Synthesis method of tungsten nitride with high catalytic performance

A technology of catalytic performance and synthesis method, applied in nitrogen-metal/silicon/boron binary compounds, nanotechnology for materials and surface science, nanotechnology, etc., can solve the problems of high preparation cost and long preparation time, Achieve high reaction activity, improve catalytic performance, and increase heat treatment speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

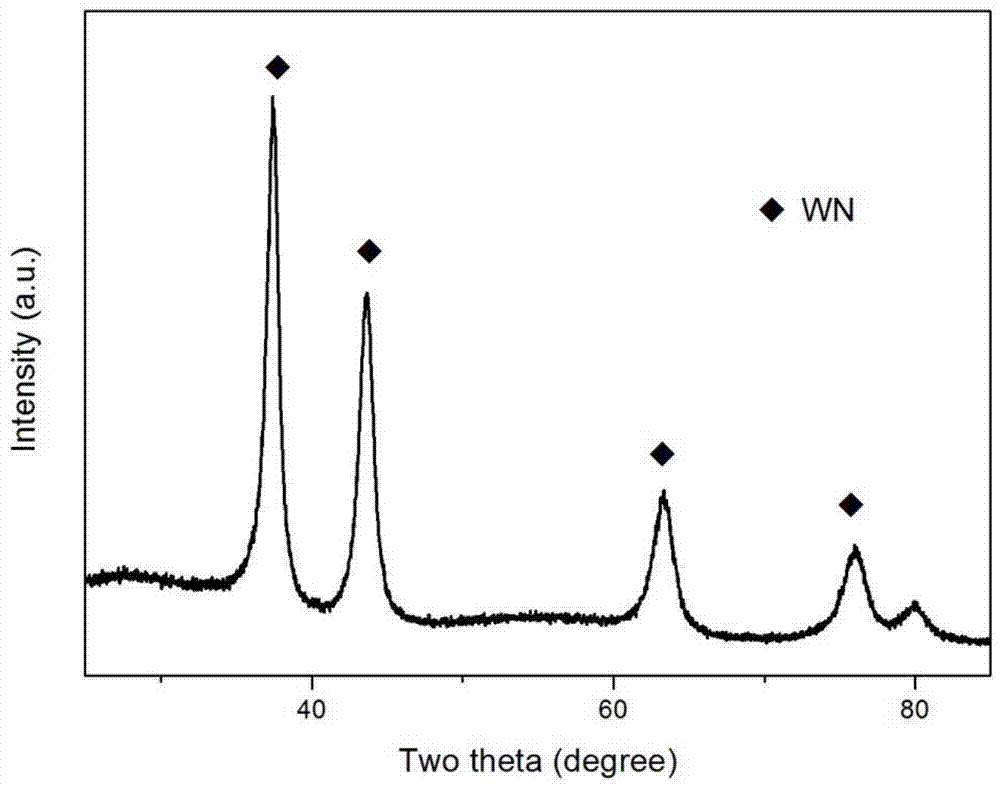

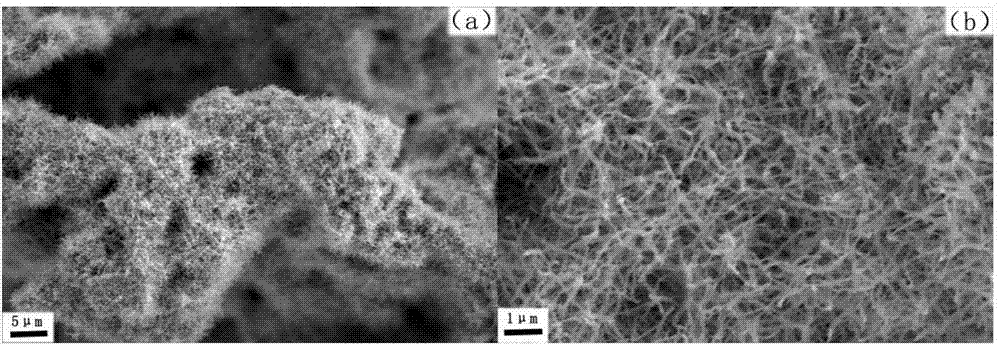

[0022] Weigh ammonium metatungstate ((NH 4 ) 6 h 2 W 12 o 40 )0.01mol, ammonium nitrate (NH 4 NO 3 )0.24mol, urea (CO(NH 2 ) 2 ) 0.072mol, ethylenediaminetetraacetic acid (EDTA) 0.005mol. Dissolve the raw material powder in an appropriate amount of deionized water and stir until completely dissolved, then heat at a constant temperature of 200°C, and react after the solution is evaporated to dryness to obtain the precursor tungsten oxide powder. Nitriding the precursor at 650°C in ammonia gas and keeping it warm for 2 hours to obtain tungsten nitride with a diameter of 30-80nm.

Embodiment 2

[0024] Weigh ammonium metatungstate ((NH 4 ) 6 h 2 W 12 o 40 )0.01mol, ammonium nitrate (NH 4 NO 3 )0.24mol, urea (CO(NH 2 ) 2 ) 0.072mol, ethylenediaminetetraacetic acid (EDTA) 0.005mol. Dissolve the raw material powder in an appropriate amount of deionized water and stir until completely dissolved, then heat at a constant temperature of 200°C, and react after the solution is evaporated to dryness to obtain the precursor tungsten oxide powder. Nitriding the precursor at 750°C in ammonia gas and keeping it warm for 2 hours to obtain tungsten nitride with a diameter of 30-100nm.

Embodiment 3

[0026] Weigh ammonium metatungstate ((NH 4 ) 6 h 2 W 12 o 40 )0.01mol, ammonium nitrate (NH 4 NO 3 )0.3mol, citric acid (C 6 h 8 o 7 ) 0.072mol, ethylenediaminetetraacetic acid (EDTA) 0.005mol. Dissolve the raw material powder in an appropriate amount of deionized water and stir until completely dissolved, then heat at a constant temperature of 200°C, and react after the solution is evaporated to dryness to obtain the precursor tungsten oxide foam. Nitriding the precursor at 900°C in ammonia gas and keeping it warm for 1 hour to obtain tungsten nitride with a diameter of 50-100nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com