Patents

Literature

147results about How to "Craft quick" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

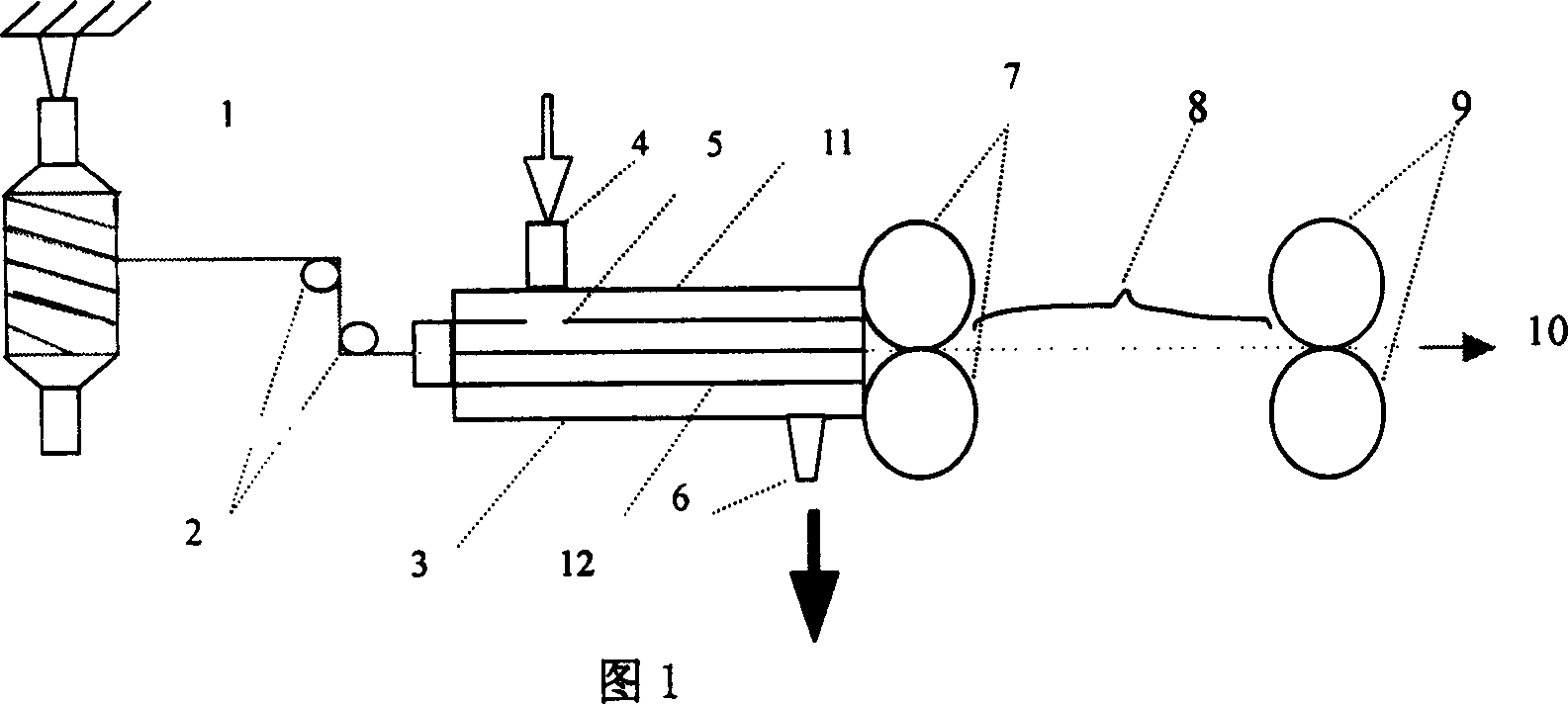

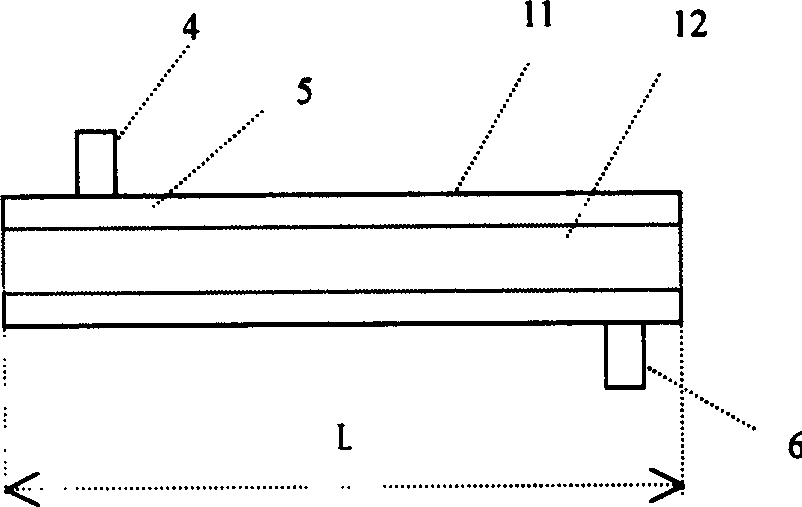

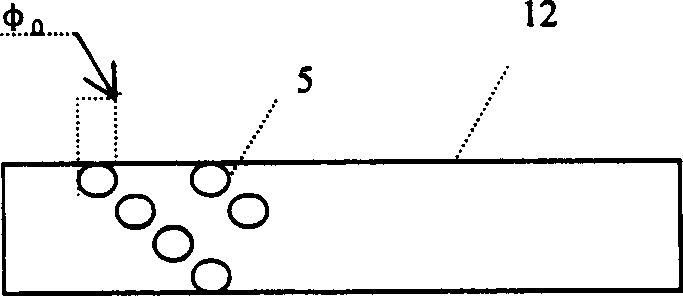

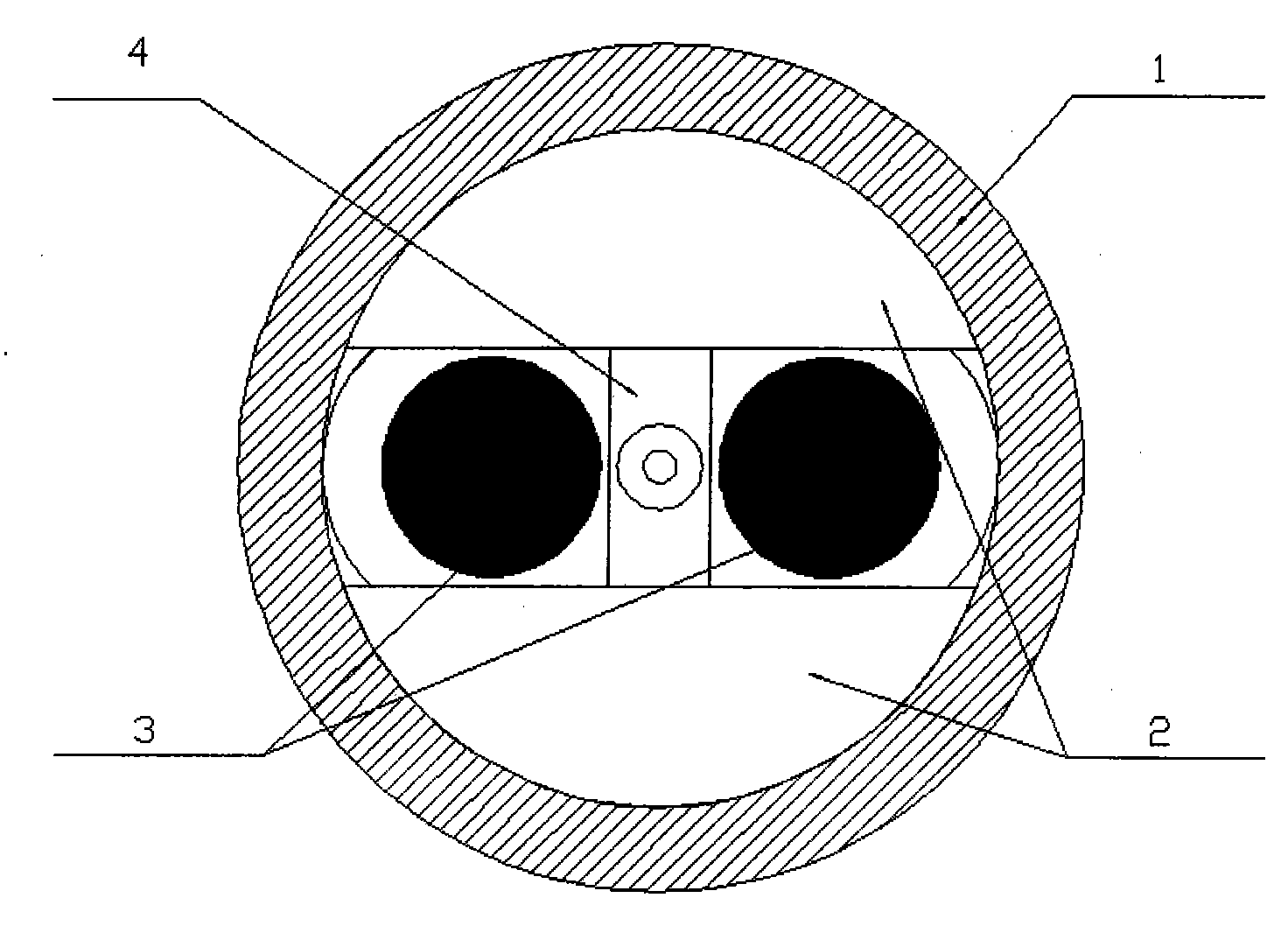

Method and device for improving fiber yarn forming performance

A method for improving the spinning performance of fibres features that the fibres are modified by a thermal shape-fixating equipment in their spinning procedure. Said thermal shape-fixating equipment is composed of internal tube and external tube. When the fibres pass through the internal tube, they are acted by high-temp steam to make their macro-molecular chains flexible and extended.

Owner:WUHAN TEXTILE UNIV

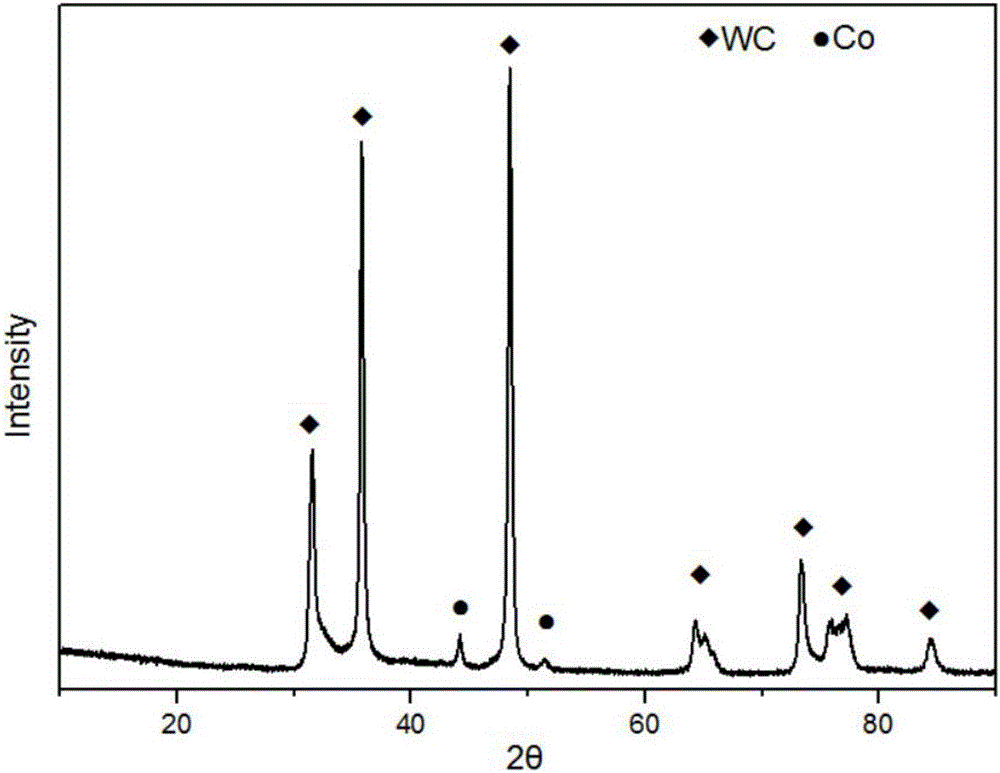

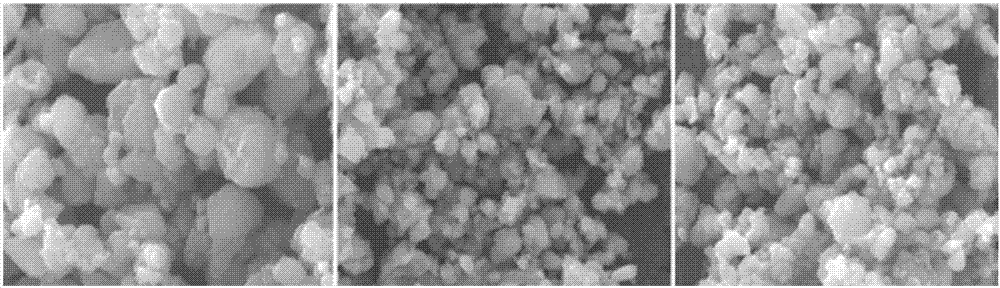

Preparation method of WC-Co nano powder added with grain growth inhibitor

The invention provides a preparation method of WC-Co nano powder added with a grain growth inhibitor, and belongs to the technical field of powder metallurgy and powder preparation. The preparation method comprises the following steps: ammonium metatungstate, cobalt nitrate, fuel, ammonium nitrate, metal salt with a needed amount of the added grain growth inhibitor and an organic carbon source are used as raw materials, and oxide / carbon composite powder is prepared by adopting a low-temperature combustion synthesis method; and then carbonization is carried out under atmosphere protection or vacuum to obtain the WC-Co nano powder mixed with the grain growth inhibitor. According to the preparation method, the low-temperature combustion synthesis method belongs to a liquid-phase synthesis method, molecular-level mixing is achieved, so that diffusion range of the carbon in the carbonization process is short, and the requirements for the reaction temperature requirement and the reaction time requirement are low; and in addition, the raw materials are simple to obtain, the equipment is simple, the process is fast, and large-scale production can be realized.

Owner:UNIV OF SCI & TECH BEIJING

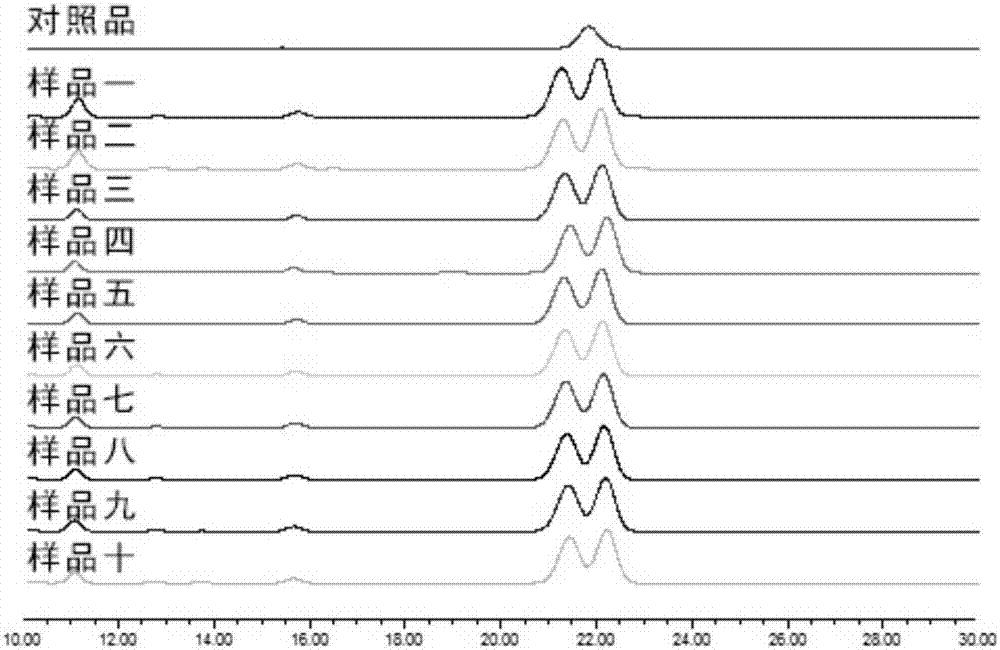

Semen armeniacae amarae formula granules as well as preparation and quality control methods thereof

InactiveCN107271589AAchieve quality controlReach the efficacyComponent separationGranular deliveryIsomerizationMedicine

The invention belongs to the technical field of traditional Chinese medicine formula granules and particularly relates to semen armeniacae amarae formula granules as well as preparation and quality control methods thereof. The L-amygdalin and D-amygdalin ratio range considering both the curative effect and safety (low toxicity) is determined through study on the ratio of L-amygdalin to D-amygdalin in classical prescription decoction containing semen armeniacae amarae, semen armeniacae amarae formula granule extraction process parameters capable of guaranteeing the L-amygdalin and D-amygdalin ratio range are determined through process purification, high performance liquid chromatography is used for quantitative analysis in the quality control method, the amygdalin isomerization course is controlled by regulating process parameters such as decoction water amount and decoction time for semen armeniacae amarae decoction pieces during preparation, the semen armeniacae amarae formula granules meeting the quality requirement are prepared and has the same effect with classical prescriptions, and quality control of the semen armeniacae amarae formula granules is realized.

Owner:安徽九洲方圆制药有限公司

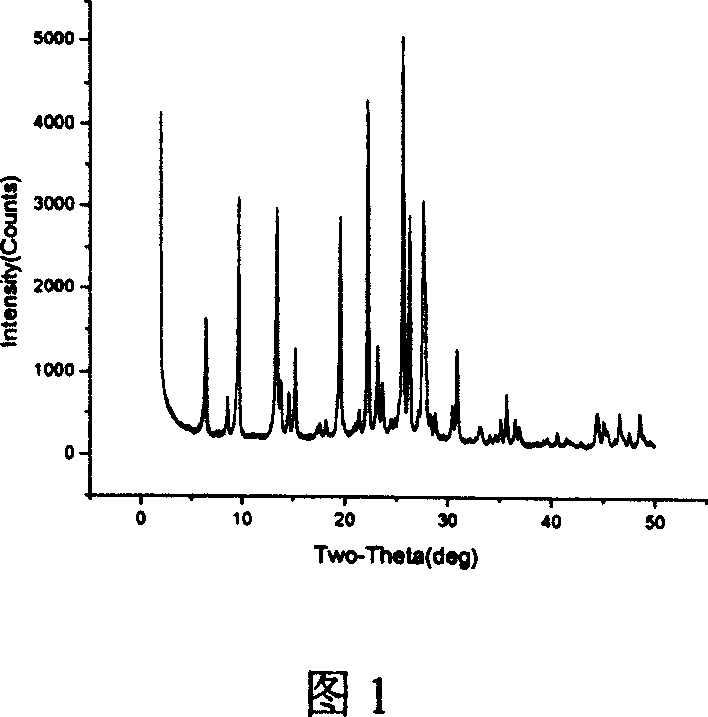

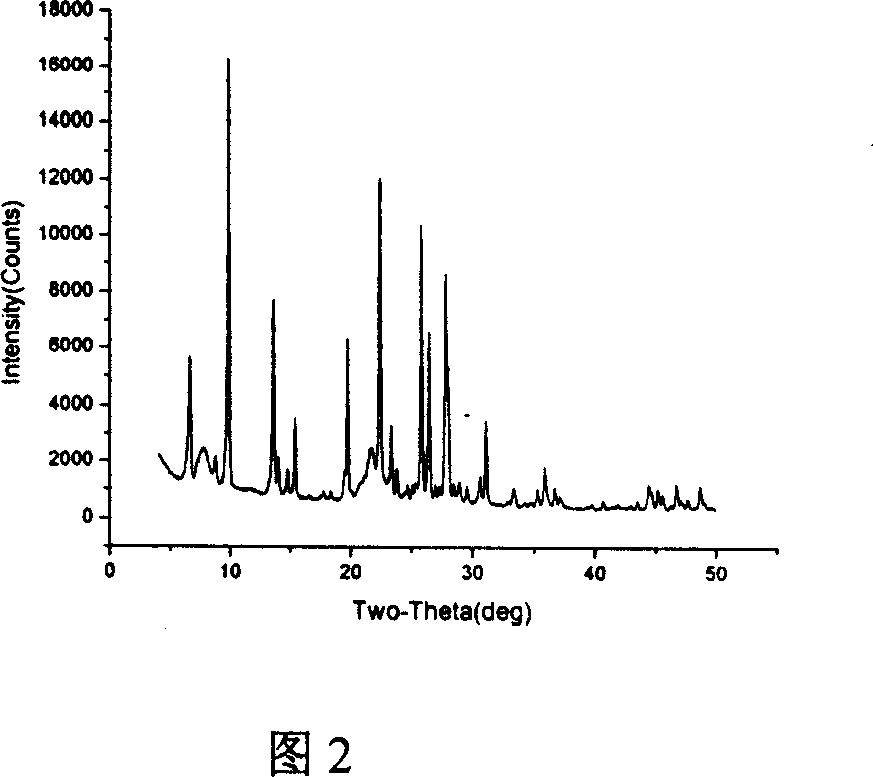

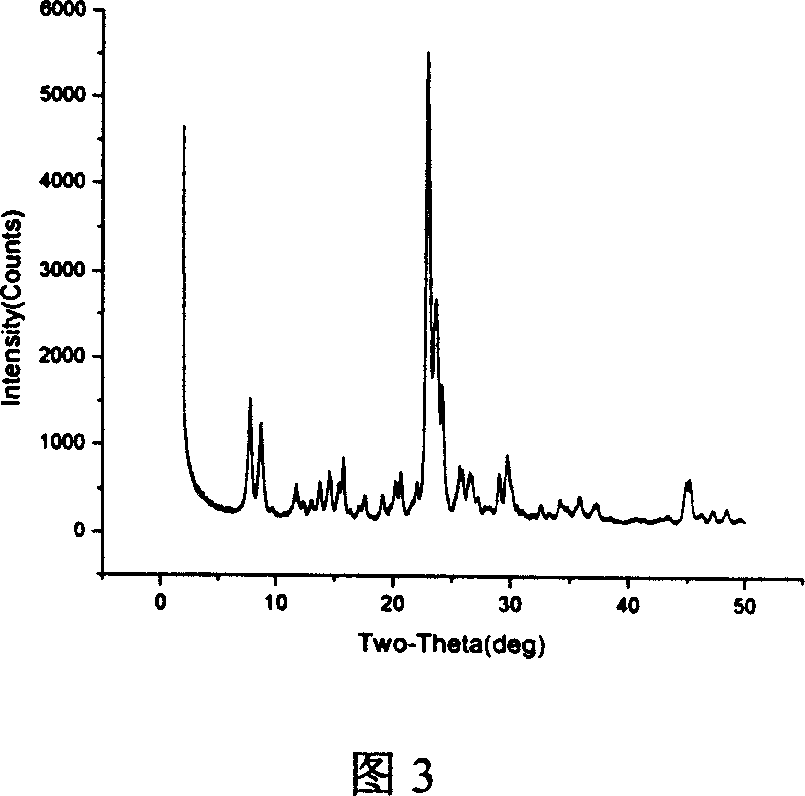

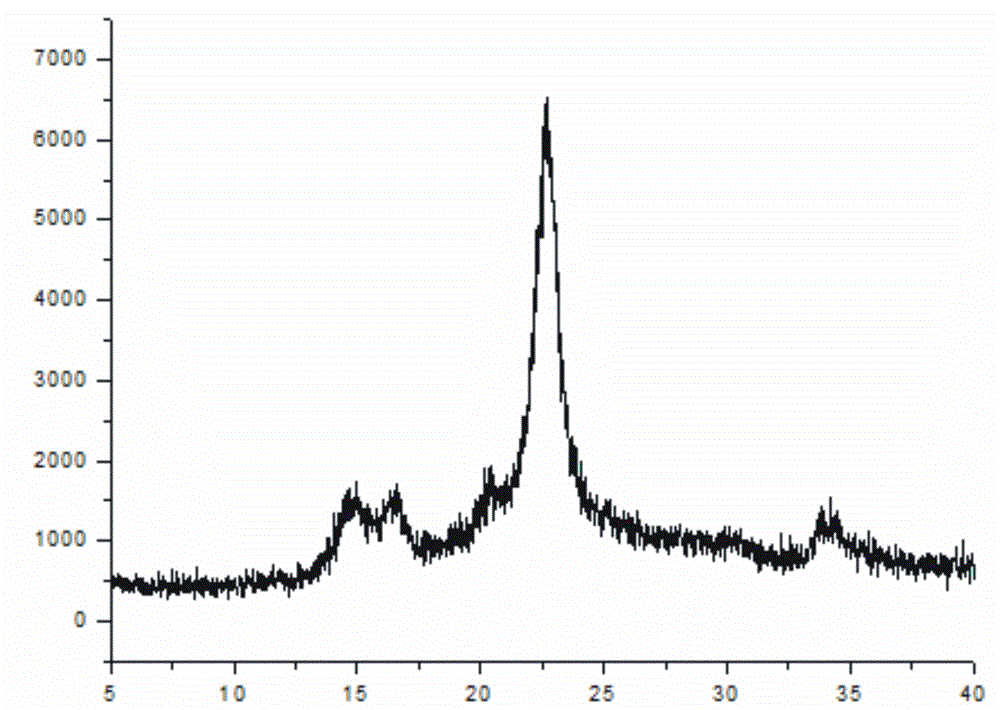

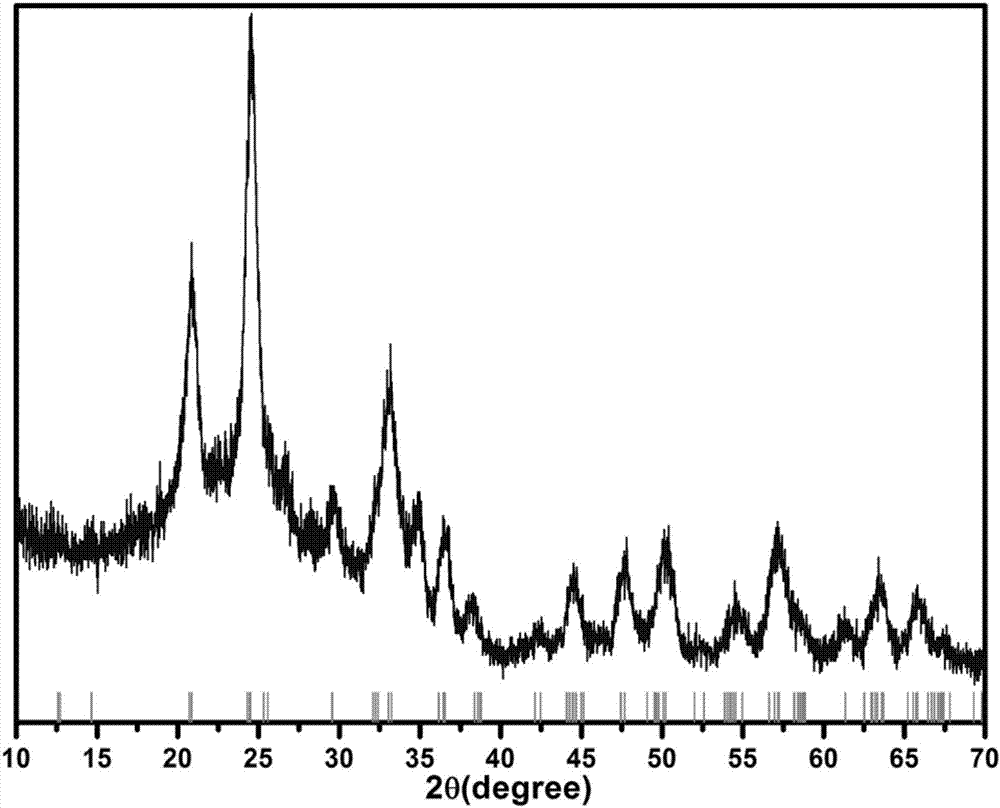

Synthesis method for zeolite

InactiveCN101033071AHigh yieldAvoid lostMordenite aluminosilicate zeoliteSynthesis methodsCombinatorial chemistry

Owner:BEIJING UNIV OF CHEM TECH

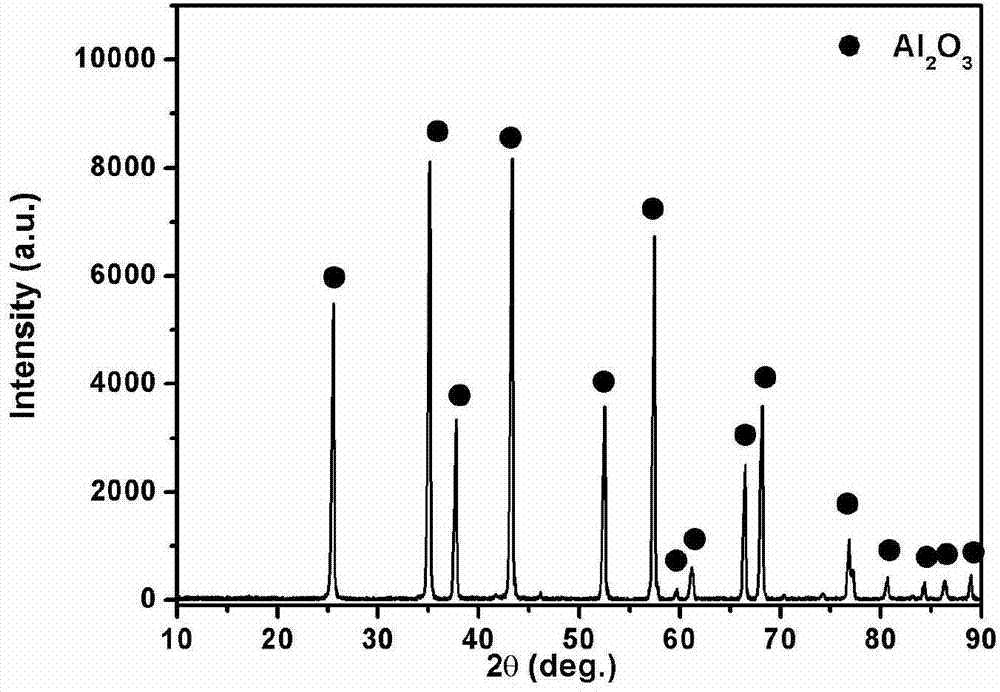

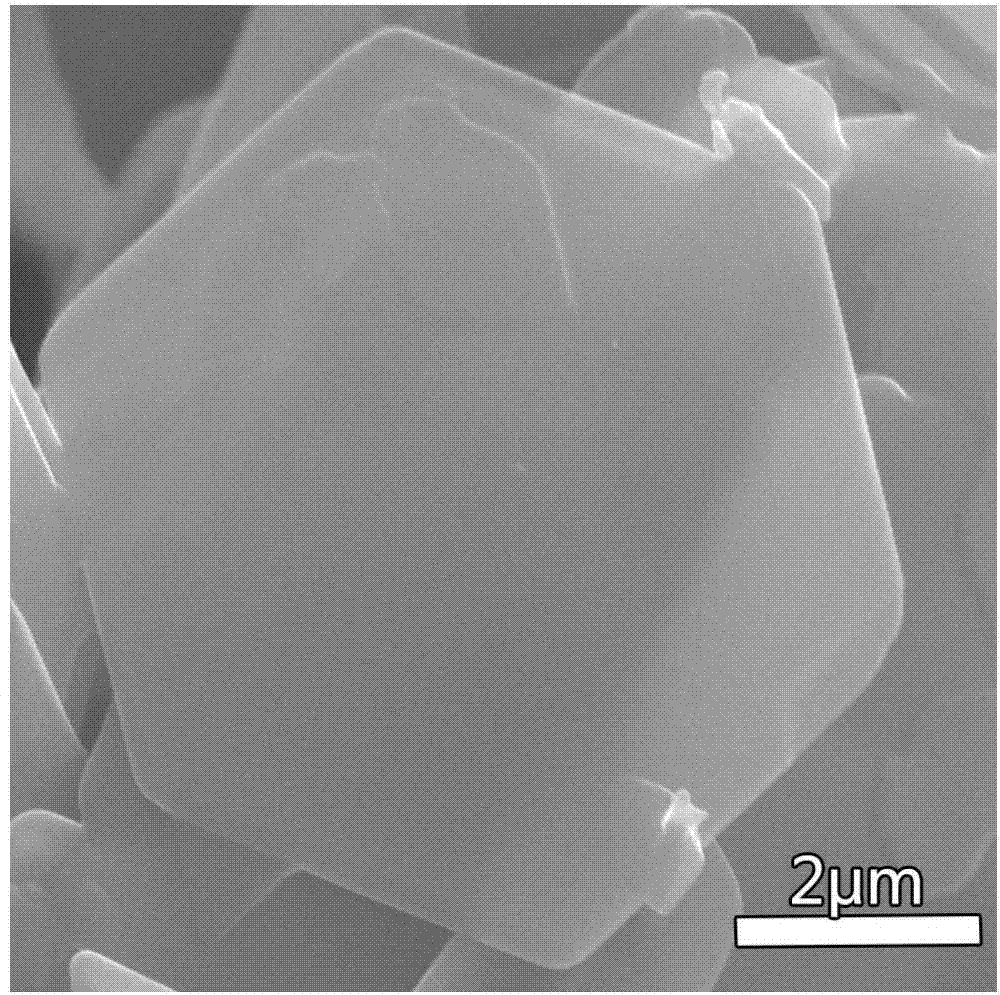

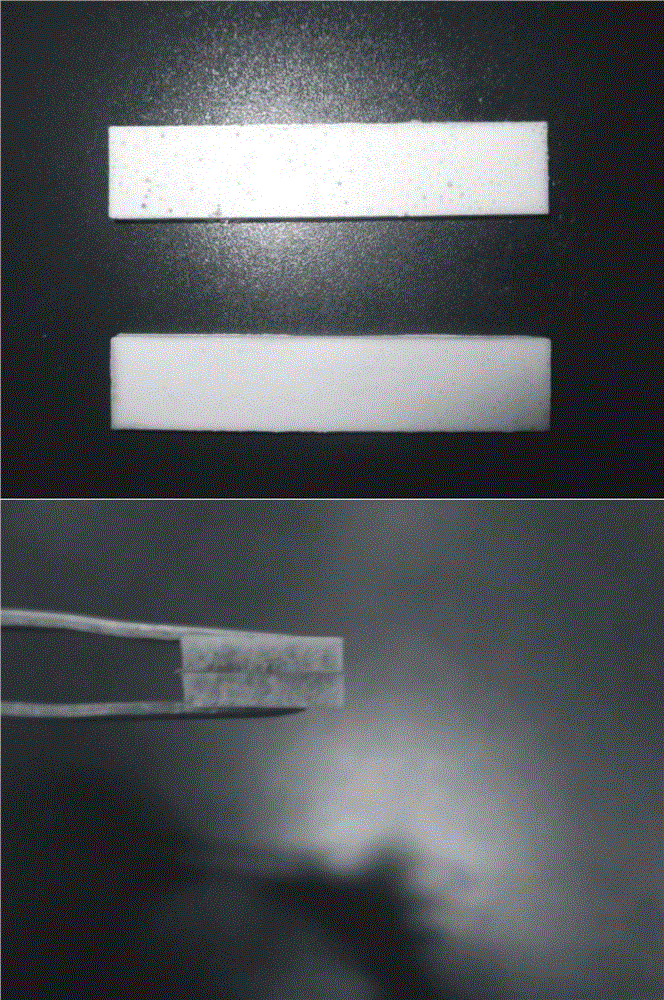

Preparation method of flaky alumina

ActiveCN104724741ASimple processCraft quickAluminium oxides/hydroxidesAir atmosphereMaterials preparation

The invention discloses a preparation method of a flaky alumina and belongs to the technical field of ceramic powder material preparation. The preparation method mainly comprises the following steps: preparing a solution from such raw materials as an aluminum source, an amine organic matter and an assistant agent in a certain ratio, heating and stirring, and pyrolyzing after the solution is volatilized and concentrated to obtain a precursor powder; and putting the precursor powder in a flowing air atmosphere at 800-1700 DEG C for reacting for 2-4 hours, and finally obtaining the flaky alumina having the particle size of 3-8 microns and the diameter-to-thickness ratio of 25-80. The preparation method of the flaky alumina is simple in equipment, short in process period, high in efficiency and low in cost.

Owner:UNIV OF SCI & TECH BEIJING

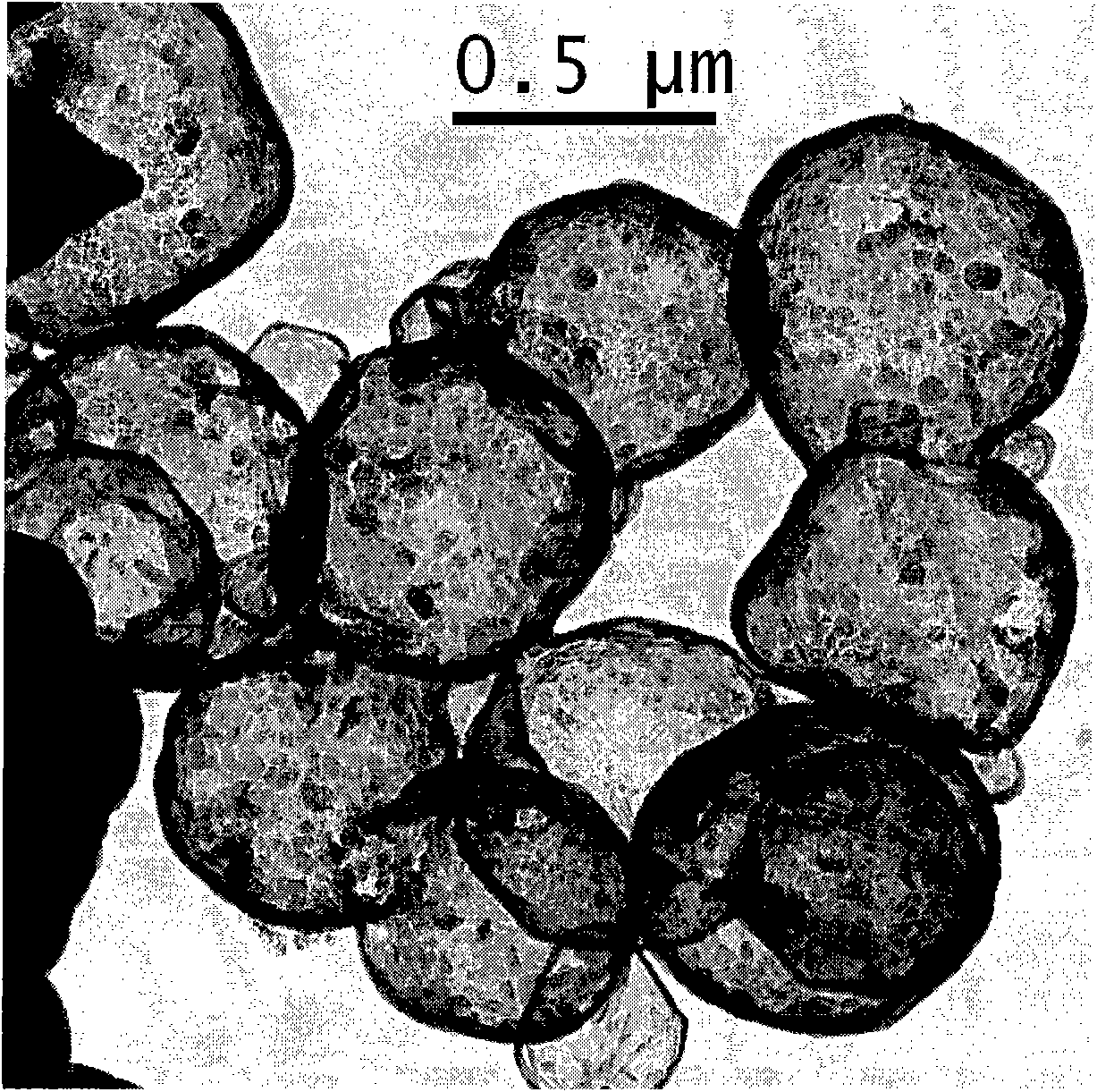

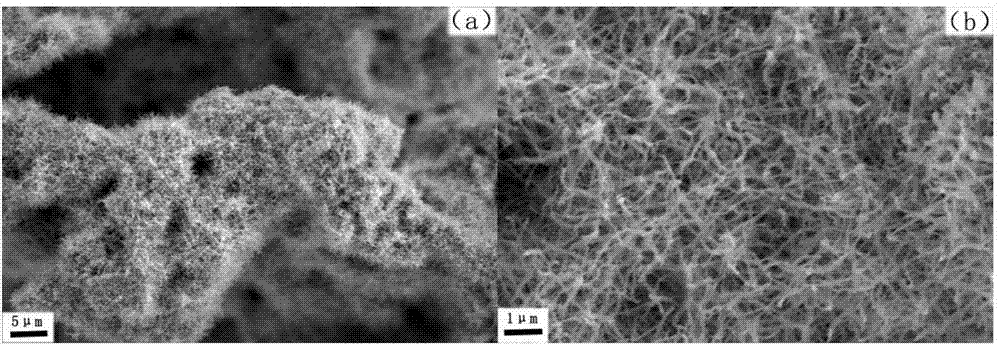

Preparation method of high-graphitized nanometer carbon material

InactiveCN101559938AHigh degree of graphitizationParticle size controllableNanostructure manufactureMicrowave ovenCarbon nanotube

The invention relates to a preparation method of a high-graphitized nanometer carbon material. The method comprises the following steps: (1), uniformly mixing magnetic metal or metal oxide particles with a solid organic carbon precursor material, wherein the magnetic metal or metal oxide particles in the mixture account for 10 to 80 percent of the total weight; and (2) putting the mixture in a microwave oven and processing in microwave for 3 seconds or longer under the microwave power of 300W to 3000W so as to obtain carbon-wrapped magnetic metal nanometer particles or a multi-wall carbon nanometer pipe material. The prepared carbon material has high graphitization degree, controllable grain diameter and thickness, simple technology, low preparation cost, high product purity, wide selective raw material range and easy mass preparation.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

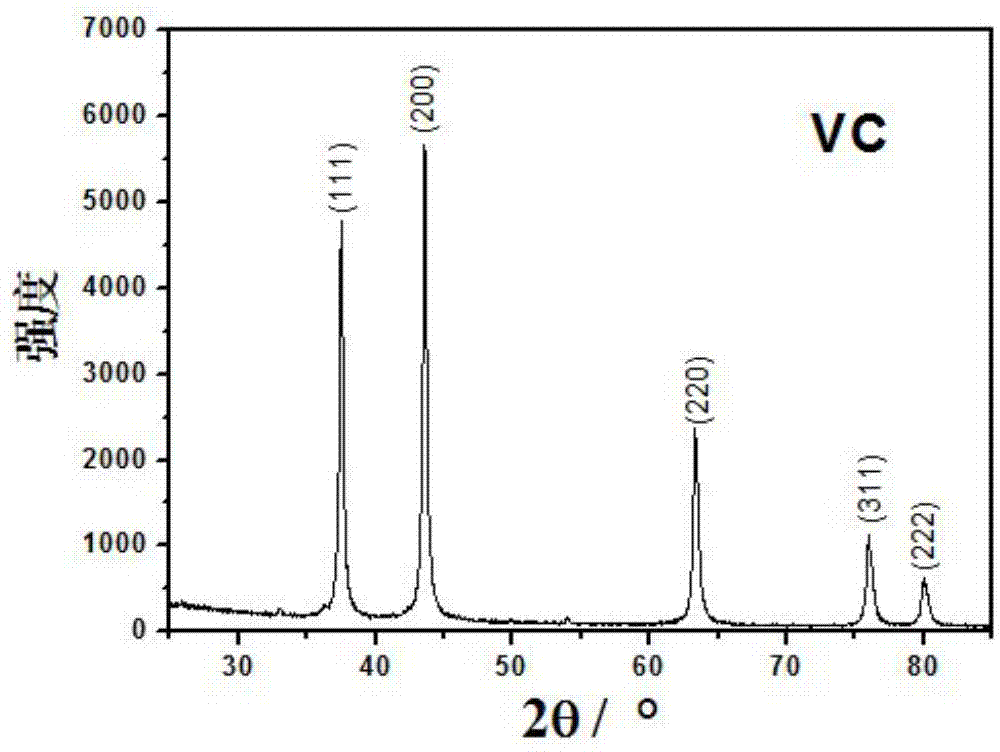

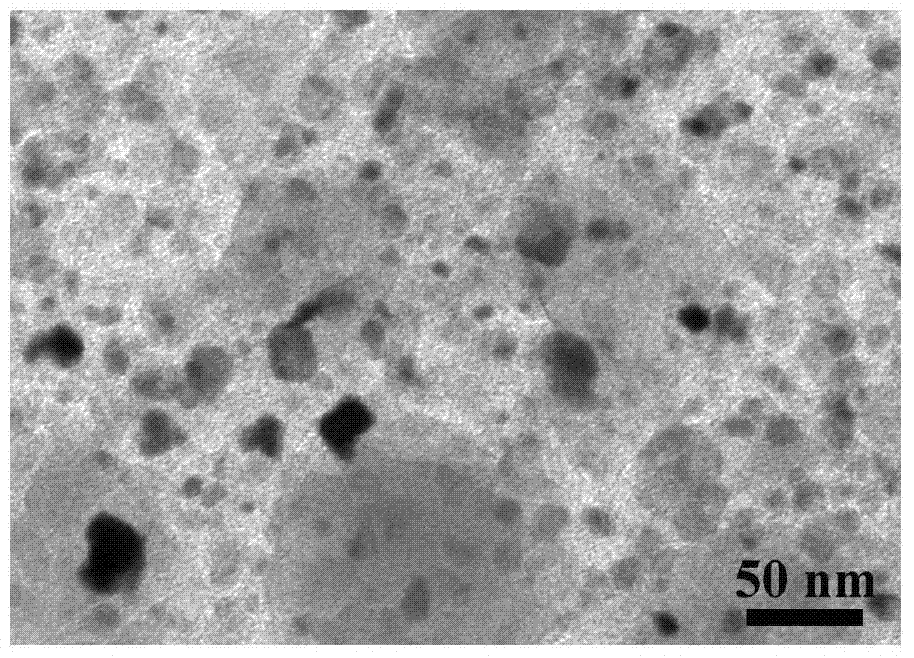

Method for producing nano-sized vanadium carbide powder

The invention relates to a method for producing nano-sized vanadium carbide powder, belonging to the technical field of preparing ceramic powder. The method comprises the following processes: (1) mixing a vanadium source, a carbon source and an auxiliary into a solution according to a certain proportion; (2) heating the solution, so that the solution is volatilized, concentrated and decomposed to obtain precursor powder containing the vanadium source and the carbon source; and (3) reacting the precursor powder for 1-5 hours at the temperature of 700-1300 DEG C under certain atmosphere. The method is simple in technology, low in cost, and easy to industrialize, and the obtained vanadium carbide powder has a particle size of less than 50nm, and good dispersity.

Owner:UNIV OF SCI & TECH BEIJING

Biberberine for injection as veterinary herb medicine composite preparation and preparation technique and use thereof

ActiveCN101417008ASignificant contributionSimple processAntibacterial agentsAntipyreticCompounded preparationsRespiratory disturbances

The invention relates to a double coptis for injection as a veterinary herbal medicine compound preparation and a preparation technique as well as an application thereof. The compound preparation is made from the following parts of medicines by weight: 1250 portions to 3750 portions of honeysuckle, 1250 portions to 3750 portions of scutellaria and 2500 portions to 7500 portions of forsythia. Sustained release accessories contain 200 portions of hydroxypropyl methylcellulose and 100 portions of sodium carboxymethylcellulose. The containing of sustained release accessories can reduce injection times for large animals and the stress response of large animals. The veterinary herbal injection preparation has the functions of antiviral, antibacterial, anti-inflammatory and antipyretic analgesic effects, as well as improving immunity and the like, and can be applied to epidemic diarrhea, transmissible gastroenteritis, swine paratyphoid, septicemia caused by various diseases, cough, dyspnea, skin cyanosis, arthrocele, lameness, swine reproduction and respiratory disturbance syndrome and cow mastitis caused by streptococcosis, haemophilus parasuis infection, contagious pleuropneumonia, swine lung plague in veterinarian clinical practice.

Owner:JIANGXI ZHONGCHENG MEDICINE GROUP

Long-acting antibacterial multifunctional coating based on bionic dopamine as well as preparation method and application thereof

PendingCN112717207AImprove stabilityImprove the bactericidal effectSurgeryPharmaceutical containersAnti bacteriaDopamine

The invention provides a long-acting antibacterial multifunctional coating based on bionic dopamine as well as a preparation method and an application thereof. The preparation method comprises the following steps: carrying out ultrasonic cleaning on a base material by using acetone, absolute ethyl alcohol and ultrapure water in sequence; immersing the obtained base material into dopamine rapid deposition liquid for reaction to obtain a base material coated with a polydopamine coating; washing the obtained base material with deionized water, and drying; soaking the obtained base material in a multifunctional coating aqueous solution for reaction, and obtaining a functional coating on the surface of the base material; washing the obtained base material with ultrapure water and then drying; wherein Cu<2+> and H2O2 are dissolved in the dopamine rapid deposition liquid, and the multifunctional coating aqueous solution contains a hydrophilic polymer or a zwitterionic polymer. The preparation process is simple, conditions are mild, deposition preparation time is greatly shortened, and the method is suitable for large-scale industrial production.

Owner:SHANDONG UNIV

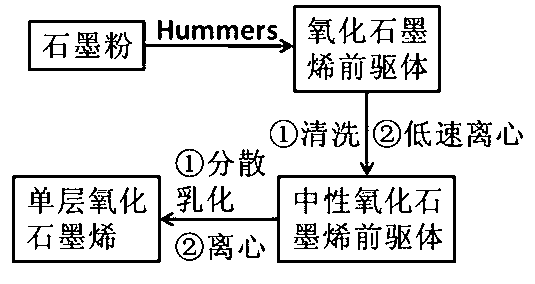

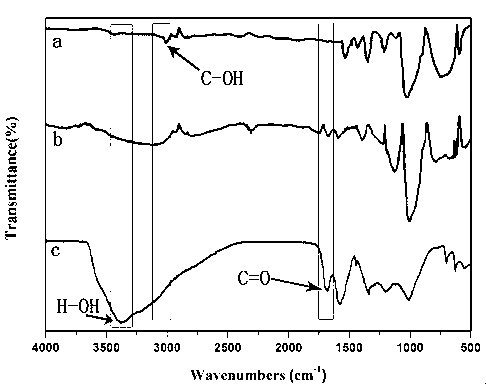

Method for preparing graphene oxide by dispersed emulsion assisted with Hummers method

InactiveCN102701199AReduce the number of layersSimple processCarbon compoundsEmulsionMonolayer graphene

The invention discloses a method for preparing graphene oxide by dispersed emulsion assisted with a Hummers method. The method comprises the following steps of: firstly preparing graphene oxide precursor suspending liquid by adopting the Hummers method, repeatedly washing the graphene oxide precursor suspending liquid with ultrapure water and centrifuging at a low speed to obtain neutral graphene oxide precursor, finally dispersing the neutral graphene oxide precursor into the ultrapure water, and dispersing the neutral graphene oxide precursor by a laboratory dispersed emulsifying machine at a high speed so as to improve the interlamellar spacing of grapheme, thus finally obtaining monolayer graphene oxide by low-speed centrifugation. The process is simple, fast, safe and environment-friendly and is conducive to large-scale industrial production, and the number of layers of the graphene oxide can be effectively reduced. The prepared graphene oxide can be used as a drug carrier and mechanics enhancement phase of a composite material and can be used for preparing high drug carrying or high mechanical property miniature oxidation graphite-base composite materials. A reduction product of the grapheme can be widely used for preparing grapheme-base complex materials of energy storage materials, chemical / biologic sensors, conductive materials, and the like.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

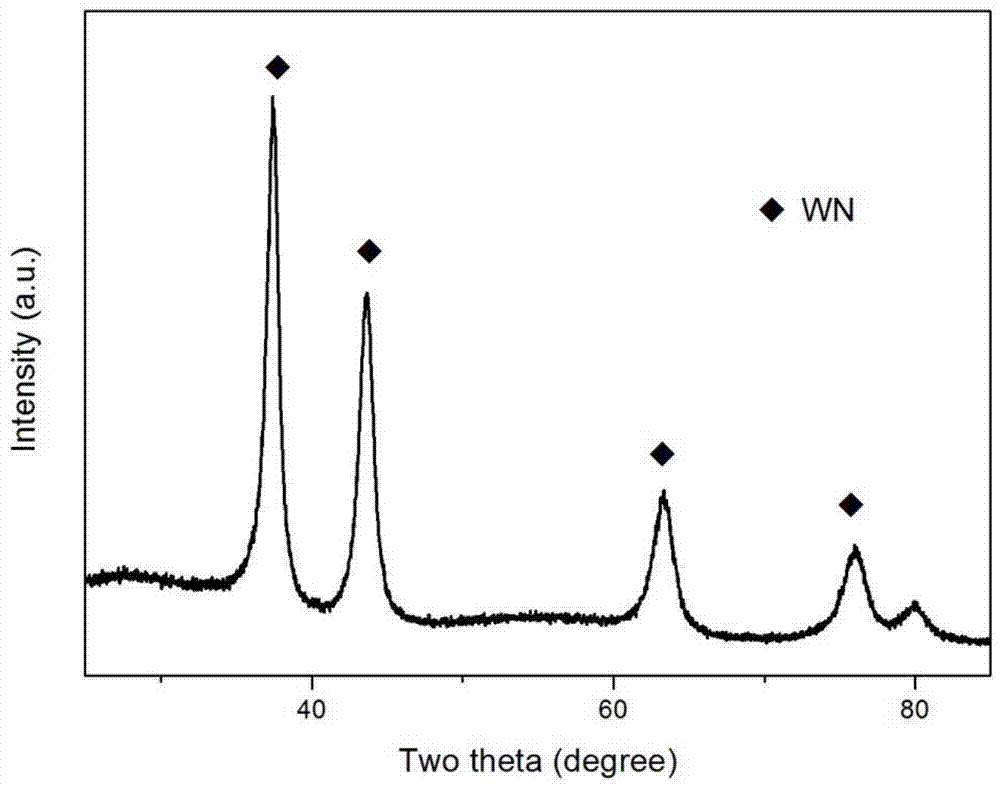

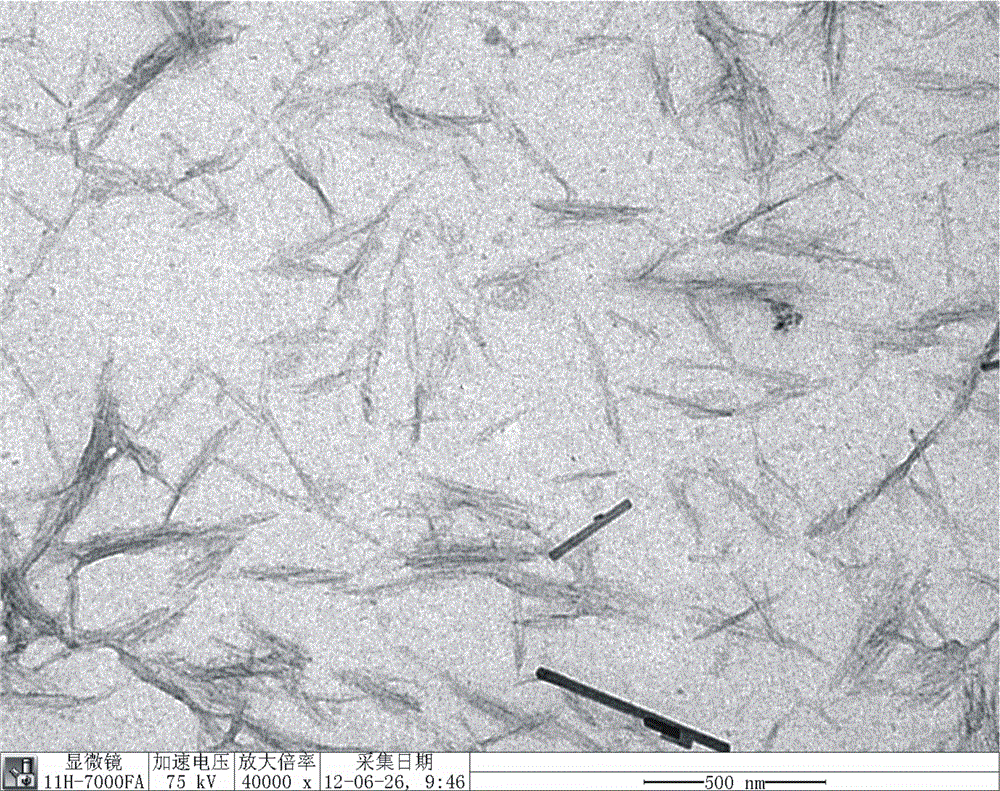

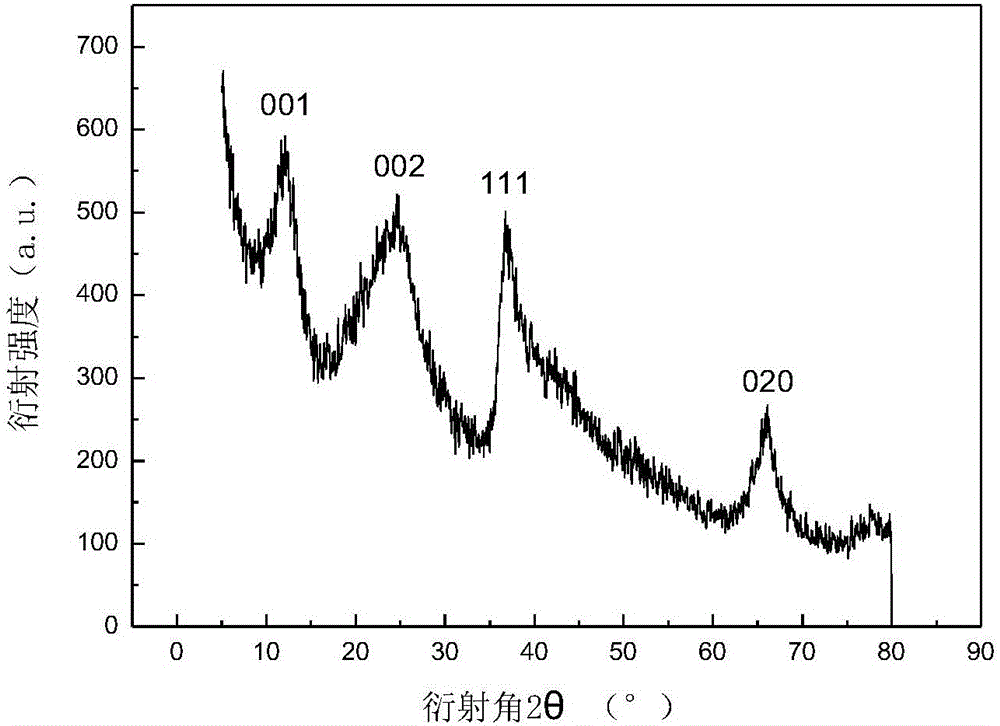

Synthesis method of tungsten nitride with high catalytic performance

ActiveCN104743529AShort processLow costMaterial nanotechnologyNitrogen-metal/silicon/boron binary compoundsSynthesis methodsTungsten nitride

The invention discloses a method for preparing nano tungsten nitride, belonging to the technical field of powder metallurgy preparation. The method comprises the following steps: synthesizing and preparing a tungsten oxide precursor through a solution method; and nitriding the tungsten oxide precursor in ammonia gas to obtain nanocrystalline tungsten nitride powder, wherein the particle size of the powder is 30-120nm. By virtue of the method disclosed by the invention, the problems that ultrafine nanocrystalline powder can be difficultly prepared by a traditional preparation method and the preparation time is long in the traditional preparation method can be solved. The tungsten nitride powder prepared by using the method disclosed by the invention is controllable in particle size, low in cost and high in utilization rate of raw material powder and has remarkable catalytic performance.

Owner:UNIV OF SCI & TECH BEIJING

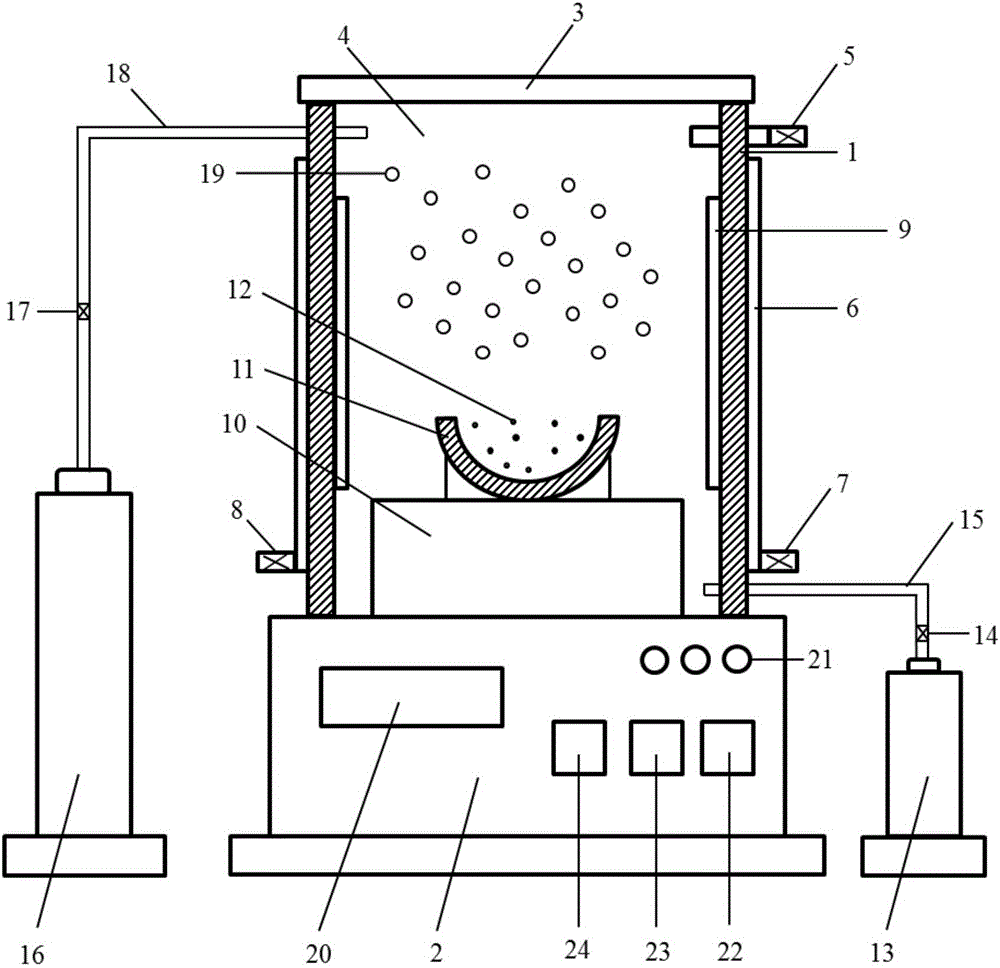

Method for preparing rare earth oxide doped tungsten and molybdenum spherical powder for 3D printing

PendingCN110722171AEvenly dispersedSmall particlesAdditive manufacturing apparatusTransportation and packagingSpray GranulationSolution combustion

The invention provides a method for preparing rare earth oxide doped tungsten and molybdenum spherical powder for 3D printing, and belongs to the technical field of powder metallurgy powder preparing.According to the specific preparing method, a low-temperature solution combustion synthesizing method is adopted for preparing rare earth oxide / tungsten oxide (molybdenum oxide) composite powder, then, hydrogen reduction is conducted to obtain rare earth oxide doped nano tungsten (molybdenum) powder, then, atomizing granulation equipment is used for granulating nano powder, and after the nano powder is roasted, ground and screened, the spherical tungsten (molybdenum) powder for 3D printing can be obtained. Raw materials are simple and easy to obtain, the equipment is simple, the technology israpid, a large number of products can be prepared within the short time, and the method is suitable for large-scale production. The rare earth oxide in the prepared tungsten and molybdenum sphericalpowder can be evenly scattered, particles are fine, oxide particle segregation cannot happen, and the rare earth oxide adding amount can be adjusted through the low-temperature solution combustion synthesizing process. The prepared tungsten and molybdenum spherical powder is excellent in sphericity degree and mobility and is extremely suitable for the 3D printing technology.

Owner:UNIV OF SCI & TECH BEIJING

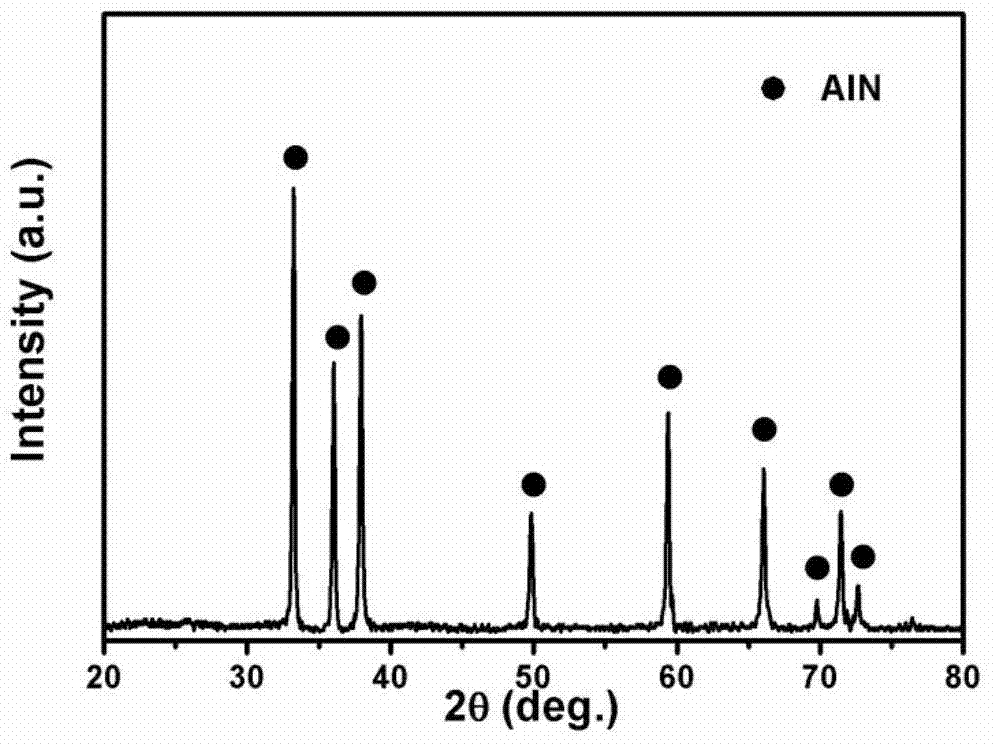

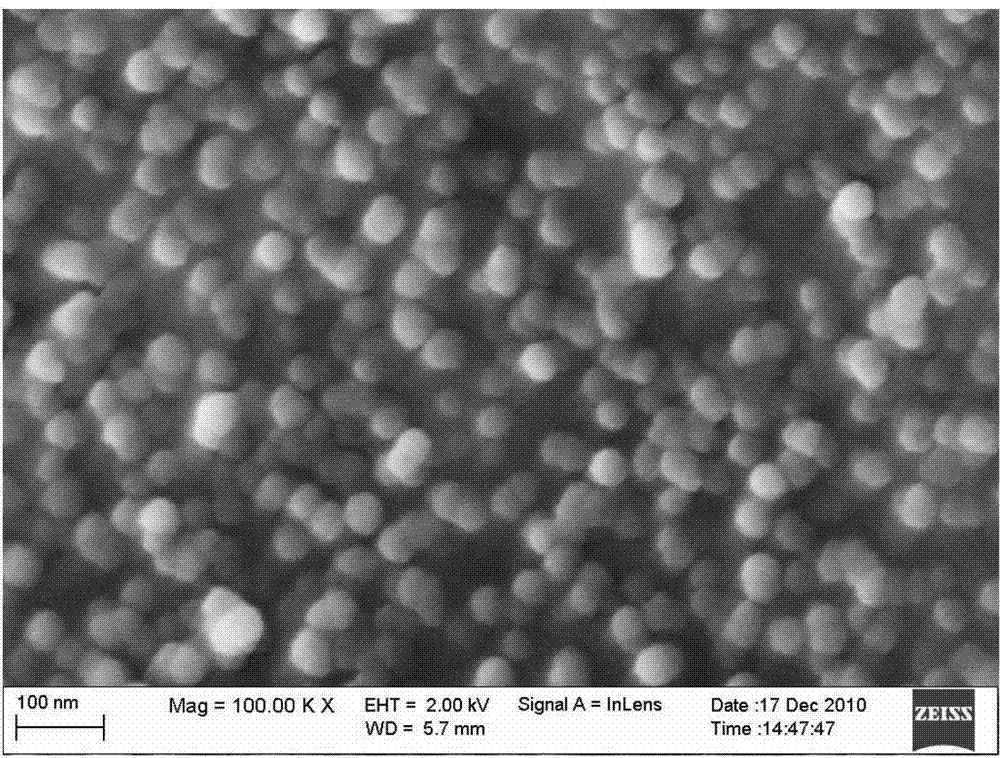

Preparation method of nano aluminium nitride powder

The invention discloses a preparation method of nano aluminium nitride powder, belonging to the technical field of nano material preparation. The preparation method comprises the following steps: preparing a solution according to a certain proportion by adopting aluminium sources, water-soluble carbon sources and assistant agents as raw materials; heating the solution, so that the solution is decomposed after being volatilized and concentrated, thus obtaining precursor powder; reacting the precursor powder in a certain atmosphere at 1200-1800 DEG C for 1-5 hours; treating the powder after reaction in the air at 500-800 DEG C for 1-3 hours, thus obtaining the nano aluminium nitride powder. The preparation method is simple in process and low in cost and can be used for obtaining the nano aluminium nitride powder which has good degree of sphericity and dispersibility and has a particle size smaller than 50nm.

Owner:UNIV OF SCI & TECH BEIJING

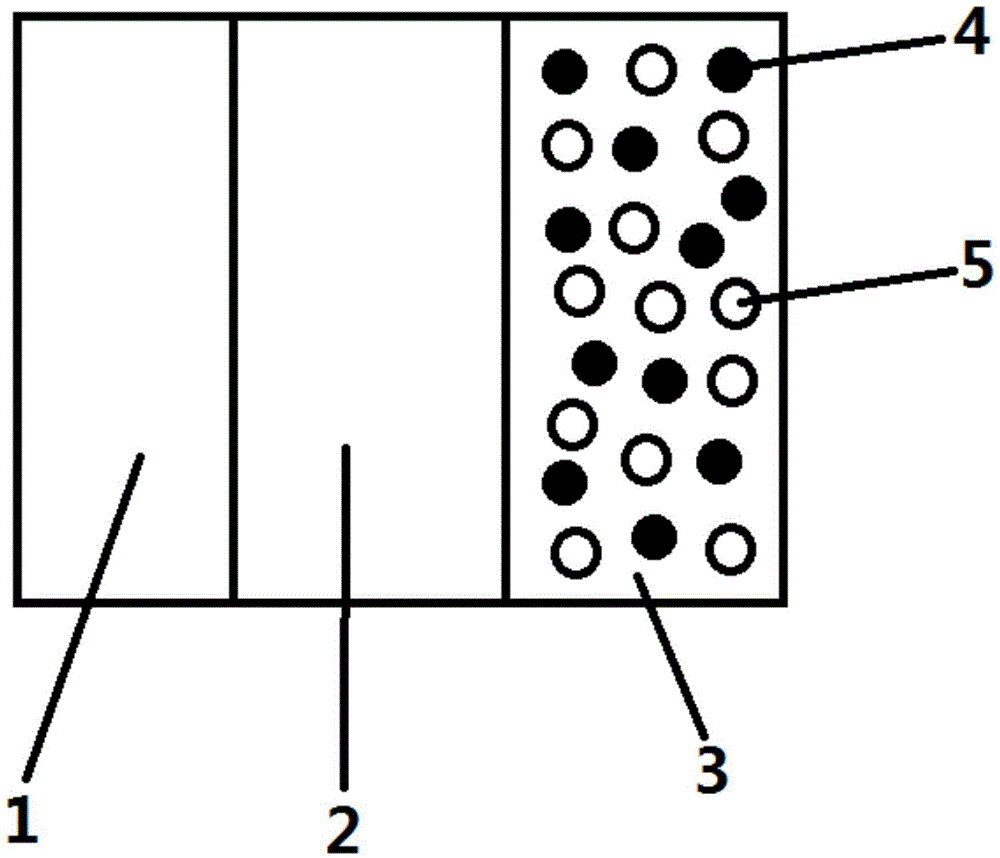

Composite type air filter screen and preparation method thereof

InactiveCN105521664AGood filtering effectGuaranteed use effectDispersed particle filtrationTransportation and packagingComposite structureEngineering

The invention provides a composite type air filter screen and a preparation method thereof. The composite type air filter screen includes a primary-efficiency filter screen, a particulate filter screen and a smell filter screen; the primary-efficiency filter screen, the particulate filter screen and the smell filter screen are sequentially connected to form the composite type air filter screen; the composite type air filter screen is provided with a lifetime indicating device. The composite type air filter screen allows the primary-efficiency filter screen, the particulate filter screen and the smell filter screen to be composited and superimposed to form a composite structure with three-layer filtration, and thus the filter effect is significant; moreover, the composite type air filter screen also is provided with the lifetime indicating device, so that the purification effect and the lifetime state of the composite type filter screen can be reflected in real time, a user can determine whether the filter screen needs to be replaced according to needs, and the use effect and user experience are ensured. The preparation method of the composite type air filter screen has the advantages of simple and fast process, and convenience for mass production.

Owner:HANGZHOU WEIDAI ENVIRONMENT TECH CO LTD

Method for preparing sianchau particle medicinal granules with multiple health care functions

InactiveCN101244120ANo pollution in the processRaw materials are cheap and easy to getMetabolism disorderDigestive systemCelsius DegreeRotary evaporator

The invention discloses a method for making an immortal grass granule with various health-caring functions. The steps are as follows: 1) Extracting the function ingredients: (1) Cut the whole immortal grass into grass segments the lengths of which are less than two centimeters; (2) Add 5 percent sodium carbonate (weight percentage) ethanol water with the volume fraction as 60 to 70 percent to the grass segments to lixiviate and the liquid-to-solid ratio is 18:1. Lixiviate continuously for three times after heating up to 70 to 80 degrees Celsius with three hours respectively for the first two times and one hour for the last time. Add a right amount of water to the lixiviating process in order to control the concentration of the filtrate, use a 200 mesh screen to leach the grass residue and merge the filtrate of three times; 2) Concentrating the function ingredients: (1) Put the merged extractant in the rotary evaporator and recycle the ethanol at 75 degrees Celsius; (2) Concentrate the filtrate to 1:1, that is, concentrate the filtrate into an immortal grass ointment which has the same quality to the invested immortal grass. The method has the advantages of simple and quick technology, low cost and high yield, and is suitable for industrial scale production.

Owner:刘富来

All-biomass composite modified foamed material and preparation method thereof

Owner:WUHAN UNIV OF TECH

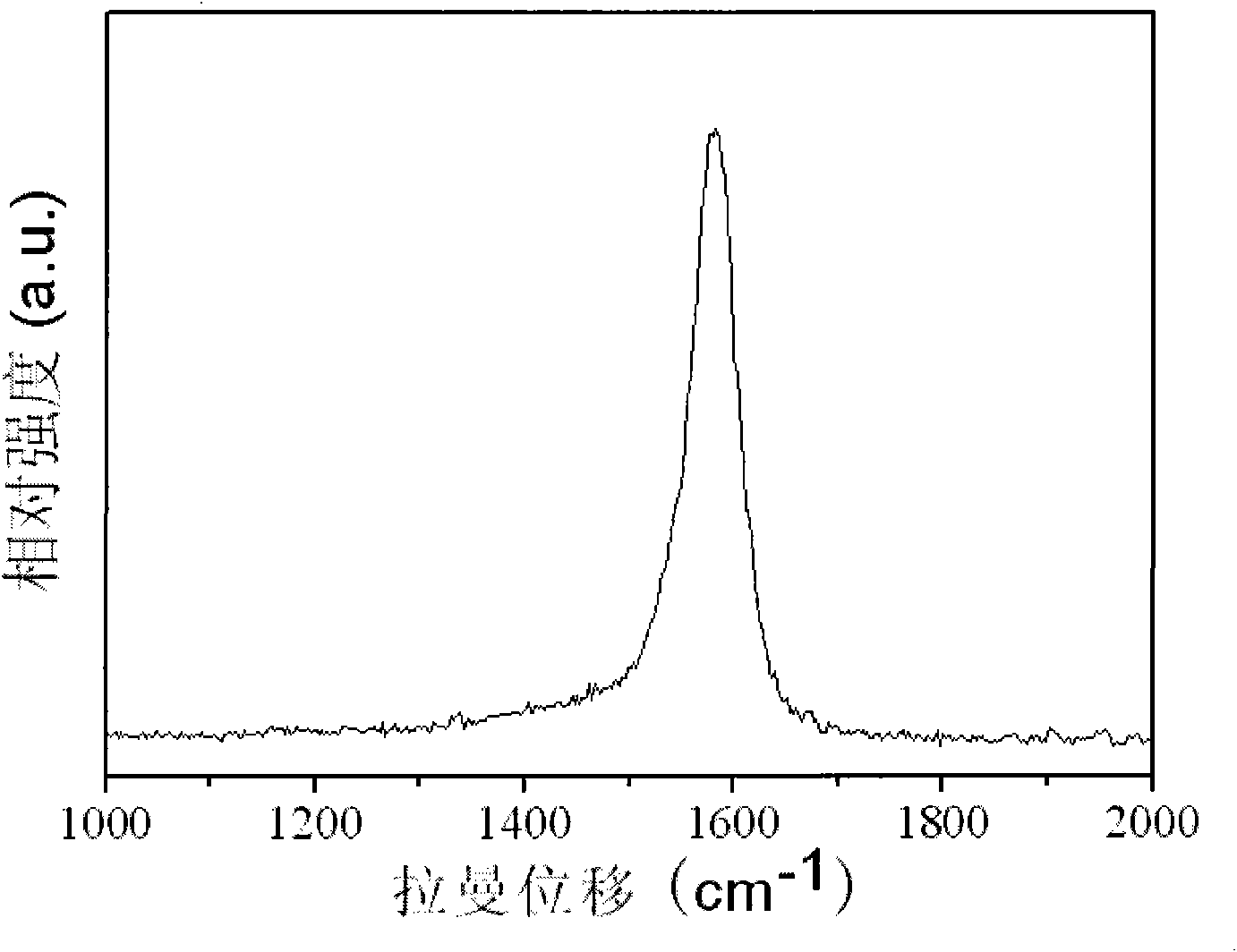

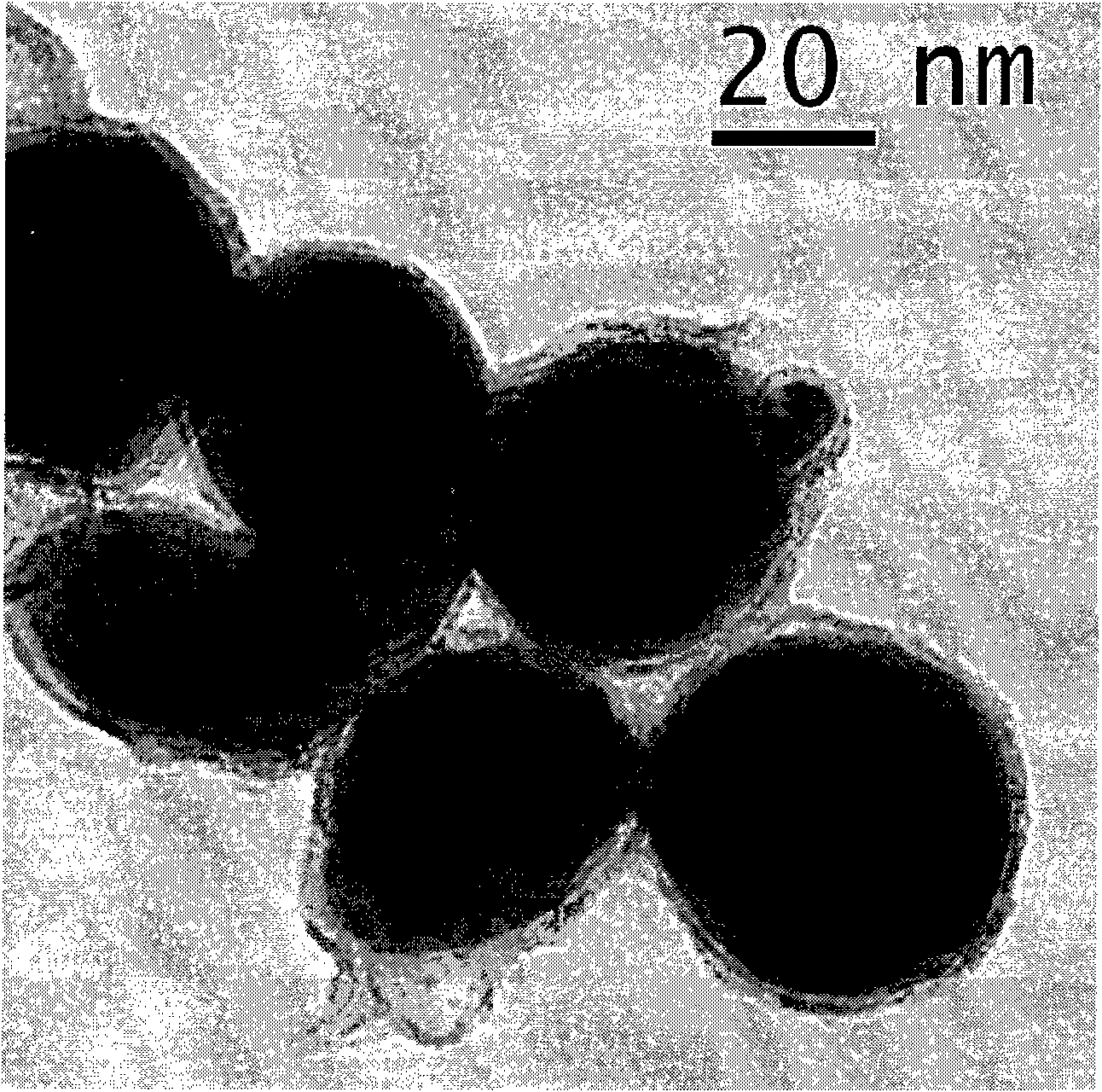

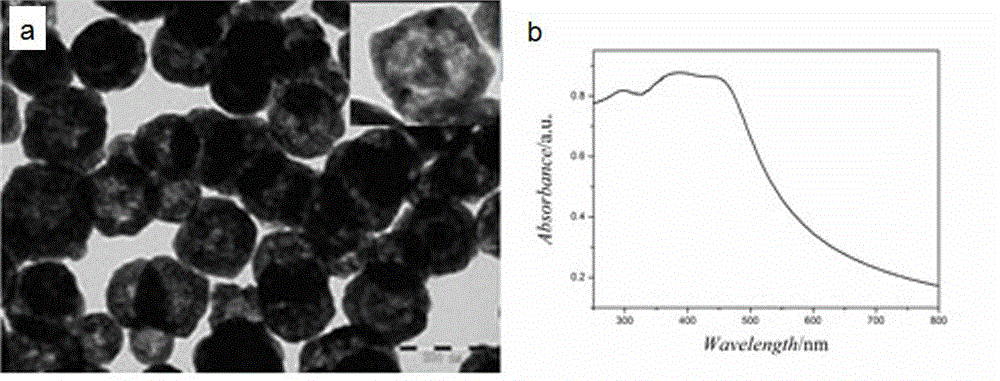

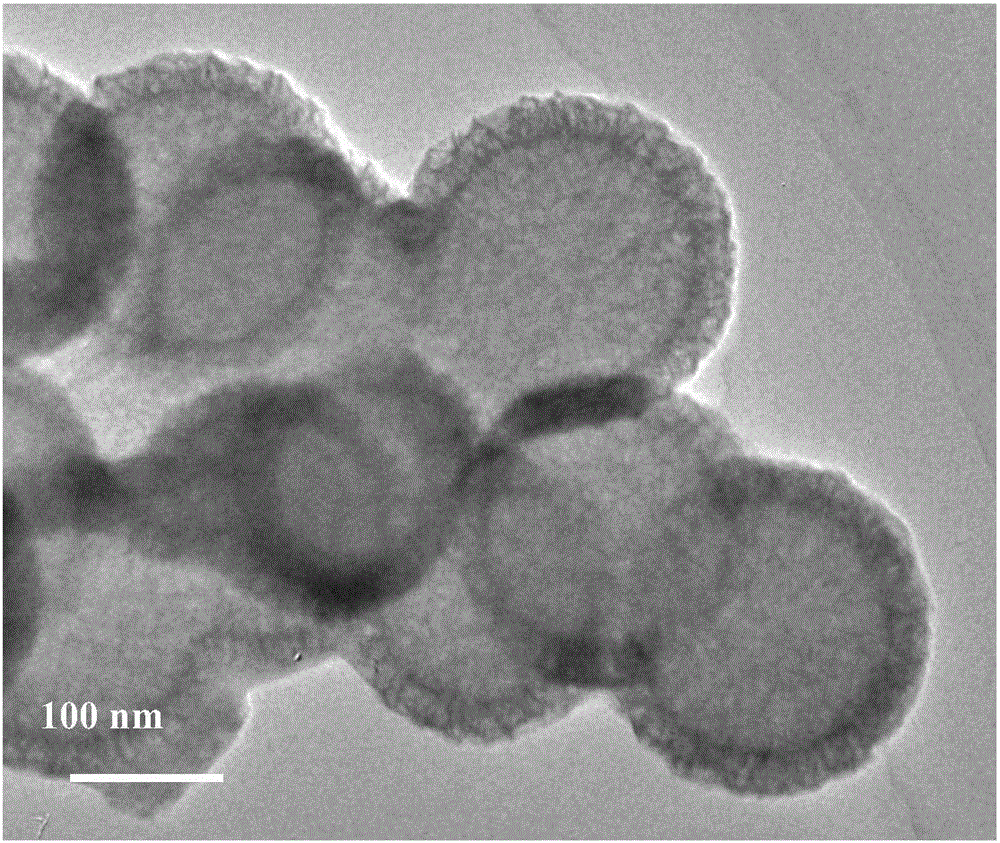

Rapid preparation method of AU@Cu2O nanocomposite in yolk-shell structure

The invention relates to a rapid preparation method of an AU@Cu2O nanocomposite in a yolk-shell structure. According to the nano material, the coverage degree of a shell layer can be controlled by regulating parameters of concentration, temperature and the like of CTAB. The preparation method comprises the following main steps: (1) adding a certain quantity of Vitamin C in mixed liquor of CuSO4.5H2O and cetyl trimethylammonium bromide (CTAB), stirring, and dissolving; (2) adding 3ml of aqueous solution of gold octahedron in the solution; (3) keeping the solution for 20min at the temperature of 60 DEG C, and then adding a certain quantity of NaOH solution dropwise; and (4) carrying out centrifugation on the obtained product, washing precipitates with deionized water and ethanol for many times, and finally dispersing in an ethanol solution. The AU@Cu2O nano material in the yolk-shell structure has very important application value in the aspects of catalysis, surface-enhanced raman scattering (SERS) and the like.

Owner:UNIV OF JINAN

Method for extracting quercetin from guava leaves

InactiveCN106749145AReduce wasteSave resourcesOrganic chemistryChromatographic separationHplc method

The invention provides a method for extracting quercetin from guava leaves. The method comprises the following steps: taking dried guava leaves as a raw material, preparing alcohol extract, preparing extract powder, carrying out recrystallization with boiling water, carrying out recrystallization with ethyl alcohol, and carrying out sephadex column chromatographic separation, so that quercetin is obtained, wherein a TLC method is adopted for identifying quercetin, and an HPLC method is adopted for determining quercetin content. The method provided by the invention has the advantages that waste of quercetin in the guava leaves is effectively reduced, and resource is saved; meanwhile, the raw material is available, environmental pollution is hardly produced, technology is simple, practicable and quick, the obtained quercetin is relatively low in cost, high in purity and high in yield, and the method provided by the invention is applicable to industrial scale production.

Owner:FOSHAN UNIVERSITY

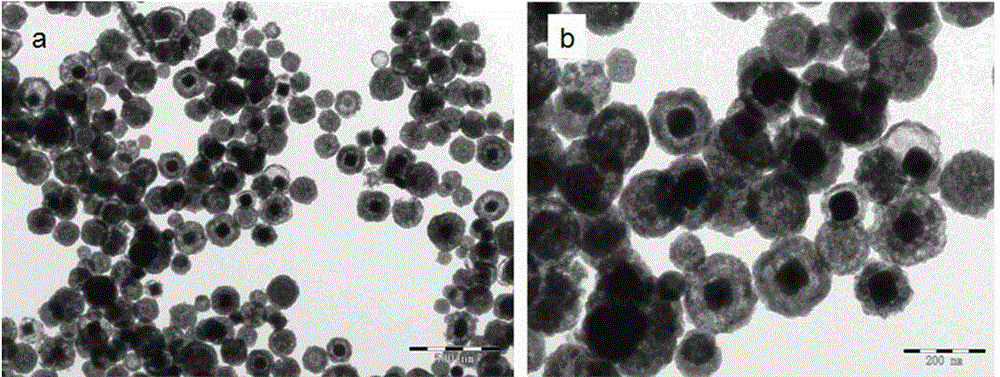

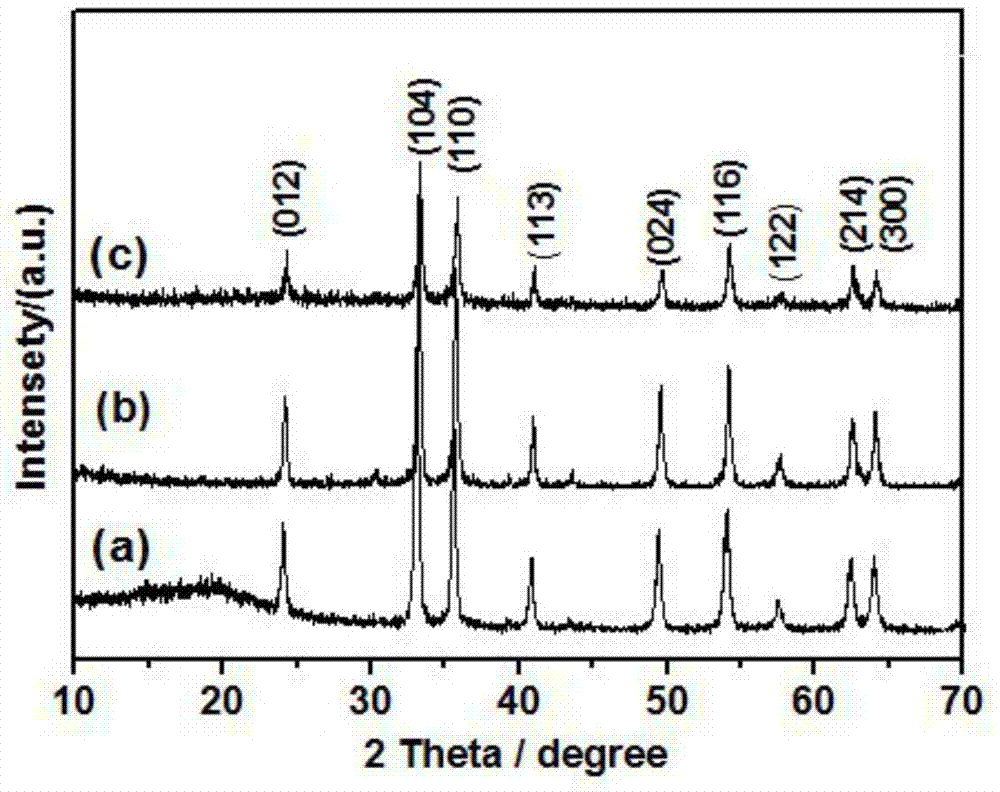

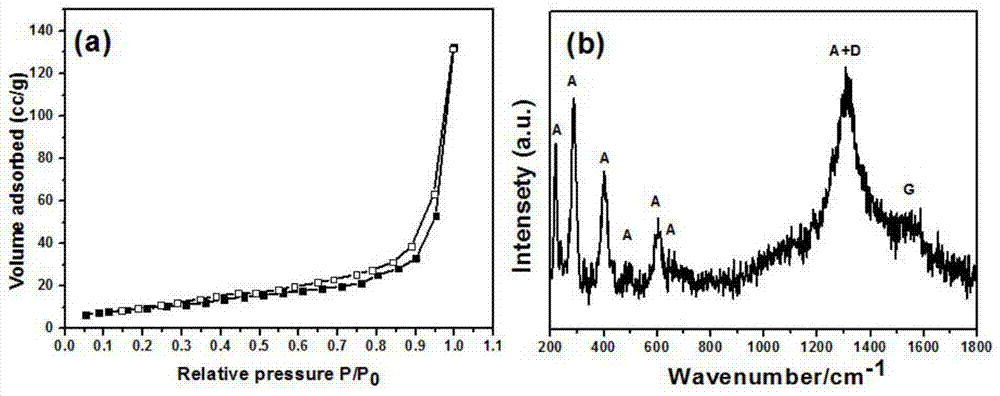

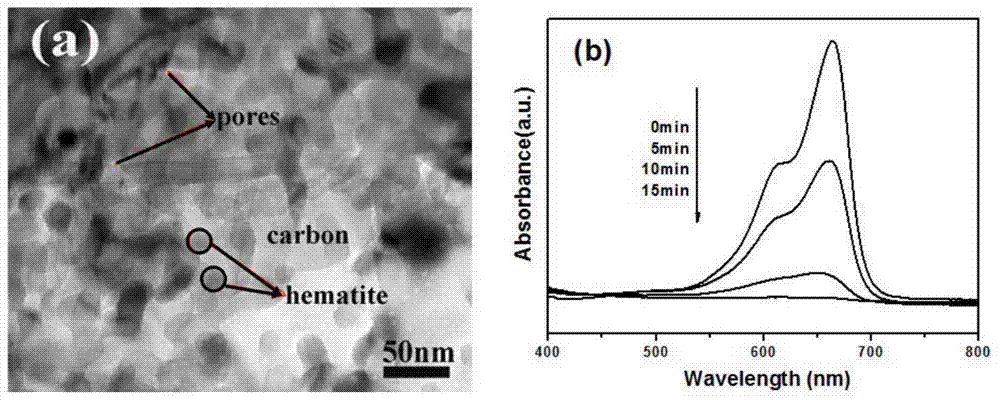

Preparation method of carbon-ferric oxide nanocomposite material

ActiveCN104492437AWell mixedImprove photocatalytic performanceMetal/metal-oxides/metal-hydroxide catalystsPhotocatalytic degradationMaterials science

The invention discloses a preparation method of a carbon-ferric oxide (alpha-Fe2O3) nanocomposite material, belonging to the field of synthesizing an inorganic material. The carbon-ferric oxide nanocomposite material is obtained through one-step reaction by adopting an ferrous source, a carbon source and an auxiliary as raw materials, without the need of subsequent treatment, and the prepared carbon-ferric oxide nanocatalyst and ferric oxide realize nanoscale composition, the specific surface area is large, the carbon-ferric oxide nanocomposite material has a mesoporous structure, the solar utilization rate is high, the catalysis performance is good, and the carbon-ferric oxide nanocomposite material can be used in the field of a functional material, especially the field of photocatalytic degradation of organic pollutants. According to the preparation method, the raw materials are easily available, a template, a surfactant, a precipitator and the like are not needed during the preparation process, the technology is simple, the production cost is low, and large-scale production is easy to realize.

Owner:UNIV OF SCI & TECH BEIJING

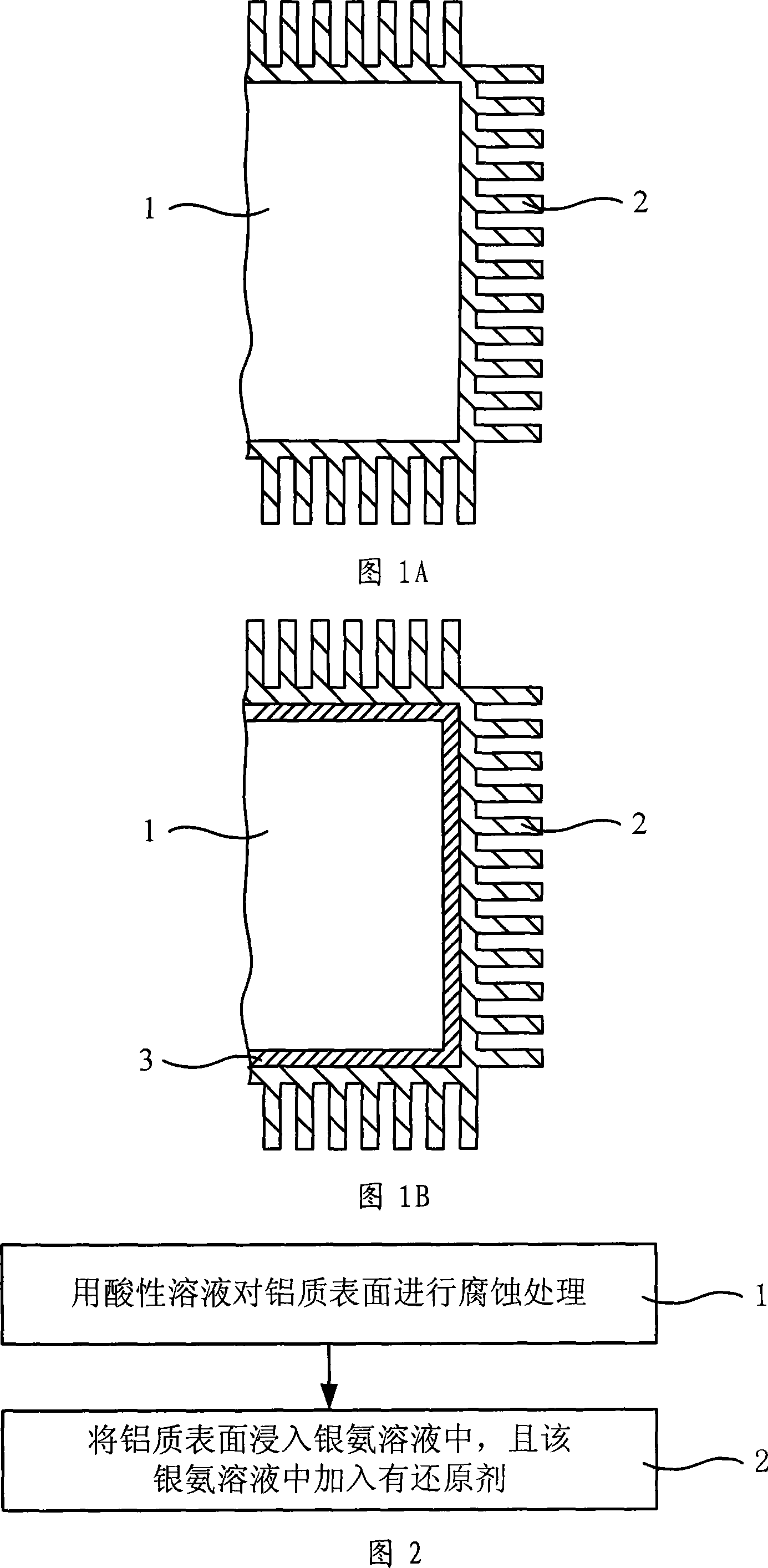

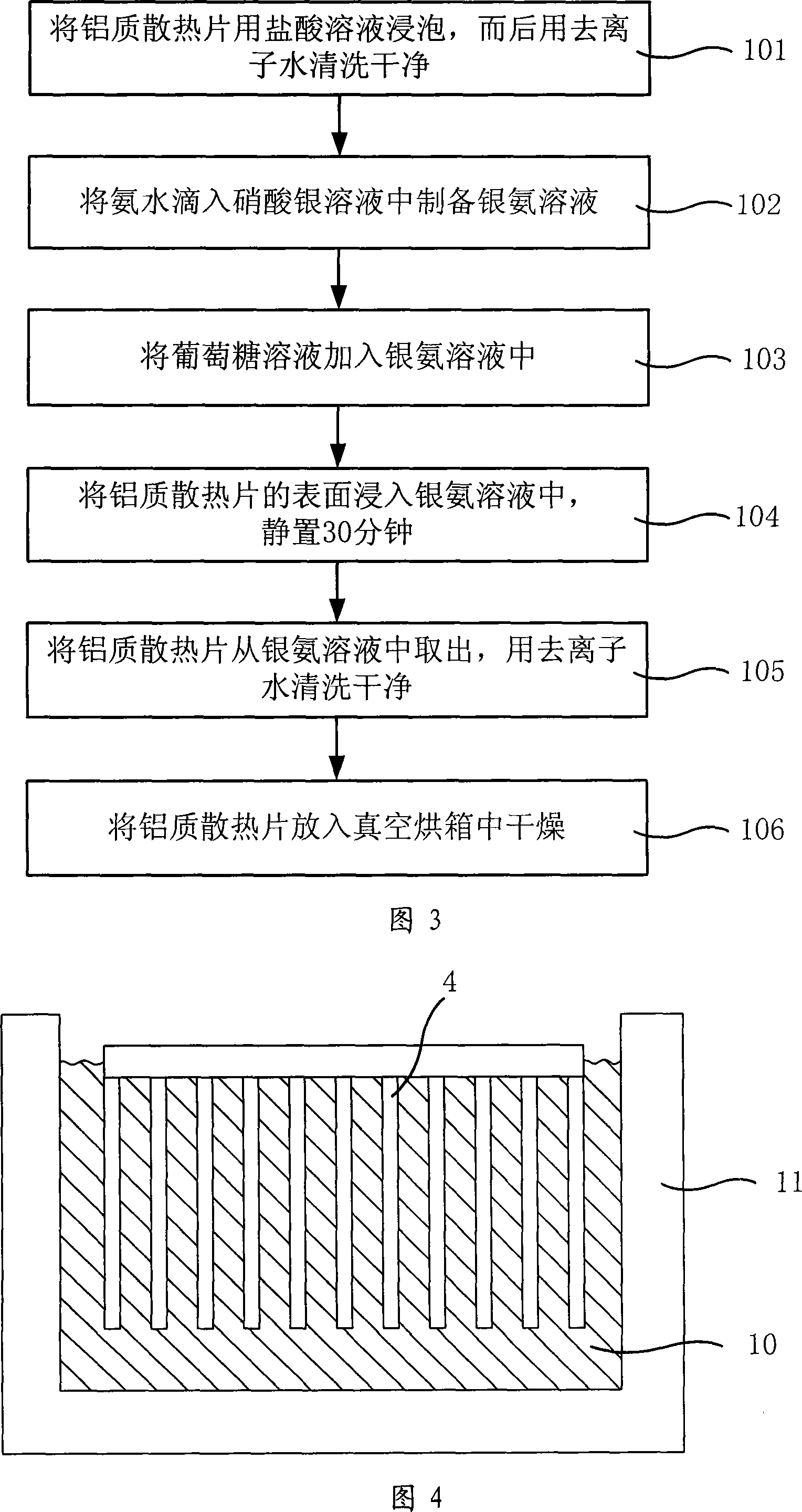

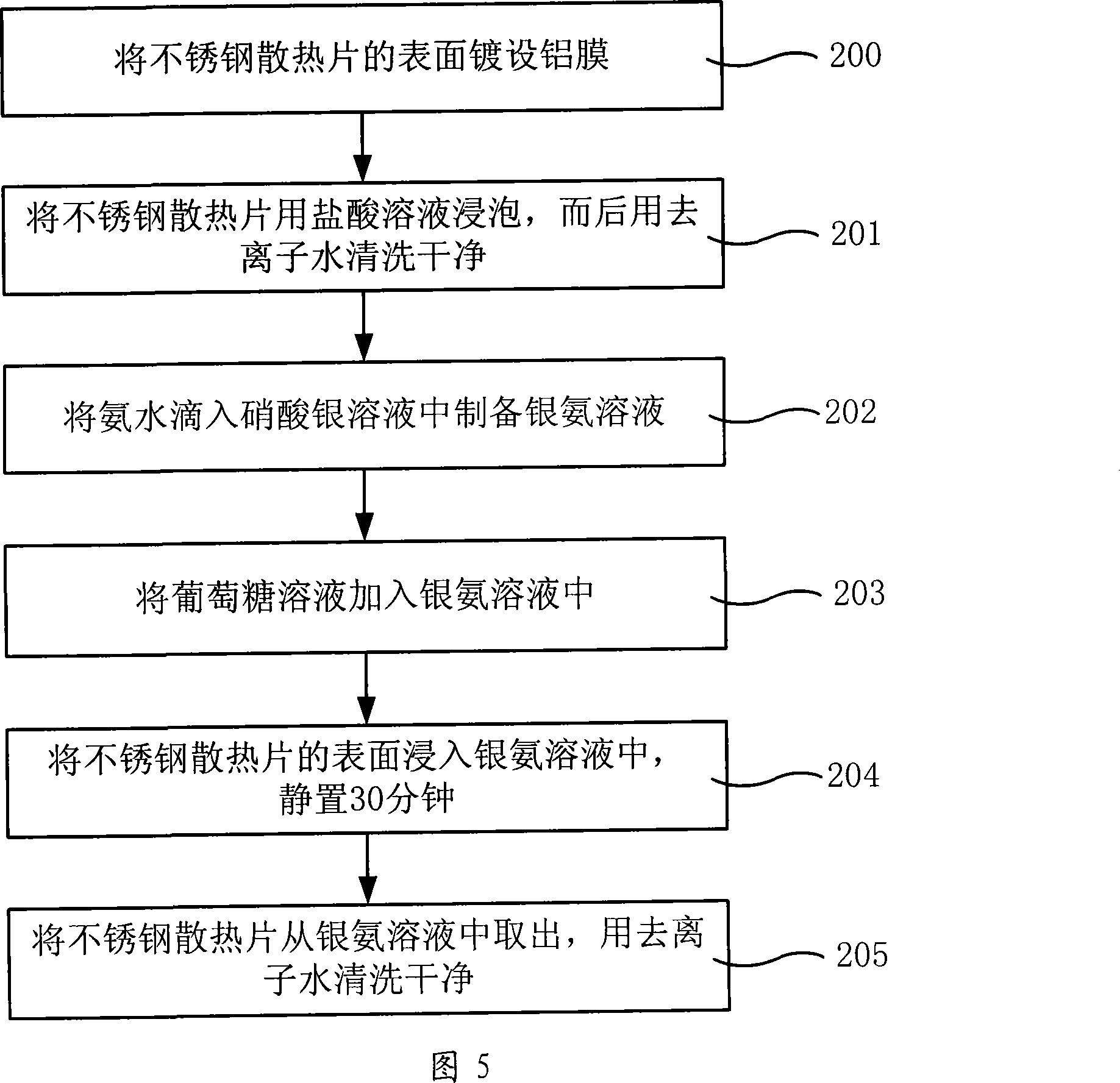

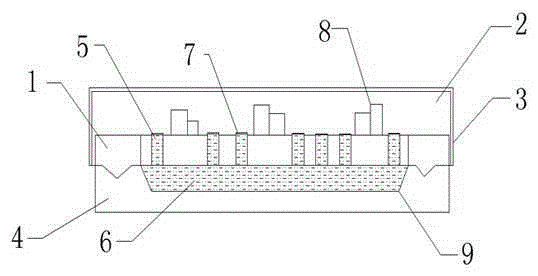

Heat radiator and surface treating method thereof

InactiveCN101160037AIncreased cooling surface areaSimple structureSemiconductor/solid-state device detailsSolid-state devicesThermal coefficientThermal transmittance

The invention relates to a radiation device and a surface processing method. The radiation device includes a radiation body, wherein, the radiation body is made of aluminum material or the outer surface is provided with an aluminum film; the aluminum surface of the radiation surface is attached with silver micron cluster. The surface processing method of the radiation device includes the following steps: use acid solution to perform corrosion processing on the aluminum surface of the radiation body; and immerge the aluminum surface after corrosion processing into silver amine solution, which contains a reducing agent for silver ions exchange. The invention improves the radiation efficiency, because of large radiation surface area attached with silver micron cluster and large silver thermal coefficient. The radiation device surface processing method of the invention has the advantages of convenient and simple process course and easy operation realization.

Owner:BOE TECH GRP CO LTD

Fresh sweet corn normal-temperature fresh-keeping method

ActiveCN102524384ARetain nutrientsFresh tasteSeed preservation by heatingCounter pressureEngineering

The invention discloses a fresh sweet corn normal-temperature fresh-keeping method, which comprises the following steps that: 1) fresh sweet corns are peeled, corn silk is removed, and the treated corns are washed after the fresh sweet corns are harvested; 2) the sweet corns are placed into an internal package bag, the internal package bag is vacuumized, the vacuum package bag is placed inside an outer package bag, and then the outer package bag is inflated by nitrogen gas and is sealed; 3) the well-packed sweet corns are arranged inside a counter-pressure sterilization pot to be steamed; 4)temperature inside the counter-pressure sterilization pot is decreased while the pressure is maintained constant; 5) the pressure and the temperature inside the pot are slowly reduced; and 6) the sweet corns are taken out of the pot and are stored and kept fresh below the temperature of 25 DEG C. The method has simple, convenient and rapid process, and the color preservation, sterilization and freshness preservation of the corns can be integrated by adopting the indirect heating method. The method is simple and rapid to operate, has low cost, short processing time and low processing cost, canpreserve more nutrients of the sweet corns, and can prevent the decrease of soluble solids of the fresh sweet corns when the fresh sweet corns are frozen in low-temperature to preserve the freshness.

Owner:TIANJIN JIESHENG DONGHUI FRESH PRESERVATION TECH

Antistatic flame-retardation circuit board

InactiveCN105199646AImprove adaptabilityExtended service lifeNon-macromolecular adhesive additivesMacromolecular adhesive additivesSilica gelElectronic component

A disclosed antistatic flame-retardation circuit board comprises a circuit board main body, a sealing layer arranged on the circuit board main body, and a protective layer arranged on the sealing layer; the sealing layer fixedly seals the side, carrying electronic components, of the circuit board main body; and the protective layer wraps the sealing layer. The side, possessing soldering tin, of the circuit board main body is provided with a heat radiation layer, and the heat radiation layer and the circuit board main body are in connection by employing a mutually-matched concealed, overlapped or plug-in way; the circuit board main body is provided with a plurality of through holes, one side of the heat radiation layer is provided with a groove, the groove is filled with a heat-conduction liquid, and the heat-conduction liquid is capable of freely flowing in the groove and the through holes; and the connection position of the heat radiation layer and the circuit board main body is sealed by using pouring silica gel. The circuit board possesses excellent antistatic, moistureproof and electrical-isolation performances, also possesses the characteristics of good flame retardation, heat radiation and the like.

Owner:中山市实翔电子科技有限公司

Efficient environment-friendly low-temperature composite phase change cold accumulating agent, as well as preparation method and application thereof

ActiveCN104726072ASimple preparation processThe production process is fastFood preservationHeat-exchange elementsPotassiumPhase change

The invention discloses an efficient environment-friendly low-temperature composite phase change cold accumulating agent. The cold accumulating agent is prepared from the following components in percentage by mass: 5-11 percent of potassium chloride, 10-15 percent of sodium chloride, 0.1-0.6 percent of citric acid, 1-1.5 percent of sodium tetraborate, 0.5-2 percent of guar gum and 70-83.4 percent of water. The invention further discloses a method for preparing the efficient environment-friendly low-temperature composite phase change cold accumulating agent, and application of the efficient environment-friendly low-temperature composite phase change cold accumulating agent in the field of storage and fresh preservation. Compared with a traditional cold accumulating agent preparation process, the process has the characteristics of convenience and rapidness, the prepared cold accumulating agent is transparent or translucent gel, and has the characteristics of safety, no pollution, efficiency, large latent heat of phase change and small condensate depression. Experiments prove that the phase-change temperature is between minus 21 and minus 24 DEG C, and the latent heat of phase change is 280-320kJ / kg.

Owner:南京久鼎环境科技股份有限公司

Method of preparing nano-crystalline powdered alloy powder

The invention provides a method of preparing nano-crystalline powdered alloy powder, and belongs to the field of a powder metallurgy preparation technology. The method comprises the steps: preparing an oxide precursor by adopting a solution method; carrying out reductive sintering on the precursor powder in hydrogen; and obtaining pure nickel-tungsten alloy powder with fine crystal particles. According to the method provided by the invention, all raw materials are mixed by using a liquid phase, reactants can be uniformly mixed on an atom level, and the problem that the alloy powder is difficult to mix can be solved; meanwhile, the method has the characteristics of low cost and high use ratio of raw material powder; in addition, because the nano-crystalline powdered alloy powder is plied as nano-crystalline powder, and the method is higher in rigidity, wearability, corrosion resistance, resistance to high temperature oxidation and the like.

Owner:UNIV OF SCI & TECH BEIJING

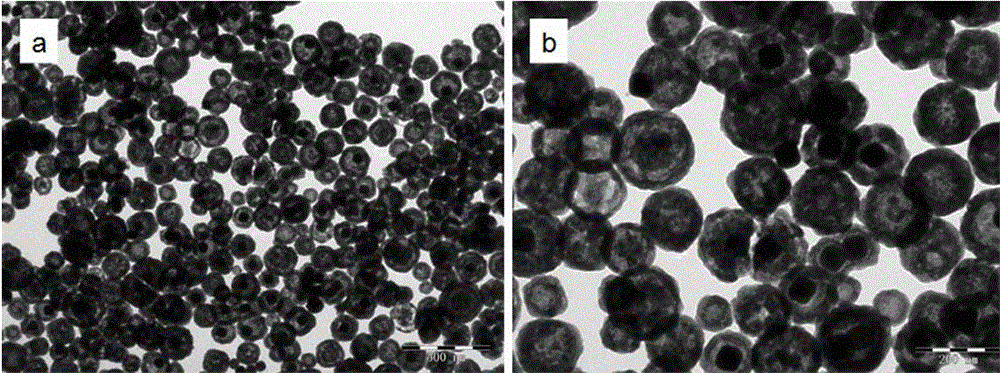

Rapid preparation method of manganese oxide/carbon sphere composite material for three-dimensional (3D) printing

InactiveCN105869922AAdvanced technologyAccurate and informative dataHybrid capacitor electrodesHybrid/EDL manufactureManganese oxideCapacitance

The invention relates to a rapid preparation method of a manganese oxide / carbon sphere composite material for three-dimensional (3D) printing. Aiming at the problems of small electrode capacity and low specific capacitance of a capacitor, the manganese oxide / carbon sphere composite material is prepared according to the steps of taking a carbon sphere as a carbon source and potassium permanganate as a manganese doping agent, preparing a solution, carrying out ultrasonic dispersing processing, synthesizing a manganese oxide / carbon sphere, carrying out washing, suction filtering and vacuum drying, and carrying out heating and sintering with vacuum microwave. The preparation method is advanced and rapid in process and accurate and full in data, a product is black powder, the particle diameter of the powder is less than or equal to 200 nanometers, the product purity reaches 99.3%, the specific capacitance index is 114F / g, the preparation method is an advanced method for rapid preparation of the manganese oxide / carbon sphere composite material, and the material can be used for a 3D printing technology.

Owner:TAIYUAN UNIV OF TECH

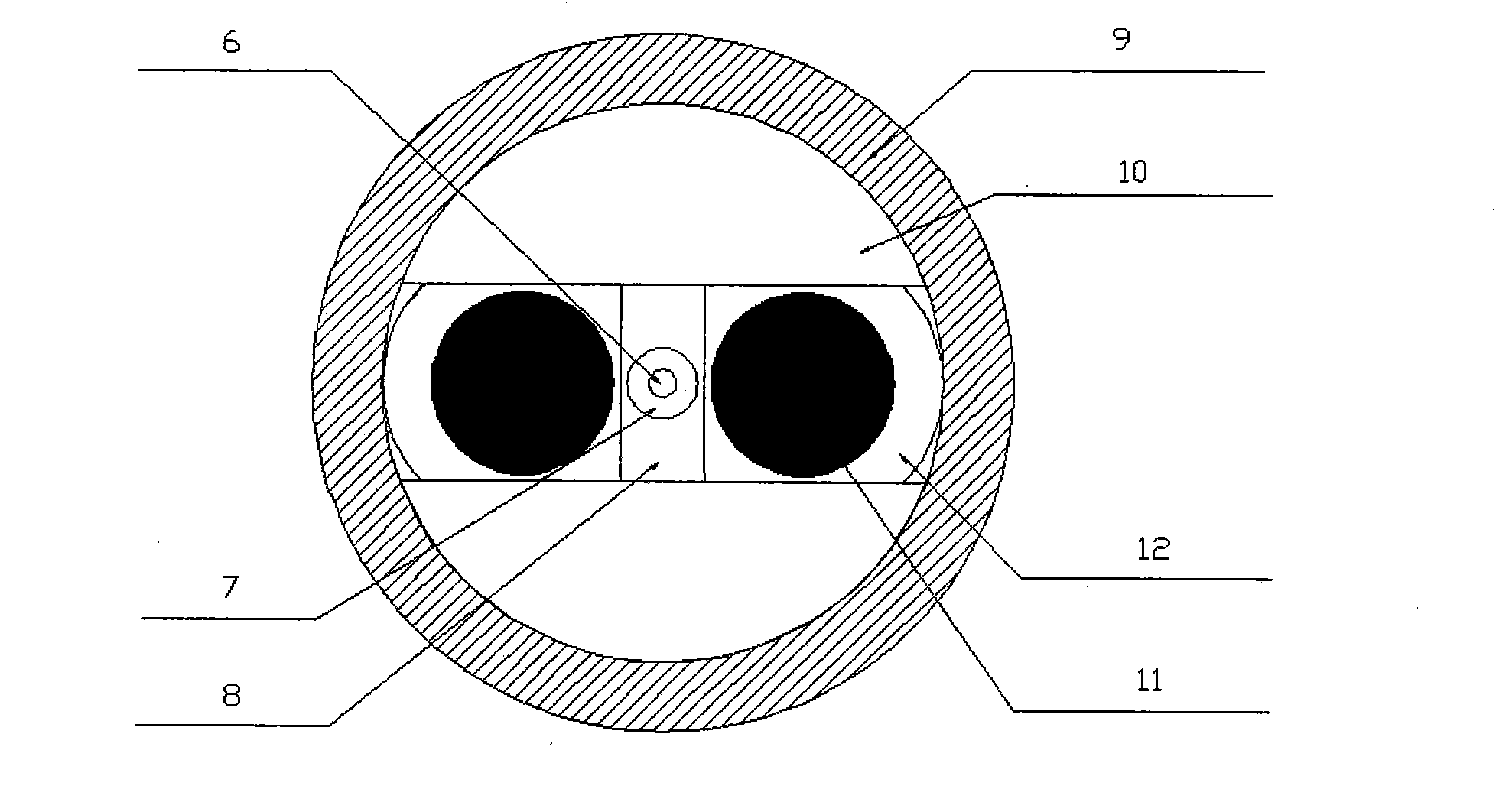

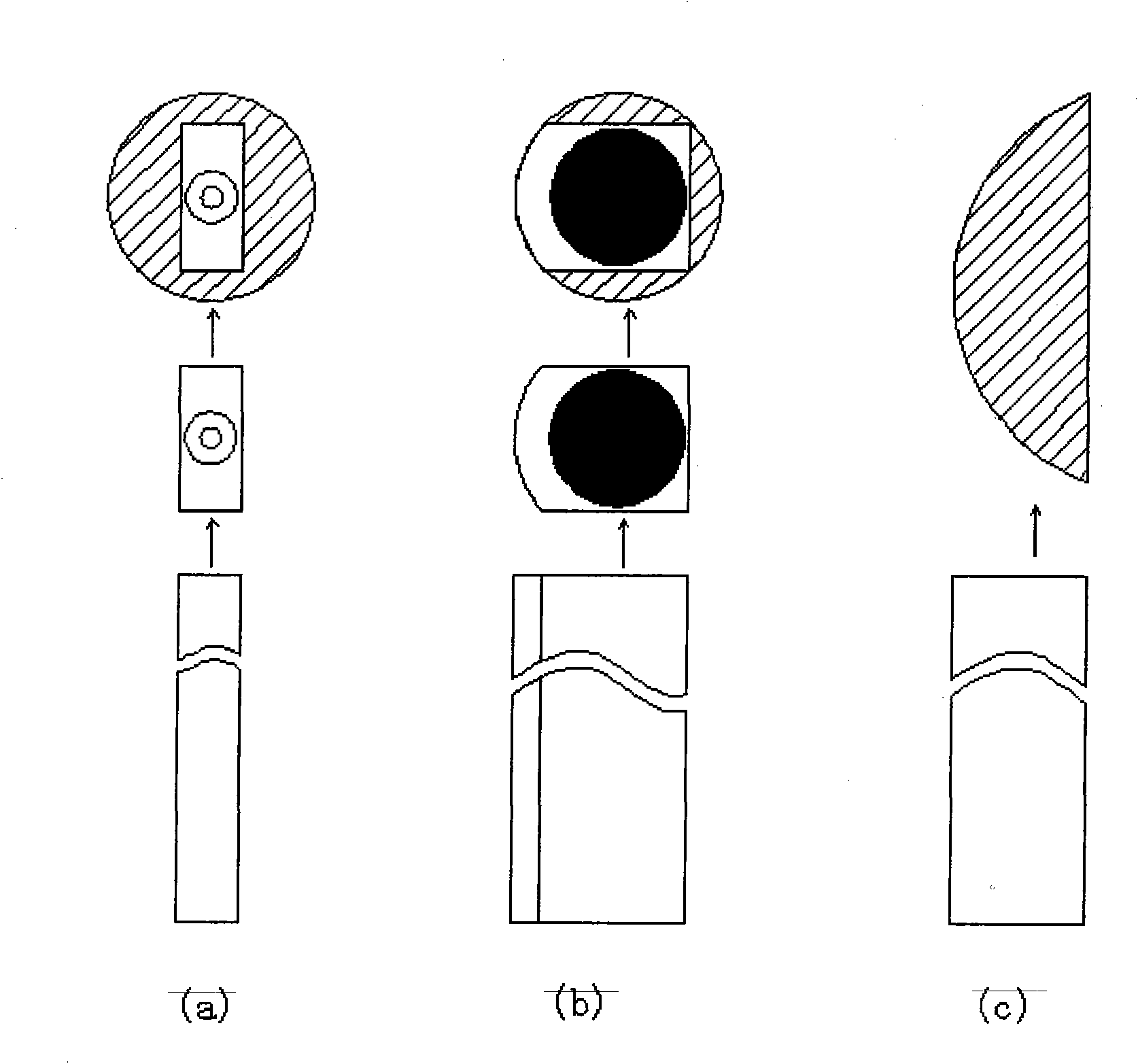

Method for synthesizing and preparing module of panda polarization maintaining optical fiber preformed rod

InactiveCN101833127AImprove machining accuracyImprove efficiencyGlass making apparatusOptical fibre with polarisationComputer modulePolarization-maintaining optical fiber

The invention relates to the field of optical fiber communication, in particular to the method for synthesizing and preparing a module of a panda polarization maintaining optical fiber preformed rod. According to the division of the cross section of the panda polarization maintaining optical fiber preformed rod, the preformed rod is divided into four modules, namely, a circular casing module, a single-mode module which contains a core rod, two stress modules which contain a stress rod respectively, and two curved quartz-filled modules; the core rod, the stress rod, filling rods and the like are cut into required component modules by machining ways, such as linear cutting; after being ground and polished, each module is placed in a quartz casing to be combined; one end of the combined polarization maintaining optical fiber preformed rod is coned; nitrogen is introduced into the casing; and the polarization maintaining optical fiber preformed rod is drawn into a panda polarization maintaining optical fiber. The method of the invention has the advantages of precisely machining both large-size preformed rods and small-size preformed rods and guaranteeing precise positioning of structure size, along with low cost, high machining accuracy and speed, massive production, high efficiency, and relatively mature, simple, quick and convenient process.

Owner:上海傲世控制科技股份有限公司

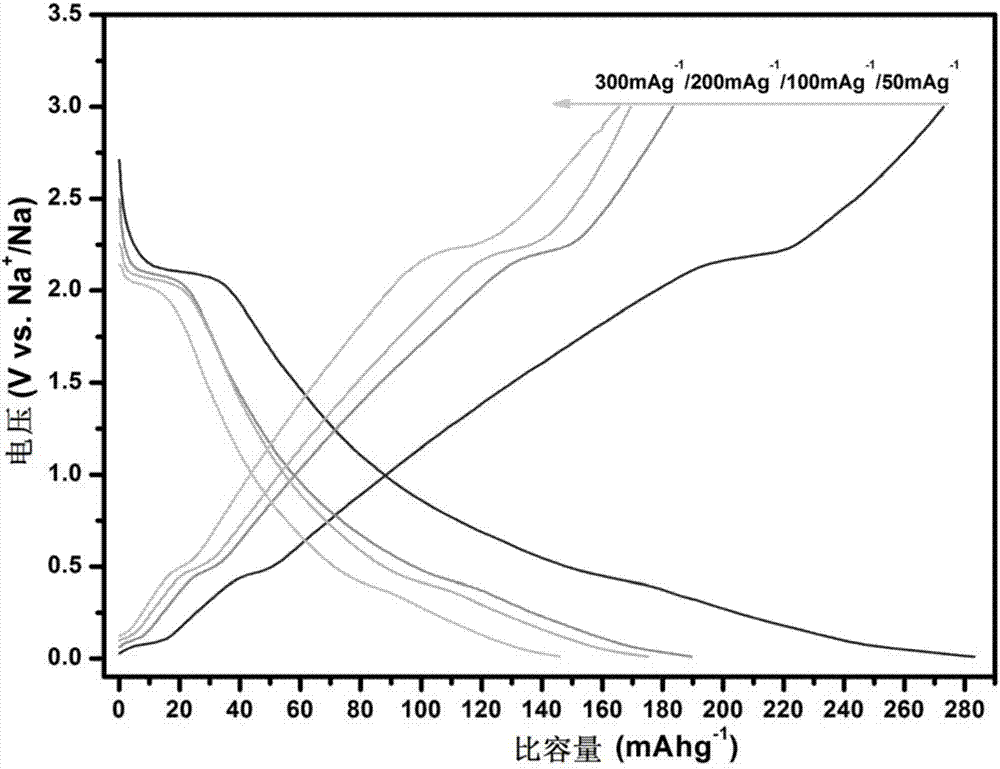

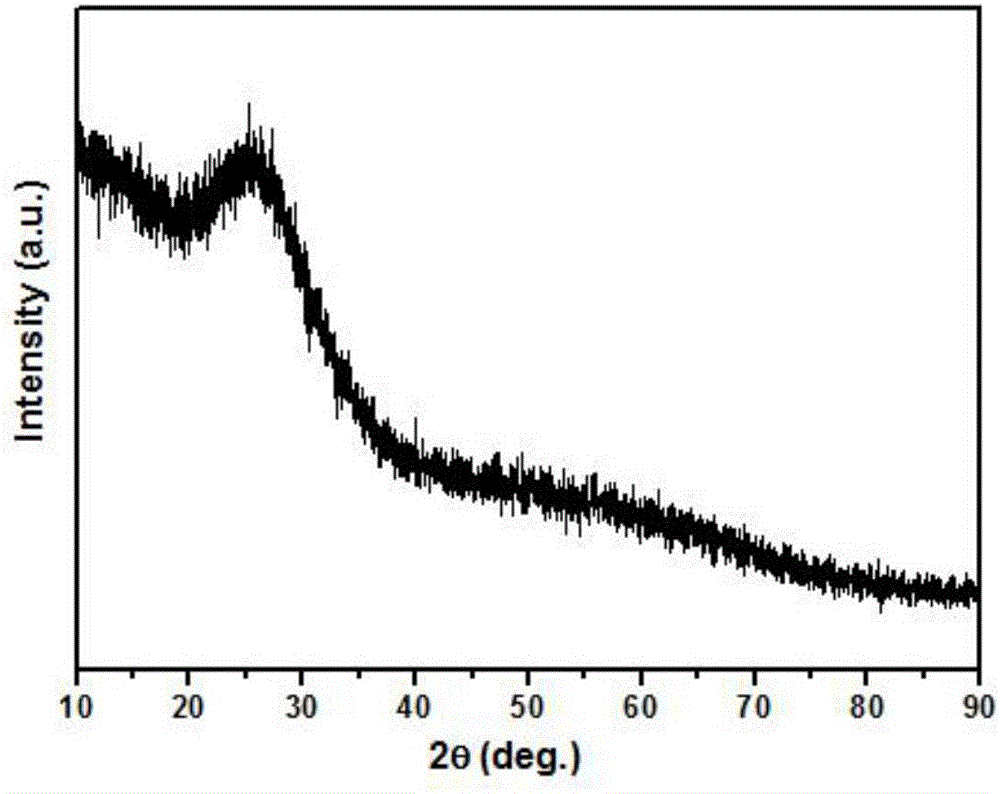

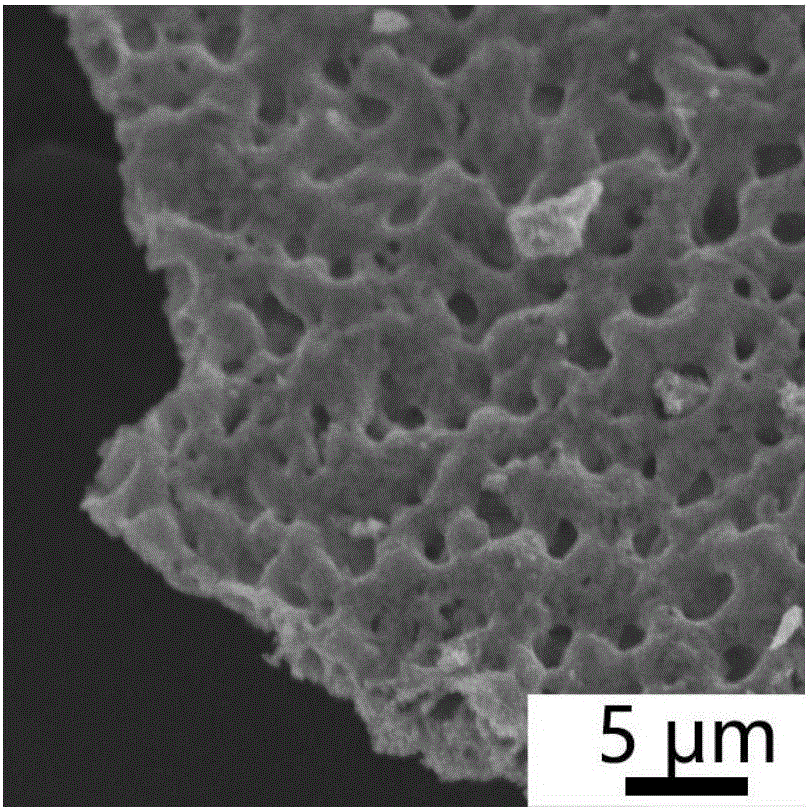

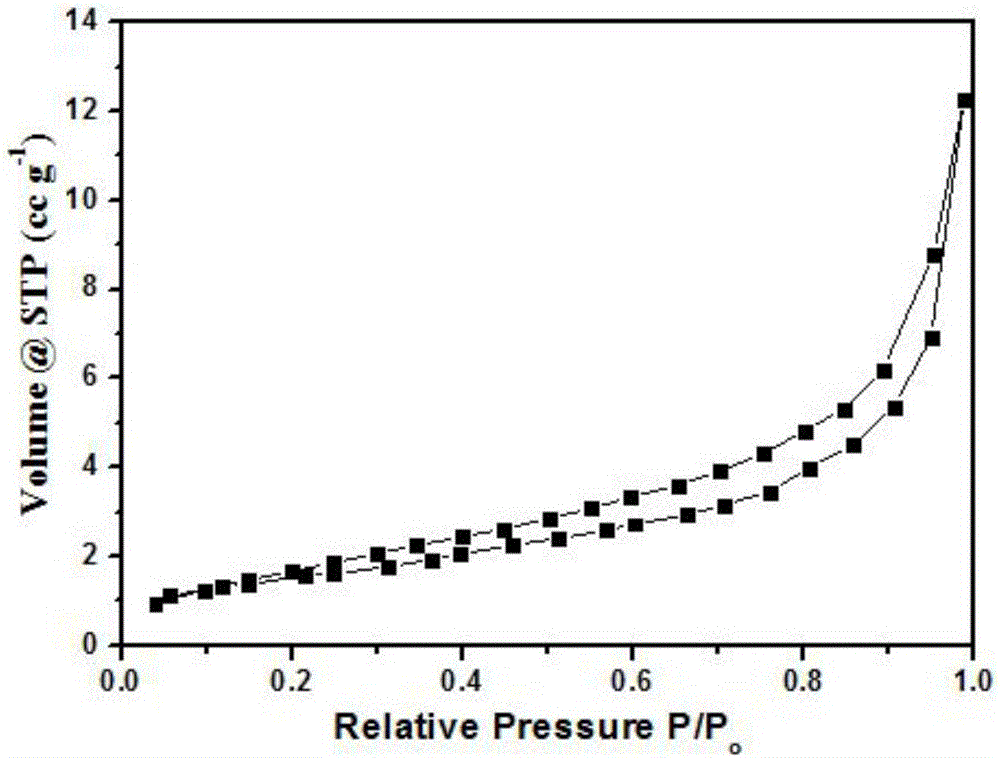

Sodium-ion battery negative electrode material and preparation method thereof

InactiveCN107093712ALow working voltageIncrease energy densityCell electrodesSecondary cellsWater bathsHigh energy

The invention belongs to the field of battery negative electrode materials, and particularly relates to a sodium-ion battery negative electrode material and a preparation method thereof. The sodium-ion battery negative electrode material comprises a manganese titanium phosphate ternary material with the general formula as Mn0.5Ti2(PO4)3; the preparation method comprises the steps that a manganese source, a titanium source, a phosphate source and an chelating agent are acquired, the manganese source, the titanium source, the phosphate source and the chelating agent are dissolved into water, and after water bath and drying, a Mn0.5Ti2(PO4)3 sol is obtained; the Mn0.5Ti2(PO4)3 sol is subjected to vacuum drying or freeze drying to obtain a Mn0.5Ti2(PO4)3 precursor; the Mn0.5Ti2(PO4)3 precursor is subjected to calcining treatment in inert atmosphere, and the sodium-ion battery negative electrode material is obtained. The sodium-ion battery negative electrode material has the advantages of low working voltage, high energy density, stable cycle performance and good rate capability.

Owner:SOUTHWEST UNIV +1

Method for producing carbon composite amorphous vanadium oxide powder

ActiveCN106159225AComposite uniformReduce compoundingCell electrodesSecondary cellsCarbon compositesNew energy

The method relates to a method for producing carbon composite amorphous vanadium oxide powder, and belongs to the field of new energy resources. A process comprises the following steps: preparing a solution from raw materials, namely, a vanadium source, a fuel, an auxiliary and a carbon source, according to a certain proportion; heating the solution in a certain atmosphere, and performing combustion synthesis reaction after the solution is volatilized and concentrated to form gel; self-maintaining the reaction to finally obtain the carbon composite amorphous vanadium oxide powder by virtue of heat released by combustion reaction. A large amount of gas is generated in a reaction process, so that not only can a powder product be effectively prevented from being agglomerated, but also a mesoporous structure can be formed. A liquid phase mixing manner is adopted, so that amorphous vanadium oxide granules with small granularities can be closely combined and uniformly dispersed with carbon. The raw materials are readily available, the method is simple, low in cost and high in industrialization rate, and the prepared carbon composite amorphous vanadium oxide powder has high capacity and high cyclic stability when being used as an anode material for a lithium battery.

Owner:UNIV OF SCI & TECH BEIJING

Method for directly producing mineral cotton with hot-melted titanium-containing blast furnace slag

The invention discloses a method for directly producing mineral cotton with hot-melted titanium-containing blast furnace slag. The method comprises the steps of introducing the hot-melted titanium-containing blast furnace slag with an acidity coefficient higher than 1.1 and a viscosity coefficient higher than 0.5 Pa.S into a slag ladle; simultaneously blowing coal gas to perform treatments of thermal insulation and homogenization for the hot-melted titanium-containing blast furnace slag in the slag ladle; and then centrifuging or blowing the treated hot-melted titanium-containing blast furnace slag to obtain mineral cotton fibers. Water consumption in a water-quenched slag process can be prevented, because the method is in no need of water-quenching the melted slag to a solid state, so that water can be saved effectively; and pollutions to atmosphere and surface water can be prevented. With the method, most of sensible heat of the blast furnace melted slag can be utilized effectively, thereby saving fuels effectively. Production cost can be reduced and production period is shortened because of omitting a reformulating process for adjusting the acidity of the melt by adding silica. The method has the characteristics of water conservation, energy conservation, environmental protection, low cost and simple and fast process, and realizes the integrated utilization of solid resources of the titanium-containing blast furnace slag.

Owner:HEBEI IRON AND STEEL

Pyrochlore concentrate obtaining method

The invention belongs to the technical field of resource utilization and recovery, and in particular, relates to a pyrochlore concentrate obtaining method. The method comprises the following steps: ores containing pyrochlore are grinded; the ores are separated by using a table; tailings are discarded to obtain reselected concentrates; the pulp concentration and the pH value of the reselected concentrates are adjusted; sodium silicate and hydroximic acid collecting agents are added in pulp in succession; foam products are collected; the pulp concentration and the pH value of the foam products are adjusted; sodium silicate is added; and the foam products are collected as pyrochlore concentrates. The pyrochlore concentrate obtaining method solves the technical problems of complicated process,difficult control and low production efficiency in a traditional pyrochlore obtaining method, and achieves the technical effects of convenient and fast process, easy control, reduction of the production cost and improvement of the production efficiency.

Owner:BEIJING RES INST OF URANIUM GEOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com