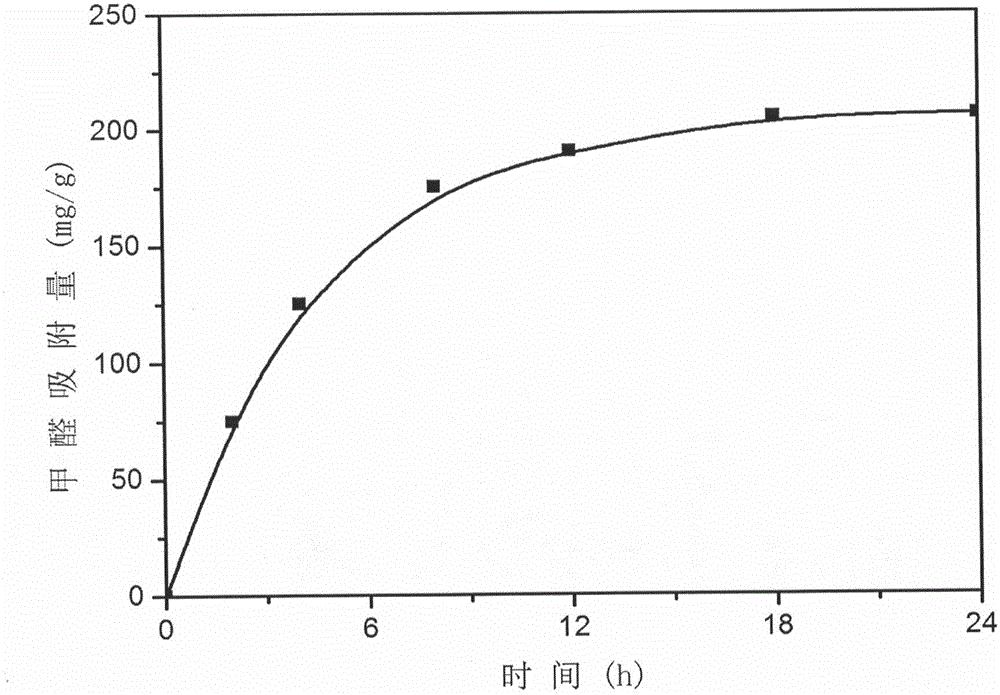

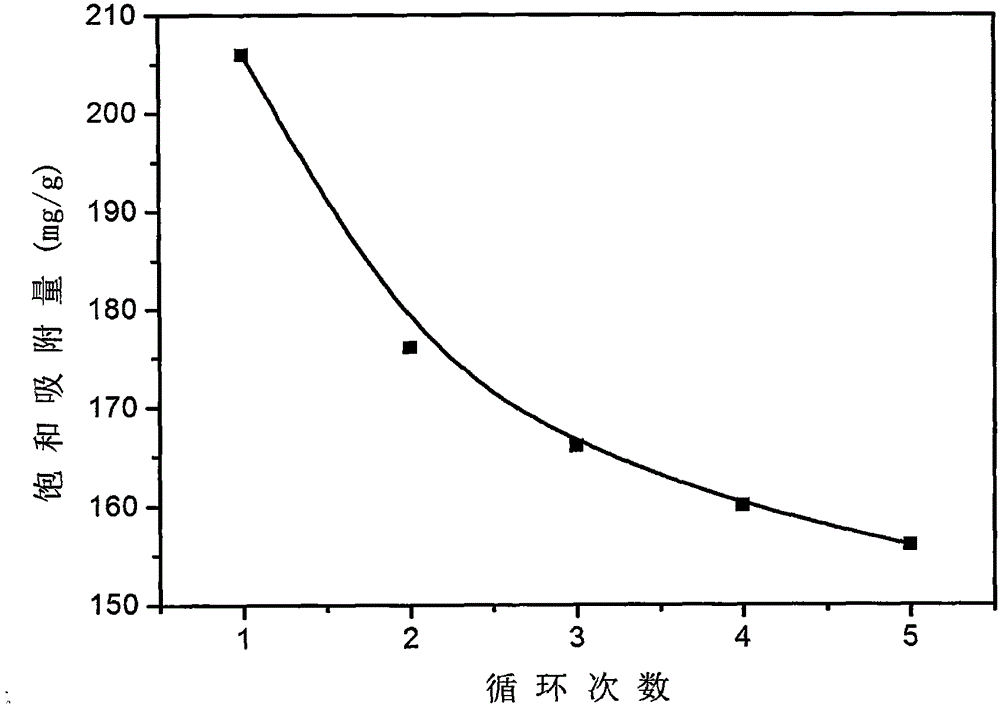

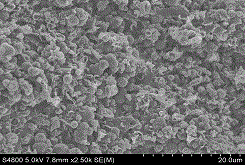

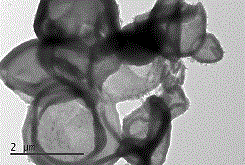

Preparation method of graphene sponge material used for air purification

The invention relates to a preparation method of an adsorption material, and more specifically relates to a preparation method of a graphene sponge material used for air purification, and especially applications of the graphene sponge material in air purification. The graphene sponge material is of a three-dimensional net structure composed of graphene nanosheet and carbon nanotube. The preparation method comprises following steps: 1) a mixed aqueous solution prepared from oxidized graphene and carbon nanotube is subjected to ultrasonic treatment; and 2) an obtained solution is delivered into a reaction vessel, is heated to a constant temperature, is cooled naturally, and then is subjected to freeze drying so as to obtain the graphene sponge material. The graphene sponge material is capable of solving problems in conventional adsorption processes. Compared with the prior art, the specific surface area of the graphene sponge material is large; and adsorption performance and cycling performance are excellent.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

Preparation method and application of glucose-based porous carbon supercapacitor electrode material

ActiveCN106783209AControl areaControl pore structureCarbon compoundsHybrid capacitor electrodesCapacitancePorous carbon

The invention relates to a preparation method and application of a glucose-based porous carbon supercapacitor electrode material. The preparation method includes the following steps that glucose, thiourea and lauryl sodium sulfate are dissolved in 100 ml of water, ultrasonic treatment is conducted for 5 min, and then the mixture is transferred into a polytetrafluoroethylene reaction kettle for a hydrothermal reaction; the obtained product is washed three times with distilled water and alcohol, dried and activated with KOH at 650-850 DEG C; the obtained activated product is washed with a diluted acid solution and then washed with distilled water to be neutral, and the glucose-based porous carbon supercapacitor electrode material is finally obtained after drying. The preparation process is simple, and the preparation method is controllable. The prepared glucose-based porous carbon supercapacitor electrode material has the advantages of being stable in structure, excellent in electrochemical property, good in circulating property, high in specific capacitance and the like, and is very suitable for serving as the electrode material to be applied to the supercapacitor field.

Owner:江苏锦记智能电气科技有限公司

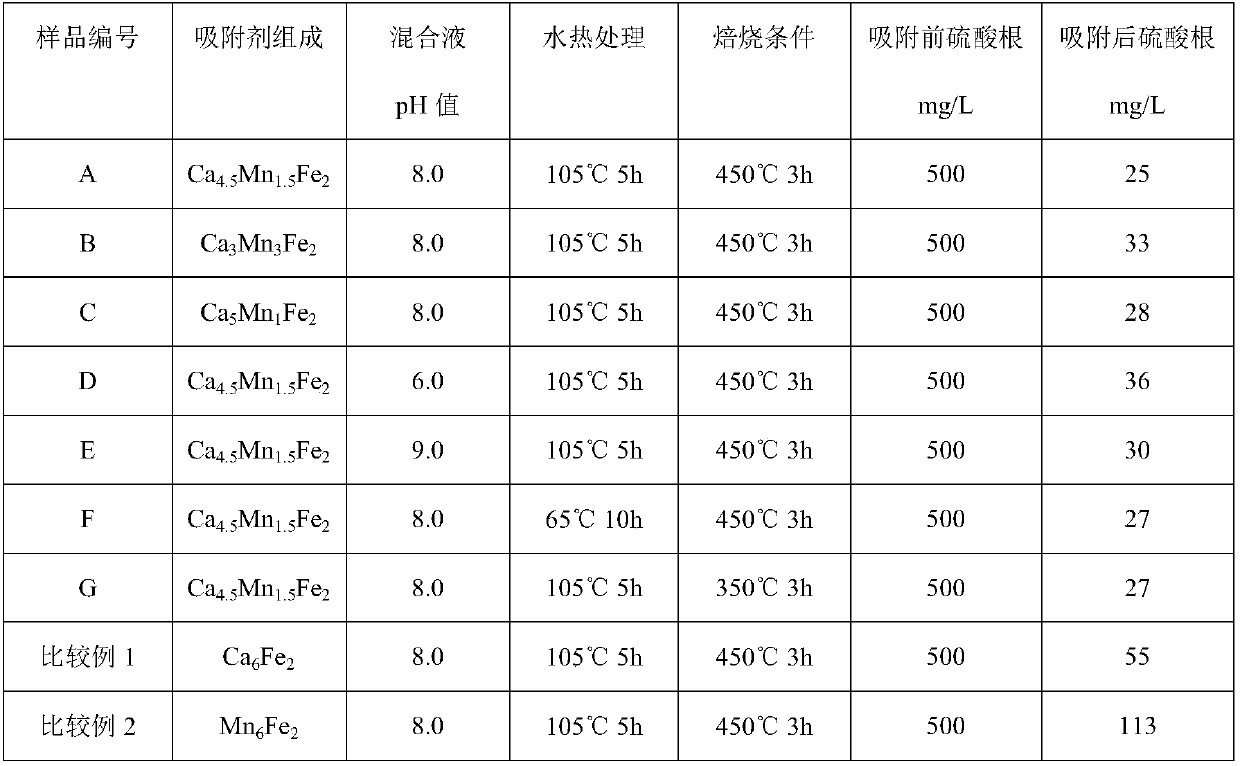

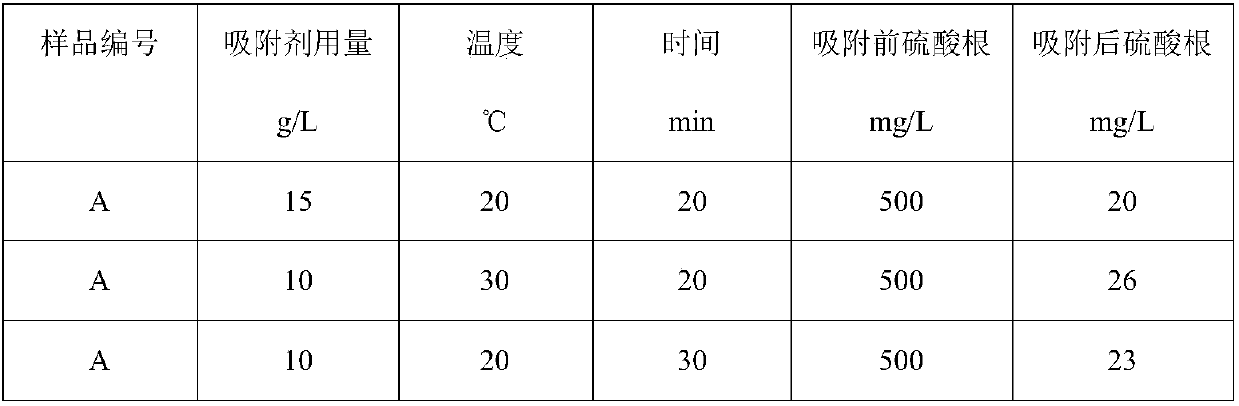

Adsorbent for efficiently adsorbing sulfate ions in water, and preparation method thereof

ActiveCN109692648AImprove adsorption capacityReduce dosageOther chemical processesWater contaminantsSorbentWastewater

The invention relates to an adsorbent for efficiently adsorbing sulfate ions in water, and a preparation method thereof. In the prior art, the removal efficiency of the sulfate ions in the industrialwastewater is not high. A purpose of the present invention is mainly to solve the problem in the prior art. According to the technical scheme, a hydrotalcite-like structure CaxMn6-xFe2(OH)18.4H2O as an adsorbent is prepared by combining co-precipitation and hydrothermal treatment, and x is 3-5.5. With the technical scheme, the problem in the prior art is well solved. According to the present invention, the adsorbent prepared by the method can efficiently remove sulfate ions from water, and can be used in the field of environmental protection.

Owner:CHINA PETROLEUM & CHEM CORP +1

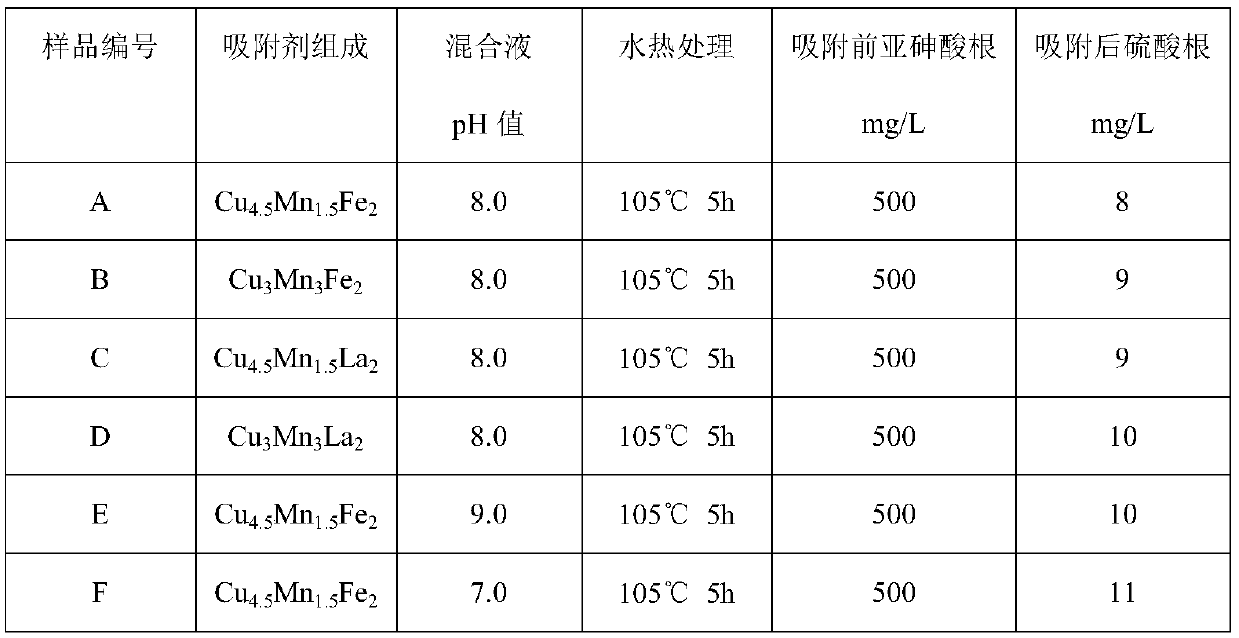

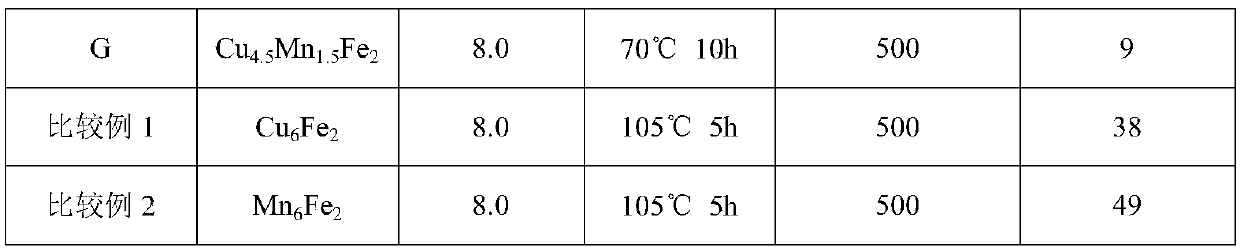

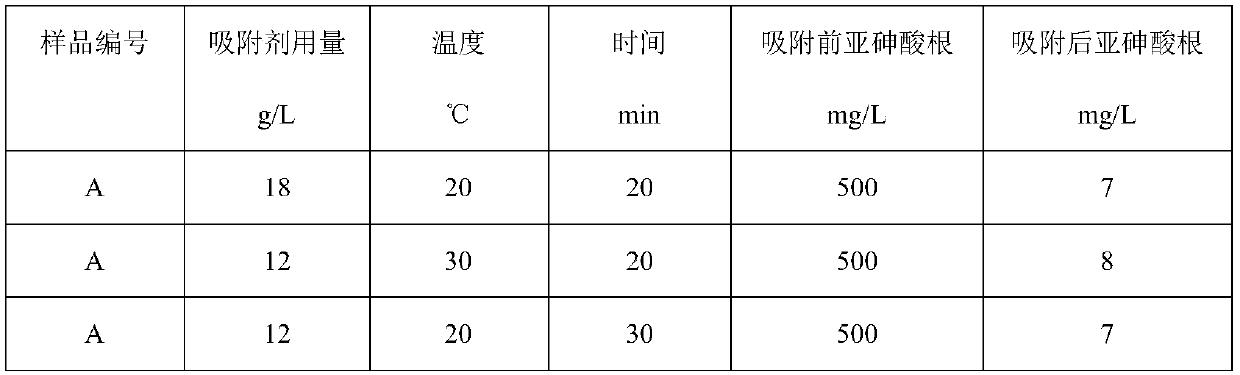

Adsorbent for efficiently removing arsenite ions from water, and preparation method thereof

ActiveCN109692650AImprove adsorption capacityReduce dosageOther chemical processesWater contaminantsSorbentWastewater

The invention provides an adsorbent for efficiently removing arsenite ions from water, and a preparation method thereof, and relates to an adsorbent for efficiently adsorbing arsenite ions in water, and a preparation method thereof. In the prior art, the removal efficiency of the arsenite ions in the wastewater solution is not high. A purpose of the present invention is mainly to solve the problemin the prior art. According to the technical scheme, a metal complex CuxMn6-xLa2(OH)18.4H2O or CuxMn6-xFe2(OH)18.4H2O as an adsorbent is prepared by combining co-precipitation and hydrothermal treatment, and x is 2-5. With the technical scheme, the problem in the prior art is well solved. According to the present invention, the adsorbent prepared by the method can efficiently remove arsenite ionsfrom water, and can be used in the field of environmental protection.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for preparing nickel porous materials based on nickel oxalate and sodium chloride co-mixing reducing method

The invention discloses a method for preparing nickel porous materials based on a nickel oxalate and sodium chloride co-mixing reducing method, relates to a nickel porous material preparing method, and belongs to the technical field of metal porous material preparing. After nickel oxalate powder and sodium chloride powder are subjected to ball grinding and evenly mixed, reducing is conducted, thereducing temperature is 400-450 DEG C, and nickel powder and sodium chloride powder evenly-mixed powder is obtained; then, pressing is conducted at 100 MPa-200 MPa, sintering is conducted at 700-800 DEG C, and a sintered blank with certain strength is obtained; and finally, a water dissolving method is used for removing sodium chloride in the sintered blank, and the nickel porous materials are obtained. The preparing method has environment friendliness, and the prepared porous materials have the characteristics that porosity is high, hole distribution is uniform, and the hole diameter is controllable.

Owner:CENT SOUTH UNIV

Preparation method for carbon-based zeolite molecular sieve composite separation membrane

InactiveCN109603571AImprove antioxidant capacityControl pore structureSemi-permeable membranesMolecular sieveMolding machine

The invention discloses a preparation method for a carbon-based zeolite molecular sieve composite separation membrane. The preparation method comprises the following concrete steps: with phenolic resin as a raw material, preparing a binder, a pore-forming agent and the like, uniformly mixing the phenolic resin, the binder, the pore-forming agent and the like, carrying out extrusion on a molding machine so as to form a tubular original membrane, and carrying out natural drying and carbonization treatment so as to prepare a tubular carbon supporting membrane; synthesizing a zeolite molecular sieve sol from Al2O3, SiO2, Na2O, H2O and EtOH in a certain molar ratio according to a certain addition order under the condition of stirring through a feeding method; placing the tubular carbon supporting membrane into a crystallization vessel filled with the zeolite molecular sieve sol, placing the crystallization vessel into an oven, carrying out crystallization, taking a crystallized membrane outof the oven, carrying out quenching, cleaning and drying, and removing a template agent so as to prepare the carbon-based zeolite molecular sieve composite separation membrane. The invention relatesto the technical field of zeolite molecular sieve composite membranes. The preparation method provided by the invention has the following advantages: a layer of a zeolite molecular sieve material is compounded onto the surface of a carbon supporting body, so the pore structure of the surface of a carbon membrane can be controlled; the gas permeability of the carbon membrane is improved; and a separation membrane with good oxidation resistance can be prepared.

Owner:HUANGSHAN UNIV

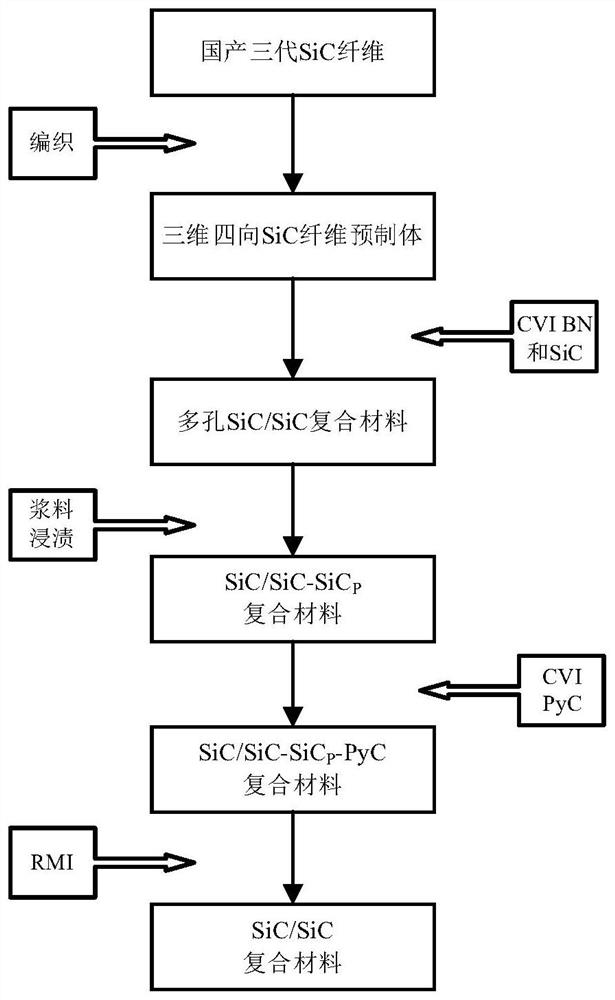

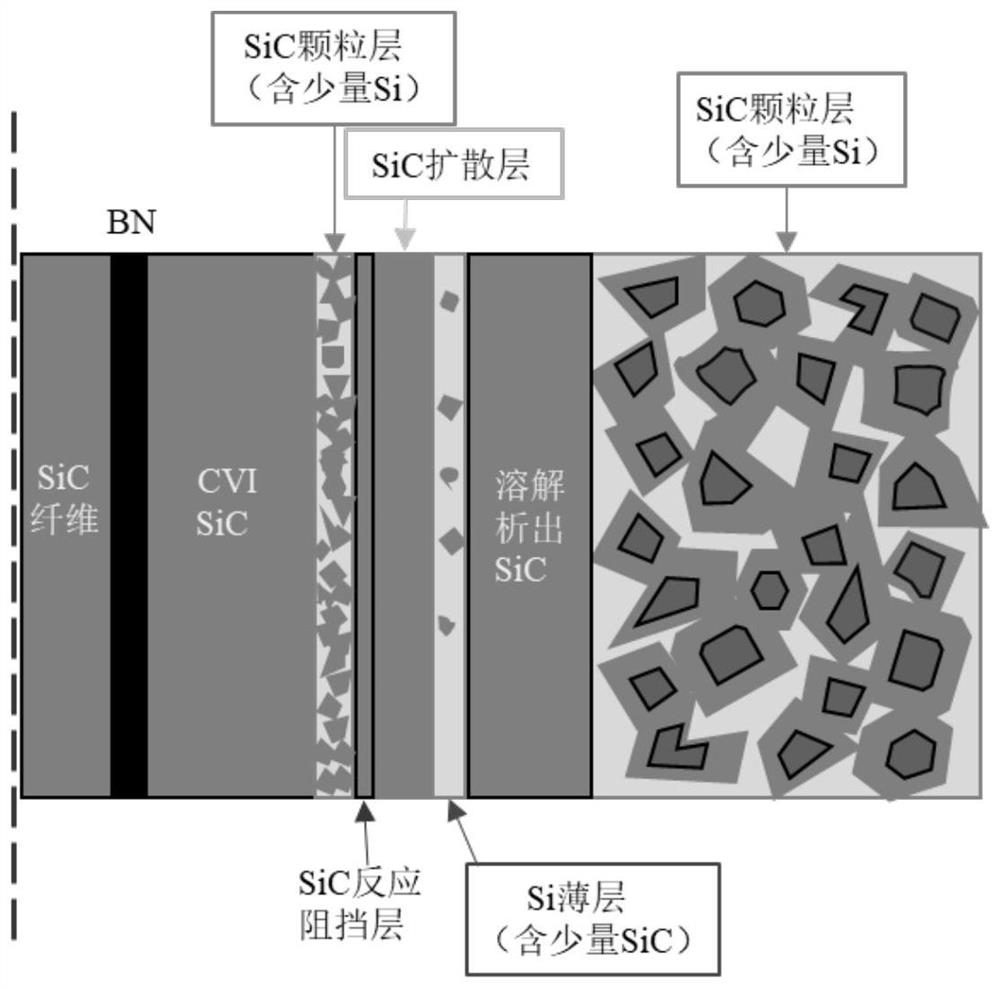

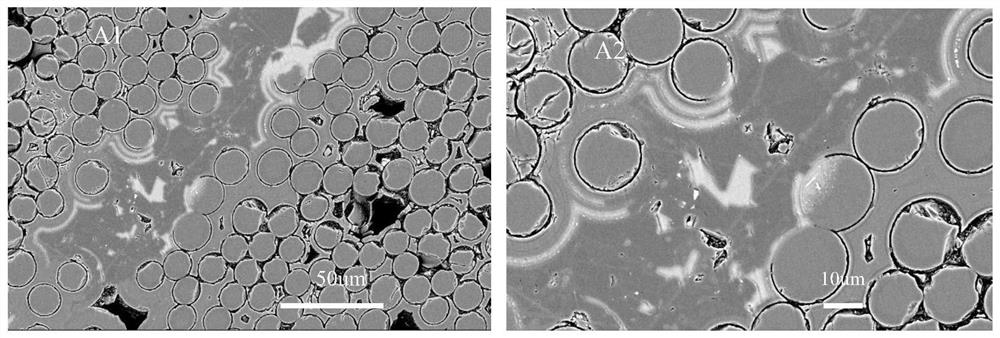

SiC/SiC composite material high-density multilayer matrix and preparation method thereof

The invention relates to a SiC / SiC composite material high-density multilayer matrix and a preparation method thereof. Prepared SiC particle (SiCp) slurry is introduced into a porous SiC / SiC composite material through vacuum impregnation and pressure impregnation methods, then a certain content of pyrolytic carbon is prepared in the porous SiC / SiC composite material by adopting a CVI method, the SiC particles are uniformly wrapped by the pyrolytic carbon, and finally, densification of the SiC / SiC composite material is completed through reaction of pyrolytic carbon and molten silicon by adopting an RMI method. SiC particles with different particle sizes are sequentially introduced to form a layered structure, so that a genetic effect is generated on subsequently prepared PyC and SiC matrixes, a uniform SiC matrix phase with a high volume fraction is obtained, the density of the composite material is increased, the energy of crack propagation is increased, and the mechanical property of the composite material is effectively improved. The composite material prepared by the method has a SiC matrix phase with high volume fraction and uniform distribution, high mechanical property and low open porosity, and solves the problems of low SiC phase content, non-uniform distribution and insufficient toughness in the SiC / SiC matrix prepared by the existing RMI process method.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

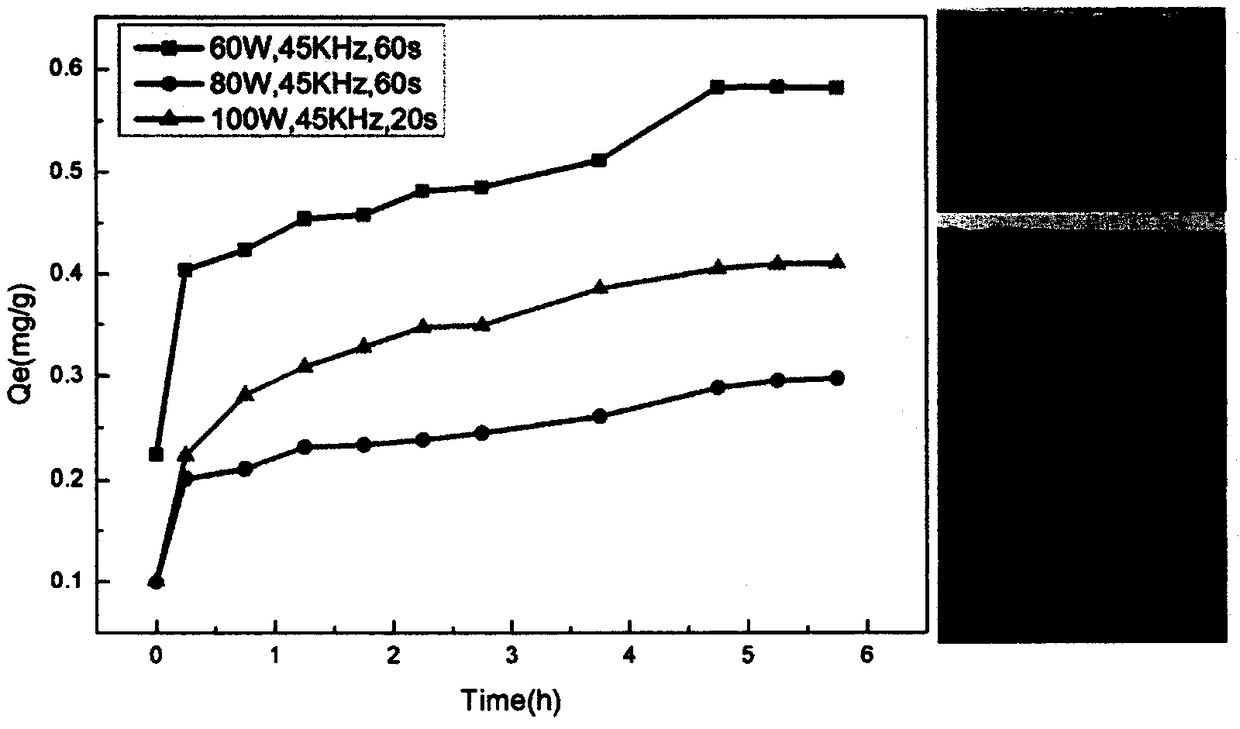

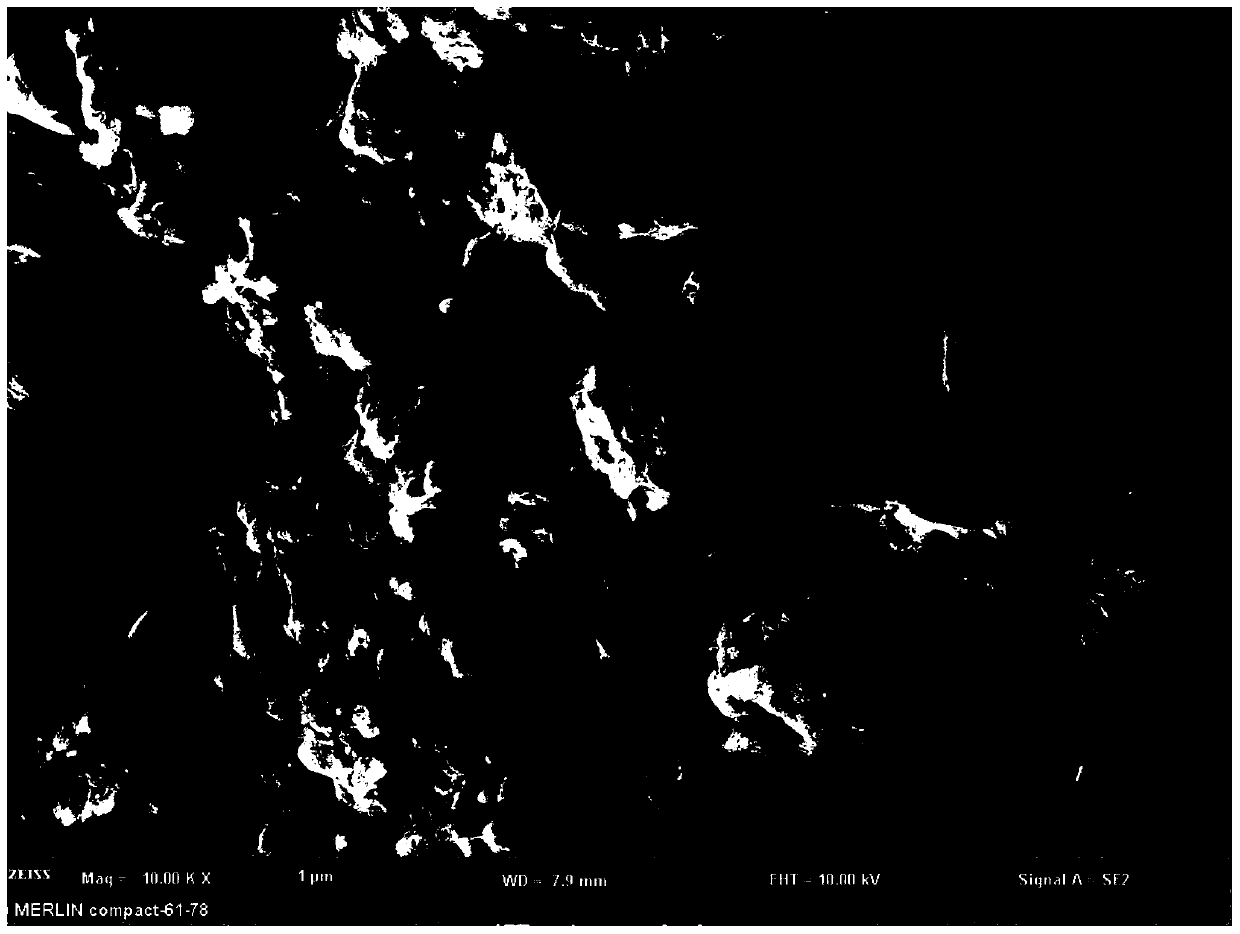

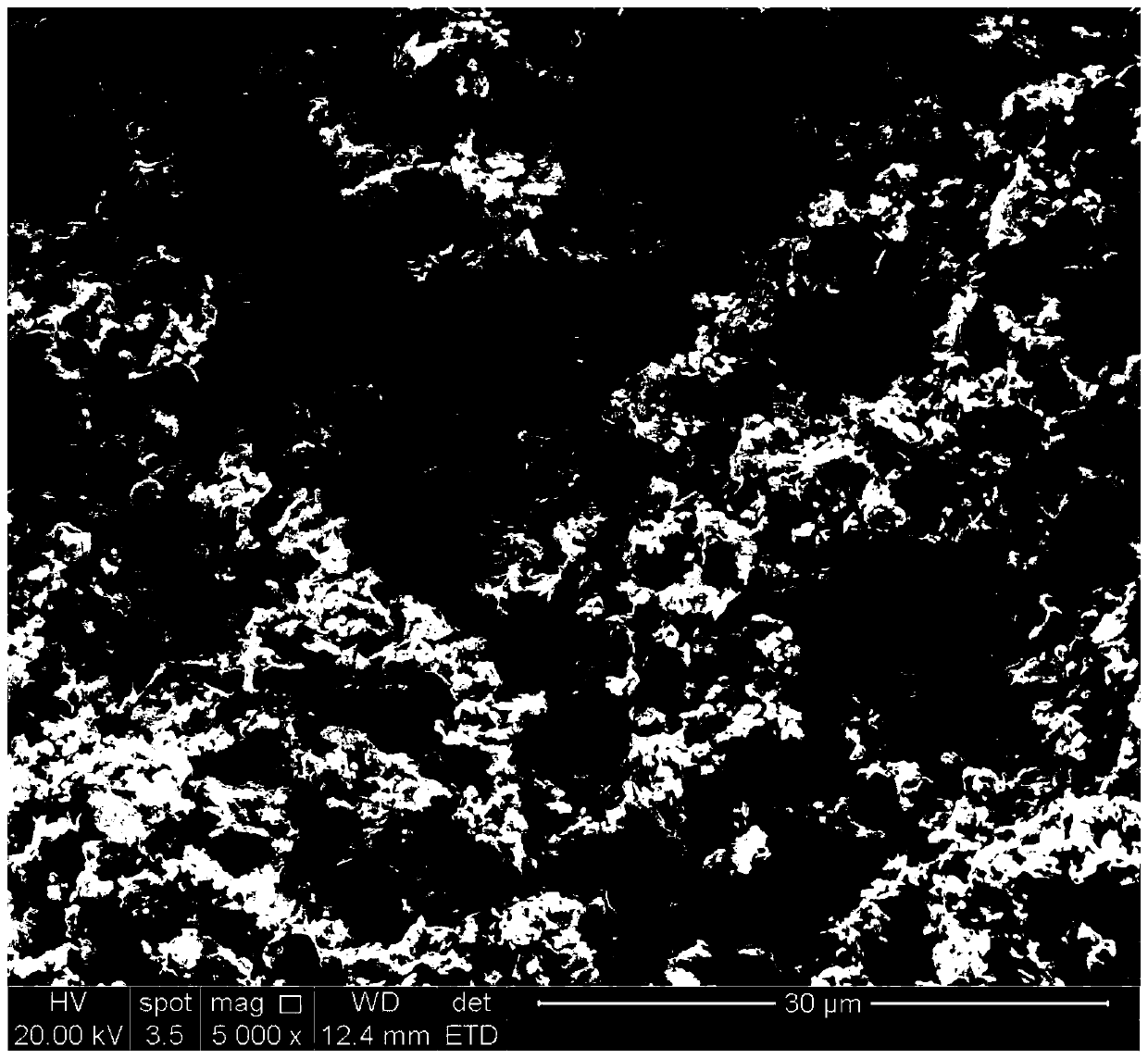

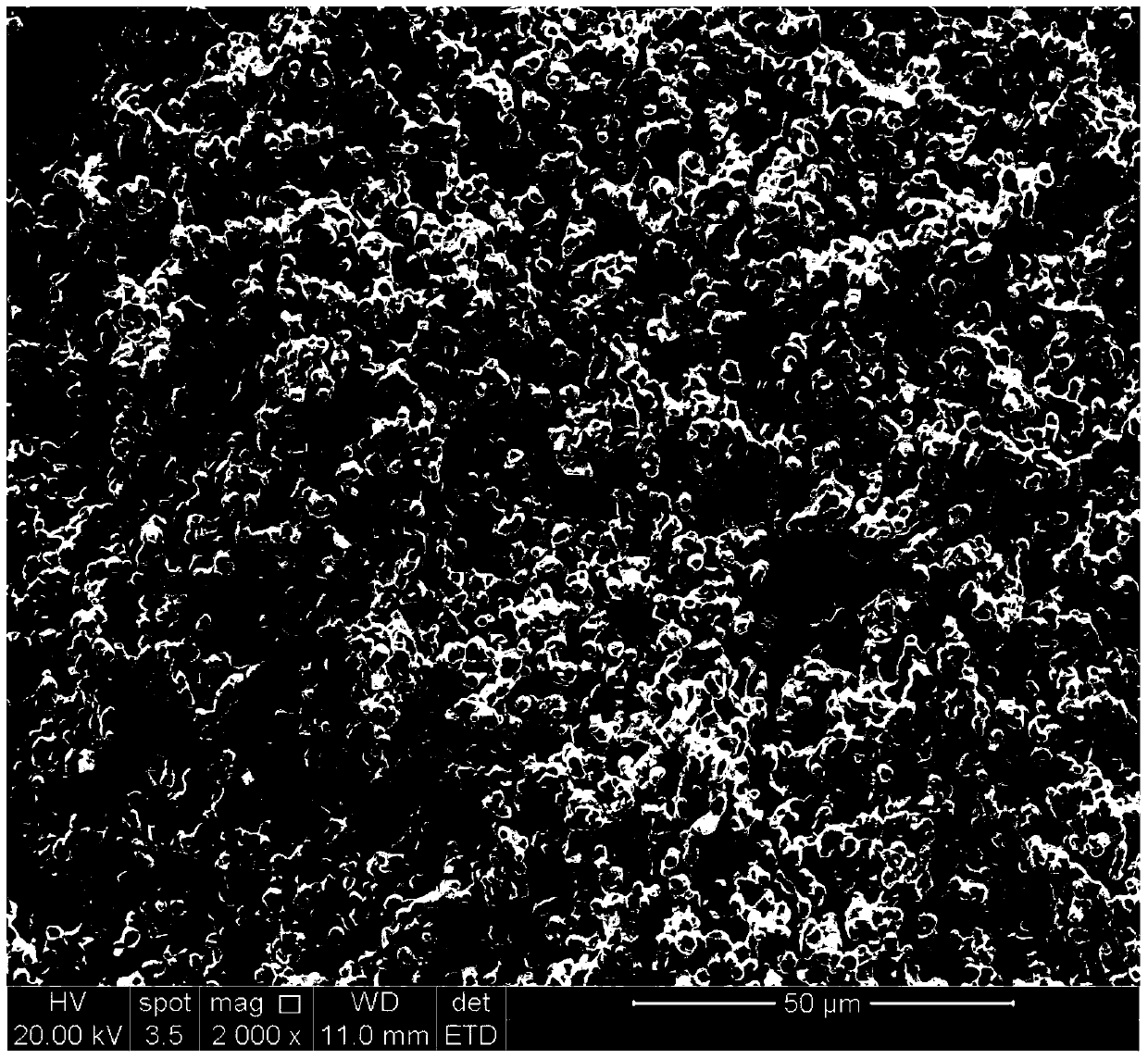

Method of preparing multiwall carbon nano-tubes/polyvinylidene fluoride porous film material via ultrasonic-assisted phase inversion process

InactiveCN108097223AControl pore structureEasy to operateOther chemical processesWater contaminantsWater bathsCarbon nanotube

The invention relates to a method of preparing a multiwall carbon nano-tubes / polyvinylidene fluoride porous film material via an ultrasonic-assisted phase inversion process. The method includes stepsof: 1) adding MWCNTs to DMF and performing ultrasonic dispersion until complete uniform dispersion, adding PVDF powder to the MWCNT / DMF system and heating and stirring the mixture to form a homogenousfilm-casting liquid, sealing the film-casting liquid, allowing the film-casting liquid to stand at room temperature overnight for removing foams; 2) scrape-coating the liquid on a glass board to forma film, placing the glass board along with the film into an ultrasonic instrument to perform ultrasonic treatment at different power, frequency and ultrasonic time, placing the glass board in distilled water bath to volatile the solvent, thus forming the MWCNT / DMF porous film material; and 3) drying the MWCNT / DMF porous film material in a vacuum drying box and storing the product.

Owner:TIANJIN POLYTECHNIC UNIV

Method for preparing porous tungsten material based on W-Fe-C system corrosion method

The invention relates to a method for preparing a porous tungsten material based on a W-Fe-C system corrosion method. The method comprises the following specific steps that 1), a compound block body is formed by low-temperature sintering, wherein tungsten powder, iron powder and carbon powder are uniformly ball-milled, mixed powder is obtained, the mixed powder is loaded into a graphite grinding tool, and a tungsten iron block body is obtained by discharging plasma sintering; 2), iron in a base material is corroded by a chemical etching method, wherein the tungsten iron block body is placed inan excess dilute sulfuric acid solution, and the dilute sulfuric acid solution is heated to 40-80 DEG C, and a porous tungsten green body with the micron pore diameter is obtained; and 3), porous tungsten is prepared by high-temperature sintering, wherein the porous tungsten green body obtained in the step 3) is subjected to vacuum pressure-free sintering, and the porous tungsten material is obtained. The porous tungsten material is uniform in pore distribution, consistent in structure and free of obvious defects, the porosity is 25.8-78%, the pore size is 1-10 micrometers, and the application is wide.

Owner:WUHAN UNIV OF TECH

Preparation process of porous carbon nanospheres

ActiveCN110577223ANo collapseGood lookingMaterial nanotechnologyCarbon compoundsPorous carbonCarbonization

The invention discloses a preparation process of porous carbon nanospheres, and the preparation process comprises the following steps: s1, preparing a ZnCl2 solution; s2, adding 2, 6-diaminopyridine into the ZnCl2 solution, and stirring until the 2, 6-diaminopyridine is completely dissolved; s3, adding formaldehyde into the solution prepared in the step S2 until the reaction is complete so as to obtain a solution A; s4, carrying out centrifugal treatment on the solution A, and drying a centrifugal precipitate to obtain polytriazine; s5, calcining the polytriazine to obtain a carbonized productB; and s6, washing and drying the carbonized product B to obtain the porous carbon nanospheres; wherein the concentration of the ZnCl2 solution is more than 0.5 mg / mL and less than 4mg / mL. Accordingto the invention, the ZnCl2 solution with a relatively low concentration, the 2, 6-diaminopyridine and formaldehyde are polymerized to form polytriazine nanospheres as a carbon precursor, ZnCl2-containing polytriazine is carbonized, carbonization and foaming processes are carried out at the same time, the polytriazine is converted into porous carbon nanospheres C-PFZ, the surface of the formed C-PFZ is free of collapse and good in overall morphology, and meanwhile, the formed C-PFZ shows excellent electrochemical performance as an EDLC electrode.

Owner:ANHUI UNIV OF SCI & TECH

Low-carbon magnesia carbon brick and preparation method thereof

The invention relates to a low-carbon magnesia carbon brick and a preparation method thereof. The technical scheme is as follows: 78-93 wt% of magnesia particles, 0.1-2 wt% of organic additives and 5-20 wt% of absolute ethyl alcohol are placed in a stirrer, stirred for 2-6 hours at a rotating speed of 300-600 rpm, dried at 80-110 deg c for 12-24 hours, and sieved to obtain pretreated magnesia particles with a particle size of 1-5 mm. Then, 63-75 wt% of the pretreated magnesia particles, 20-32 wt% of magnesia fine powder, 2-5 wt% of flake graphite, 1-3 wt% of an antioxidant and 2-5 wt% of thermosetting phenolic resin are used as raw materials to be uniformly mixed, pressed and molded at 150-200 MPa, and then cured at 180-240 deg c for 18-24 hours to prepare the low-carbon magnesia carbon brick. The invention has the characteristics of low production cost, simple process and easy industrial production, and the prepared low-carbon magnesia carbon brick has high thermal shock stability, high high-temperature bending strength and good slag erosion resistance.

Owner:WUHAN UNIV OF SCI & TECH

A kind of preparation method of lignin-based mesoporous carbon material

ActiveCN109704334BImprove stabilityHigh mechanical strengthCarbon compoundsOn/in inorganic carrierAcid waterPhysical chemistry

The invention discloses a preparation method of a lignin-based mesoporous carbon material. The preparation method comprises the following steps: crushing straw, adding the crushed straw into an alkaline solution, carrying out a reaction for 0.5-5 hours to obtain a reaction solution, adjusting the pH value to 5-12 by using an acid, and then carrying out sedimentation, washing and drying to obtain lignin with a high silicon content; putting the lignin with a high silicon content in an inert atmosphere furnace, carrying out heating to 500-1000 DEG C at a temperature rising rate of 1-20 DEG C / min,and carrying out heat-preservation carbonization for 0.5-5 hours; finally mixing the carbonized lignin with a potassium hydroxide solution, putting the mixture into an inert atmosphere furnace, carrying out heating to 500-1000 DEG C at a temperature rising rate of 1-20 DEG C / min, and carrying out a heat-preservation carbonization reaction for 0.5-5 hours; and carrying out cooling to normal temperature, sequentially carrying out washing with acidic water and pure water to neutrality, and carrying out drying to obtain the mesoporous carbon material. The preparation process of the method provided by the invention is simple, the solvent can be recycled, the preparation process is simple, the conditions are mild, and the pore structure of the mesoporous carbon material can be accurately controlled.

Owner:NANJING TECH UNIV

Method for preparing spherical active cardon with base of asphalt riched in mesopores

InactiveCN1247453CIncrease the rate of oxidation reactionsInhibition of contractionCarbon compoundsWorking-up pitch/asphalt/bitumenActivated carbonPetroleum

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

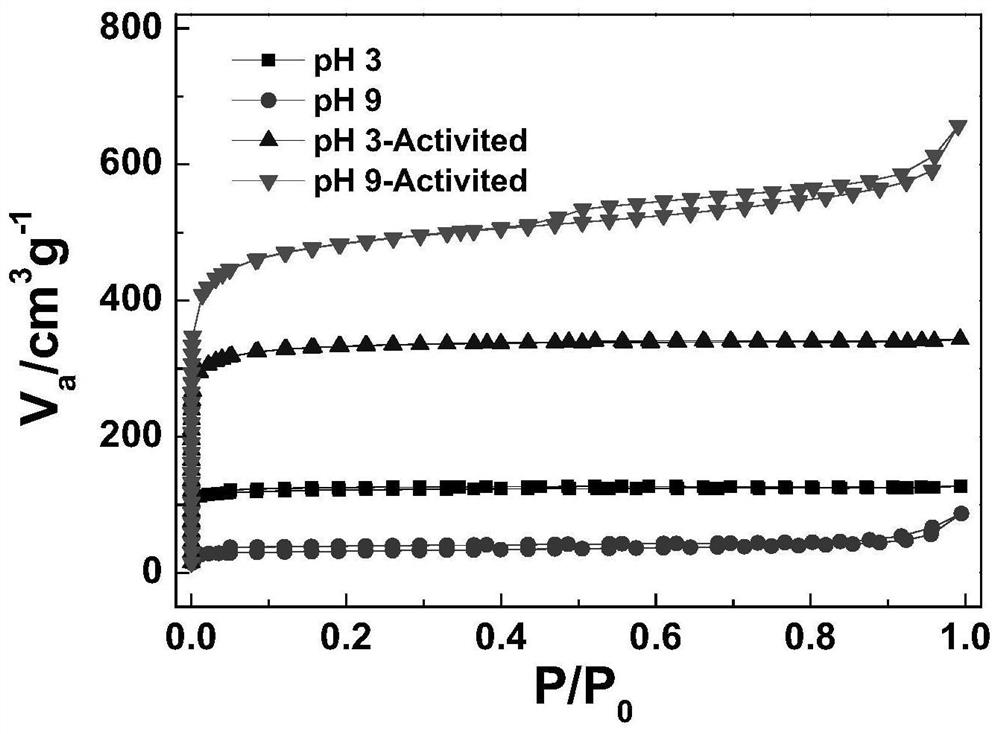

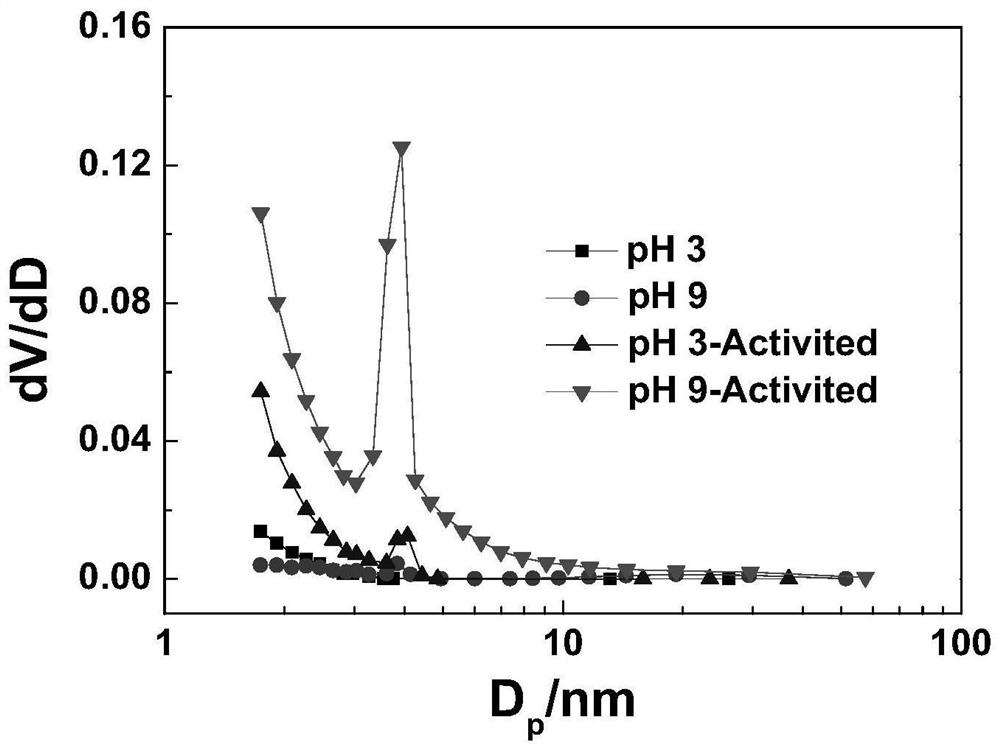

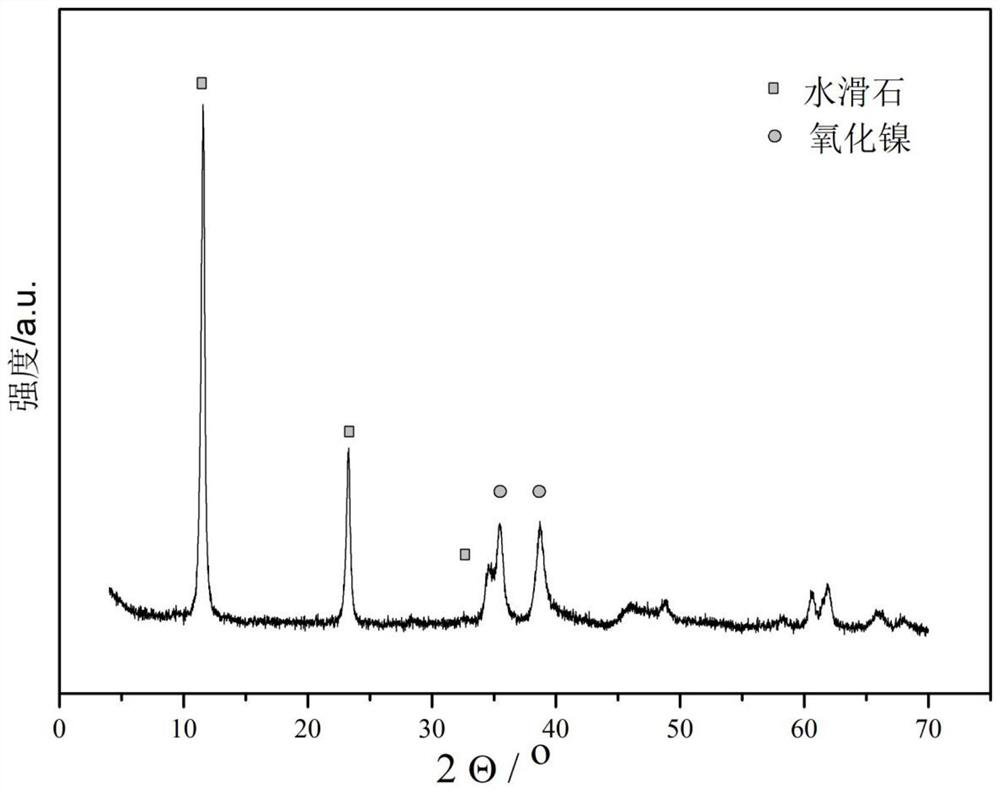

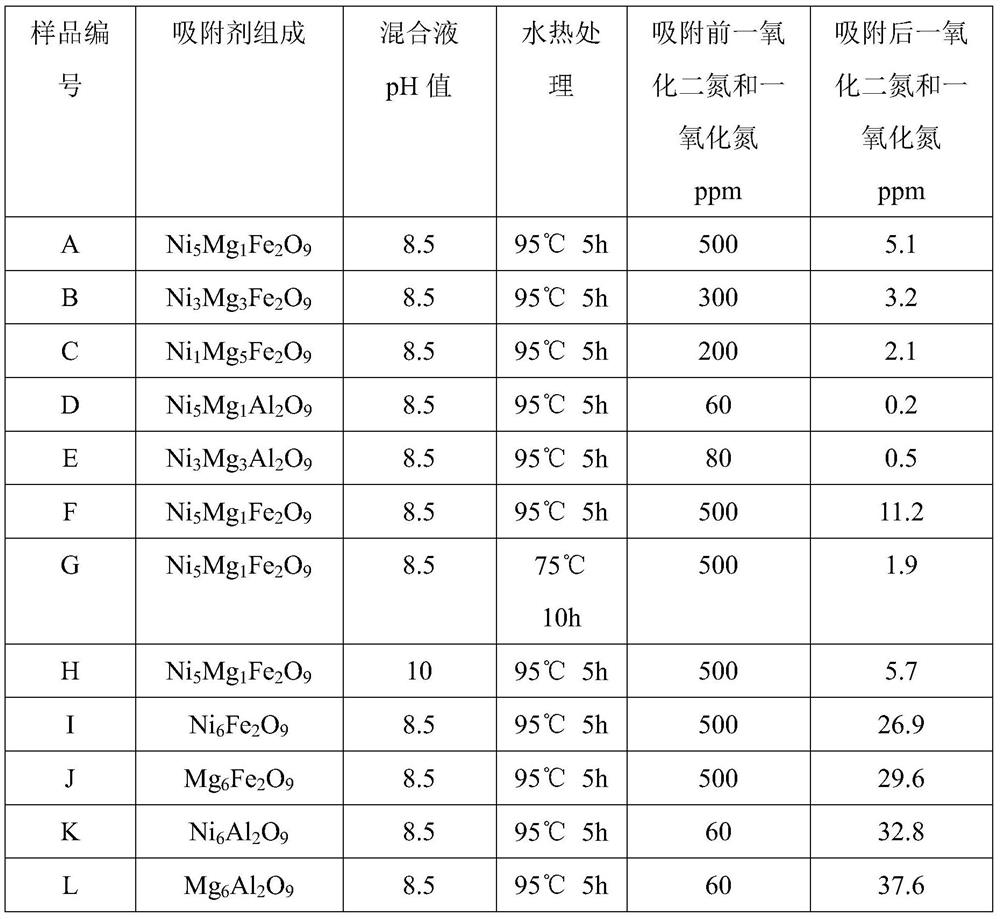

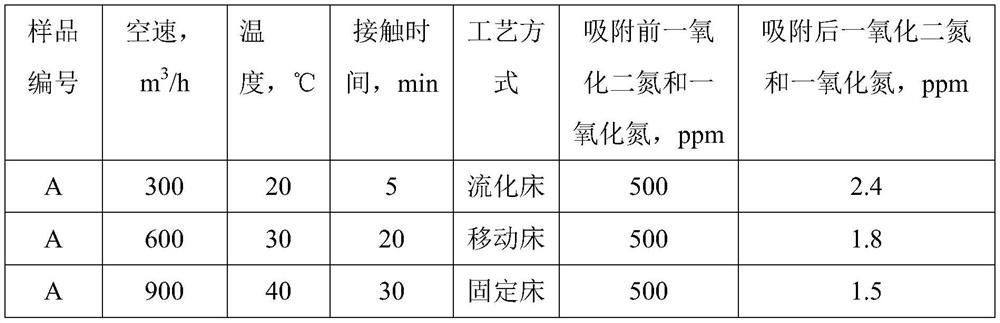

Adsorbent for removing nitric oxide in fluid as well as preparation method and application of adsorbent

ActiveCN112755953AReduce dosageFast adsorptionIon-exchange process apparatusNitrous oxide captureNitrogen oxidesSorbent

The invention discloses an adsorbent for removing nitric oxide in fluid as well as a preparation method and application of the adsorbent. The composition of the adsorbent is Ni<x> Mg<6-x>Fe<2>O<9> or Ni<x>Mg<6-x> Al<2>O<9>, wherein x is equal to 1-6. The preparation method of the adsorbent comprises the following steps of: dropwise adding an alkaline solution into a solution containing nickel, magnesium and iron or aluminum to carry out precipitation reaction, and then carrying out hydrothermal crystallization, drying, roasting and the like to obtain the adsorbent. The adsorbent has the characteristics of high efficiency of removing nitrogen oxide in fluid, simple preparation method, environment-friendly and pollution-free production process, simple operation and the like.

Owner:CHINA PETROLEUM & CHEM CORP +1

Corundum-mullite thermal insulation material and preparation method thereof

InactiveCN109437866AWide variety of sourcesReduce manufacturing costCeramicwareThermal insulationNeutral atmosphere

The invention relates to a corundum-mullite thermal insulation material and a preparation method thereof. The invention adopts the technical scheme comprising the following steps: uniformly mixing a corundum fine powder, a bauxite fine powder, aluminum hydroxide, a quartz sand fine powder, ammonium metavanadate and thermosetting phenolic resin, performing compression molding, performing thermal treatment for 3 to 5 hours in neutral atmosphere at 900 to 1200 DEG C, and performing breaking, ball milling and screening, so as to obtain ball milled materials and granules; mixing the ball milled materials, the corundum fine powder, the bauxite fine powder, ferrosilicon nitride, hydroxyethyl cellulose and water, and performing ball milling, so as to obtain slurry; then uniformly mixing the granules, the corundum fine powder, the ball milled materials and the slurry, performing compression molding, drying, and performing thermal insulation for 3 to 5 hours at 1400 to 1600 DEG C, so as to obtain the corundum-mullite thermal insulation material. The method is wide in material source and low in production cost, and the formed corundum-mullite thermal insulation material has the characteristics of low volume density, high strength and excellent thermal insulation performance.

Owner:WUHAN UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com